Method and device for producing high-purity antimony

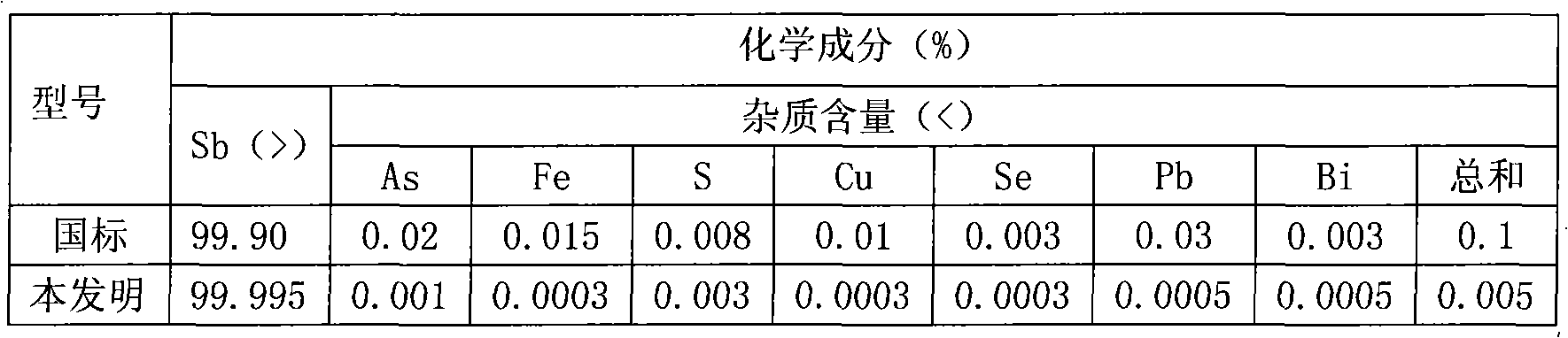

A high-purity, crucible technology, applied in the field of high-purity antimony production, can solve the problems of labor-intensive, serious impurity reflux, easy softening, etc., and achieve the effect of simple equipment processing, good condensation effect and high product purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

