Patents

Literature

58results about How to "Mass production possible" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for preparing foam material reinforced silica aerogel composite material

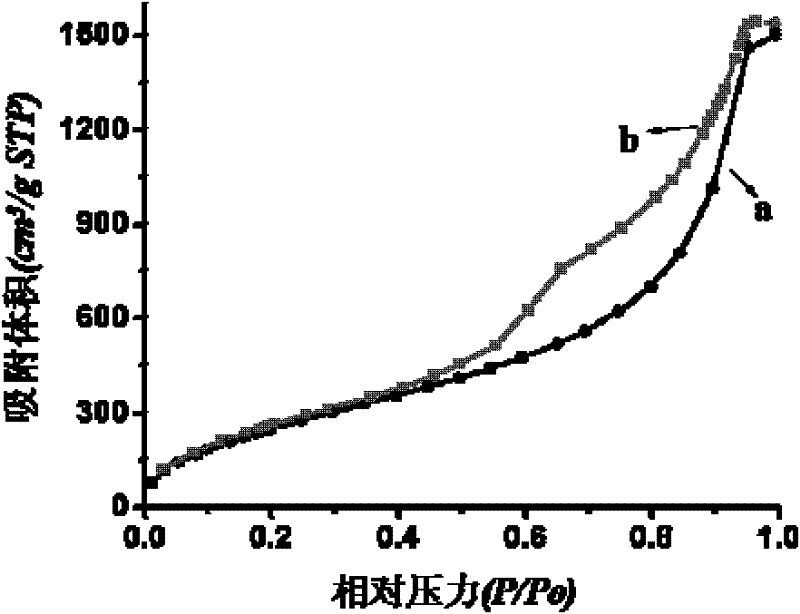

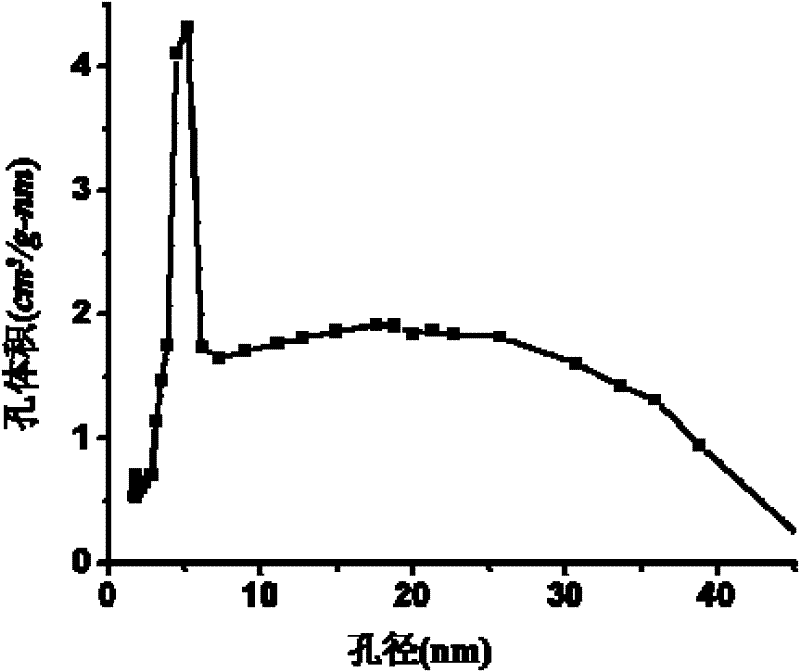

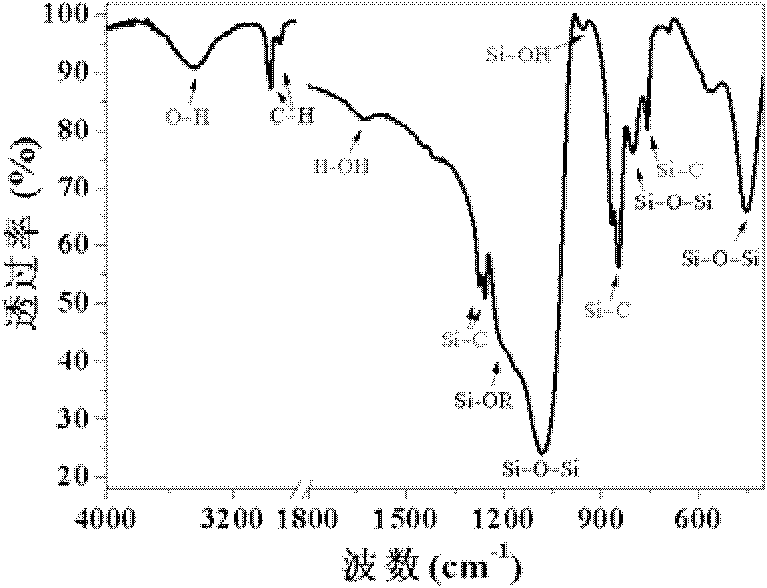

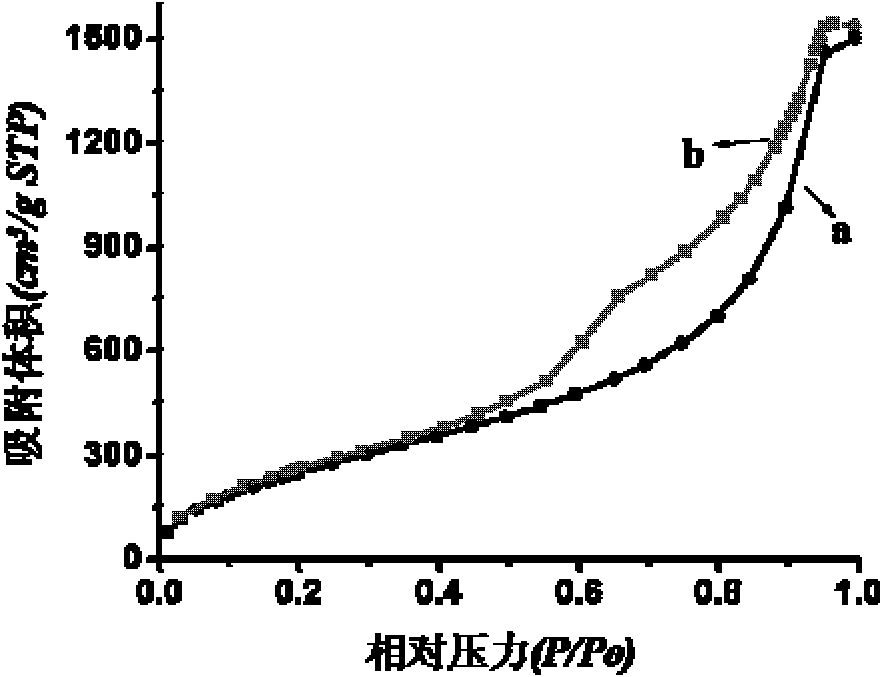

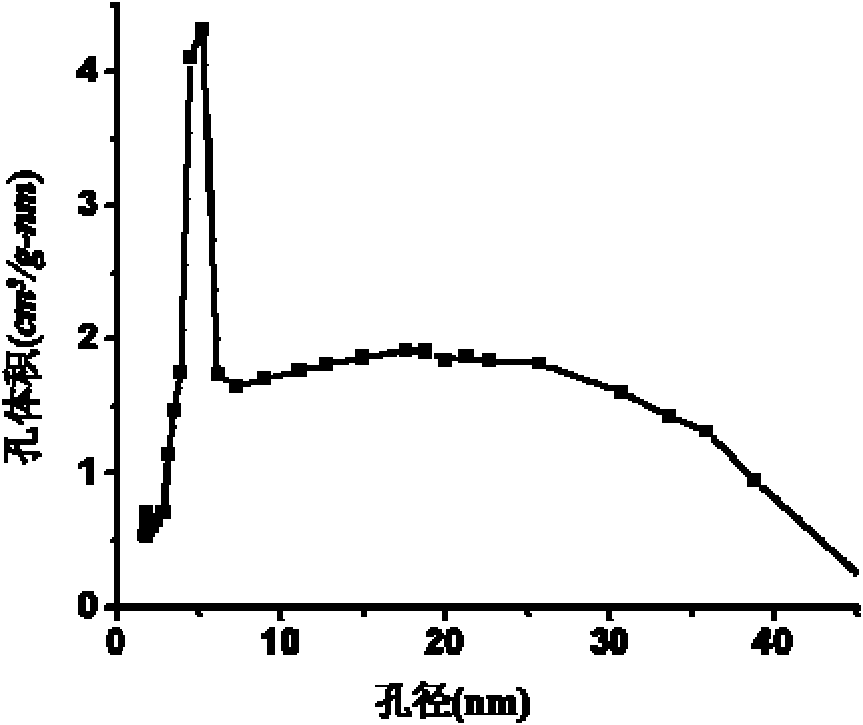

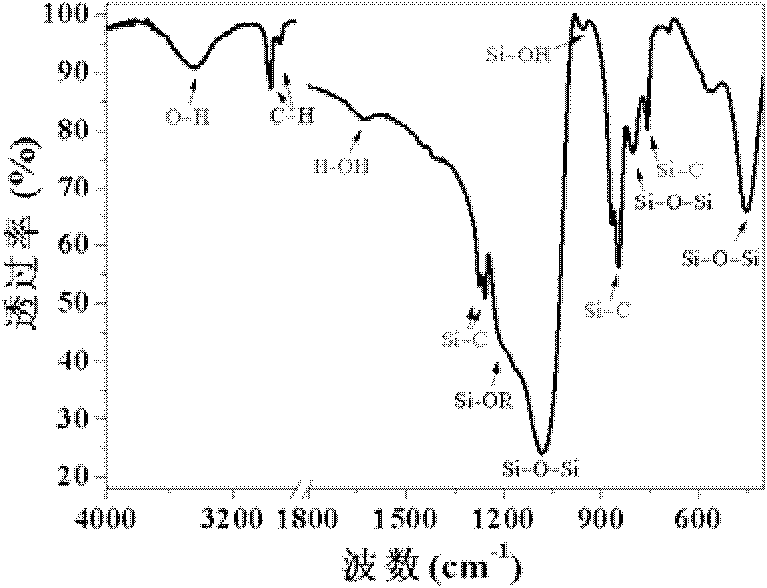

The invention discloses a method for preparing a foam material reinforced silica aerogel composite material and relates to silica aerogel. The method comprises the following steps of: preparing silica plural gel and aging the silica plural gel, modifying and drying. Through test, porosity is 80 t o 95 percent, density is 0.15 to 0.5g / cm<3>, the Brunauer-Emmett-Teller (BET) specific surface area is 600 to 1,100m<2> / g, and a water contact angle is 130 to 160 degrees; the foam material reinforced silica aerogel composite material is super hydrophobic; aerogel pore size distribution is relativelycentralized and the pore size of the aerogel is 2 to 50nm; and coefficient of heat conductivity is 0.01 to 0.035 W / (m.K), compression strength is 0.3 to 2Mpa (2 percent deformation), and elastic modulus is 1 to 5 Mpa. Meanwhile, the foam material reinforced silica aerogel composite material has good heat insulation performance, and adsorption performance, environment-friendliness and the other excellent performance. The method is simple, is short in a cycle, low in cost, and high in safety, and contributes to large-scale production; and by the method, excellent performance of the aerogel can be kept and the mechanical property of aerogel can be improved.

Owner:ZHONGKE RUNZI (CHONGQING) ENERGY SAVING TECH CO LTD

Resin for polyurethane shoe with extremely-low density and high hardness and preparation method thereof

The invention relates to resin for a polyurethane shoe with extremely-low density and high hardness and a preparation method thereof, belonging to the chemical field. The resin is prepared by foaming a component A and a component B at a certain condition through a polyurethane foaming machine and injecting the mixture into a shoe mold. The component A is formed by mixing polyalcohol A1, polymer of polyester polyol A2, a cross-linking agent, a polyesterdiol chain extender, a catalyst, an organic silicon foam stabilizer, a water foaming agent and the like; and the component B is a prepolymer prepared by reacting polyisocyanates, polyester polyol B1 and polyether polyol B2. The invention has the advantages of maintaining higher hardness of products at lower density and greatly reducing the productions cost of production manufacturers of the polyster type polyurethane shoe. In addition, the invention has easily-obtained raw material, favorable repeatability of products and capability of realizing batch production.

Owner:无锡双象新材料有限公司

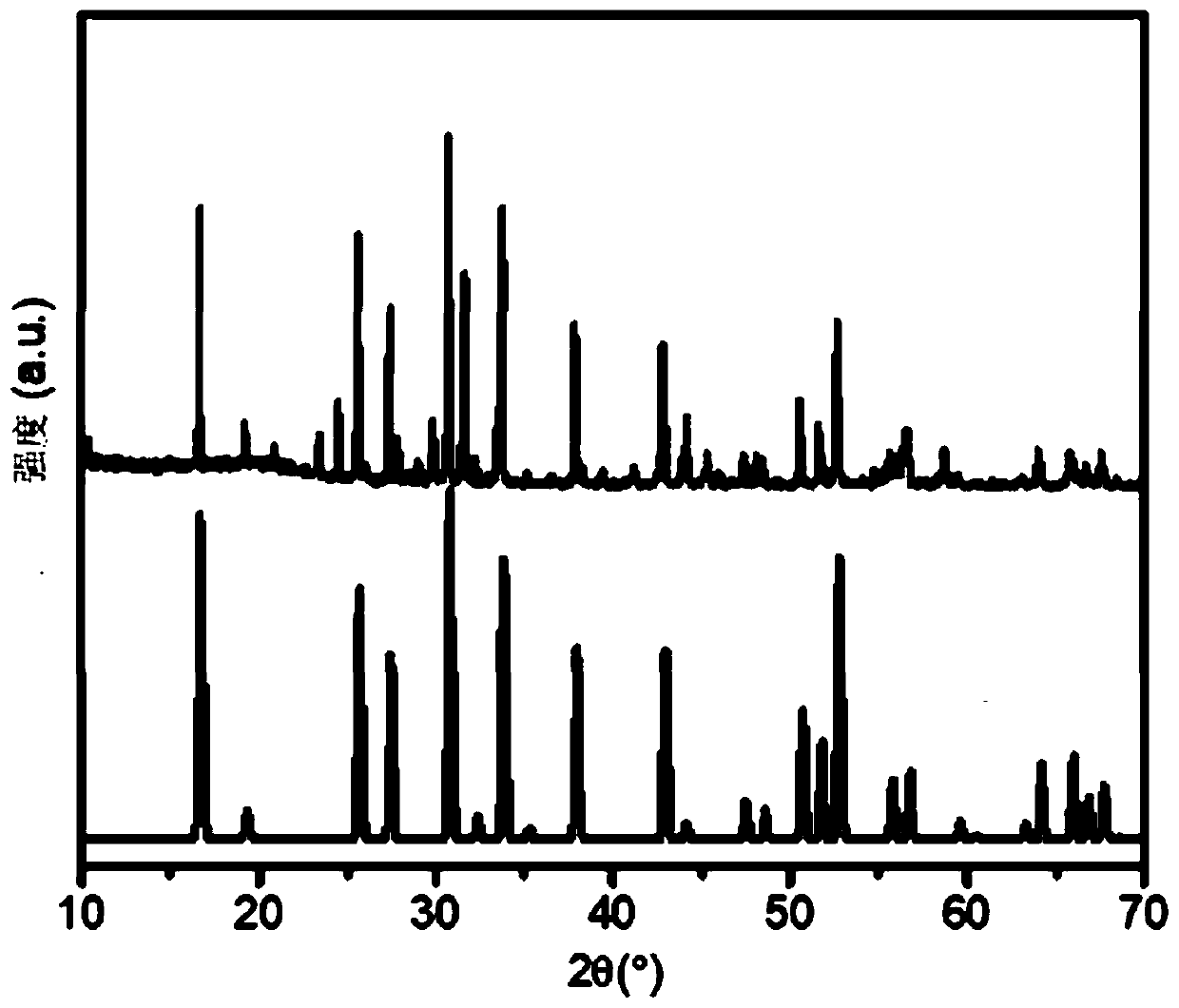

Lithium lanthanum zirconium oxide solid electrolyte, preparation method thereof and lithium ion battery

ActiveCN109818051AReduce interface impedanceImproved magnification performanceSecondary cellsSolid state electrolyteInterfacial impedance

The invention belongs to the field of all-solid-state lithium batteries, and discloses a lithium lanthanum zirconium oxide solid electrolyte. The lithium lanthanum zirconium oxide solid electrolyte comprises 60-75wt% of a polymer, 8-15wt% of a lithium salt and 15-30wt% of a lithium lanthanum zirconium oxide three-dimensional porous inorganic network, wherein the polymer is compounded in the lithium lanthanum zirconium oxide three-dimensional porous inorganic network in situ. The invention also discloses a preparation method of the lithium lanthanum zirconium oxide solid electrolyte and application of the lithium lanthanum zirconium oxide solid electrolyte in the field of lithium ion batteries. The lithium lanthanum zirconium oxide three-dimensional porous network provides a continuous lithium ion transmission channel, so that the ionic conductivity is higher. Meanwhile, due to the existence of the lithium lanthanum zirconium oxide three-dimensional porous network, certain mechanical properties are provided for the composite solid electrolyte, the growth of lithium dendrites can be inhibited, and the high-temperature performance and safety of the battery are improved. Therefore, theinterfacial compatibility and stability between the solid electrolyte and the electrode are optimized and improved, and the formed all-solid-state lithium battery has the advantages of being stable in cycle performance, high in rate capability, low in interfacial impedance and good in stability.

