Automatic bean curd drying and forming machine

A tofu skin and forming machine technology, applied in cheese substitutes, dairy products, applications, etc., can solve the problems of complex equipment structure, low production efficiency, inconvenient maintenance and operation, etc., and achieves reasonable and simple structure, easy implementation, and improved hygiene. Environmental and product quality effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

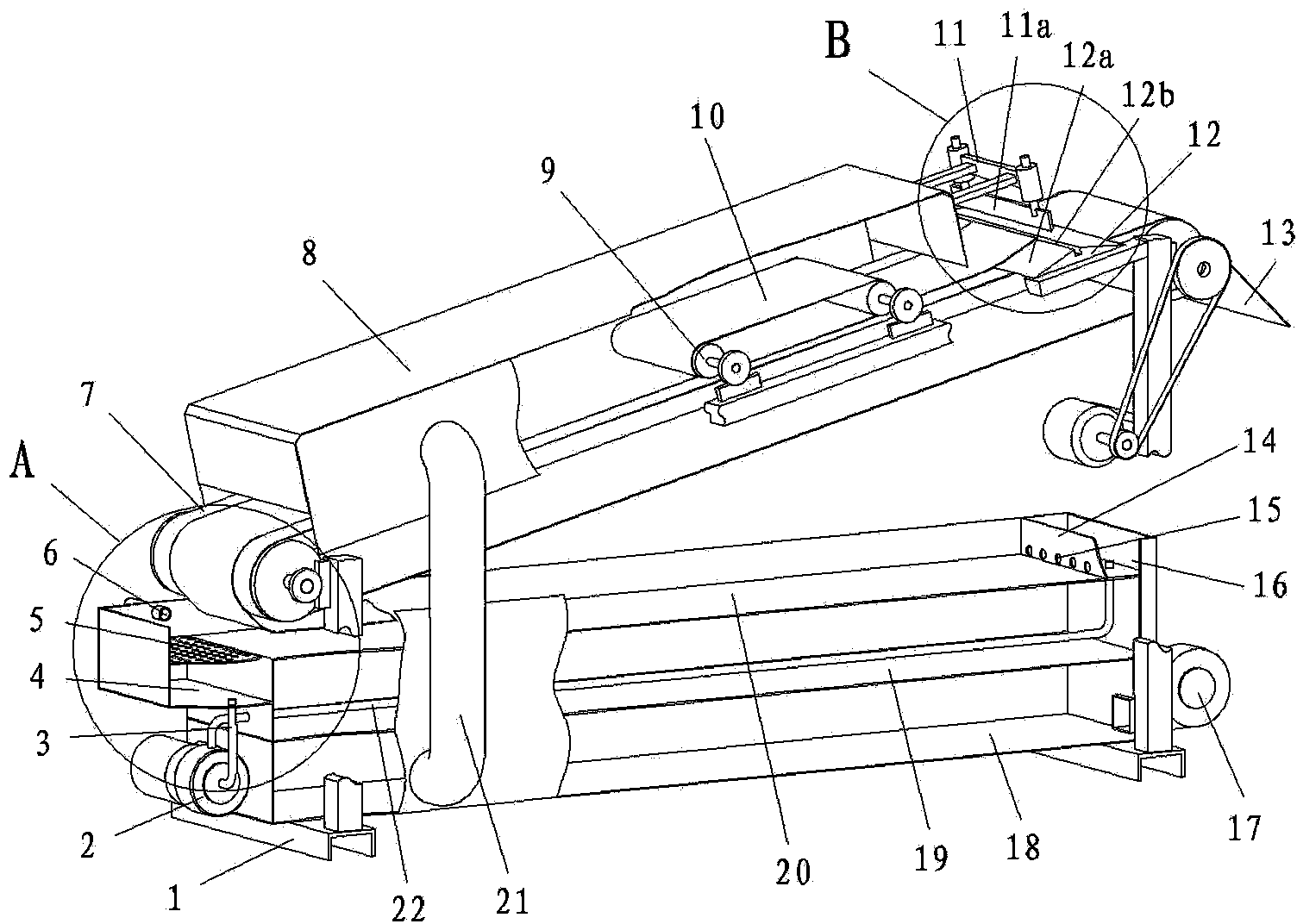

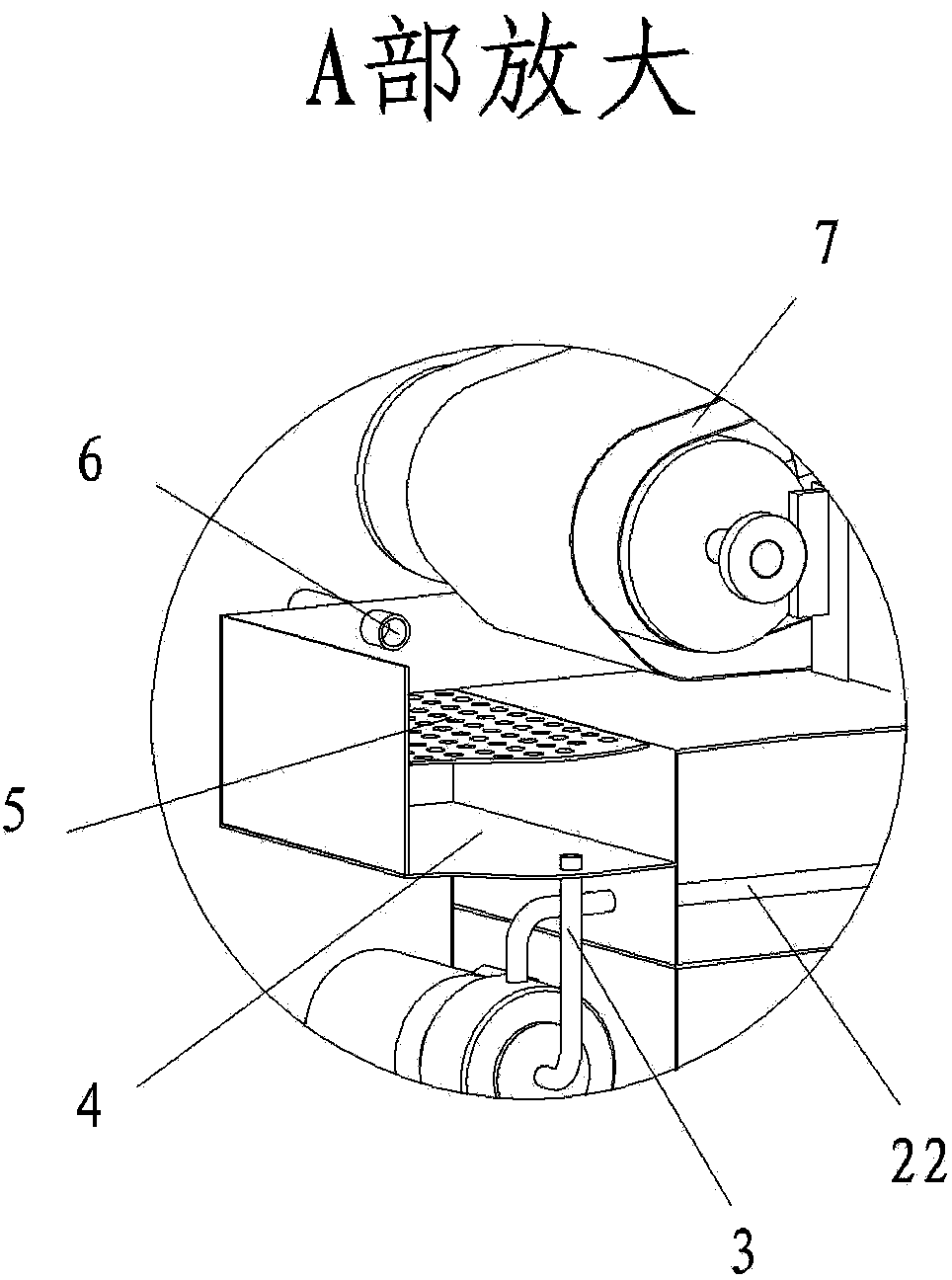

