Patents

Literature

109 results about "Plasma Enhancement" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Graphene and metal nanoparticle composite film preparation method

ActiveCN102660740AEasy to useExpansion of Industrialization ProspectsMaterial nanotechnologySuperimposed coating processComposite filmSurface plasmon

Owner:SOUTHEAST UNIV

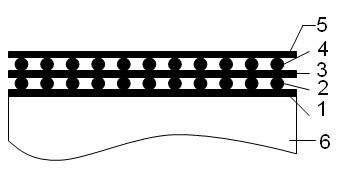

Method for manufacturing diamond-like film and part with coating manufactured thereby

InactiveCN1827845AIncrease productivityChemical vapor deposition coatingCarbon filmDiamond-like carbon

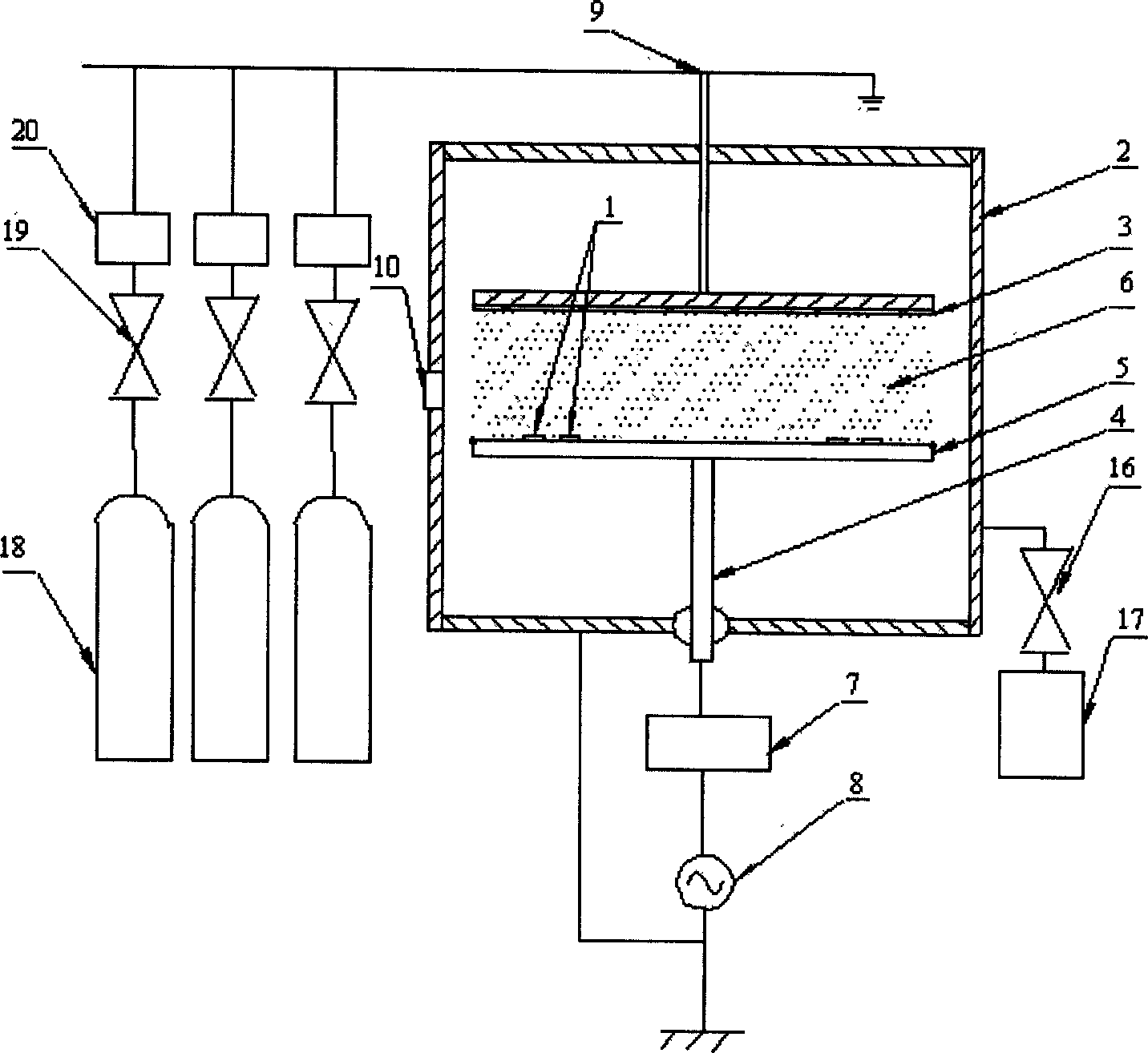

The invention provides the radio-frequency excited plasma enhancement chemical vapour deposition method, comprising the following steps: depositing a layer of sheet metal on the background, then depositing nitride or carbonide on sheet metal, and depositing adamantine carbon film on the nitride or carbonide. The invention also provides the part with composite coating which is made by the method, and the base material of the part is metal or ceramic or glass or organic resin. The invention provides the radio-frequency excited plasma enhancement chemical vapour deposition method device, which comprises more than one metal sputtering source, and evacuated chamber which comprises plasma generating chamber and plasma treatment chamber. In the plasma treatment chamber there is plasma treatment chamber to make the coating homogeneous and isotropism. Adjust electric voltage, current and Ar, N2 and carbonaceous gas content to deposit high adhesive force adamantine carbon film.

Owner:NORTHEASTERN UNIV

Hardmask of amorphous carbon-hydrogen (a-C:H) layers with tunable etch resistivity

InactiveUS6835663B2Decorative surface effectsSemiconductor/solid-state device manufacturingHydrogenForming gas

A process of using a-C:H layer as a hardmask material with tunable etch resistivity in a RIE process that alleviates the addition of a layer forming gas to the etchant when making a semiconductor device, comprising:a) providing a semiconductor substrate;b) forming a hardmask of amorphous carbon-hydrogen (a-C:H) layer by plasma enhancement over the semiconductor substrate;c) forming an opening in the hardmask layer to form an exposed surface portion of the hardmask layer; andd) etching the exposed surface portion of the hardmask layer without the addition of a layer forming gas using RIE to form a trench feature with sufficient masking and side wall protection.

Owner:POLARIS INNOVATIONS LTD

Method for magnetron sputter deposition

ActiveUS20060251917A1Reduce pressureElectric discharge tubesVacuum evaporation coatingIon bombardmentJet engine

Owner:SOUTHWEST RES INST

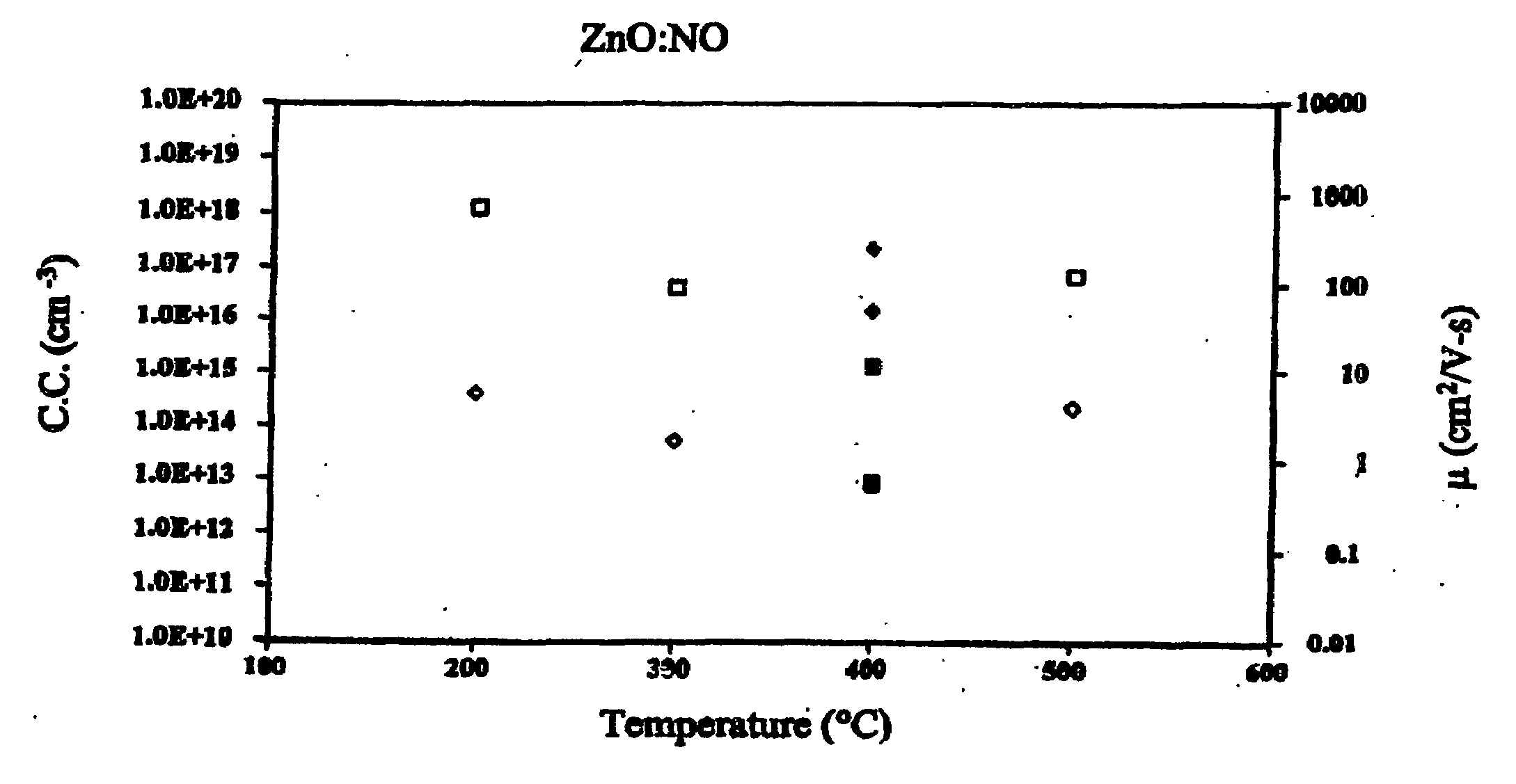

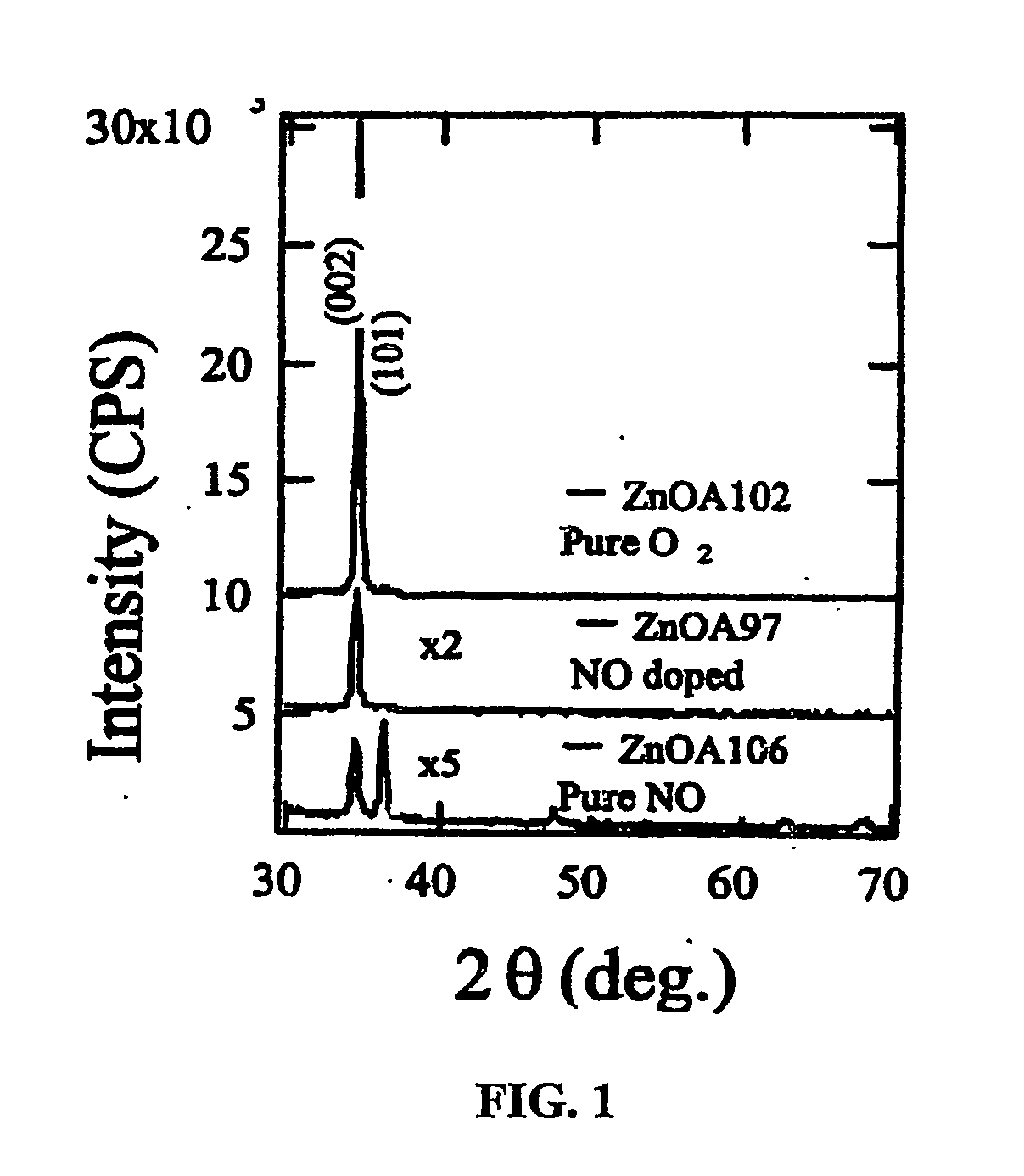

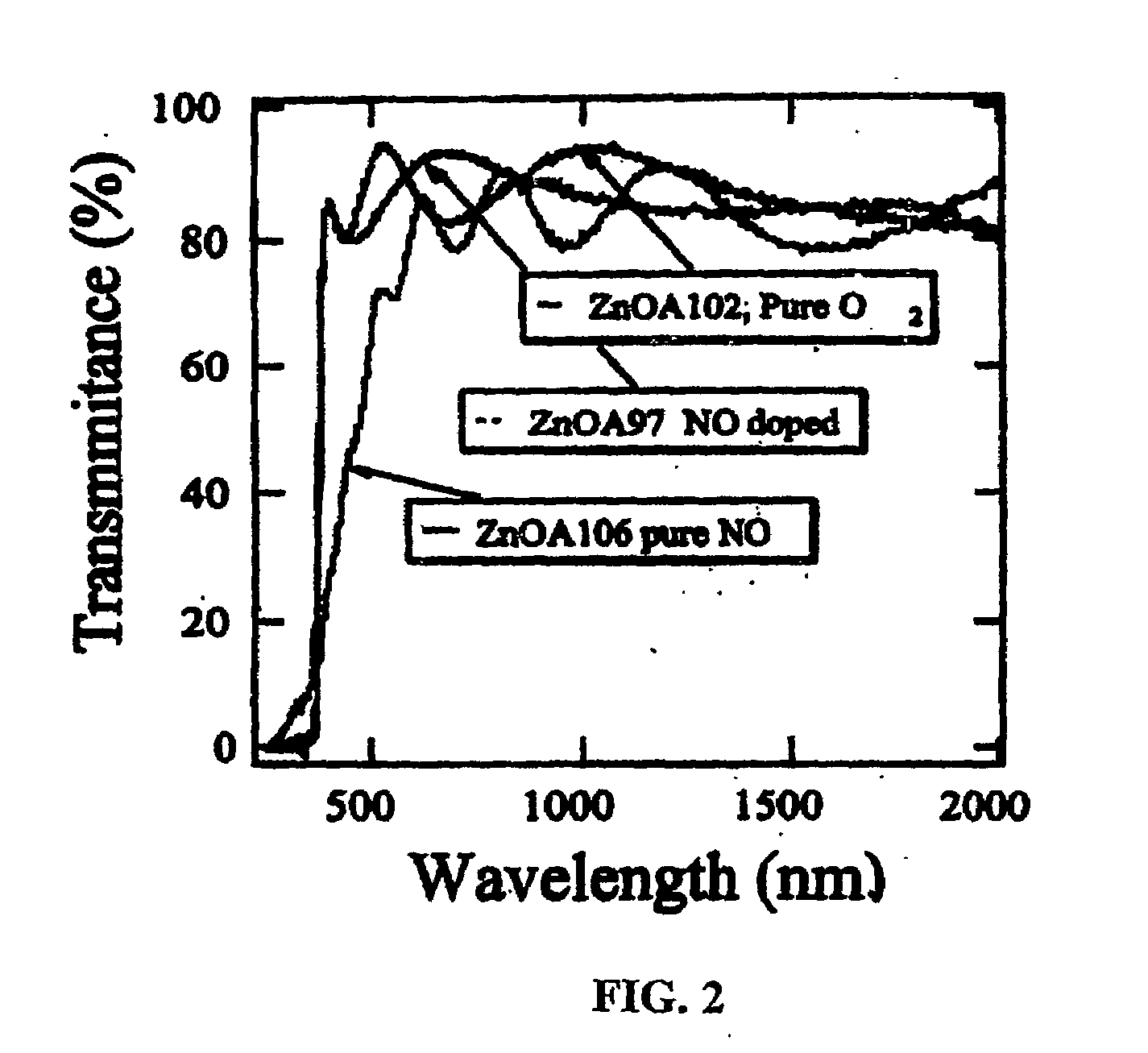

Method for Producing High Carrier Concentration P-Type Transparent Conducting Oxides

InactiveUS20080118777A1High carrier concentrationImprove mobilitySemiconductor/solid-state device manufacturingSpecial surfacesDecompositionNitrogen

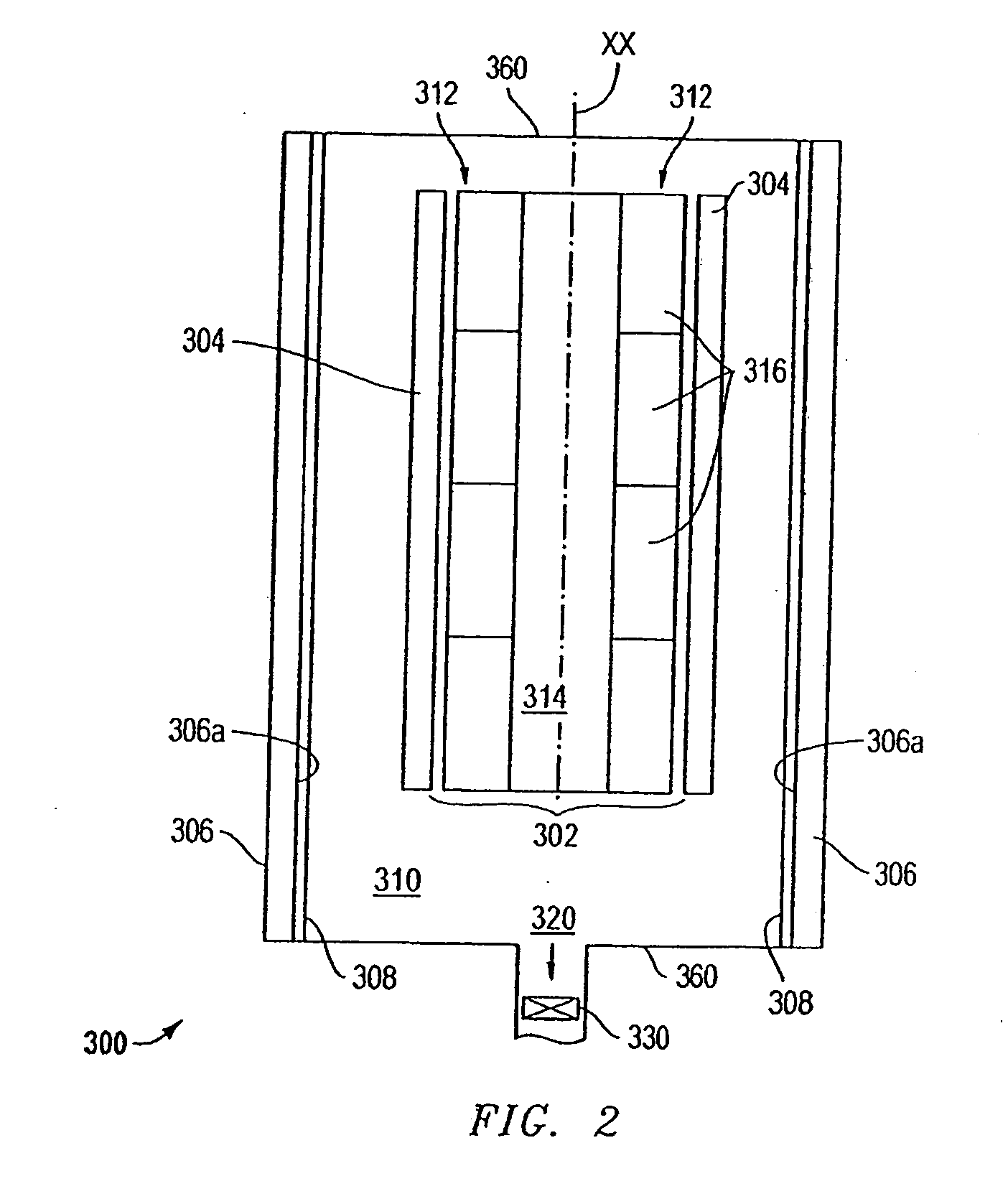

A method for producing transparent p-type conducting oxide films without co-doping plasma enhancement or high temperature comprising: a) introducing a dialkyl metal at ambient temperature and a saturated pressure in a carrier gas into a low pressure deposition chamber, and b) introducing NO alone or with an oxidizer into the chamber under an environment sufficient to produce a metal-rich condition to enable NO decomposition and atomic nitrogen incorporation into the formed transparent metal conducting oxide.