Owner:SOUTH UNIVERSITY OF SCIENCE AND TECHNOLOGY OF CHINA

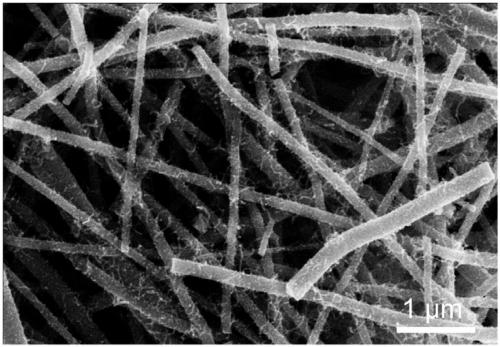

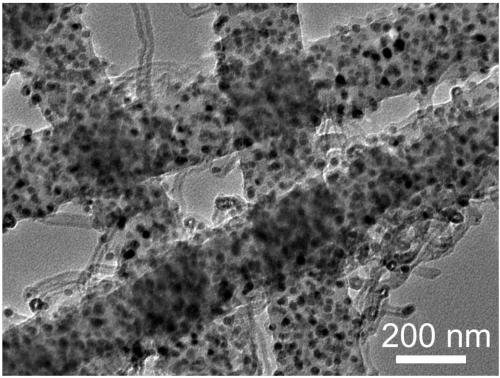

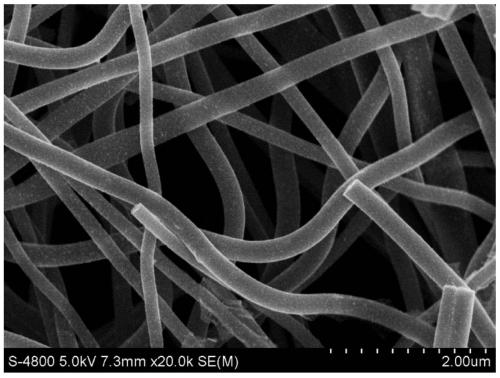

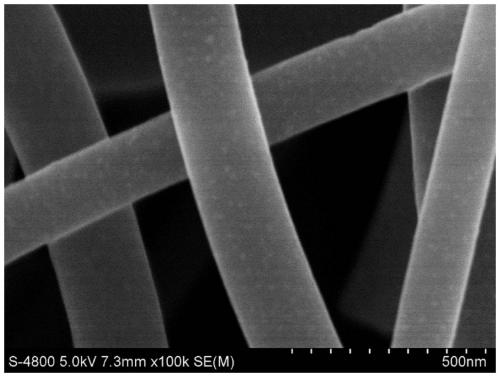

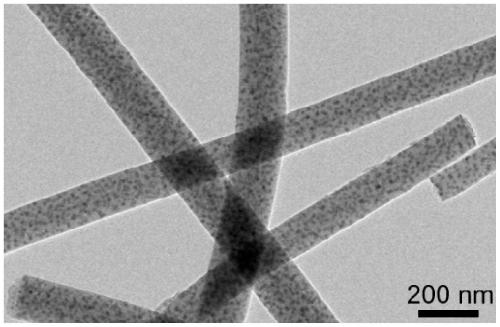

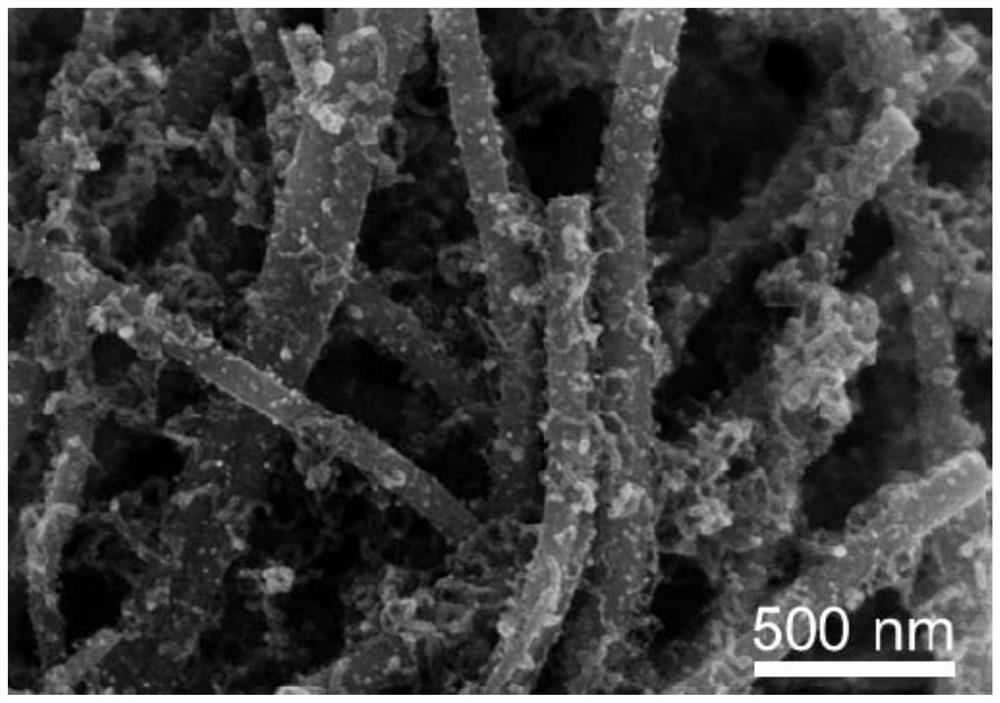

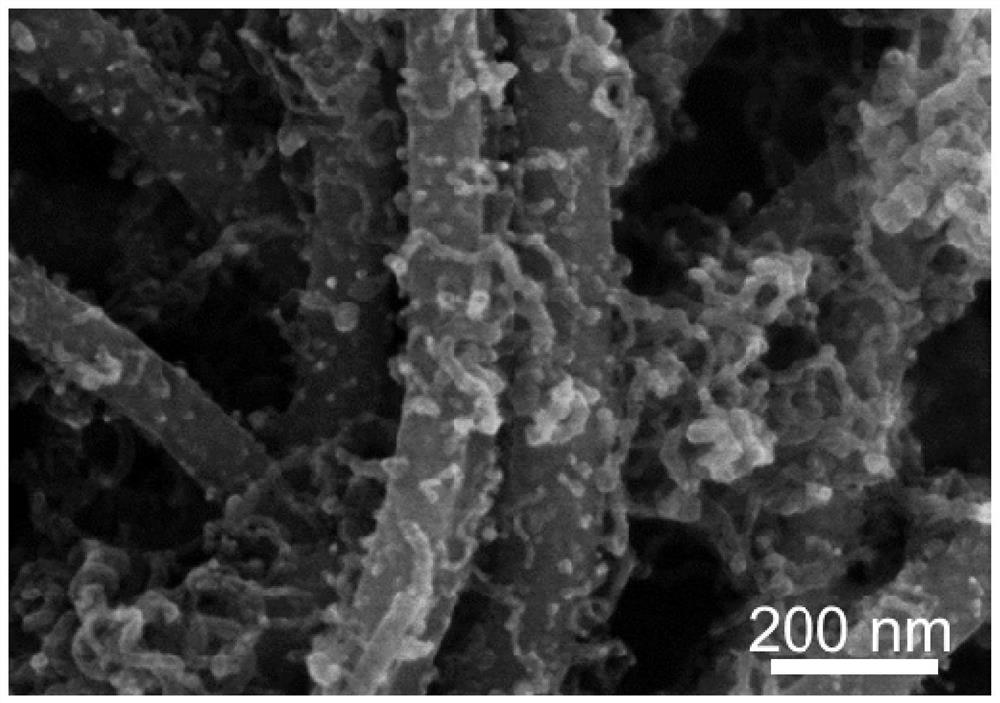

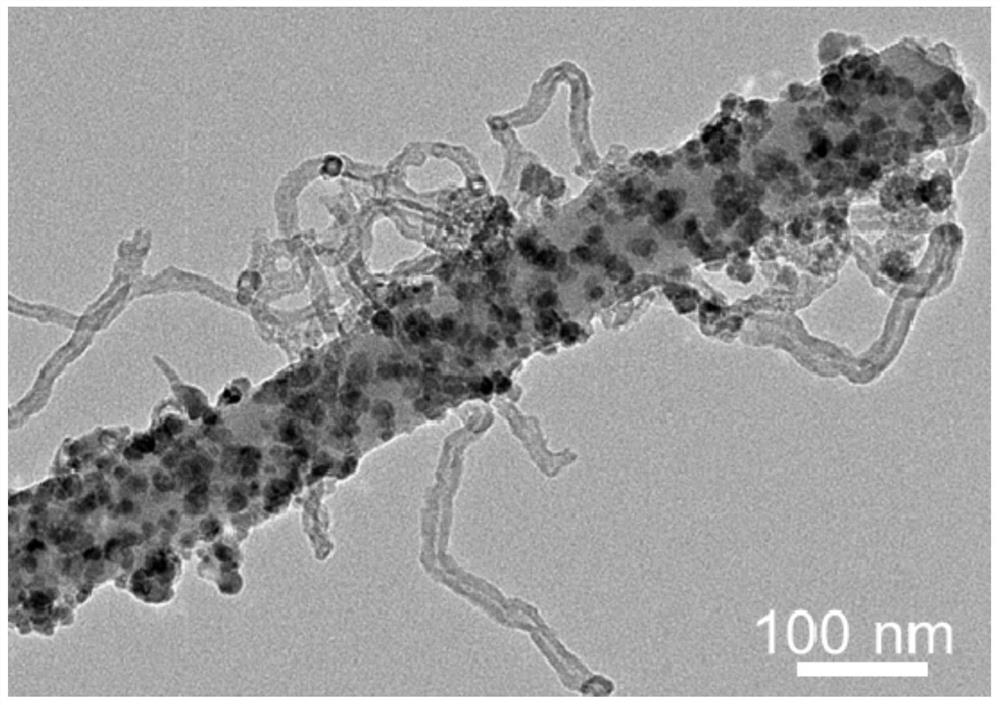

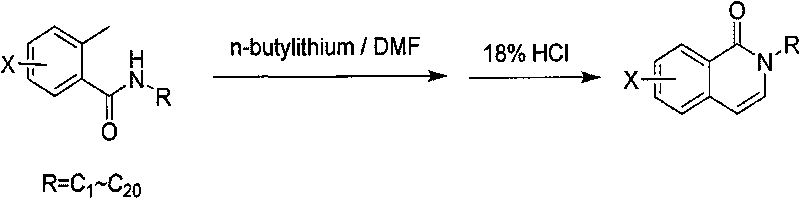

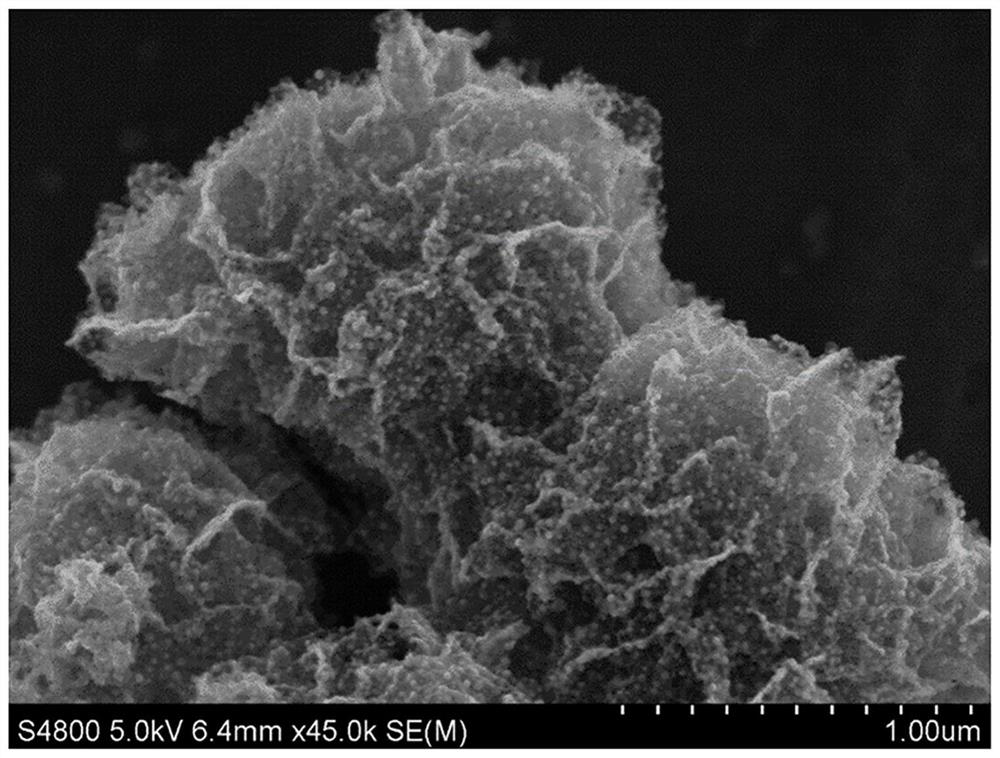

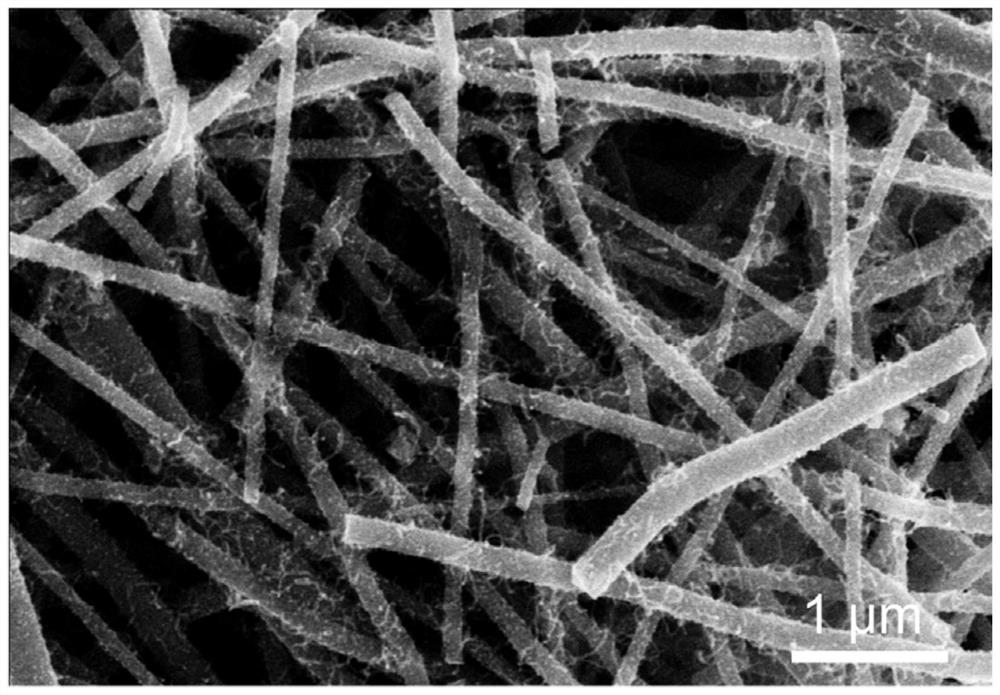

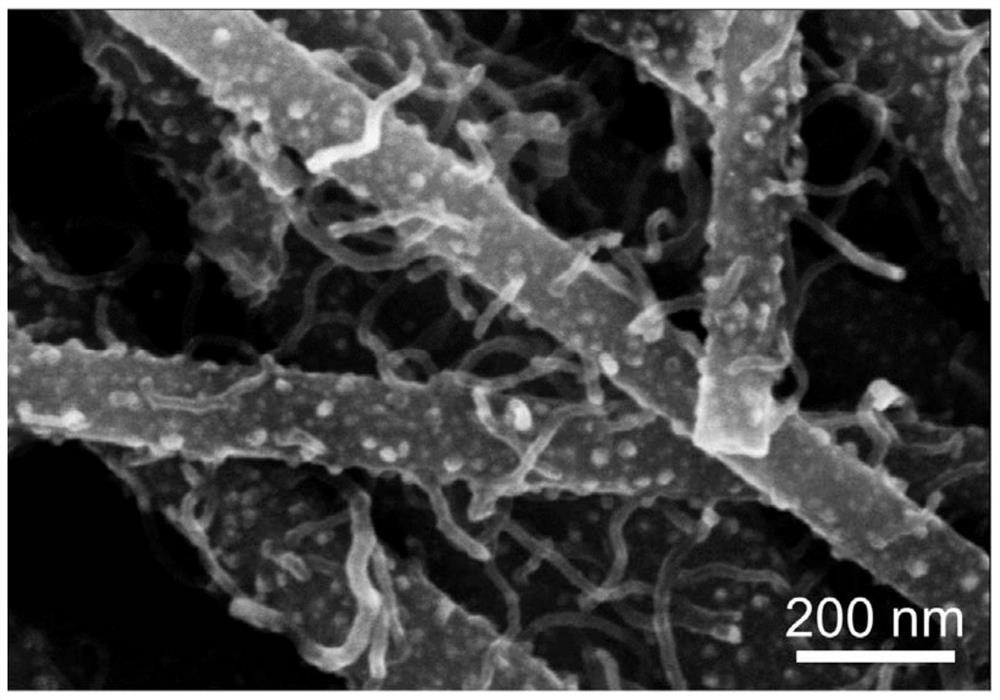

Preparation method of Ni3Fe-loaded nitrogen-doped carbon nanometer composite material, and product and applications thereof