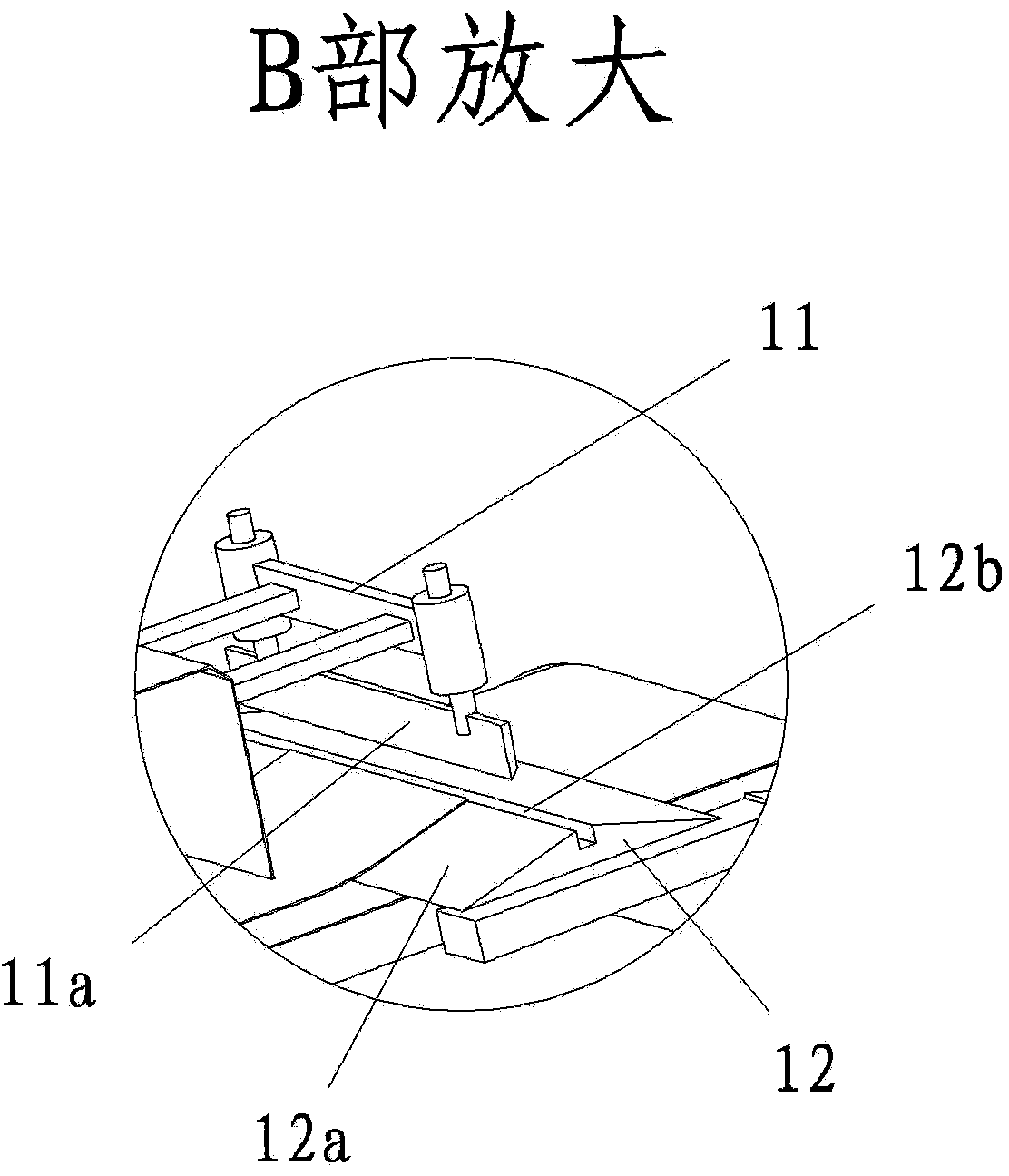

[0020] Such as figure 1 , figure 2 , image 3 Shown, a kind of bean curd skin automatic drying molding machine provided by the present invention, it comprises: frame 1 and hot air chamber 18 on it, heating chamber 19, crust groove 20, conveying device and drying tunnel 8, hot air chamber, The main body of the heating chamber and the crusting tank is made of H-shaped steel, which is integrated into a three-layer elongated container. The upper layer is the crusting tank with an open top, the middle is the heating chamber, and the lower layer is the hot air chamber. This structure can make the heating chamber The heat is transferred to the crusting tank and the hot air chamber to make full use of it. The conveying device is set along the top of the crusting tank. The front end is close to the crusting tank, and the rear end is a distance away from the top of the crusting tank. The conveyor belt on the conveying device is cotton cloth Belt; one end of the skinning tank is provi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com