Patents

Literature

86results about How to "Suitable for large-scale production needs" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Low-cost back-contact cell production method suitable for mass production

InactiveCN103746040AReduce processing complexityReduce lossesFinal product manufacturePhotovoltaic energy generationProcess engineeringSolar cell

The invention discloses a low-cost back-contact cell production method suitable for mass production, which is used for producing solar cells. The low-cost back-contact cell production method suitable for mass production has the advantages that since a laser process (laser boring) is adopted, conventional unilateral diffusion is adopted, special leakage protection measures are taken around holes and other processes are consistent with the processes for producing conventional cells, the process is simple, the cost of added equipment is low and the product performance and the finished product rate are superior to the existing scheme.

Owner:JIANGSU SUNPORT POWER CORP LTD

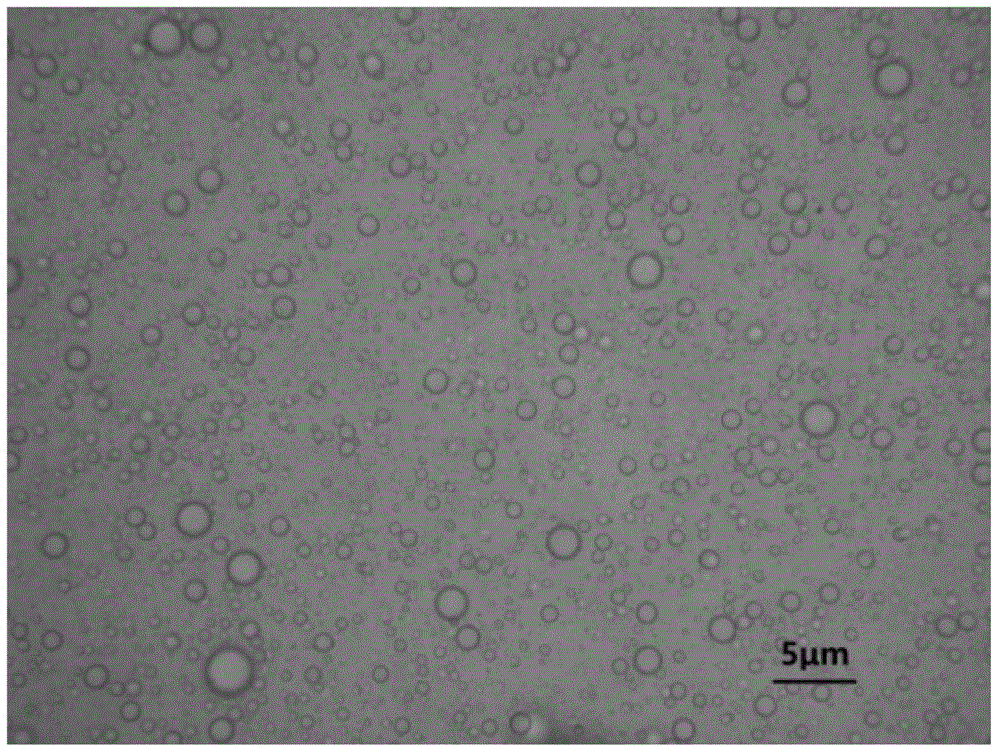

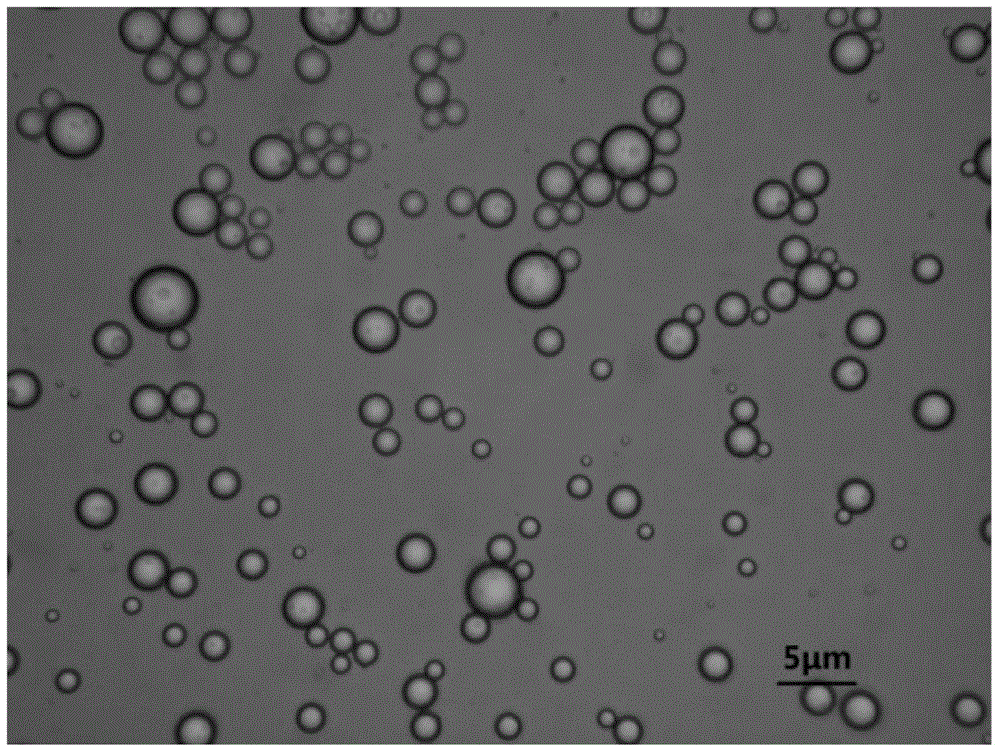

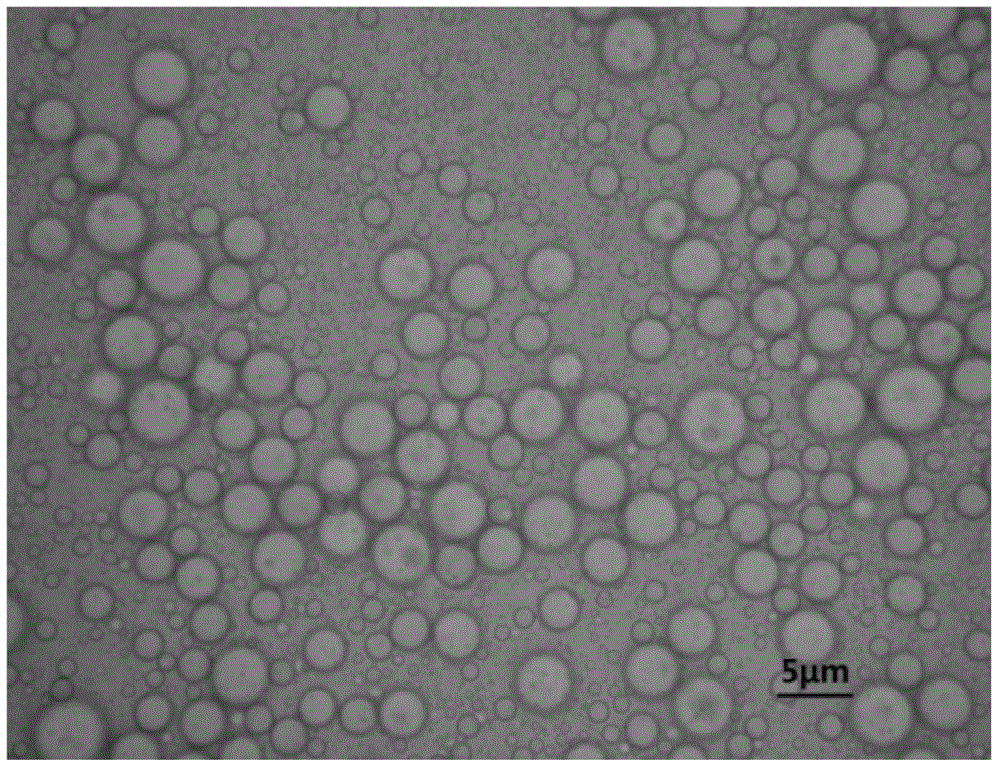

Preparation method of Nisin double layer microcapsule suitable for high temperature baking food

InactiveCN104472646AReduced loss of inhibitionOvercome the unfavorable factors of limited application rangeDough treatmentBakery product preservationHydrogenEmulsion

The invention relates to a preparation method of Nisin double layer microcapsule suitable for high temperature baking food. The preparation method of the Nisin double layer microcapsule suitable for the high temperature baking food includes: mixing Nisin and chitosan according to a mass ratio which ranges from 1:1 to 1:10 so as to obtain a solution, and then regulating PH (potential of hydrogen) of the solution to 2.5-7.5, adding Tween80 and PEG into the solution so as to emulsify the solution and obtain emulsion, and then slowly dripping a sodium tripolyphosphate solution into the emulsion so as to prepare chitosan microcapsule with the Nisin embedded under stirring functions, processing the Nisin chitosan microcapsule, and finally mixing and stirring the Nisin chitosan microcapsule and xanthan gum so as to obtain the Nisin double layer microcapsule, wherein a mass ratio between the sodium tripolyphosphate solution and the chitosan is 3:1-10:1. Compared with a free state Nisin product, the encapsulated Nisin product prepared by using the preparation method of the Nisin double layer microcapsule suitable for the high temperature baking food is strong in tolerance to PH, temperature and enzymes, can be processed along with food, and can not influence the fermentation process of fermented food, and high temperature and high pressure in processing can enable the Nisin double layer microcapsule to rapidly release the Nisin, and therefore influences of embedding wall materials on antibacterial effects of the Nisin are eliminated.

Owner:TIANJIN UNIVERSITY OF SCIENCE AND TECHNOLOGY

Compound rhodiola wine and preparation method thereof

InactiveCN103627610AReasonable and scientific combination of raw materialsPromotes recovery of physiological functionsDigestive systemAlcoholic beverage preparationFritillaria cirrhosaGymnadenia conopsea

The invention discloses compound rhodiola wine and a preparation method thereof and belongs to healthcare tonic wine for people to drink and a preparation method thereof. Materials for preparing active ingredients of the compound rhodiola wine are as follows: rhodiola, sea-buckthorn, saffron crocus, cordyceps sinensis, areneria kensuensis, gymnadenia conopsea, and the like. The preparation method of the compound rhodiola wine comprises the following steps: adding the rhodiola, the areneria kensuensis, and the like, into water for extraction; adding the sea-buckthorn, saffron crocus, cordyceps sinensis, and the like, into liquor and soaking; crushing fritillaria cirrhosa, mixing each extracted material, uniformly stirring, stewing and ageing, filtering, and filling into bottles to obtain the compound rhodiola wine.

