Patents

Literature

152results about How to "Play a role in bonding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Preparation method of NdFeB magnet with high coercivity

InactiveCN107578912AReduce machining costsSimple production processInductances/transformers/magnets manufactureMagnetic materialsMicrometerTerbium

The invention relates to a preparation method of an NdFeB magnet with high coercivity. The method includes the following steps that heavy rare earth powder is mixed with an anti-oxidizing agent, a binder and an organic solvent to prepare uniform slurry, wherein the heavy rare earth powder refers to one or a mixture of Dy, hydrogenated dysprosium, Tb and terbium hydride, the mass ratio of the heavyrare earth powder in the slurry is 40-80%, the mass ratio of the anti-oxidizing agent is 5-20%, the mass ratio of the binder is 2-10% and the balance organic solvent, and the anti-oxidizing agent refers to the anti-oxidizing agent containing fluorine; after the slurry covers the surface of a sintered magnet, the thickness of the slurry is controlled to 20-100 micrometers, and drying is then conducted; the dried magnet is then sintered, and aging treatment is conducted. The method can reduce the use amount of heavy rare earth powder such as Dy and Tb, meanwhile, the requirement of the grain boundary diffusion technology for the size of a product is met, the problem that fluoride and oxide coating powder is easy to fall off is solved, and the manufacturing process is simple.

