Coating removing method for diamond coated tool

A diamond coating and cutting tool technology, applied in metal material coating process, coating, gaseous chemical plating, etc., to achieve high production efficiency and excellent decoating quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

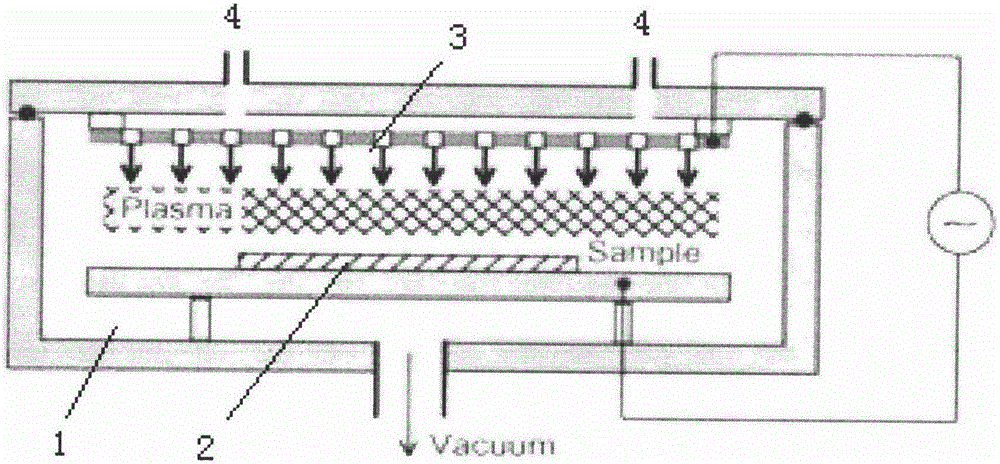

[0018] This embodiment takes the diamond-coated finishing end mill after wear as an example, and is applicable to all diamond-coated tools. The decoating process is carried out in plasma-enhanced chemical vapor deposition equipment. The specific decoating process is as follows:

[0019] (1) Fix the worn diamond-coated tool 2 on the sample stage of the vacuum chamber of the plasma-enhanced chemical vapor deposition equipment.

[0020] (2) Evacuate the vacuum chamber 1 of the plasma-enhanced chemical vapor deposition equipment to below 1-5×10-3Pa. The equipment adopts the plasma beam generated by 36Hz microwave, heats it to between 350-420°C, opens the gas inlet 4, and Oxygen, Cl 2 , ClO 2 The mixed gas with HCl is input into the vacuum chamber, the input speed of the gas is more than 0.6 liters / minute, the processing time is 10-15 min, and the working pressure is not lower than 100Pa when the gas is injected for processing. Simultaneously activate the plasma-enhanced plasma ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com