Owner:CHENGDU SHENGHONGYUAN SCI & TRADING

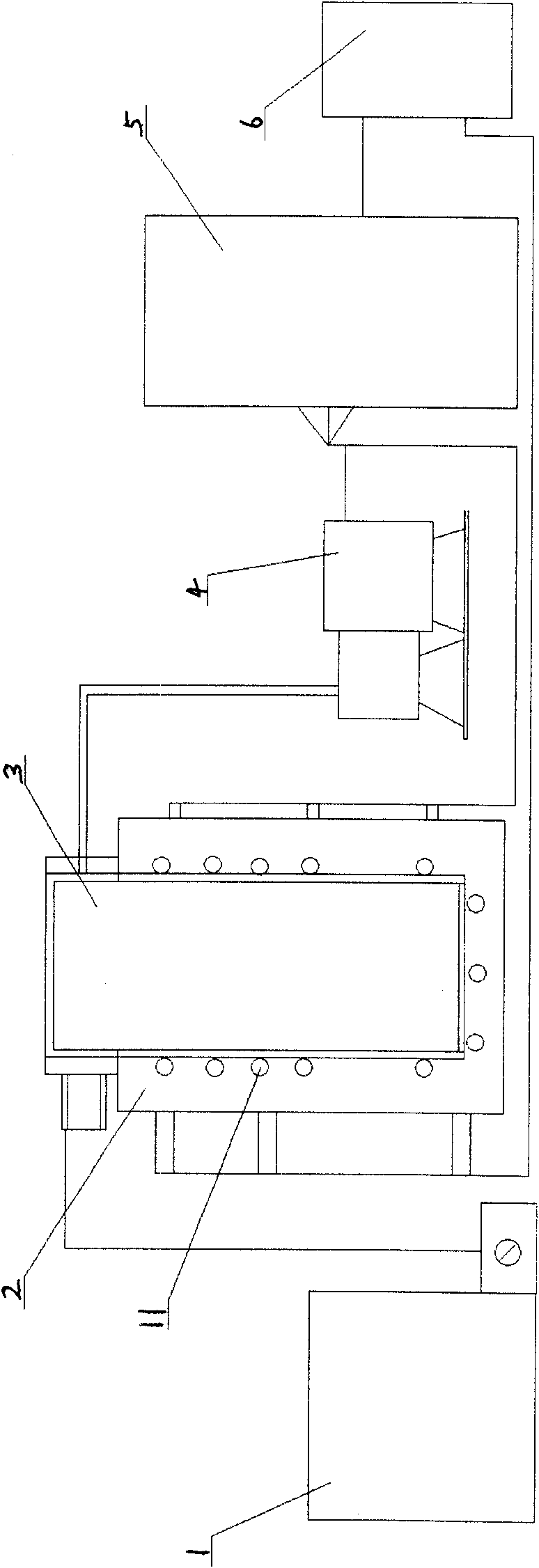

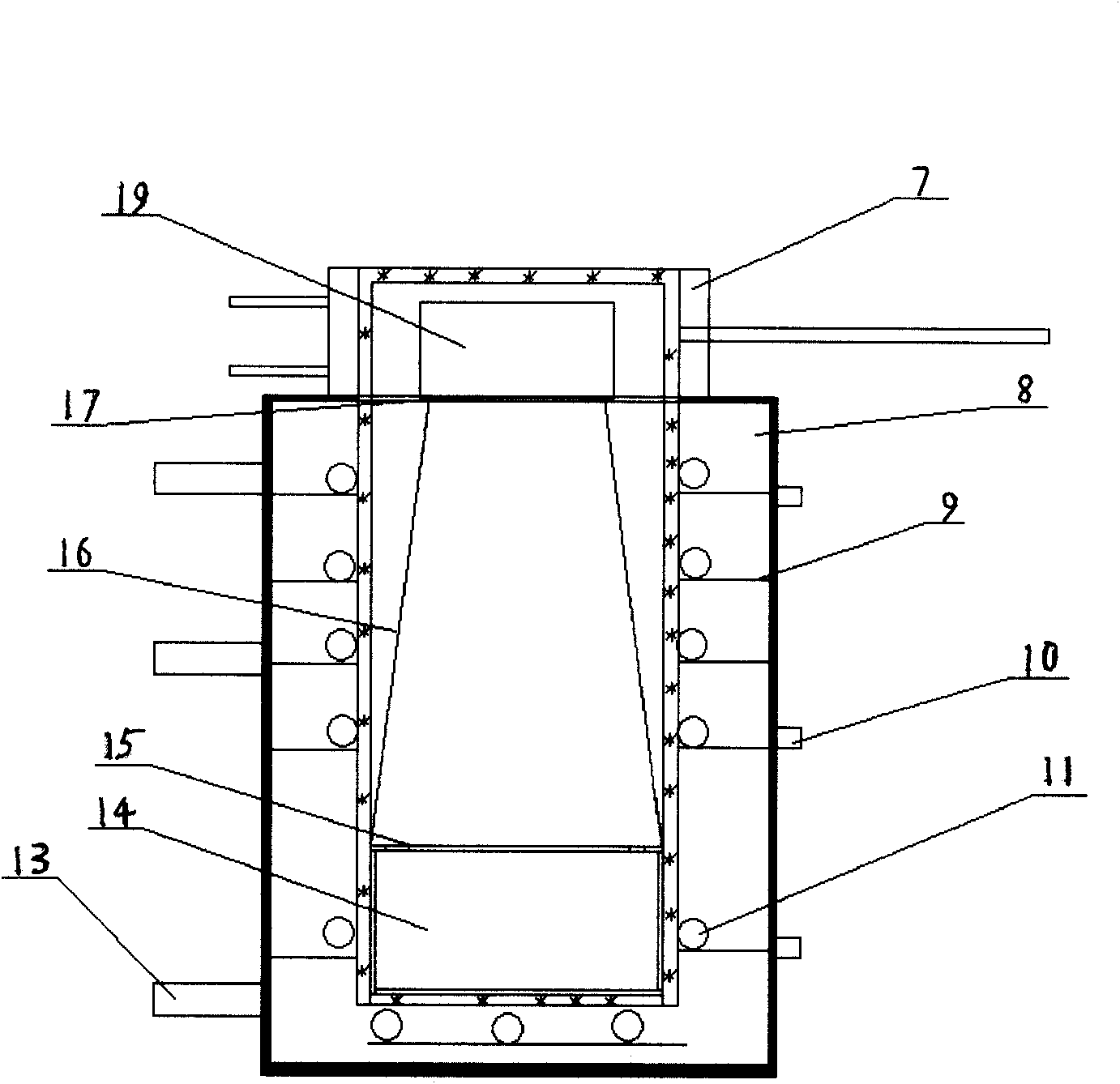

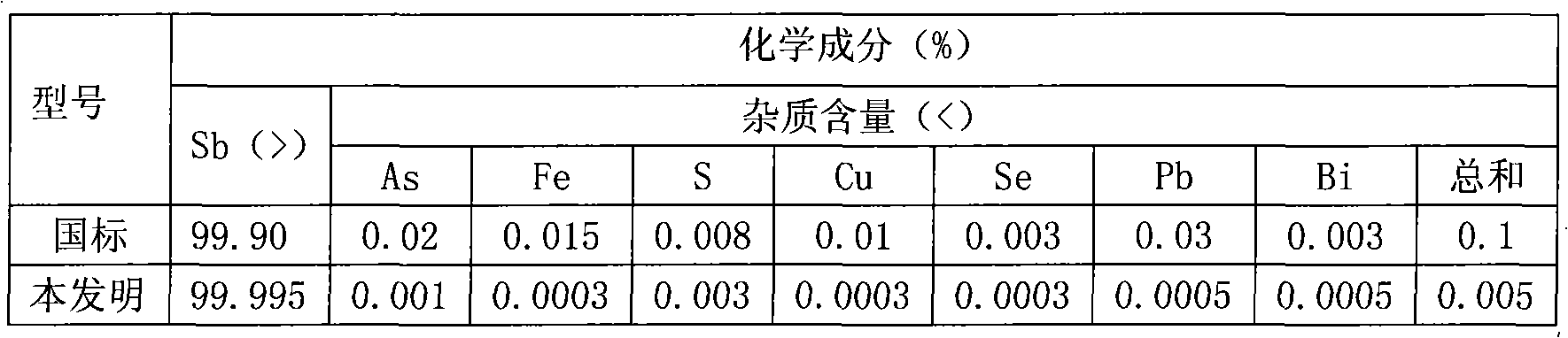

Method and device for producing high-purity antimony

The invention relates to a method and device for producing high-purity antimony, and belongs to the field of high-purity non-ferrous metal metallurgy in the smelting industry. The method comprises the following technological steps: 1, putting needle antimony in a crucible, arranging the crucible into a vacuum tank, starting a water cooling system and a vacuum pump, and controlling the vacuity below 13 Pa; 2, controlling the bottom temperature of the crucible to between 600 and 900 DEG C, the medium temperature to between 500 and 650 DEG C and the top temperature to between 350 and 450 DEG C, and preserving the temperature for 1 to 3 hours; and 3, continuously raising the temperature of the bottom of the crucible to between 650 and 900 DEG C, volatilizing the antimony through holes, contacting the antimony with a conical titanium plate, condensing the antimony on the titanium plate, preserving the temperature to completely volatilize the antimony, and remaining impurities with high boiling point such as lead in the crucible. The method and the device have high production speed, low energy consumption and simple equipment processing, and are suitable for requirement of mass production. A water jacket is adopted for cooling, so the condensing effect is good; and the impurities are not refluxed basically, the purity of products is high, and the production process has no pollution and no pollutant emission.

Owner:株洲科迪亚实业有限公司

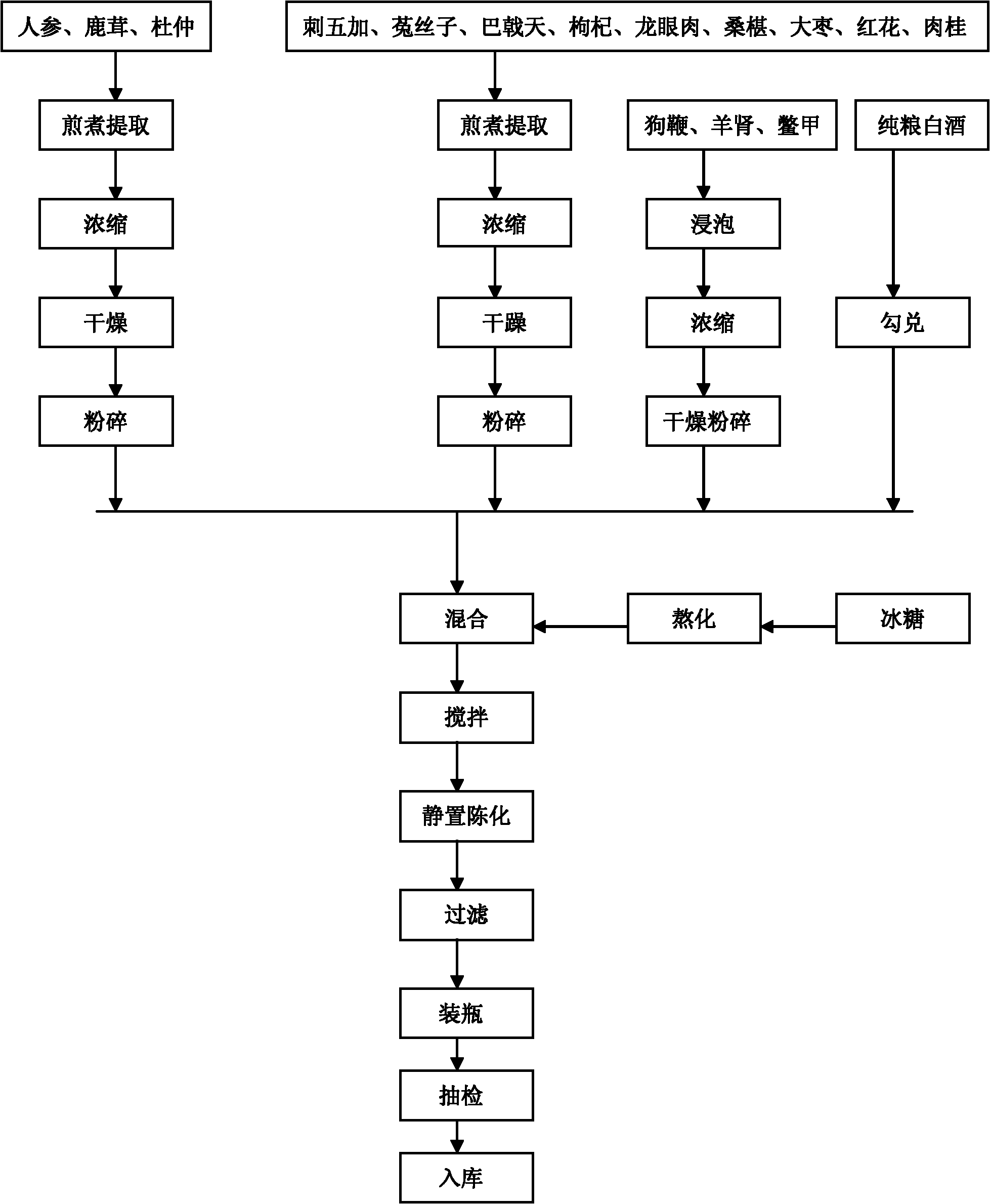

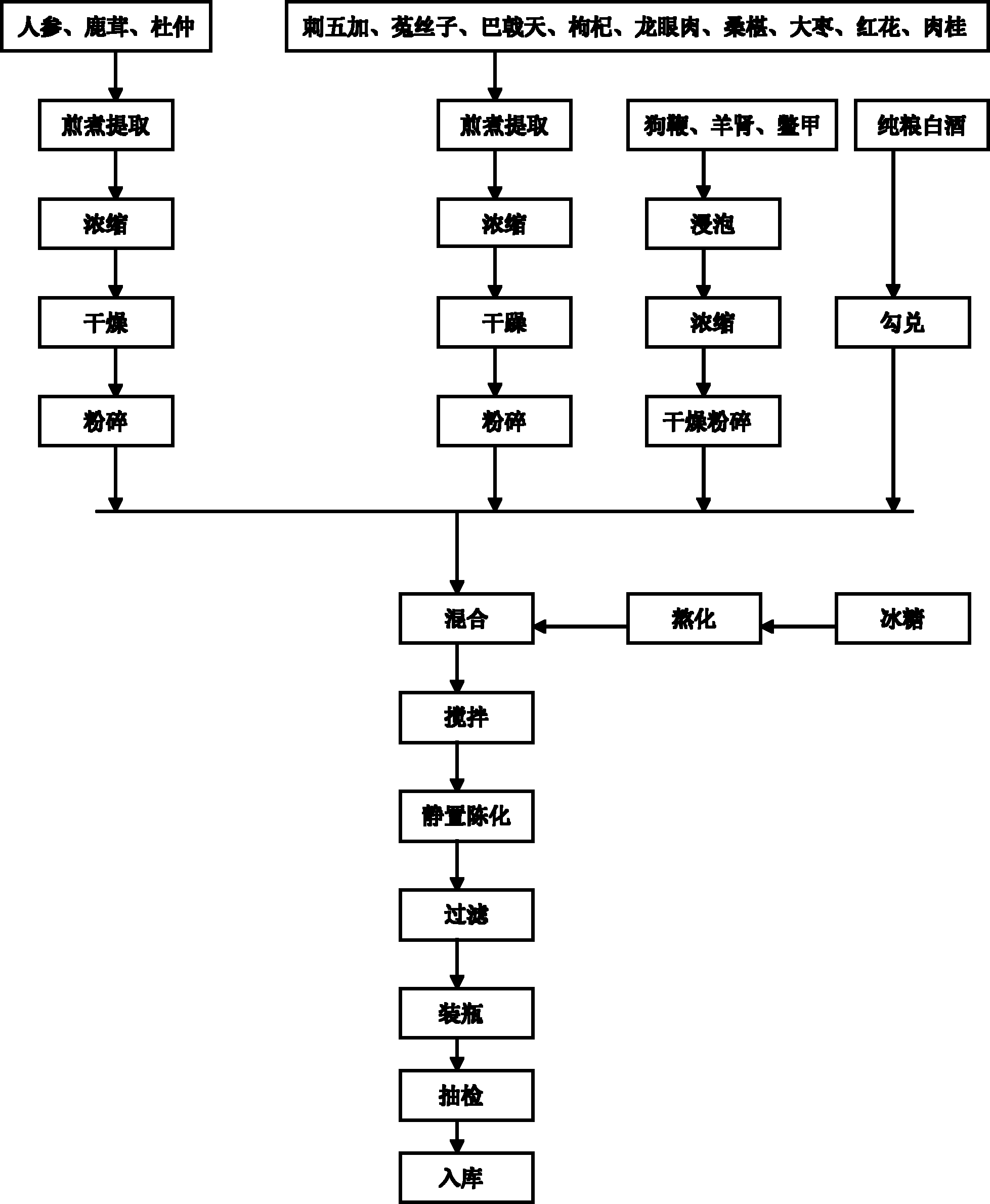

Compound ginseng antler and eucommia bark health-care wine and preparation method thereof

ActiveCN102061247ACompatibility is scientific and reasonableAnti-fatigueAlcoholic beverage preparationMedicinal herbsPenis

The invention discloses compound ginseng antler and eucommia bark health-care wine and a preparation method thereof, which belong to drinking health-care tonic wine for human beings and a preparation method thereof. The drinking wine is prepared from medicinal materials including ginseng, cartialgenous, eucommia bark, panax root, south dodder seed, medicinal indianmulberry root, wolfberry fruit, arillus longan, cinnamon, dog penis, sheep kidney, turtle shell and the like and by a technical method. The invention has the advantages that: 1, the raw materials for preparing the active ingredients of the wine are natural, and the raw material are mixed reasonably and scientifically; 2, based on strengthening liver and tonifying kidney, the wine can condition five organs, tonify qi and blood, promote the restoration of physiological function and has antifatigue, immune and regulating health-care functions and other health-care functions; and 3, the production process is simple, reduces production cost and is suitable for large scale production.