Owner:YANTAI ZHENGHAI MAGNETIC MATERIAL

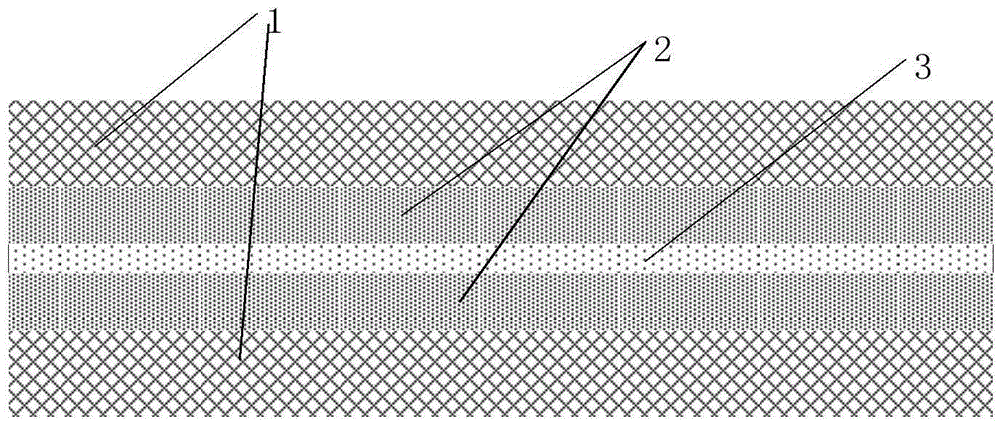

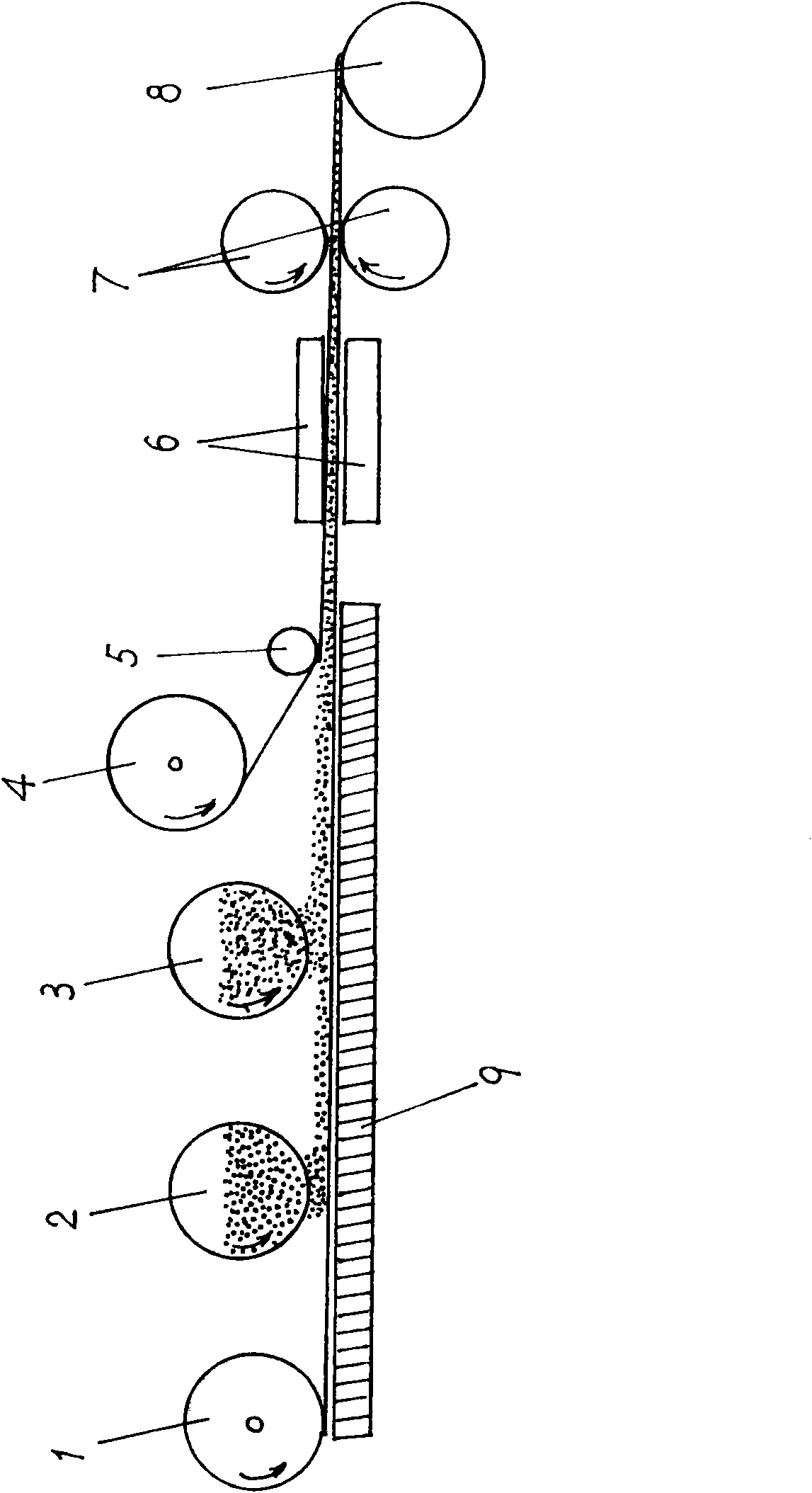

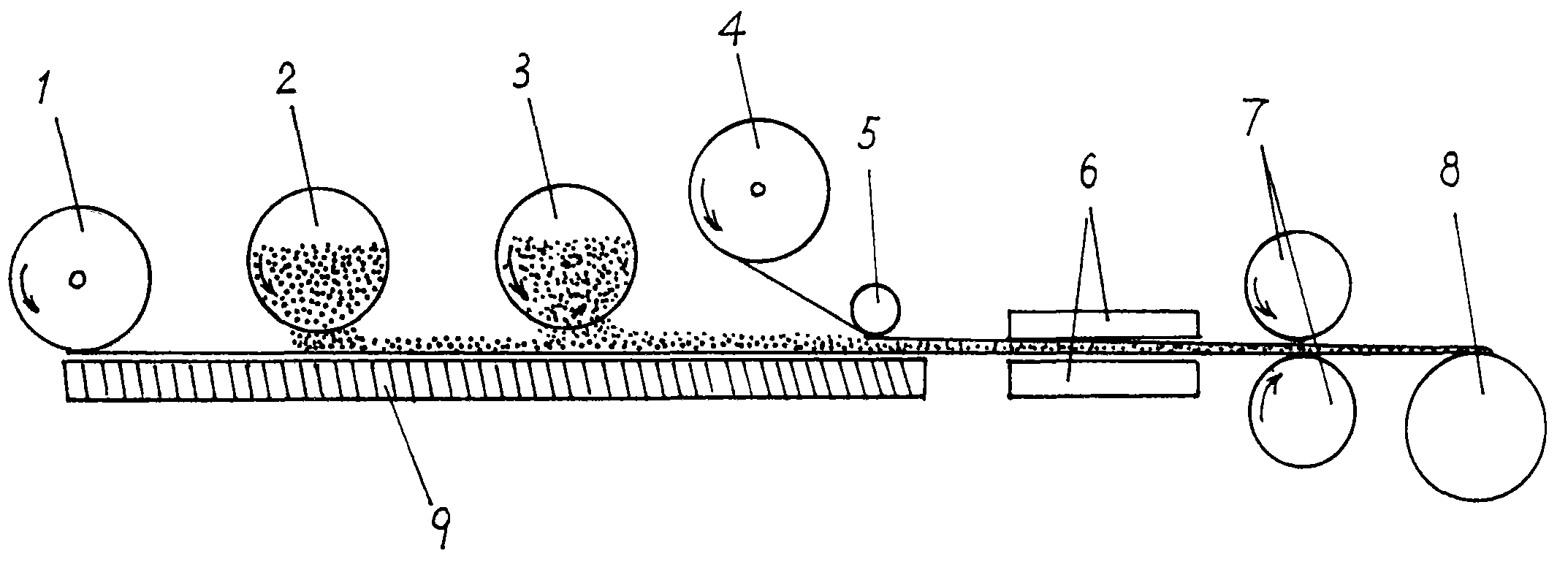

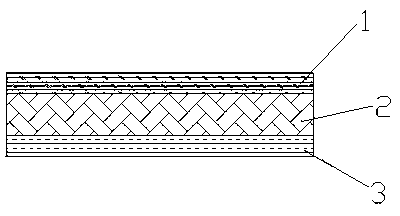

Composite non-woven fabric ceramic diaphragm for lithium ion battery and preparation method thereof

ActiveCN105304846AImprove stabilityImprove featuresSecondary cellsCell component detailsCeramic coatingSolvent

The invention discloses a composite non-woven fabric ceramic diaphragm for a lithium ion battery and a preparation method thereof. The composite non-woven fabric ceramic diaphragm for the lithium ion battery comprises two layers of non-woven fabric base materials and a ceramic coating composited between the two layers of non-woven fabric base materials. The preparation method comprises the following steps: (1) dissolving macromolecule organic matter in a solvent to form macromolecular solution; (2) dispersing inorganic particles in the macromolecular solution to form organic and inorganic mixture; (3) first coating one side of one non-woven fabric base material evenly with the organic and inorganic mixture, and then pressing the other layer of non-woven fabric base material on a coating layer, and performing drying and rolling to form the composite diaphragm. The problems that the lithium ion battery diaphragm is poor in heat resistance, absorbs water easily, drops easily and is not high in mechanical strength are solved.

Owner:TIANNENG SAFT ENERGY JOINT CO

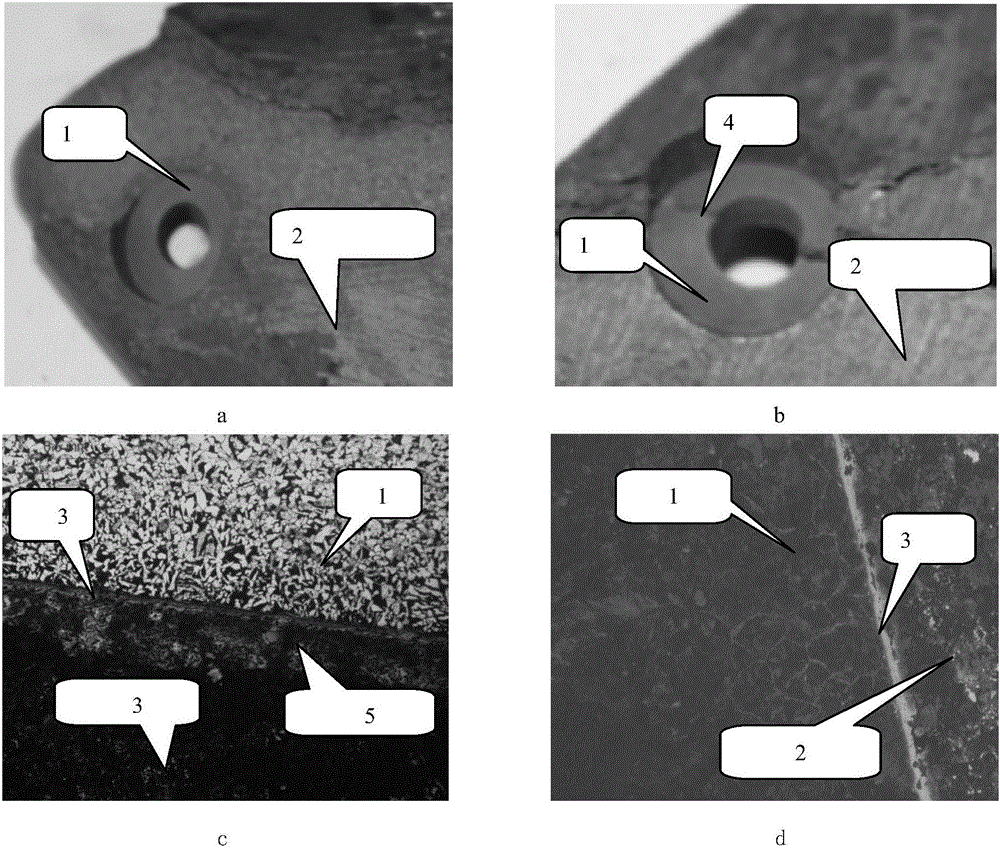

Bonding method of powder metallurgy iron-based friction material layer and steel backing and bonding material

Provided is a bonding method of a powder metallurgy iron-based friction material layer and a steel backing and a bonding material. According to the bonding method, mixed powder is paved and spread to achieve the bonding of a copper-based powder metallurgy material and the steel backing along with the bonding of spraying metal powder and organic solvent at the normal temperature; the bonding material with the thickness of 0.05-0.15mm is added between a powder metallurgy iron-based friction material and the steel backing; after being sintered, the powder metallurgy iron-based friction material and the steel backing are made to have a good bonding property and the steel backing brittleness and cracks are prevented. Tin is added in a formula of the bonding material, and the tin is made to form a liquid phase, and the tin is diffused in the interior of the bonding material and the contact portion of the bonding material and the steel backing to form an alloy body which can exert the bonding effect, and the effectiveness of bonding is enhanced. When added copper powder ensures the thickness of the bonding material to reach 0.05-0.15mm, the added copper powder can reduce the possibility that carbon in a friction material is diffused toward the steel backing, and thus the embrittlement of the steel backing due to carbon infiltration is prevented, in addition, the shearing strength of the bonding material can be effectively improved.