Owner:ALLIANCE FOR SUSTAINABLE ENERGY

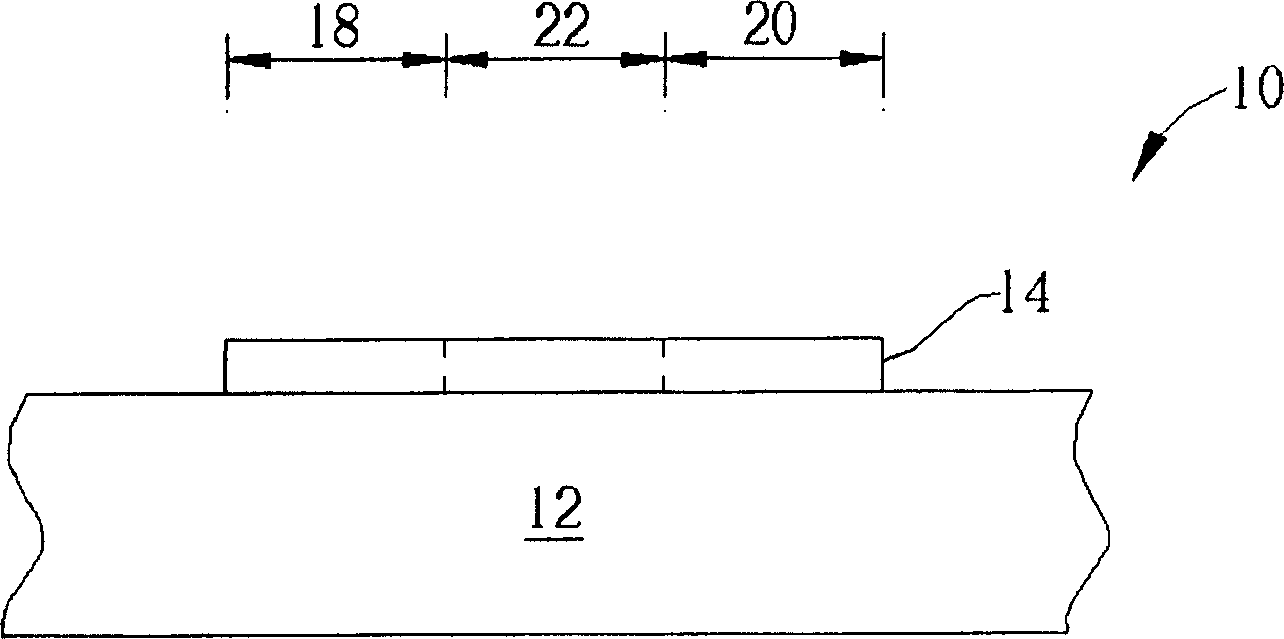

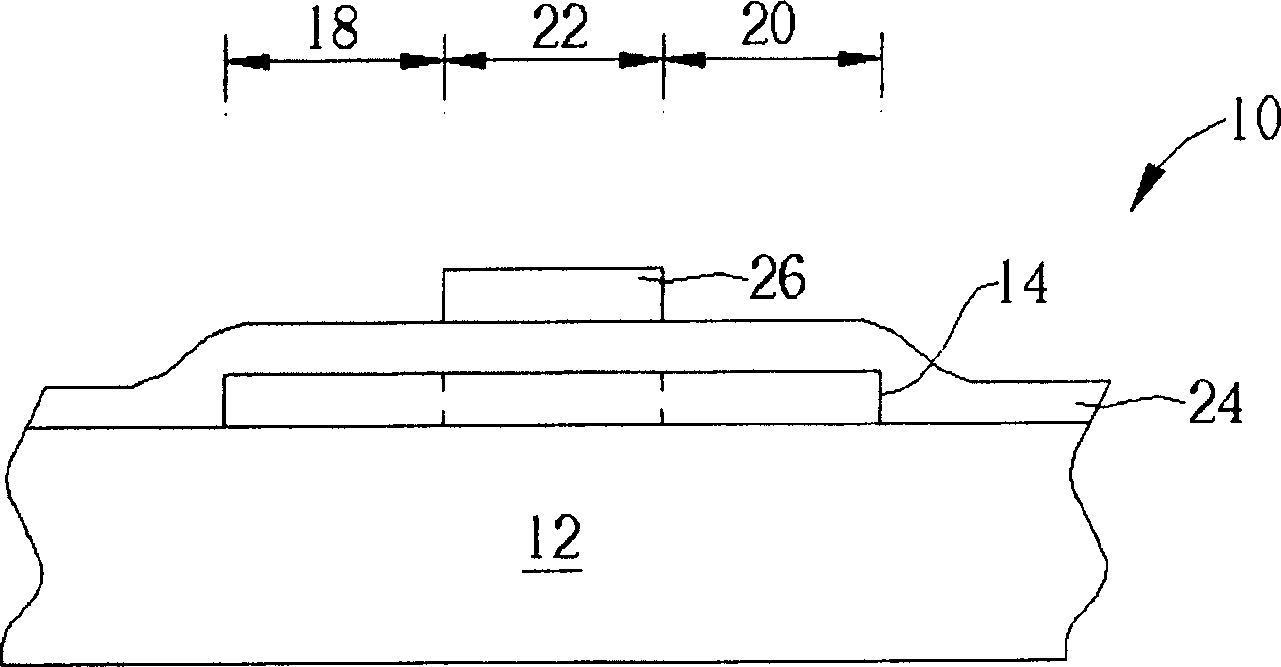

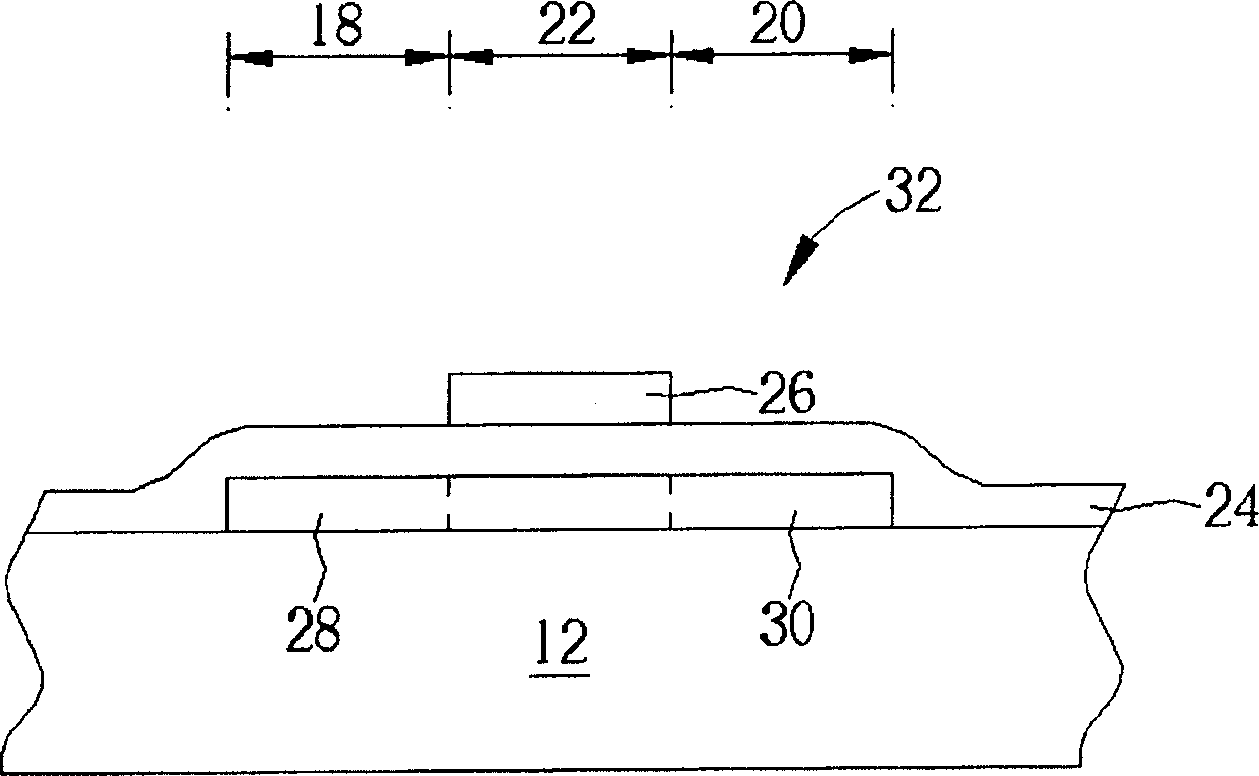

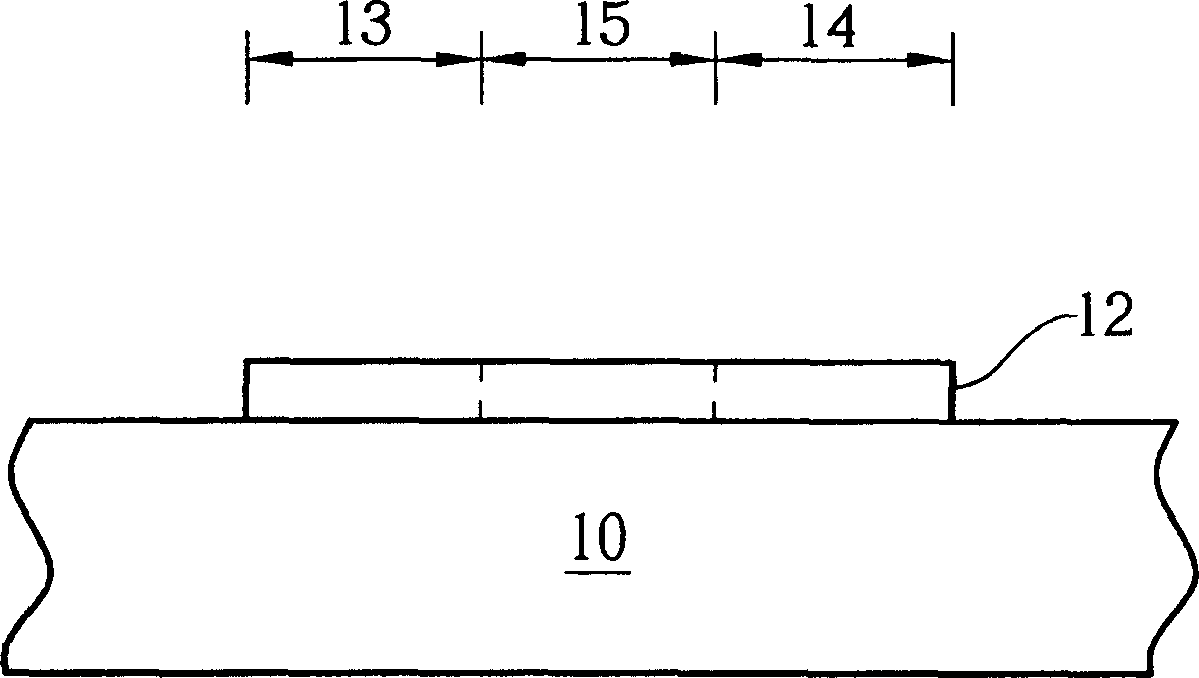

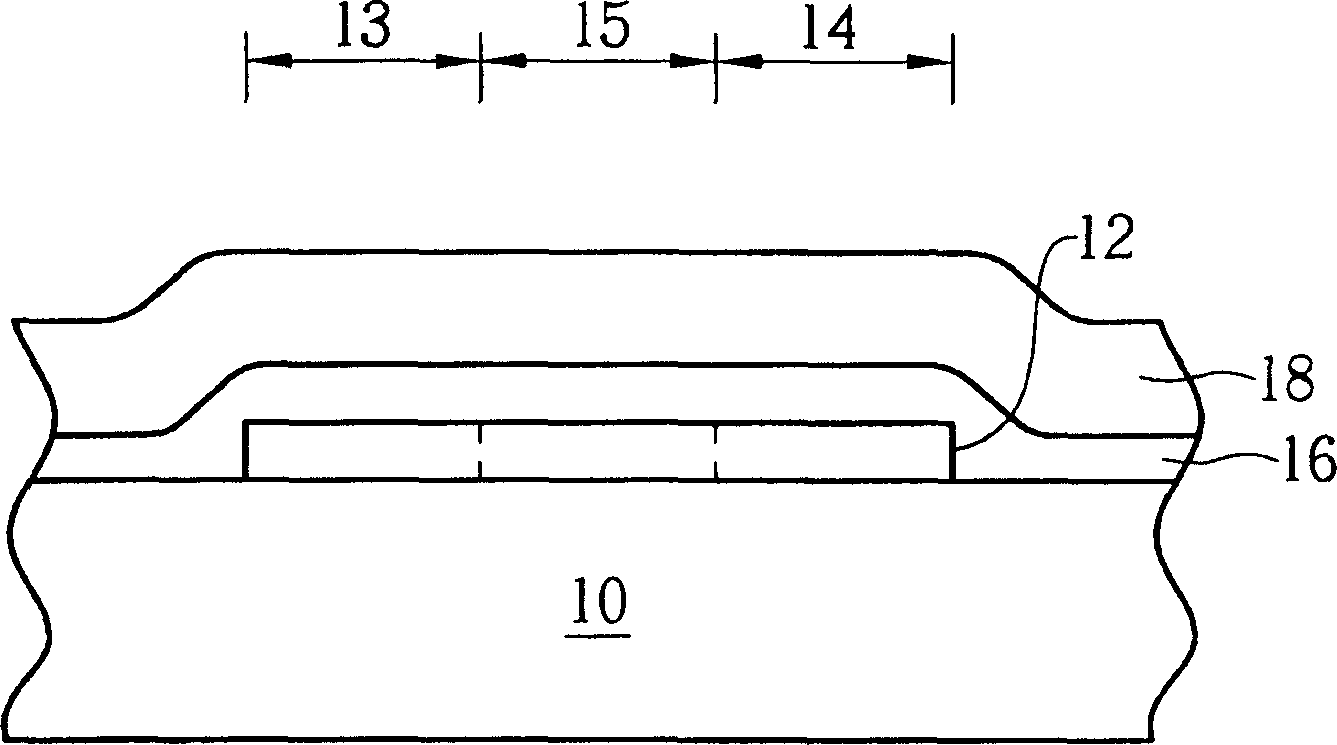

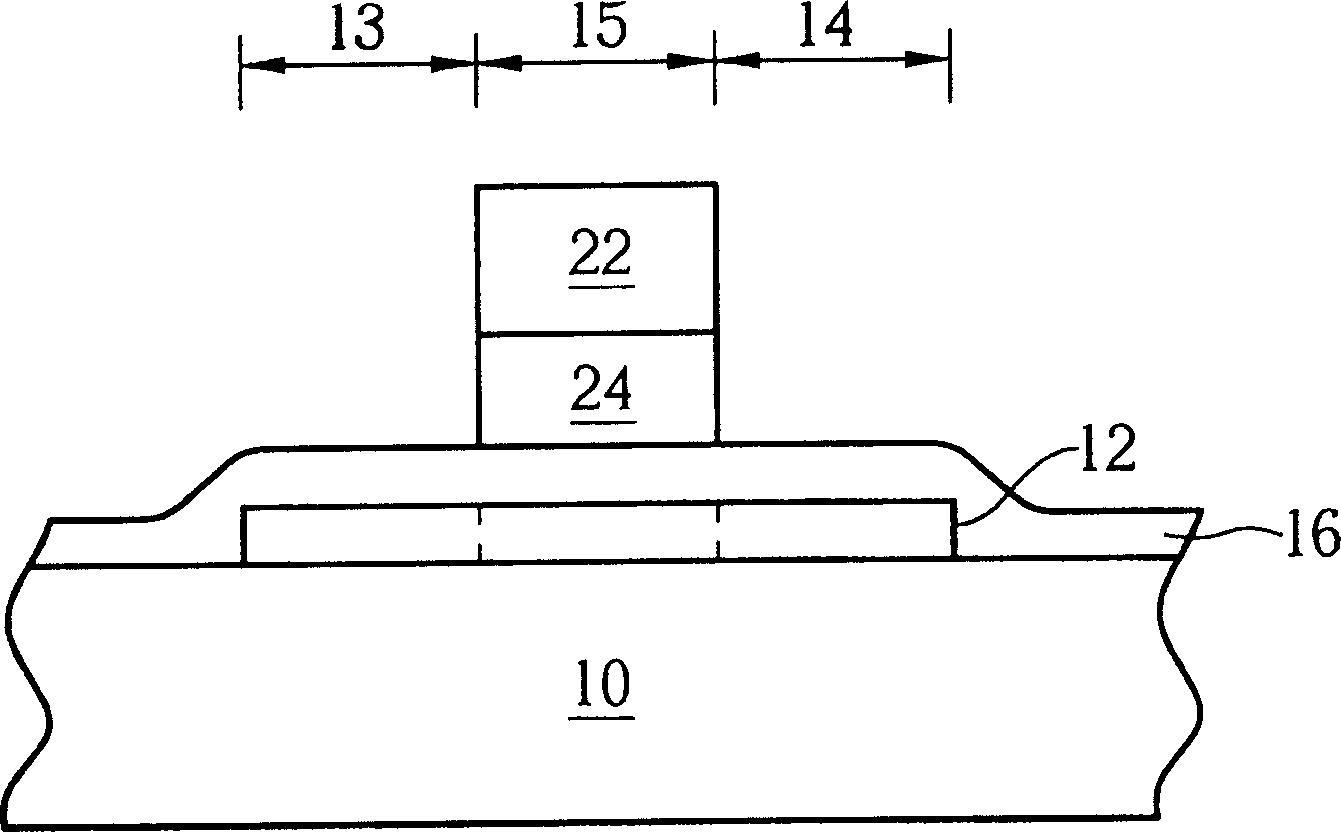

Method for manufacturing low-temperature polysilicon thin-film transistor

InactiveCN1567550AImprove electrical performanceImprove reliabilitySemiconductor/solid-state device manufacturingNon-linear opticsSilanesGas phase

The invention discloses a low temperature polycrystalline silicon thin film transistor making method, firstly forming a polycrystalline silicon thin film, a grid insulating layer and a grid on a substrate surface, successively forming a source and a drain around the gird, then making two plasma enhancement chemical gas phase deposition processes to respectively form a silicon nitride layer and a silicone layer with tetraethoxy silane as the principal covering the grid and the polycrystalline silicon thin film surface, and finally forming a contact hole above the source and drain, respectively and filling an electric conduction layer to connect with them, respectively.

Owner:TPO DISPLAY

Preparation method for resistive random access memory

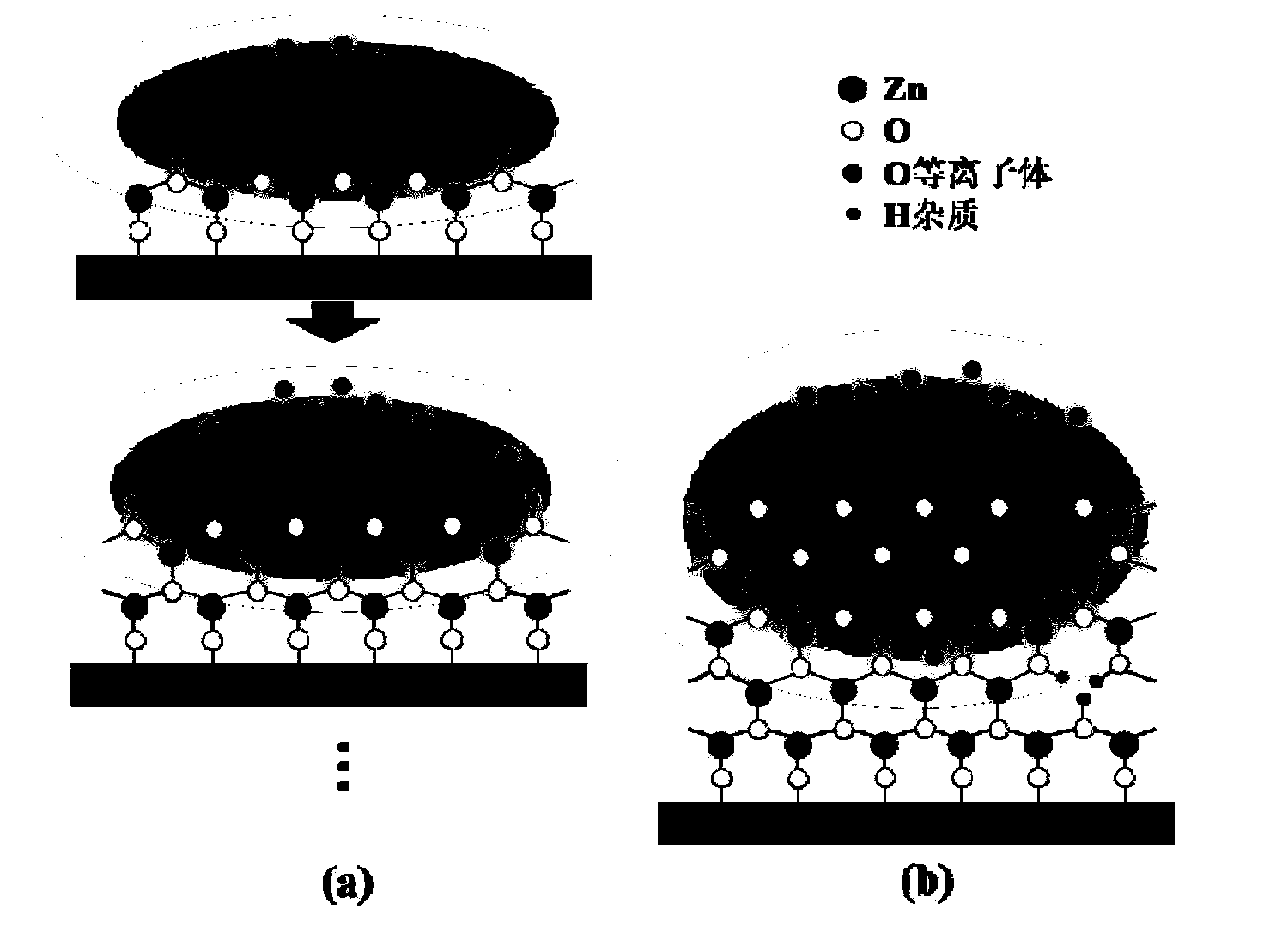

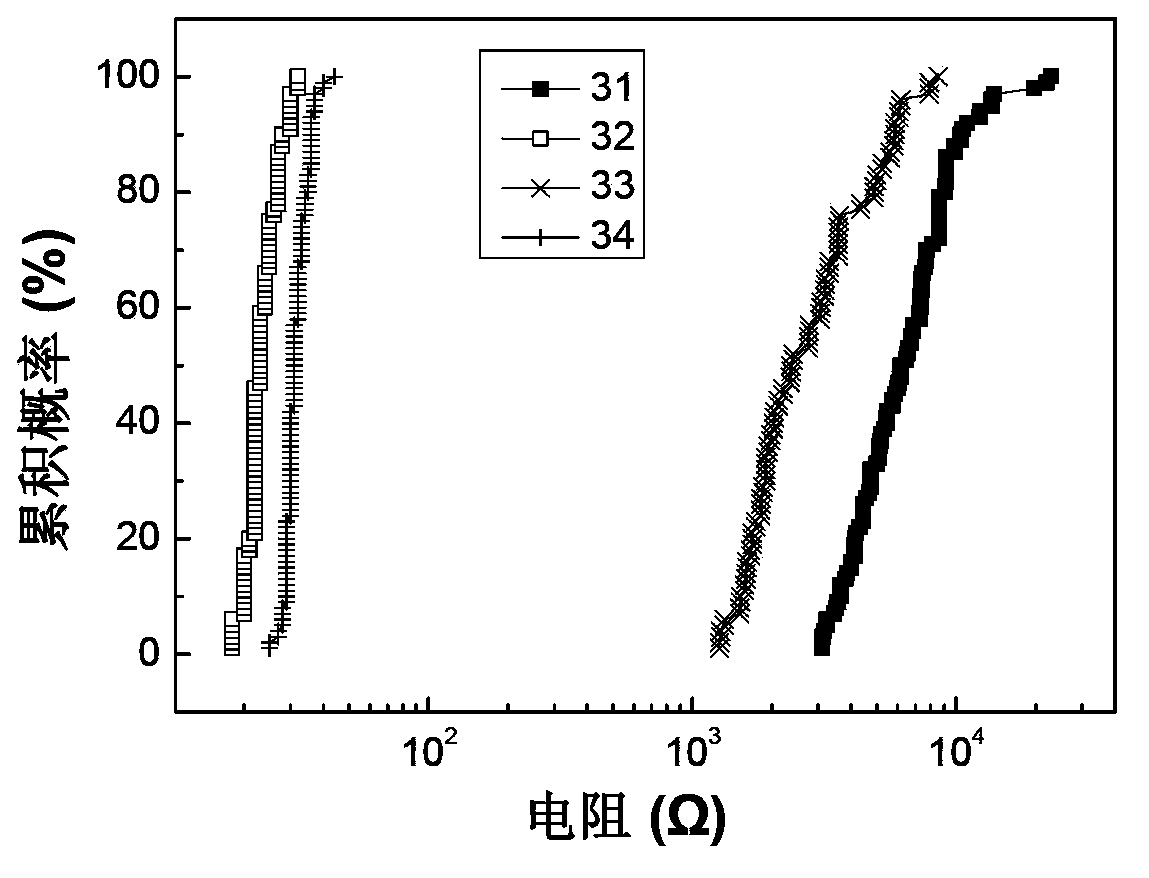

ActiveCN103441214AEfficient removalHigh on/off ratioElectrical apparatusElectrical resistance and conductanceStatic random-access memory

The invention discloses a preparation method for a resistive random access memory. The resistive random access memory comprises a bottom electrode, a resistance change dielectric layer material and a top electrode which are assembled in sequence. Preparation of the resistance change dielectric layer material includes the following steps that firstly, a first precursor, first inert gas, a second precursor and second inert gas are fed into a reactor in order, and a monolayer metallic oxide film is deposited on the bottom electrode through a cycle of hot atomic layer deposition; secondly, a plasma enhancement process is carried out on the film; finally, the steps are carried out circularly and alternately. In the preparation process of a resistance change dielectric layer, a brand new in-situ plasma enhancement hot atomic layer deposition technology is brought in, so the surface appearance and defects of the metallic oxide film can be adjusted on a large scale; the resistive random access memory obtained through the preparation method can achieve precision control over device resistance switching characteristics to enable the device switch ratio and erase / write voltage to be adjusted, and has excellent resistance change stability.

Owner:ZHEJIANG UNIV

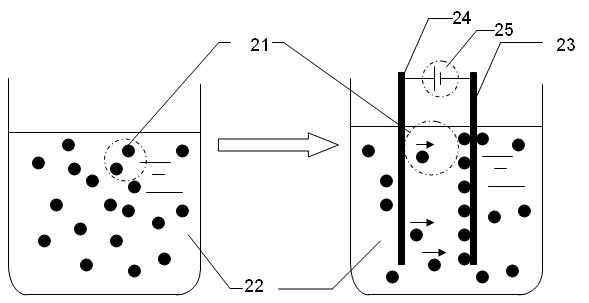

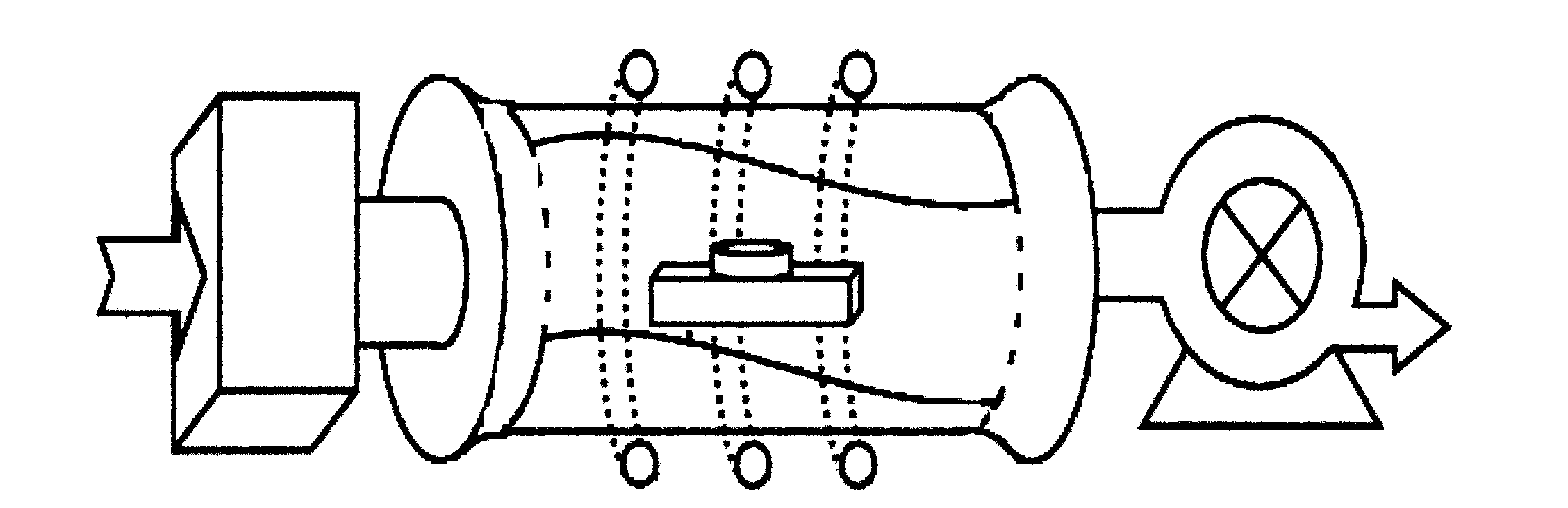

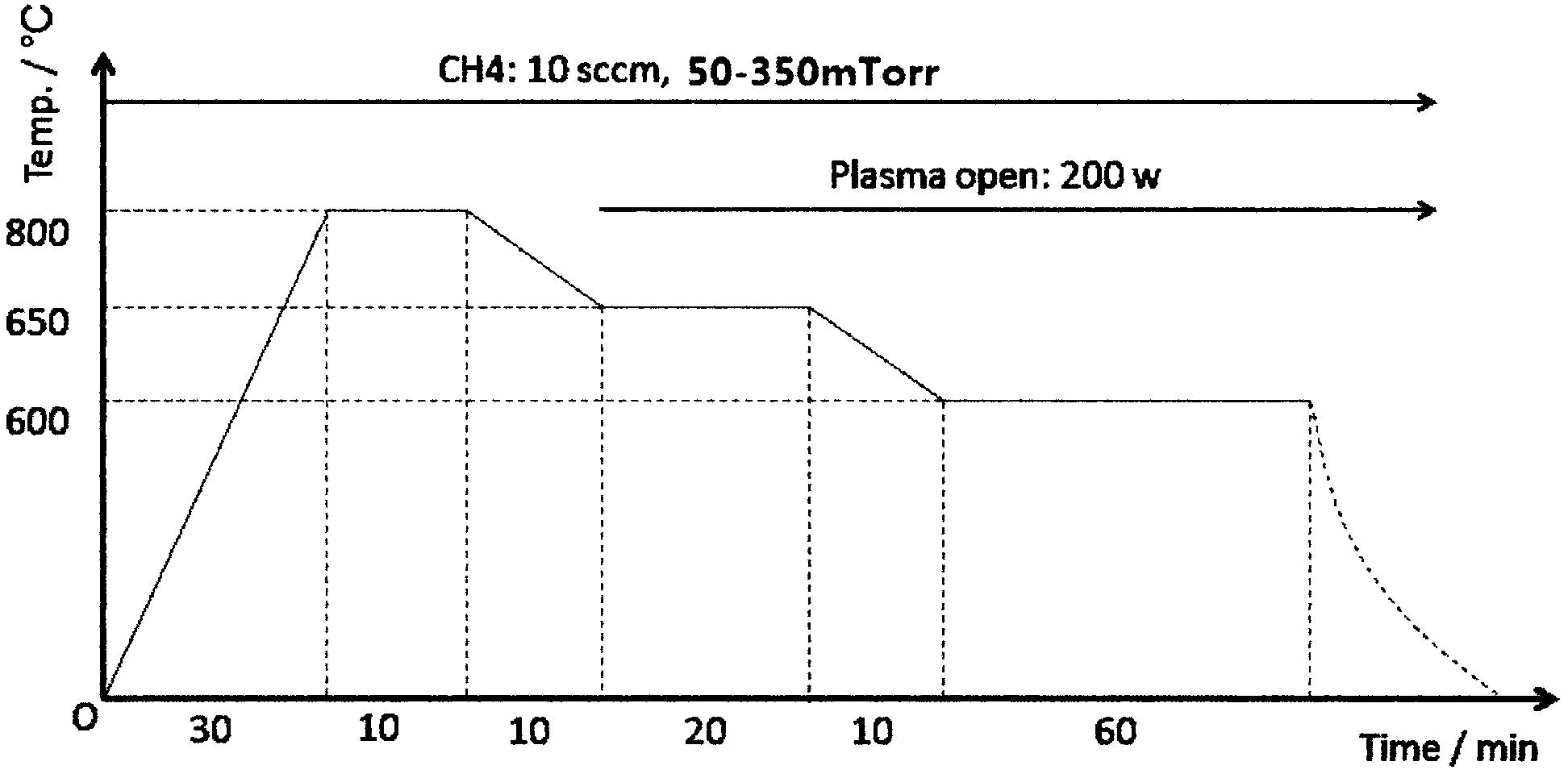

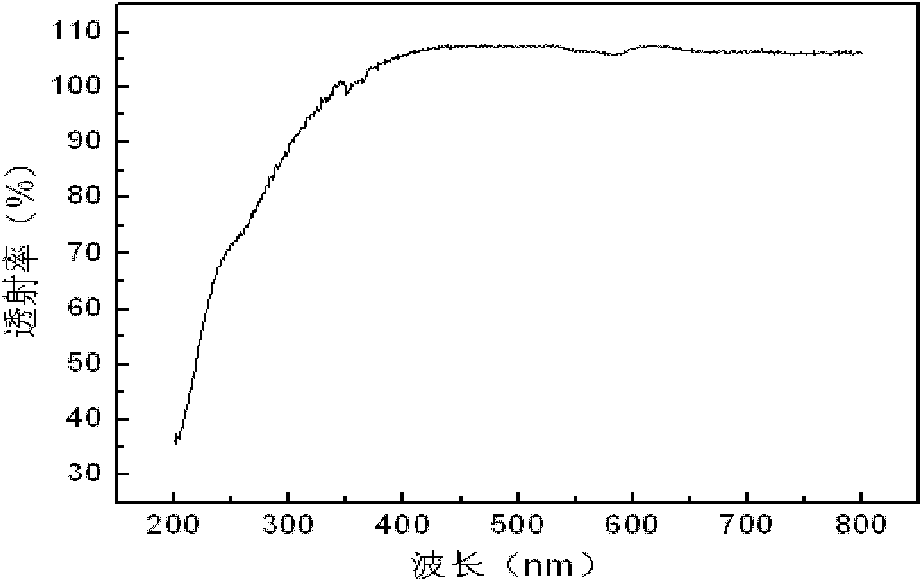

Method for preparing graphene film on nonmetallic substrate at low temperature

The invention discloses a method for preparing a graphene film on a nonmetallic substrate at low temperature. By adopting the method disclosed by the invention, a plasma source is introduced to the graphene film preparation process by using a technology of chemical vapor deposition method to prepare a uniform graphene film on the non-catalytic non-metallic substrate, the technology for preparing the graphene by means of traditional chemical vapor deposition method is improved, the direct growth of the graphene on the surface of a semiconductor base material and an insulator medium base material are achieved to realize target application, the shortcoming that the uniform and high-quality graphene film on a curved surface or a surface with a three-dimensional structure cannot be prepared by using the traditional method is overcome, and the subsequent necessary metal etching and graphene transfer steps during graphene preparation by the traditional chemical vapor deposition method are eliminated; as plasma enhancement effect is utilized, the method disclosed by the invention effectively reduces graphene preparation temperature, not only is energy saving, but also is practical, simultaneously, the method reduces working procedures, reduces cost, and has a pretty good application prospect in the aspects of preparing a transparent electrode material and constructing an electronic component and a photoelectron component.