Owner:四川回春堂生物科技有限公司

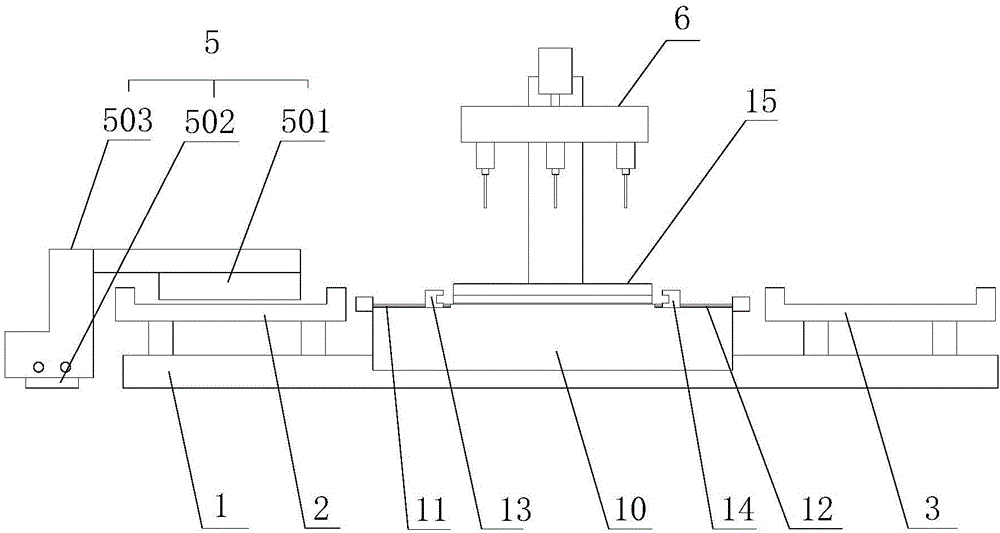

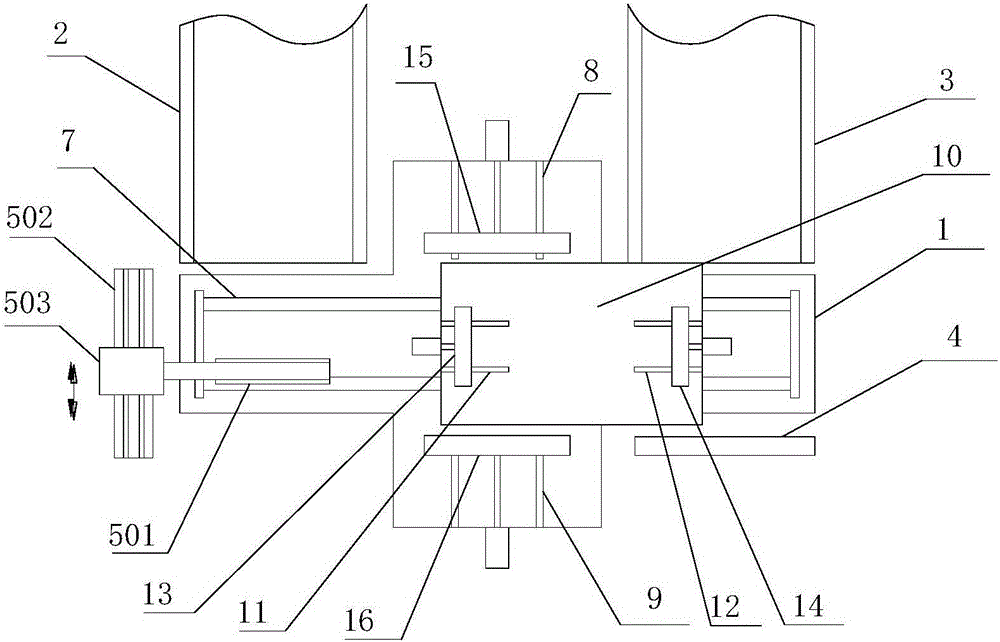

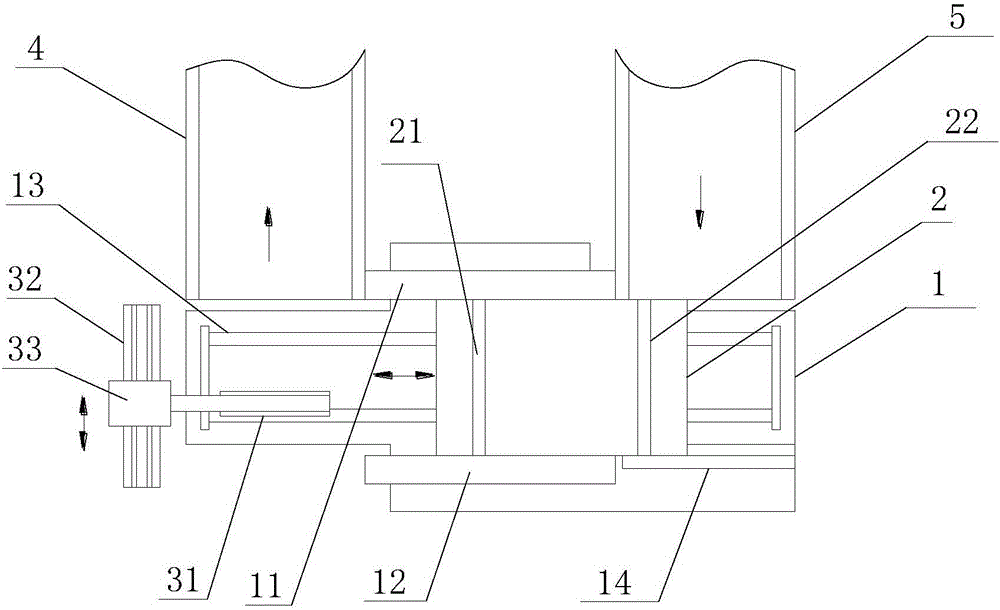

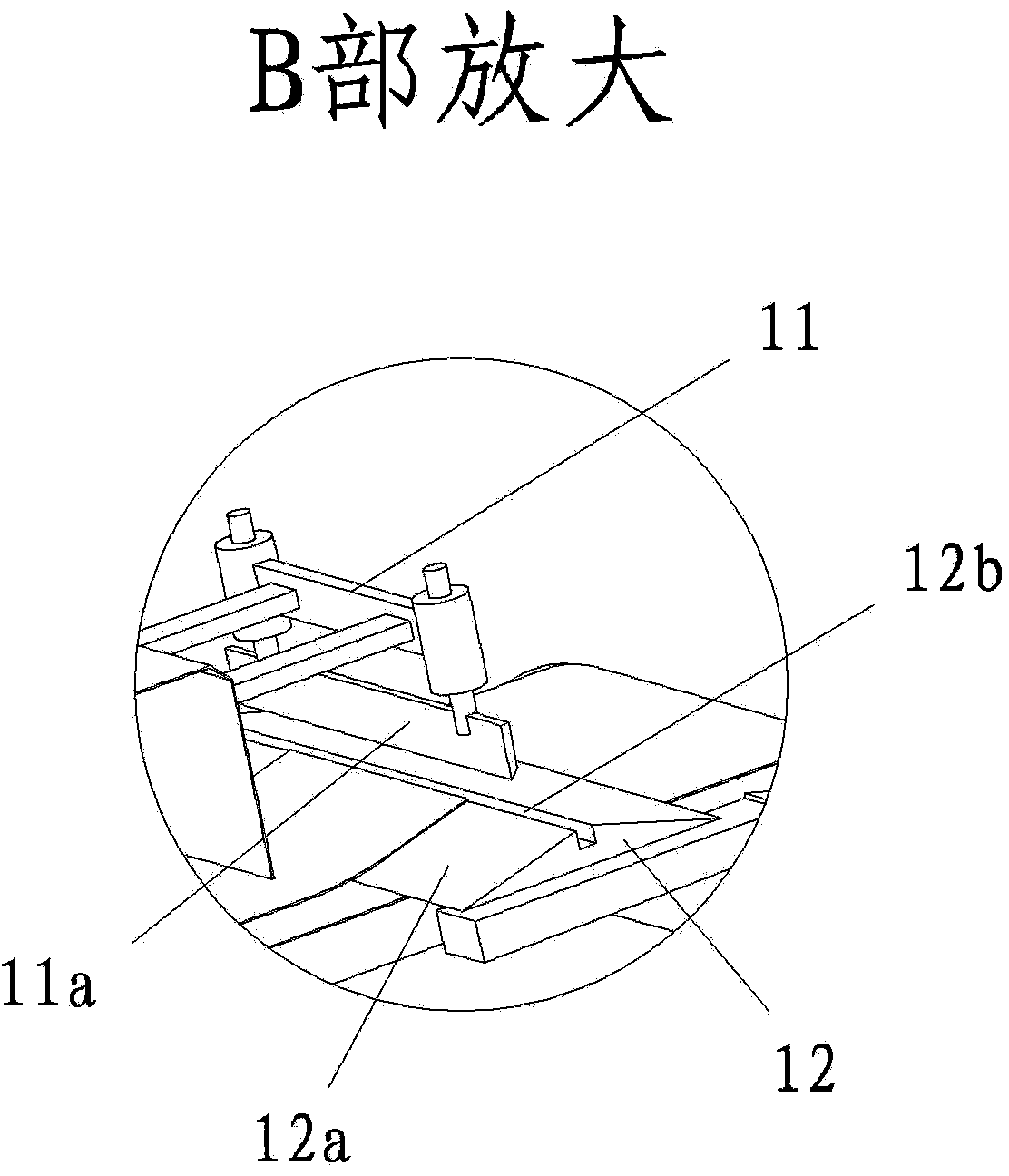

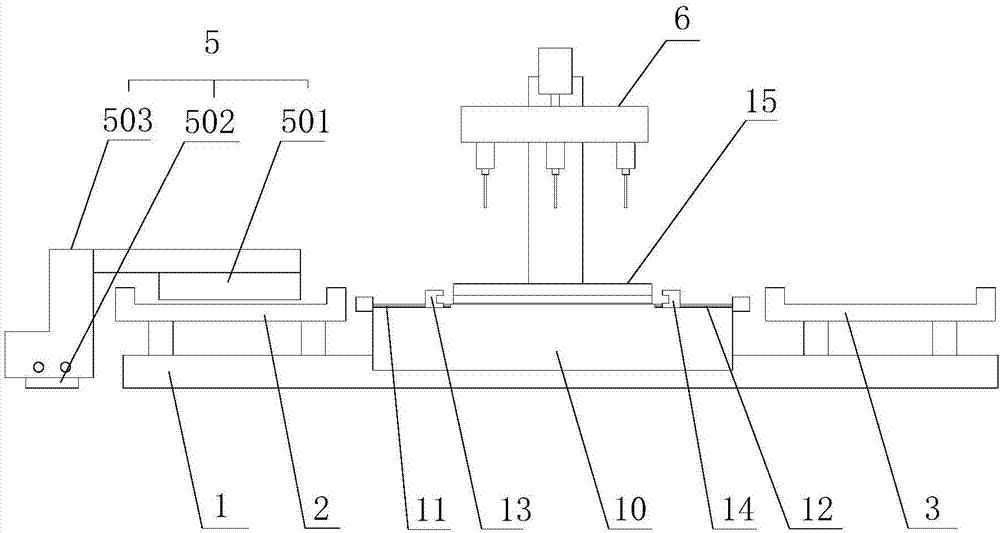

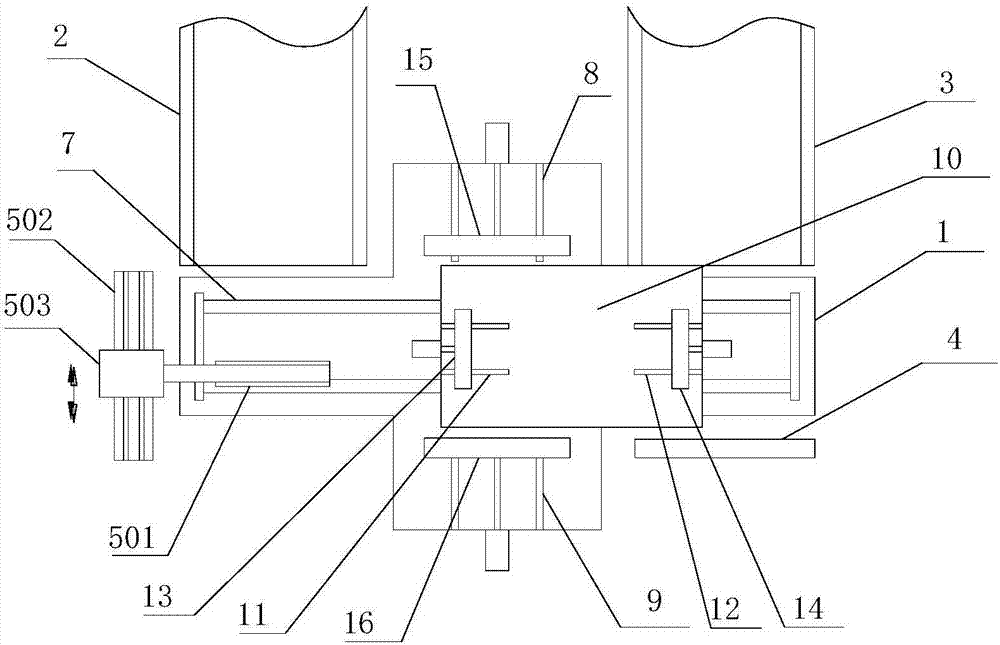

Printed circuit board (PCB) automatic clamping continuous drilling device

InactiveCN106239613ARealize continuous drilling operationShorten fixed timeMetal working apparatusEngineeringPrinted circuit board

The invention discloses a printed circuit board (PCB) automatic clamping continuous drilling device which comprises a base, a first conveying device, a second conveying device, a material baffle, a material pushing device, a drilling device, a first driving mechanism, a second driving mechanism, a third driving mechanism, a fourth driving mechanism and a fifth driving mechanism. PCB continuous drilling operation is performed through mutual matching of the base, the first conveying device, the second conveying device, the material baffle, the material pushing device, the drilling device, the first driving mechanism, the second driving mechanism, the third driving mechanism, the fourth driving mechanism and the fifth driving mechanism, PCB clamping fixing time is saved, and the PCB automatic clamping continuous drilling device meets large-scale production requirements of enterprises.

Owner:王沁仪

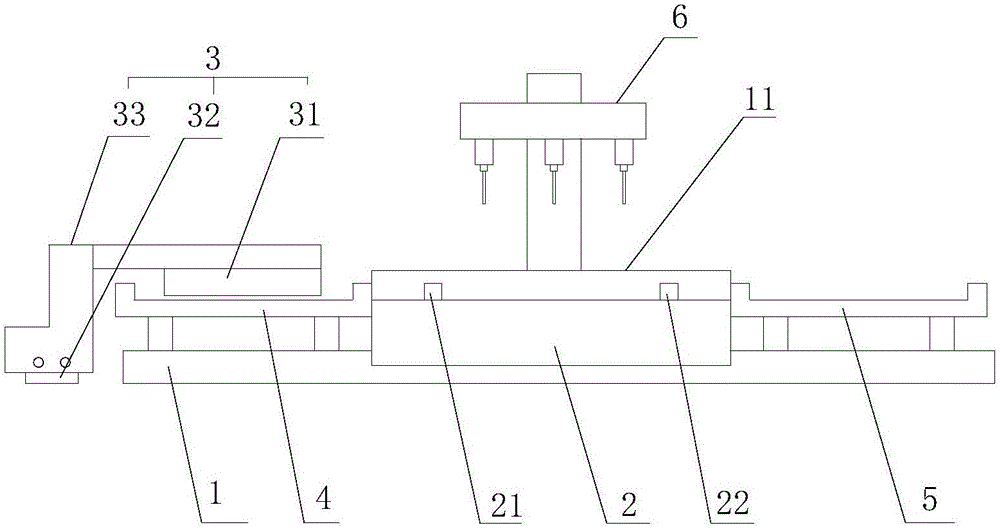

Clamping-free continuous drilling equipment for PCB (Printed Circuit Board)

InactiveCN106238773ARealize continuous drilling operationShorten the timeBoring/drilling machinesReciprocating motionEngineering

The invention discloses clamping-free continuous drilling equipment for a PCB (Printed Circuit Board). The drilling equipment comprises a base, a sliding table, a push device, a first transfer device, a second transfer device, a drilling device and a driving device, wherein a first stop block, a second stop block, a blocking plate and a guide rail are arranged on the base; the sliding table is installed on the guide rail, and a guide passage is formed on the sliding table; the first transfer device comprises a feeding passage, and the second transfer device comprises a discharge passage; the push device comprises a push block on the same straight line as the discharge passage and a driving mechanism for driving the push block to move linearly in the extension direction of the discharge passage; the driving device is used for driving the sliding table to reciprocate linearly on the guide rail, and the sliding table has a first position, a second position and a third position in the moving process; the drilling device is used for drilling the PCB. The drilling equipment can be used for realizing continuous drilling on the PCB, and is suitable for large-scale production of enterprises.

