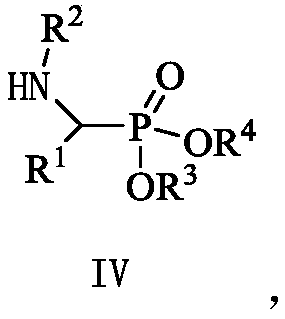

Method for preparing alpha-phosphoramidate compound

A compound and phosphite technology, applied in chemical instruments and methods, compounds of Group 5/15 elements of the periodic table, organic compounds/hydrides/coordination complex catalysts, etc., can solve the problems of difficult recycling and catalyst preparation The process is complicated and cannot be recycled, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

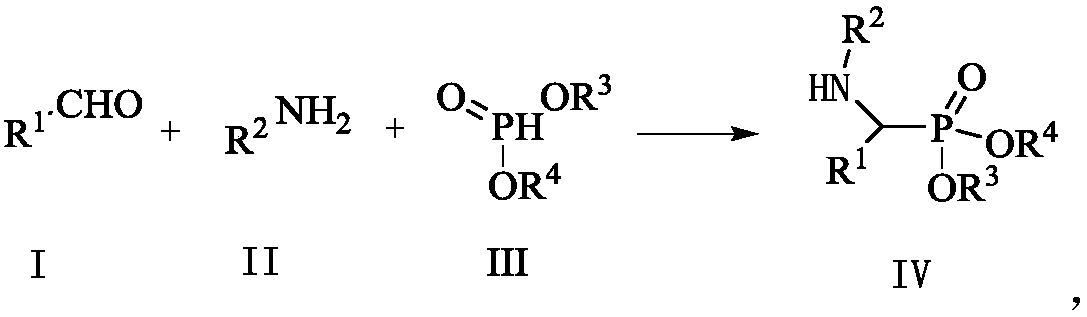

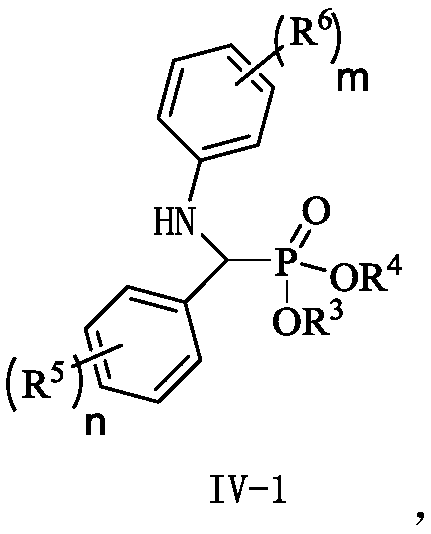

Method used

Image

Examples

Embodiment 1

[0081] Preparation of catalyst (ionic liquid):

[0082] Put 7.91g of triethylamine and 15.10g of trinitromethane in a 100mL round-bottomed flask and stir for 1-2 hours at normal temperature and pressure to obtain 23.01g of yellow liquid with a yield of 100%.

Embodiment 2

[0084] In a 25mL round bottom flask, add 10mmol (1.06g) benzaldehyde, 10.2mmol (0.95g) aniline, 10.3mmol (1.28g) trimethyl phosphite, 0.5mmol the catalyst prepared by Example 1, room temperature (15 ~25°C) for stirring and reacting for 30 minutes, adding water to quench the reaction, filtering, washing, and recrystallizing with an appropriate amount of ethanol to obtain α-anilino-benzyl dimethyl phosphate with a yield of 95%. The aqueous phase was washed twice with 2 mL of ethyl acetate, separated, and distilled at atmospheric pressure to recover the catalyst.

Embodiment 3

[0086] In a 250mL round bottom flask, add 10mmol (1.36g) 4-methoxybenzaldehyde, 10mmol (1.38g) 4-nitroaniline, 12mmol (1.32g) trimethyl phosphite, 0.01mmol catalyst, room temperature ( Stir the reaction at 15~25°C for 30 minutes, add water to quench the reaction, filter, wash, and recrystallize with an appropriate amount of ethanol to obtain α-(4-nitroanilino)-(4-methoxyphenyl)methylphosphoric acid di Methyl ester, yield 95%. The aqueous filtrate was washed twice with 2 mL of ethyl acetate, separated, and the water was distilled off under reduced pressure at a vacuum of 0.095 MPa to recover the catalyst.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com