Owner:XIAN AVIATION BRAKE TECH

Material for multifunctional shoe pad and preparation method thereof

InactiveCN102102299AImprove antibacterialGood moisture absorptionInsolesFibre treatmentMoisture absorptionNonwoven fabric

The invention relates to a material for a multifunctional shoe pad, which contains three layers of materials, wherein common fabrics are arranged on the bottom layer; antibiosis non-woven fabrics are arranged on the upper layer; and the middle layer contains high water-absorption resin particles covered by the inorganic nanometer silver antibacterial agent on the surface and hard micro beads covered by the hot melt adhesive on the surface. A preparation method comprises the following steps: (1) coating materials: on a support plate, covering the antibiosis non-woven fabrics, spreading the hard micro beads and high water-absorption resin particles, and covering the common fabrics; (2) heating: heating the compound three-layered materials; (3) hot-pressing: hotly pressing the heated compound three-layered materials so as to form the material for multifunctional shoe; and (4) collecting the finished products. Before the step (1) is performed, the steps of covering the surface of the hard micro bead with hot melt adhesive and covering the surface of the high water-absorption resin with the antibacterial agent are performed. The material for multifunctional shoe has the advantages that the prepared materials have high moisture-absorption property and functions of antibiosis, deodorization and massaging sole of the foot, the functions are lasting, the effects of antibiosis and deodorization are obvious, and the materials are easily produced and have bright application prospect.

Owner:SHANGHAI ANNI CRYSTAL DESIGN

Display device

ActiveCN109671353ANo collapseSolve the technical problem of collapseIdentification meansDisplay device

The invention provides a display device, which comprises a first functional member, a second functional member, wherein the second functional member is provided with a support part for supporting thefirst functional member when the display device is deformed, an adhesive layer, wherein the adhesive layer is used for bonding the second functional member and the first functional member, the thickness of the bonding layer is not less than the thickness of the supporting part; based on that the thickness of the bonding layer in the structure is not less than the thickness of the supporting part,when the display device is not deformed, the bonding layer is arranged between the supporting part and the functional members to achieve bonding, when the display device is deformed, after an opticalglue layer and other bonding layers are deformed to a certain extent, the supporting part arranged on the first functional member is contacted with the second functional member to play a supporting role, so that the bonding layer cannot be continuously extruded to discharge glue outwards and cannot collapse, and the technical problem that the optical glue collapses due to overlarge deformation ofa prior display device is solved.