Owner:王沁仪

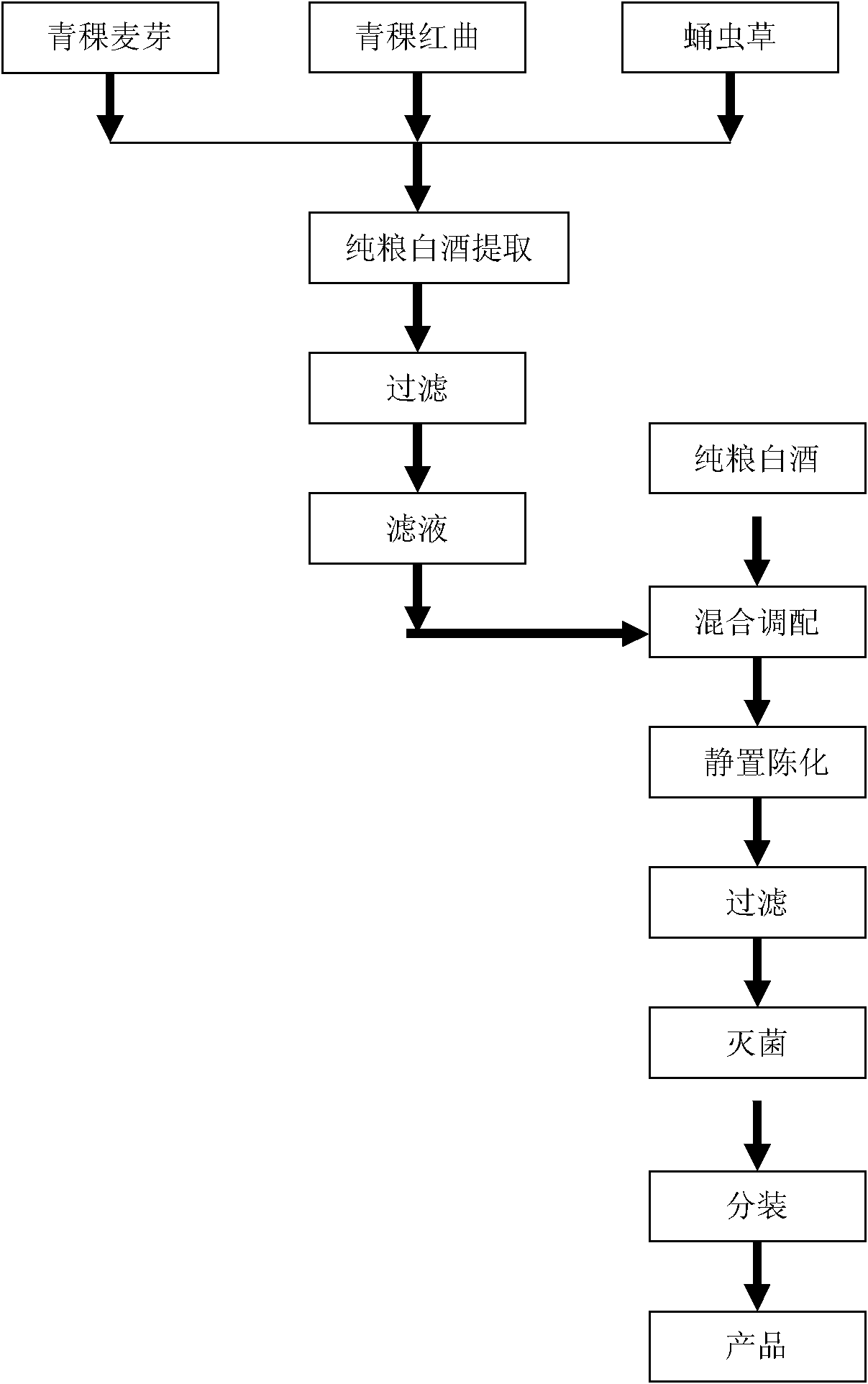

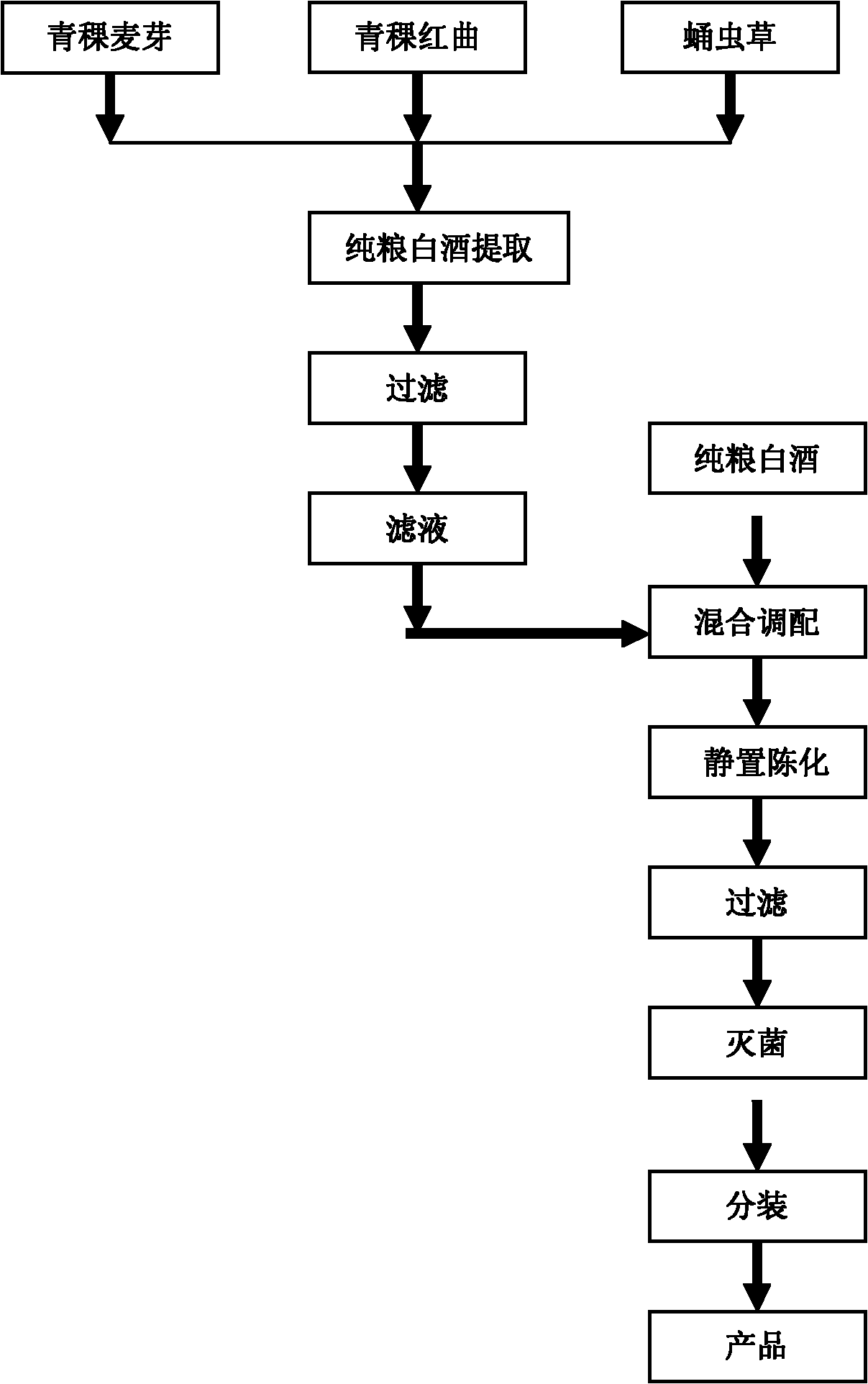

Barley monascus prepared wine and preparation method thereof

ActiveCN101967442ACompatibility is scientific and reasonableImprove immunityAntinoxious agentsAlcoholic beverage preparationCordyceps militarisWhite spirit

The invention relates to barley monascus prepared wine and a preparation method thereof, belonging to health-care nourishing wine for people to drink, in particular to health-care nourishing wine using the barley monascus as a main raw material and a preparation method thereof. The wine comprises the following raw materials in percentage by weight: 8-12 percent of barley malt, 18-22 percent of barley monascus and 4-6 percent of cordyceps militaris. The preparation method comprises the following steps of: soaking and filtering the barley malts, the barley monascus and the cordyceps militaris with pure grain white spirit to obtain filter liquor; putting the filter liquor into the pure grain white spirit and uniformly stirring; and standing still, aging, filtering and bottling. The product has the advantages of reasonable and scientific raw material matching and abundant nutrition constituents and has the effects of resisting fatigues and enhancing the immune function.

Owner:西藏月王药诊生态藏药科技有限公司

Compound sealwort and radix pseudostellariae wine and preparation method thereof

InactiveCN103589615ACompatibility is scientific and reasonableAnti-fatigueAntinoxious agentsAlcoholic beverage preparationCodonopsis pilosulaLiquorices

The invention belongs to the field of drinkable healthcare and tonic wines, and relates to a compound sealwort and radix pseudostellariae wine and a preparation method thereof. The compound sealwort and radix pseudostellariae wine mainly comprises the following raw materials: sealwort, radix pseudostellariae, codonopsis pilosula, morinda officinalis, dogwood, herba epimedii, semen cuscutae, mulberry, Chinese wolfberry, rehmanniae vaporata, lalang grass rhizome, liquorice and the like. The preparation method comprises the steps: extraction, combination and other steps. The invention has the following benefits: 1. the raw materials for preparing the active ingredients of the wine are natural, and the raw material combination is reasonable and scientific; 2. on the basis of the functions for tonifying Qi, reinforcing the kidney and strengthening tendons and bones, the wine can harmonize the five internal organs, tonify Qi and blood, promote the recovery of physiological functions, and achieve the healthcare functions of fatigue resistance, immunoregulation and the like; 3. the production procedures are simple, so as to reduce the product costs and meet the requirements for scale production.

Owner:伍班贵 +2

Polygonatum kingianum seed treatment method

InactiveCN106922248AShorten the time periodImprove germination rateSeed and root treatmentAfter treatmentSeed treatment

The invention discloses a Polygonatum kingianum seed treatment method, which comprises the following steps: (S1) selecting high quality plump-eared seeds, and mixing with sand; (S2) kneading the mixture of seeds and sand, and removing green skin; (S3) mixing seeds after green skin removal with sand, and grinding in a machine; and (S4) screening out sand and reserving seeds. After treatment, the Polygonatum kingianum seeds can be directly sown with no need of dormant period treatment, so as to remarkably reduce treatment period and cost. In addition, the seedling emergence period of the seeds is effectively shortened, the rate of emergence is increased, and the treatment method is in favor of seed and seedling growth.

Owner:红河道地中药材开发有限公司

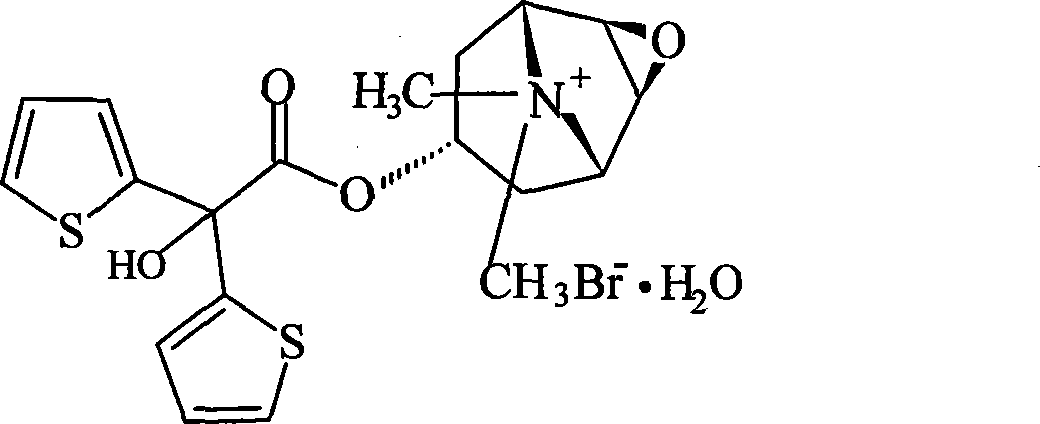

Capsule type tiotropium bromide inhalation powder

ActiveCN101032484AGuaranteed content uniformitySimple processPowder deliveryAerosol deliveryActive componentTIOTROPIUM BROMIDE MONOHYDRATE

The present invention discloses one kind of tiotropium bromide capsule atomized powder preparation, which includes tiotropium bromide or tiotropium bromide monohydrate in 0.04-1.5 wt% and fine lactose powder of size smaller than 15 microns for adsorbing tiotropium bromide or tiotropium bromide monohydrate. The present invention also provides the preparation process of the atomized powder preparation. The tiotropium bromide capsule atomized powder preparation has simple preparation process, excellent flowability and homogeneously distributed active component.

Owner:NANJING CAVENDISH BIO ENG TECH +1

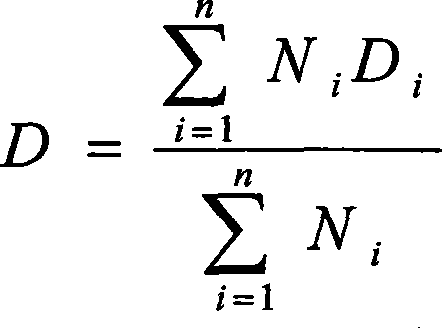

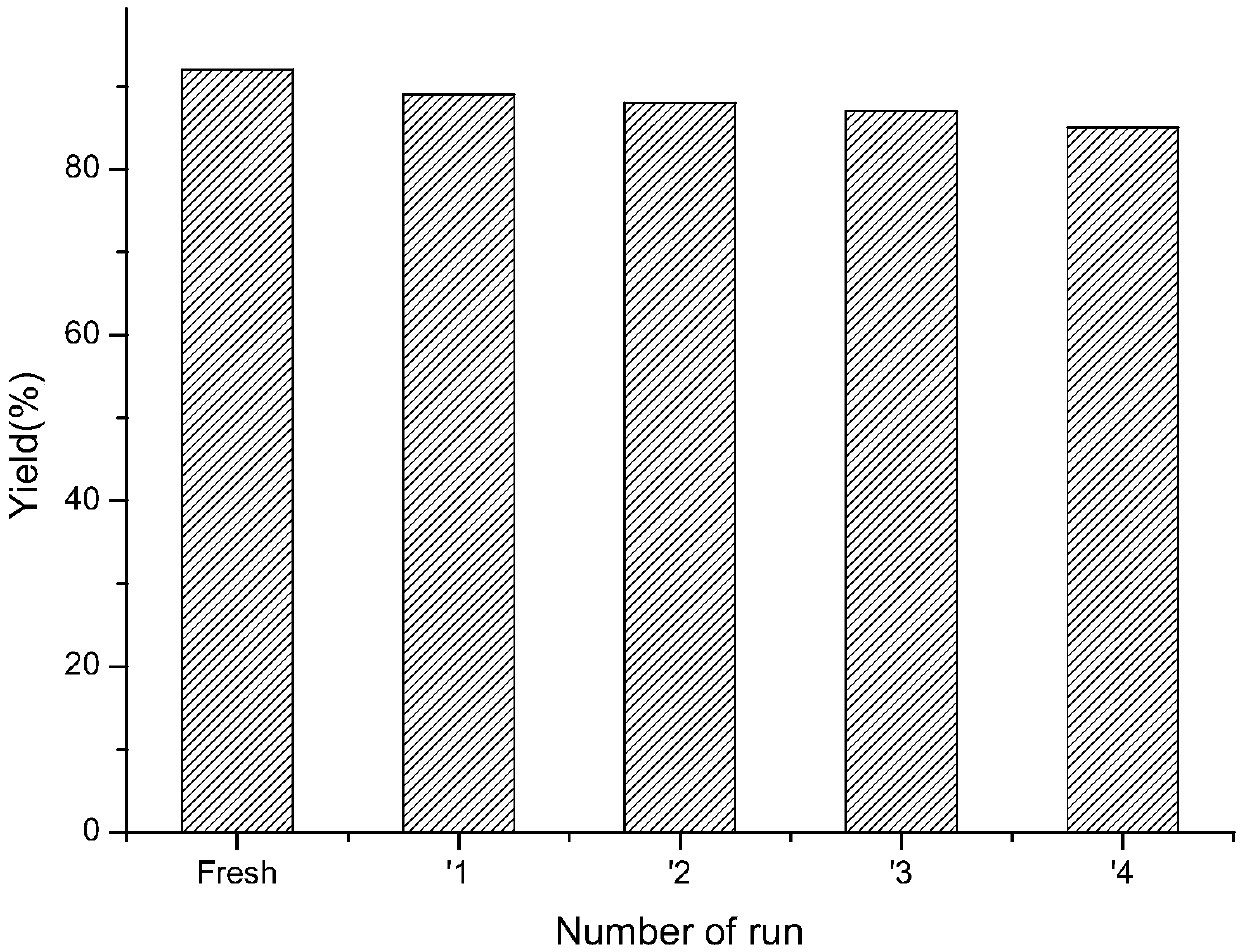

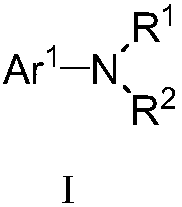

Preparation method of diarylamine compound

ActiveCN109608401ACatalytic activity unchangedAchieving zero emissionsOrganic-compounds/hydrides/coordination-complexes catalystsEther preparation by ester reactionsNitrogenous heterocyclic compoundNitrogen

The invention relates to a preparation method of a diarylamine compound. Specifically, under the catalysis of cuprous oxide supported by chitosan, the arylation reaction used for a nitrogen-containingheterocyclic compound is achieved, and the corresponding diarylamine compound is obtained. The preparation method of the diarylamine compound has the advantages that the process conditions are simple, the yield is good, the operability is strong, and the functional group tolerance is wide.

Owner:盐城锦明药业有限公司 +1

Method for massively producing all-female loaches

InactiveCN106259089AShort training periodHigh yieldClimate change adaptationPisciculture and aquariaWeatherfishFish species

The invention discloses a method for massively producing all-female loaches. The method for massively producing the loaches comprises the steps that healthy and good female fishes are screened for backup parents, prenatal intensive cultivation and artificial spawning inducement are conducted, and all-female diploid fries are obtained by adopting a gynogenesis method achieved through heterologous sperm stimulation and cold shock treatment; artemia larvae soaked with a methyltestosterone male sex hormone solution with the concentration of 50 mg / kg are continuously taken as baits for 30 days, and XXo+ female fishes in the loach fries are subjected to sex reversal to be XXo+ physiological male fishes; the full-female diploid normal fish fries mate with the physiological male fishes, and then the 100 full-female loaches are massively produced. Compared with the prior art, the method has the advantages that the full-female loaches are massively produced by combining a gynogenesis technology with a sex reversal technology, and therefore the per mu yield and the culturing benefit are significantly increased; by means of the gynogenesis technology, a pure line can be rapidly established, very rich materials can be provided for genetic breeding, the breeding cycle of the full-female loaches can be shortened, and the gynogenesis technology is suitable for the massive production requirements and easier to apply and popularize.

Owner:FISHERIES RES INST ANHUI ACAD OF AGRI SCI

Shrimp sauce containing spice

The invention belongs to the technical field of food processing and particularly relates to shrimp sauce containing spice. The shrimp sauce is prepared from, by mass, 20-30 parts of chili, 8-19 parts of edible plant oil, 12-20 parts of shrimp meat, 3-8 parts of edible salt, 1-3 parts of white granulated sugar, 1-3 parts of monosodium glutamate, 10-15 parts of garlic, 3-9 parts of fermented soybeans, 5-10 parts of soybeans and 5-10 parts of spice. The spice comprises ground cinnamon, cinnamon powder, anise, coriandrum seeds, purple perilla and fennel seeds. The flavor of the shrimp sauce containing the spice is different from that of common shrimp sauce in the market and is unique, and health of people is not affected on the premise that the unique flavor of the shrimp sauce containing the spice is kept.