ActiveCN109248703ARegular shapeImprove hydrogen evolution activityCatalyst activation/preparationElectrodesElectrospinningAir atmosphere

The invention discloses a preparation method of a Ni3Fe-loaded nitrogen-doped carbon nanometer composite material, and a product and applications thereof. The preparation method comprises following steps: 1, a Ni<2+> / Fe<3+> / PVP mixed sol is prepared; 2, the Ni<2+> / Fe<3+> / PVP mixed sol is subjected to electrostatic spinning so as to obtain solid carbon fiber film; 3, the solid carbon fiber film issubjected to pre-oxidation at air atmosphere at 200 to 300 DEG C, programmed heating is adopted for heat processing at 400 to 1000 DEG C at an inert atmosphere so as to obtain the Ni3Fe-loaded nitrogen-doped carbon nanometer composite material. The preparation method is low in cost, is easy, and is universal; the obtained Ni3Fe-loaded nitrogen-doped carbon nanometer composite material is of a one-dimensional composite structure (carbon nanometer fiber and carbon nanotube); Ni3Fe alloy particles can be embedded into the carbon nanometer fiber and carbon nanotube uniformly; the Ni3Fe-loaded nitrogen-doped carbon nanometer composite material can be taken as a water electrolysis hydrogen evolution electrocatalytic material, and possesses relatively high activity and excellent stability.

Owner:NANJING NORMAL UNIVERSITY

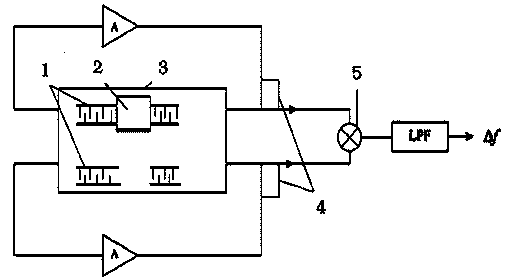

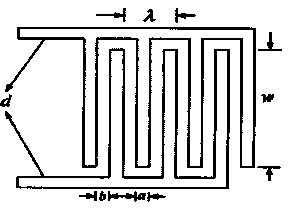

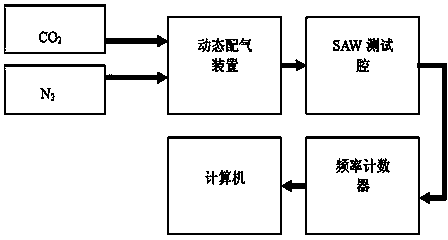

Manufacturing method of all-printed electronic carbon dioxide thin-film SAW (Surface Acoustic Wave) sensor

InactiveCN103994939ASimple processLow costWeighing by absorbing componentThin film sensorMechanical engineering

The invention relates to a manufacturing method of an all-printed electronic carbon dioxide thin-film SAW (Surface Acoustic Wave) sensor. The manufacturing method disclosed by the invention specifically comprises the following steps: selecting a piezoelectric substrate; designing and printing an electrode; preparing and printing a sensitive material; and designing and printing a driving circuit. Compared with the traditional microelectronic process, the carbon dioxide thin-film SAW sensor prepared based on printed electronics has the obvious advantages of being low in cost, simple and rapid in manufacturing process, environmentally friendly and the like.

Owner:TIANJIN UNIVERSITY OF TECHNOLOGY

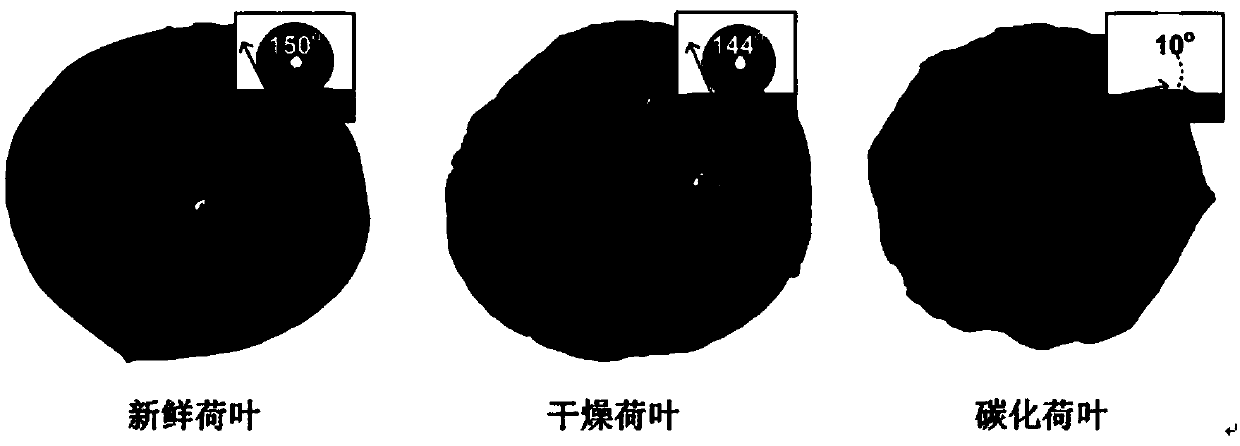

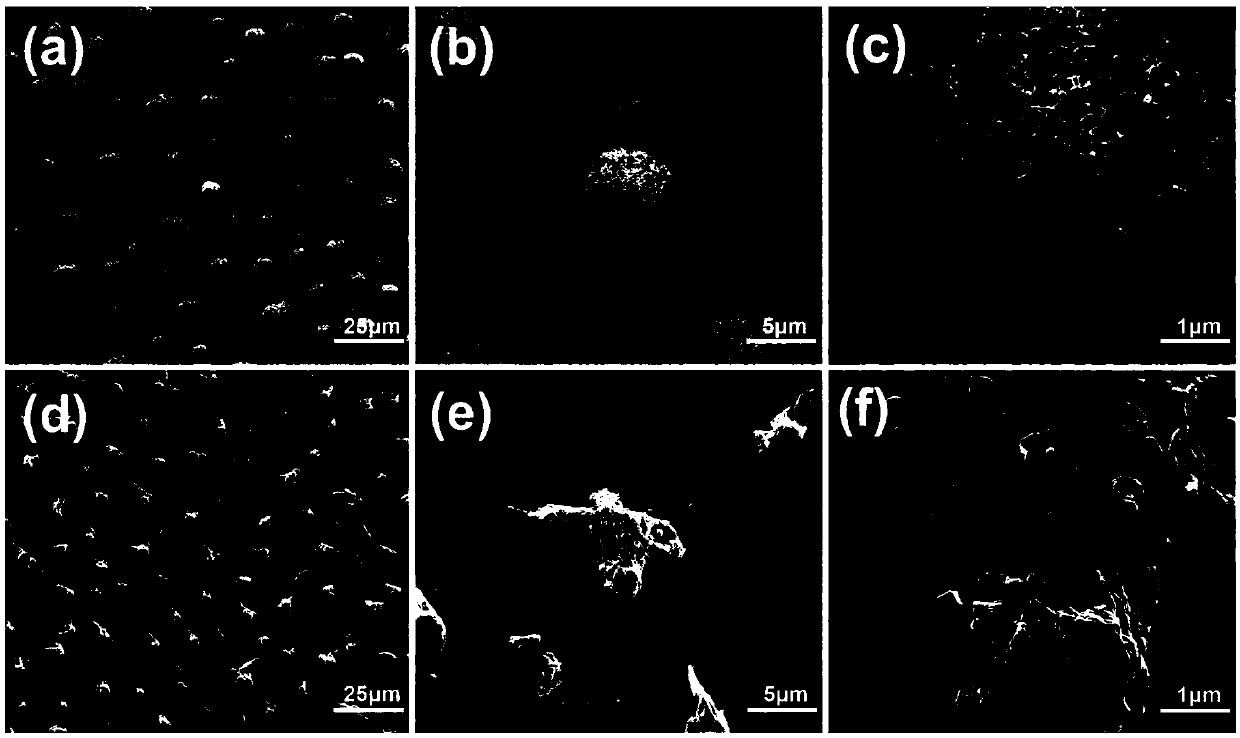

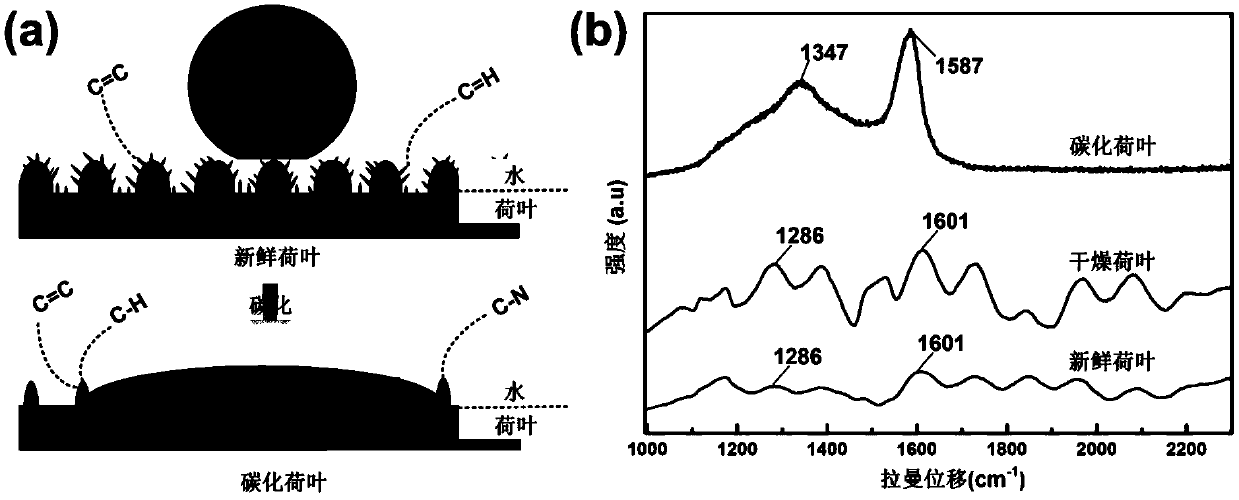

Lotus leaf-based photothermal conversion material preparing method

ActiveCN109575886ALow cost of preparationGood repeatabilityHeat-exchange elementsSteam generation using solar heatSolar waterChemistry

A lotus leaf-based photothermal conversion material preparing method belongs to the technical field of preparation of solar energy photothermal conversion materials. The lotus leaf-based photothermalconversion material preparing method comprises 1) cleaning and drying fresh lotus leaves; 2) freezing the processed lotus leaves at -18--24 DEG C for 12-24 h to obtain a frozen sample A; 3) drying thefrozen sample A in a vacuum freeze-drying cabinet at a vacuum degree of 6-10 Pa and a temperature of -30--50 DEG C for 48-72 h to obtain a dried sample B; 4) carbonizing the sample B in a nitrogen atmosphere at 500-700 DEG C for 4-6 h to obtain carbonized lotus leaves. The lotus leaf-based photothermal conversion material preparing method has the advantages of being low in preparation cost, goodin repeatability, simple in process, capable of achieving large-scale production and the like; the obtained carbonized lotus leaves have properties of hydrophilicity, transmission water channels, highthermal and light absorbency and the like and can be applied to the field of solar water evaporation.

Owner:UNIV OF ELECTRONIC SCI & TECH OF CHINA

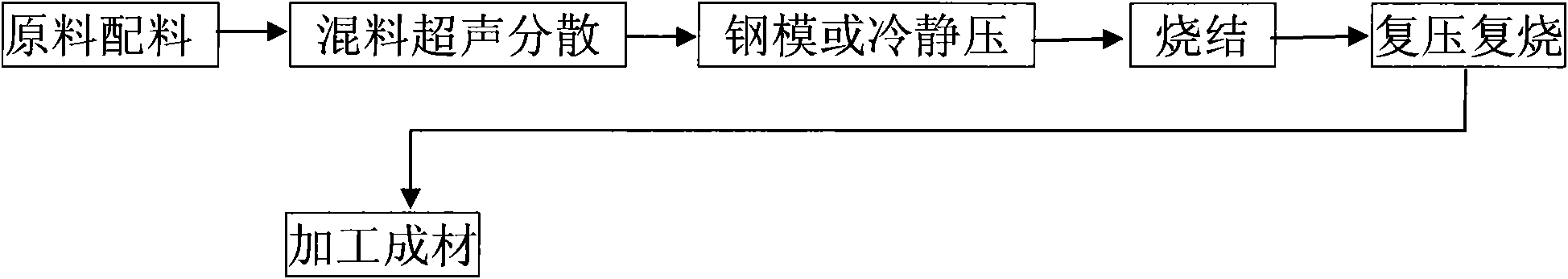

Preparing method of silver-base metal acid-salt electrical-contact composite material

InactiveCN101656160AReduce the use temperaturePrevent arc blowingElectric switchesMicrometerElectricity

The invention relates to an electrical-contact composite material, in particular to a preparing method of a silver-base metal acid-salt electrical-contact composite material, which belongs to the technical field of material smelting. The method comprises the following steps: mixing silver-base powder of which the granularity is lower than 20 micrometer and metal acid-salt powder in a powder mixerto lead the tin or copper element content to be 6 to 15 percent of the total weight, uniformly mixing the silver-base powder and the metal acid-salt powder by ultrasonic waves of which the frequency is from 10 to 30 KHz, and compressing the mixed powder into biscuits; sintering the biscuits at a temperature from 500 to 800 DEG C into ingot billets, and recompressing and resintering the ingot billets at a temperature from 500 to 800 DEG C; and sending the recompressed and resintered billets into an extruder to directly extrude out wire rods, and processing the wire rods into finished products.The method has simple technology and excellent processing performance, better solves the problem of the temperature rise of the electrical-contact material, improves the integrated performance of thematerial, and overcomes the problem in the processing and the use of the electrical-contact material in prior.

Owner:KUNMING UNIV OF SCI & TECH

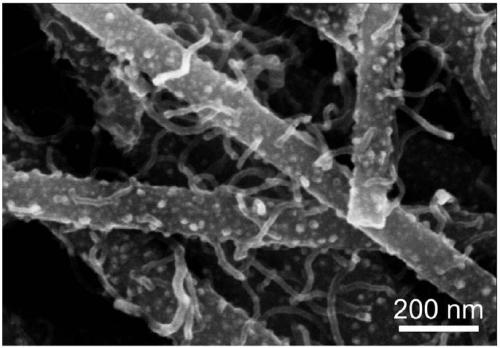

Preparation method and application of hollow structure Co3O4/CeO2 nanoparticle loaded nitrogen doped carbon nanofiber material

ActiveCN110124713AFast transferFast outputPhysical/chemical process catalystsElectrodesFiberSolid carbon

The invention discloses a preparation method of a hollow structure Co3O4 / CeO2 nanoparticle loaded nitrogen doped carbon nanofiber material and application thereof. The preparation method comprises thefollowing steps: 1) preparing a CO<2+> / Ce<3+> / PVP mixed sol; 2) electrospinning the CO2+ / Ce3+ / PVP mixed sol to obtain a solid carbon fiber film; and 3) preoxidizing the solid carbon fiber film in anair atmosphere of 200-300 DEG C, performing heat treatment in an inert atmosphere of 400-1000 DEG C with programmed temperature rise, and obtaining the hollow structure Co3O4 / CeO2 nanoparticle loadednitrogen doped carbon nanofiber composite material by utilizing the Kirkendall effect of nano materials. The preparation method is low in cost, simple and universal. The prepared material is a one-dimensional carbon nanofiber material; hollow Co3O4 / CeO2 composite nanoparticles are uniformly embedded in carbon nanofiber; and the material can be used as an electrolytic water oxygen evolution electrocatalytic material and has higher activity and excellent stability.