Owner:满锦梦

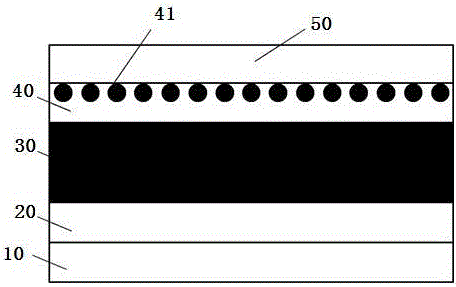

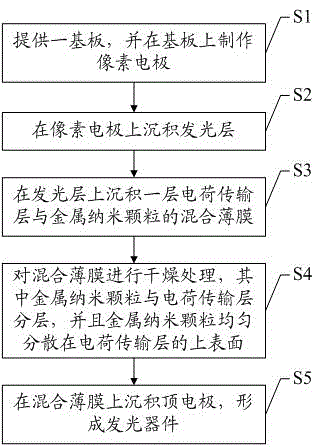

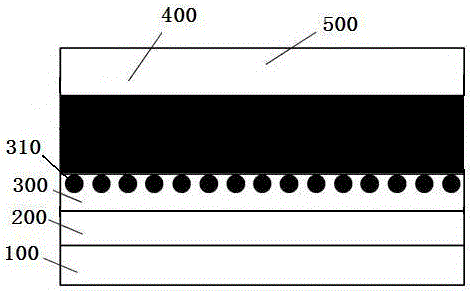

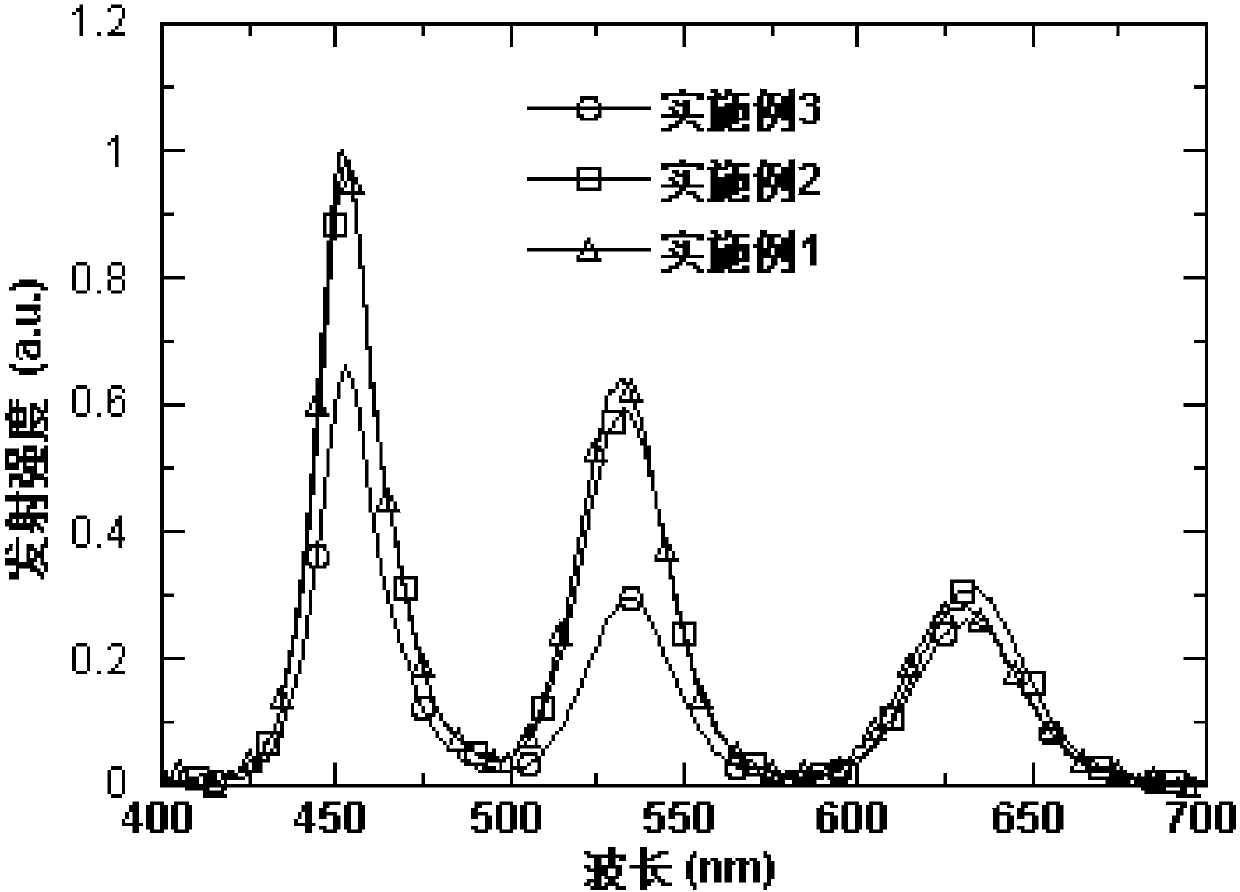

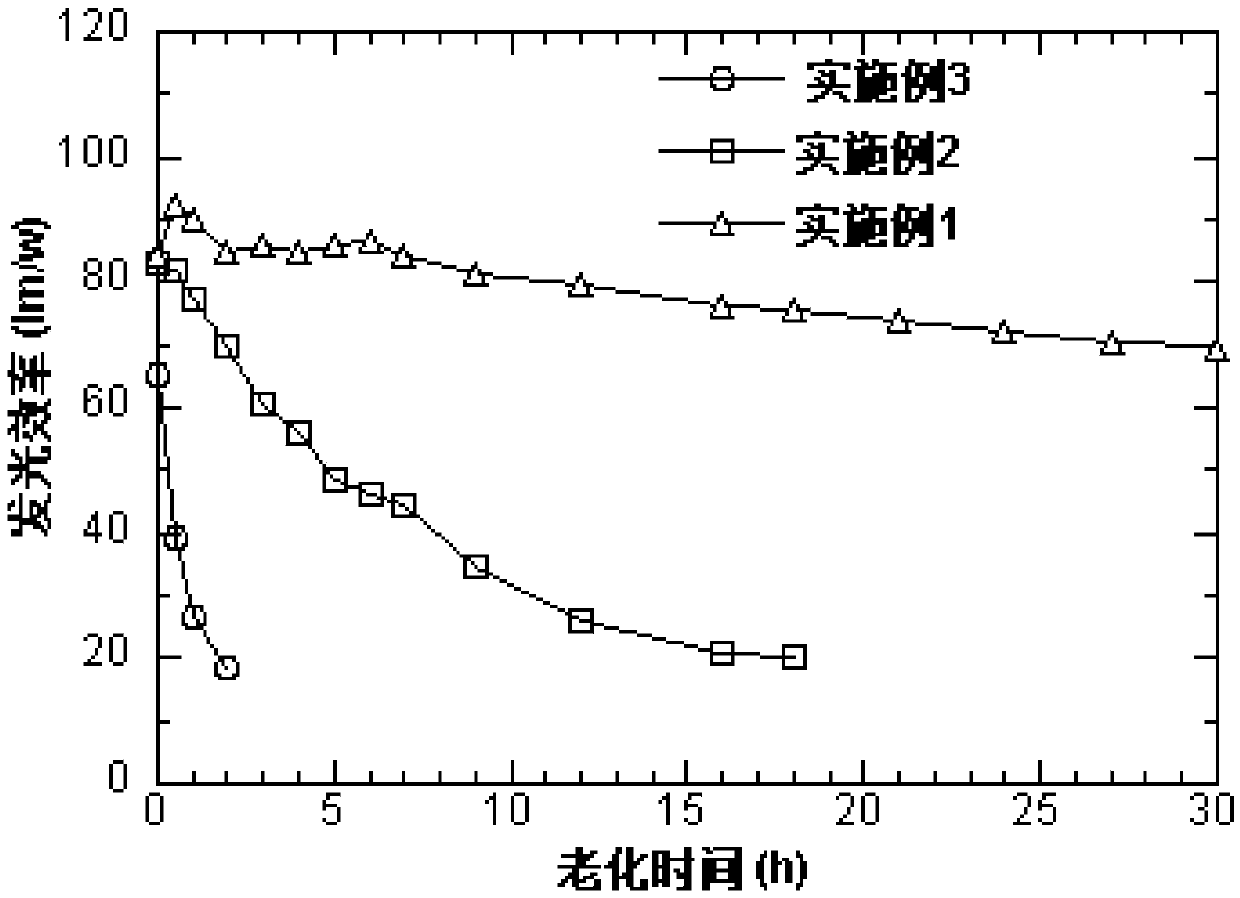

Light-emitting device and preparation method thereof

ActiveCN106450016AImprove performanceMaterial nanotechnologySolid-state devicesTransport layerPlasma Enhancement

The invention discloses a light-emitting device and a preparation method thereof. The light-emitting device comprises, from the bottom up, a substrate, a pixel electrode, a light-emitting layer, a charge transport layer and a top electrode, wherein the upper surface of the charge transport layer is distributed by metal nanoparticles. By blending the metal nanoparticles with the charge transport material, the metal nanoparticles are gathered on the surface of the charge transport layer of the light-emitting device, thereby realizing control of space between the metal nanoparticles and the light-emitting layer easily and effectively, and furthermore, improving the performance of the light-emitting device by effectively utilizing a surface plasma enhancement effect of the metal nanoparticles.

Owner:TCL CORPORATION

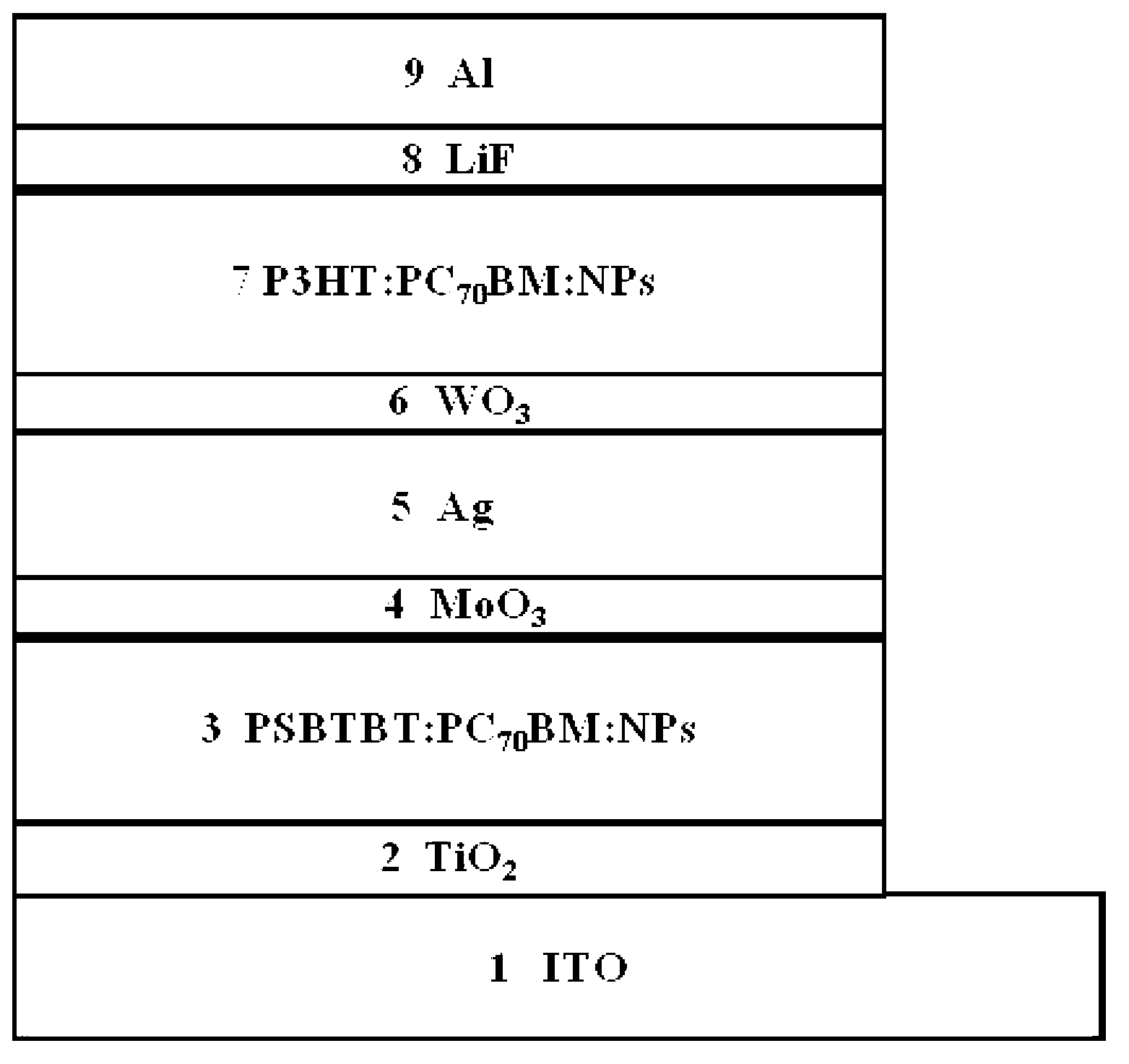

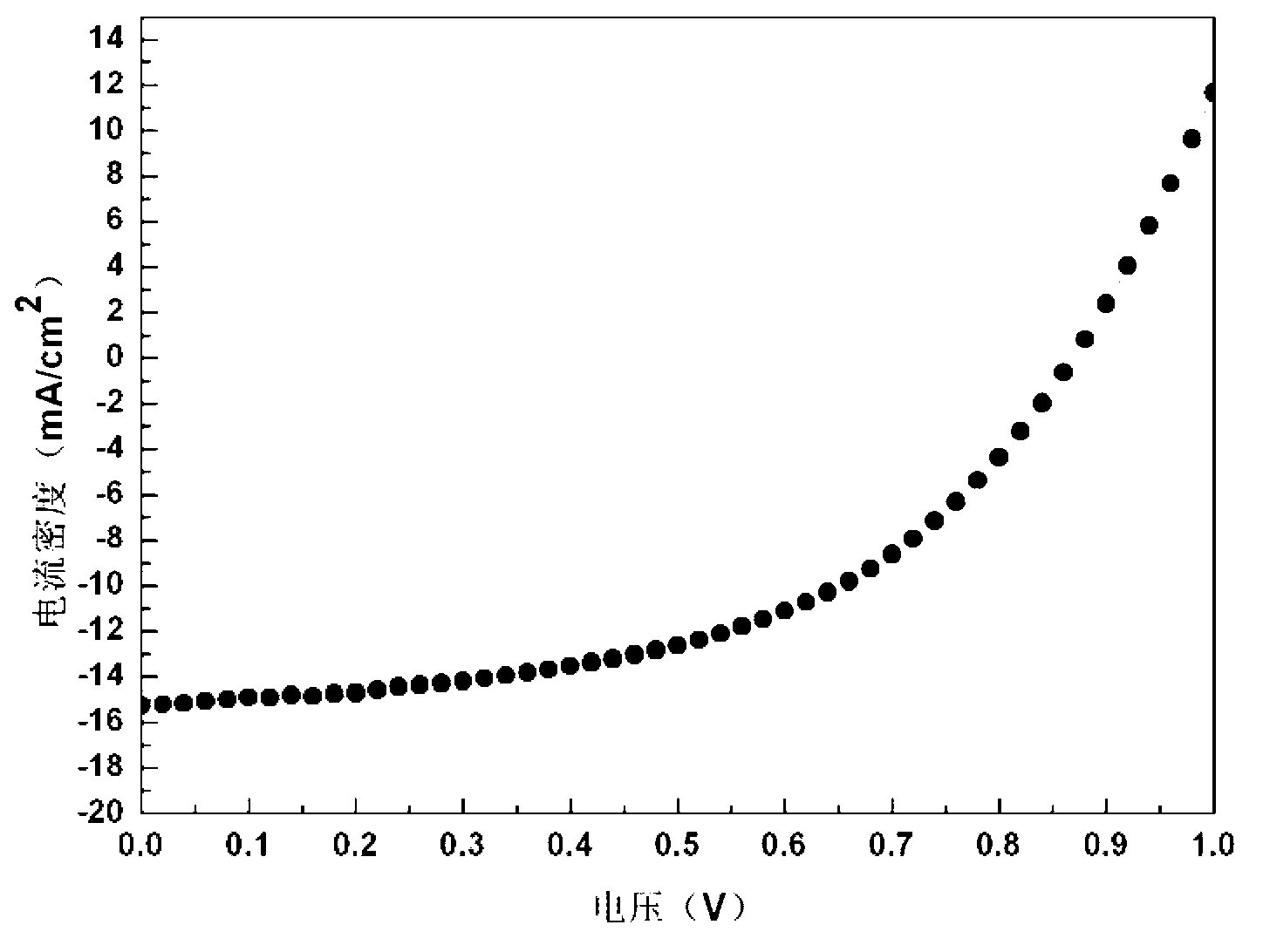

Three-terminal parallel polymer solar cell based on metal nanoparticle doping and preparation method of solar cell

InactiveCN103227287AUniform film formationSmall fluctuationSolid-state devicesSemiconductor/solid-state device manufacturingElectronic transmissionIndium tin oxide

The invention discloses a three-terminal parallel polymer solar cell based on metal nanoparticle doping and a preparation method of the solar cell, and belongs to the technical field of polymer solar cells. The solar cell sequentially consists of ITO (Indium Tin Oxide) conductive glass serving as a substrate and a cathode, a TiO2 electronic transmission layer, a PSBTBT:PC70BM:NPs active layer, an MoO3 hole transmission layer, an Ag anode, a WO3 hole transmission layer, a P3HT:PC70BM:NPs active layer, an LiF electronic transmission layer and an Al cathode, wherein a mass ratio of the P3HT:PC70BM:NPs active layer is 1:1:(0.02-0.05), and NPs represents Au or Ag nanoparticles. According to the solar cell and the preparation method, two subcells form a parallel structure, light absorbing ranges of active layers of the subcells are complementary, metal nanoparticles are doped in the active layer of each subcell, and a utilization ratio of sunlight by the solar cell is increased by utilizing a plasma enhancement effect nearby the metal nanoparticles, so that the performance of the solar cell is improved.

Owner:JILIN UNIV

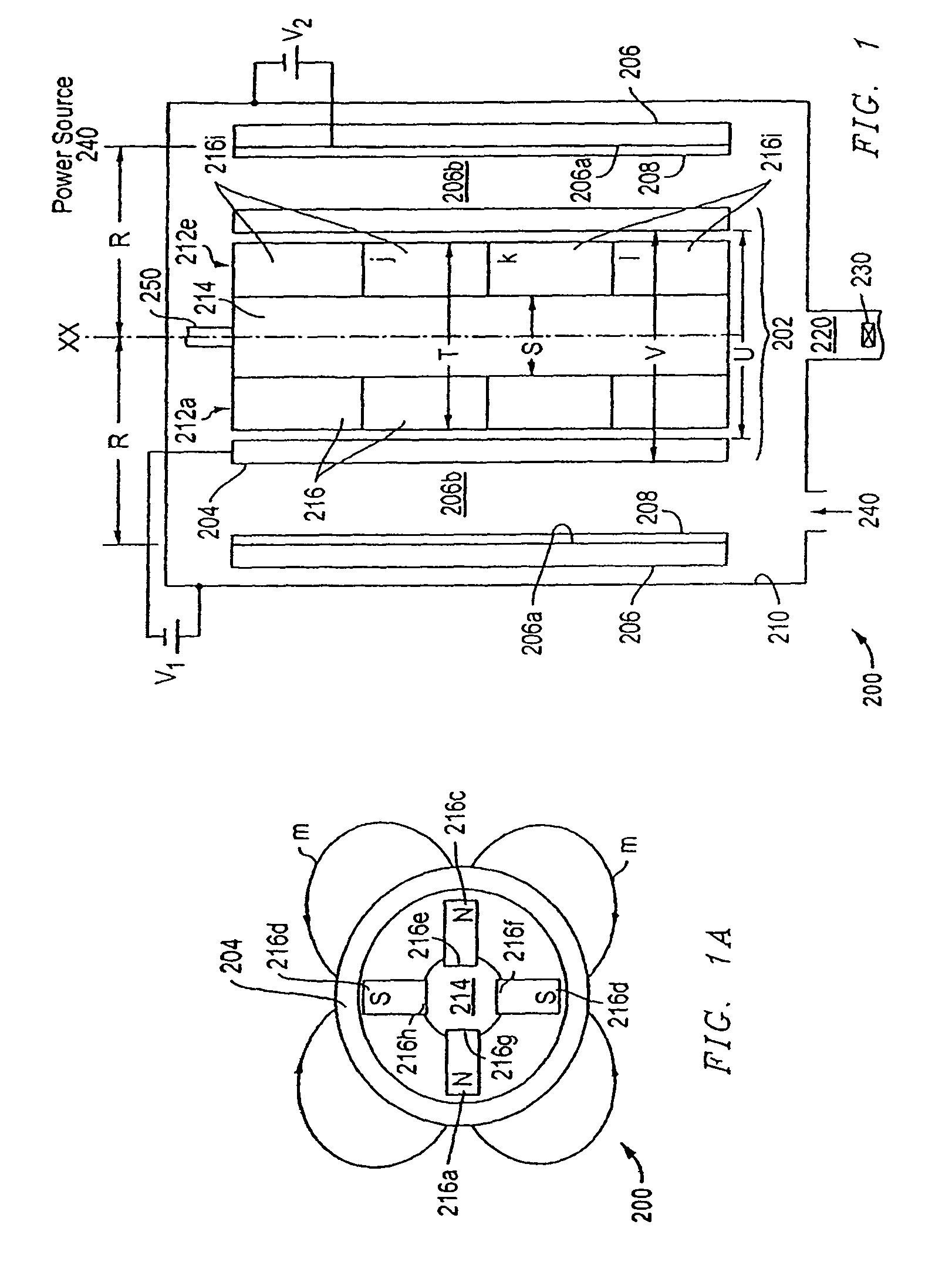

ECR-plasma source and methods for treatment of semiconductor structures

InactiveUS20050287824A1Improvement in principal parametersReduce noise levelElectric discharge tubesSemiconductor/solid-state device detailsMicrowaveSemiconductor structure

The invention relates to microelectronics, more particularly, to methods of manufacturing solid-state devices and integrated circuits utilizing microwave plasma enhancement under conditions of electron cyclotron resonance (ECR), as well as to use of plasma treatment technology in manufacturing of different semiconductor structures. Also proposed are semiconductor device and integrated circuit and methods for their manufacturing. Technical result consists in improvement of reproducibility parameters of semiconductor structures and devices processed, enhancement of devices parameters, elimination of possibility of defects formation in different regions, and speeding-up of the treatment process.

Owner:OBSCHESTVO S OGRANICHENNOI OTVETABTVENNOSTJU EPILAB

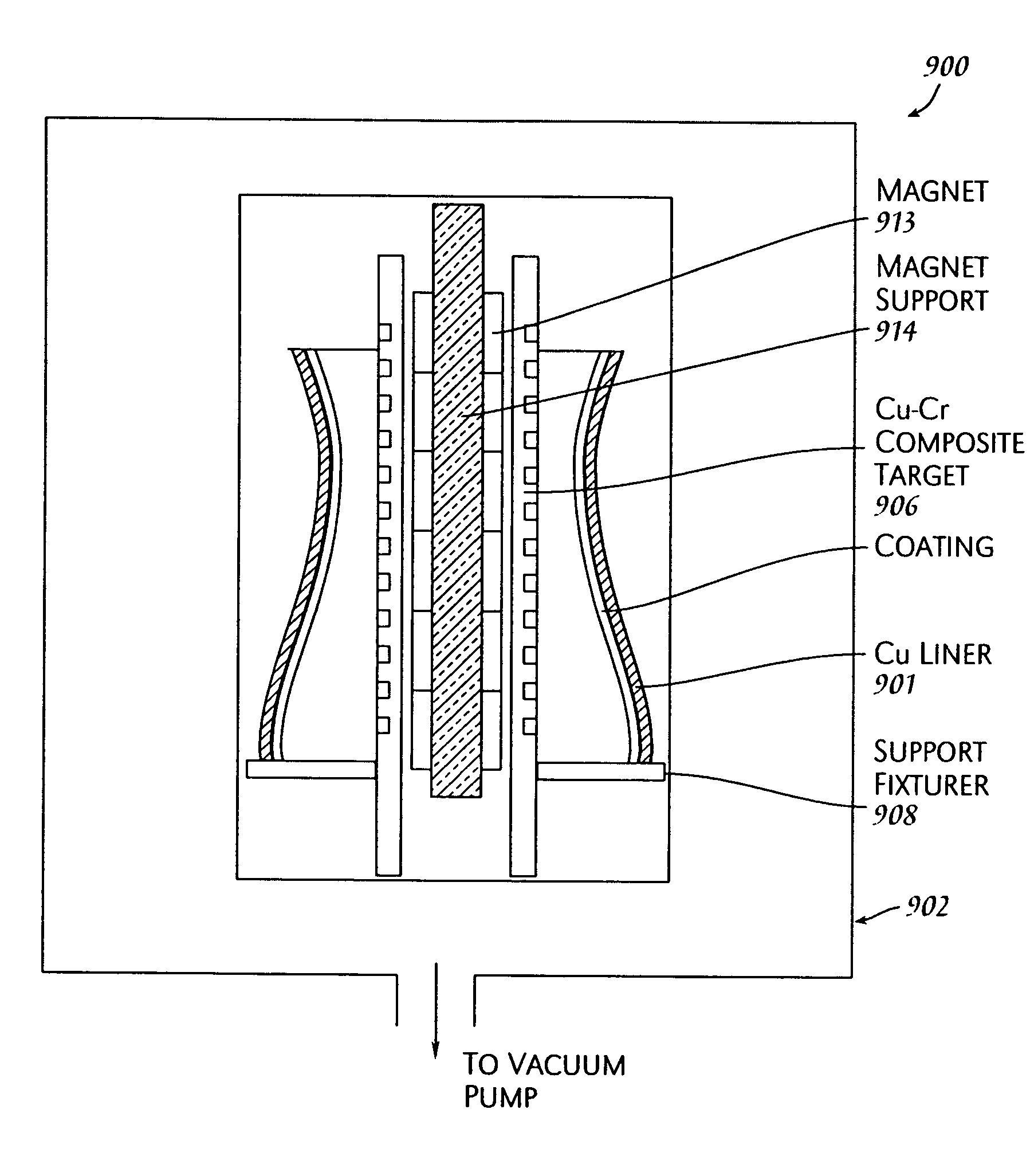

Method for magnetron sputter deposition

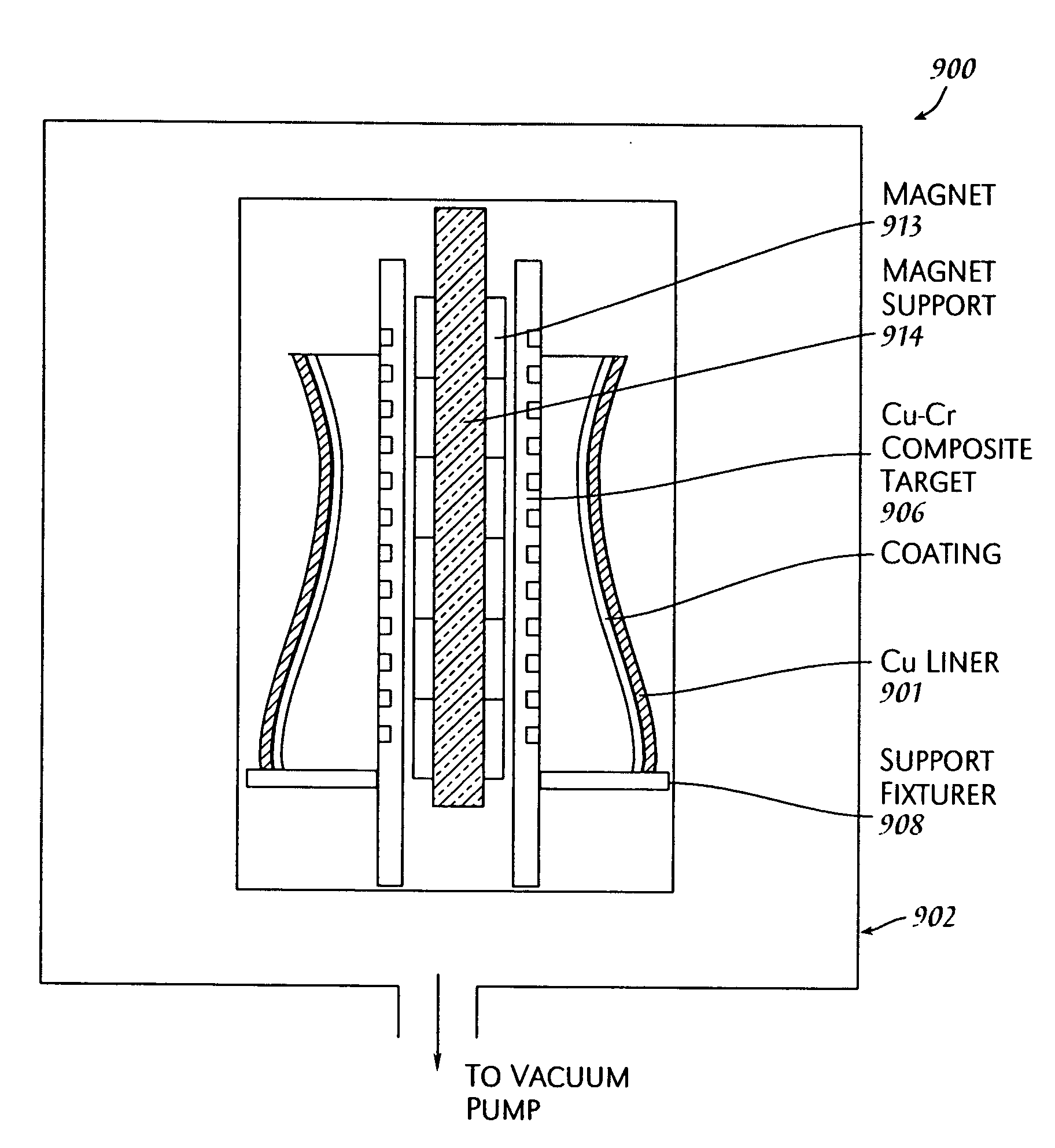

ActiveUS7790003B2Electric discharge tubesVacuum evaporation coatingCombustion chamberIon bombardment

A method for depositing a nanostructured coating comprising chromium or a copper-chromium mixture on a workpiece. The workpiece may comprise a hollowed structure such as a rocket or jet engine combustion chamber liner. The method comprises providing a magnetron and an external sputter target material comprising chromium or a copper-chromium composite and effecting a magnetron sputter deposition to deposit a substantially uniform nanostructured coating comprising said sputter target material on said workpiece. The method may include plasma enhancement wherein a filament is utilized to produce a plasma that effects an ion bombardment on the workpiece during the magnetron sputter deposition process. The invention also includes the nanostructured coatings deposited by these methods and workpieces coated thereby.

Owner:SOUTHWEST RES INST

Method for manufacturing low-temperature polysilicon thin-film transistor

InactiveCN1567549AImprove moisture resistanceHigh dielectric strengthSemiconductor/solid-state device manufacturingGas phaseOptoelectronics

The invention relates to a method of making low temperature polycrystalline silicon thin film transistor (LTPS TFT), firstly forming a polycrystalline silicon layer containing a channel region, successively making first and second plasma enhancement chemical gas phase deposition procedures so as to in sequence form a silicon oxide layer with tetraethyl silicon hydroxide as the principal and a compound grid insulating layer composed of a silicon nitride layer, and finally forming a grid electrode and source / drain of the LTPS TFT.