Owner:成都宽窄美食投资有限公司

Corn thresher for agricultural production

The invention discloses a corn thresher for agricultural production, which comprises a body, a threshing cavity is arranged at the top center of the body, a threshing hole and a plurality of communication holes are arranged on the bottom wall of the threshing cavity, a screening cavity is arranged inside the body, and a threshing hole is arranged in the threshing hole. There is a threshing rod, the center of the outer circular surface of the threshing rod is evenly equipped with a number of corncob cutters, the bottom end of the body is evenly provided with a number of legs, and a support plate is arranged between all the legs, and the top of the support plate is fixedly connected The motor, the top side of the body is provided with a support rod, the top of the support rod is fixedly connected to the horizontal plate, the bottom end of the horizontal plate is fixedly connected with a cylinder corresponding to the threshing hole, and the telescopic rod of the cylinder is fixedly connected with the threshing rod. Top cone; the present invention only needs to manually complete the feeding, and all other threshing processes are completely completed automatically by the equipment, which greatly reduces the work intensity and improves the production efficiency, and is suitable for large-scale production needs. materials can be used to reduce labor costs.

Owner:迟一

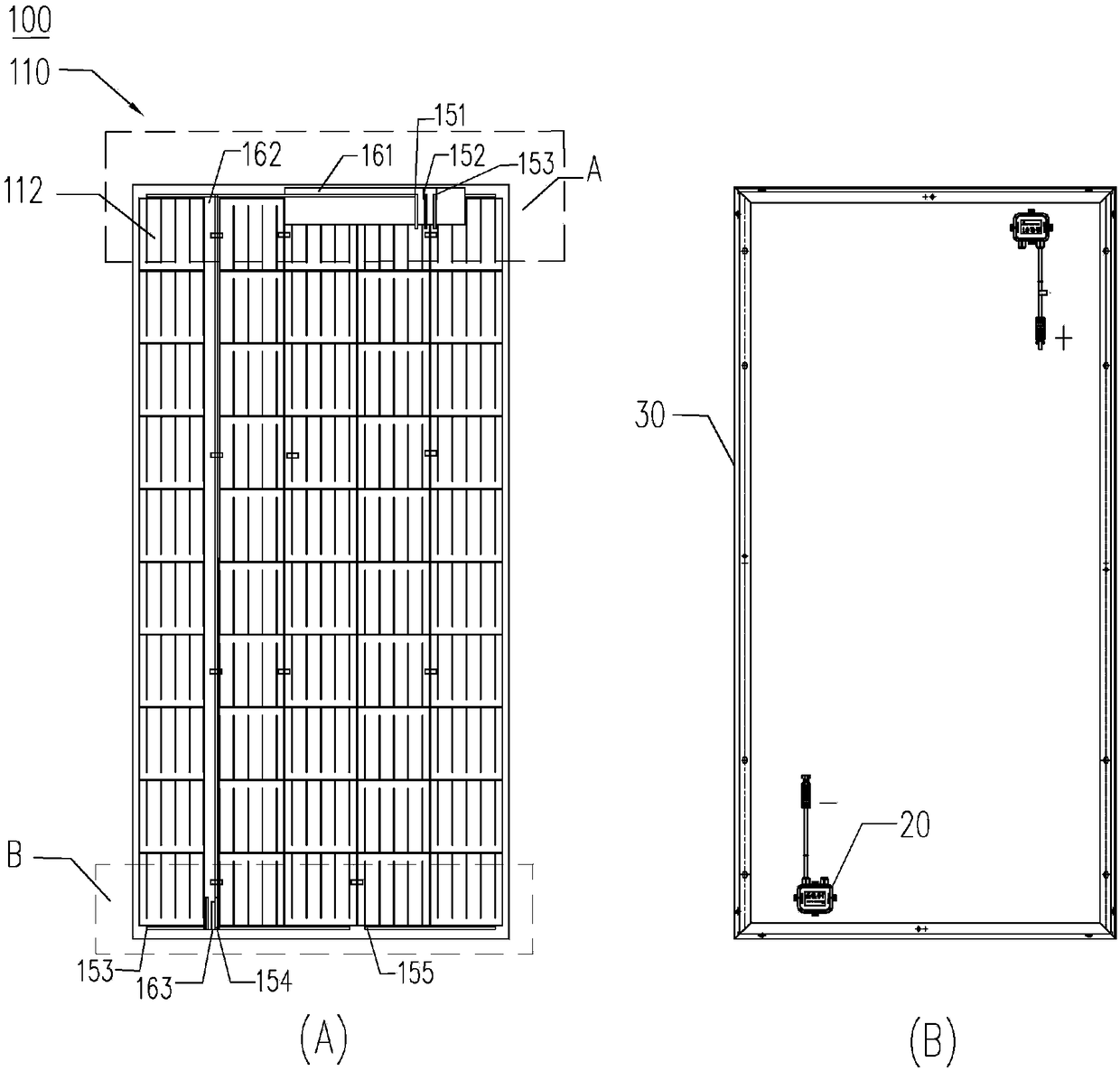

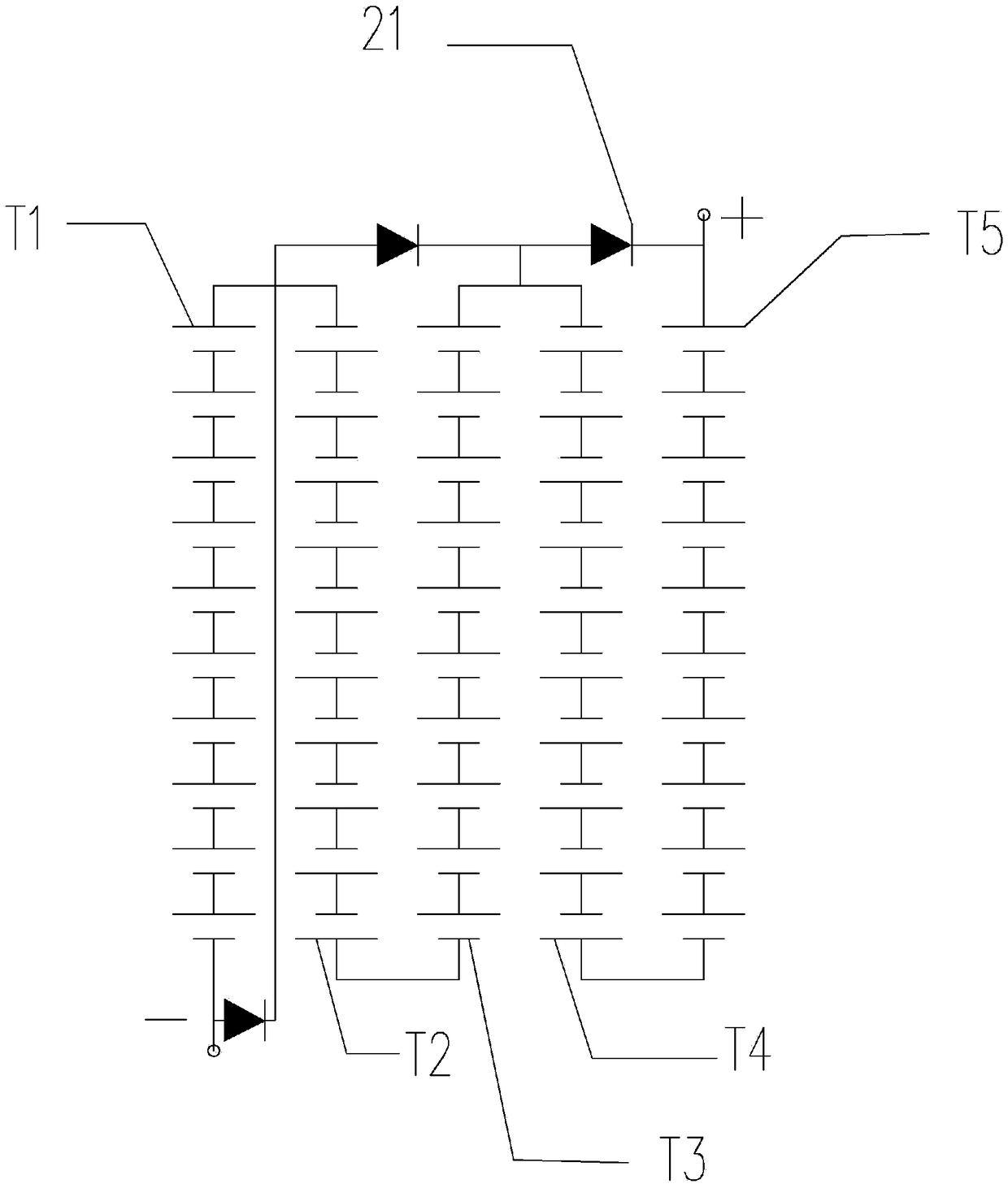

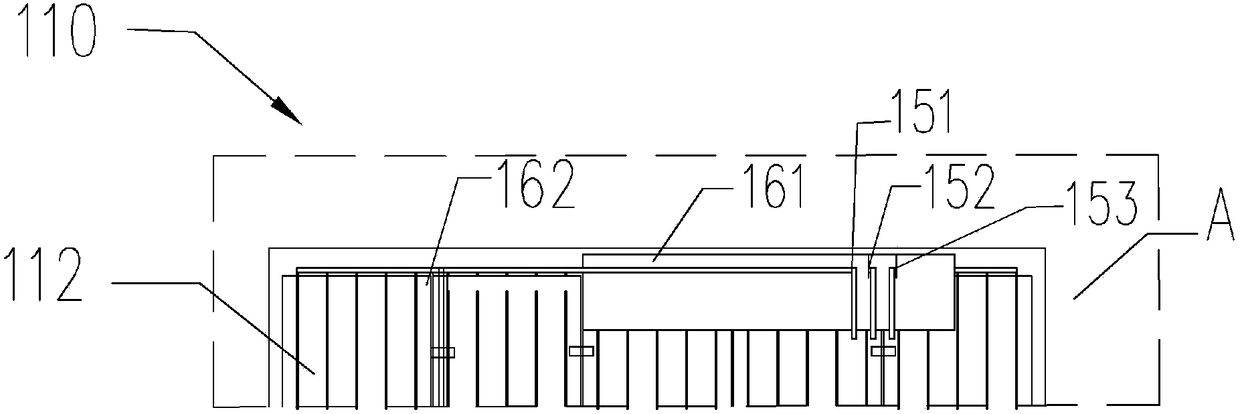

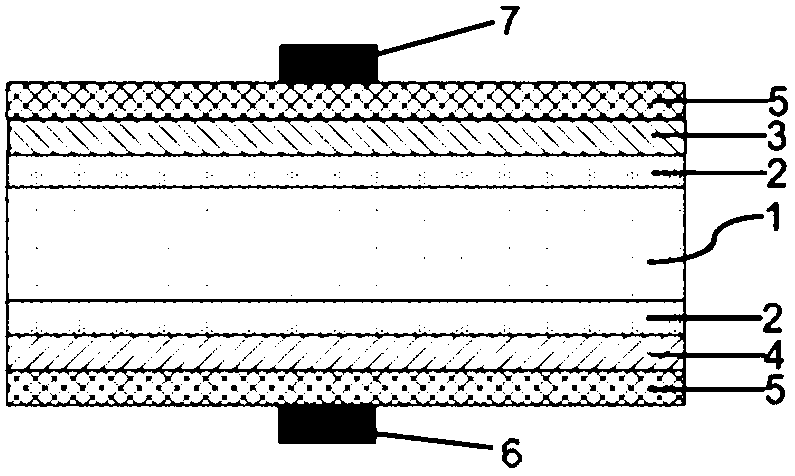

Solar photovoltaic assembly

PendingCN108493281ASimple processing technologySimple and fast operationPhotovoltaicsPhotovoltaic energy generationEngineeringJunction box

Disclosed in the invention is a solar photovoltaic assembly comprising a battery panel and two two-into-one junction boxes. A piece of tempered glass, a high-permeability EVA board, a battery string,a high-cut EVA and a back board are arranged from top to bottom in a lamination layer sequence; and the two two-into-one junction boxes are arranged at the upper and lower opposite angles of the backboard.

Owner:SUZHOU AIKANG PHOTOELECTRIC TECH CO LTD

Production method of waterproof corrugated carton

PendingCN110605872AImprove pass rateImprove waterproof performanceMechanical working/deformationBox making operationsSurface layerCarton

The invention relates to a production method of a waterproof corrugated carton. The method is characterized by comprising the following steps of S1, preparing a corrugated board; S2, carrying out waterproof treatment on a surface layer of the corrugated board; and S3, carrying out die cutting, mark pressing and carton nailing / carton gluing on the waterproof treated corrugated board prepared in theS2, and then the waterproof corrugated carton is obtained. The invention further discloses the waterproof corrugated carton produced according to the production method of the waterproof corrugated carton. The production method of the waterproof corrugated carton is simple and feasible in process, low in production cost, good in production efficiency, and high in finished product qualification rate; and the produced waterproof corrugated carton is remarkable in waterproof effect and large in mechanical strength.

Owner:苏州市恒顺纸塑有限公司

Preparation method for horn comb semi-finished product

InactiveCN108669762AAvoid deformationNot prone to crackingHair combsHigh volume manufacturingWaste material

The invention relates to a preparation method for a horn comb semi-finished product. The preparation method comprises the following steps of initial semi-finished product manufacturing, softening process and cooling sizing process. According to the preparation method, after good selected ox horn raw materials are washed and placed for 4-6 months under the normal temperature condition, the raw materials are cut into initial semi-finished products, then the softening processing is conducted, finally the cooling sizing processing is conducted, so that the prepared horn combs cannot easily deformand fracture, the product quality is improved, the service life is prolonged, waste material production is also greatly reduced, and the production cost is reduced, and the preparation method is simple, can be easily mastered, achieves mass production, and is applicable to scale production requirements.

Owner:仁怀市唯一角制工艺加工厂

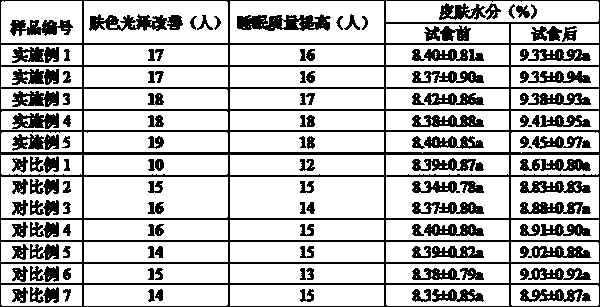

Healthy drink containing collagen

InactiveCN110537649AHas beauty and body effectsGood health effectFood ingredient functionsPolysaccharide/gum food ingredientsNutritive valuesFood additive

The invention relates to a healthy drink containing collagen. The healthy drink is characterized in that the healthy drink is prepared from the following raw materials in percentage by weight: 3-6% ofcollagen powder, 0.1-0.3% of hesperidin, 0.05-0.3% of almond powder, 0.05-0.15% of lentinan, 0.5-2% of watermelon juice, 1-3% of peach juice, 0.1-0.3% of tomato powder, 0.1-0.4% of a seaweed polysaccharide, 0.2-0.5% of a lycium barbarum polysaccharide, 0.1-0.5% of aloe emodin, 0.1-0.6% of glycyrrhizic acid, 0.1-0.8% of red grape concentrated fruit powder, 0.03-0.05% of a food additive, 0.01-0.06%of a sweetener, 0.01-0.03% of a food flavor and the balance of water. The invention further discloses a preparation method of the healthy drink containing the collagen. According to the disclosed healthy drink containing the collagen, the nutritional value is high, the health care effect is good, the absorption capacity of a human body is high, taste is good, mouthfeel is good, very high biological activity is achieved, anti-decomposition ability is high, and the synthesis force of human body collagen can be effectively improved; in addition, the nutritional ingredients of the healthy drink are retained, beauty body effect is also achieved, and thus the practical value of the drink is obviously improved.