Owner:NANJING NORMAL UNIVERSITY

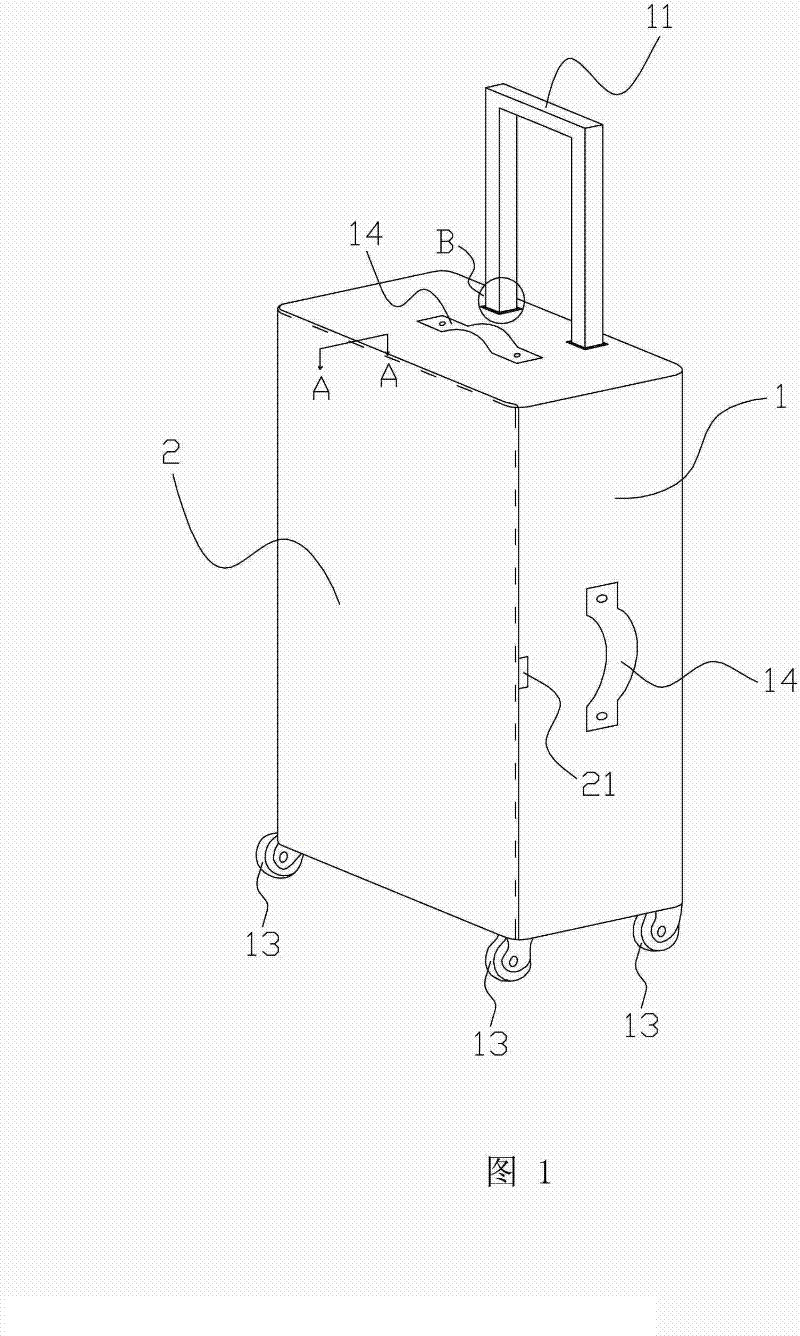

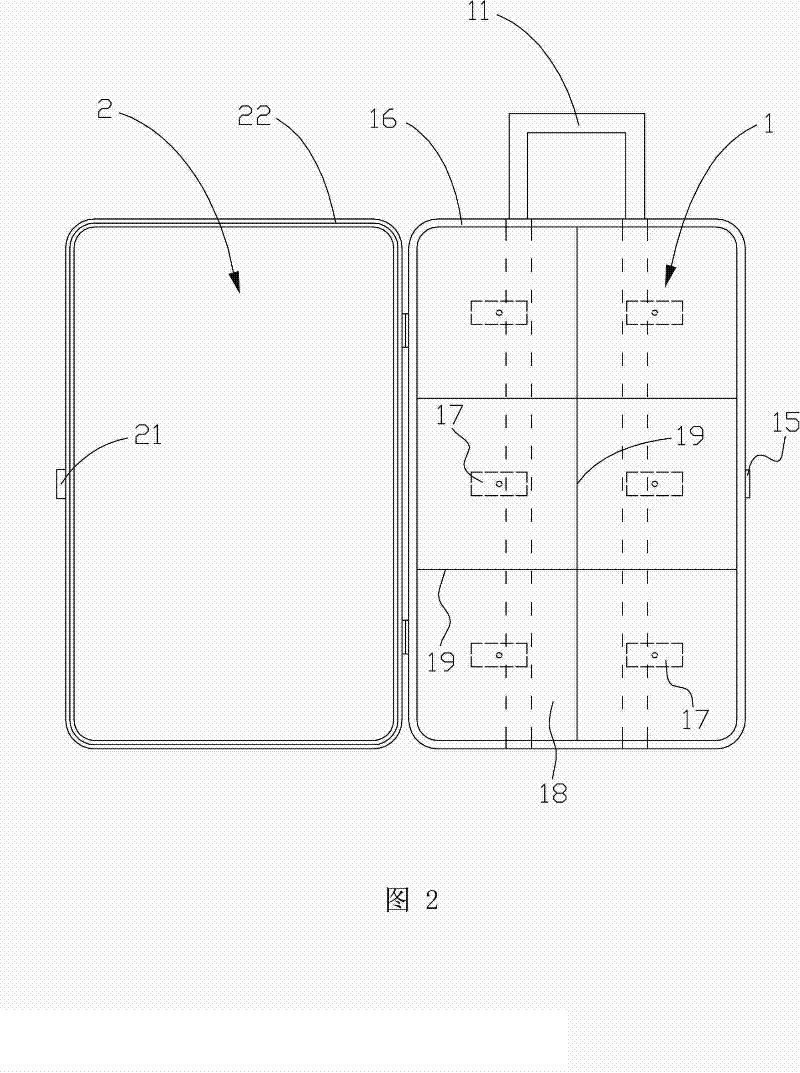

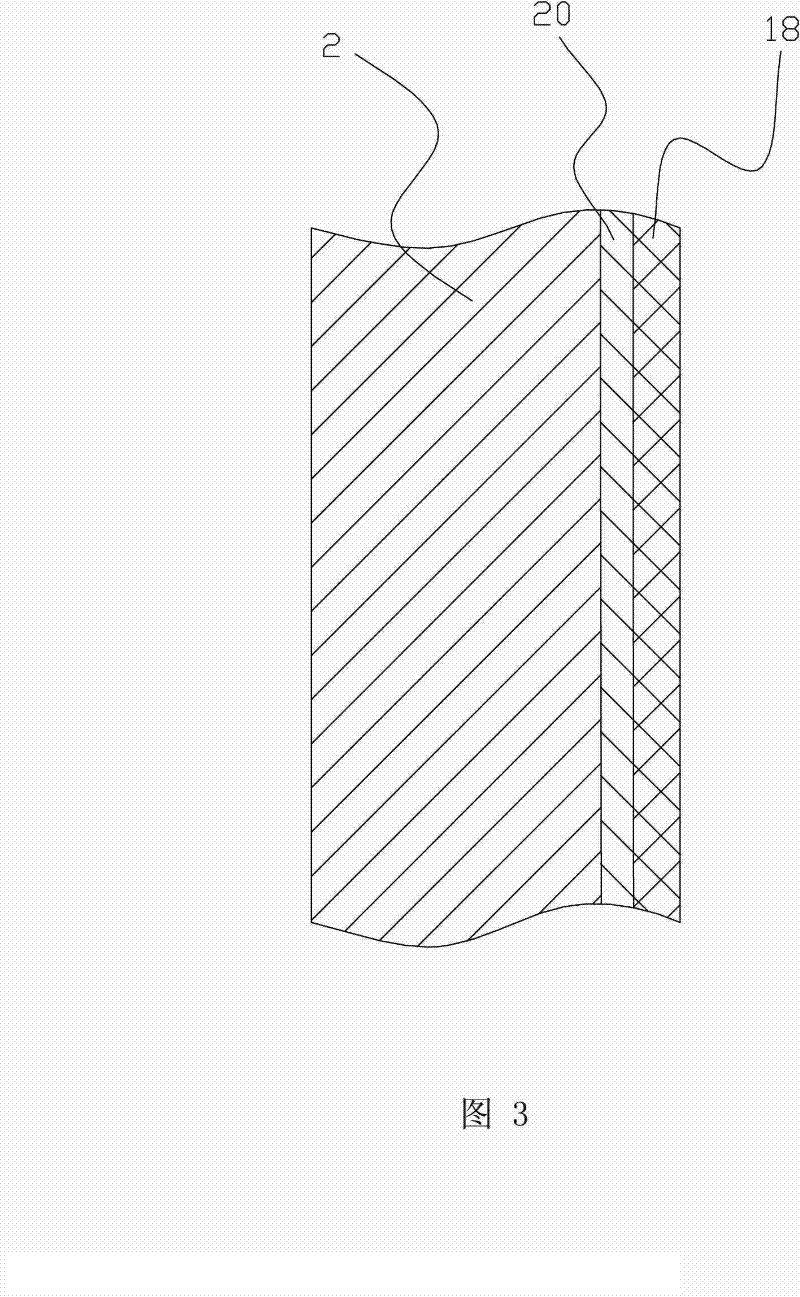

Novel suitcase

InactiveCN102440503ARealize mechanized productionReduce manufacturing costHandbagsLuggageResource savingEngineering

The invention discloses a novel suitcase which comprises a case body and a cover body, wherein the case body is integrally formed by a light metal piece and is provided with an opening, the cover body is matched with the case body, the cover body is movably connected and tightly buckled on the case body, the case body is provided with a telescopic pull rod, rolling wheels are arranged at the lower part of the case body, at least one lifting handle is arranged on the case body, a layer of replaceable cloth or leather which is fully distributed on the outer surface is adhered on each of the case body and the cover body, or a decorative layer pattern is spray-coated on the outer surface of each of the case body and the cover body. The suitcase disclosed by the invention can realize mechanized production, is low in manufacturing cost and high in production efficiency, and can further greatly save production process steps and labor resources; the suitcase can be used for rental, and the cloth, the leather or the pattern layers can be replaced according to the needs of users; one suitcase can be used as multiple suitcases, so that the suitcase is resource-saving and particularly suitable for fashion women; and the suitcase is good in sealing property and can also be used as a life buoy.

Owner:吴楚兴 +1

NiS/NiO heterojunction-loaded nitrogen-doped carbon nano composite material and preparation method and application thereof

ActiveCN111659439ALarge specific surface areaIncrease contactCatalyst activation/preparationElectrodesFiberAir atmosphere

The invention provides a NiS / NiO heterojunction-loaded nitrogen-doped carbon nano composite material and a preparation method and application thereof. The preparation method comprises the following steps: S1, preparing Ni < 2 + > / PVP mixed sol; S2, performing electrostatic spinning on the Ni < 2 + > / PVP mixed sol to obtain a solid carbon fiber film; and S3, pre-oxidizing the solid carbon fiber film in an air atmosphere, and sequentially carrying out heat treatment in an inert atmosphere, oxidation treatment in the air atmosphere and sulfuration vapor deposition to obtain the NiS / NiO heterojunction-loaded nitrogen-doped carbon nano composite material. PVP selected in the method is cheap and easy to obtain, and compared with a traditional method for preparing the water electrolysis oxygen evolution electrocatalyst material, the method is simple and feasible in process, low in cost and easy to operate, and large-scale production can be achieved.

Owner:NANJING NORMAL UNIVERSITY

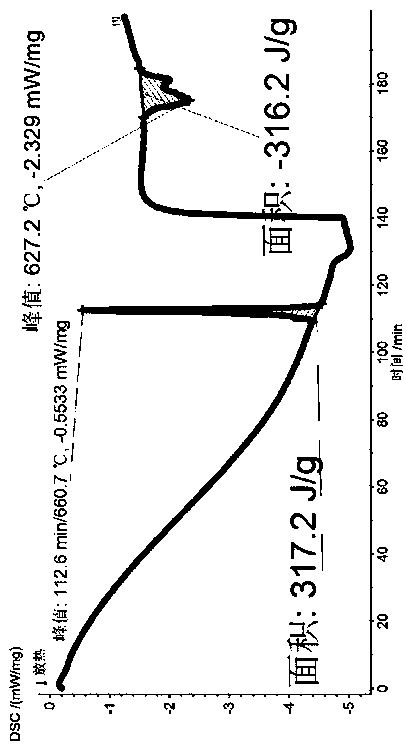

Preparation method of core-shell structure high-temperature phase-change heat accumulation material

The invention relates to a preparation method of a core-shell structure high-temperature phase-change heat accumulation material and belongs to the technical field of heat accumulation materials. Thepreparation method comprises the following steps: adding aluminum powder into a nickel chloride solution; dropwise adding an ammonium fluoride solution and ammonia water in sequence and carrying out reaction; then carrying out high-temperature roasting to obtain the core-shell structure Al@NiO-Al2O3 high-temperature phase-change heat accumulation material. According to the core-shell structure Al@NiO-Al2O3 high-temperature phase-change heat accumulation material prepared by the invention, aluminum has good performance including relatively great melting heat, high coefficient of thermal conductivity, low evaporation pressure and the like; NiO-Al2O3 is combined with a shell so that a shell structure is dense and the thickness is increased; then the material can bear chemical corrosion of liquid-state metal with a fused state, and also can bear pressure caused by volume expansion; the material can provide relatively good mechanical strength, but also can be used for enhancing the heat-conduction performance.

Owner:KUNMING UNIV OF SCI & TECH

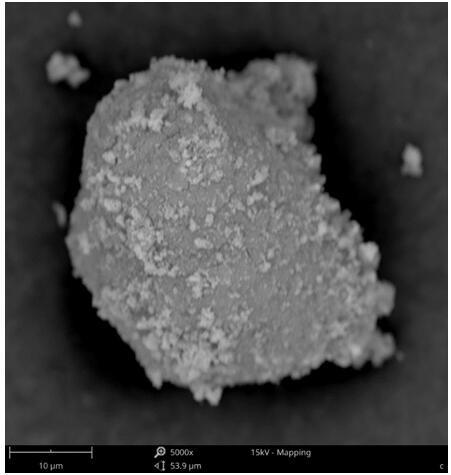

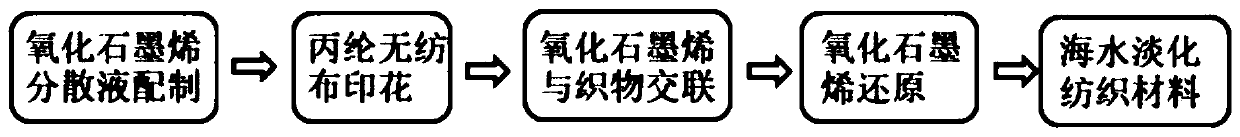

Preparation method of textile material for photo-thermal sea water desalination

InactiveCN110846896AImprove evaporation efficiencyCost-effectiveFibre typesDyeing processPolypropyleneWoven fabric

The invention discloses a preparation method of a textile material for photo-thermal sea water desalination. The preparation method includes the steps: A preparing 10-25g / L graphene oxide dispersion liquid to serve as printing paste, and performing single-side printing on a polypropylene needling non-woven fabric; B soaking and rolling the non-woven fabric in crosslinking finishing fluid twice, and pre-drying the non-woven fabric at the temperature of 80-100 DEG C to obtain a graphene oxide printing polypropylene fabric; C soaking the graphene oxide printing polypropylene fabric into reductionfinishing fluid; D taking out the soaked polypropylene fabric, washing the polypropylene fabric by deionized water, and drying the polypropylene fabric to obtain the textile material for photo-thermal sea water desalination. According to the method, stable and low-cost non-woven materials serve as a thermal insulating layer and a water channel, solar energy is effectively utilized, and water is sufficiently supplied for the surface of a photo-thermal material. The prepared photo-thermal conversion material is high in evaporation efficiency, any electric drive is omitted by the aid of solar drive, and cost performance is high. The method is simple to operate, low in cost, green and environmentally friendly, mass production can be achieved, and functional application of a textile is widened.