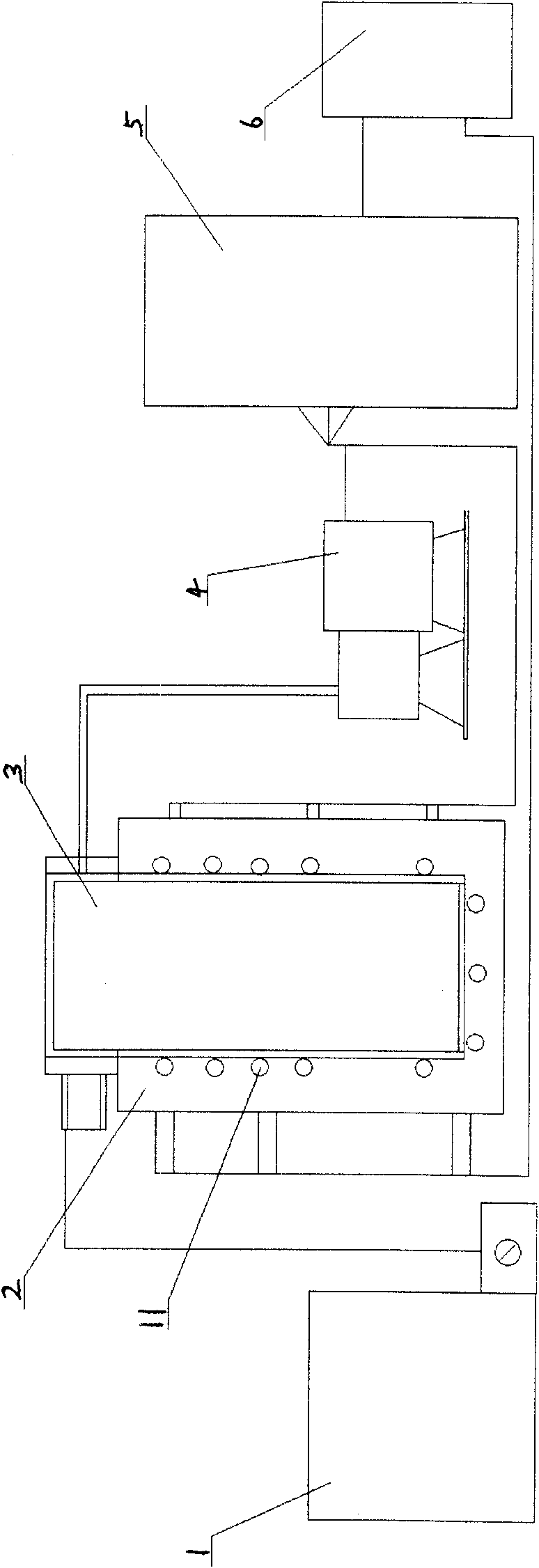

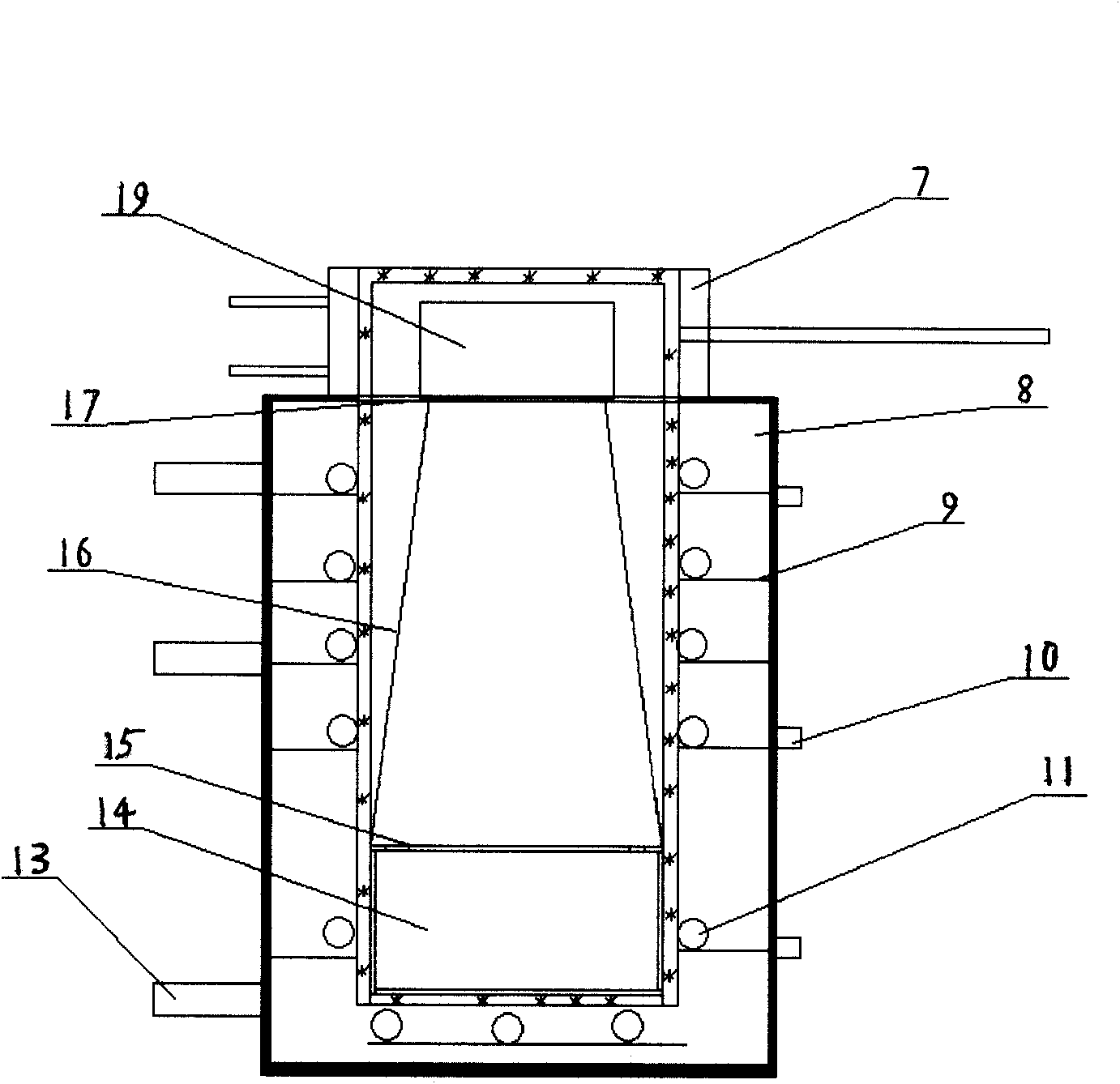

[0014] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0015] The specific technological process of the present invention is as follows: first step, put the crude antimony into the crucible, then put the crucible into the vacuum tank, place the conical titanium plate on the crucible cover, cover the stainless steel cover and stainless steel sealing sleeve, close the Put on the lid of the vacuum tank, turn on the water cooling system, and start the vacuum pump; control the vacuum degree below 13Pa; the second step, control the temperature at the bottom of the crucible at 600-900 degrees, the middle temperature at 500-650 degrees, and the upper temperature at 350- 450 degrees, keep warm for 1 to 3 hours, so that the impurities such as arsenic with low boiling point are volatilized first. Since the hollow stainless steel sealing sleeve is in the position of the water jacket, the temperature is low, so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com