Owner:无锡嬿侣生物科技有限公司

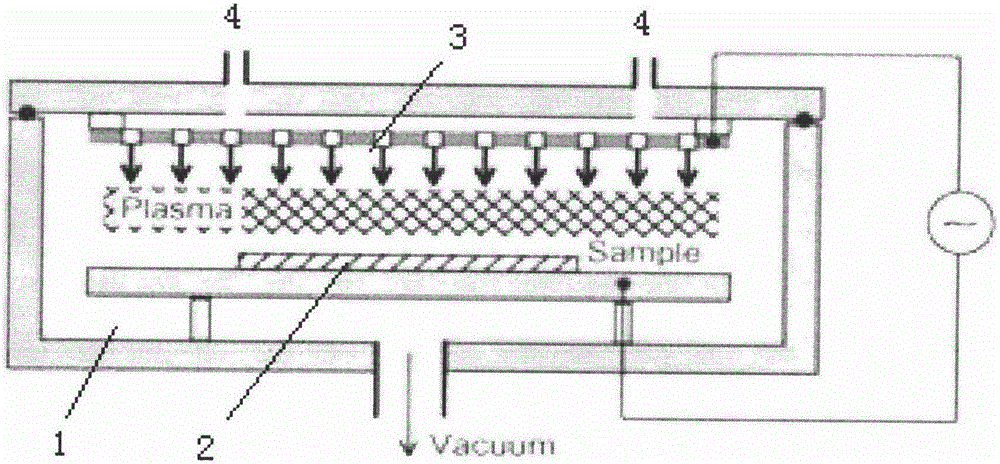

Coating removing method for diamond coated tool

InactiveCN105695949AExcellent stripping qualitySuitable for large-scale production needsChemical vapor deposition coatingMicroparticleOxygen

The invention discloses a coating removing method for a diamond coated tool. The coating removing method comprises the steps that the abraded diamond coated tool is cleaned with acetone and ethyl alcohol; the abraded diamond coated tool is fixed to the center of a sample table of plasma enhancement chemical vapor deposition equipment, vacuumizing is conducted on the plasma enhancement chemical vapor deposition equipment till the pressure is below 1-5*10-3 Pa, plasma beams generated by 3GHz microwaves are adopted by the equipment, the heating temperature is 350-420 DEG C, gases including oxygen, Cl2, ClO2 and HCl are introduced, and the treatment time is 10-15 min; protective gas is introduced after the treatment is finished, and the tool is taken out after cooling; and microparticles on the surface of the tool are cleaned away with acetone after the tool is taken out, a tool basal body is exposed, and accordingly coating removing is finished.

Owner:SUZHOU LEJING NEW MATERIAL TECH CO LTD

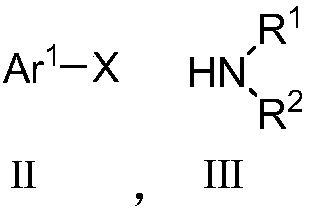

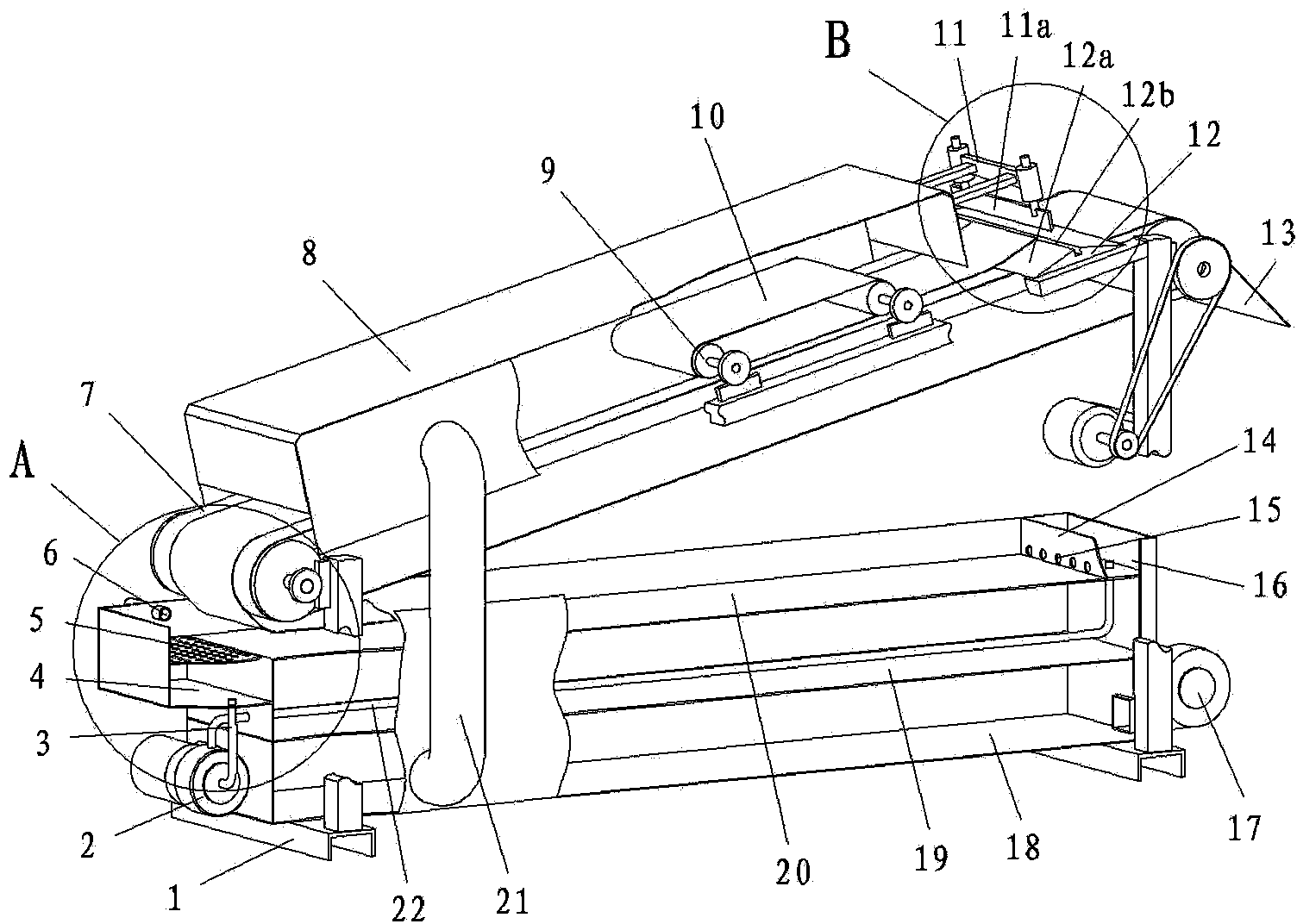

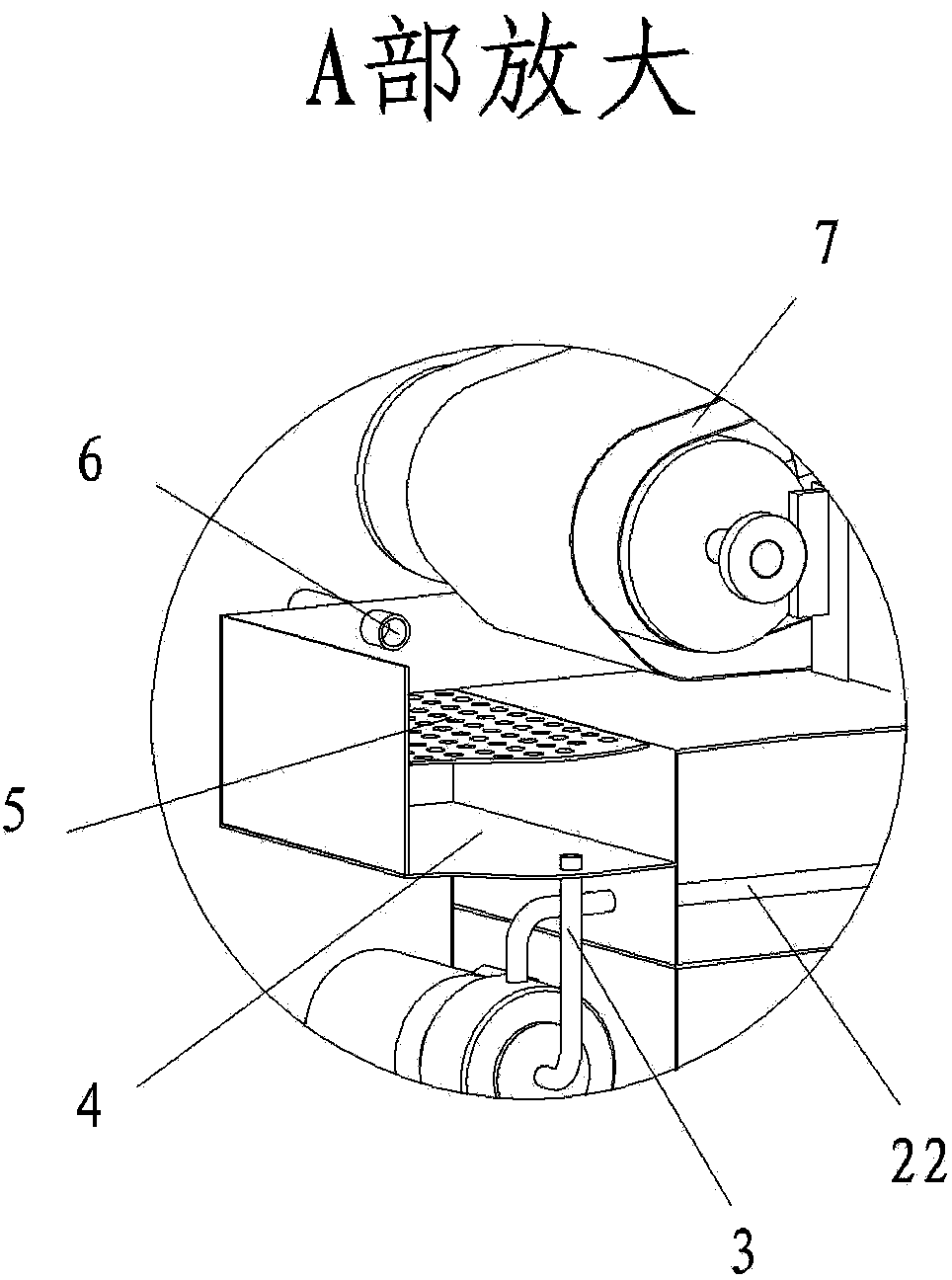

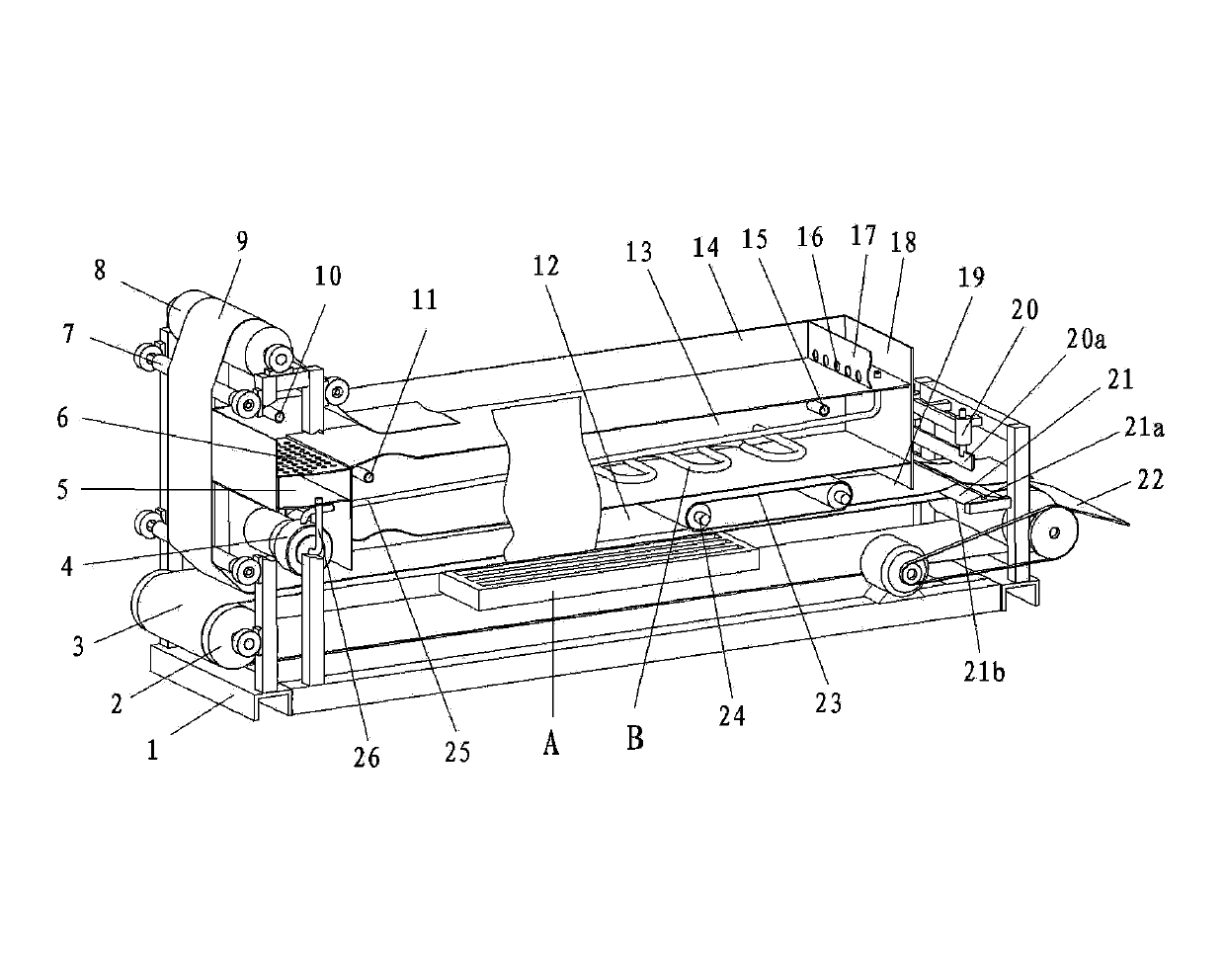

Automatic bean curd drying and forming machine

InactiveCN103444902ATake advantage ofSimple structureCheese manufactureFood scienceEngineeringHeating energy

The invention discloses an automatic bean curd drying and forming machine which comprises a stander (1), a hot air chamber (12), a heating chamber (13), a crusting trough (14), a conveying device and a drying tunnel (8), wherein a leveling device is arranged in the drying tunnel; a soybean milk feeding trough (18) is arranged at one end of the crusting trough, and a soybean milk trough (5) and a soybean milk conveying pump (4) are arranged at the other end of the crusting trough; the soybean milk conveying pump is connected with the soybean milk trough and the soybean milk feeding trough through a soybean milk feeding pipe (26) and a soybean milk conveying pipe (25); a scraper blade (21), an electromagnetic section cutter (20) and a material receiving plate (22) are arranged at one end of the conveying device; a blower (17) is arranged at one end of the hot air chamber, and an air supply pipe (22) connected with the drying tunnel is arranged at the other end of the hot air chamber. By virtue of the technical scheme, the automatic bean curd drying and forming machine is simple in structure, high in production efficiency and low in labor intensity, makes full use of heat energy and space, improves the sanitation environment and the quality of a product, and is suitable for requirement of large-scale production.