Owner:WUHAN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

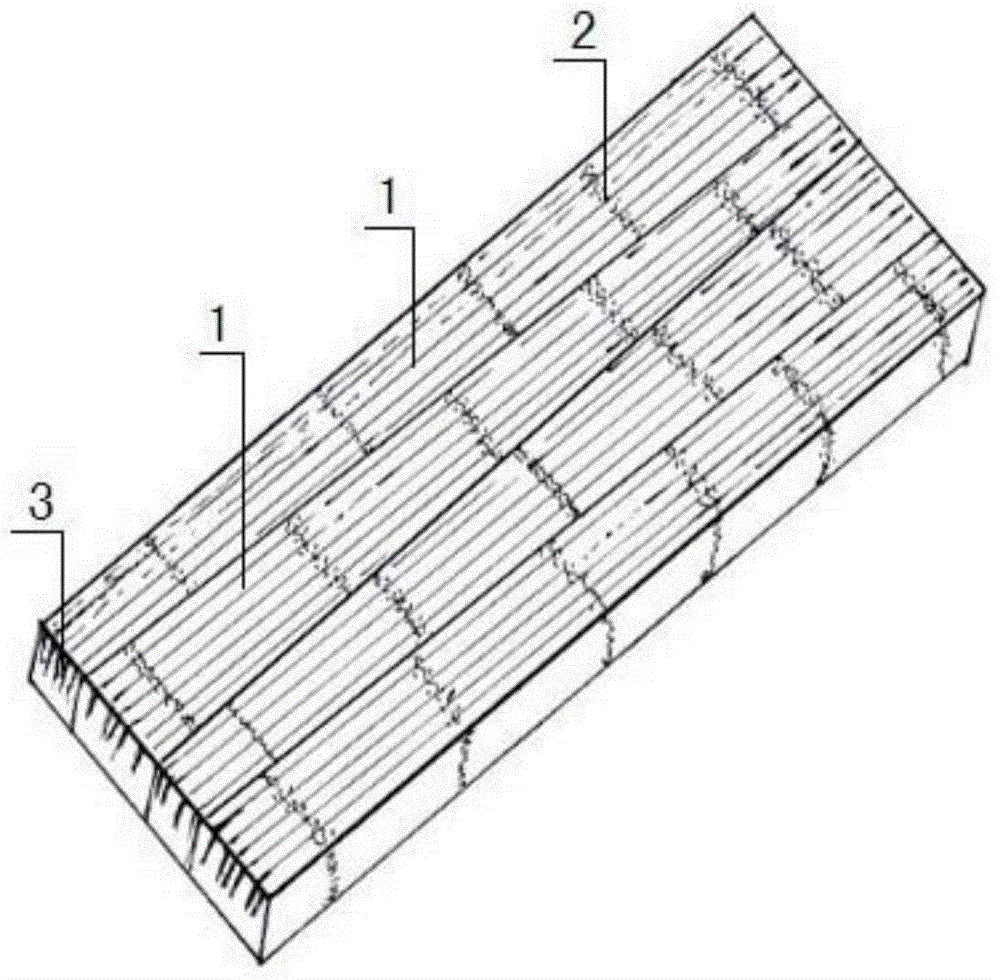

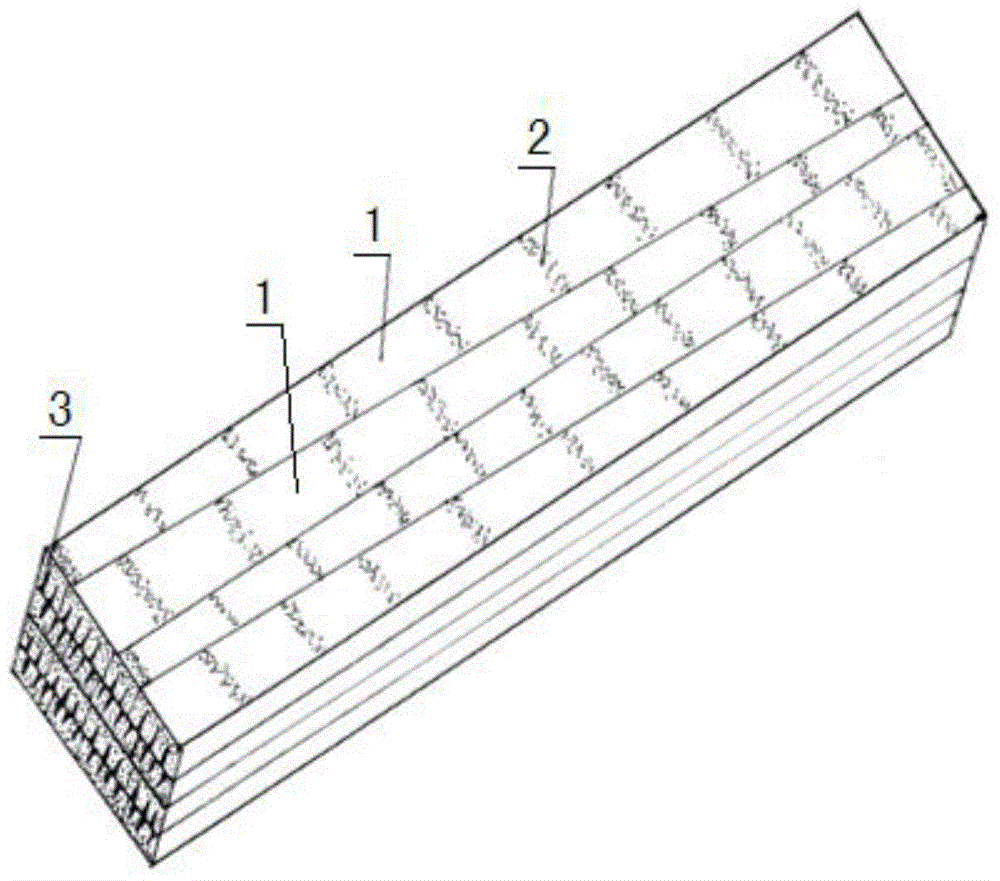

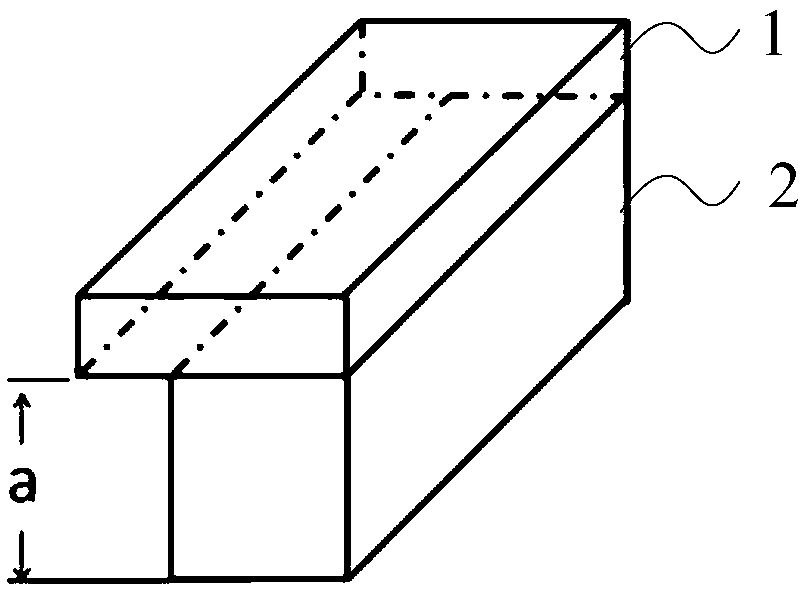

Formaldehyde-free bamboo recombined, plasticized and polymerized building structure material and production technique

ActiveCN104875247AFew slicesReduce the amount of cuttingLamination ancillary operationsWood treatment detailsFiberPolymer resin

The invention discloses a formaldehyde-free bamboo recombined, plasticized and polymerized building structure material and a production technique. The formaldehyde-free bamboo recombined, plasticized and polymerized building structure material is structurally characterized in that at least two separate expanded bamboo recombined, plasticized and polymerized veneer layers are overlaid, and fiber lignin in bamboo is grafted with polymer resin compounds, and the polymer resin compounds are plasticized and polymerized with the bamboo under the hot-melt state to form an integer; when the separate expanded bamboo recombined, plasticized and polymerized veneer layers are overlapped, tabasheer layers are opposite, and bamboo green layers are opposite. Using ratio of bamboo is increased; working efficiency is improved, and cost of unit products is lowered; mechanical property of bamboo is maintained fully; the recombined plasticized and polymerized bamboo is filled with the polymer resin to modify the bamboo, and the material becomes an environment-friendly material suitable for building structures.

Owner:湖南風河竹木科技股ふん有限公司

High temperature resistant adhesive for carbon materials and preparation method thereof

InactiveCN106634744AImprove temperature resistanceHigh solid phase residual rateNon-macromolecular adhesive additivesAldehyde/ketone condensation polymer adhesivesFuranBoride

The present invention relates to a high temperature resistant adhesive for carbon materials and a preparation method thereof. The high temperature resistant adhesive is composed of high residual carbon resi and a compound filler. The ratio of the high residual carbon resin to the compound filler is 100:(55-95). The high residual carbon resin comprises phenolic resin, furan resin, benzoxazine resin, etc. The compound filler consists of two or more of graphite powder, boron powder, boron carbide, boron nitride, zirconium powder, silicon powder, zirconium boride, zirconium oxide, etc., and a curing agent corresponding to the high residual carbon resin, and the compositions are selected according to use temperature of the materials to be adhered. The high temperature resistant adhesive has the characteristics of being high in applicable temperature and wide in temperature range, can be used for a long time at 800 DEG C or more, has excellent electrical and thermal conductivity at the high temperature, and effectively solves the problems that currently when the high temperature resistant adhesive is applied at 800 DEG C or more, the adhesive strength is relatively low, the electrical and thermal conductivity is low, etc.

Owner:INNER MONGOLIA AEROSPACE HONGGANG MACHINERY

Air electrode and preparation method thereof

The invention discloses an air electrode and a preparation method thereof. The electrode comprises a catalytic layer, a first waterproof carbon powder layer, a current collector layer, and a second waterproof carbon powder layer which are subjected to hot-press fitting. The waterproof carbon powder layers comprise acetylene black and high-density low-pressure polyethylene. The catalytic layer comprises active carbon, acetylene black and high-density low-pressure polyethylene. According to the electrode preparation method, preparation processes of the waterproof carbon powder layers and the catalytic layer are integrated, and a traditional catalytic membrane is changed into catalytic powder. According to the air electrode provided by the invention, the waterproof carbon powder layers are firmly fitted with the catalytic layer. During a long-time discharge cycle, the waterproof carbon powder layers and the catalytic layer can not be easily separated, such that battery circulation service life is prolonged.

