Method for manufacturing diamond-like film and part with coating manufactured thereby

A manufacturing method and diamond technology, applied in the direction of gaseous chemical plating, metal material coating process, coating, etc., can solve the problems of complex rotation and difficulty of the substrate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

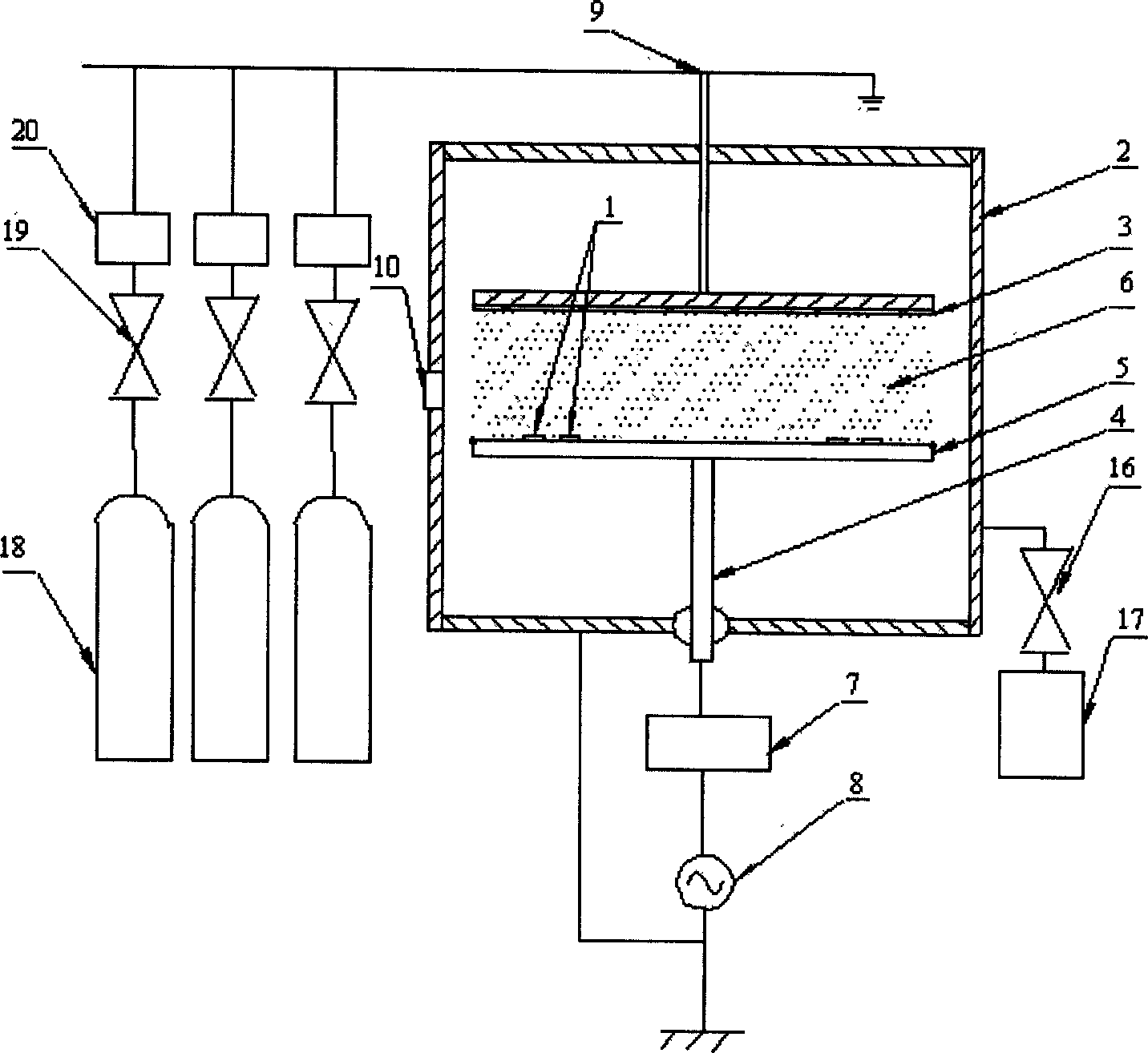

[0037] Embodiment 1: Deposit Ti / TiN / TiC / DLC composite carbon film on stainless steel sheet

