Short-process efficient cold-rolling preparation method of high-silicon steel thin strip

A high-silicon steel and short-process technology, which is applied in the field of fast, efficient and short-process preparation of high-silicon steel, can solve problems such as iron core loss, achieve the effects of reducing iron loss, increasing assembly coefficient, and improving plasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

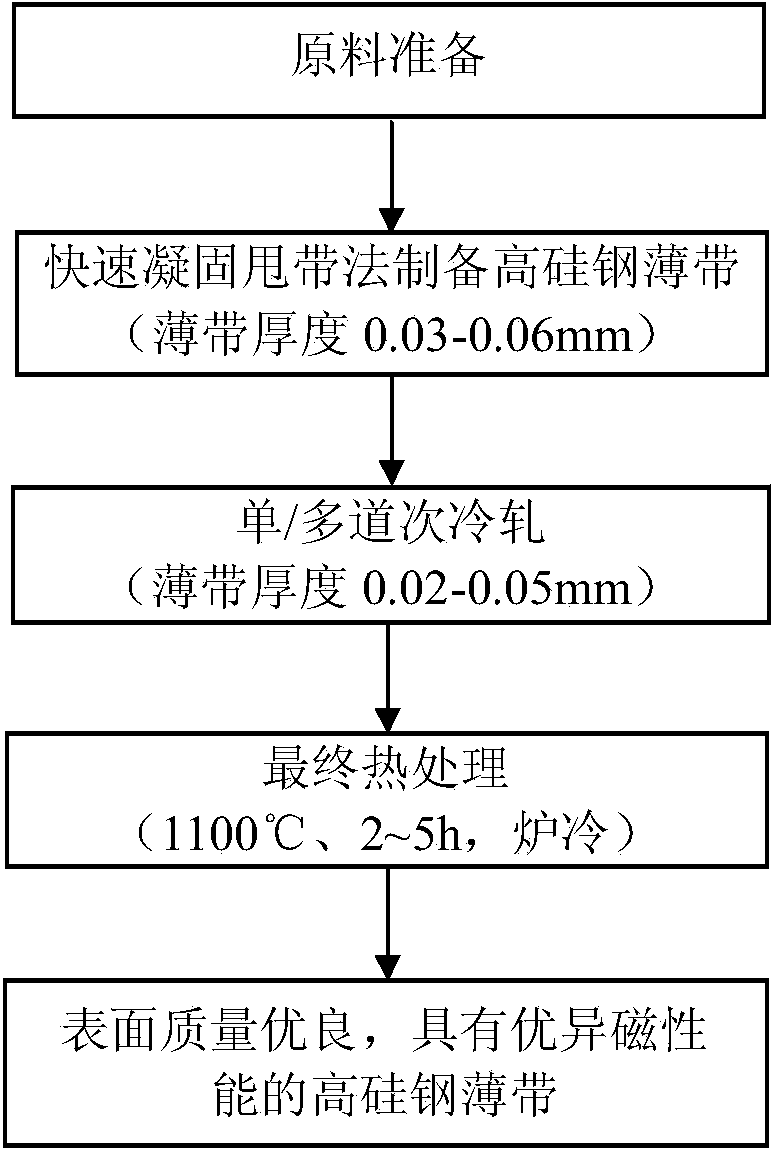

[0020] The high-silicon steel thin strip is prepared by rapid solidification method, and its thickness is further reduced by cold rolling method, and the surface quality is improved to improve its high-frequency magnetic properties. During the cold rolling process, the reduction amount of the first rolling pass is controlled to further improve the plasticity, so that a thin strip with a thickness of 0.02 mm can be obtained. Its process route is as figure 1 shown.

[0021] The specific process flow is:

[0022] (1) Raw material preparation: use industrial pure iron (industrial pure iron DT0, iron content 99.5%) and crystalline silicon (purity 99.9%) as raw materials, and mix according to the ratio of silicon content 6.5wt.%.

[0023] (2) Rapid solidification stripping: heat and smelt the raw material, and in the molten liquid state, use the stripping method to rapidly solidify it to obtain a high-silicon steel thin strip with a thickness of 0.03mm.

[0024] (3) Cold rolling:...

