Method for manufacturing low-temperature polysilicon thin-film transistor

A polysilicon thin film and thin film transistor technology, which is applied in semiconductor/solid-state device manufacturing, optics, instruments, etc., can solve problems such as poor step coverage, easy generation of holes, and differences in protection capabilities, so as to improve electrical performance and reliability , good ladder coverage, and increased protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

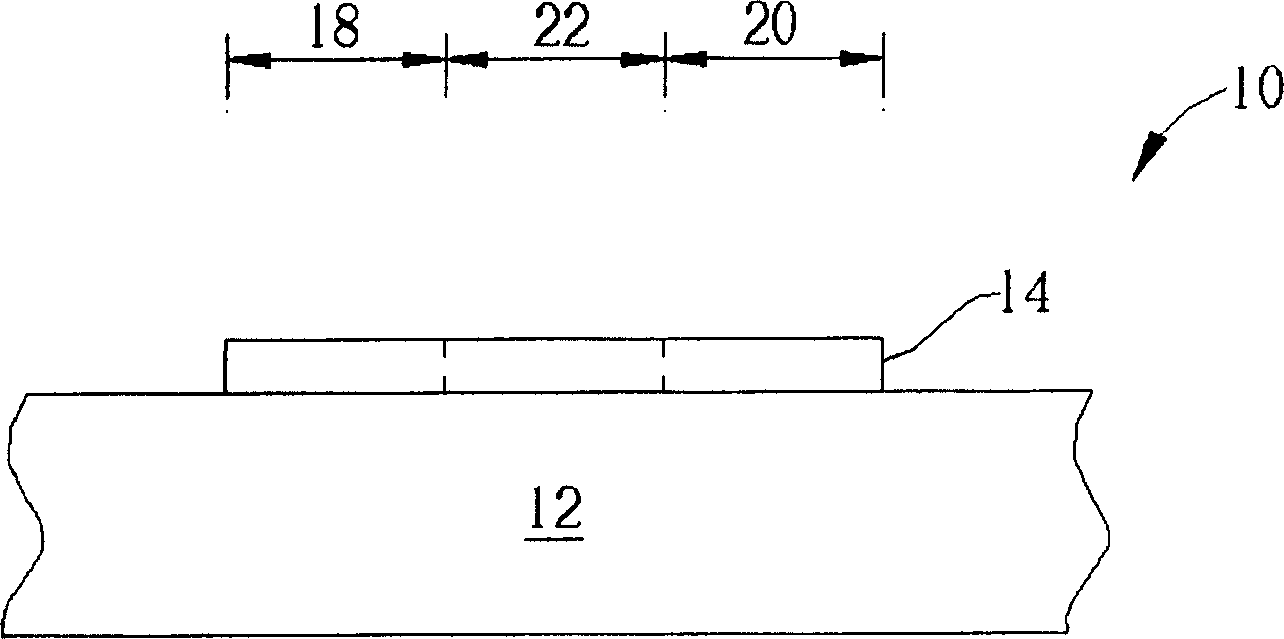

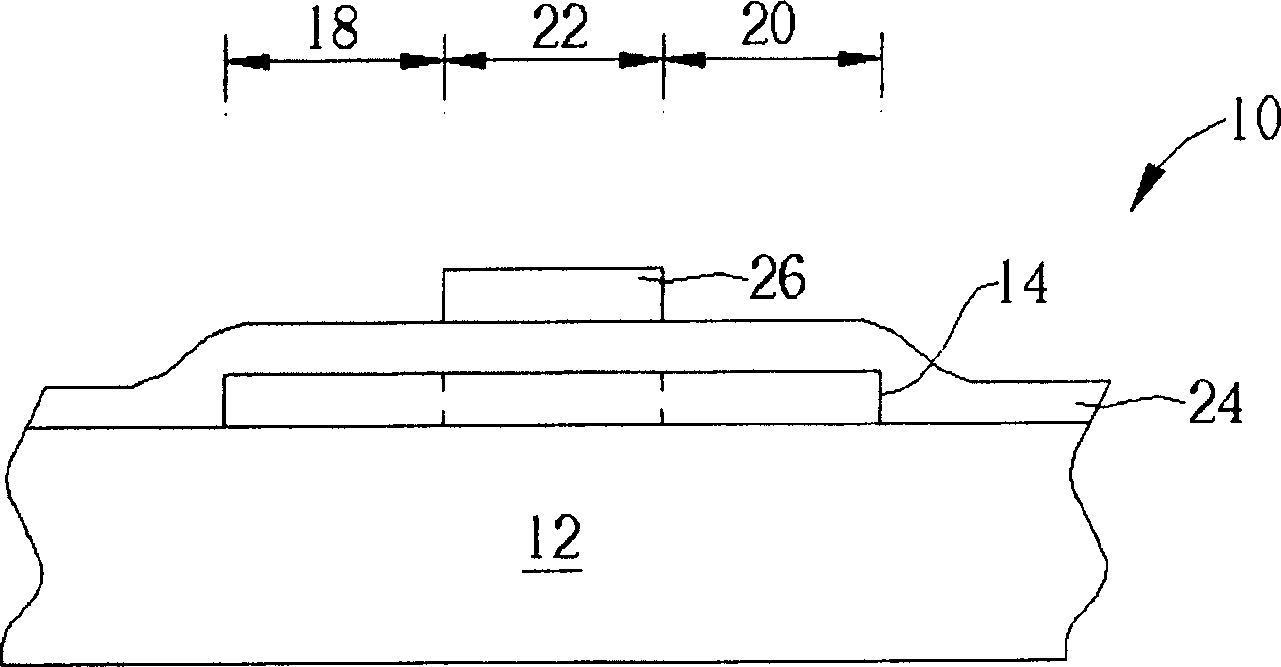

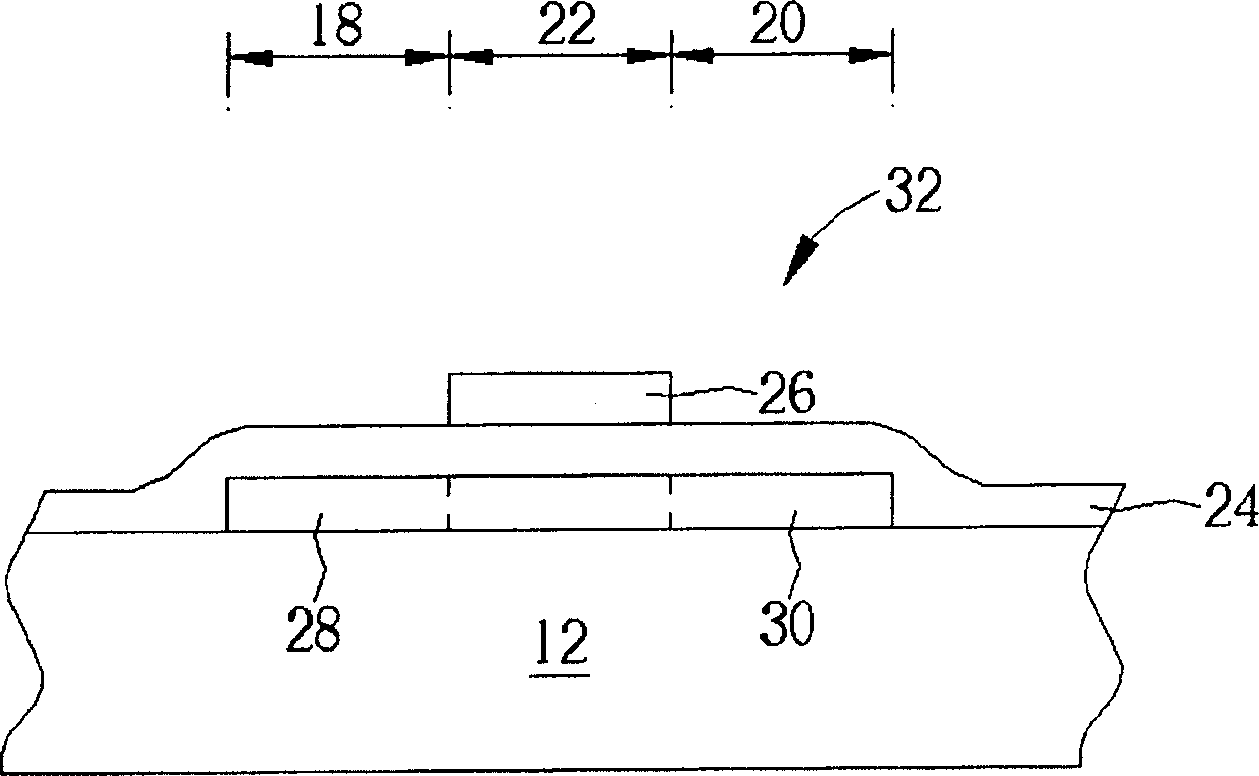

[0039] Please refer to Figure 5 to Figure 8 , Figure 5 to Figure 8 It is a schematic diagram of a method for fabricating a low-temperature polysilicon thin film transistor according to the present invention. As mentioned above, a display panel usually includes a plurality of low temperature polysilicon thin film transistors to respectively drive the pixel electrodes on the display panel. For the convenience of illustration, only one low temperature polysilicon thin film transistor is represented in the following figures. Such as Figure 5 As shown, a chemical vapor deposition process or a sputtering process is first performed to form an amorphous silicon film (not shown) with a thickness of about 500 angstroms on a display panel 110, and an excimer laser annealing process (excimer laser annealing process) to recrystallize the amorphous silicon thin film into a polysilicon thin film 114, and then perform a first photolithography and etching process to pattern the polysilico...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com