Owner:沈金永

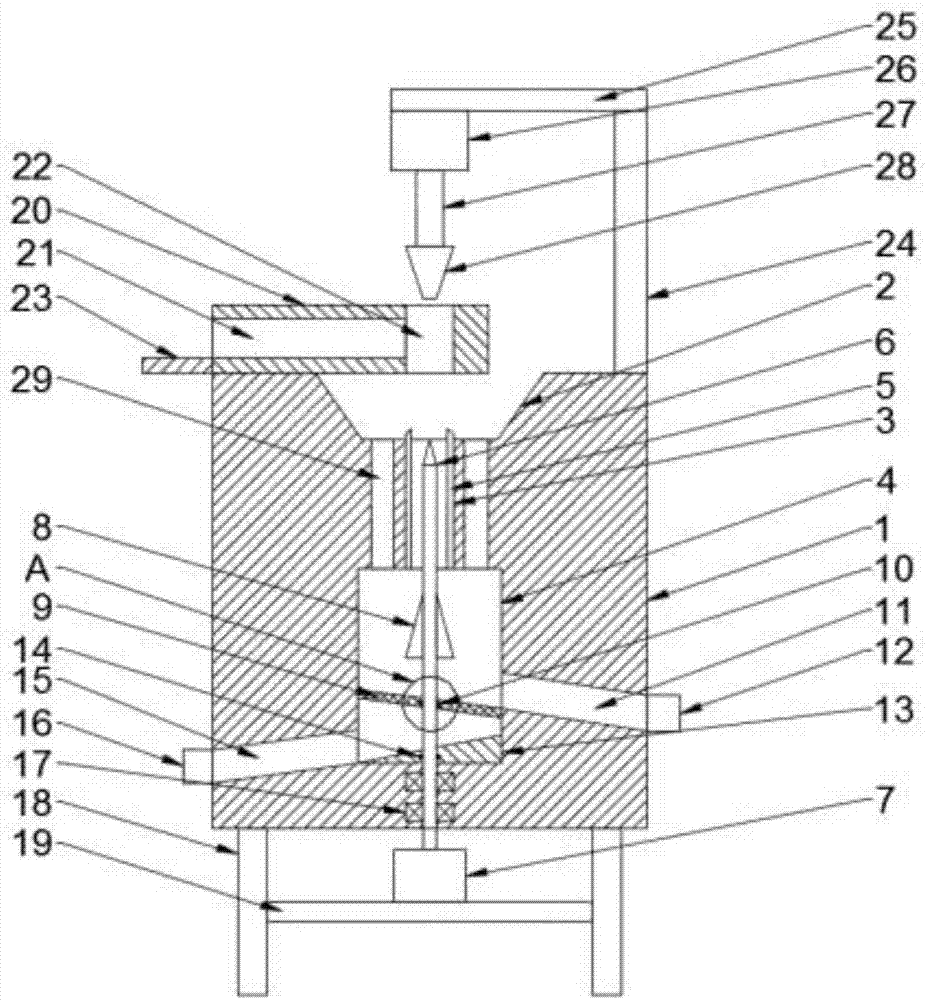

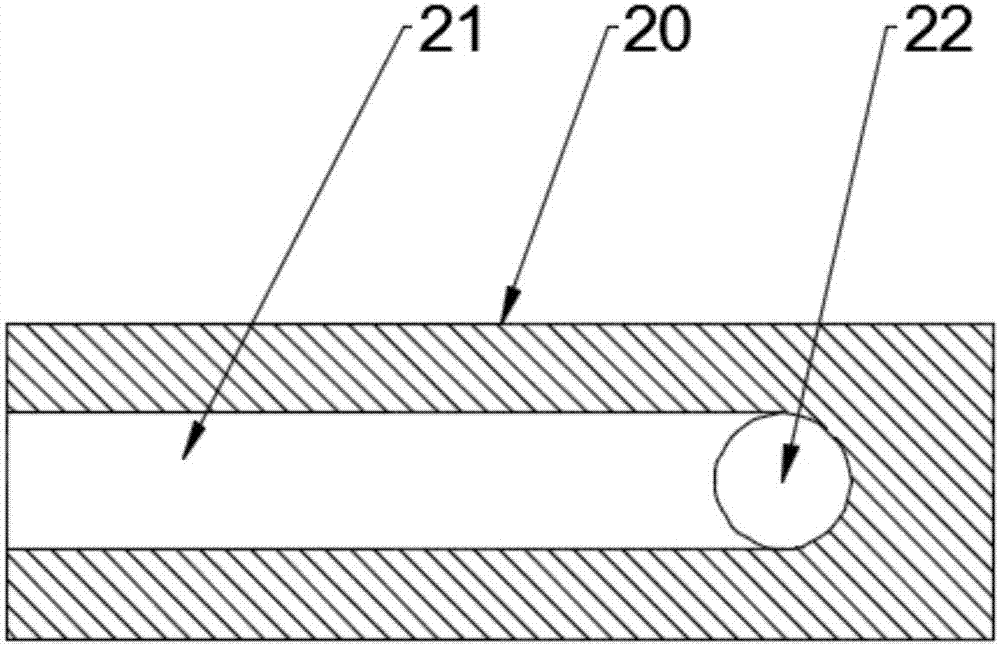

Lower drying type automatic soya milk film forming machine

InactiveCN103461517ASimple structureIncrease productivityCheese manufactureFood scienceMechanical engineeringHeating energy

A lower drying type automatic soya milk film forming machine comprises a frame (1), wherein conveying rollers (2) are arranged at two ends of the frame, between which a conveying belt (3) is arranged; a drying groove (12), a heating room (13) and a soya milk film forming groove (14) are formed above the middle part of the frame; a soya milk inlet groove (18) is formed in one end of the soya milk film forming groove, and a soya milk groove (5) is formed in the other end of the soya milk film forming groove; a soya milk conveying pump (4), a film lifting roller (8) and a group of film supporting rolls (7)are arranged at one end of the soya milk groove; a soya milk inlet pipe (26) is arranged between the soya milk conveying pump and the soya milk groove; a soya milk conveying pipe (25) passing through the heating room is connected between the soya milk conveying pump and the soya milk conveying groove; a scraping plate (21), an electromagnetic segment cutter (20) and a material receiving plate (22) are arranged at one end of the soya milk conveying groove; a pair of driving rollers (24) is arranged in a drying groove, and a leveling belt (23) is connected between the driving rollers. Due to the adoption of the technical scheme, the soya milk film forming machine is reasonable in structure, makes the best of heat energy and space, is convenient to maintain and manage, and has the advantages of high efficiency, convenience in operation and the like.

Owner:沈金永

Surface treating agent for synthetic leather and preparation method thereof

InactiveCN110128936AEasy to prepareEasy to operatePolyurea/polyurethane coatingsCarboxylic saltEther

The invention discloses a surface treating agent for synthetic leather. The composition comprises the following components in parts by weight: 10-20 parts of polyethylene glycol monoallyl ether modified hyperbranched polysiloxane, 30-40 parts of acrylic acid modified waterborne polyurethane, 6-(1'-tert-butyldimethylsiloxyethyl)-3-(2"-tetrahydrofuryl)-7-oxo-4-thio-1-azabicyclo[3.2.0]heptyl-2-ene-2-allyl carboxylate, 2-5 parts of 2-trimethylsiloxy-1,1,5,5,5-hexafluoropentyl-2-ene-4-one, 3-6 parts of an emulsifier, 0.2-0.4 part of an initiator, 1-3 parts of a flatting agent, 1-3 parts of a delustering agent and 40-50 parts of deionized water. The invention also discloses a preparation method and a use method of the surface treatment agent for the synthetic leather. The surface treatment agentis remarkable in surface treatment effect, excellent in comprehensive performance, good in water resistance, solvent resistance, hydrolysis resistance and wear resistance, high in adhesiveness and good in permeability and leveling property. And the synthetic leather subjected to surface treatment is smoother and softer in hand feeling.

Owner:江苏多森新材料科技有限公司

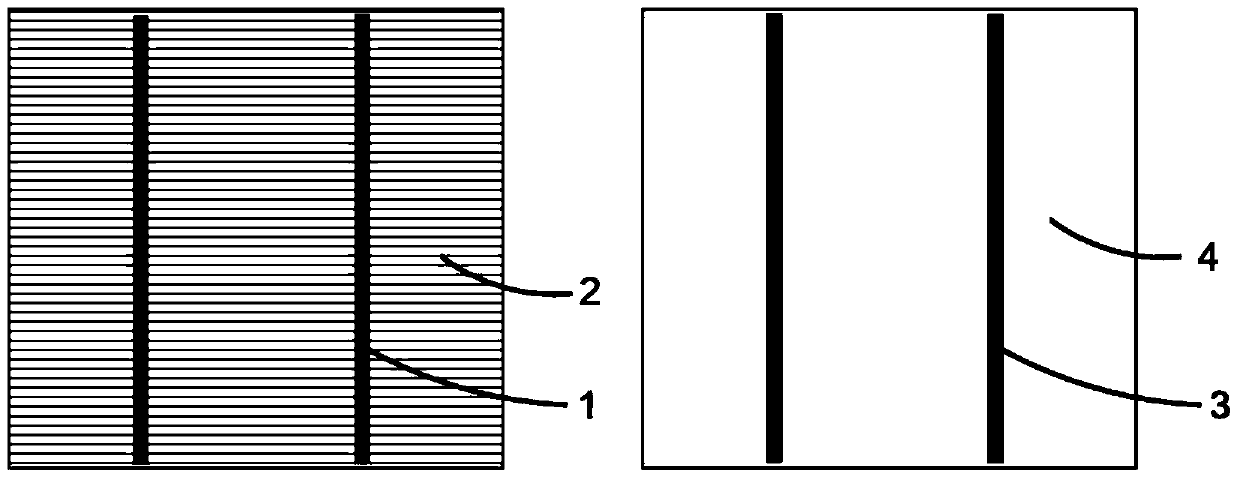

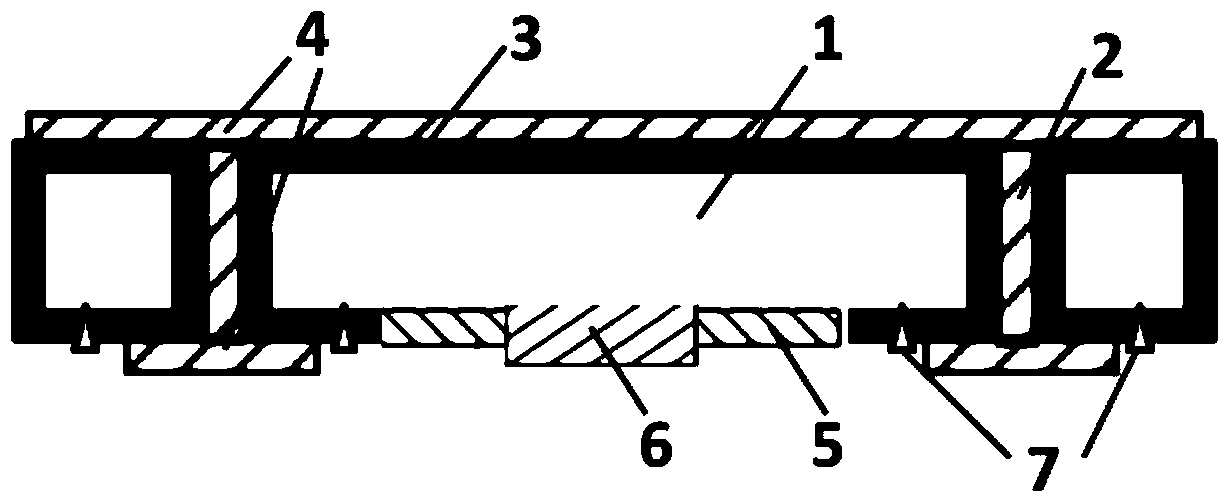

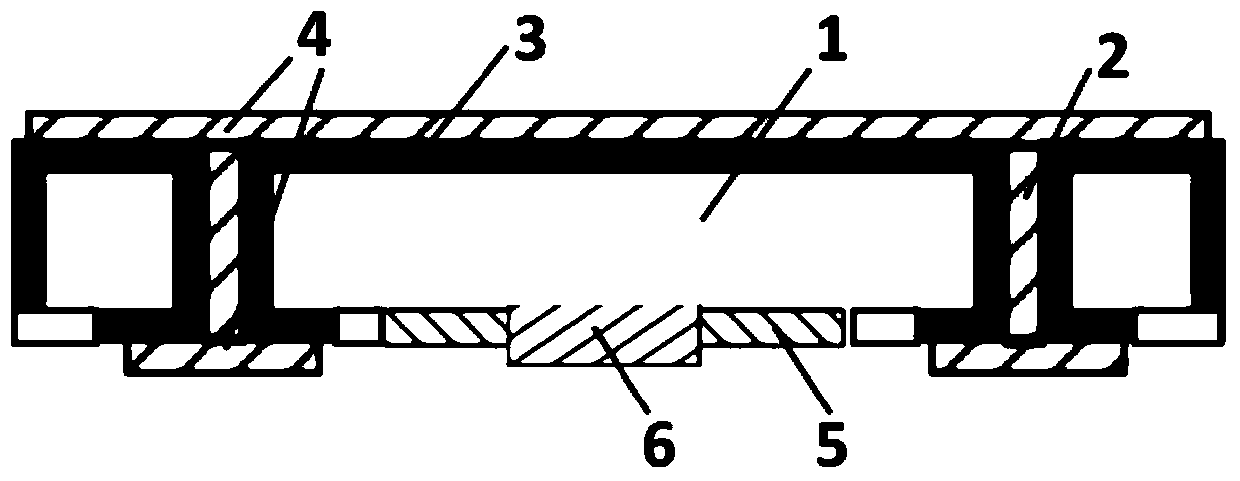

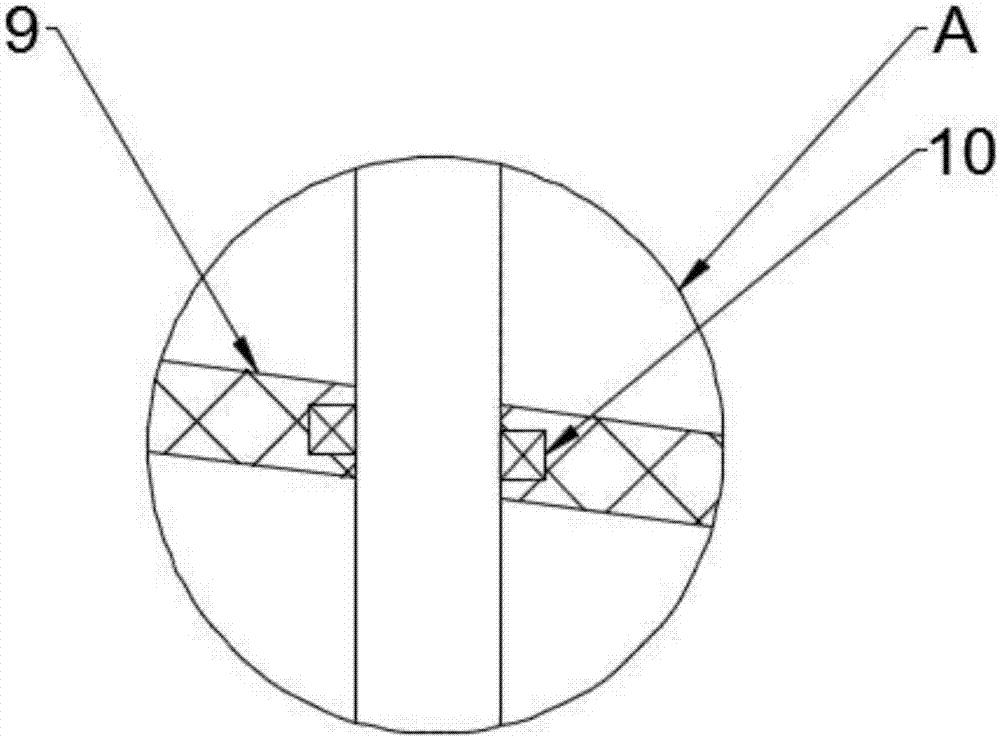

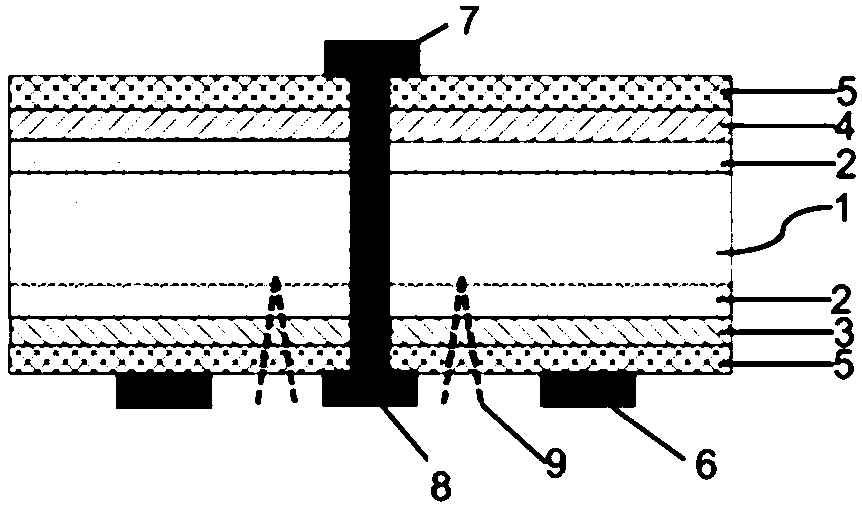

MWT heterojunction silicon solar cell suitable for mass production and preparation method thereof

PendingCN109473492ASuitable for large-scale production needsSimple methodFinal product manufacturePhotovoltaic energy generationElectrically conductiveN type silicon

The invention discloses an MWT heterojunction silicon solar cell suitable for mass production and a preparation method thereof. The cell comprises an N-type silicon substrate, and an intrinsic amorphous silicon passivation layer or a silicon oxide passivation layer on the front surface of the N-type silicon substrate is provided with an N-type amorphous silicon film layer. An intrinsic amorphous silicon passivation layer or a silicon oxide passivation layer on the back surface of the N-type silicon substrate is provided with a P-type amorphous silicon film layer. The front surface of the cellis provided with a front metal electrode, and the back surface is provided with a back metal electrode and a hole metal electrode. The outer periphery of each hole metal electrode point is etched witha continuously closed insulating scribe line, and the insulating scribe line penetrates a TCO transparent conductive film and the P-type amorphous silicon film layer on the back surface of the cell.In the method, the emitter of the P-type amorphous silicon film is placed on the back surface of the cell, so that there is no leakage problem in an N-type base region of the hole metal electrode andthe sidewalls, and the method of laser etching of the insulating scribe line around the back hole metal electrode points is used for isolating the P-type amorphous silicon film and the above TCO transparent conductive film, and prevents the short circuit fault from the back positive electrode region.