Owner:TPO DISPLAY

Surface plasma enhancement-based nano laser

InactiveCN105552716AImprove optical output powerImprove performanceLaser active region structureMicro nanoSurface plasmon

The invention discloses a surface plasma enhancement-based nano laser, belongs to the fields of micro-nano optics and photoelectronics, and particularly relates to a nanowire laser. According to the solving scheme, an insulating medium with a certain thickness is firstly sputtered on the surface of a zinc oxide nanowire as a buffer layer, so that the insulating medium evenly coats the surface of the nanowire; and a metal film layer is sputtered, and evenly coats the surface of an insulating layer to form the surface plasma laser of an annular mechanism of the nanowire / insulating medium / metal film. The surface plasma enhancement-based nano laser has the advantages of being small in volume, simple in structure, high in reliability and the like; and a bran-new technical approach is provided for improvement of the performance of the nano laser.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

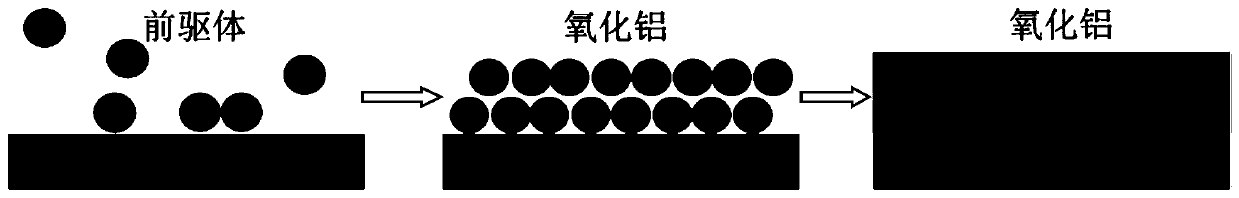

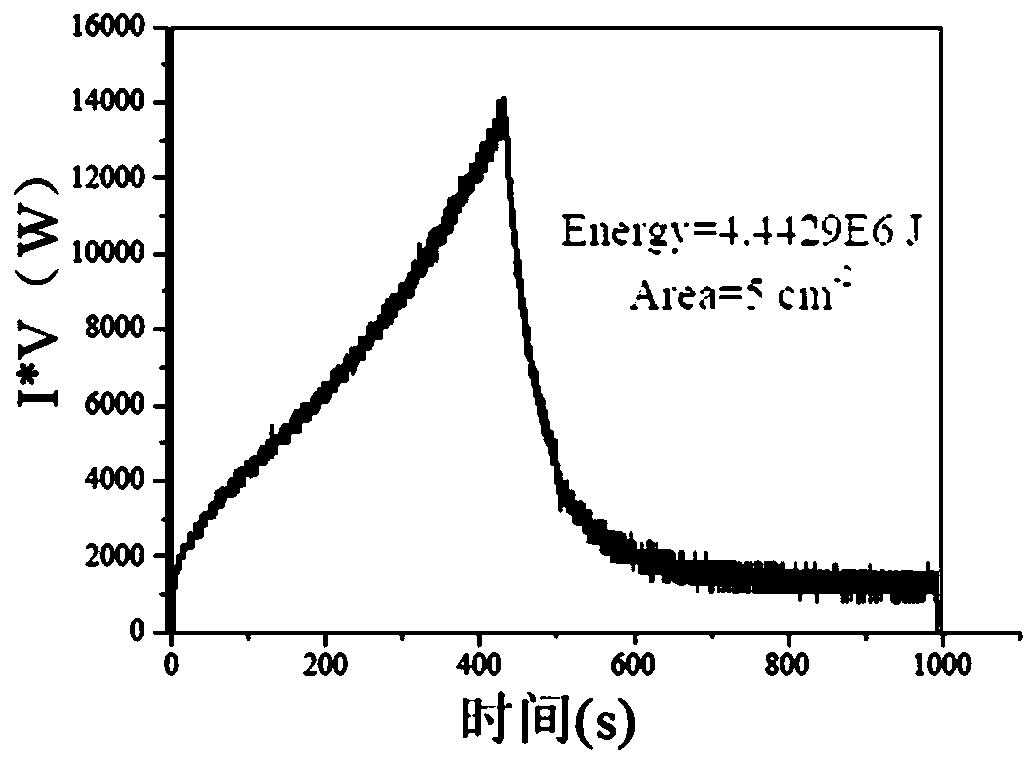

Energy saving preparation method for aluminum electrolytic capacitor anodic aluminum foil

ActiveCN110819965AReduce consumptionSurface reaction electrolytic coatingChemical vapor deposition coatingAluminum metalAluminum foil

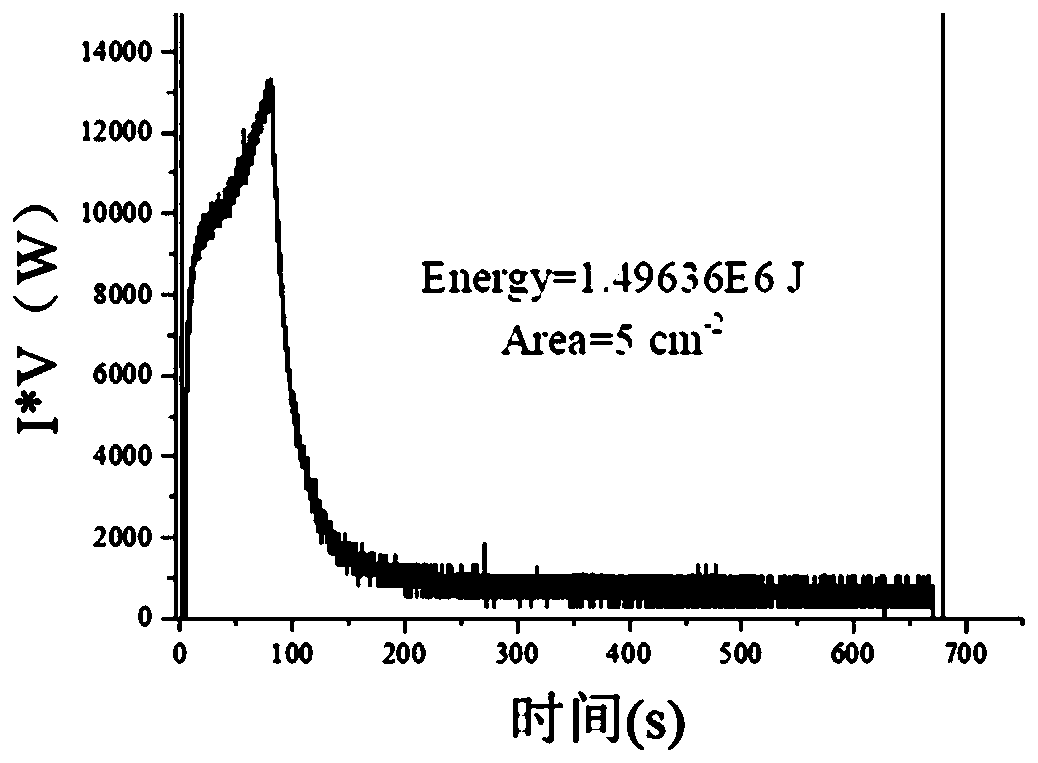

The invention discloses an energy saving preparation method for an aluminum electrolytic capacitor anodic aluminum foil and belongs to the field of aluminum electrolytic capacitors. The energy savingpreparation method comprises the steps that an aluminum metal organic compound is used as a precursor by utilizing a vapour deposition method supplemented by plasma enhancement, an aluminium oxide dielectric medium is grown on the surface of a corroded aluminum foil and then is subjected to high-temperature heat treatment, then anodic oxidation, annealing and filling formation are performed, and the aluminum electrolytic capacitor anodic aluminum foil is obtained. According to the energy saving preparation method for the aluminum electrolytic capacitor anodic aluminum foil, by means of the vapour deposition technology supplemented by plasma, a layer of Al2O3 can be rapidly and evenly deposited on the surface of the corroded foil directly, compared with a traditional water treatment method,conversion by the strong electric field action is not needed, therefore, the energy consumption in the anodic oxidation process is reduced by 33.8%-66.2%.

Owner:XI AN JIAOTONG UNIV

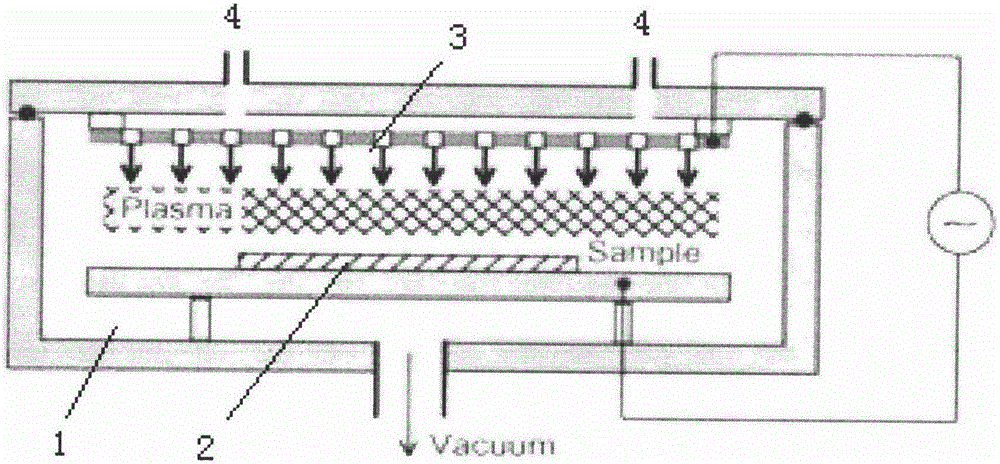

Method for preparing hydrogen-containing diamond-like carbon film

InactiveCN102002683AIncrease growth rateChemical vapor deposition coatingCarbon filmDiamond-like carbon

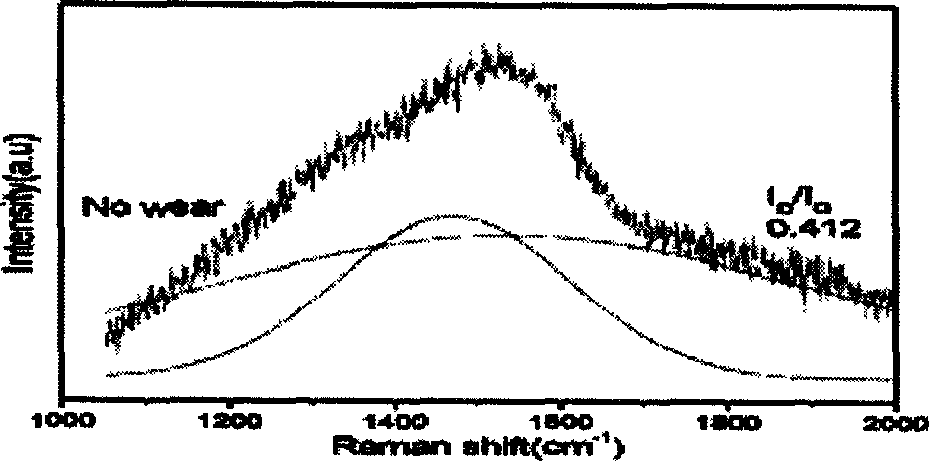

The invention relates to a method for preparing a hydrogen-containing diamond-like carbon film, relating to diamond-like carbon films. The preparation method of the hydrogen-containing diamond-like carbon film comprises the following steps of: placing a substrate with a front surface over against a source electrode into a plasma enhancement type chemical vapor deposition growth cavity, and cleaning the plasma enhancement type chemical vapor deposition growth cavity and the surface of the substrate in a sputtering way by using plasmas; vacuumizing the plasma enhancement type chemical vapor deposition growth cavity, accessing a hydrogen-containing gas, regulating working pressure and radio frequency power, and growing the hydrogen-containing diamond-like carbon film; after the growth is closed, stopping introducing the hydrogen-containing gas, and completely extracting a tail gas so as to obtain the hydrogen-containing diamond-like carbon film. The plasma enhancement type chemical vapor deposition method which reversely places the substrate into the growth cavity parallel to the source electrode and then regulates the distance between the substrate and the source electrode and changes the working pressure and the radio frequency power can modulate an optical band gap of the diamond-like carbon film in a wider range, obviously enhance the growth rate of the diamond-like carbon film and meet the requirements for future application of the diamond-like carbon film.

Owner:XIAMEN UNIV

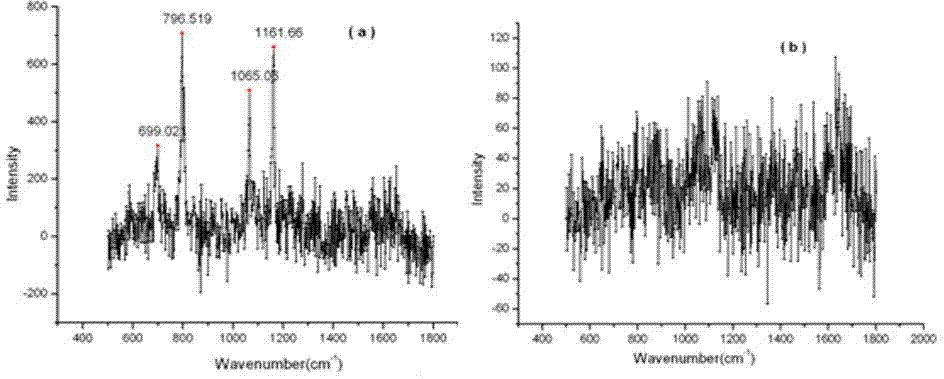

Method of optical waveguide enhancement mechanism and Raman spectrometer

ActiveCN102967593AIncrease energy densityFavorable excitation conditionsRaman scatteringFiberRefractive index

The invention relates to a design concept of Raman spectrum of an optical waveguide enhancement mechanism, and the design concept of the Raman spectrum of the optical waveguide enhancement mechanism is used for identifying substance and qualitatively and quantitatively analyzing property of the substance. A Raman spectrometer consists of a metal film, thick glasses, a sample cell and a metal film, and is capable of directly coupling a laser in a wavelength of 785 nm into a waveguide layer between two metal layers to generate an ultrahigh-order guide mode so as to enhance Raman scattering, wherein the ultrahigh-order guide mode has an ultrahigh light intensity and is irrelevant with polarization. The enhancement is different from surface plasma enhancement, and metal nanometer sol is unnecessary to be added; and the enhancement is also different from a resonance Raman effect and liquid core fiber Raman enhancement, and has no requirement on wavelength of an incident light and refractive index of a sample.

Owner:启东市德聚邻信息科技有限公司

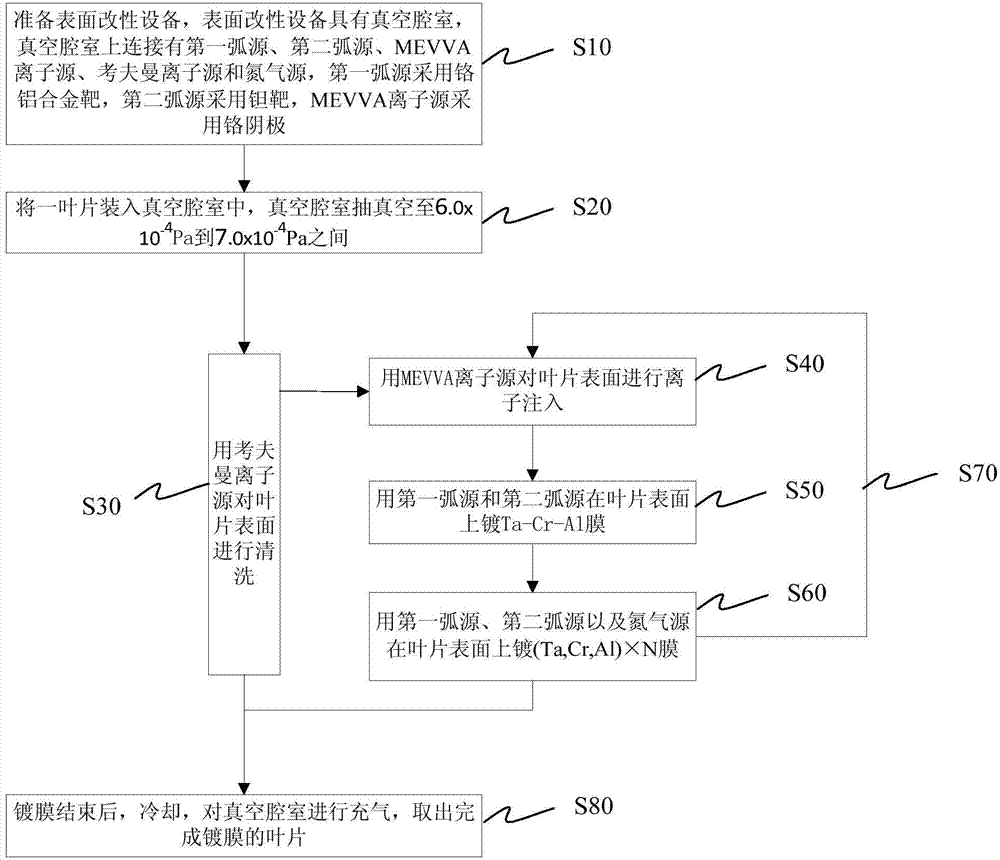

Preparation method of compressor blade coating and surface modifier

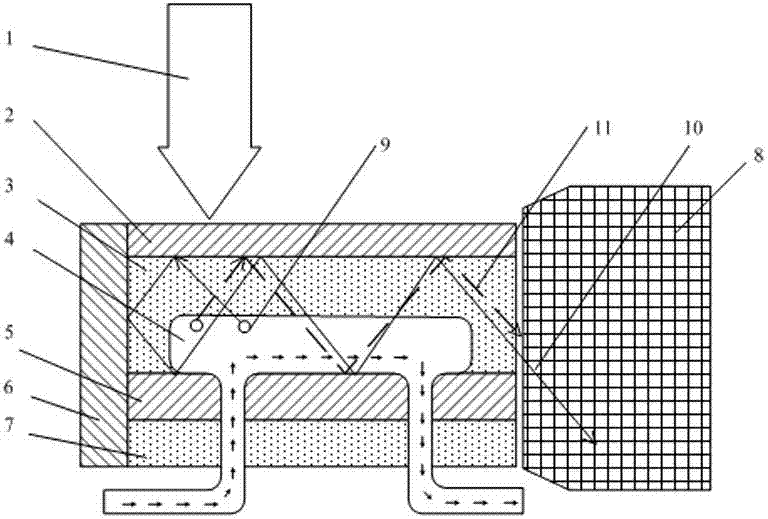

InactiveCN104328385AImprove the problem of poor deposition uniformityAccelerated corrosionVacuum evaporation coatingSputtering coatingEngineeringMagnetic filtration

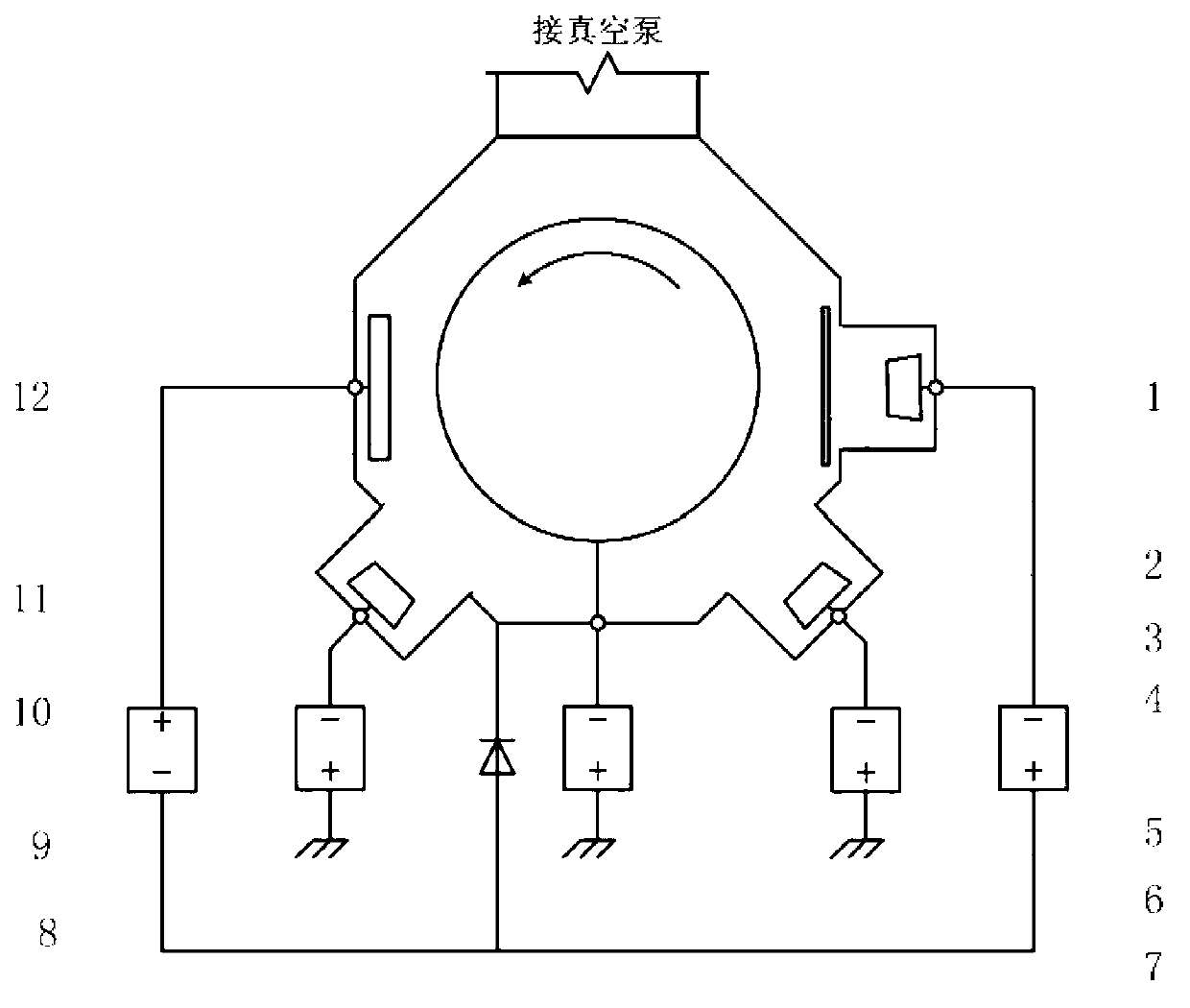

The invention discloses a preparation method of a compressor blade coating and a surface modifier. The preparation method comprises the following steps: putting a blade into the vacuum chamber of the surface modifier and vacuuming, and connecting a first arc source, a second arc source, an MEVVA ion source, a kaufmann ion source and a nitrogen source to the vacuum chamber; cleaning the surface of the blade by use of the kaufmann ion source; performing ion injection on the surface of the blade by use of the MEVVA ion source; coating the surface of the blade with a Ta-Cr-Al film by use of the first arc source and the second arc source; depositing a (Ta, Cr, Al)*N film on the surface of the blade by use of the first arc source, the second arc source and the nitrogen source; and orderly and repeatedly completing coating. According to the preparation method of the compressor blade coating, the problem of poor deposition uniformity of the complex-structure film of the blade is improved by use of cathode magnetic filtration and plasma enhancement technologies; and meanwhile, the high temperature corrosion resistance and the erosion resisting capacity of the blade surface are improved by adopting a novel Al doped Ta-Cr-N nano multi-layer film.