Owner:NANTONG UNIVERSITY

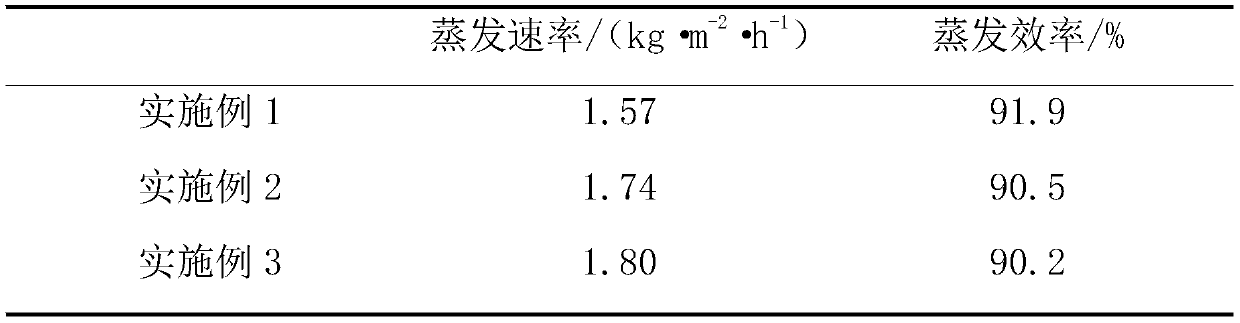

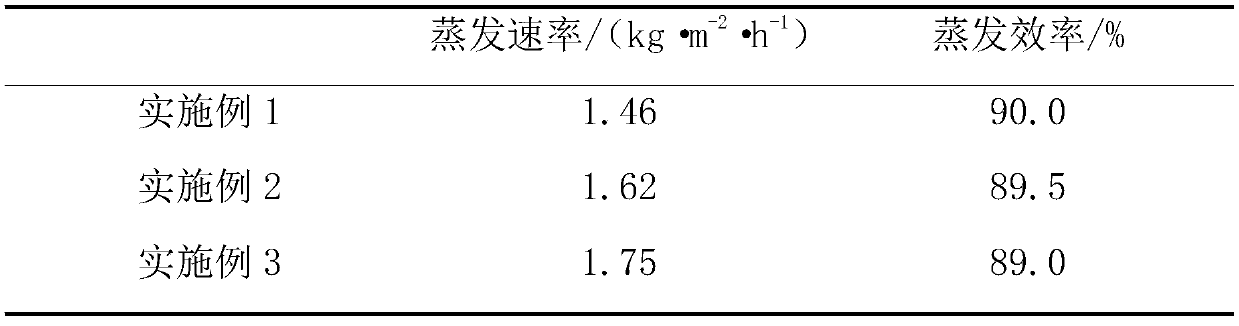

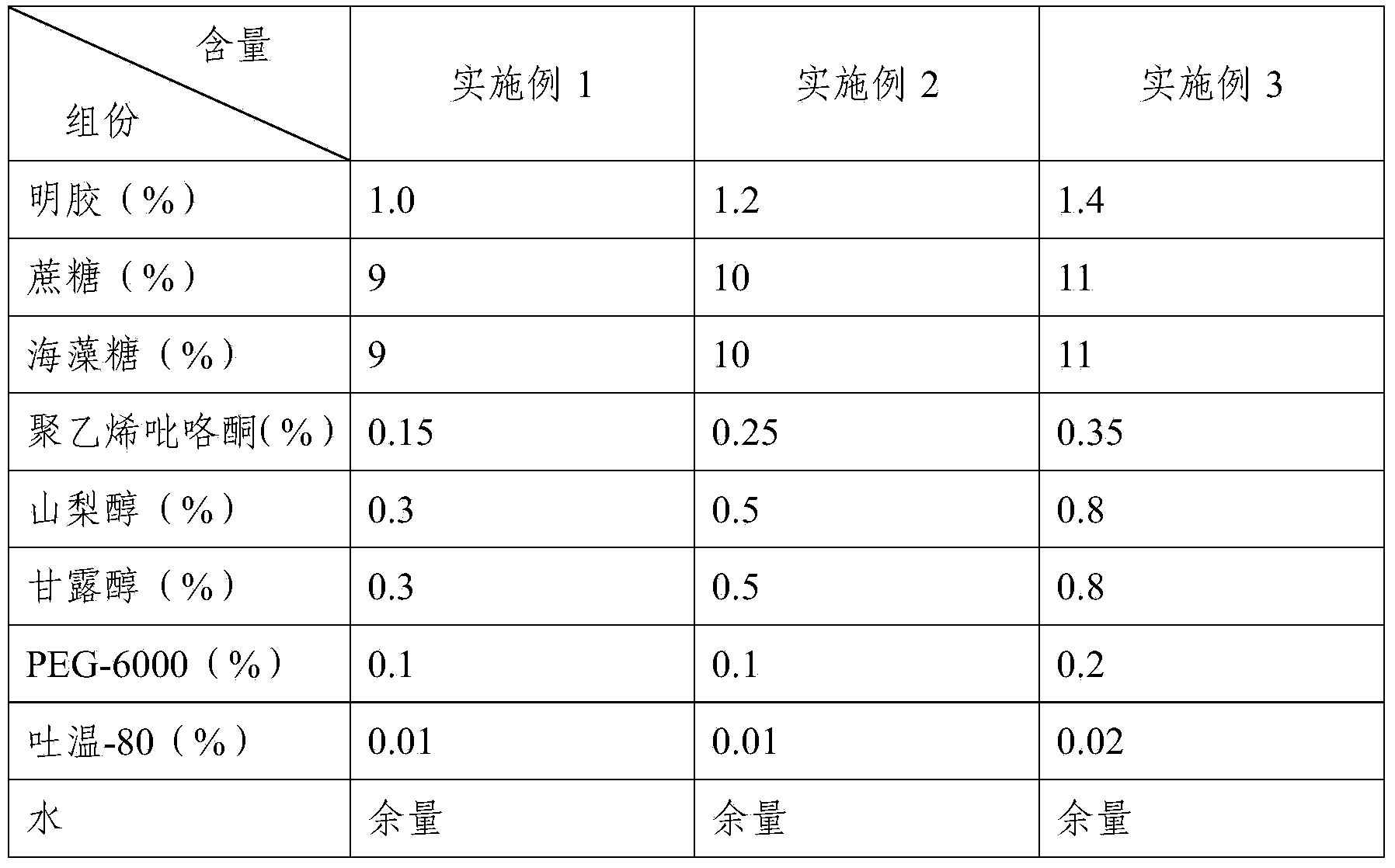

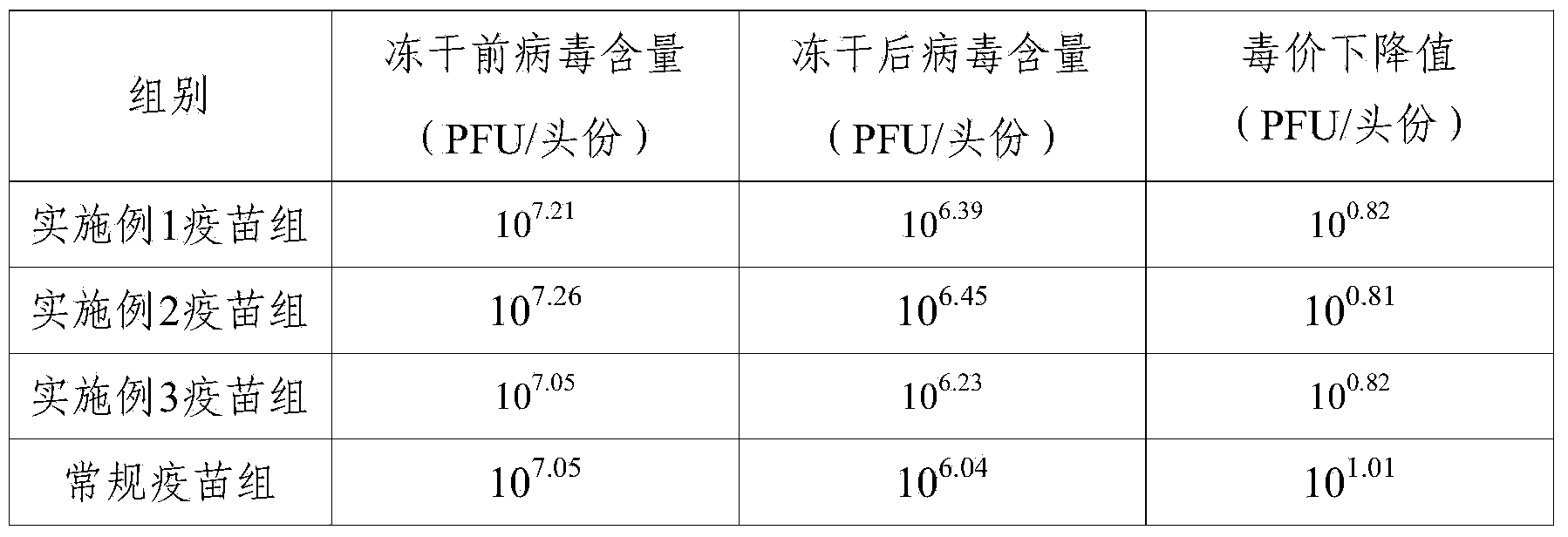

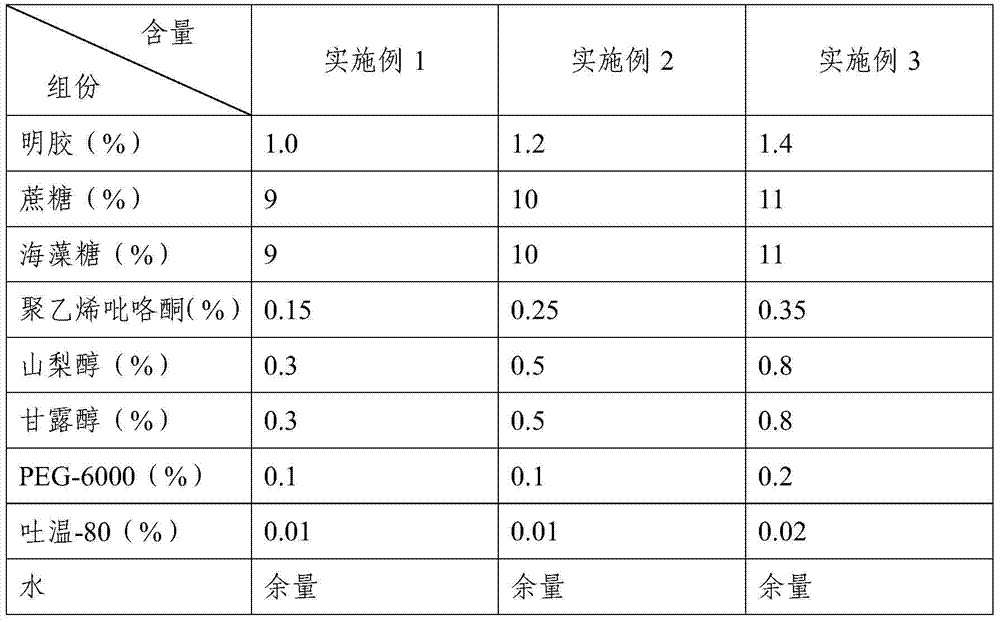

Porcine Japanese encephalitis live vaccine heat-resistant lyophilized protective agent as well as preparation method and application thereof

ActiveCN103656661AAvoid damageReduce loss ratePowder deliveryViral antigen ingredientsProtective antigenSucrose

The invention provides a porcine Japanese encephalitis live vaccine heat-resistant lyophilized protective agent. The protective agent comprises the following components in percentage by weight: 1.0-1.4% of gelatin, 9-11% of sucrose, 9-11% of trehalose, 0.15-0.35% of polyvinylpyrrolidone, 0 .3-0.8% of sorbitol, 0.3-0.8% of mannitol, 0.1-0.2% of PEG-6000, and 0.01-0.02% of tween-80, the pH value of the protective agent is 7.5, and the components are added with water to be dissolved and sterilized at high temperature to obtain the protective agent.The lyophilized protective agent disclosed by the invention is mixed with a porcine Japanese encephalitis live vaccine virus solution, and freeze-drying is carried out to obtain a lyophilized vaccine. The heat-resistant lyophilized protective agent disclosed by invention is simple in formulation, easy in preparation, suitable for large-scale production, has good protection efficacy for vaccines, and can ensure that the vaccines can be preserved for 10 days effectively at the normal temperature, even at the temperature of 37 DEG C, and preserved for 24 months at the temperature of 2-8 DEG C.

Owner:CHINA ANIMAL HUSBANDRY IND

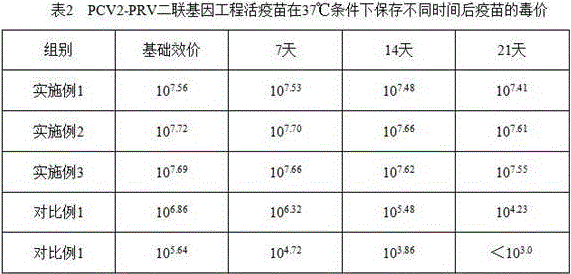

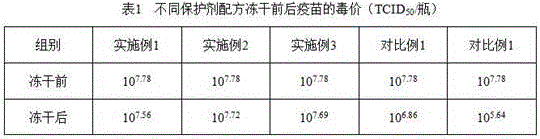

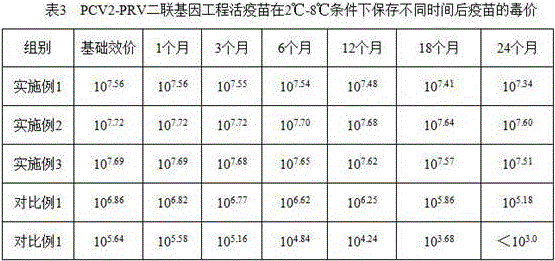

Heatproof freeze-drying protecting agent for recombined pseudorabies virus vaccines and preparation method of heatproof freeze-drying protecting agent

ActiveCN105561317AImprove protectionImprove securityViral antigen ingredientsAntiviralsVaccine StabilitySaccharum

The invention relates to a heatproof freeze-drying protecting agent for recombined pseudorabies virus vaccines. The heatproof freeze-drying protecting agent comprises, by weight, 4-8% of trehalose, 0-3% of cane sugar, 0.2-0.8% of sorbitol, 1-3% of polyvinylpyrrolidone K-30, 4-7% of soybean protein isolate, 0.5-1% of wheat proteolysis product and the balance injection water. The invention further provides a preparation method of the heatproof freeze-drying protecting agent for the recombined pseudorabies virus vaccines. The heatproof freeze-drying protecting agent is simple in formula, easy to prepare and suitable for mass production, has the advantages of high vaccine stability, prolonged vaccine shelf life and the like, and does not contain gelatin and animal source ingredients. Safety of the vaccines is high when the protecting agent is applied to the vaccines.