Owner:北京九能京通新能源科技有限公司

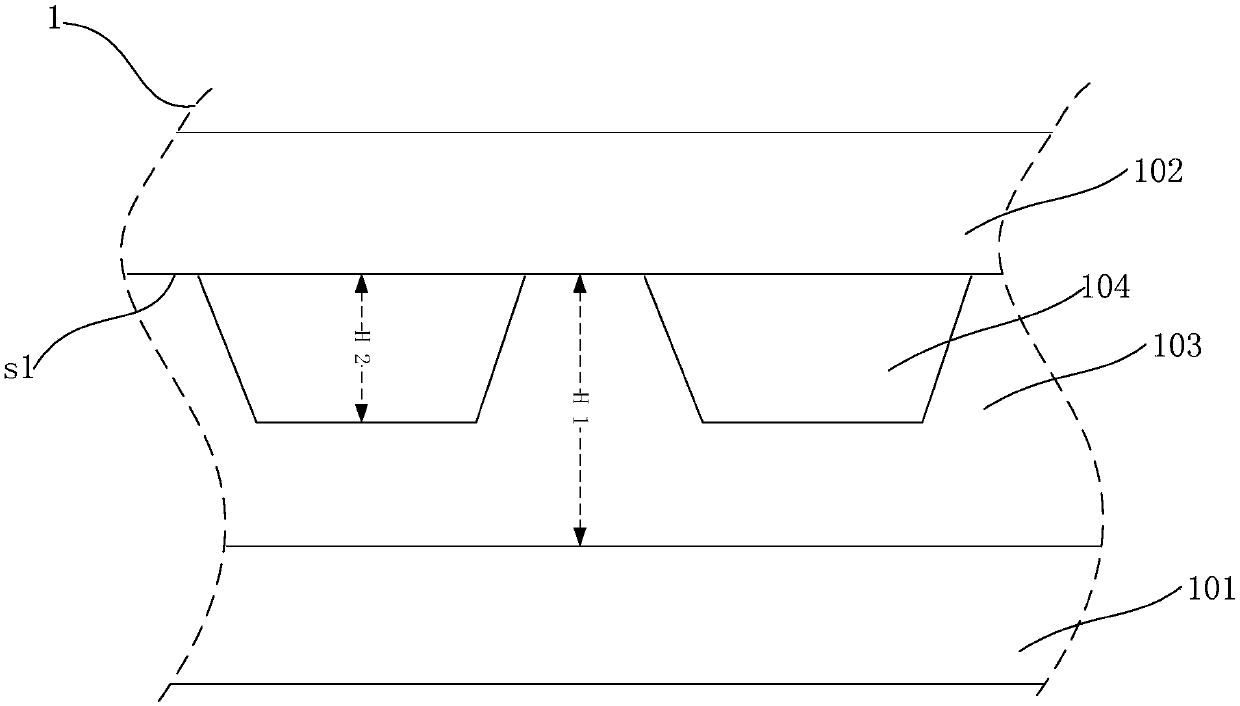

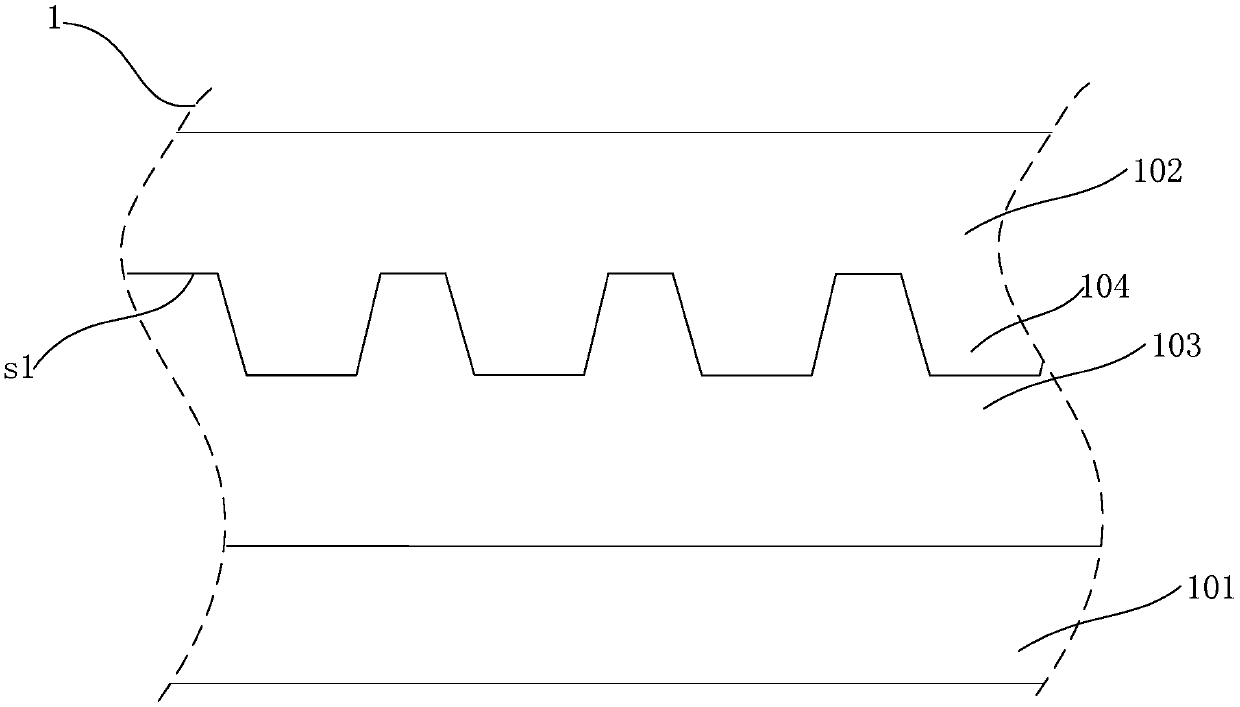

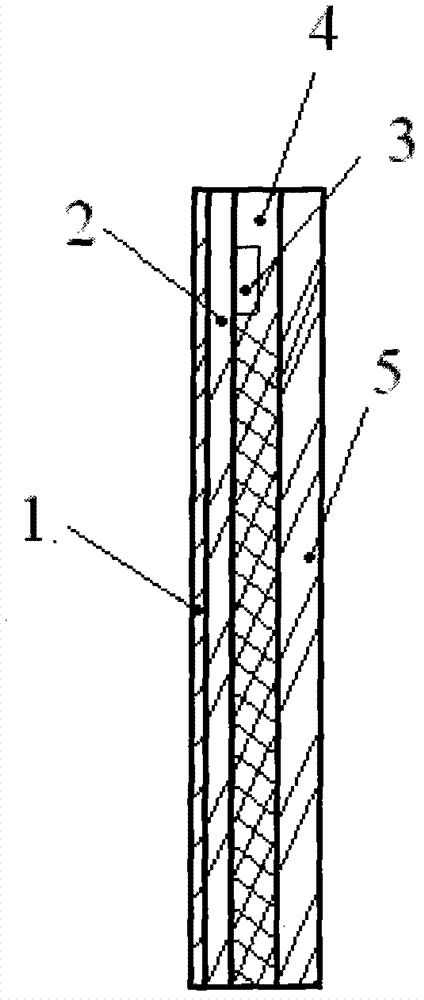

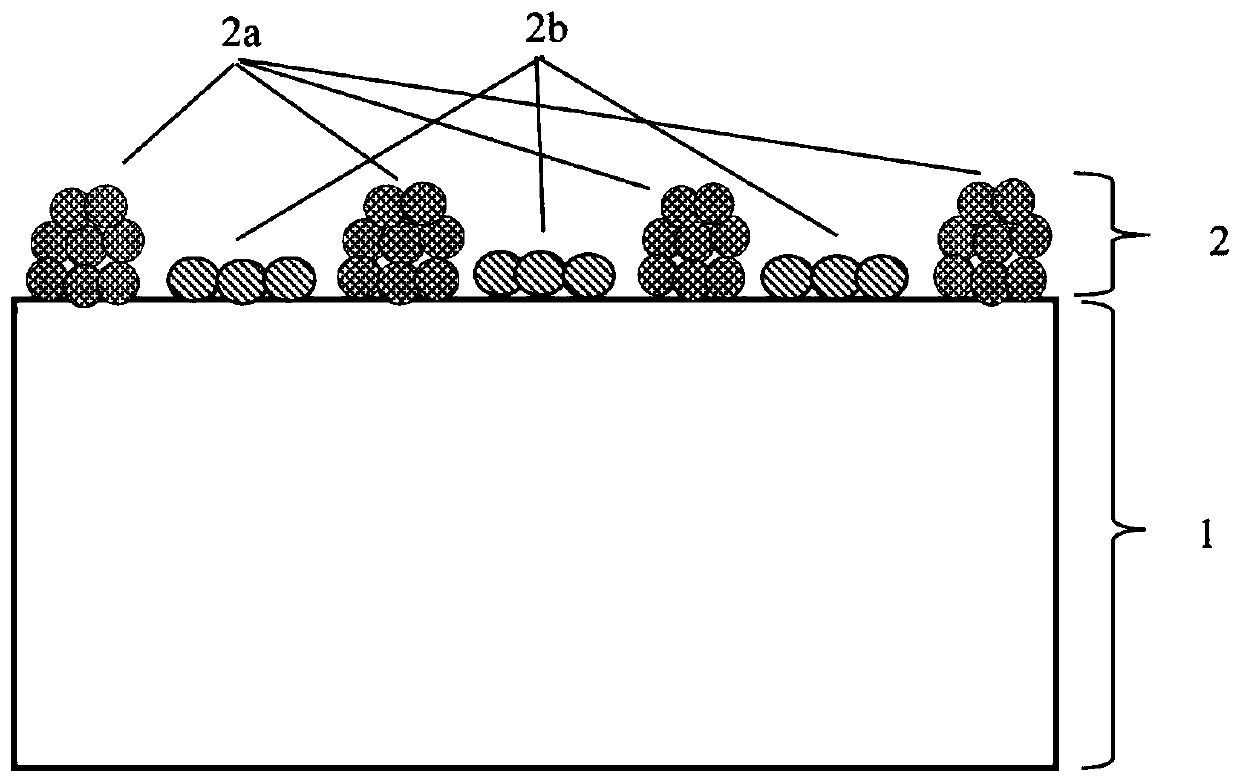

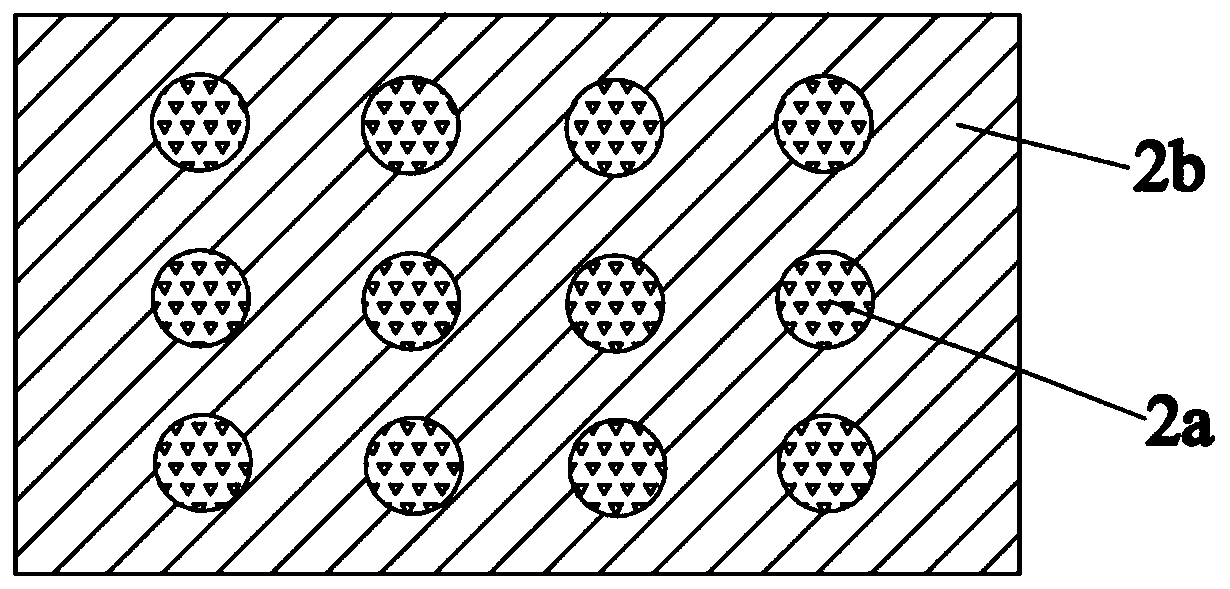

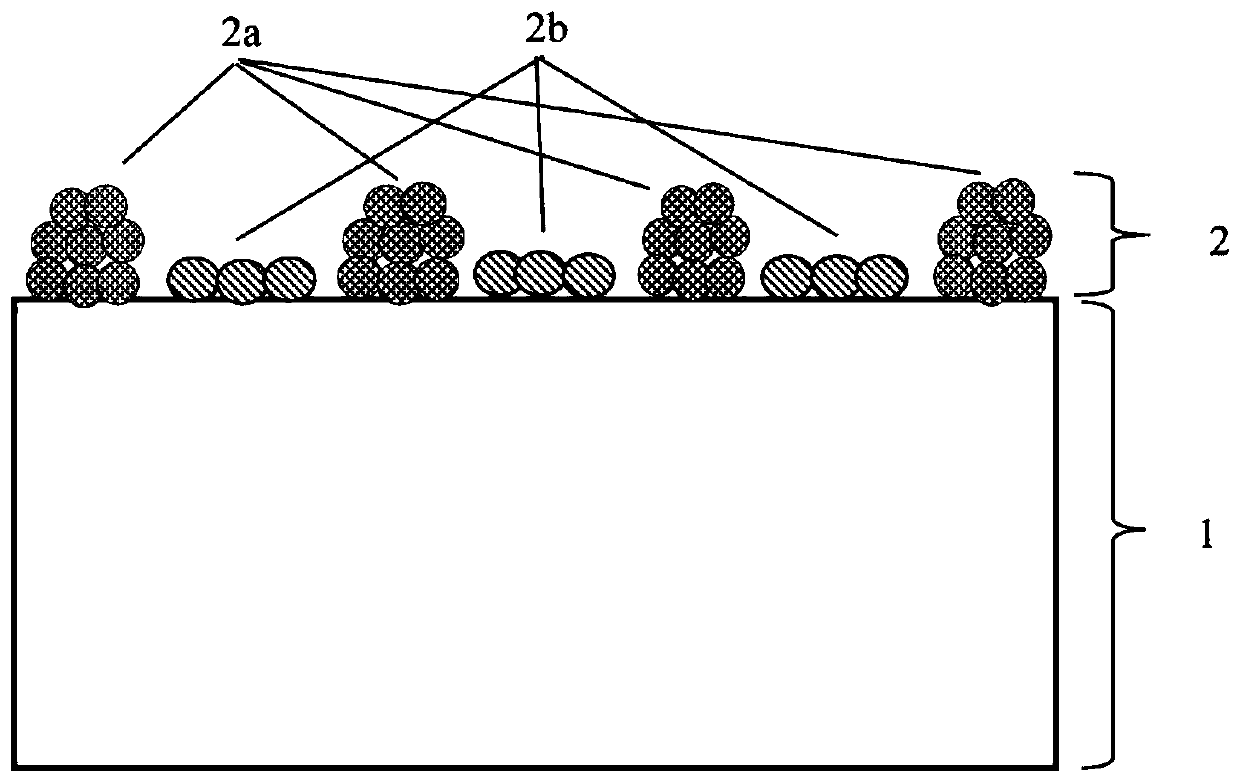

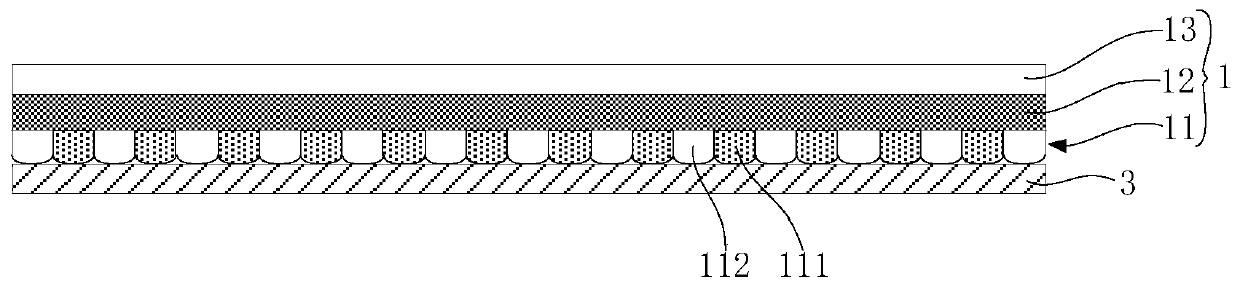

Diaphragm for lithium-ion battery and lithium-ion battery containing diaphragm

PendingCN110010831ASolve the deformationImprove battery performanceSecondary cellsCell component detailsDeformation ProblemElectrical battery

The invention belongs to the technical field of lithium-ion batteries, and particularly relates to a diaphragm for a lithium-ion battery. The diaphragm comprises a diaphragm body, wherein at least onesurface of the diaphragm body is coated with a functional coating, the functional coating includes a first polymer, a second polymer and an adhesive, and the particle size distribution range value ofthe first polymer