Preparation method of compressor blade coating and surface modifier

A technology of surface modification and compressor, which is applied in the direction of coating, superimposed layer coating, metal material coating process, etc., can solve the problems of poor uniformity of coating, insufficient comprehensive protection performance of blade surface, etc., and achieve high temperature resistance Corrosion and erosion ability, the effect of improving poor deposition uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

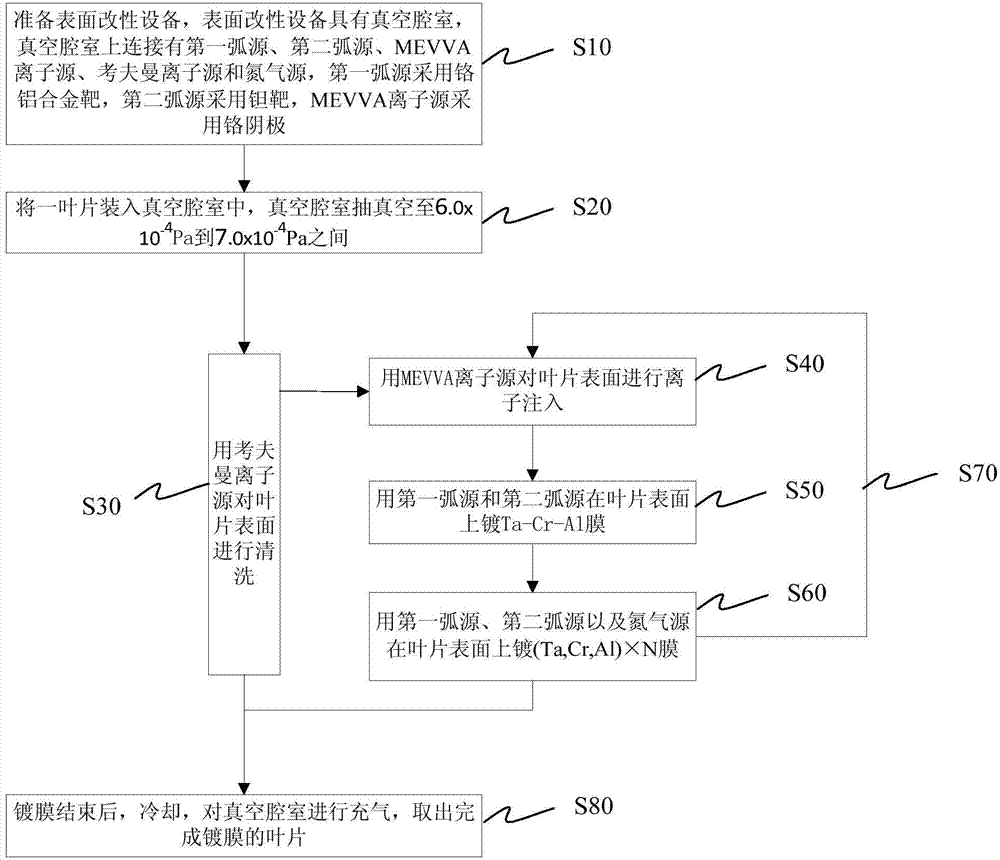

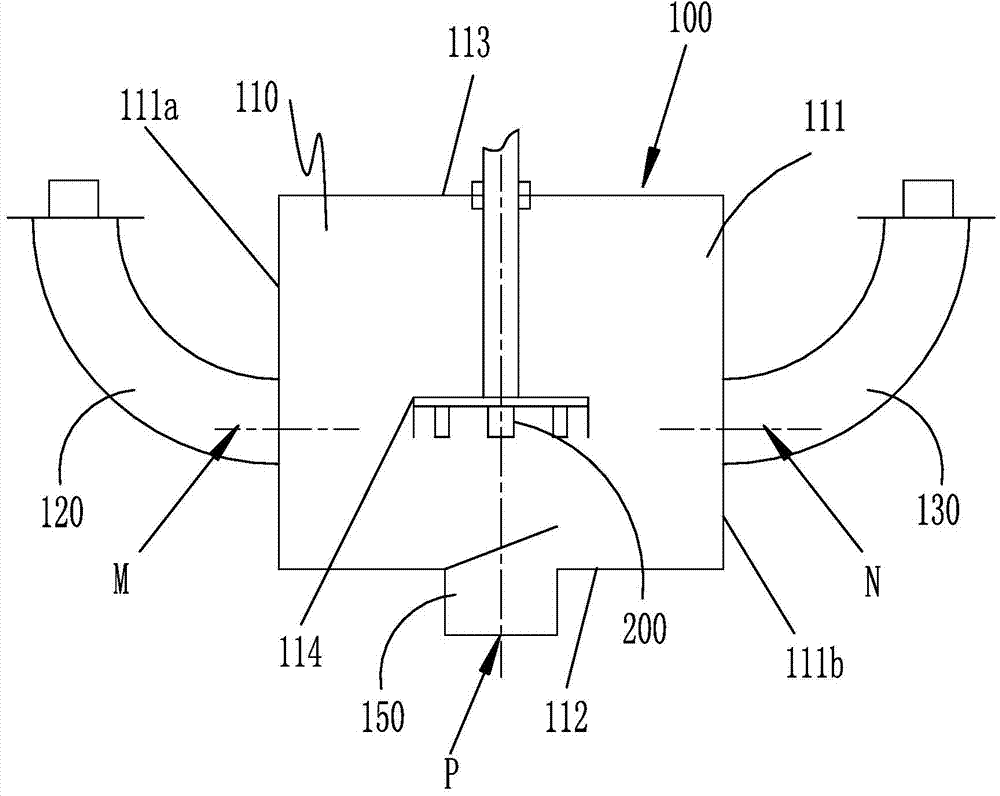

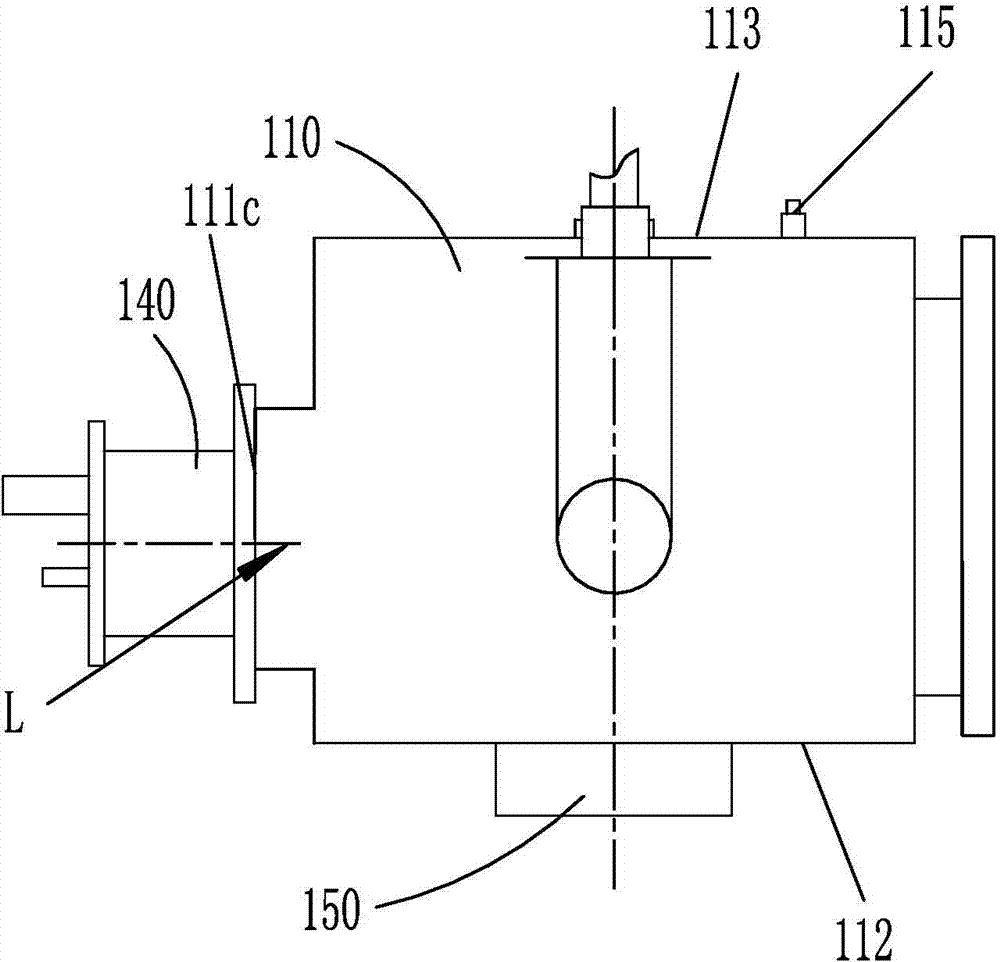

[0065] The preparation method of compressor blade coating of the present invention is as figure 1 shown. refer to Figure 2 to Figure 4 , Figure 2 to Figure 4 In order to realize the surface modification equipment for the preparation of the compressor blade coating of the present invention, the surface modification equipment of the compressor blade coating of the present invention will be firstly described below.

