A kind of airtight protective coating and preparation method thereof

A protective coating and airtight technology, applied in coatings, epoxy resin coatings, primers, etc., can solve problems such as poor adhesion to substrates at welding points, poor airtightness of sealed cabins, and poor sealing effects , to achieve the effect of dense paint film, good airtight protection effect and excellent adhesion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

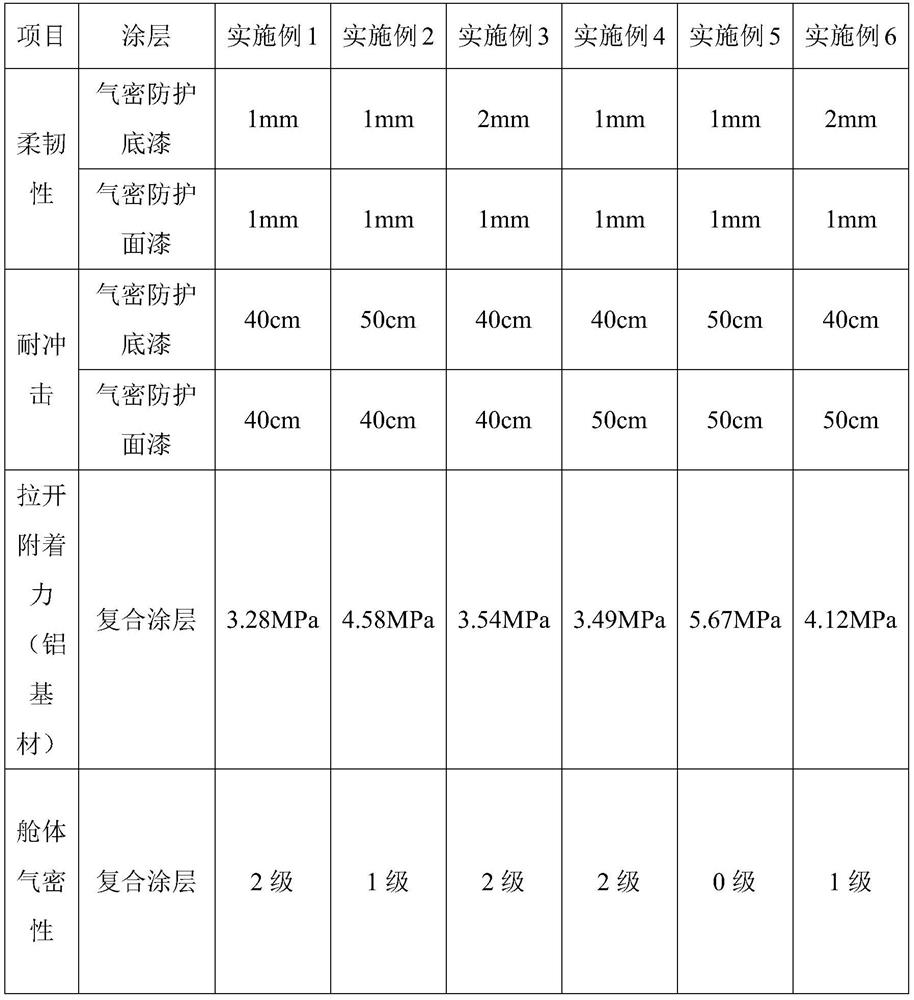

Examples

Embodiment 1

[0035] (1) Airtight protective primer

[0036] A1 component

[0037] a. Add 12 parts of epoxy resin E-12 and 36 parts of E-44 to 32 parts of xylene and 16 parts of n-butanol mixture, and disperse at a high speed of 1200 rpm for 15 minutes to obtain a resin dispersion;

[0038] b. Add 0.5 parts of BYK-A530, 0.5 parts of BYK-054, 0.5 parts of BYK-358N, and 0.5 parts of BYK-320 into the prepared resin dispersion, stir well and finally add 2 parts of A187, and disperse at high speed for 15 minutes at 1200rpm , to get the A1 component.

[0039] B1 component

[0040] Add 30 parts of polyamide resin 140 and 40 parts of modified cashew nut shell oil phenalkamide resin 3117 into a mixture of 24 parts of xylene and 6 parts of n-butanol, and disperse at a high speed of 1200 rpm for 15 minutes to obtain component B1.

[0041] When in use, mix components A1 and B1 at a mass ratio of 4:1 to make a sample.

[0042] (2) Airtight protective topcoat

[0043] (1) Modified polyaspartic acid ...

Embodiment 2

[0054] (1) Airtight protective primer

[0055] A1 component

[0056] a. Add 10 parts of epoxy resin E-12 and 40 parts of E-44 to 36 parts of xylene and 10 parts of n-butanol mixture, and disperse at a high speed of 1200 rpm for 15 minutes to obtain a resin dispersion;

[0057] b. Add 0.5 parts of BYK-A530, 0.5 parts of BYK-054, 0.5 parts of BYK-358N, and 0.5 parts of BYK-320 into the prepared resin dispersion, stir well and finally add 2 parts of A187, and disperse at high speed for 15 minutes at 1200rpm , to get the A1 component.

[0058] B1 component

[0059] Add 25 parts of polyamide resin 140 and 45 parts of modified cashew nut shell oil phenolic amide resin 3117 to a mixture of 24 parts of xylene and 6 parts of n-butanol, and disperse at high speed for 15 minutes at 1200 rpm to obtain component B1.

[0060] When in use, mix components A1 and B1 at a mass ratio of 4:1 to make a sample.

[0061] (2) Airtight protective topcoat

[0062] (1) Modified polyaspartic acid es...

Embodiment 3

[0073] (1) Airtight protective primer

[0074] A1 component

[0075] a. Add 8 parts of epoxy resin E-12 and 40 parts of E-44 to 32 parts of xylene and 16 parts of n-butanol mixture, and disperse at a high speed of 1200 rpm for 15 minutes to obtain a resin dispersion;

[0076] b. Add 0.5 parts of BYK-A530, 0.5 parts of BYK-054, 0.5 parts of BYK-358N, and 0.5 parts of BYK-320 into the prepared resin dispersion, stir well and finally add 2 parts of A187, and disperse at high speed for 15 minutes at 1200rpm , to get the A1 component.

[0077] B1 component

[0078] Add 20 parts of polyamide resin 140 and 50 parts of modified cashew nut shell oil phenalkamide resin 3117 into a mixture of 24 parts of xylene and 6 parts of n-butanol, and disperse at high speed for 15 minutes at 1200 rpm to obtain component B1.

[0079] When in use, mix components A1 and B1 at a mass ratio of 4:1 to make a sample.

[0080] (2) Airtight protective topcoat

[0081] (1) Modified polyaspartic acid est...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adhesivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com