is greater than the particle size distribution range value of the second polymer. Compared with the prior art, the first polymer with a large particle size distribution range valueplays a supporting role, thereby being capable of forming a clearance between a pole plate and the diaphragm, providing an expansion space for the pole plate, and solving a deformation problem of thebattery; and the second polymer with a small particle size distribution range value plays a bonding role, thereby forming good contact with the pole plate after a hot processing process, thus forminga good interface between the diaphragm and the pole plate, and improving the battery performance. In addition, the invention further provides a lithium-ion battery containing the diaphragm for the lithium-ion battery.

Owner:东莞市魔方新能源科技有限公司

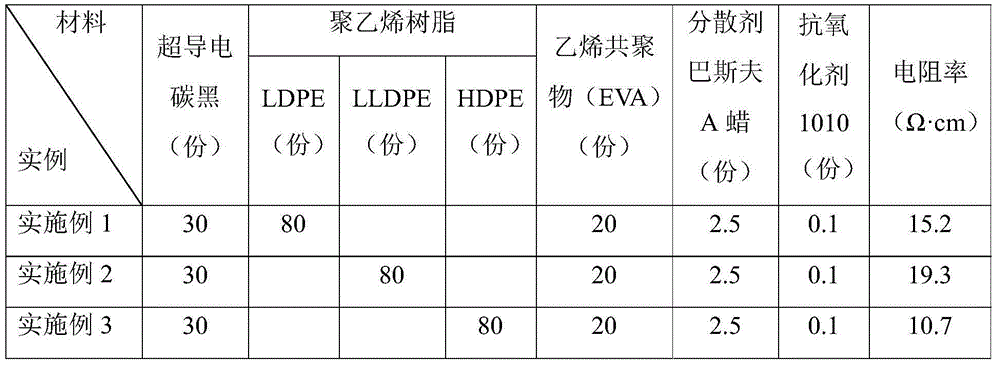

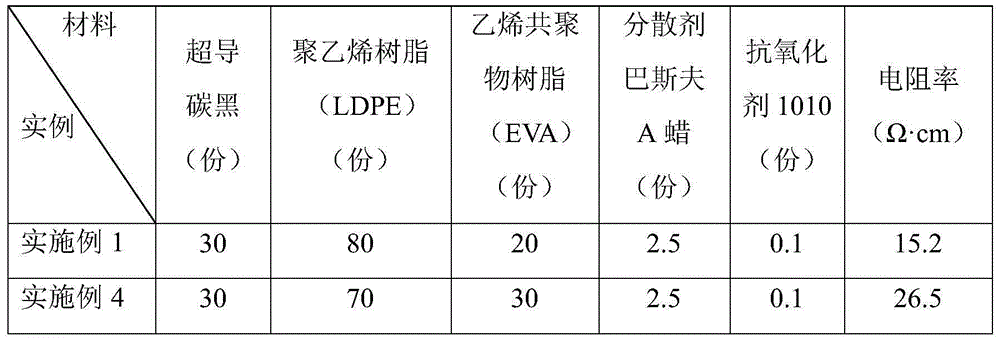

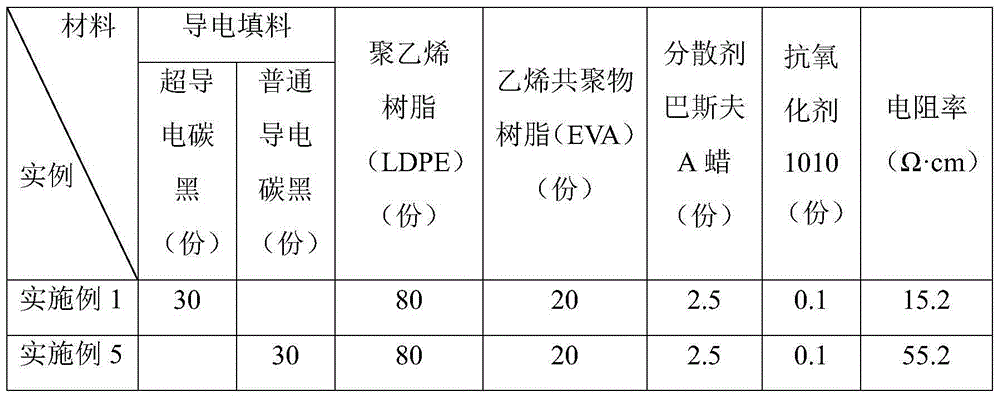

Electric-conductive heating glue and preparation method thereof

InactiveCN104817984AAvoid uneven heatingImprove energy efficiencyNon-macromolecular adhesive additivesBuilding materialChemistry

The invention relates to electric-conductive heating glue which includes following components, by mass: 15-45 parts of a electric-conductive heating filling material, 60-85 parts of polyethylene resin, 15-40 parts of ethylene copolymer resin, 1-5 parts of a dispersing agent and 0.1-2 parts of an anti-oxidizing agent. The electric-conductive heating glue not only is safe to use and can maintain uniform heating for long period, but also has a bonding effect. The invention also provides the preparation method of the electric-conductive heating glue. The electric-conductive heating glue can satisfy development requirements in the following fields: electric-heating building materials, household appliances, equipment shields, antifreezing devices and the like products.