Owner:JIANGSU SUNPORT POWER CORP LTD

Health-preserving wine

InactiveCN106222033ACompatibility is scientific and reasonableFatigue time delayDigestive systemAlcoholic beverage preparationRed yeast riceRadix Astragali seu Hedysari

The invention discloses health-preserving wine. Active ingredients of the health-preserving wine is prepared from the following raw materials in parts by weight: 15 to 30 parts of herba cistanche, 15 to 25 parts of polygonum multiflorum, 15 to 30 parts of fructus lycii, 15 to 20 parts of radix achyranthis bidentatae, 10 to 20 parts of poria cocos, 10 to 20 parts of radix ophiopogonis, 10 to 15 parts of fructus psoraleae, 5 to 15 parts of Chinese angelica, 15 to 25 parts of mulberry fruit, 4 to 8 parts of safflower, 4 to 6 parts of fructus gardeniae, 4 to 6 parts of red yeast rice, 30 to 60 parts of radix puerariae, 2 to 10 parts of ginseng, 4 to 12 parts of radix astragali seu hedysari, 3 to 11 parts of poria with hostwood, 7 to 15 parts of largehead atractylodes rhizome, 6 to 14 parts of prepared rhizome of rehmannia, 8 to 16 parts of rhizome of rehmannia, and 6 to 14 parts of codonopsis pilosula. The health-preserving wine has the advantages that the health-care functions of nourishing, preserving health and the like are realized; the production procedure is simple, the production cost is reduced, and the health-preserving wine is suitable for large-scale production requirements.

Owner:北海古力酒业股份有限公司

Aqueous anti-corrosion coating and preparation method thereof

InactiveCN110157333AThe preparation method is simple and easy to operateDevice dependency is smallFireproof paintsAnti-corrosive paintsIonWeather resistance

The invention discloses an aqueous anti-corrosion coating which is characterized by consisting of the following components in parts by weight: 40-60 parts of emulsified asphalt, 15-25 parts of an aqueous filming ionomer, 1-3 parts of di(3-triethoxy silicon propyl) fumarate, 1-3 parts of 3-(2-propylene seleno-)-L-alanine, 0.3-0.5 part of methyl racemization-(E)-7-[5-tertiary-butyl dimethyl silylation oxymethyl-2,6-diisopropyl-4-(4-fluorophenyl)-3-pyridyl]-5-hydroxy-3-oxo-6-heptanoate, 1-3 parts of L-zinc carnosine modified alginic acid, 10-15 parts of an aqueous graphene slurry hectorite composition, 3-6 parts of an emulsifier, 0.5-1 part of an initiator, 1-3 parts of a thickening agent and 40-50 parts of deionized water. The invention furthermore discloses a preparation method of the aqueous anti-corrosion coating. The aqueous anti-corrosion coating disclosed by the invention is remarkable in corrosion-resistant and waterproof effect, good in comprehensive property, good in stability and weather resistance, rapid in drying speed and green and environmental-friendly in production and use process.

Owner:HUNAN CHENLI NEW MATERIAL CO LTD

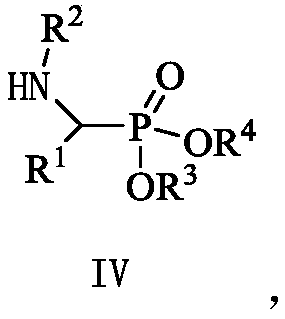

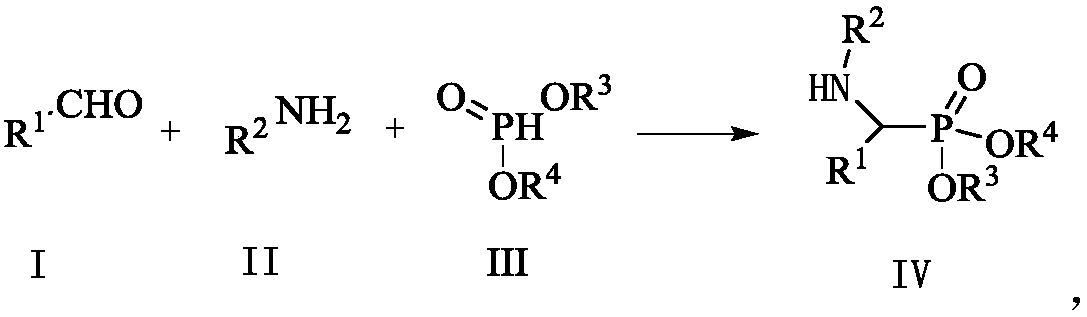

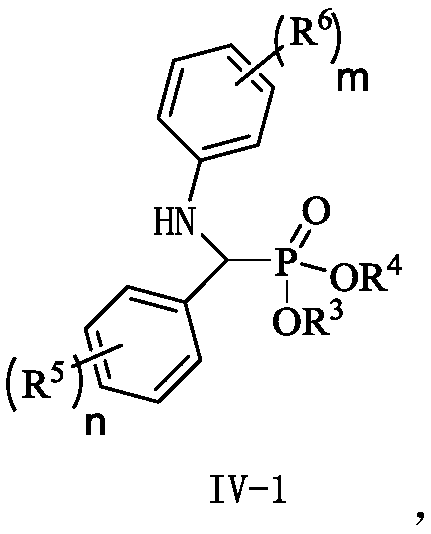

Method for preparing alpha-phosphoramidate compound

ActiveCN109608493AWide variety of sourcesEasy to manufactureOrganic-compounds/hydrides/coordination-complexes catalystsGroup 5/15 element organic compoundsProcess conditionsPhosphoramidate

The invention provides a method for preparing an alpha-phosphoramidate compound. The method comprises the step of subjecting aromatic aldehyde, amine and phosphite to a tri-ingredient domino reactionunder the condition of ionic liquid, thereby preparing the alpha-phosphoramidate compound. The process conditions are simple, the operability is high, and thus, a novel scheme is provided for large-scale production of the alpha-phosphoramidate compound.

Owner:盐城锦明药业有限公司 +1

A continuous drilling equipment for automatic clamping of pcb board

InactiveCN106239613BAchieve clampingRealize automatic clamping workMetal working apparatusEngineeringPrinted circuit board

The invention discloses a printed circuit board (PCB) automatic clamping continuous drilling device which comprises a base, a first conveying device, a second conveying device, a material baffle, a material pushing device, a drilling device, a first driving mechanism, a second driving mechanism, a third driving mechanism, a fourth driving mechanism and a fifth driving mechanism. PCB continuous drilling operation is performed through mutual matching of the base, the first conveying device, the second conveying device, the material baffle, the material pushing device, the drilling device, the first driving mechanism, the second driving mechanism, the third driving mechanism, the fourth driving mechanism and the fifth driving mechanism, PCB clamping fixing time is saved, and the PCB automatic clamping continuous drilling device meets large-scale production requirements of enterprises.

Owner:王沁仪

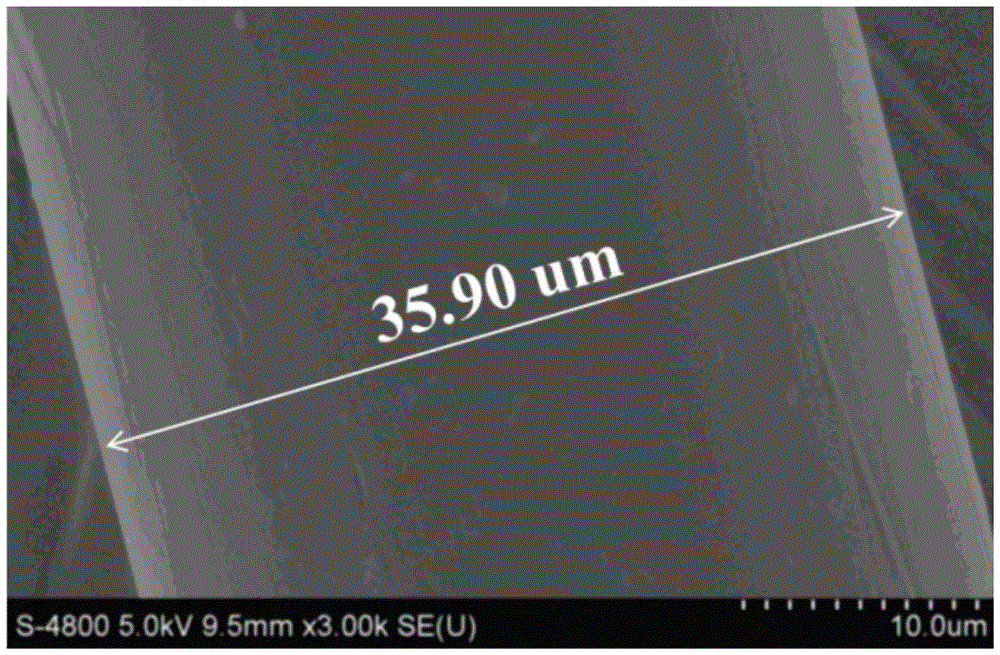

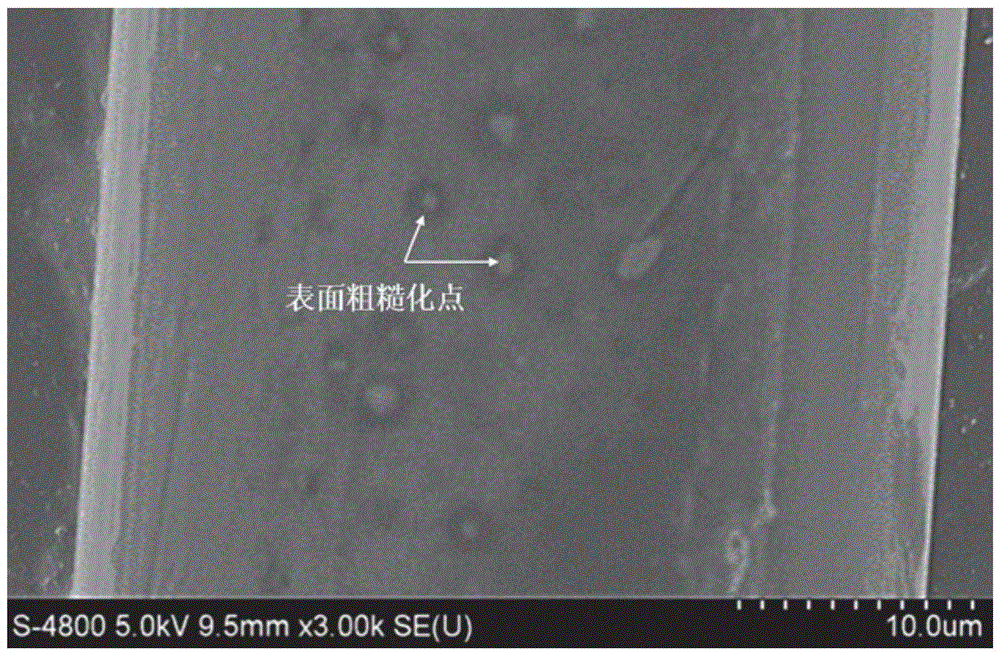

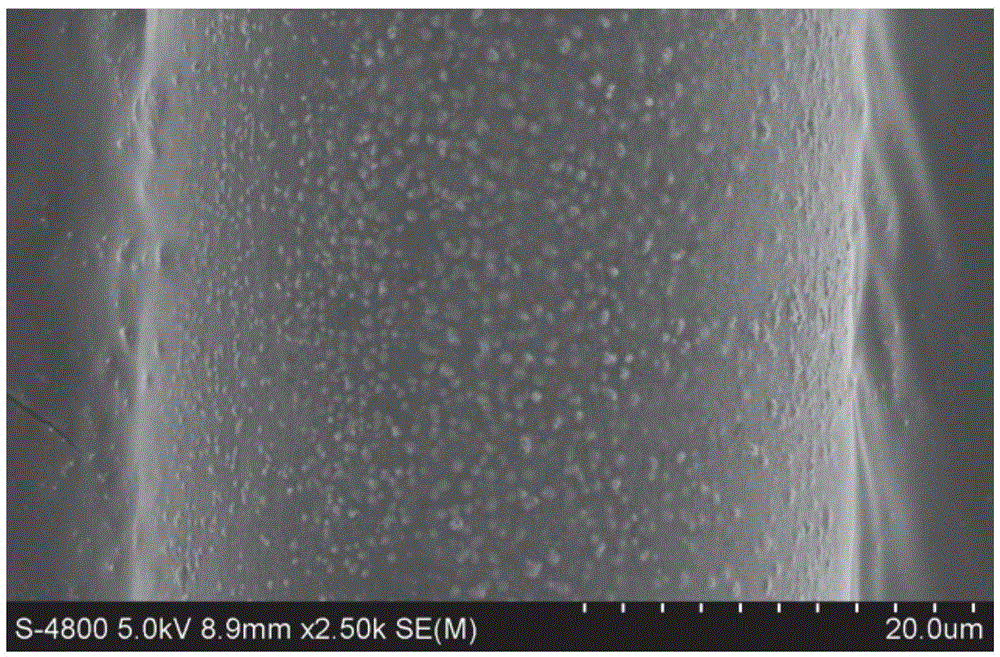

A kind of silver-plated conductive polyester fiber and preparation method thereof

The invention discloses a silver-plated conductive polyester fiber and a preparation method thereof, which belong to the field of conductive fibers. The silver-plated conductive polyester fiber of the invention comprises polyester fiber and a silver layer coated on the surface layer of the polyester fiber, and the polyester fiber and the silver layer There is an ITO layer. The preparation method sequentially includes: washing out of fiber oil, roughening of fiber surface, coating of ITO sol layer, sensitization and silver plating. The present invention introduces an indium tin oxide (ITO) sol layer between the silver layer and the fiber. The introduction of the ITO layer can solve the affinity between the metal simple substance and the fiber polymer on the one hand, and improve the bonding fastness between the silver layer and the fiber. On the other hand, the introduction of this layer realizes the construction of an ITO-Ag composite structure on the surface of the fiber, which can significantly improve the conductivity of the silver-plated conductive fiber while reducing the thickness of the coating. And the process is simple, the condition is mild, and it is suitable for the needs of large-scale production.

Owner:优纤科技(丹东)有限公司

Flocking glue for textile and preparation method of flocking glue

ActiveCN110527465AThe preparation method is simple and easy to operateDevice dependency is smallPolyureas/polyurethane adhesivesMacromolecular adhesive additivesChemistryMoisture resistance

The invention discloses flocking glue for textile. The flocking glue is characterized by comprising components in parts by weight as follows: 30-40 parts of hyperbranched waterborne polyurethane acrylate, 10-20 parts of O-(vinyloxybutyl)-N-(triethoxysilylpropyl)urethane, 8-12 parts of L-menthyl acrylate, 5-10 parts of polynorbornene-2,3-dicarboxylic polytetrahydrofuran glycol ester, 10-15 parts ofacrylic acid-2,3-epoxy propyl ester modified 1-aminobenzotriazole, 5-8 parts of acrylic acid hexahydro-4,7-methylene-1H-indenyl ester, 1-4 parts of an emulsifier, 0.3-0.6 part of an initiator, 5-10 parts of ethanol and 50-60 parts of water. The invention also discloses a preparation method of the flocking glue for textile. The flocking glue for textile has good wear resistance, moisture resistance, water resistance, solvent resistance and heat resistance, good flocking effect, excellent performance stability and high peel strength.

Owner:朱建余

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com