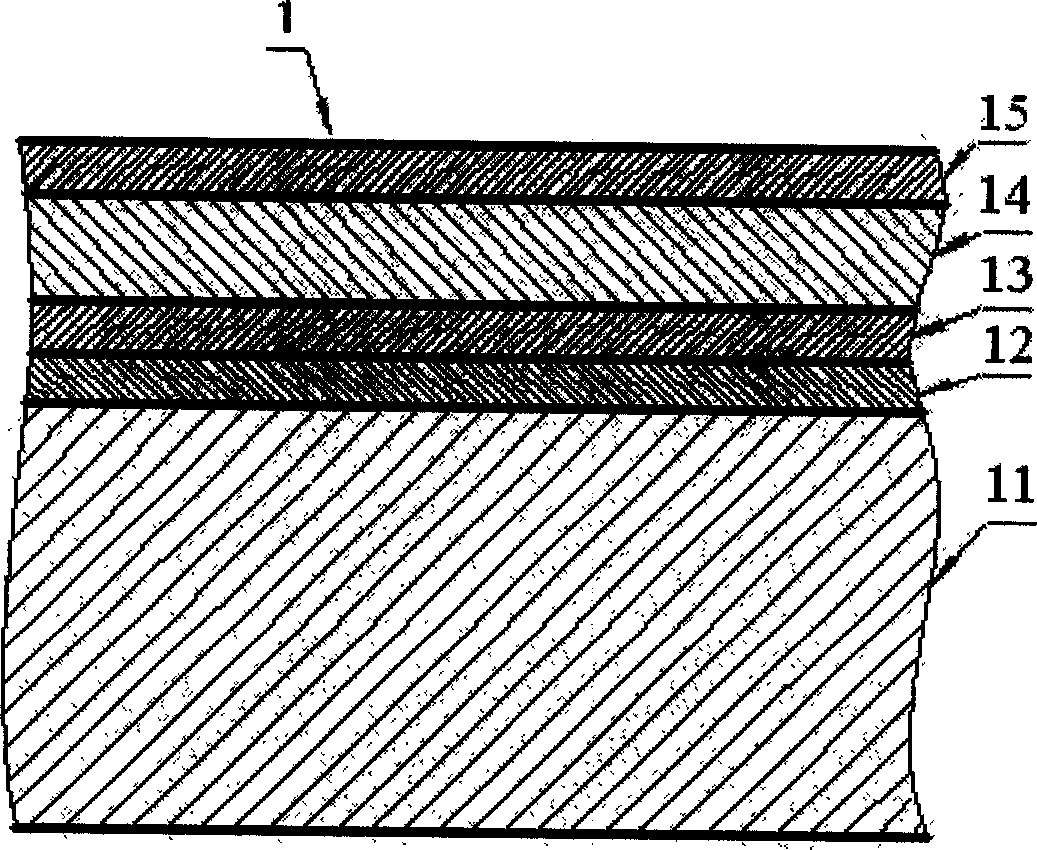

[0038] figure 1 One of the DLC film-clad components 1 has a substrate 11, a metal film 12, a nitride film 13, a carbide film 14 and a carbon film 15 superimposed on at least a part of the substrate 11, which are sequentially deposited on the substrate.

[0039] The base 11 is made of stainless steel (such as 1Cr18Ni9Ti). The metal layer contains one or several elements that make up the base. In this example, the metal layer, nitride layer, and carbide layer are Ti, TiN, and TiC, respectively. The carbon film 15 is a DLC film. In this example, the metal film 12, the nitride film 13 and the carbide film 14 were formed using a rotary magnetron arc ion plating deposition device (see Table 1 for general growth conditions of samples).

[0040] Work step

Current (A)

Pressure (Pa)

Substrate temperature (℃)

the gas

time (min)

Ti

150

5.0*10 -1 ...

Embodiment 2

[0061] Example 2 Deposition of Ti / TiN / TiC / DLC composite carbon film on stainless steel sheet with magnetron sputtering combined with RFPECVD equipment

[0062] On the basis of the RFPECVD equipment of the present invention in preceding example 1, magnetron sputtering is combined with PECVD equipment, thereby realized the deposition diamond-like carbon film and intermediate transition layer (as metal, nitride, carbide) on a piece of equipment etc.) to improve the deposition efficiency.

[0063] Figure 6The shown RFPECVD apparatus includes a cylindrical plasma generation chamber 37 (upper part) and a similarly cylindrical plasma processing chamber 38 (lower part), and these form a vacuum chamber (film formation chamber). The two chambers are on the same axis, and the two chambers are connected up and down. The plasma generation chamber 37 is provided with an antenna-shaped RF coil 31 along its outer wall, and the coil connector 28 is connected to a matching box and a 13.56 MH...

Embodiment 3

[0071] Embodiment 3 deposits Cr / CrN / CrC / DLC composite carbon film on razor blade

[0072] On the basis of the RFPECVD equipment in Example 2, microwave ECR, inductive coupling and plasma generation equipment are combined to improve deposition efficiency.

[0073] Figure 8 The RFPECVD device shown is driven by an RF power source, using microwaves to excite the reactive gas into a plasma state, and at the same time, under the contraction of the magnetic field to confine the space plasma, an electron cyclotron wave resonance plasma is formed to achieve the purpose of accelerating film formation .

[0074] In this device, metal films, metal nitride films, and metal carbides can be deposited on the surface of different substrates by using the effective sputtering of high-energy ions on the target under the confinement of the magnetic field and the chemical reaction in the high ionization rate plasma environment. Films and diamond-like carbon films can deposit composite film syst...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com