Owner:ZHAOQING DAHUANONG BIOLOGIC PHARMA

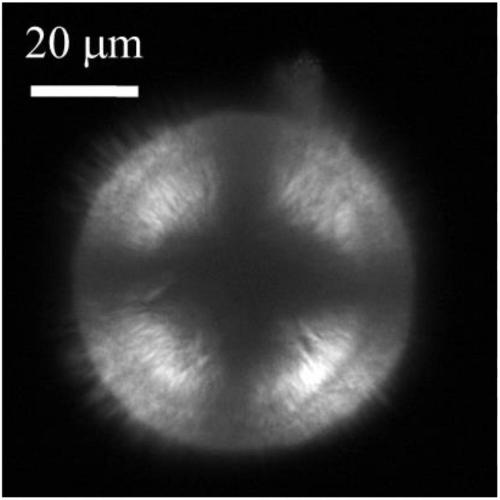

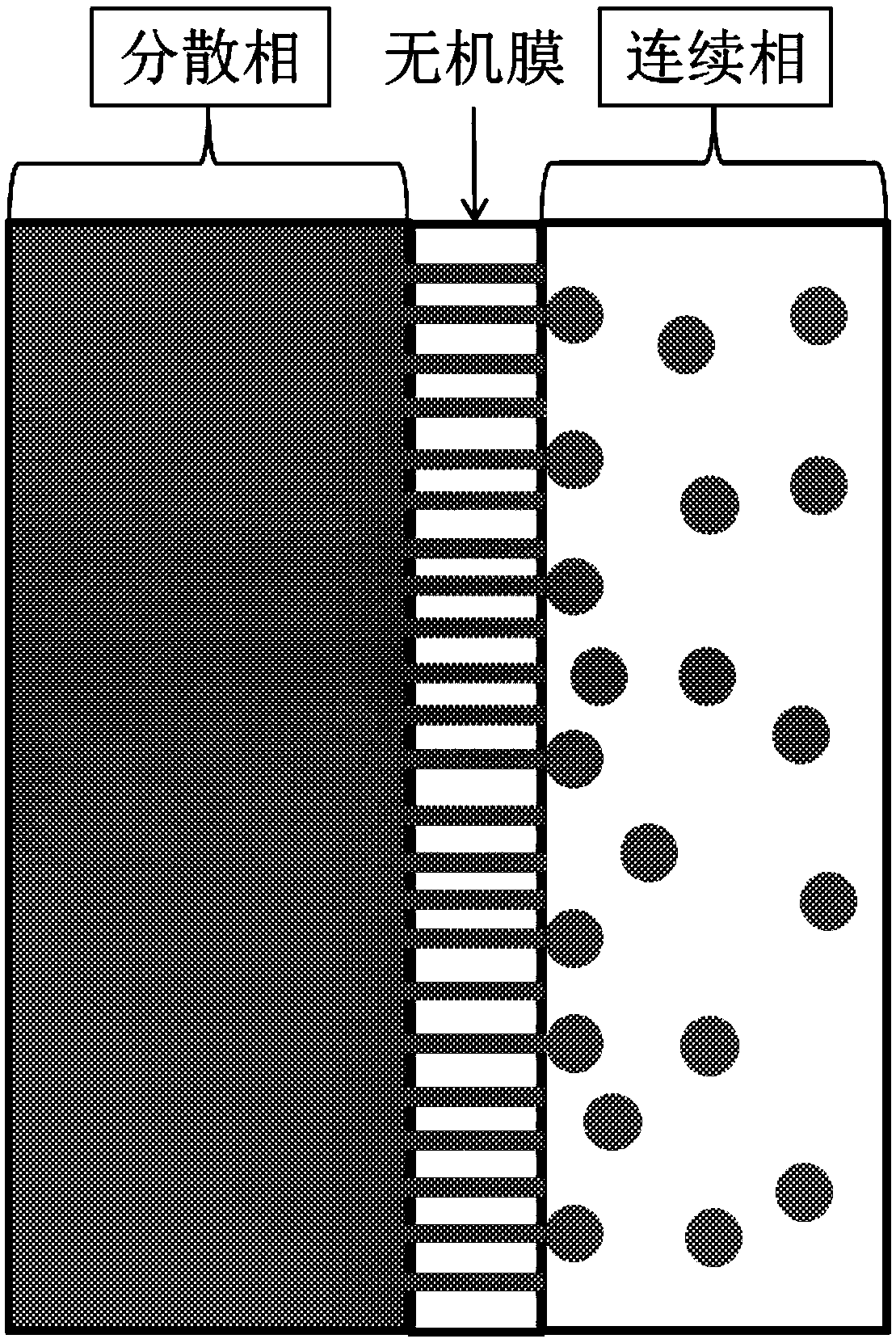

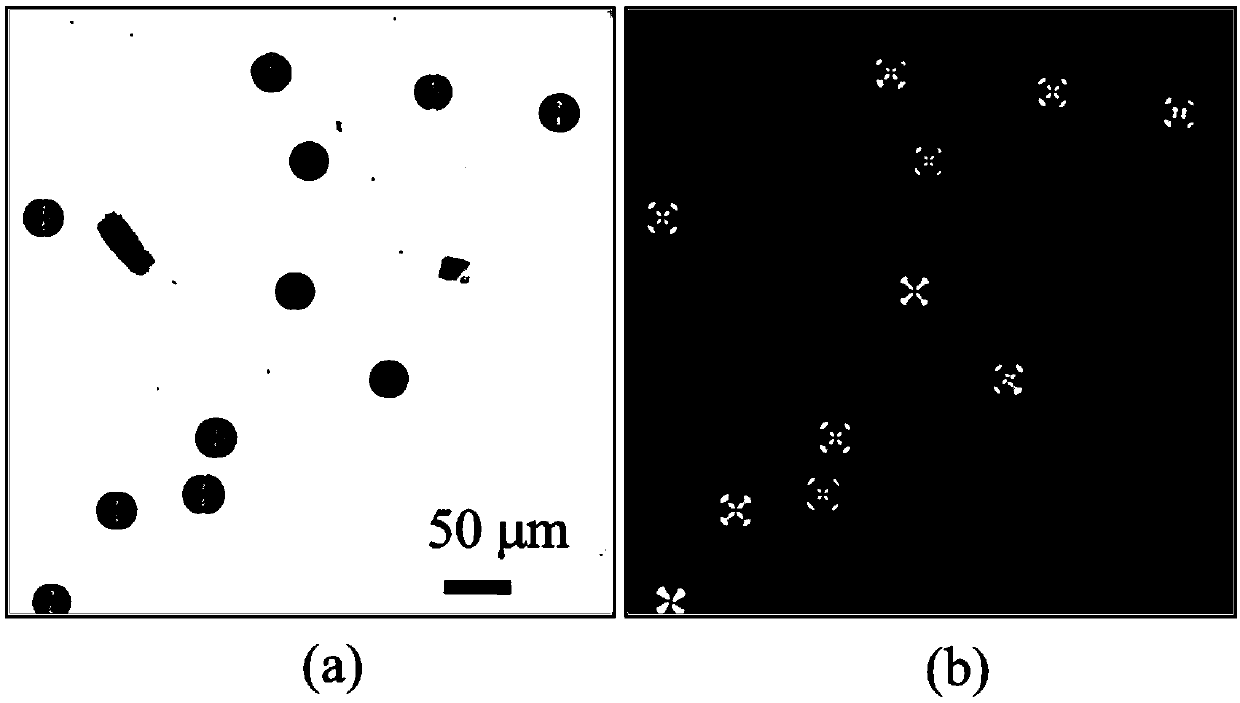

Porous silicon dioxide microspheres as well as preparation method and application thereof

ActiveCN111434610ASimple processEasy to operateSilicaOther chemical processesChemistryChromatographic separation

The invention discloses porous silicon dioxide microspheres, which have a radial conformation internal structure and pore passage arrangement, and which have a particle size of 3-300 microns. The invention also discloses a method for preparing the porous silicon dioxide microspheres, which comprises the following steps: preparing porous aminated polymer microspheres with a radial conformation internal structure and pore passage arrangement; adding a silicon dioxide precursor, and carrying out hydrolysis reaction to obtain silicon dioxide / polymer composite microspheres; calcining the silicon dioxide / polymer composite microspheres to obtain the porous silicon dioxide microspheres. The invention also discloses an application of the porous silicon dioxide microspheres in chromatographic separation. The method is simple in process, easy to operate, good in reproducibility and capable of achieving large-scale production. The porous silicon dioxide microspheres prepared by the method are controllable in particle size and orderly in internal structure and pore passage arrangement, and can be widely applied to the fields of chromatographic separation, catalytic carriers, drug controlled release and the like.

Owner:JIANGSU JICUI INTELLIGENT LCD TECH CO LTD

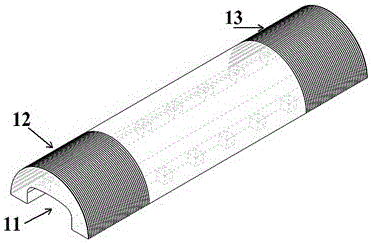

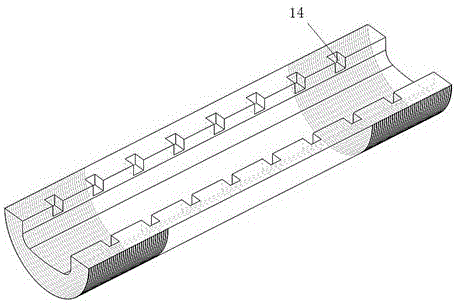

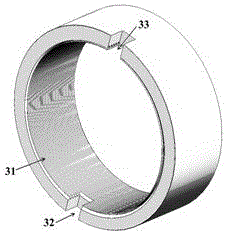

Quick-connection cylinder type connecting part for graphite composite grounding body and application of quick-connection cylinder type connecting part

InactiveCN106129644AImprove connection strengthClose electrical contactClamped/spring connectionsPulp and paper industryScrew thread

The invention discloses a graphite composite grounding body quick-connecting cylindrical connector and its application, comprising an upper semi-cylindrical body, a lower semi-cylindrical body, a left annular fixing part and a right annular fixing part; an upper semi-cylindrical body and a lower semi-cylindrical body Both have axial through grooves, and the outer surfaces of the upper half cylinder and the lower half cylinder are provided with external threads; the inner edges of both sides of the upper half cylinder and the lower half cylinder are provided with grooves at equal intervals; The inner wall of the ring fixing part and the right ring fixing part are provided with internal threads, the left side of the left ring fixing part is provided with two card slots along the radial direction, and the right side of the right ring fixing part is also provided with two card slots along the radial direction; the upper half cylinder The body is placed on the lower semi-cylindrical body to form an overall cylindrical body, and the left and right annular fixing parts are respectively set on the two ends of the overall cylindrical body. The invention is applicable to the connection of graphite composite grounding bodies, and has simple structure, convenient construction, easy transportation and carrying, no need for heavy tools such as welding, high flexibility, low cost, mass production and broad engineering application prospects.

Owner:STATE GRID CORP OF CHINA +2

Heat-resistant freeze-drying protectant for porcine Japanese encephalitis live vaccine, preparation method and application thereof

ActiveCN103656661BAvoid damageReduce loss ratePowder deliveryViral antigen ingredientsJapanese encephalitisSucrose

Owner:CHINA ANIMAL HUSBANDRY IND

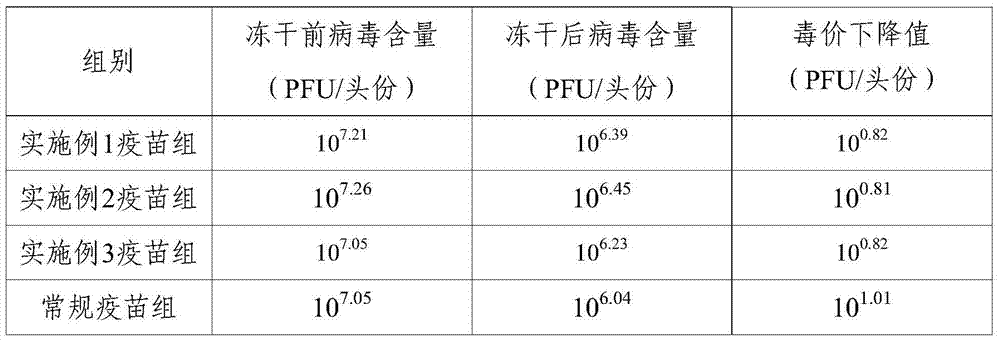

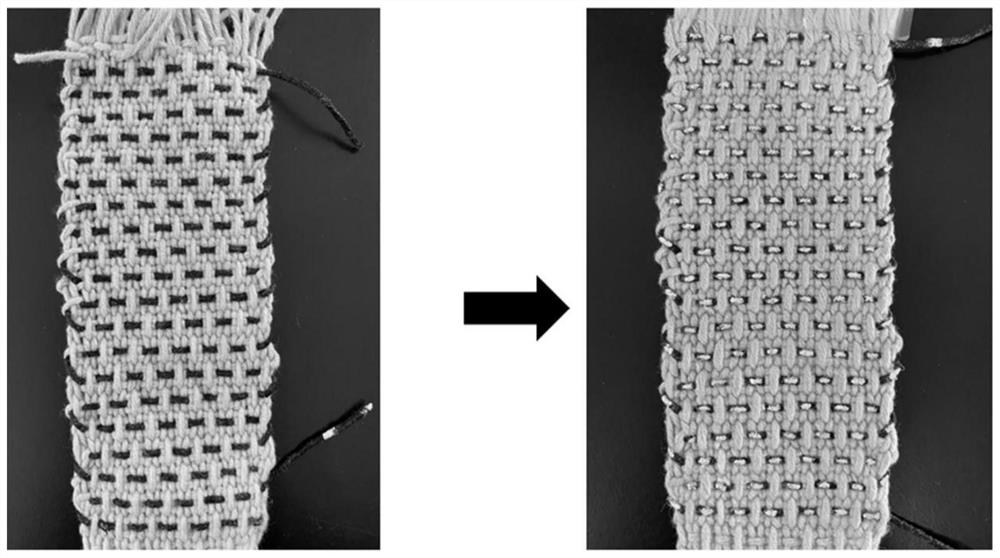

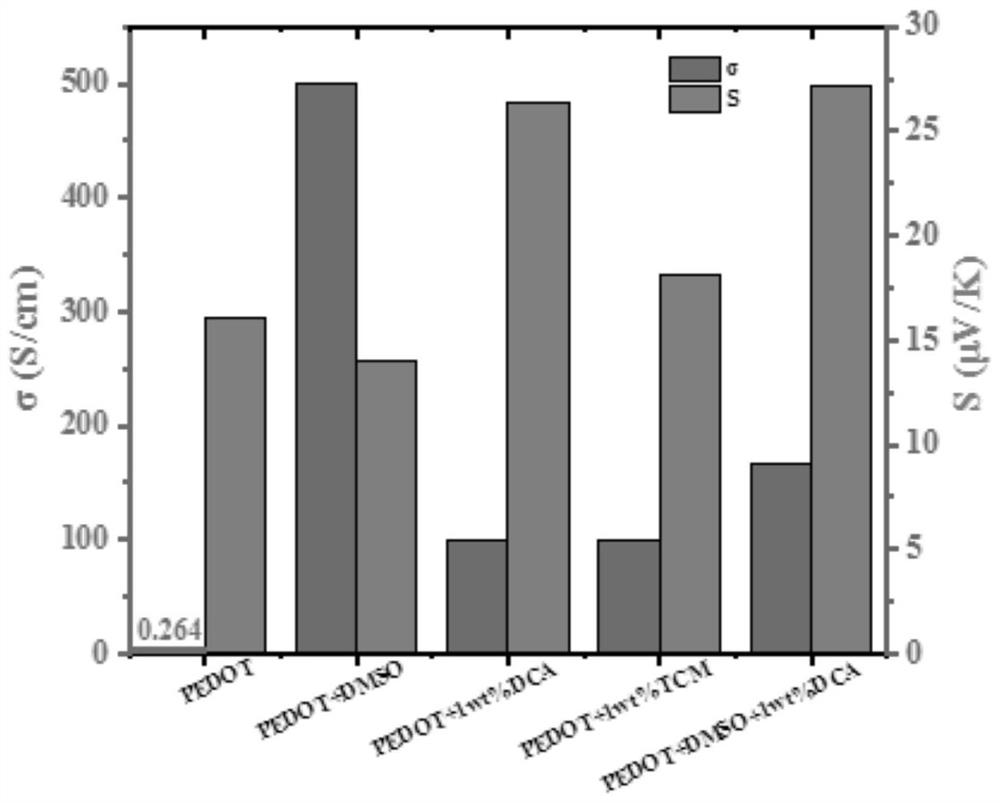

Super-flexible self-generating yarn, all-fiber-based super-flexible thermoelectric self-generating fabric and preparation method thereof

The invention provides a super-flexible self-generating yarn, a full-fiber-based super-flexible thermoelectric self-generating fabric and a preparation method thereof. According to the super-flexible self-generating yarn, a P-type thermoelectric material composed of PEDOT: PSS and ionic liquid is adopted to conduct coating modification on fibers or yarns, the film-forming property of PEDOT: PSS is remarkably improved, the yarn flexibility is enhanced, and meanwhile the thermoelectric property of the yarns is improved. An N-type thermoelectric material and the P-type thermoelectric material are coated on the surface of a yarn base material in an adjacent mode and are connected through electrodes to form a series thermoelectric path. The flexibility, thermoelectricity and power generation stability of the prepared full-fiber-based super-flexible thermoelectric self-power-generating fabric are remarkably improved, and an effective way is provided for the full-fiber-based super-flexible thermoelectric self-power-generating fabric. Therefore, the super-flexible self-generating yarn has relatively high popularization and application values in the fields of sensing device power supply, intelligent clothing and wearable electronic devices.

