Secondary airtightness sealing method of quantum dot On-chip white light LED

An encapsulation method and technology of quantum dots, applied in electrical components, circuits, semiconductor devices, etc., can solve the problems of poor air tightness and poor performance, achieve improved luminous efficiency, high luminous efficiency and high stability, improved luminous efficiency and The effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

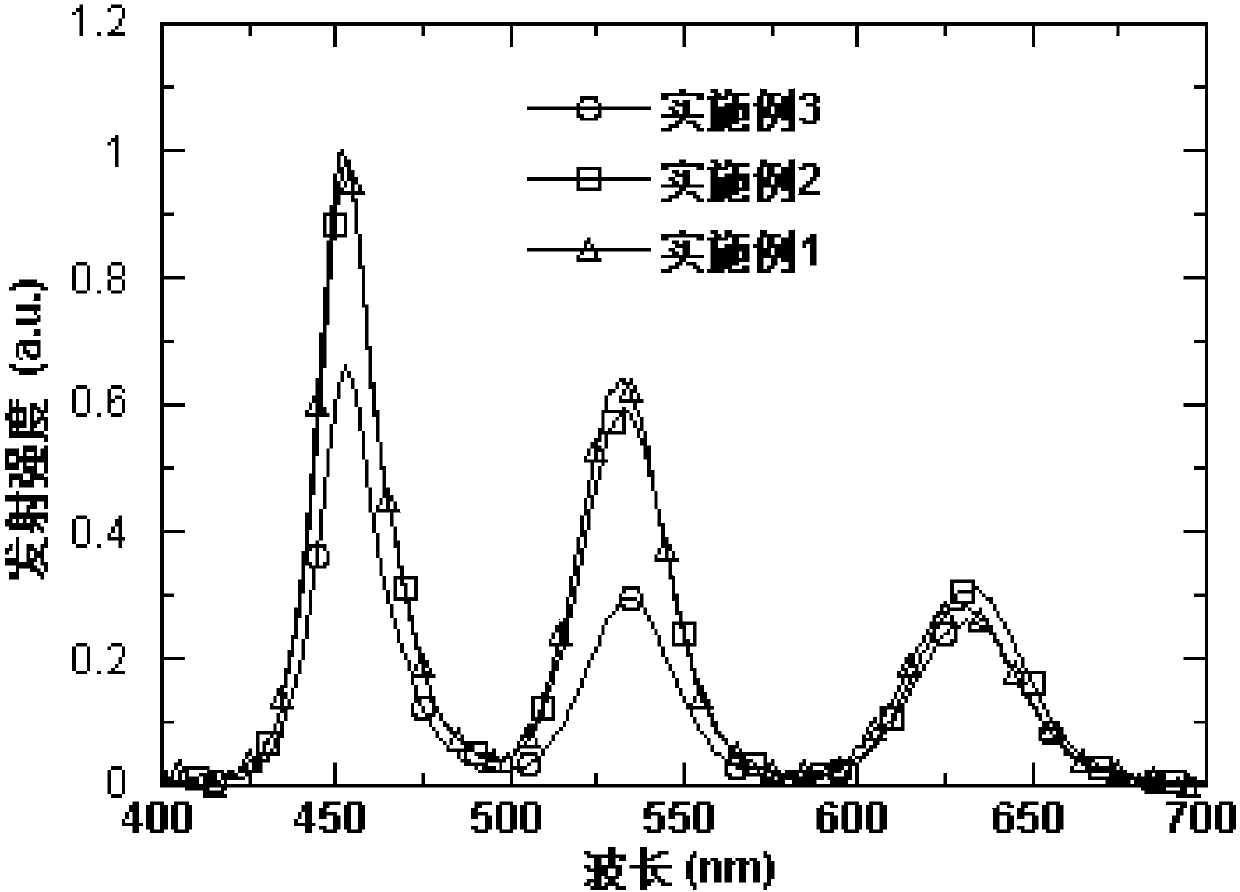

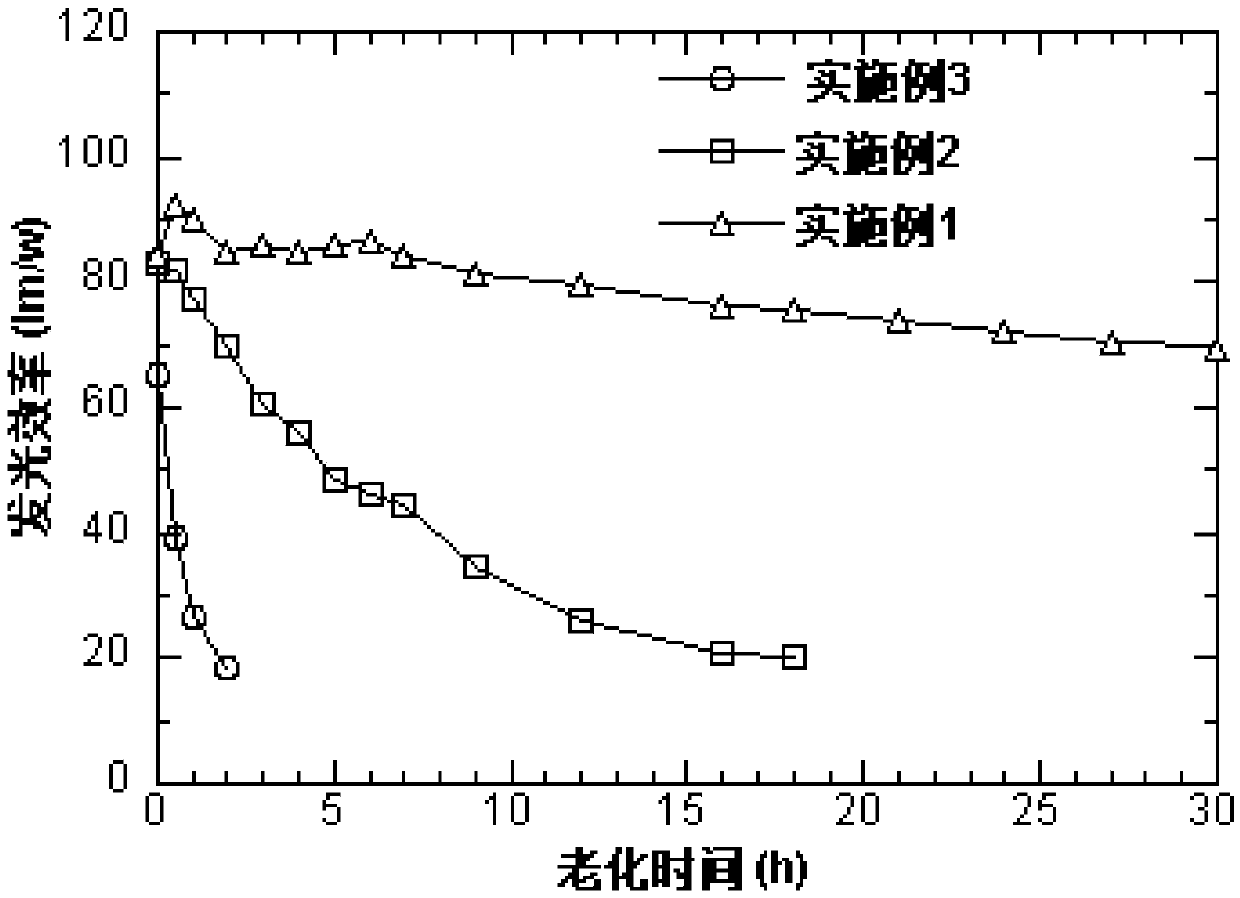

Embodiment 1

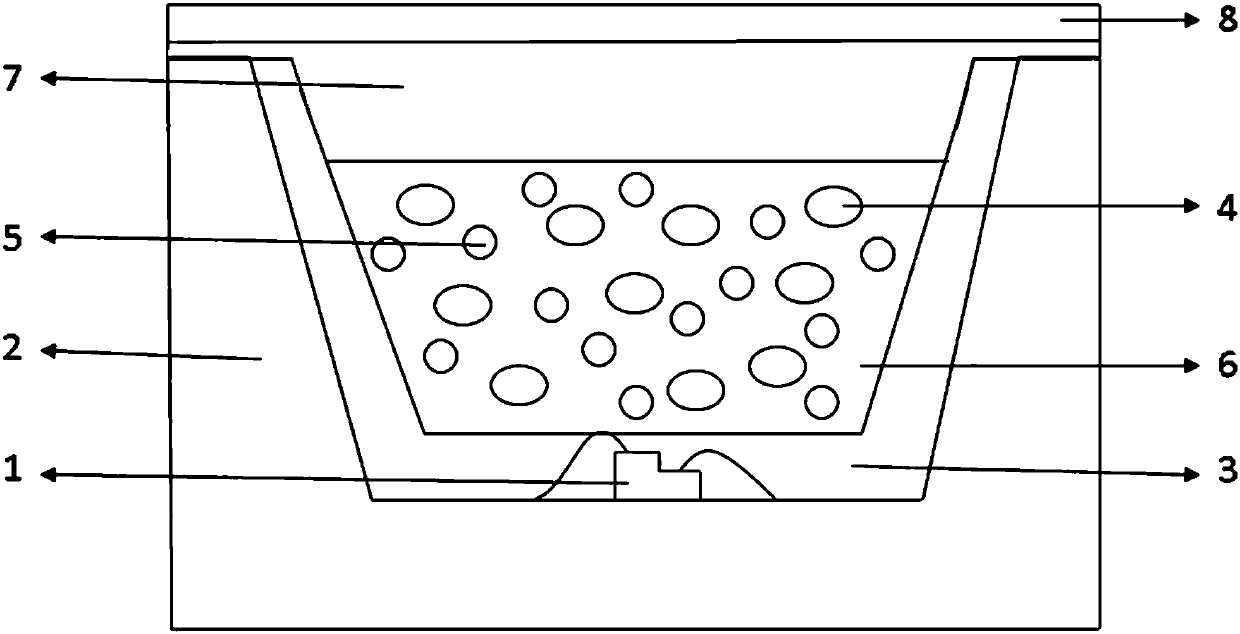

[0044] The encapsulation of quantum dot On-chip white light LED with secondary airtight protection includes the following steps:

[0045] (1) Fix the blue light chip on the bottom of the LED bracket after crystal bonding, wire bonding, and baking in the LED bracket;

[0046] (2) Move the LED bracket with the blue chip fixed into the atomic layer deposition system, and deposit an aluminum oxide film layer at 80°C to improve the ability of the LED bracket to block water and oxygen, with a thickness of 50nm;

