Preparation method of low-temperature multi-component composite coating based on plasma enhancement and rare earth modification technology

A rare earth modification, plasma technology, applied in coating, ion implantation plating, metal material coating process, etc., can solve the problems of short service life, low temperature coating adhesion, etc., to improve the adhesion, bombardment The effect of low power and strong bombardment effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

[0021] This implementation takes a sewing machine shuttle as an example to conduct a low-temperature multi-component composite coating based on plasma enhancement and rare earth modification technology.

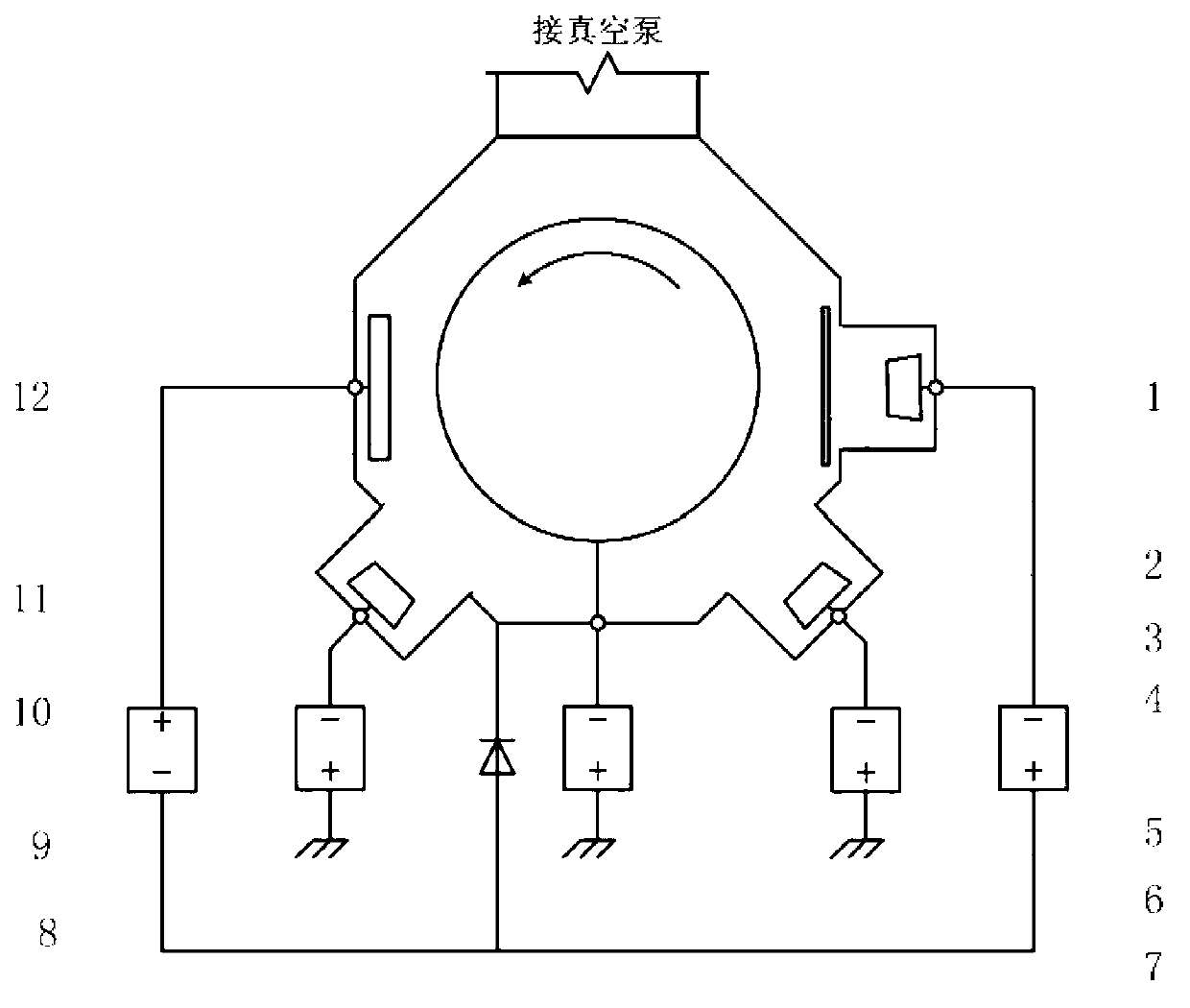

[0022] refer to figure 1 , the plasma-enhanced coating device that the present invention relates to comprises a vacuum chamber 1 and a vacuum obtaining device, a rotating workpiece table 12 is provided in the center of the vacuum chamber 1, and three cathode arc targets (2 , 4, 10); the cathodic arc target 2 has a blocking screen 3, and an auxiliary anode device 11 is provided directly opposite the cathodic arc target 2. A rotary arc ion plating plasma enhanced coating system is composed of a rotary workpiece table 12, three cathode arc targets, an auxiliary anode and a vacuum chamber 1.

[0023] The principle of plasma enhanced coating deposition method of the present invention is:

[0024] The vacuum chamber of the plasma-enhanced coating device is equipped with a cathodi...

specific Embodiment 2

[0031] This embodiment relates to a paper cutter used on a receipt machine of a certain type, which is divided into an upper blade and a lower blade. It was originally made of imported high-speed steel sheets. When cutting about 400,000 bills, the tip of the blade was blunted, and the edges of the cut bills were fuzzy and irregular, which did not meet customer requirements.

[0032] Due to the high hardness of the high-speed steel sheet and the difficulty in processing, the production cost of this paper cutter is high. However, end customers require that the service life of the blade be more than 600,000 pieces, and hope to reduce processing difficulty and cost. In order to meet customer requirements, not only reduce costs, but also improve the service life of blades, consider replacing materials, and adopt plasma multi-component composite coating technology. Considering the service conditions of the blade and the requirements for strength and toughness, it is appropriate to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hardness | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com