Owner:WUHAN TEXTILE UNIV

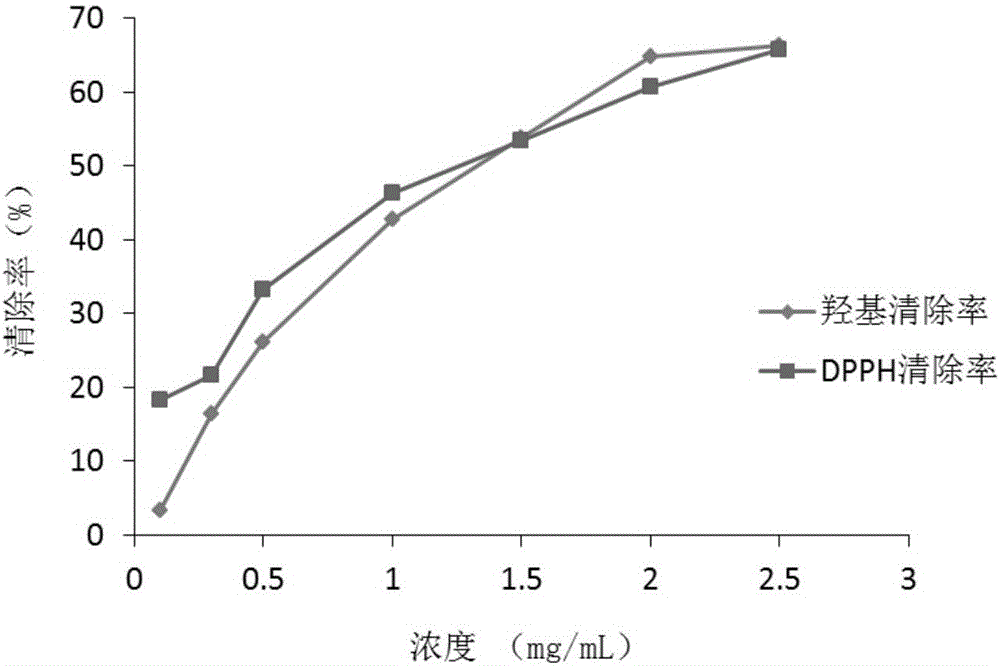

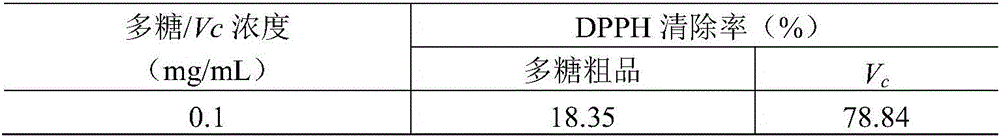

Method for extracting polysaccharides from artemisia rupestris

The invention relates to a method for extracting polysaccharides from artemisia rupestris. The method has the advantages that ultrasonic-assisted extraction technologies are adopted, proteins are removed by the aid of dynamic macroporous adsorption resin processes, accordingly, the method is high in extraction rate, low in cost and suitable for industrial mass production, the technologies are simple, the extraction rates of polysaccharide crude products from the artemisia rupestris are 3.11% at least, effects of removing more than 60% of hydroxyl free radicals and DPPH (1, 1-diphenyl-2-picyl-hydrazyl) can be realized when the concentration is 2.5 mg / mL, and the polysaccharide yield of purified polysaccharide crude products is 77.9% at least.

Owner:MINZU UNIVERSITY OF CHINA

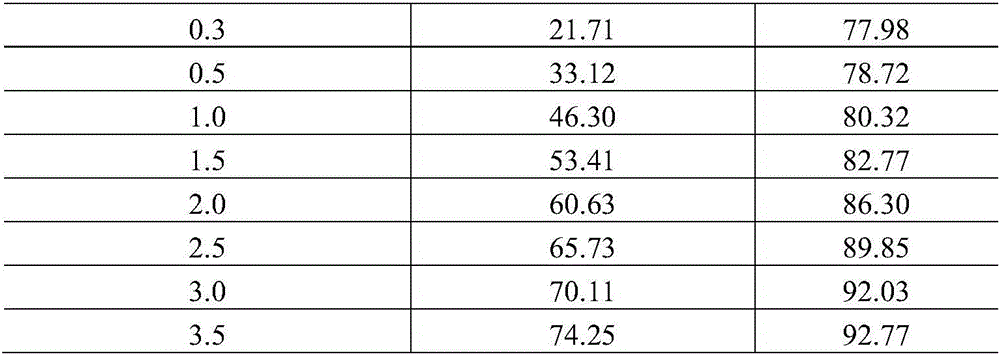

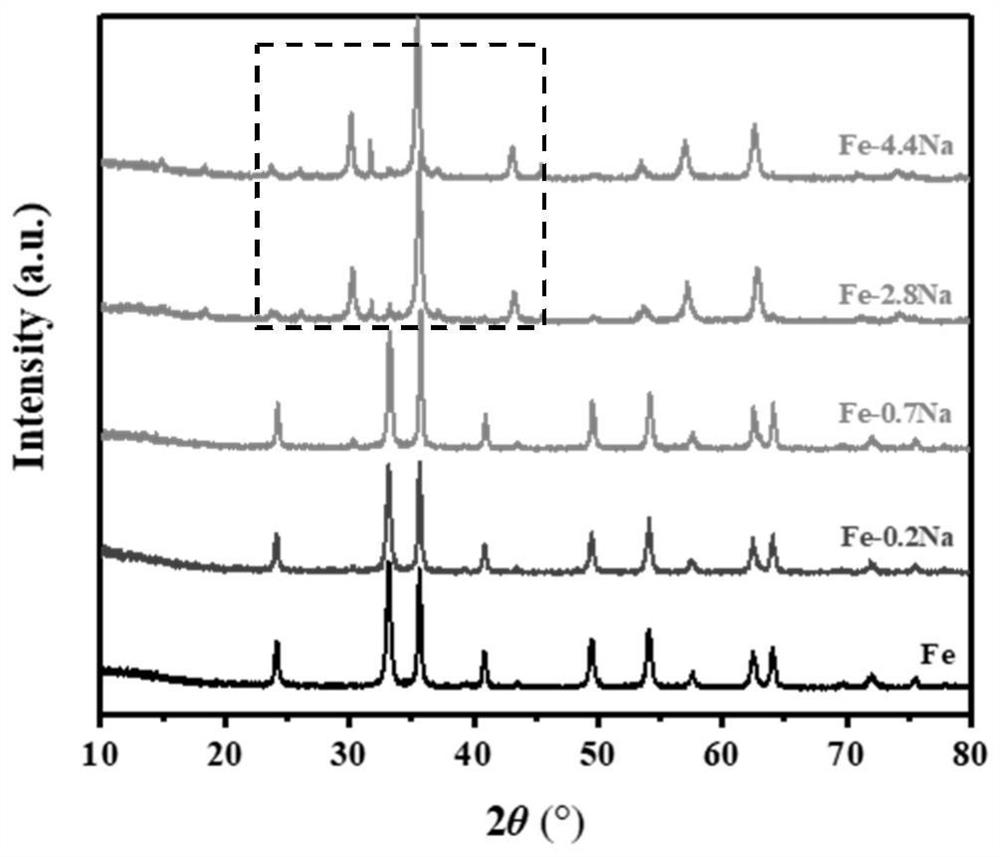

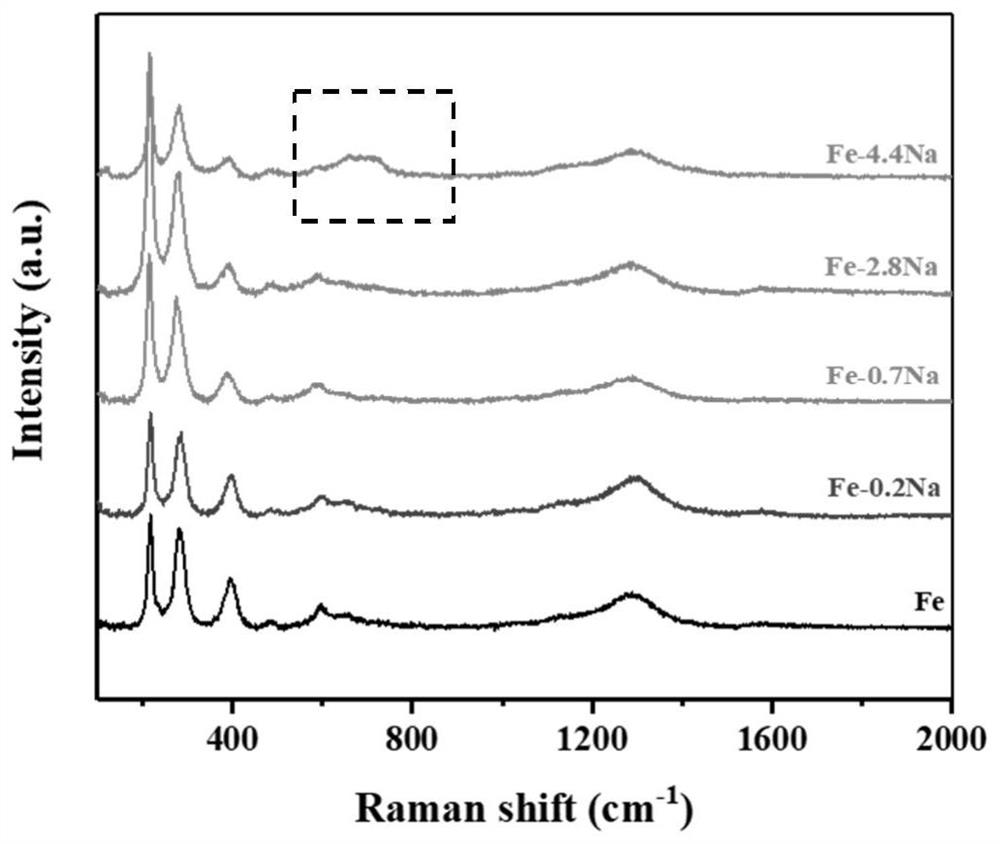

Preparation method of ferric oxide with different crystal forms

InactiveCN111825123AParticle size is not easy to growImprove frost resistanceMaterial nanotechnologyFerric oxidesPhysical chemistryIron(III) oxide

The invention relates to a preparation method of ferric oxide with different crystal forms. The preparation method comprises the following steps of: preparing a Fe precursor from Fe salt and an alkaline compound aqueous solution containing alkali metal, and controlling the content of residual alkali metal in the Fe precursor to modulate the content of alpha-Fe2O3 and gamma-Fe2O3 in calcined Fe2O3.Compared with the prior art, the preparation method provided by the invention is simple and easy to implement, a preparation method of nano iron oxide with low raw material cost, simple equipment andcontrollable crystal form is provided, and the defect of uncontrollable crystal form in the prior art is overcome; according to the fact that the proportion of alkali metal contained in Fe2O3 is increased from 0 and the crystal form is gradually changed from alpha to gamma during calcination, crystal form modulation of a nano iron oxide product is achieved through control over technological conditions; meanwhile, preparation raw materials are easy to obtain, environmental pollution is small, and industrialization is possible.

Owner:EAST CHINA UNIV OF SCI & TECH

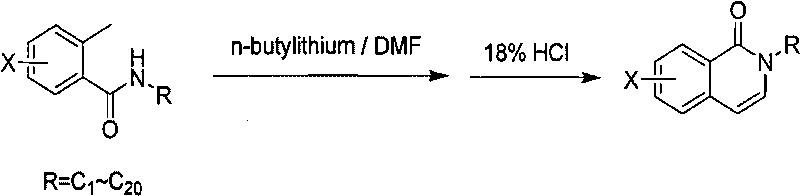

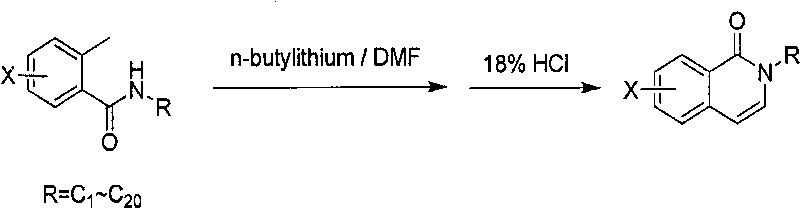

Method for producing 2-alkyl-2H-(halo)isoquinoline-1-ketone

The invention relates to a method for producing an isoquinoline derivative. In the method for producing 2-alkyl-2H-(halo)isoquinoline-1-ketone, acid amide is subjected to n-butyl lithium metallization, ring closing and dehydration to finally generate the isoquinoline derivative, namely 2-alkyl-2H-(halo)isoquinoline-1-ketone. The method has the advantages of wide sources of reaction raw materials, mild reaction conditions and easy operation, rapid reaction, simple process, high purity of the prepared product, capability of realizing large-scale production and high yield so as to meet the application requirements of industries such as medicine and the like.

Owner:大连凯飞精细化工有限公司

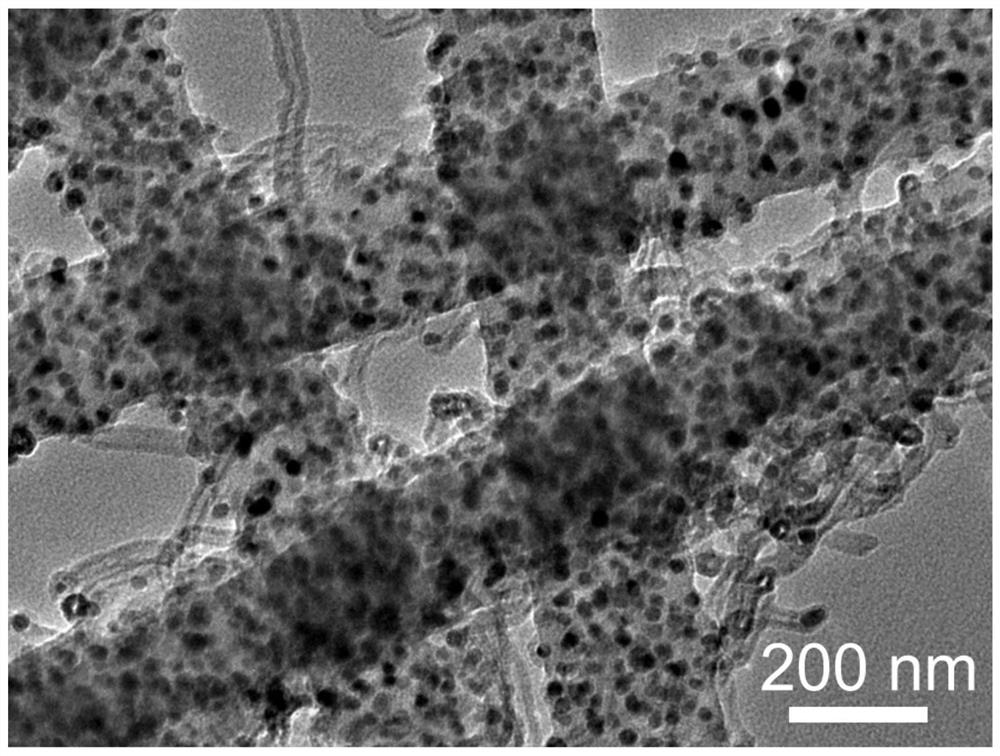

NiPd/Ni anchored nitrogen-doped carbon nanosheet composite material, and preparation method and application thereof

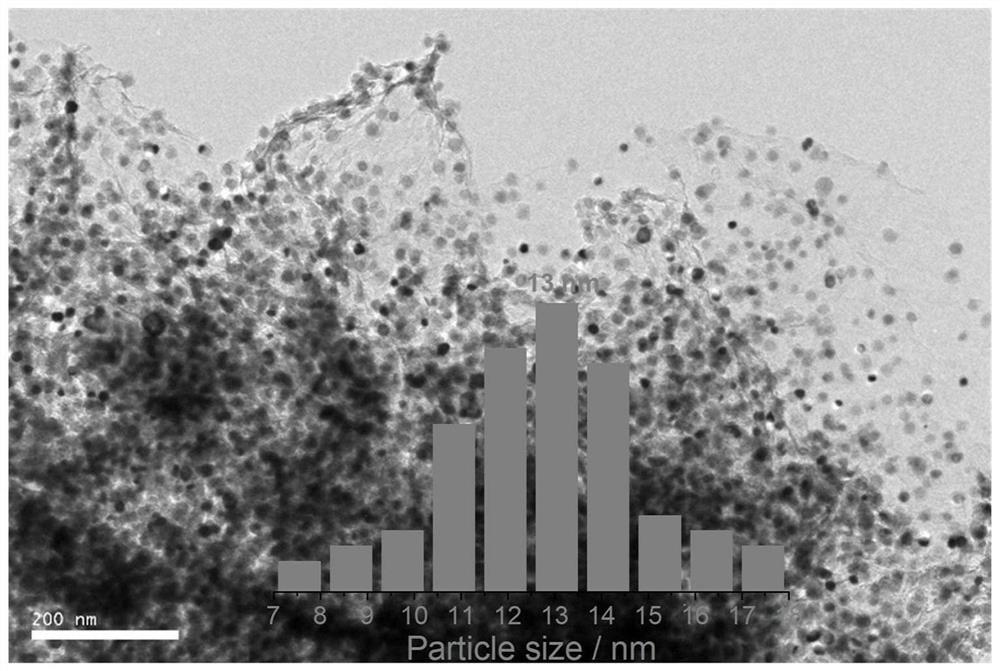

ActiveCN113394410AImprove electrochemical activityLarge specific surface areaMaterial nanotechnologyFuel and secondary cellsNanoparticleNanostructure

The invention discloses a NiPd / Ni anchored nitrogen-doped carbon nanosheet composite material, and a preparation method and application thereof. The NiPd / Ni anchored nitrogen-doped carbon nanosheet composite material takes a nitrogen-doped carbon nanosheet with a three-dimensional nanostructure as a carrier, and NiPd alloy and Ni metal elementary substance nanoparticles are uniformly anchored on the carrier. The method is simple and easy to implement, raw materials are low in cost, and large-scale production can be achieved. The NiPd / Ni anchored nitrogen-doped carbon nanosheet composite material prepared by the method disclosed by the invention has a three-dimensional nanostructure (nitrogen-doped carbon nanosheets), and NiPd alloy and Ni metal elementary substance nanoparticles with superfine particle sizes (about 13.0 nm) are uniformly anchored on the carbon nanosheets. The material can be used as an alkaline bifunctional oxygen electro-catalytic material, and has excellent activity and stability.