Owner:BEIJING RES INST OF AUTOMATION FOR MACHINERY IND

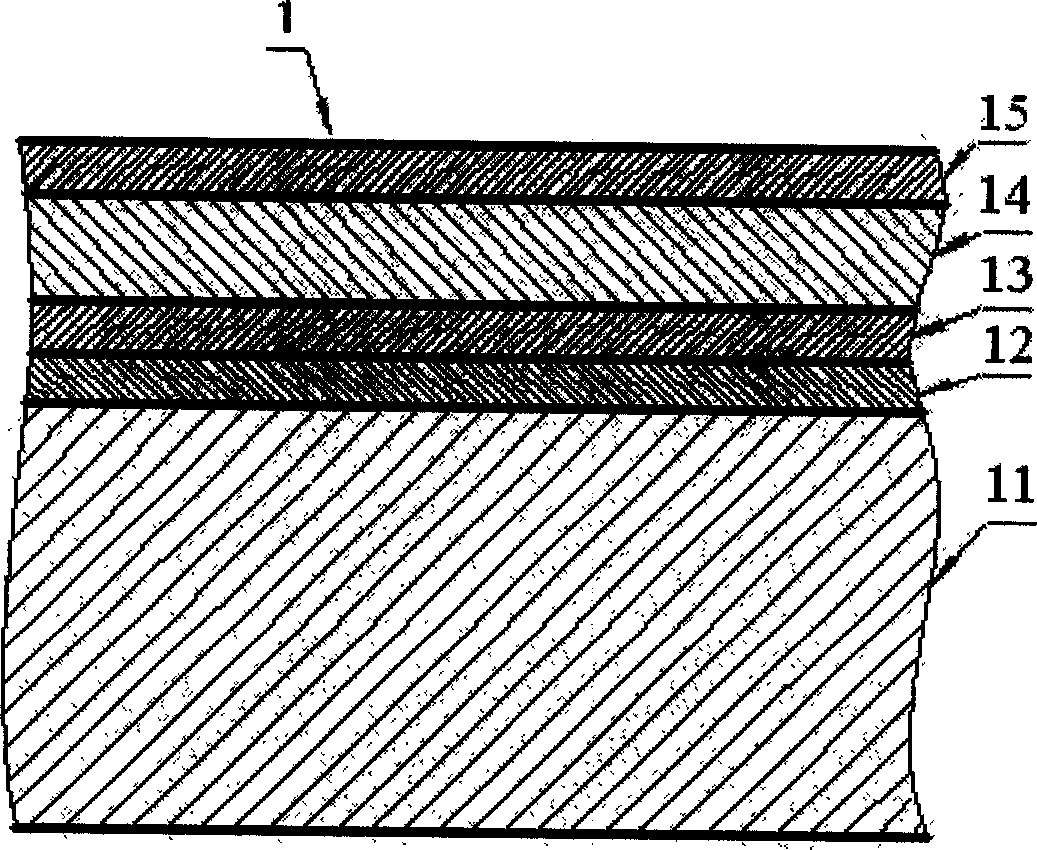

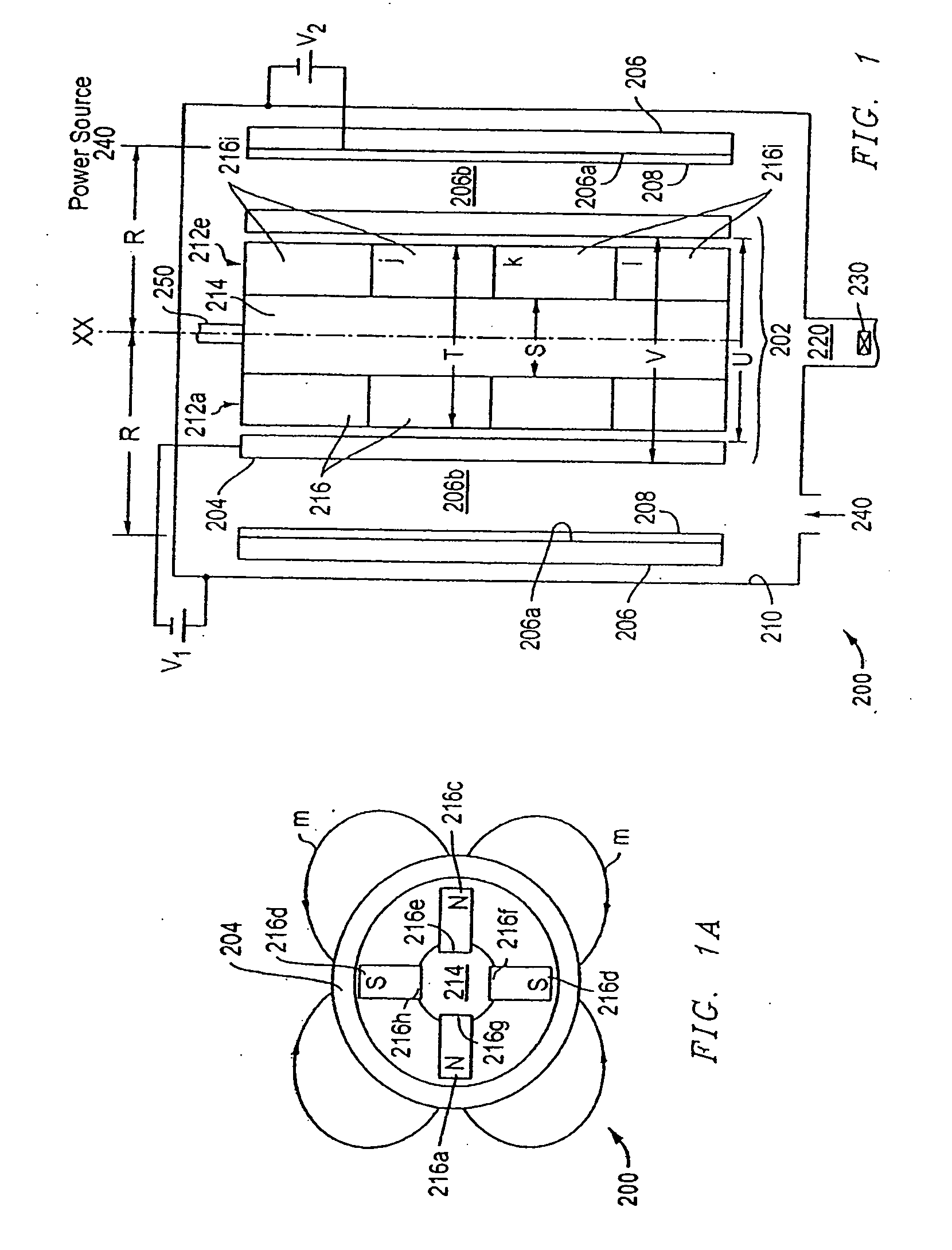

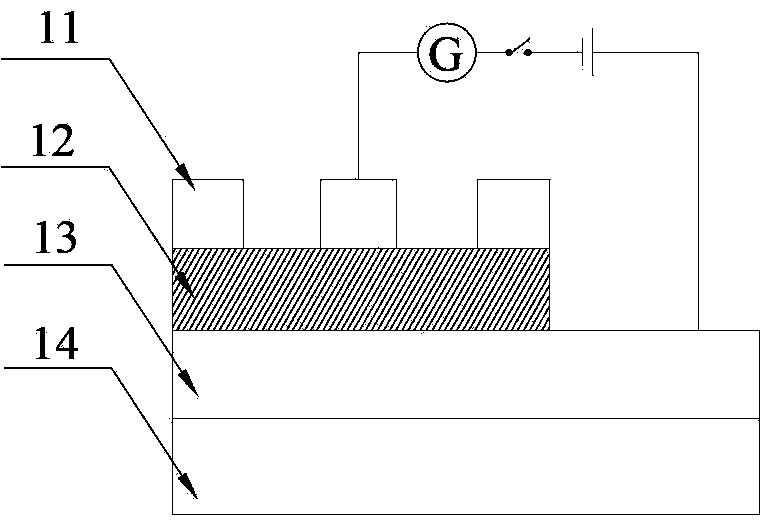

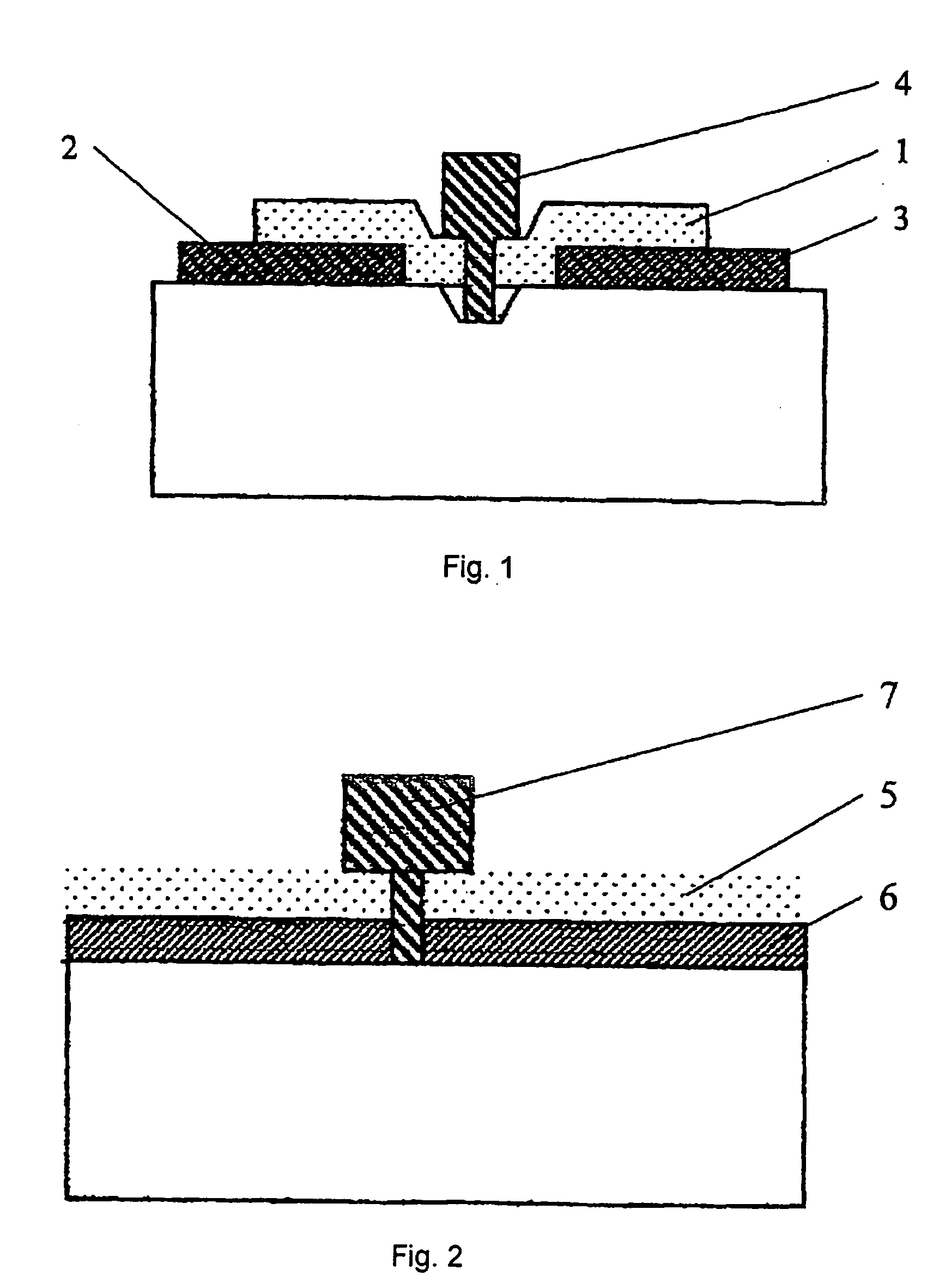

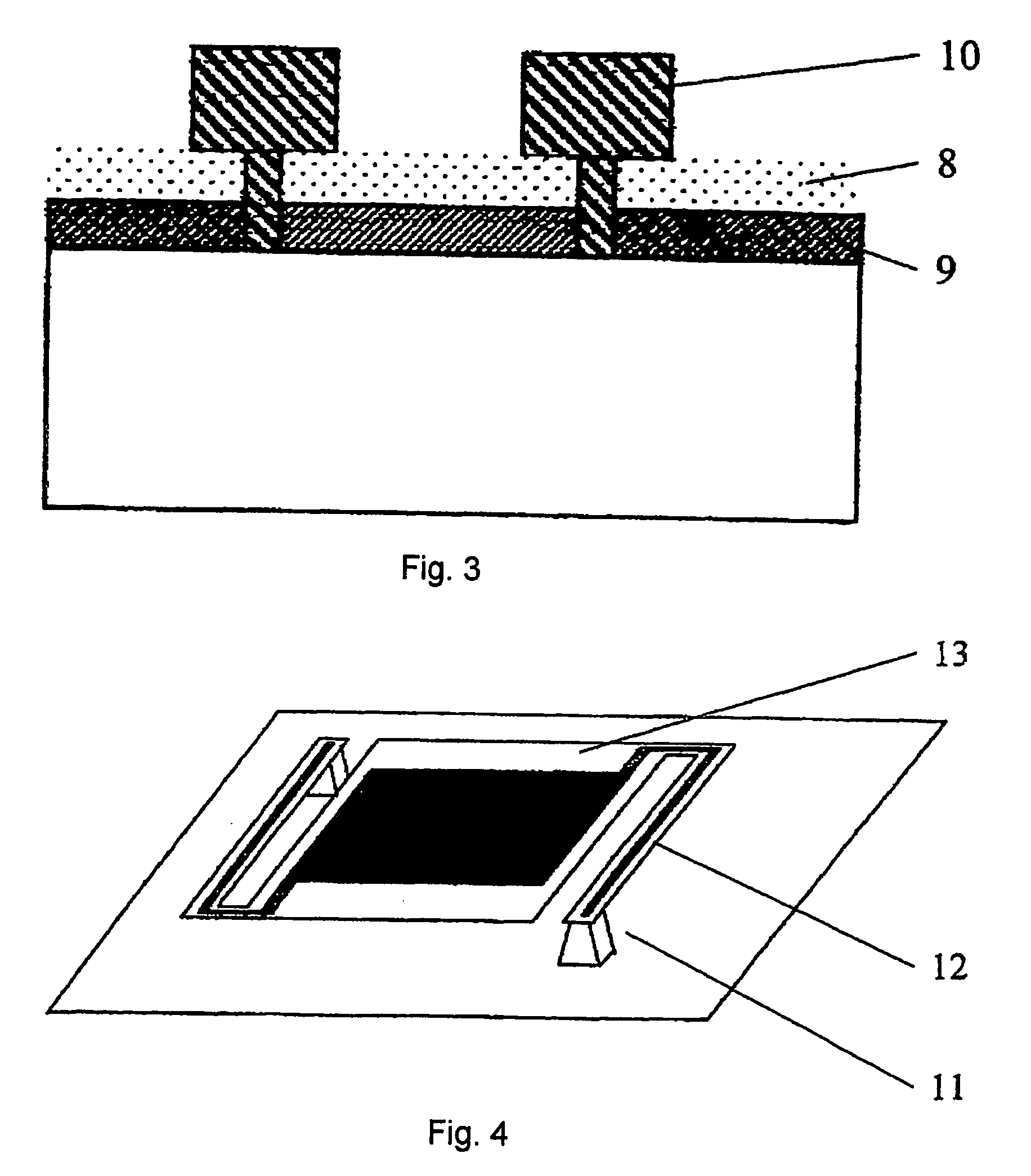

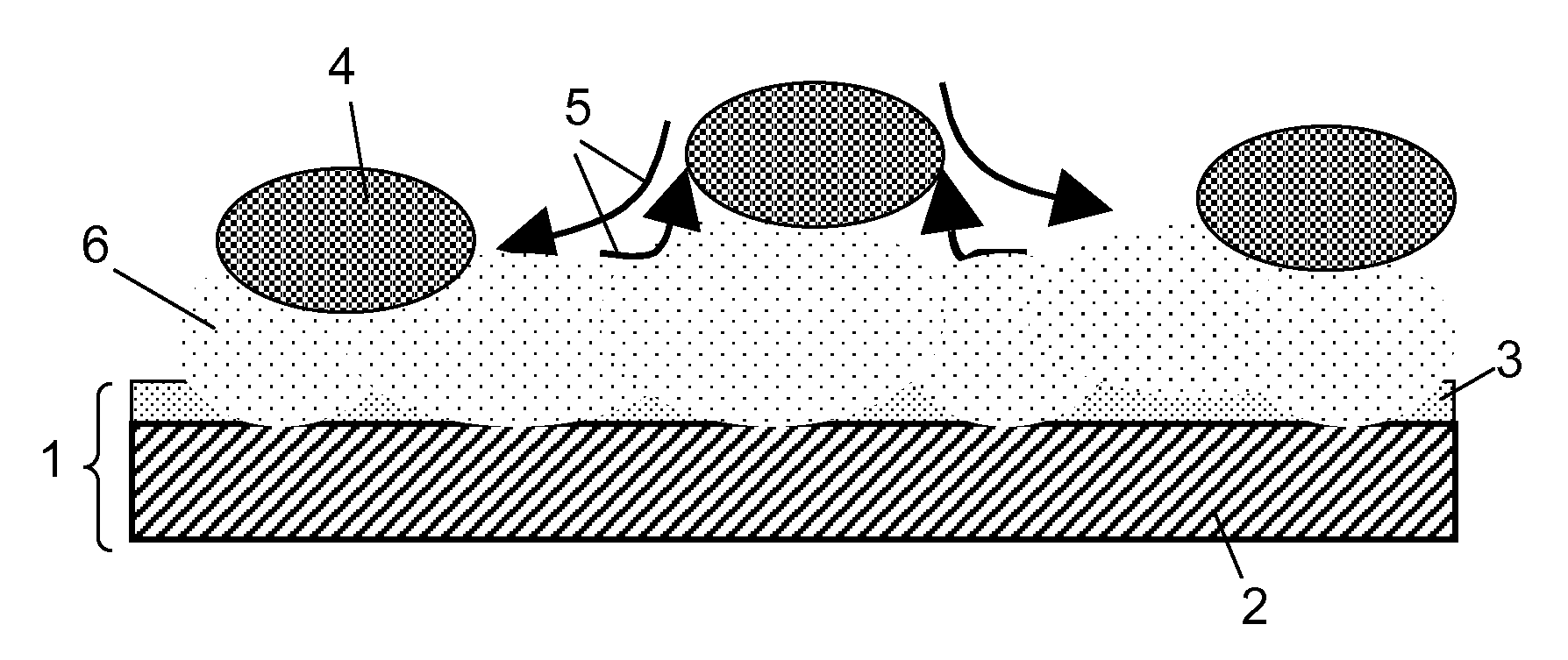

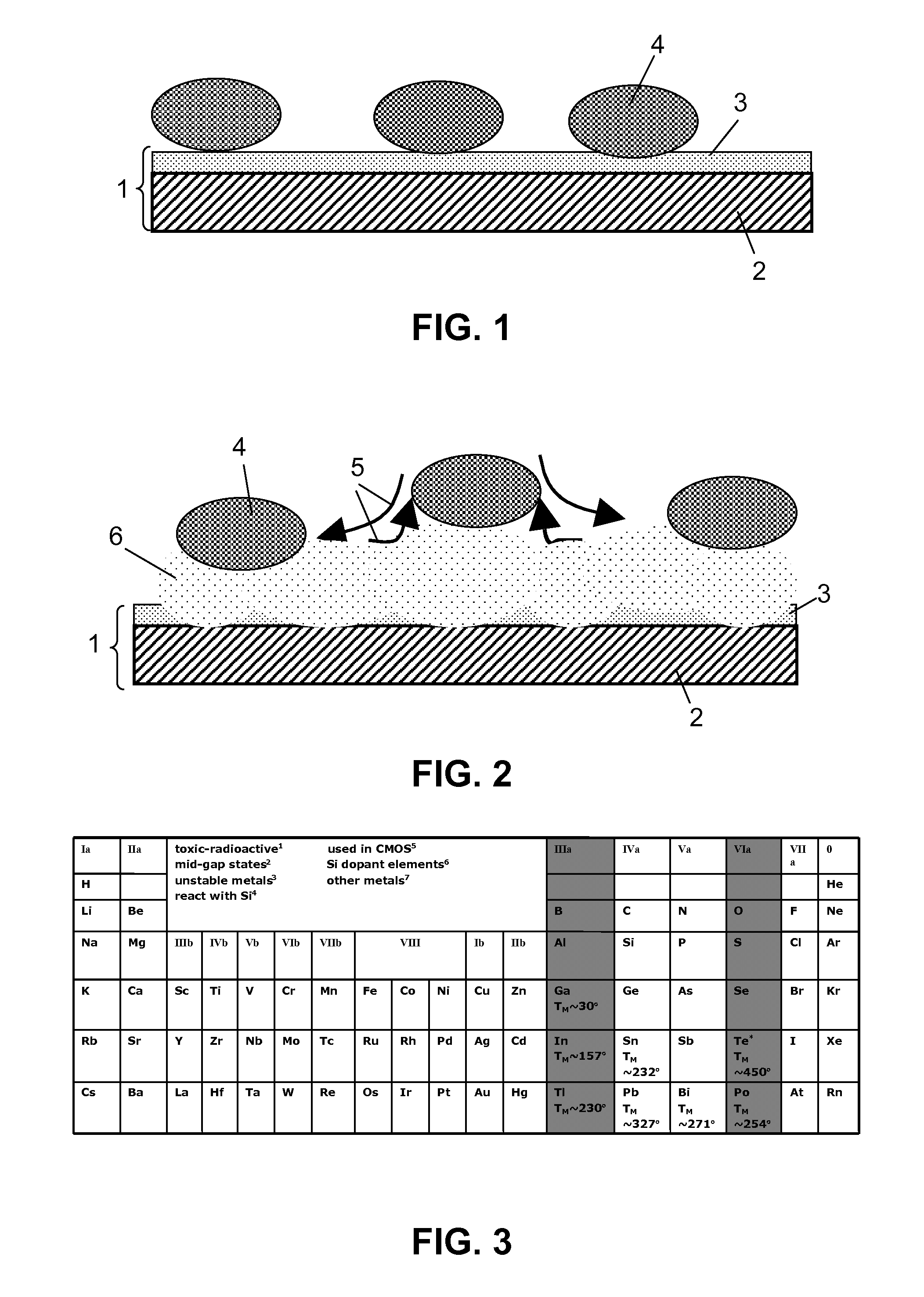

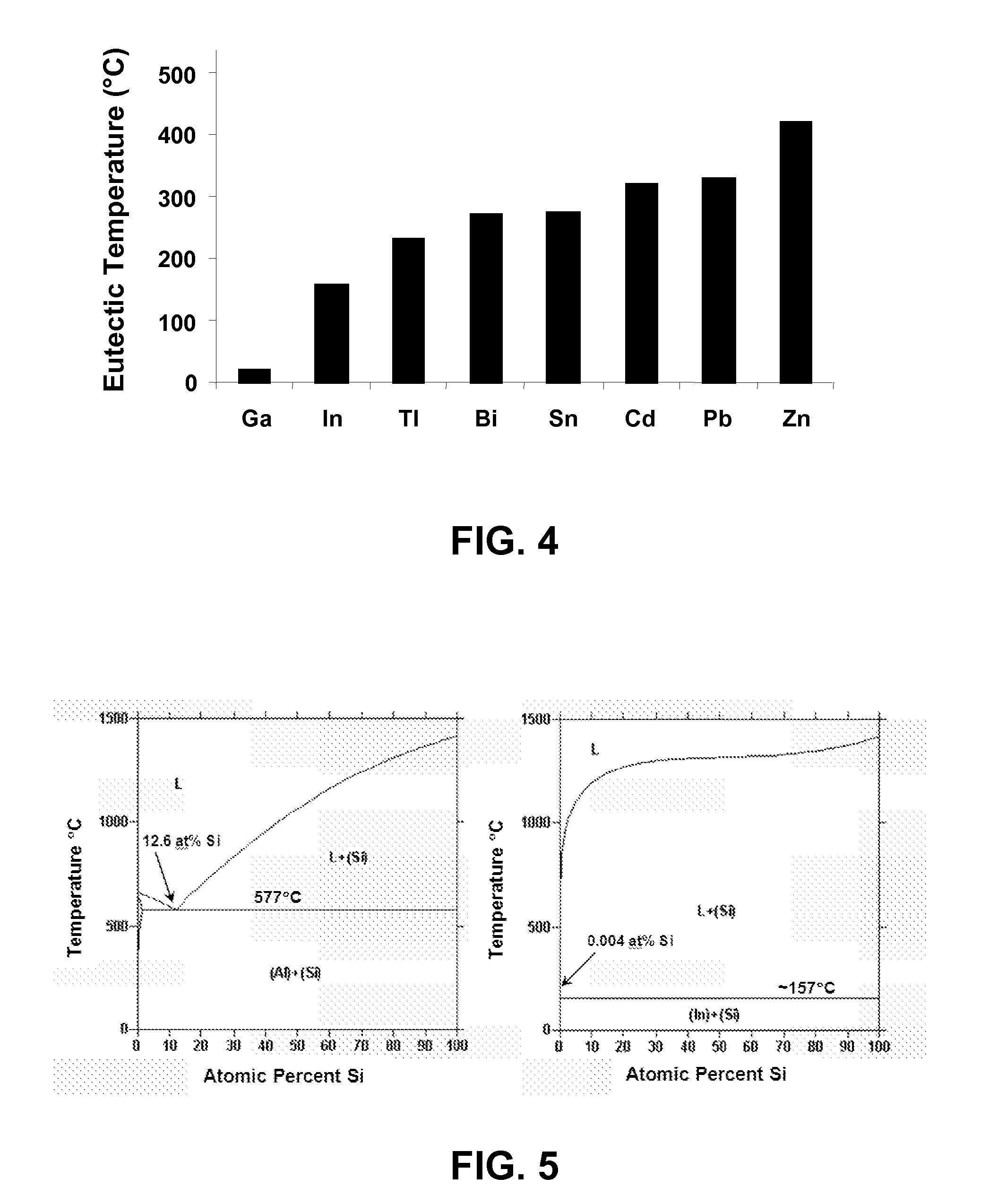

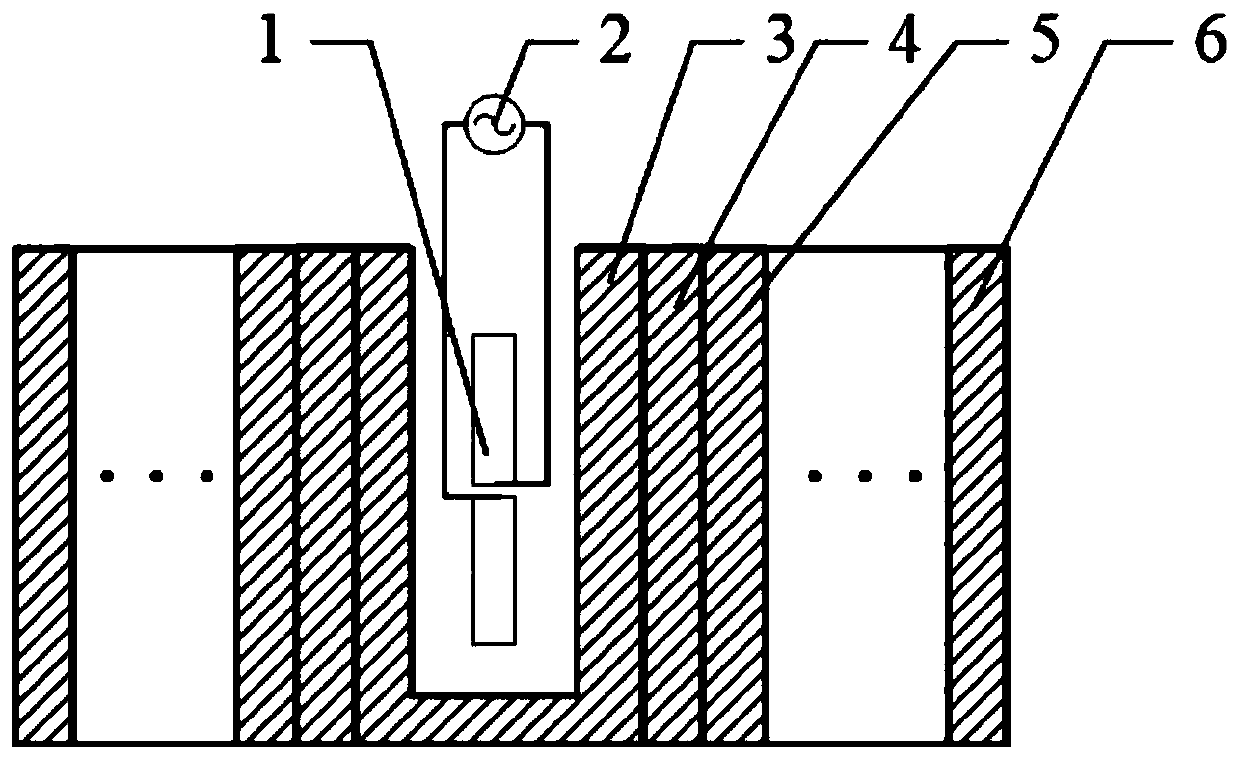

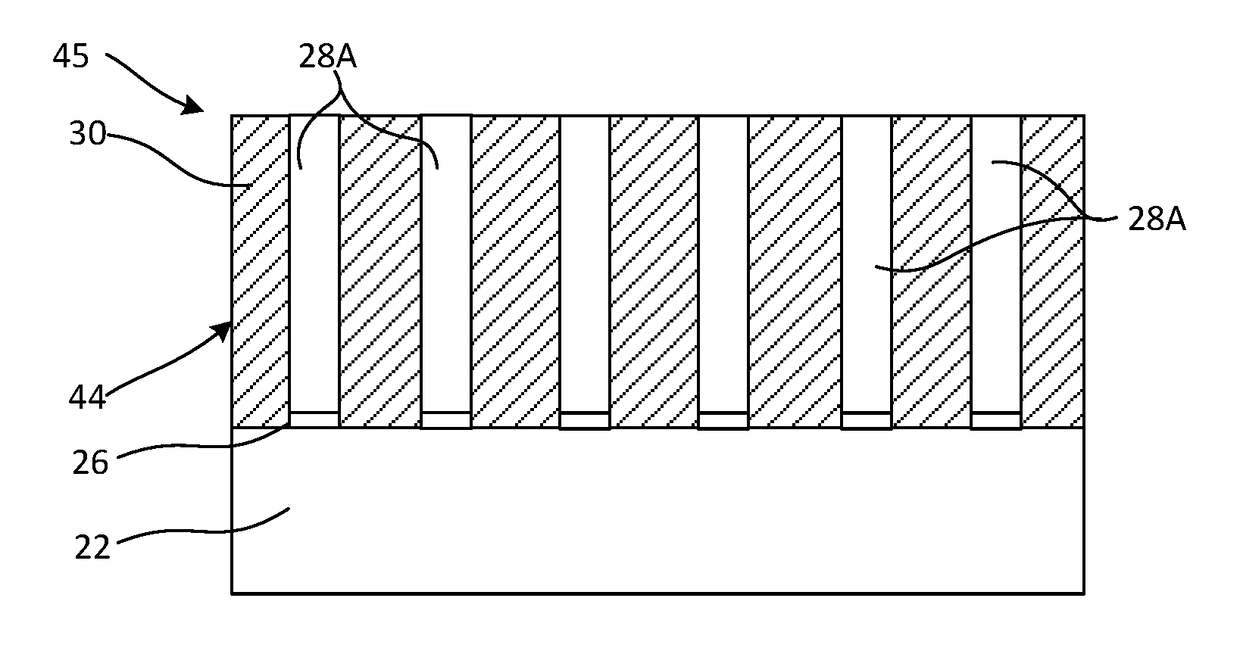

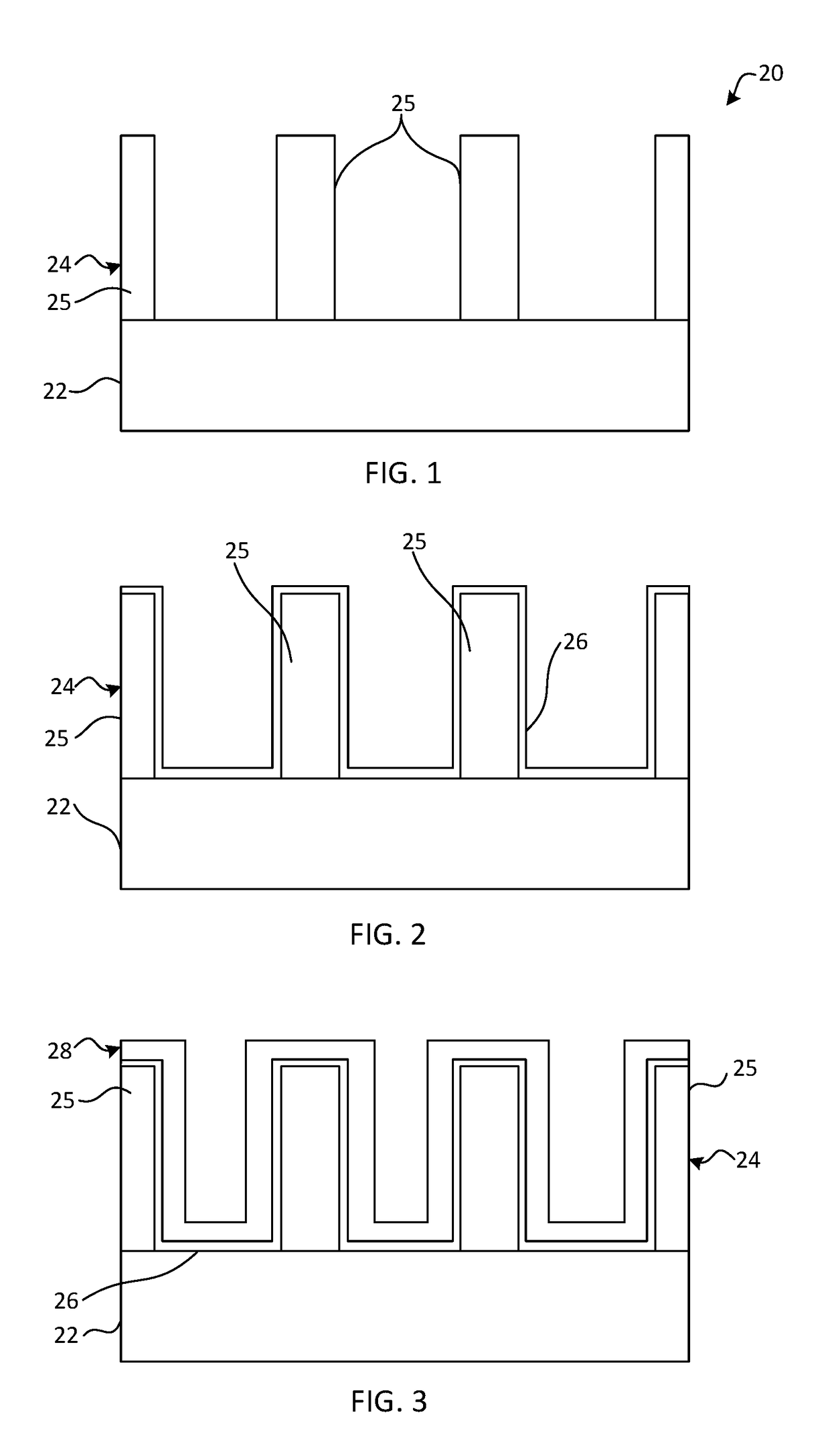

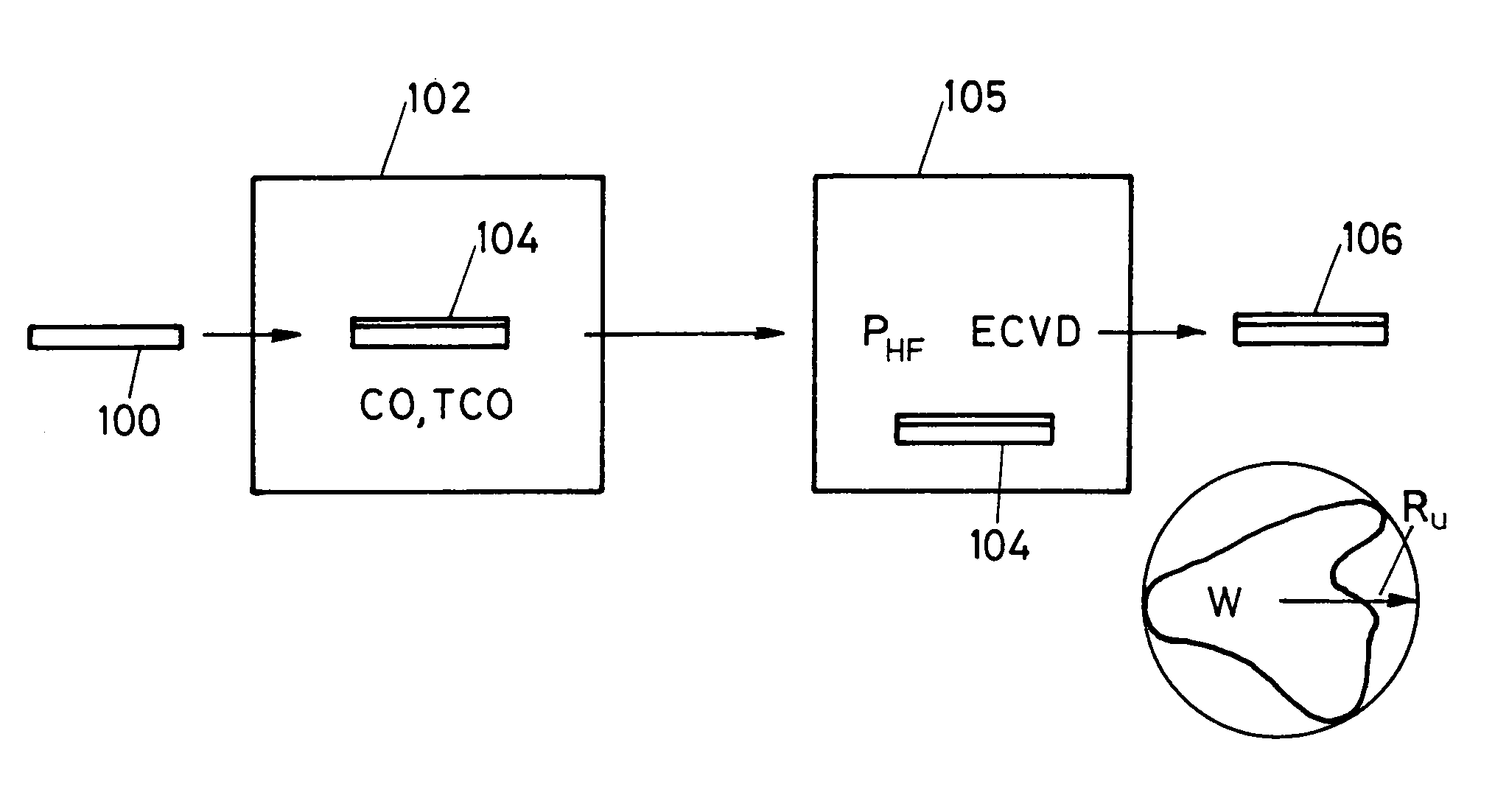

Low-temperature formation of layers of polycrystalline semiconductor material

ActiveUS7964479B2Easy to implementRequired additionSemiconductor/solid-state device manufacturingChemical vapor deposition coatingSemiconductor materialsRoom temperature

