MWT heterojunction silicon solar cell suitable for mass production and preparation method thereof

A silicon solar cell and heterojunction technology, which is applied in the manufacture of final products, circuits, photovoltaic power generation, etc., can solve the problems of short circuit of positive and negative electrodes, complex hole cross-sectional structure, etc., and achieve low equipment investment and production costs, simple and practical methods Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

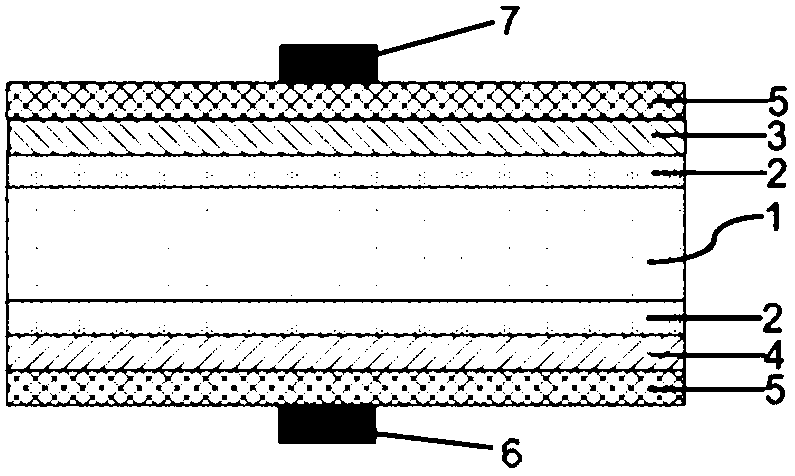

[0033] A method for preparing a MWT heterojunction silicon solar cell suitable for large-scale mass production, comprising the following specific steps:

[0034] (1) Use solar-grade N-type monocrystalline or polycrystalline silicon wafers as substrates;

[0035] (2) Carry out laser opening according to the set layout of the front metal electrode of the solar cell, the shape of the hole is cylindrical, and the diameter is 100-500 μm;

[0036] (3) using a chemical solution to clean and texture the surface of the silicon wafer after opening;

[0037] (4) Prepare an intrinsic amorphous silicon passivation film layer on both sides of the silicon wafer by PECVD, and the thickness of the intrinsic amorphous silicon passivation film layer is 5-20 nm;

[0038](5) N-type amorphous silicon film and P-type amorphous silicon film are respectively prepared on the front and back sides of the silicon wafer on which the intrinsic amorphous silicon passivation film layer is deposited by PECVD ...

Embodiment 2

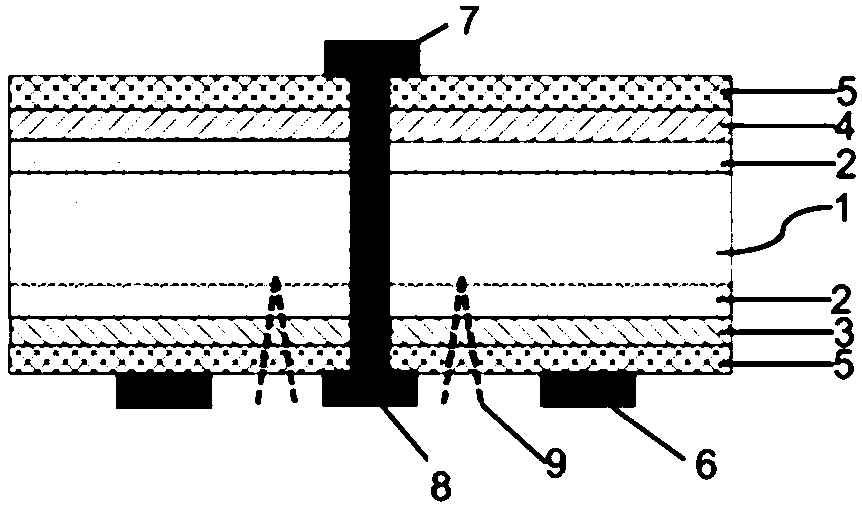

[0045] The present invention comprises the following concrete steps:

[0046] (1) Use solar-grade N-type monocrystalline or polycrystalline silicon wafers as substrates;

[0047] (2) Carry out laser opening from the back surface of the silicon wafer according to the set layout of the front metal electrode of the solar cell. The shape of the hole is an inverted cone, the diameter of the hole on the back surface is 250um, and the diameter of the hole on the front surface is 150um;

[0048] (3) using a chemical solution to clean and texture the surface of the silicon wafer after opening;

[0049] (4) with HNO 3 The method of solution or ozone ultraviolet oxidation is used to treat the front and back sides of the silicon wafer to obtain a thin dense oxide layer with a thickness of 2-10nm;

[0050] (5) N-type amorphous silicon thin-film and P-type amorphous silicon thin-film are respectively prepared on the front and back sides of the silicon wafer by PECVD. , the P-type amorpho...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com