Embodiment 2

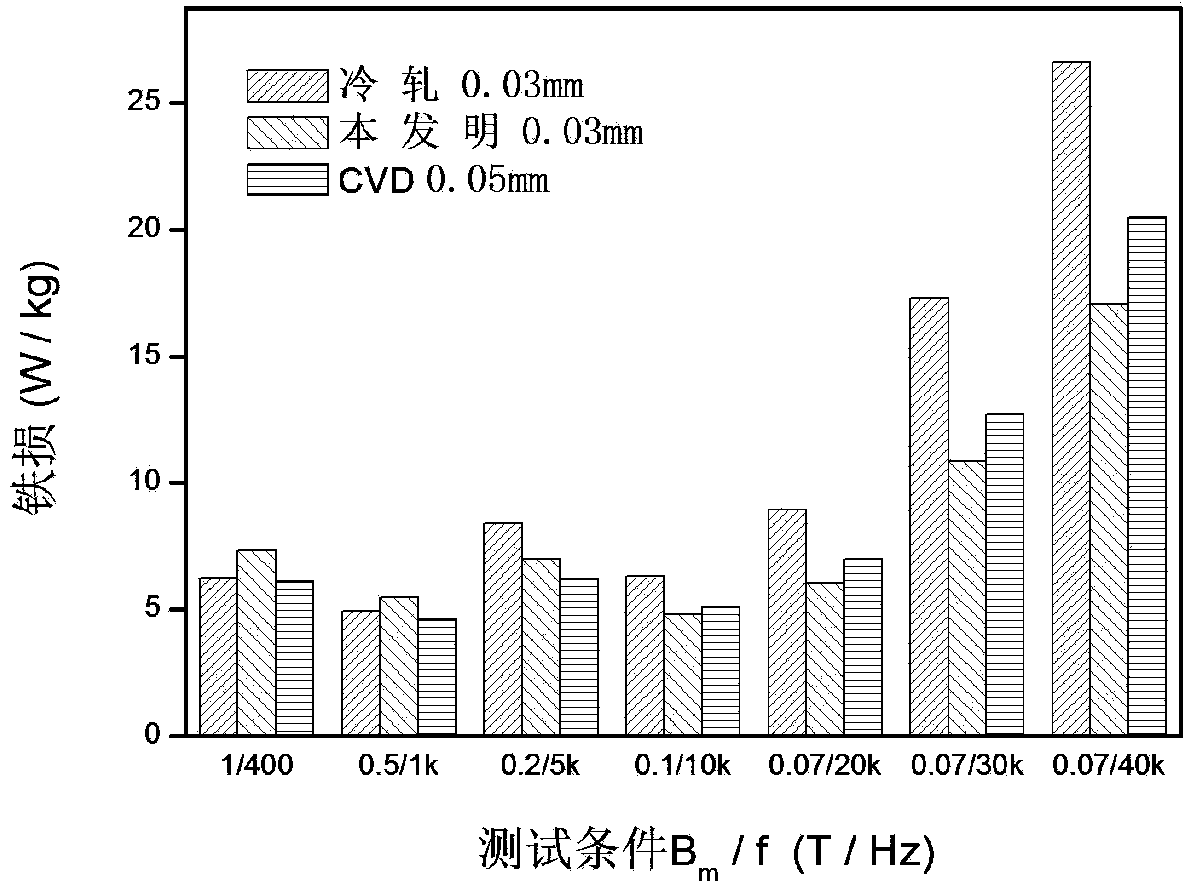

[0027] The high-silicon steel thin strip is prepared by rapid solidification method, and its thickness is further reduced by cold rolling method, and the surface quality is improved to improve its high-frequency magnetic properties. During the cold rolling process, the reduction amount of the first rolling pass is controlled to further improve the plasticity, so that a thin strip with a thickness of 0.03 mm can be obtained. Its process route is as figure 1 As shown, its magnetic properties are as figure 2 shown.

[0028] (1) Raw material preparation: use industrial pure iron (industrial pure iron DT0, iron content 99.5%) and crystalline silicon (purity 99.9%) as raw materials, and mix according to the ratio of silicon content 6.5wt.%.

[0029] (2) Rapid solidification stripping: heat and smelt the raw material, and in the molten liquid state, use the stripping method to rapidly solidify it to obtain a high-silicon steel thin strip with a thickness of 0.05mm.

[0030] (3) C...

Embodiment 3

[0033] The high-silicon steel thin strip is prepared by rapid solidification method, and its thickness is further reduced by cold rolling method, and the surface quality is improved to improve its high-frequency magnetic properties. During the cold rolling process, the reduction amount of the first rolling pass is controlled to further improve the plasticity, so that a thin strip with a thickness of 0.05 mm can be obtained. Its process route is as figure 1 shown.

[0034](1) Raw material preparation: use industrial pure iron (industrial pure iron DT0, iron content 99.5%) and crystalline silicon (purity 99.9%) as raw materials, and mix according to the ratio of silicon content 6.5wt.%.

[0035] (2) Rapid solidification stripping: heat and smelt the raw material, and in the molten liquid state, use the stripping method to rapidly solidify it to obtain a high-silicon steel thin strip with a thickness of 0.06mm.

[0036] (3) Cold rolling: the alloy thin strip obtained by rapid s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com