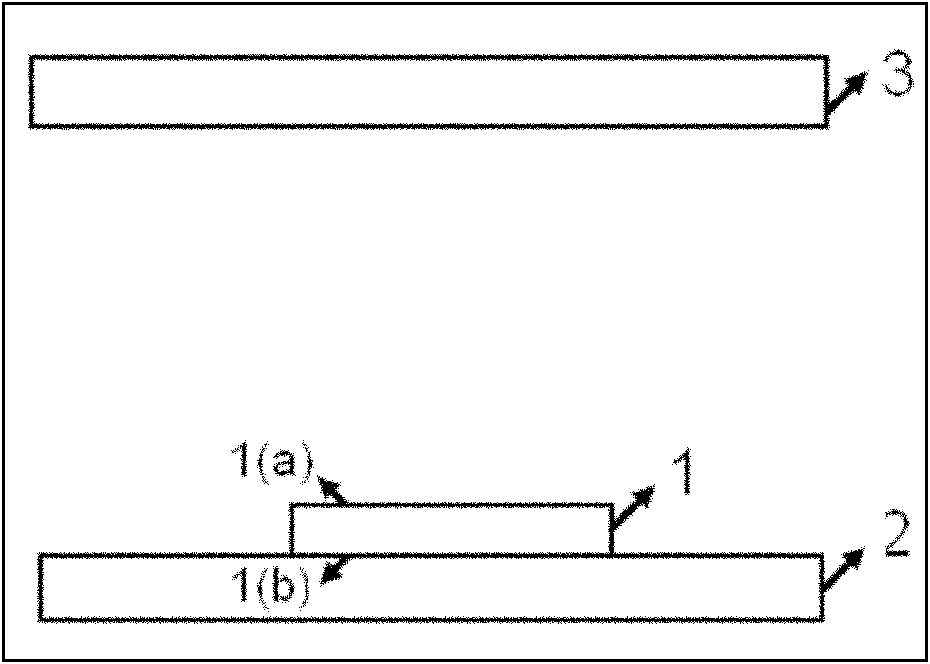

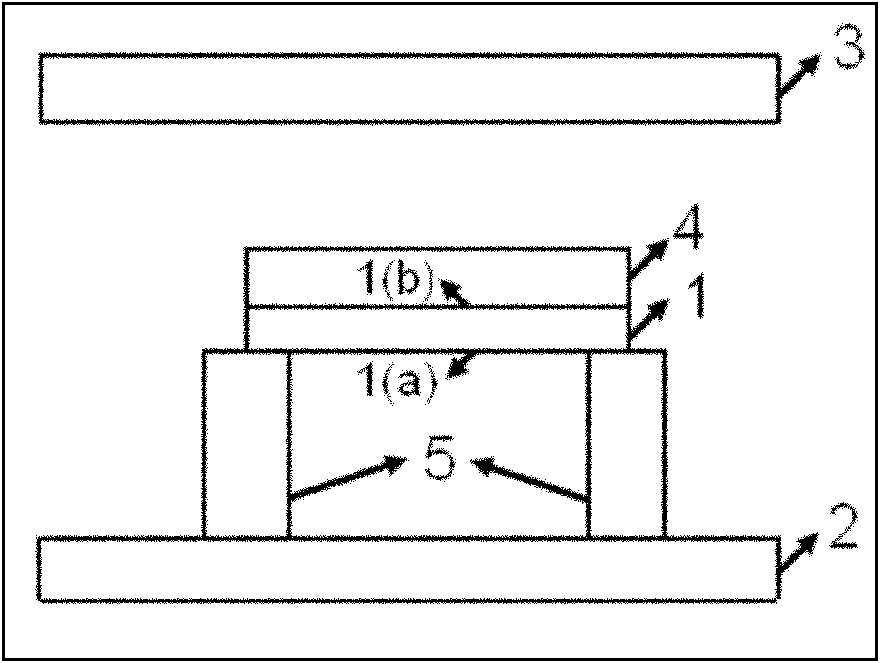

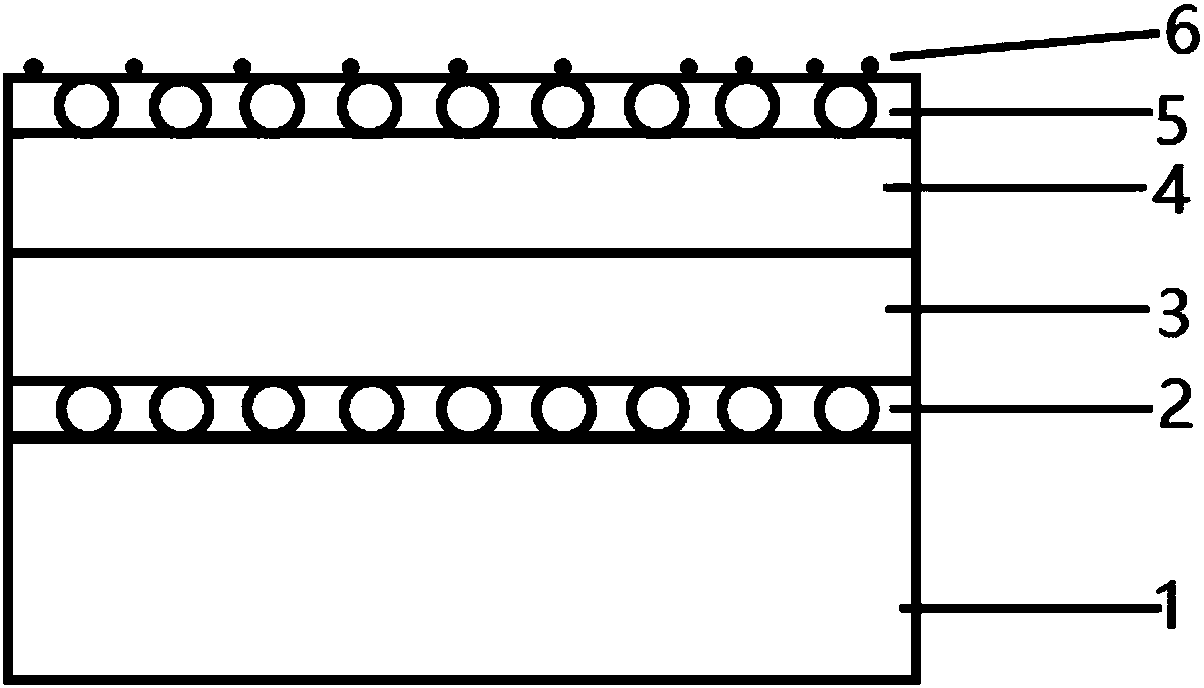

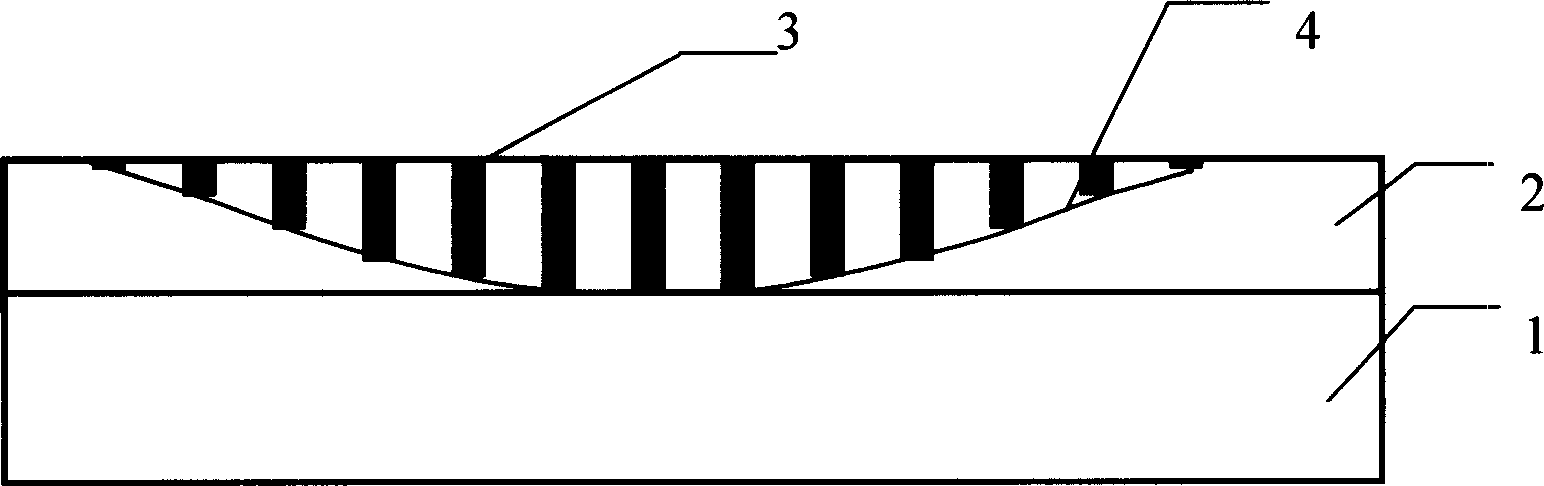

The present invention provides a method for forming a layer (6) of polycrystalline semiconductor material on a substrate (1). The method comprises providing at least one catalyst particle (4) on a substrate (1), the at least one catalyst particle (4) comprising at least a catalyst material, the catalyst material having a melt temperature of between room temperature and 500° C., or being able to form a catalyst material / semiconductor material alloy with a eutectic temperature of between room temperature and 500° C., and forming a layer (6) of polycrystalline semiconductor material on the substrate (1) at temperatures lower than 500° C. by using plasma enhancement of a precursor gas, thereby using the at least one catalyst particle (4) as an initiator. The present invention furthermore provides a layer (6) of polycrystalline semiconductor material obtained by the method according to embodiments of the present invention.

Owner:INTERUNIVERSITAIR MICRO ELECTRONICS CENT (IMEC VZW)

Preparation method of low-temperature multi-component composite coating based on plasma enhancement and rare earth modification technology

InactiveCN102994961AImprove bindingImprove friction and wear performanceVacuum evaporation coatingSputtering coatingLow temperature depositionRare earth

The invention relates to a preparation method of a low-temperature multi-component composite coating based on a plasma enhancement and rare earth modification technology. The method is characterized by comprising the following steps of: 1) in a process of preparing a rare earth modified multi-component composite coating, performing the preparation process (ion plating) of the rear earth modified multi-component composite coating in gas discharge and arc discharge through a set of plasma enhanced coating device; performing omnibearing bombardment on a workpiece by use of ions in a coating technology; and soaking the workpiece in the plasma to increase the binding force of the coating and the frictional wear performance and improve the binding force, wear resistance and oxidation resistance of the coating; and 2) in the process of preparing the rare earth modified multi-component composite coating, performing low-temperature deposition at a temperature of 200-400 DEG C to form a low-temperature multi-component composite coating based on the plasma enhancement and rare earth modification technology and having high hardness, good binding force and long service life under low-temperature conditions. According to the invention, by adopting the plasma enhanced coating and rare earth modification technology, the product performance is remarkably improved, and the service life is prolonged by more than twice over an uncoated shuttle of a sewing machine.

Owner:GUANGDONG STRONG METAL TECH

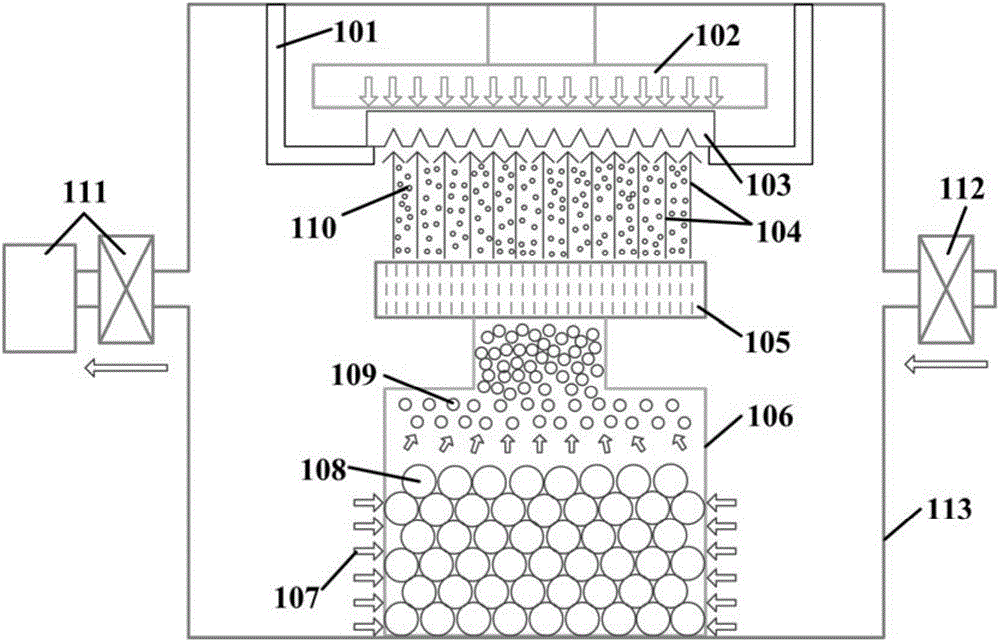

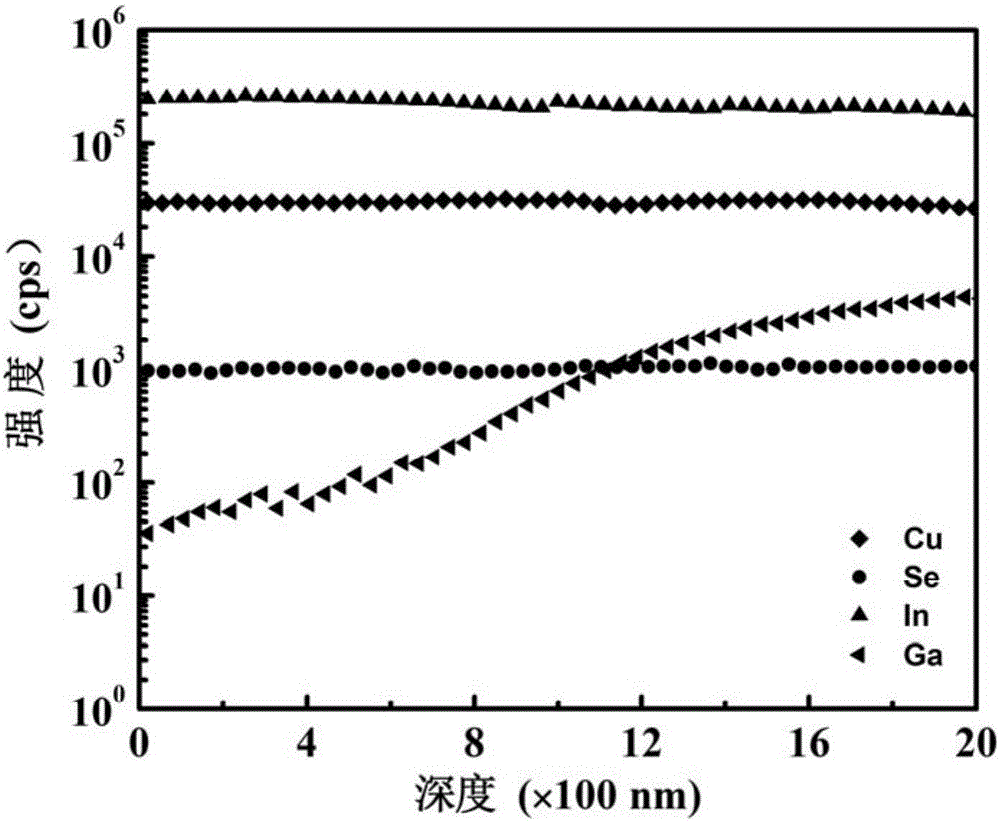

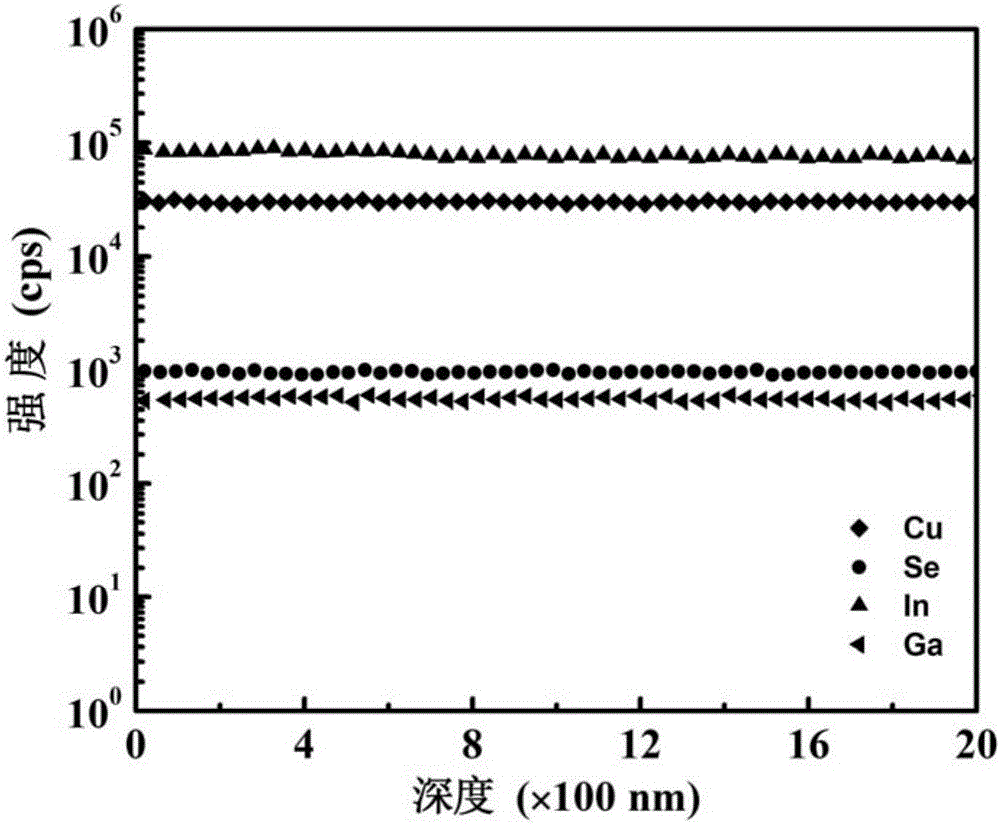

Copper indium gallium selenide thin-film solar cell uniform in gallium distribution and preparation method thereof

ActiveCN106229383AHigh activityAdequate responseFinal product manufacturePhotovoltaic energy generationIndiumCopper indium gallium selenide

The invention discloses a copper indium gallium selenide thin-film solar cell uniform in gallium distribution and a preparation method thereof. The plasma enhancement selenylation etching composite technology is introduced in the selenylation reaction process, the activity of selenium steam is improved by means of plasma, meanwhile an alloy prefabricated layer is etched by means of the plasma, redundant selenium in the alloy prefabricated layer is removed, the surface area of the alloy prefabricated layer is increased so as to achieve better diffusion and permeation of activated selenium steam, reaction of the activated selenium steam, copper, indium and gallium is made more sufficient, and uniform distribution of gallium in a thin film is achieved. All elements in components, especially gallium, of the prepared copper indium gallium selenide thin film are uniform in distribution, and conversion efficiency of the prepared copper indium gallium selenide thin-film solar cell is greatly improved.

Owner:SOUTH CHINA UNIV OF TECH

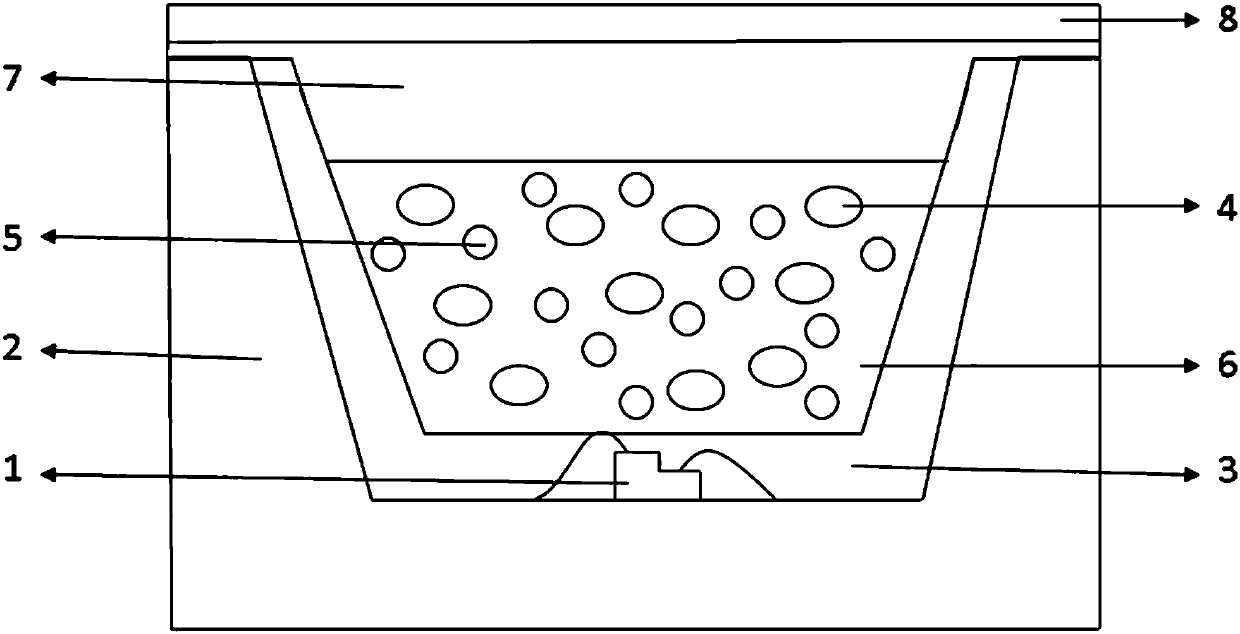

Secondary airtightness sealing method of quantum dot On-chip white light LED

InactiveCN107833963AGood airtight protectionImprove luminous efficiencySemiconductor devicesLow temperature depositionFluorescence

The invention discloses a secondary airtightness sealing method of a quantum dot On-chip white light LED. The method comprises steps of fixing a blue light chip on the bottom of an LED support; through the low-temperature deposition technology including the plasma enhancement chemical vapor deposition or atomic layer deposition, deposing waterproof and oxygen-proof transparent thin film layers onthe bottom and the inner side wall of the LED support; mixing quantum dots and transparent sealing glue into quantum dot sealing glue colloid and coating the interior of the LED support with the quantum dot sealing colloid; after carrying out heating solidification, gluing ultraviolet curing glue on the solidified quantum dot fluorescent colloid and covering the solidified quantum dot fluorescentcolloid with a glass sheet; and then carrying out ultraviolet curing, thereby finishing the secondary airtightness sealing of the quantum dot On-chip white light LED. According to the invention, waterand oxygen in the air can be further isolated; a problem of poor sealing airtightenss of the current LED device is effectively solved; and high light emitting efficiency and high stability of the quantum dot On-chip white light LED are achieved.