[0066] The surface modifying device 100 for the coating of compressor blades of the present invention is used for coating the compressor blades. As shown, the surface modification apparatus 100 of the present invention includes a vacuum chamber 110, a first arc source 120, a second arc source 130, a MEVVA ion source 140, a Kaufmann ion source 150 and a nitrogen gas source. The blade 200 is disposed in the vacuum chamber 110, and the vacuum chamber 110 includes a side wall 111 (see Figure 4 ) and the bottom wall 112, the first arc source 120, the second arc sou...

Embodiment 1

[0078] Step 10, loading the blade to be treated into the surface modification equipment. The arc source on the left side of the equipment adopts chromium-aluminum alloy target, the mass percentage content is 90% chromium-10% aluminum, and the purity is 99.8%; the arc source on the right side of the equipment adopts tantalum target, the purity is 99.8%; the MEVVA ion implantation source adopts chromium cathode, The purity is 99.8%.

[0079] Step 20: Close the furnace, turn on the mechanical pump and molecular pump, turn on the circulating water system, and evacuate to 6.0×10 -4 Pa, start crafting.

[0080] Step 30, cleaning the blade surface with a Kaufman ion source. The specific control parameters are: the ion beam energy is increased from 5kV to 30kV, and the sputtering time is 10min.

[0081] Step 40, using the MEVVA source to perform ion implantation on the surface of the blade. The specific control parameters are: the metal ion source trigger frequency is 10Hz, the ar...

Embodiment 2

[0087] Step 10, loading the blade to be treated into the surface modification equipment. The arc source on the left side of the equipment adopts chromium-aluminum alloy target, the mass percentage content is 90% chromium-10% aluminum, and the purity is 99.8%; the arc source on the right side of the equipment adopts tantalum target, the purity is 99.8%; the MEVVA ion implantation source adopts chromium cathode, The purity is 99.8%.

[0088] Step 20, close the furnace, turn on the mechanical pump and molecular pump, turn on the circulating water system, and evacuate to 7.0×10 -4 Pa, start crafting.

[0089] Step 30, cleaning the blade surface with a Kaufman ion source. The specific control parameters are: the ion beam energy is increased from 5kV to 30kV, and the sputtering time is 30min.

[0090] Step 40, using the MEVVA source to perform ion implantation on the surface of the blade. The specific control parameters are: the metal ion source trigger frequency is 15Hz, the ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com