Device and method for sealing, grouting, and reinforcing broken coal-rock masses

A technique of crushing coal and rock mass and grouting reinforcement, which is applied in shaft equipment, earthwork drilling, sealing/separation, etc., can solve the problems that cannot be widely used, poor grouting effect, and poor hole sealing, etc., and achieve Good sealing effect, low production cost and low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

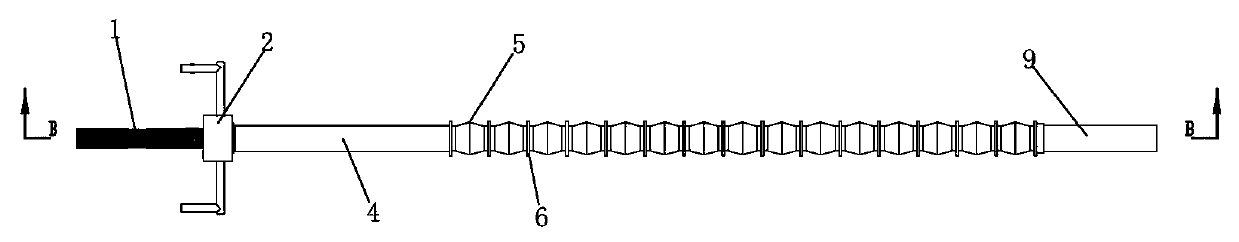

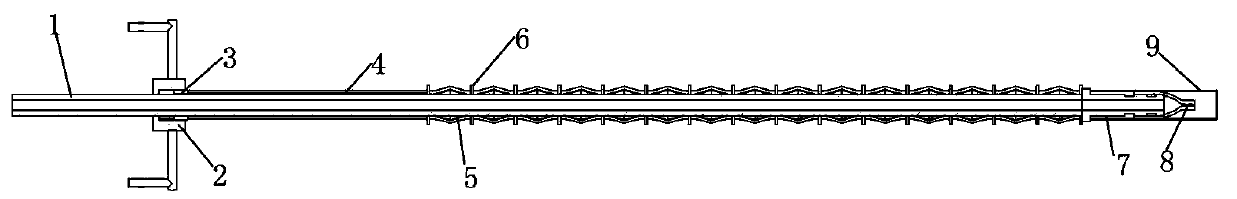

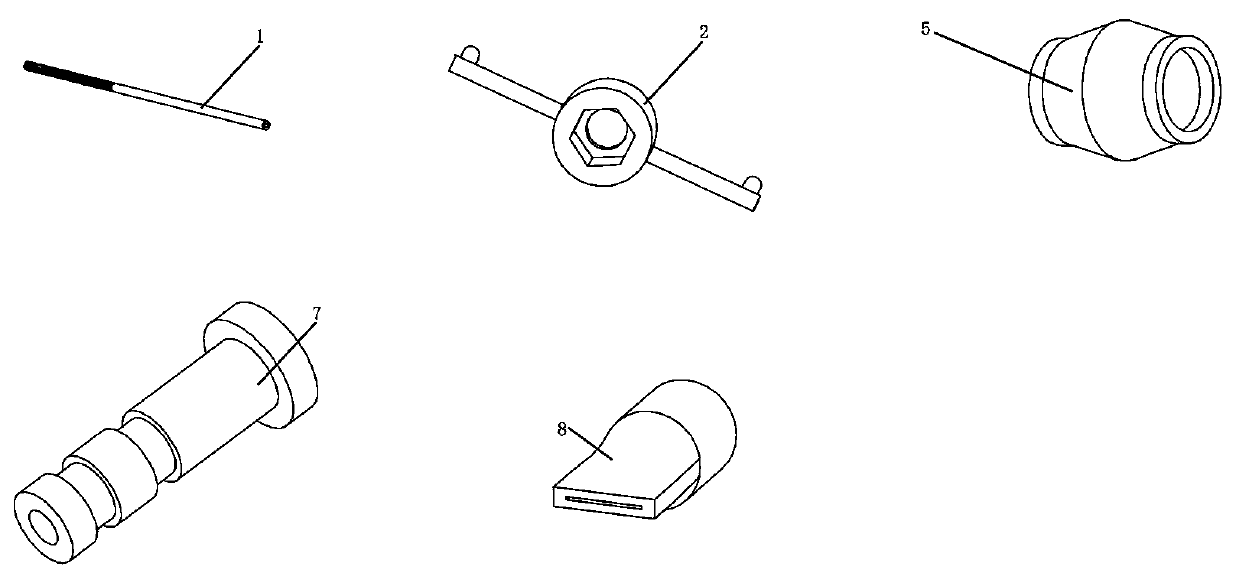

[0028] Such as figure 1 , figure 2 with image 3 As shown, a kind of soft coal and rock body sealing grouting device comprises a grouting pipe 1, the grouting pipe 1 is a hollow steel pipe, and its left end is provided with an external thread, and a nut 3 is screwed on the external thread section of the grouting pipe 1; The tail joint 7 is composed of a ring connector and a short tube, one end of the short tube is welded to the ring connector, and two ring grooves are arranged side by side at the other end; the tail joint 7 is welded through the other side of the ring connector At the right end of the grouting pipe 1 and the axes of the short pipe, the ring connector, and the grouting pipe coincide; the tail end protection tube 9 is sleeved on the periphery of the tail end joint 7 and one end is welded with the ring connector; the duckbill The valve 8 is an integrally formed structure made of rubber, including a duckbill and a cylindrical bottom, and two circular convex lin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com