Owner:SOUTH CHINA NORMAL UNIVERSITY

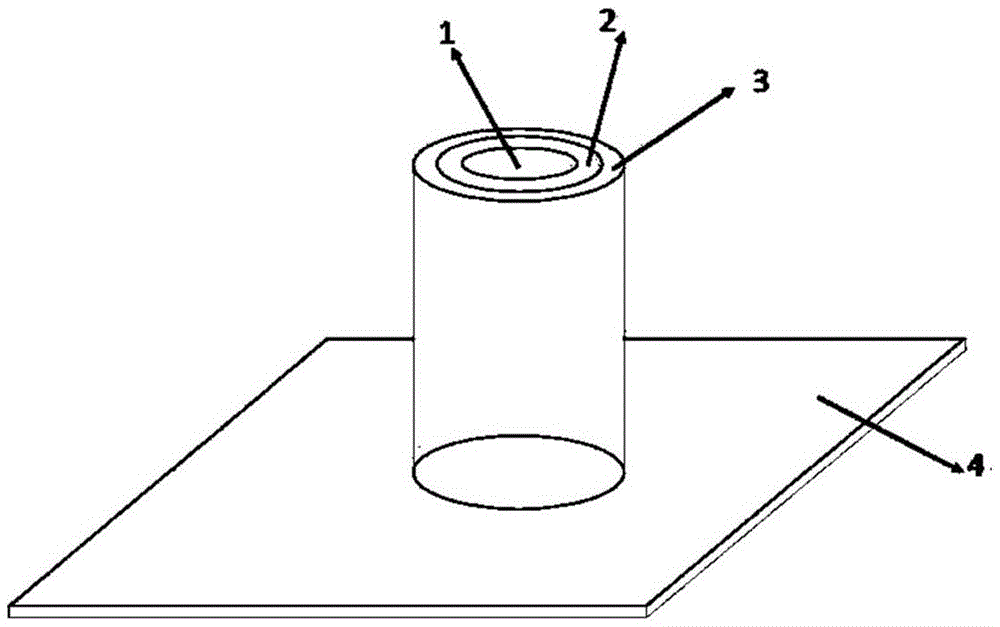

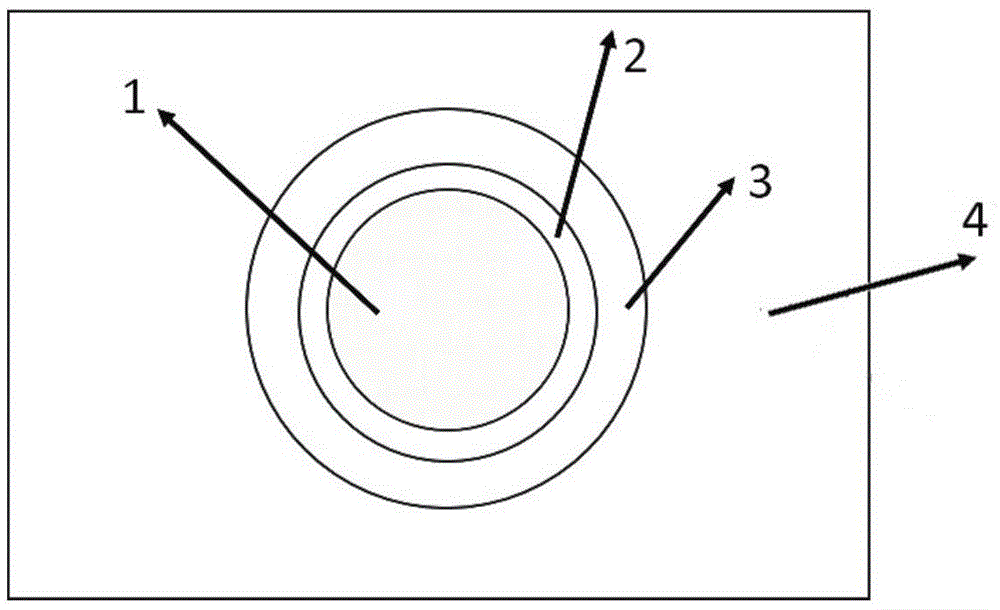

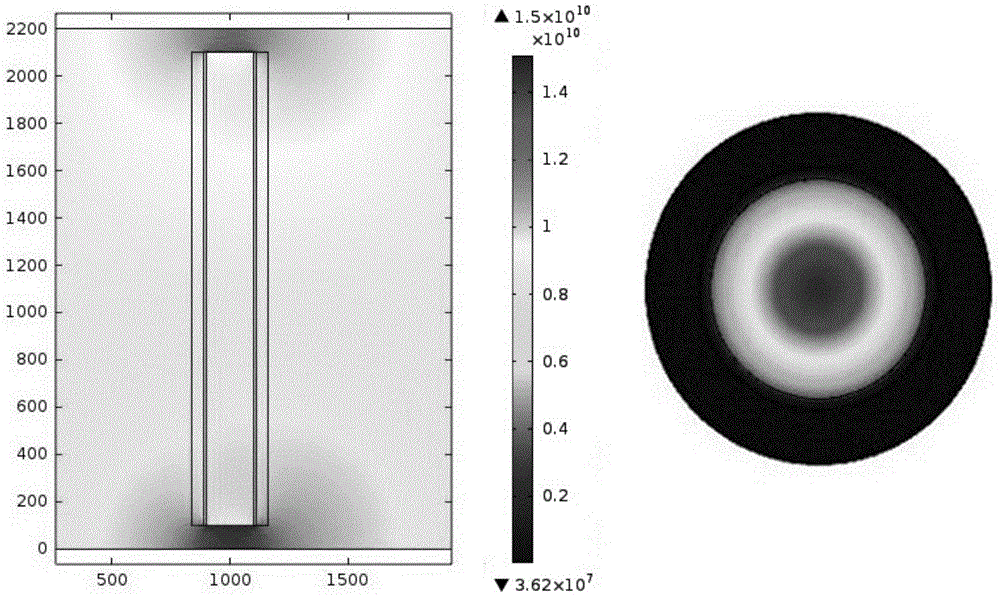

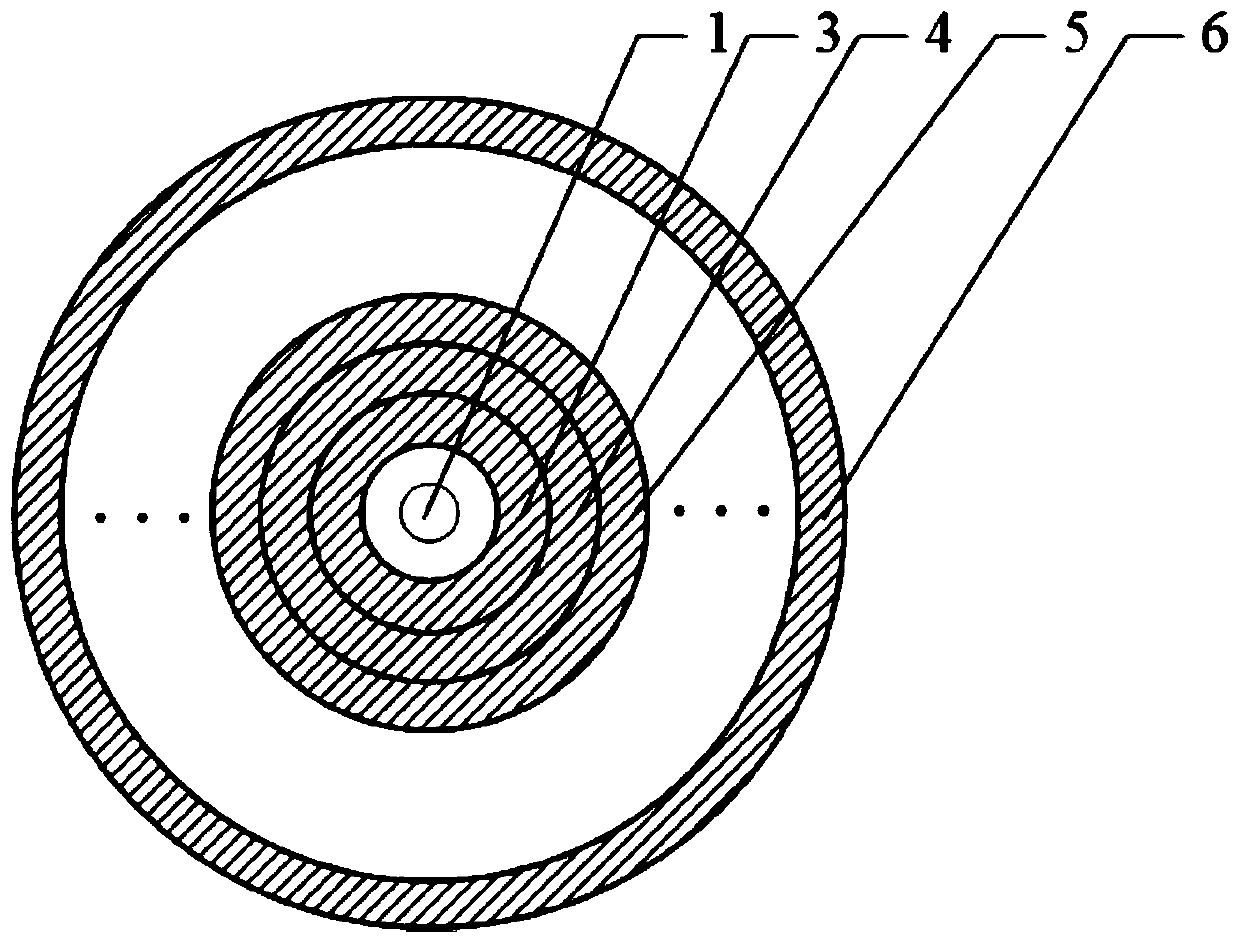

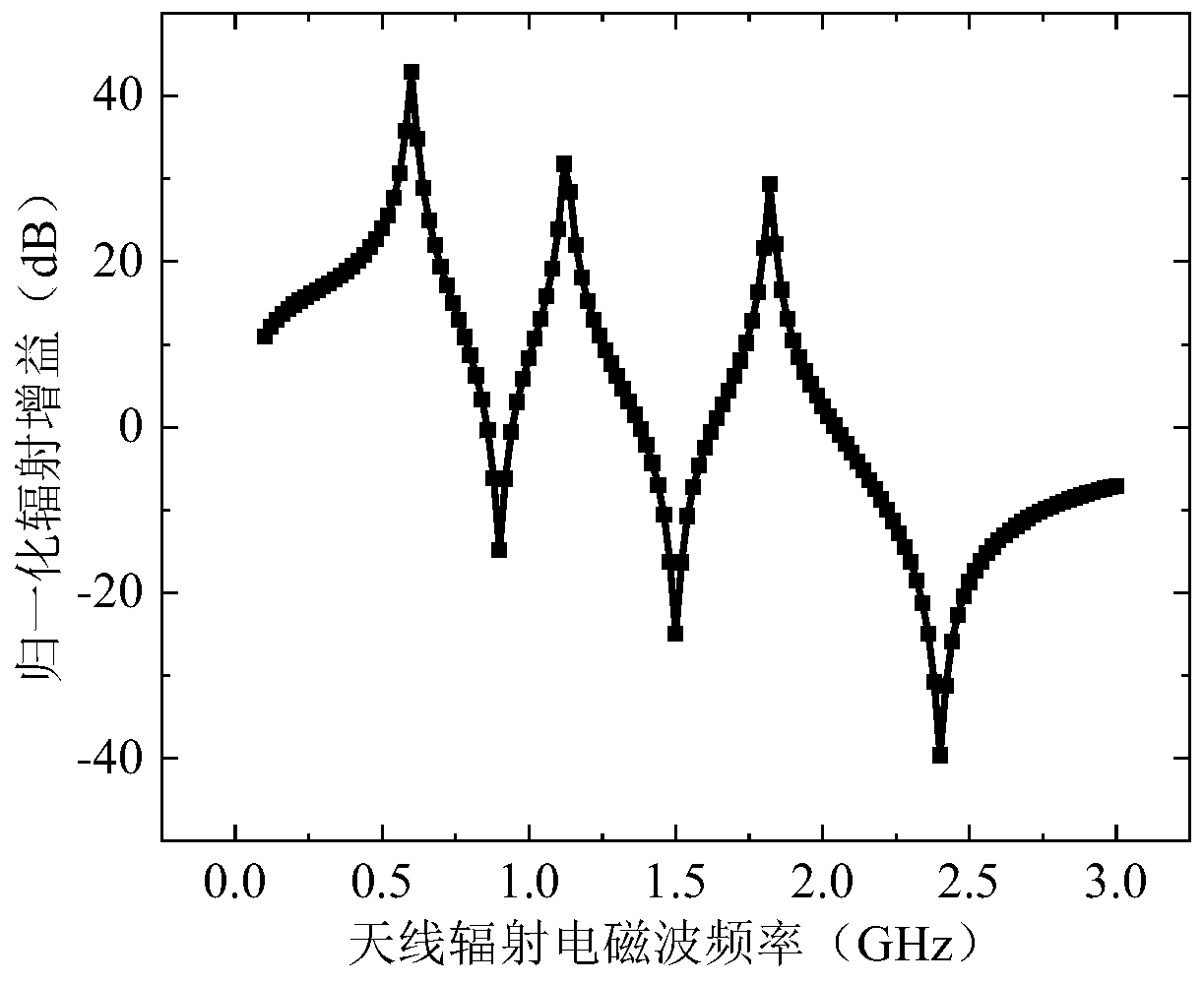

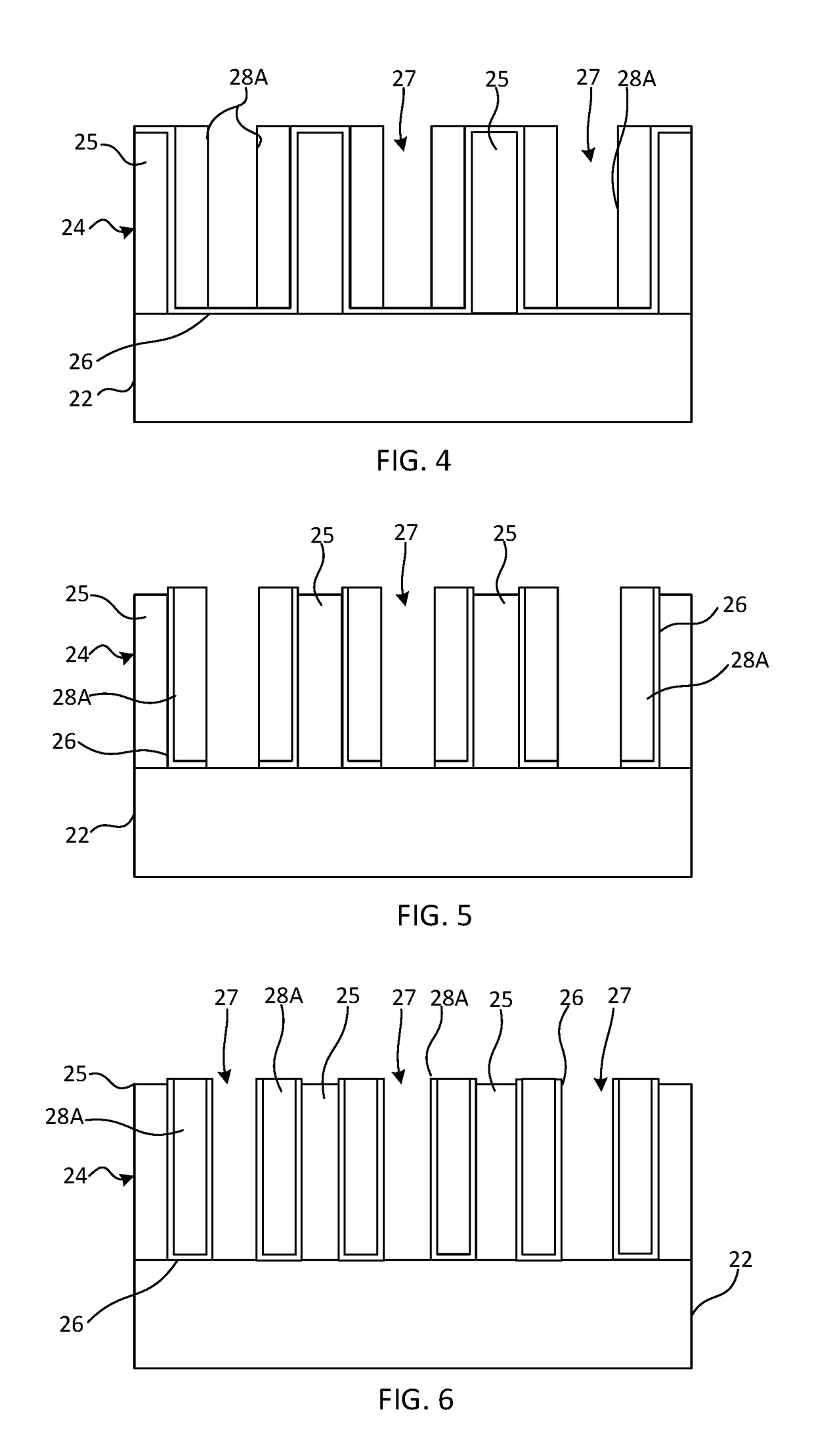

Tunable, high-resolution and multi-band enhanced plasma generating device

ActiveCN111293411AHigh strengthBoost electromagnetic signalAntenna supports/mountingsPlasma techniqueMulti bandParticle physics

The invention discloses a tunable, high-resolution and multi-band enhanced plasma generating device, and relates to the technical field of low-temperature plasma application. The invention aims to solve the problems that an existing multi-band signal transmission device is low in transmission efficiency and needs to be used in cooperation with a signal amplifier, and a single-layer plasma enhancement device is poor in band-pass frequency characteristic. N plasma covers are coaxially nested, and the N plasma covers are sequentially a first plasma cover, a second plasma cover to an N plasma cover from inside to outside; an antenna system is located in the cover of the first plasma cover; a dipole antenna is used for emitting a plurality of target waveband electromagnetic waves or receiving target waveband electromagnetic waves input by the background electromagnetic field through the N plasma covers; each plasma cover enhances the intensity of the target waveband electromagnetic wave signals emitted by the dipole antenna or extracts and enhances the target waveband electromagnetic wave signals from the background electromagnetic field, and the enhancement range is that the logarithmic gain of the power of the signals emitted by the N plasma covers is greater than or equal to 10dB. The device disclosed by the invention is used for enhancing signals.

Owner:HARBIN INST OF TECH

High aspect ratio contact metallization without seams

ActiveUS20170278800A1High aspect ratio contact structureLower resistanceSemiconductor/solid-state device detailsSolid-state devicesThermal chemical vapor depositionMetal silicide

A low resistance middle-of-line interconnect structure is formed without liner layers. A contact metal layer is deposited on source / drain regions of field-effect transistors and directly on the surfaces of trenches within a dielectric layer using plasma enhancement. Contact metal fill is subsequently provided by thermal chemical vapor deposition. The use of low-resistivity metal contact materials such as ruthenium is facilitated by the process. The process further facilitates the formation of metal silicide regions on the source / drain regions.

