Graphene and metal nanoparticle composite film preparation method

A technology of metal nanoparticles and graphene films, applied in nanotechnology, nanotechnology, nanotechnology, etc. for materials and surface science, can solve problems unfavorable to the sustainable development of the photovoltaic industry, and achieve the expansion of usage and industry globalization prospects, diversification of preparation methods, and reduction of preparation costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Graphene prepared by chemical vapor deposition and transferred to quartz substrates

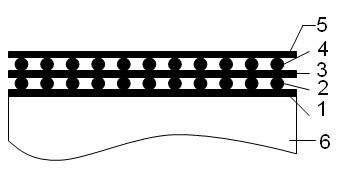

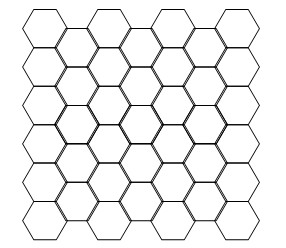

[0037] First, put the cleaned 50 micron copper foil horizontally into a vacuum tube furnace, and heat the tube furnace from 30°C to 1000°C for 70 minutes. Then, 40 ml / min of argon and 40 ml / min of hydrogen were introduced as a protective atmosphere. Insulate at 1000°C for 30 minutes. Then feed 10 ml / min of methane and 30 ml / min of hydrogen into the tube furnace, and adjust the pressure to 130 Pa. The time is 10 minutes. Decline to room temperature with 15 DEG C per minute afterwards, complete the growth of graphene thin film 1. Graphene microstructure diagram see figure 2 . After the growth is completed, the graphene obtained by the growth is spin-coated with a layer of polymethyl methacrylate organic solvent, and then placed on a heating table at 120 ° C for 2 minutes. Then put in 0.5 moles per liter of ammonium persulfate solution Corrosion removes copper. After that, the poly...

Embodiment 2

[0039] Fabrication of Metal Nanoparticle Thin Films by Electrophoresis

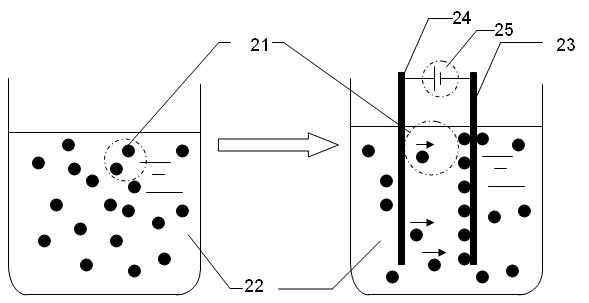

[0040] First in 7.5 milliliters concentration is the hexadecyltrimethylammonium bromide of 0.1 mole per liter, add 0.25 milliliter concentration and be the auric acid solution of 0.01 mole per liter, then add 0.6 milliliter concentration and be 0.01 mole per liter of hydroboration The sodium solution forms a gold seed solution. In the beaker, add 38 milliliters of ionized water, 8 milliliters of concentration of 0.1 moles per liter of hexadecyltrimethylammonium bromide, 1 milliliter of auric acid of 0.01 moles per liter, 3 milliliters of 0.01 moles of per liter of 1 liter of ascorbic acid to form a growth solution, and then 10 microliters of the gold seed solution was dropped into the above growth solution and stirred, and the gold nanoparticles 21 and the solution 22 were grown to obtain gold nanoparticles. Graphene / quartz substrate composite thin film 23 is used as the negative pole of DC electrode in ...

Embodiment 3

[0042] Fabrication of Metal Nanoparticle Thin Films by Vacuum Evaporation

[0043] Adopt vacuum evaporation method to prepare a layer of 1 to 20 nanometer thick gold nano film 26 on the surface of graphene film and quartz substrate composite film 23, and obtain gold by annealing at a high temperature of 450 ° C for 30 minutes in a nitrogen or hydrogen furnace. Nanoparticles 21, completing the preparation of the first metal nanoparticle film layer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com