[0047] (3) Weigh 0.2g of component A of epoxy resin AB curing glue and 0.2g of component B of epoxy resin AB curing glue into a beaker, stir evenly to obtain encapsulation glue, add 120 μl of green light quantum dots and 20 μl of red light quantum dots , Stir and mix evenly again, put it into a vacuum oven, and vacuumize for 20 minutes to remove the air bubbles in the colloid, and obtain a uniformly dispersed quantum dot fluorescent colloid;

[0048] Move the LED bracket a...

Embodiment 2

[0051] The encapsulation of quantum dot On-chip white light LED without airtight protection in a nitrogen atmosphere includes the following steps:

[0052] (1) Fix the blue light chip on the bottom of the LED bracket after crystal bonding, wire bonding, and baking in the LED bracket;

[0053] (2) Move the LED bracket with the blue chip fixed into the atomic layer deposition system, and deposit an aluminum oxide film layer at 80°C to improve the ability of the LED bracket to block water and oxygen, with a thickness of 50nm;

[0054] (3) Weigh 0.2g of component A of epoxy resin AB curing glue and 0.2g of component B of epoxy resin AB curing glue into a beaker, stir evenly to obtain encapsulation glue, add 120 μl of green light quantum dots and 20 μl of red light quantum dots , Stir and mix evenly again, put it into a vacuum oven, and vacuumize for 20 minutes to remove the air bubbles in the colloid, and obtain a uniformly dispersed quantum dot fluorescent colloid;

[0055] Move...

Embodiment 3

[0057] The encapsulation of quantum dot On-chip white light LED without airtight protection in the air atmosphere includes the following steps:

[0058] (1) Fix the blue light chip on the bottom of the LED bracket after crystal bonding, wire bonding, and baking in the LED bracket;

[0059] (2) Move the LED bracket with the blue chip fixed into the atomic layer deposition system, and deposit an aluminum oxide film layer at 80°C to improve the ability of the LED bracket to block water and oxygen, with a thickness of 50nm;

[0060] (3) Weigh 0.2g of component A of epoxy resin AB curing glue and 0.2g of component B of epoxy resin AB curing glue into a beaker, stir evenly to obtain encapsulation glue, add 120 μl of green light quantum dots and 20 μl of red light quantum dots , Stir and mix evenly again, put it into a vacuum oven, and vacuumize for 20 minutes to remove the air bubbles in the colloid, and obtain a uniformly dispersed quantum dot fluorescent colloid;

[0061] In the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com