Owner:IBM CORP

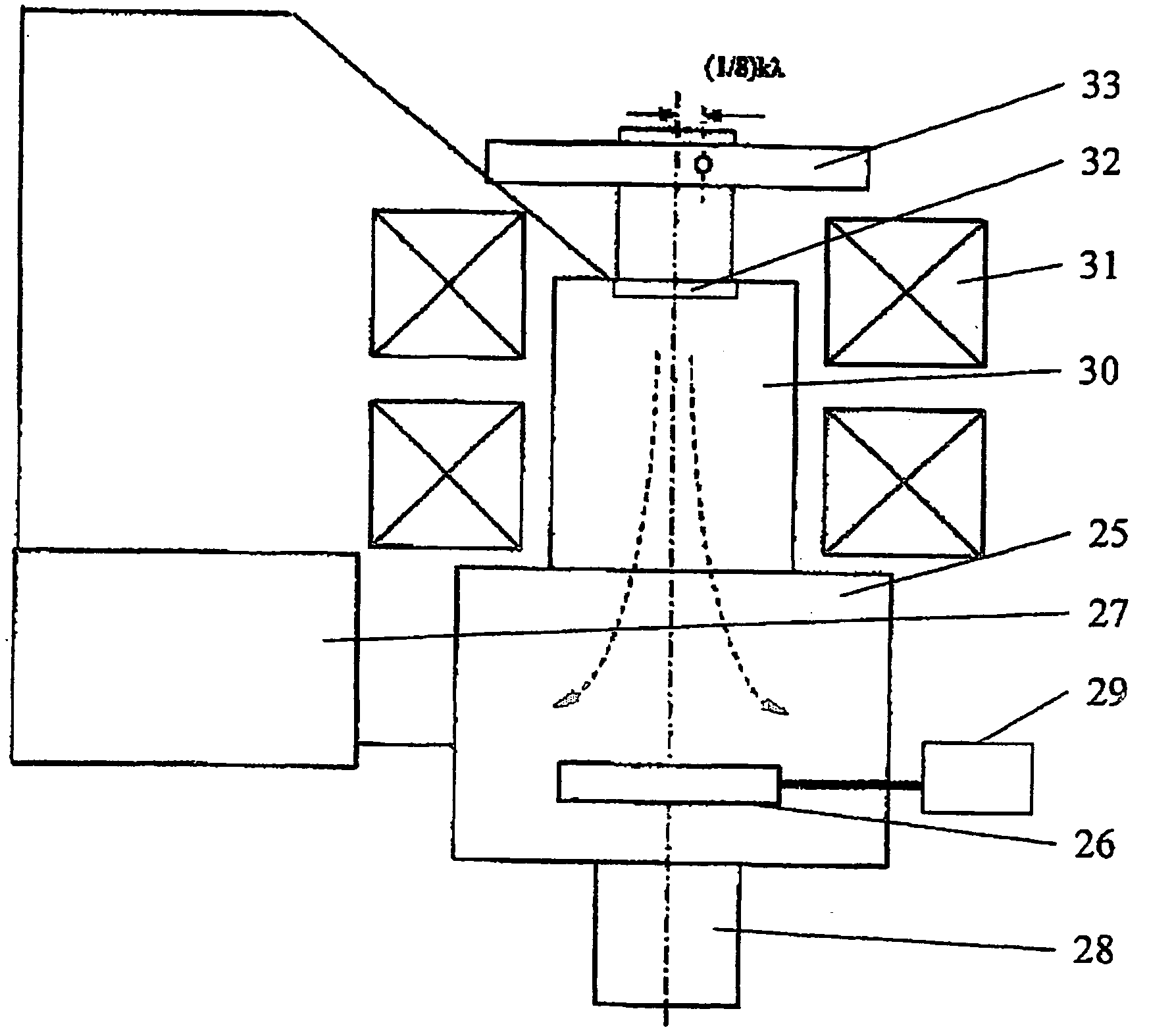

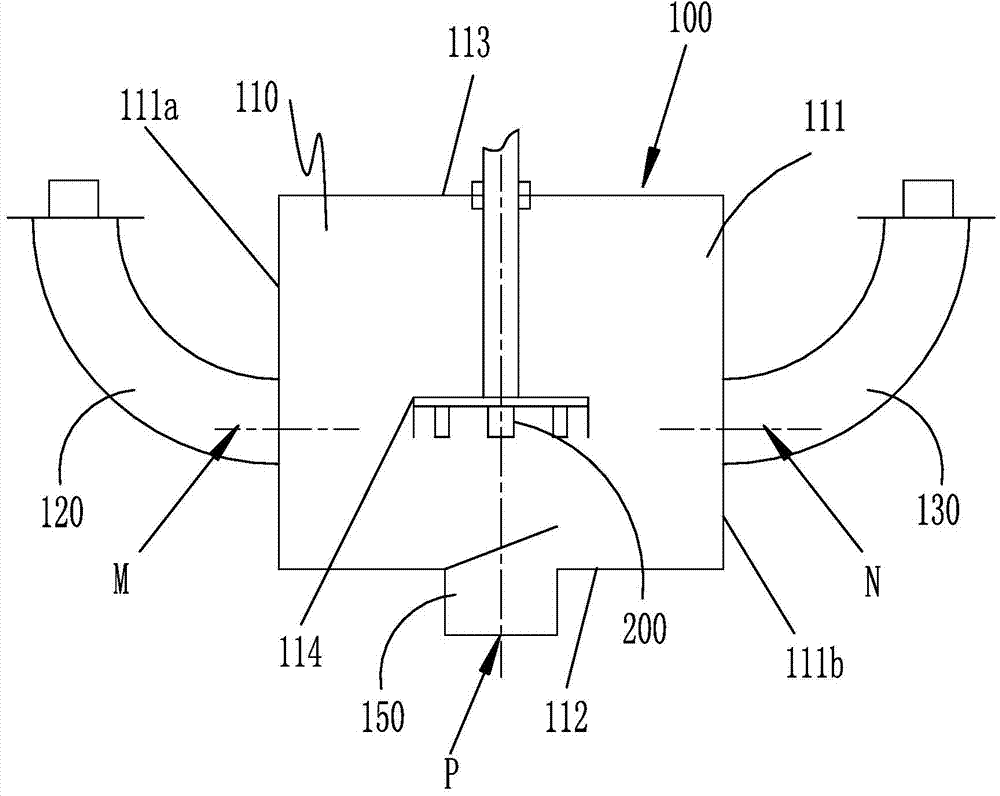

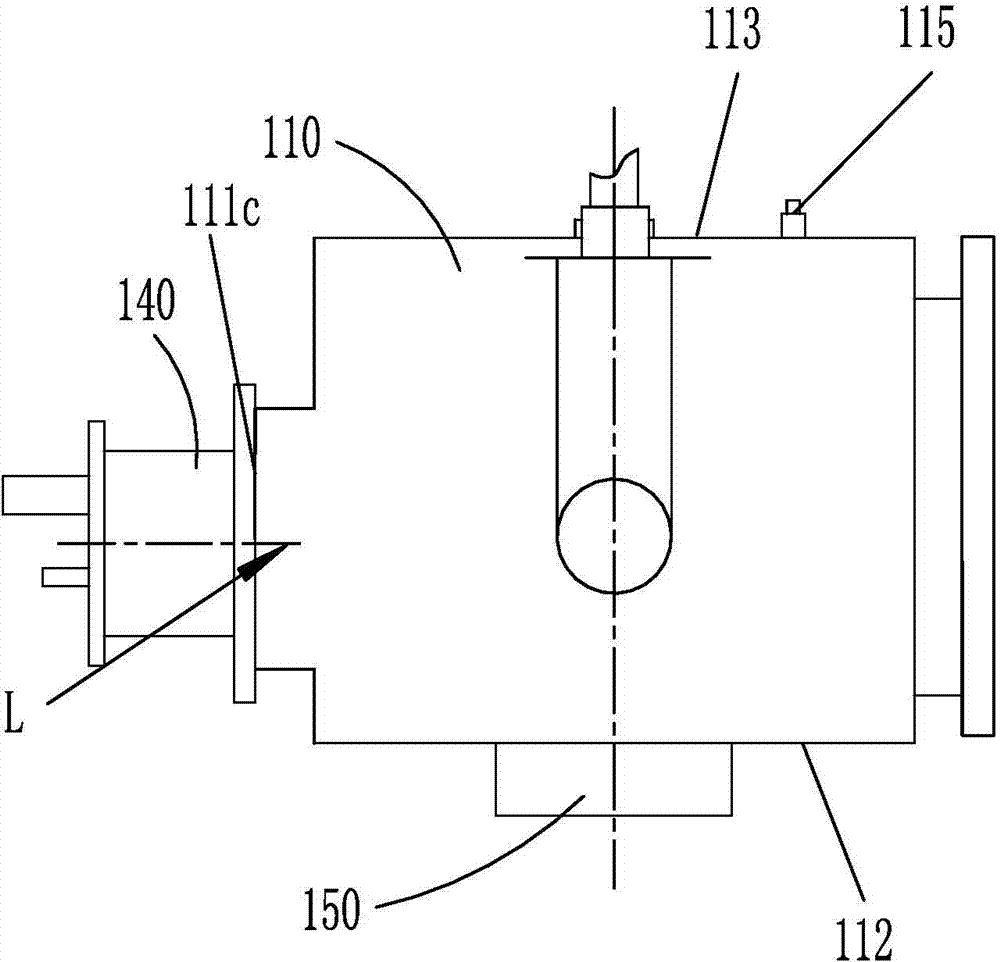

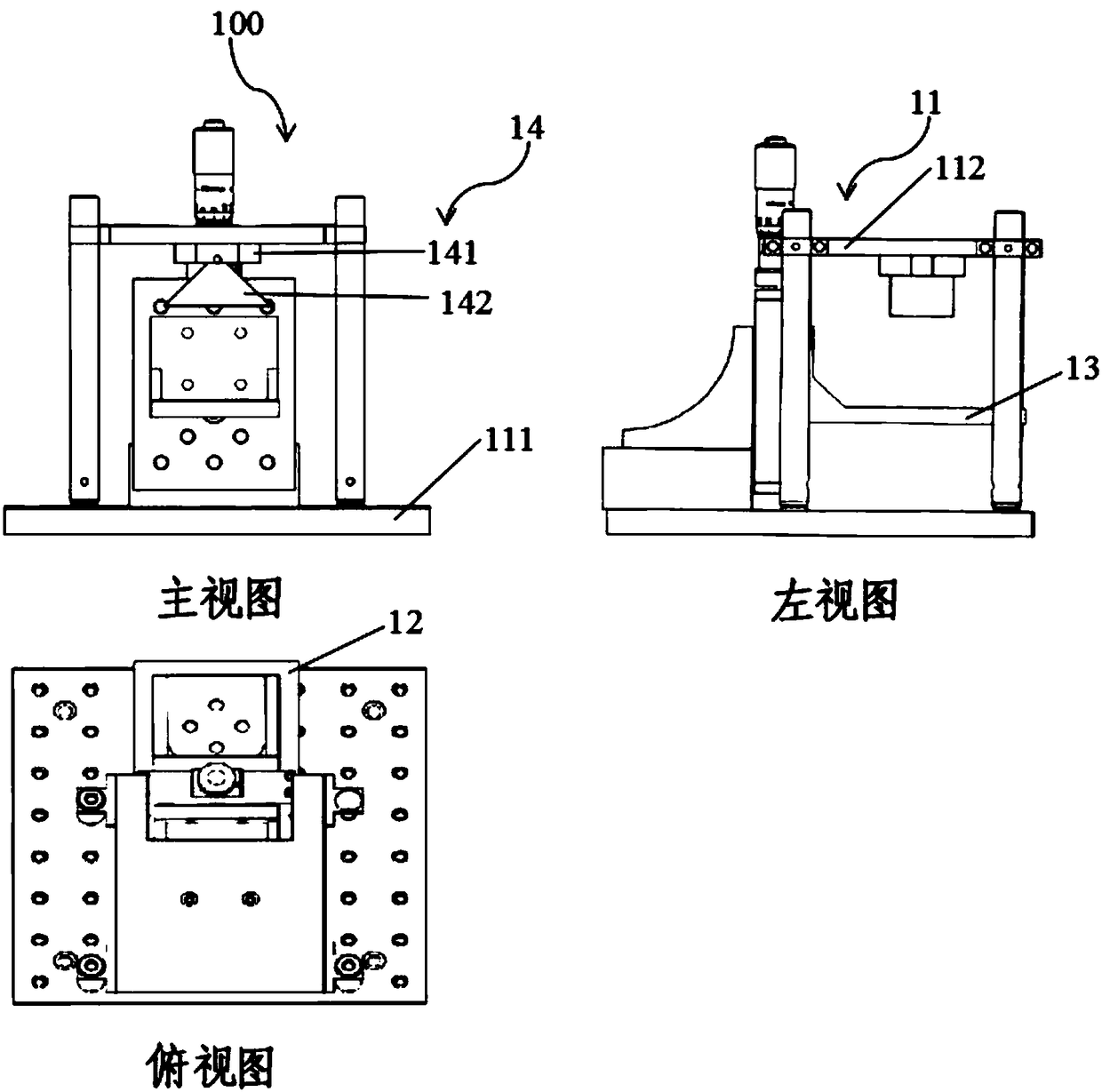

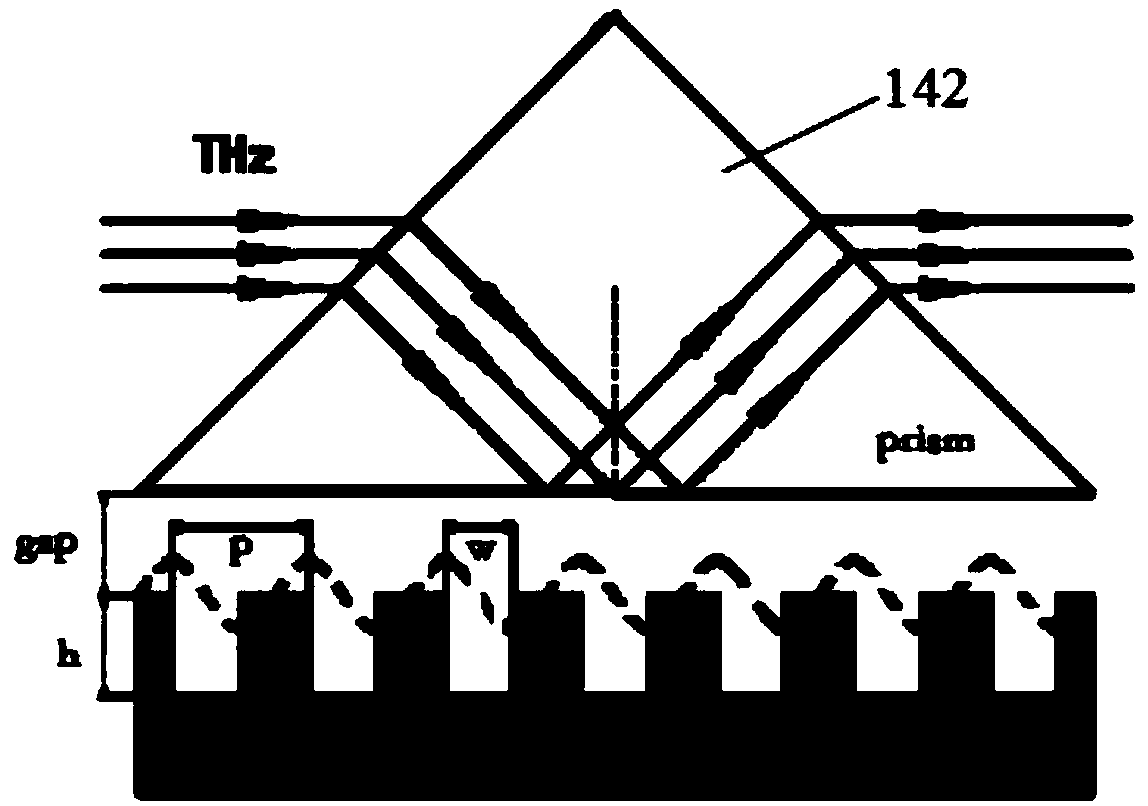

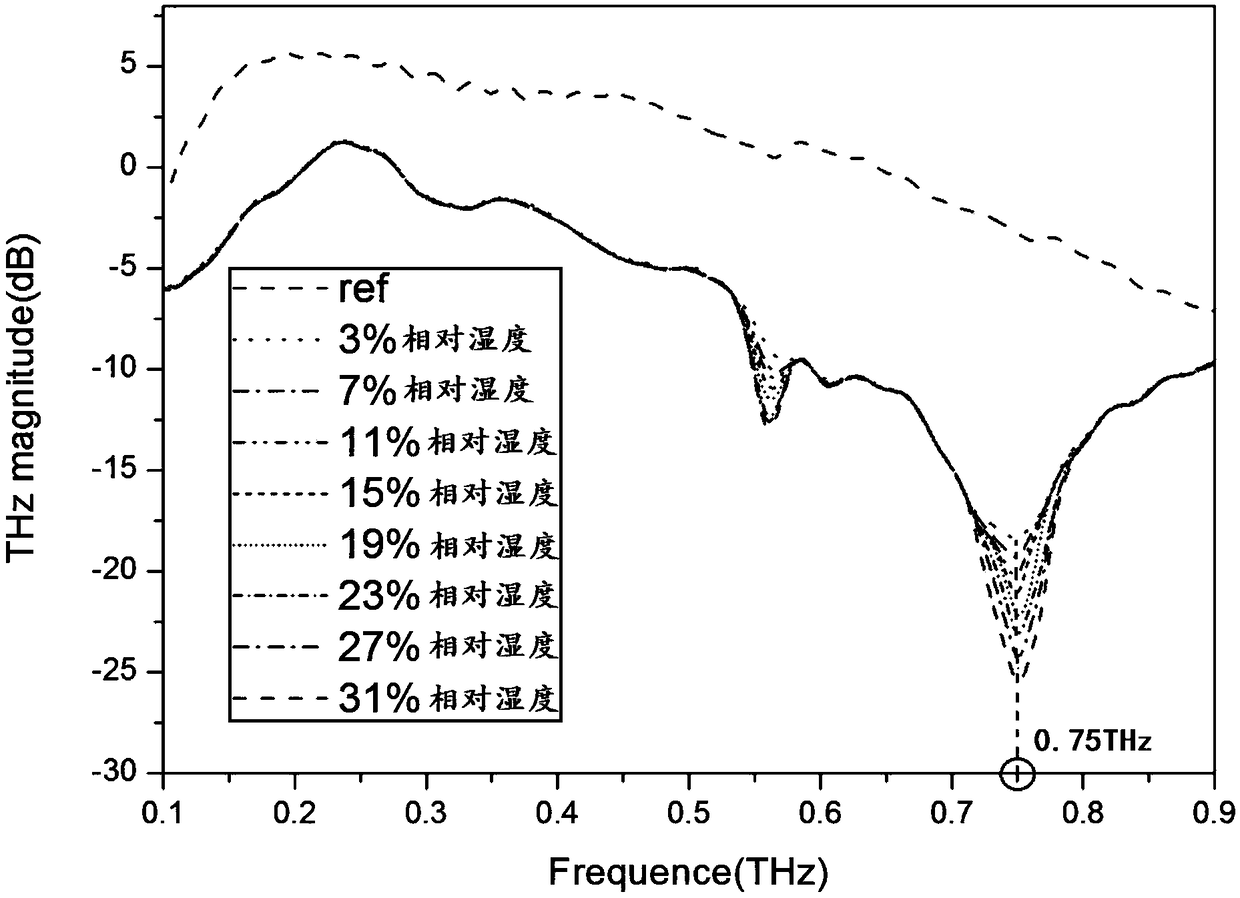

Humidity sensor based on terahertz plasma enhancement effect and system thereof

ActiveCN108088810AHigh resolutionSimple structureMaterial analysis by optical meansGratingRefractive index

The invention provides a humidity sensor which is characterized by comprising a machine frame, a mobile unit, a weighing bench, an optical grating and a prism unit, wherein the mobile unit is arrangedon the machine frame and comprises a micrometer caliper and a scale plate, the weighing bench is arranged on the mobile unit and can be driven by the mobile unit to move up and down, the optical grating is arranged on the weighing bench, the prism unit comprises a clamping assembly arranged on the machine frame and a prism clamped by the clamping assembly, the prism unit is used for receiving terahertz optical and being coupled with the optical grating to generate a resonance peak, and a refractive index of the prism is larger than that of air. According to the humidity sensor disclosed by the invention, the situation that an absorption peak of vapor in a terahertz wave band right coincides with a resonance peak of a surface plasmon polariton generated by the optical grating under the terahertz attenuation total reflection action is utilized, so that a moisture content in air can be quickly measured in real time, flexibility is greatly improved, and a resolution ratio is higher. In addition, the humidity sensor has the advantages of simple structure, wide material taking and easiness in processing.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

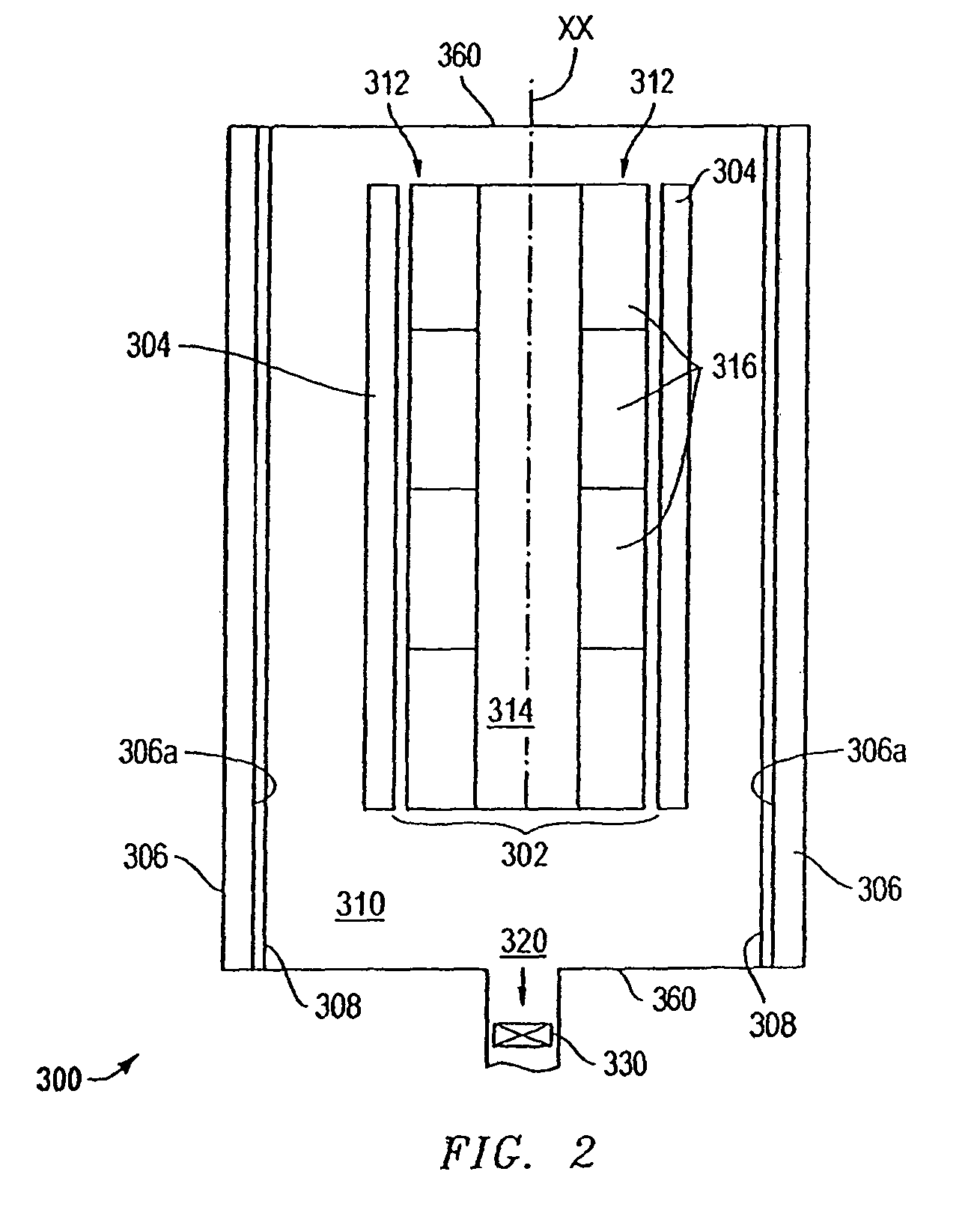

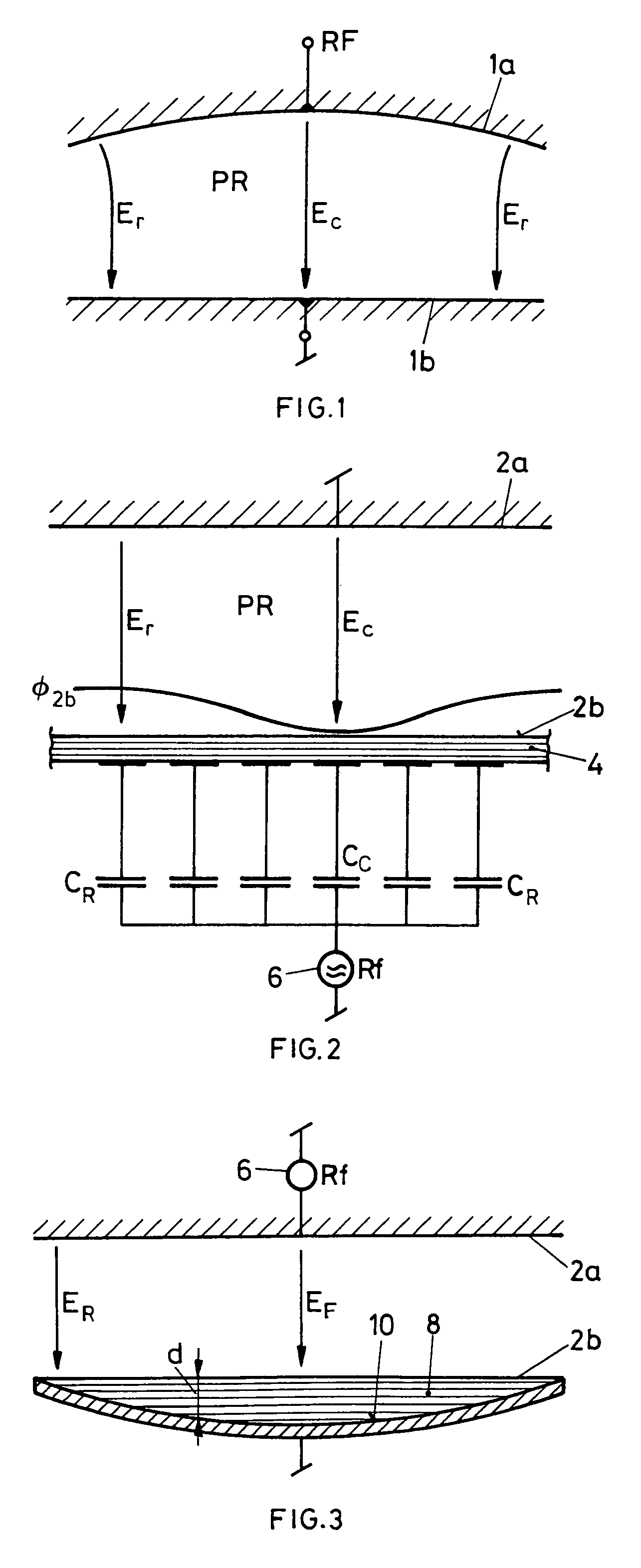

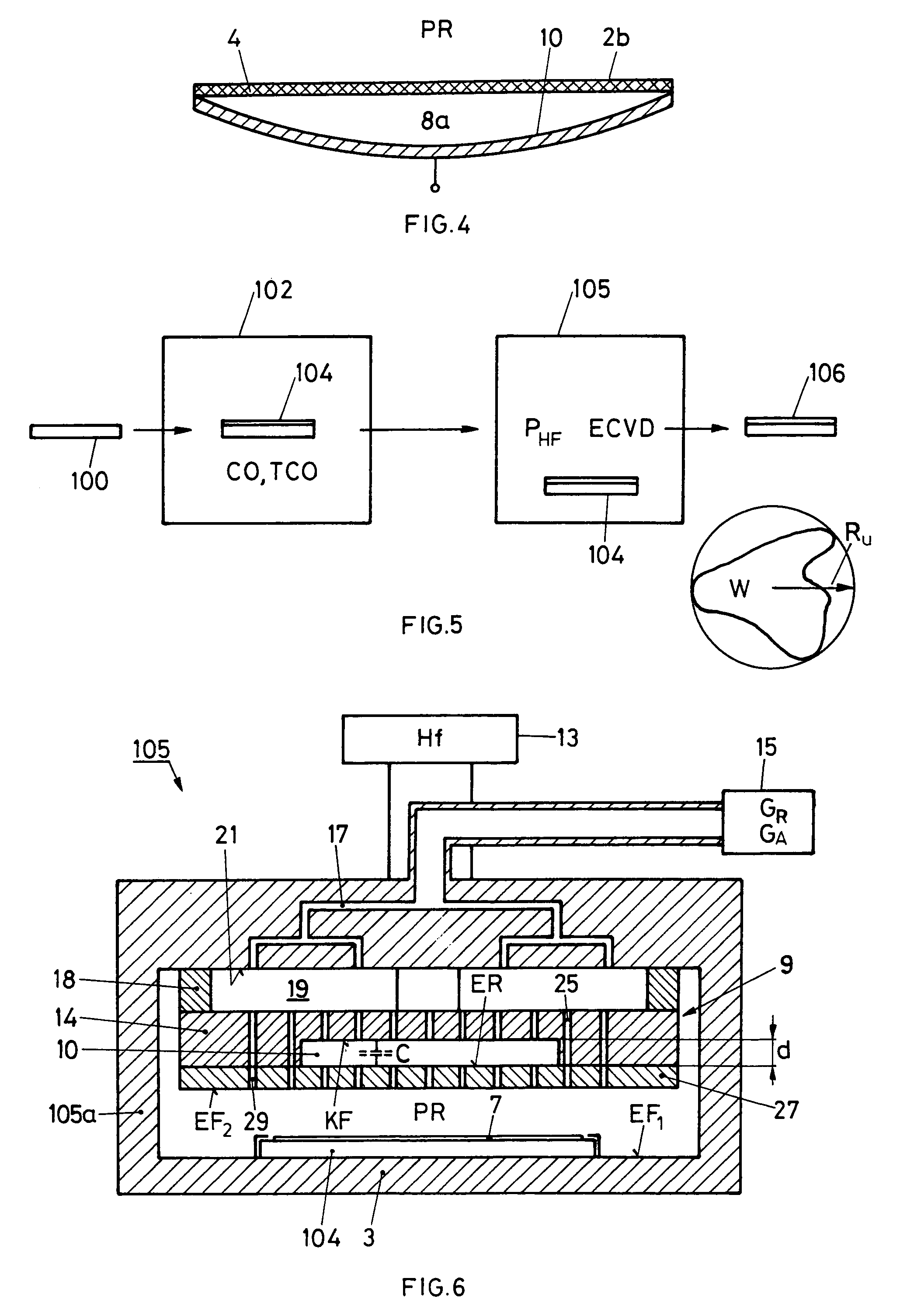

Method for manufacturing a plate-shaped workpiece

ActiveUS7449220B2Not deformReduce the effectFurnaces without endless coreElectric discharge tubesMetallic electrodeReactive gas

A method for producing a disk shaped workpiece with a dielectric substrate includes treatment in a plasma process volume between two electrode faces bounding a high-frequency plasma discharge. One electrode face is of dielectric material and is at a high-frequency potential with a varying distribution along the face. The other electrode face is metallic. Reactive gas is introduced into the process volume through an aperture pattern. The dielectric substrate, before treatment, is at least regionally coated with a layer material to whose specific resistance applies: 10−5 Ωcm≦≦10−1 Ωcm, and to the resulting surface resistance RS of the layer applies: 0<RS≦104 Ω. Subsequently, the coated substrate is positioned on the metallic electrode face and is etched or coated reactively under plasma enhancement in the plasma process volume.

Owner:EVATEC

Tungsten silicide (WSIX) deposition process for semiconductor manufacture

InactiveUSRE40114E1Reduce the temperatureSemiconductor/solid-state device manufacturingSemiconductor devicesSilanesDichlorosilane

A semiconductor manufacturing process for depositing a tungsten silicide film on a substrate includes deposition of a tungsten silicide nucleation layer on the substrate using a (CVD) process with a silane source gas followed by deposition of the tungsten silicide film with a dichlorosilane source gas. This two step process allows dichlorosilane to be used as a silicon source gas for depositing a tungsten silicide film at a lower temperature than would otherwise by possible and without plasma enhancement. Tungsten silicide films deposited by this process are characterized by low impurities, good step coverage, and low stress with the silicon substrate.

Owner:MICRON TECH INC

Coating removing method for diamond coated tool

InactiveCN105695949AExcellent stripping qualitySuitable for large-scale production needsChemical vapor deposition coatingMicroparticleOxygen

The invention discloses a coating removing method for a diamond coated tool. The coating removing method comprises the steps that the abraded diamond coated tool is cleaned with acetone and ethyl alcohol; the abraded diamond coated tool is fixed to the center of a sample table of plasma enhancement chemical vapor deposition equipment, vacuumizing is conducted on the plasma enhancement chemical vapor deposition equipment till the pressure is below 1-5*10-3 Pa, plasma beams generated by 3GHz microwaves are adopted by the equipment, the heating temperature is 350-420 DEG C, gases including oxygen, Cl2, ClO2 and HCl are introduced, and the treatment time is 10-15 min; protective gas is introduced after the treatment is finished, and the tool is taken out after cooling; and microparticles on the surface of the tool are cleaned away with acetone after the tool is taken out, a tool basal body is exposed, and accordingly coating removing is finished.

Owner:SUZHOU LEJING NEW MATERIAL TECH CO LTD

Intelligent window based on ZnO-based transparent solar cell and preparation method of intelligent window

PendingCN108022982AQuality improvementImprove conversion efficiencyMaterial nanotechnologyPhotovoltaicsInfraredNanowire

The invention provides an intelligent window based on a ZnO-based transparent solar cell and a preparation method of the intelligent window. The intelligent window comprises a glass substrate layer, afirst latticed Ag nanowire electrode layer, an n-type ZnO thin-film layer, a P-type ZnMgO thin-film layer, a second latticed Ag nanowire electrode layer and an Ag nano particle thin-film layer, wherein the above layers are sequentially arranged from bottom to top. According to the invention, the Ag nano particle thin-film layer is adopted as a mask, and the transverse overgrowth is promoted. Thedislocation annihilation is induced, and the quality of the P-type ZnMgO thin-film layer is improved. Meanwhile, the Ag nano particle layer has the local-area surface plasma enhancement effect, so that the solar conversion efficiency is improved. The self-cleaning function is further realized, so that the later maintenance cost is further reduced. In addition, a single solar cell is formed by then-type ZnO thin-film layer and the P-type ZnMgO thin-film layer, so that the solar energy is absorbed and stored by the single solar cell. In addition, due to the fact that Ag particles have excellentreflection characteristics for infrared rays, Ag nanowires and Ag nano particles can reflect most of infrared rays indoors. The effect of winter warming is achieved.

Owner:WUYI UNIV

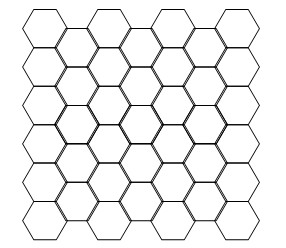

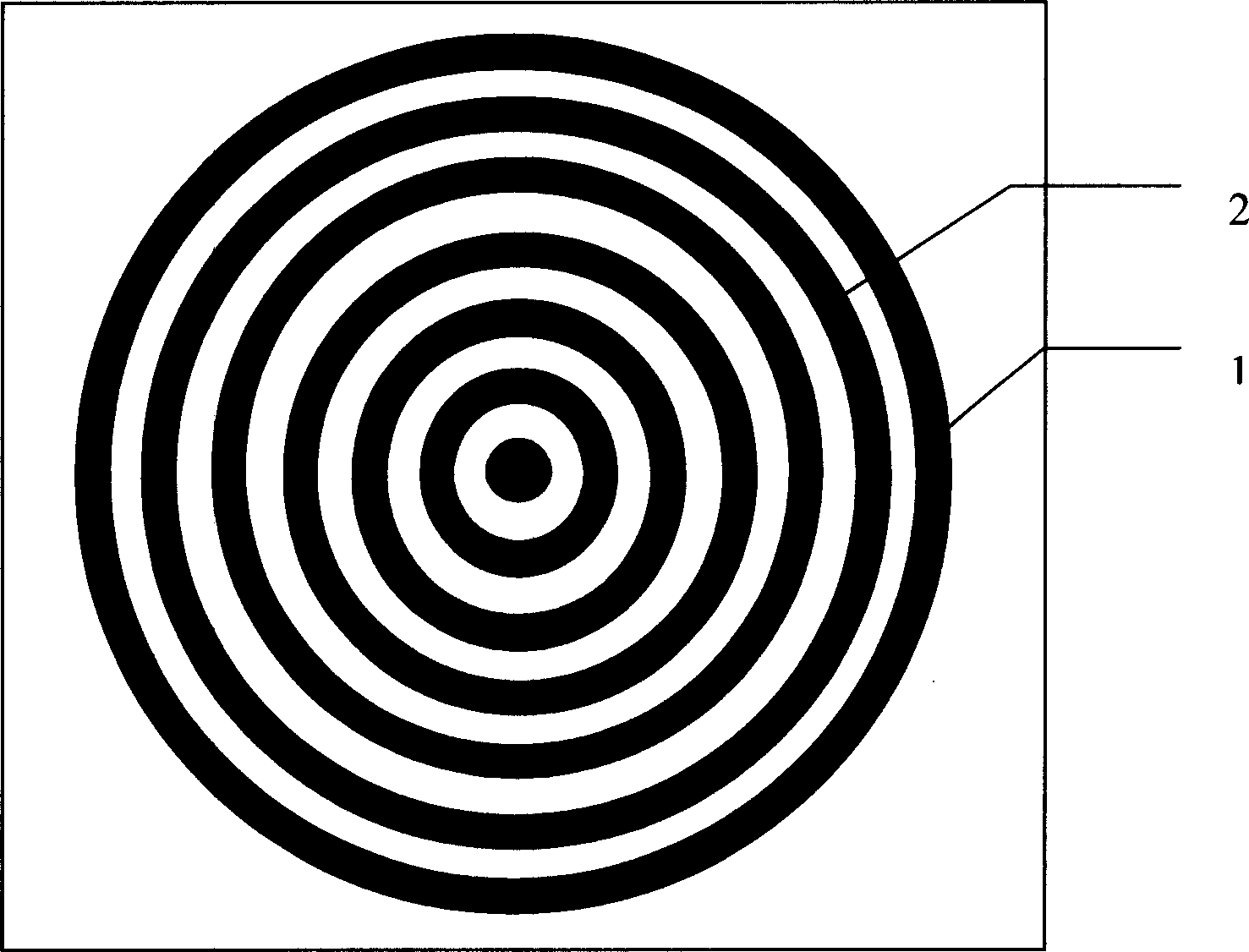

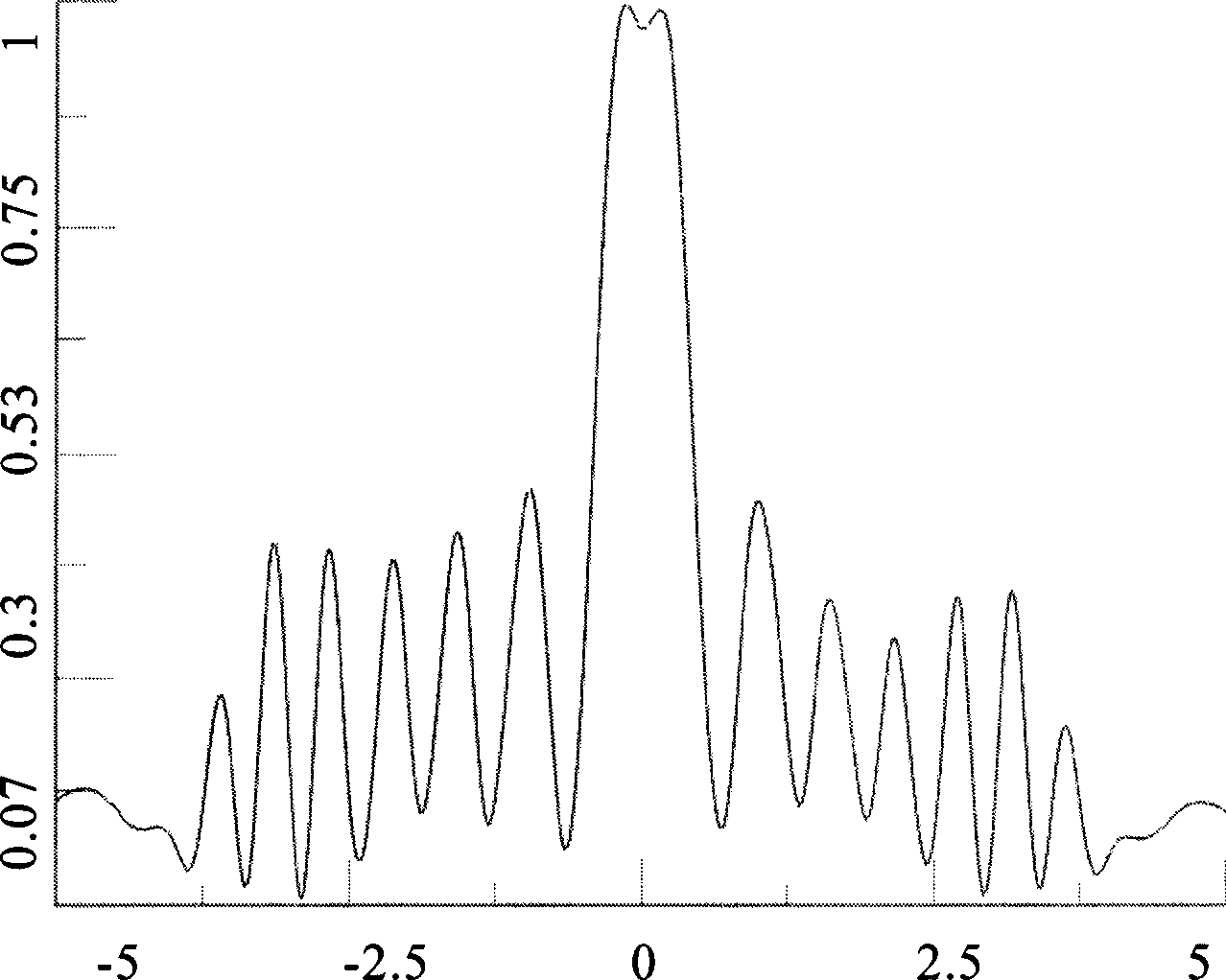

Method of reilizing electromagnetic wave function appliance based on metal micro nano structure

The invention is a method for realizing electromagnetic wave functional device based on metal micro-nano structure, firstly according to the requirement of the required functional device for outgoing light field, designing substrate material and metal layer structural parameters, and according to the diffraction theory, finding the phase relation of the surface of the functional device; then using the optical axis of the functional device as a center to arrange metallic through hole, and according to the requirement for surface plasma enhancement, arranging a plurality of grooves or concave holes on two sides of or around the through hole, according to the directional requirement of the outgoing light field, calculating the structural parameters of each groove or concave hole; and finally with the depth trace of the grooves or concave holes as a period, repeating them, thus composing the metal micro-nano structural array functional device. The invention breaks through the restriction of diffraction limit and provides an important means for nano optical and nano electronic researches.

Owner:INST OF OPTICS & ELECTRONICS - CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com