Owner:NANJING NORMAL UNIVERSITY

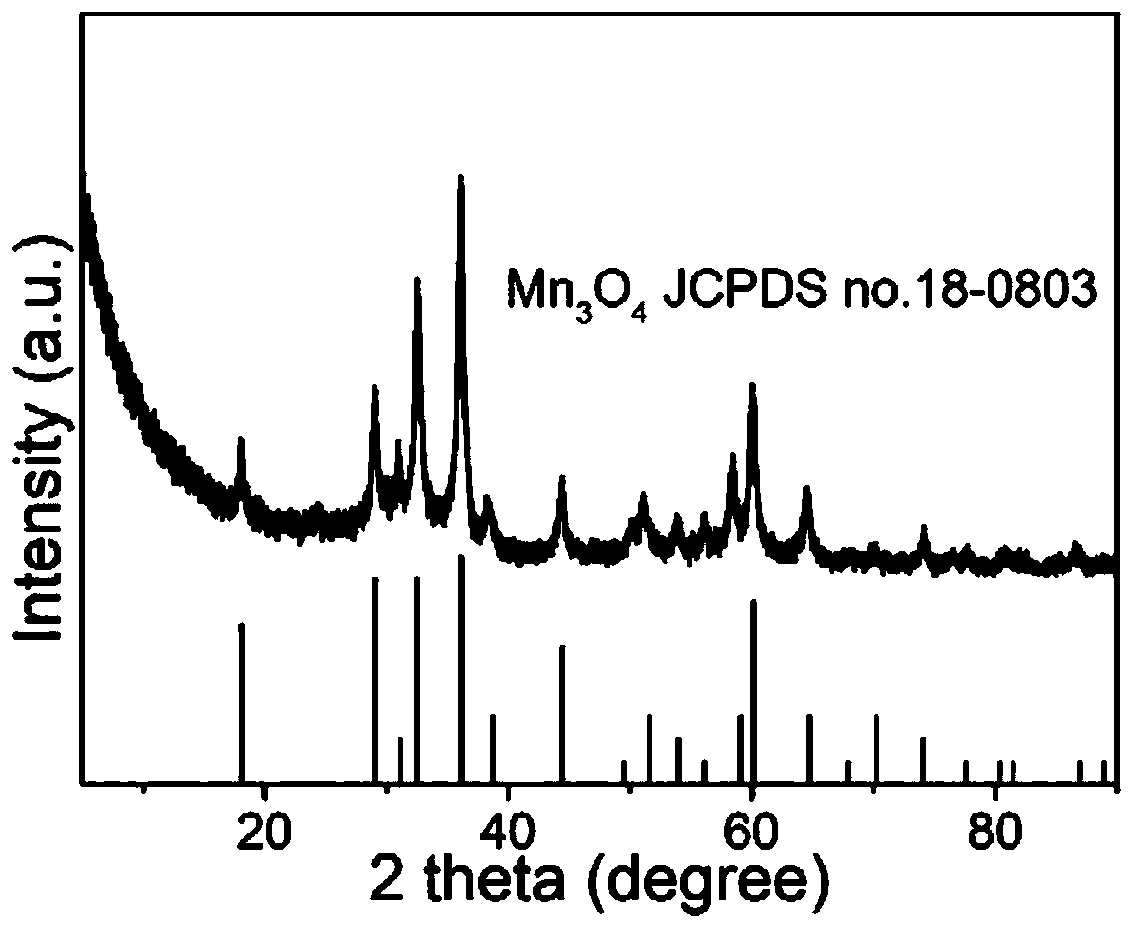

Method for preparing Fe-doped Mn3O4 carbon-nitrogen material with hollow nano-frame structure and application thereof

ActiveCN110148763AIncreased oxygen reduction activityRegular shapeCell electrodesPrussian blueZinc–air battery

The invention discloses a method for preparing a Fe-doped Mn3O4 carbon-nitrogen material with a hollow nano-frame structure and the application of the material in an oxygen reduction reaction and a zinc-air battery. The method comprises the steps of (1) separately preparing a Fe(CN)6<3-> / PVP solution and a Mn<2+> solution, (2) uniformly mixing the Fe(CN)6<3-> / PVP solution and the Mn<2+> solution and standing to obtain KMnFe(CN)6 khaki Prussian blue similar precipitation, and (3) performing alkali washing on KMnFe(CN)6 solid powder in a NaOH solution and raising the temperature to perform thermal processing at 250 DEG C to 350 DEG C in an inert atmosphere to obtain the Fe-doped Mn3O4 carbon-nitrogen material with the hollow nano-frame structure. The preparation method of the invention has the advantages of low cost and simple and universal use, the obtained material has the open hollow nano-frame structure, the material can be used as an electrocatalytic material of oxygen reduction reaction, and the material has high activity and excellent stability energy and can be applied as a positive electrode material of the zinc-air battery.

Owner:NANJING NORMAL UNIVERSITY

Method for preparing foam material reinforced silica aerogel composite material

The invention discloses a method for preparing a foam material reinforced silica aerogel composite material and relates to silica aerogel. The method comprises the following steps of: preparing silica plural gel and aging the silica plural gel, modifying and drying. Through test, porosity is 80 t o 95 percent, density is 0.15 to 0.5g / cm<3>, the Brunauer-Emmett-Teller (BET) specific surface area is 600 to 1,100m<2> / g, and a water contact angle is 130 to 160 degrees; the foam material reinforced silica aerogel composite material is super hydrophobic; aerogel pore size distribution is relativelycentralized and the pore size of the aerogel is 2 to 50nm; and coefficient of heat conductivity is 0.01 to 0.035 W / (m.K), compression strength is 0.3 to 2Mpa (2 percent deformation), and elastic modulus is 1 to 5 Mpa. Meanwhile, the foam material reinforced silica aerogel composite material has good heat insulation performance, and adsorption performance, environment-friendliness and the other excellent performance. The method is simple, is short in a cycle, low in cost, and high in safety, and contributes to large-scale production; and by the method, excellent performance of the aerogel can be kept and the mechanical property of aerogel can be improved.

Owner:ZHONGKE RUNZI (CHONGQING) ENERGY SAVING TECH CO LTD

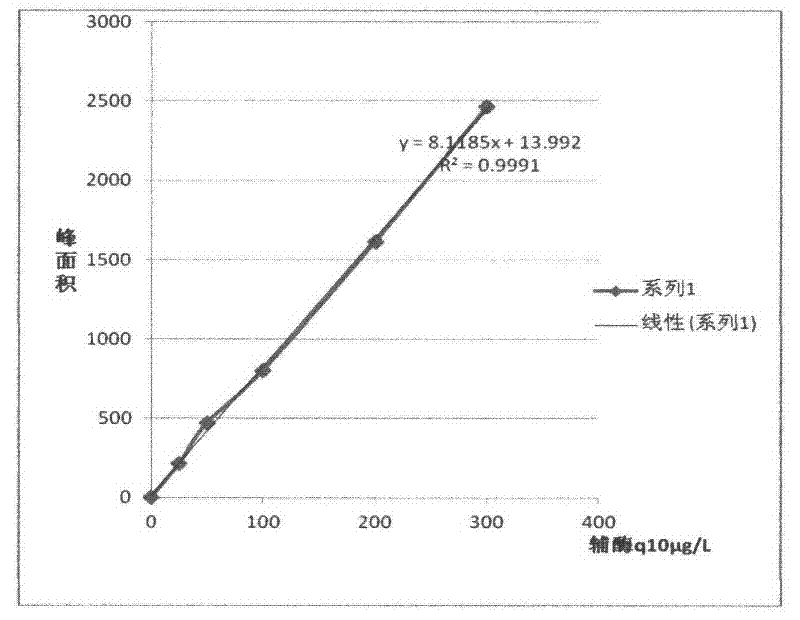

Method for producing reduced coenzyme Q10 by fermentation of recombinant strains

InactiveCN102676595AIncrease productionLow costBacteriaMicroorganism based processesTransfer geneCoenzyme F420

The invention discloses a method for producing reduced coenzyme Q10 by fermentation of recombinant strains, belonging to the technical field of molecular biology. The method comprises the steps of transferring genes for producing the reduced coenzyme Q10 into strains with reduced coenzyme Q10 ratio of more than 70%; using mutagenesis technology to screen strains with reduced coenzyme Q10 ratio of more than 90%; using the strains with the reduced coenzyme Q10 ratio of more than 90% as cultivated strains to produce the reduced coenzyme Q10. The method further improves production capacity of the gene recombinant strains by using high-yield strains built by gene engineering and mutagenesis technology, so that the method can satisfy requirement of the commercial production.

Owner:苏州海吉亚生物科技有限公司

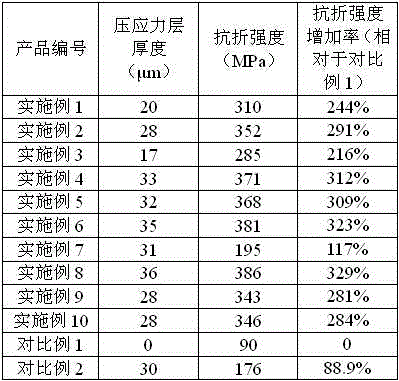

Low-cost on-line reinforcement method of aluminosilicate glass

ActiveCN103819079ASave post-cuttingShort processGlass tempering apparatusSilicate glassWorking temperature

The invention relates to a low-cost on-line reinforcement method of aluminosilicate glass, which comprises the following steps that: a high-temperature spraying device is additionally arranged on an annealing kiln of the glass; when the aluminosilicate glass enters the annealing kiln, the high-temperature spraying device atomizes high-temperature fused salt and uniformly sprays to the surface of the aluminosilicate glass; and the atomized fused salt reacts with the glass rapidly to form a compressive stress layer, so that a reinforcement effect is obtained after the aluminosilicate glass is annealed. The designed on-line reinforcement method of the glass is wide in application scope; the existing glass production technology is not required to be modified to a great extent; the investment cost is lowered; and at the same time, the on-line reinforcement method is lower in working temperature and greatly reduces raw material and energy consumption.

Owner:GLASS TECH RES INST OF SHAHE CITY OF HEBEI PROVINCE

New silicon nitride powder synthesis method

InactiveCN105712305ANo pollution in the processHigh purityNitrogen compoundsGas phaseSynthesis methods

A new silicon nitride powder synthesis method is disclosed, according to the method, a composite plasma vapor deposition process is used for preparation of nano Si3N4 powder, and the method can avoid the problems of too long heat-insulation nitriding time, too high energy consumption, easy introduction of impurities, and the like of traditional Si3N4 powder synthesis methods. The silicon nitride powder is prepared from SiCl4 or SiBr4 or SiI4 or SiH4 as a raw material by using N2-NH3-Ar as a working gas for forming plasma under 5-55kW power and then rapidly reacting in a plasma reaction vessel at 1000-1400 DEG C. The prepared silicon nitride powder has the advantages of being ultra-fine, high in purity, good in dispersion, less in environmental pollution, and the like, products are powder, and good to collect. Compared with other nano powder material preparation methods, by use of composite plasma enhancement (removal of chemical vapor deposition), the method has the characteristics of low reaction temperature, no pollution to resultants, high product purity, small particle size, high temperature, rapid warming and rapid cooling.

Owner:SHENYANG XINJIN POWDER ENG

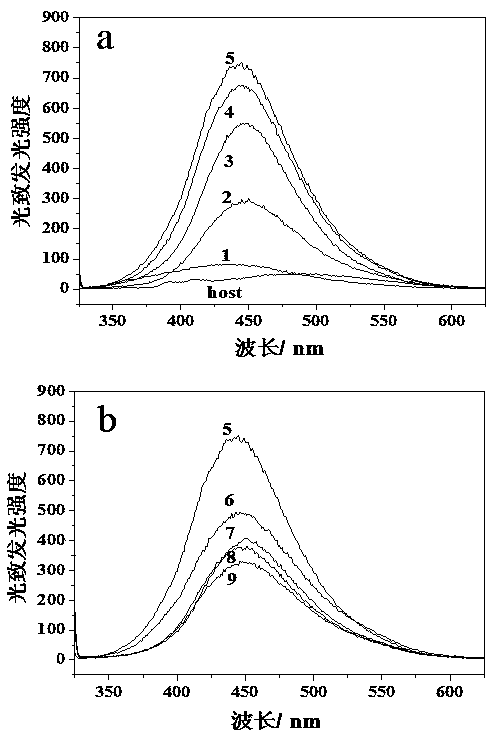

Preparation method of fluorescently-enhanced graphene quantum dots

ActiveCN108728087AImprove luminescence stabilityHigh quantum yieldCarbon compoundsNanotechnologyQuantum yieldLuminous intensity

The invention provides a preparation method of fluorescently-enhanced graphene quantum dots, the method is as follows: adding acetonitrile into a graphene quantum dot solution, performing ultrasonic cleaning in an ultrasonic cleaner for 5-10min, then transferring to a high-pressure reaction kettle, heating to 175-185 DEG C, reacting at constant temperature for 11 to 12h, and cooling to the room temperature to obtain fluorescent enhanced graphene quantum dots. According to the preparation method provided by the invention, acetonitrile is taken as the auxiliary intermediate to produce the fluorescence enhanced graphene quantum dots by one-step hydrothermal method, the luminescence stability is improved significantly with high luminescence intensity and quantum yield, at the same time, the fluorescence quenching of graphene quantum dots under the high temperature and high pressure environment is effectively prevented, and the application potential of the graphene quantum dots in the fields of photoelectric conversion, ion detection, sensor and the like is greatly expanded.

Owner:NORTHWEST NORMAL UNIVERSITY

Tartary buckwheat cake and manufacture method thereof

InactiveCN108739933AFull of nutritionStrong fragranceDough treatmentModified nutritive productsFlavorCooking & baking

The present invention relates to a tartary buckwheat cake and a manufacture method thereof, and belongs to the technical field of food processing. The tartary buckwheat cake is manufactured from tartary buckwheat fine flour, flour, white sugar, milk powder, baking soda, eggs, vegetable oil, sesame seeds, honey and fermented glutinous rice, and manufactured by steps of beating, yeast starter doughmanufacturing, material mixing, baking, etc. The tartary buckwheat cake is unique in the ingredients and technology; the fermented glutinous rice is beat into slurry; the fermented glutinous rice slurry and tartary buckwheat fine flour are fermented to manufacture yeast starter dough; and the manufactured tartary buckwheat cake is rich in nutrients, mellow in flavor, soft, glutinous, fragrant andsweet, high in elasticity and toughness, good in adhesion, not easy to disperse and crack, moist, smooth and fragrant in mouthfeel, stable in quality and mouthfeel, sweet after eating, and endless inaftertaste, wins praises and favors from the public, and overcomes shortcomings that tartary buckwheat cakes in the prior art are not soft enough, easy to disperse and crack, relatively dry and astringent in mouthfeel, etc. The manufacture method is simple and easy to control in operation processes, can realize large-scale production, and can greatly improve the occupation rate of the tartary buckwheat cake in the market.

Owner:威宁县蒋凤明苦荞系列食品厂

a load ni 3 Preparation method of Fe-based nitrogen-doped carbon nanocomposite and its resulting materials and applications

ActiveCN109248703BImprove electrochemical activityMany catalytically active sitesCatalyst activation/preparationElectrodesFiberAir atmosphere

The invention discloses a loaded Ni 3 The preparation method of the nitrogen-doped carbon nanocomposite material of Fe and its obtained material and application thereof, the preparation method comprises the following steps: 1) preparing Ni 2+ / Fe 3+ / PVP mixed sol; 2) the Ni 2+ / Fe 3+ / PVP mixed sol is electrospun to obtain a solid carbon fiber film; 3) After the solid carbon fiber film is pre-oxidized in an air atmosphere at 200-300°C, the temperature is programmed to rise in an inert atmosphere at 400-1000°C. heat treatment, namely the load Ni 3 Nitrogen-doped carbon nanocomposites of Fe. The preparation method of the present invention is low in cost, simple and general, and the prepared material is a one-dimensional composite structure (carbon nanofiber and carbon nanotube), and Ni 3 Fe alloy nanoparticles are uniformly embedded in carbon nanofibers and carbon nanotubes. This material can be used as an electrocatalytic material for electrolysis of water and hydrogen evolution, and has high activity and excellent stability.

Owner:NANJING NORMAL UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com