Owner:NANJING GREEN WOOD CO LTD

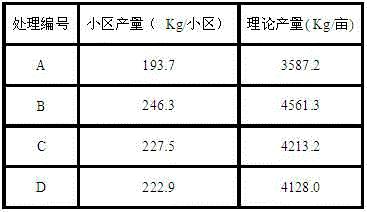

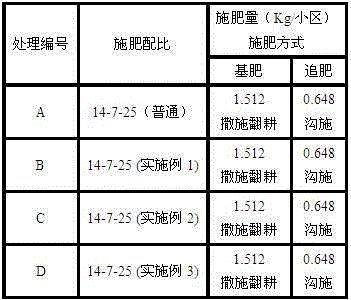

Activated humic acid formulated fertilizer special for sweet potatoes and preparation method of formulated fertilizer

InactiveCN104892309AThe formula is scientific and reasonableEasy to granulateFertilizer mixturesAmmonium sulfateAmmonium molybdate

The invention discloses an activated humic acid formulated fertilizer special for sweet potatoes, and relates to the technical field of a formulated fertilizer special for crops. The activated humic acid formulated fertilizer is prepared from a raw material of a urea melt liquid for spraying activated humic acid and a raw material for solid granulation, wherein the urea melt liquid comprises urea, ammonium sulfate, humic acid, and water, and the raw material for solid granulation comprises urea, industrial monoammonium phosphate, potassium sulfate, ammonium bicarbonate, anhydrous magnesium sulfate, boric acid, ZnEDTA, FeEDTA, MnEDTA, CuEDTA, and ammonium heptamolybdate. According to the invention, the formulated fertilizer special for sweet potatoes is scientific in formula and comprehensive in nutrition. On the one hand, the added activated humic acid can buffer change of water, fertilizer, air, and heat in soil, and can reduce harmful effects on growth of sweet potatoes, so that the stress resistance of sweet potatoes is enhanced, on the other hand, the added activated humic acid contains a fulvic acid component, which can stimulate growth of sweet potatoes and enhance resistibility of sweet potatoes.

Owner:STANLEY AGRI GRP CO LTD

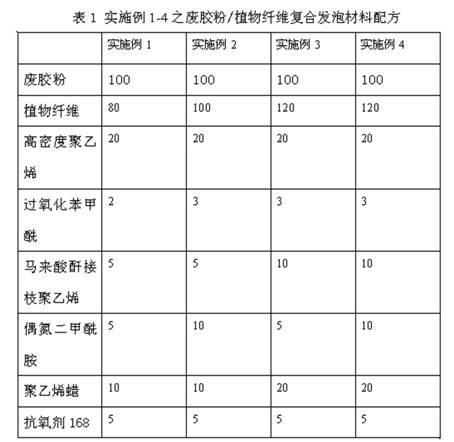

Scrap rubber powder/vegetable fiber composite foaming material and preparation process thereof

The invention discloses a scrap rubber powder / vegetable fiber composite foaming material and a preparation process thereof. The scrap rubber powder / vegetable fiber composite foaming material is prepared from the following components in part by weight: 80 to 120 parts of scrap rubber powder, 80 to 120 parts of vegetable fibers, 20 to 50 parts of high density polyethylene, 2 to 3 parts of benzoyl peroxide, 5 to 20 parts of maleic anhydride grafted polyethylene, 5 to 15 parts of azodicarbonamide, 10 to 30 parts of lubricating agent and 1 to 5 parts of heat stabilizer. The product can be granulated by dynamic extrusion and foamed by die pressing and has a simple preparation process, high cost performance and low cost. The scrap rubber powder / vegetable fiber composite foaming material can be used for manufacturing mute floors, floor tiles, buffer shockproof packaging materials such as inside linear, and the like.

Owner:HUNAN UNIV OF TECH

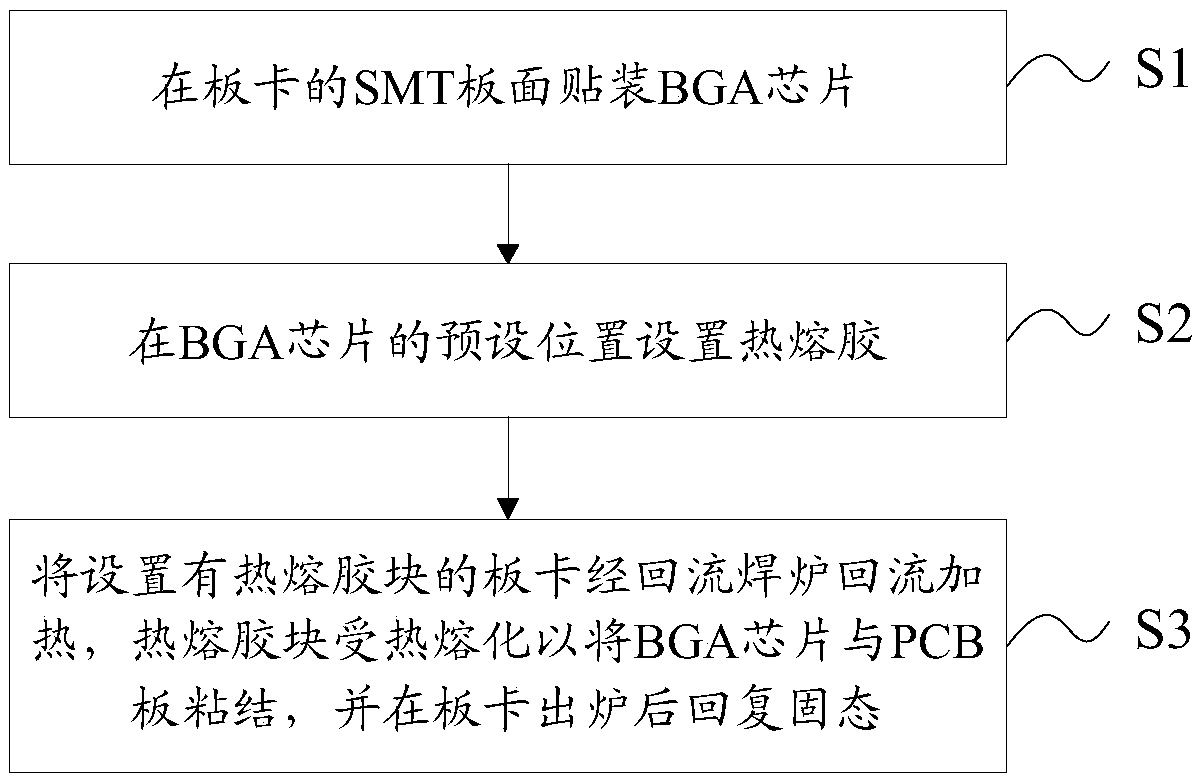

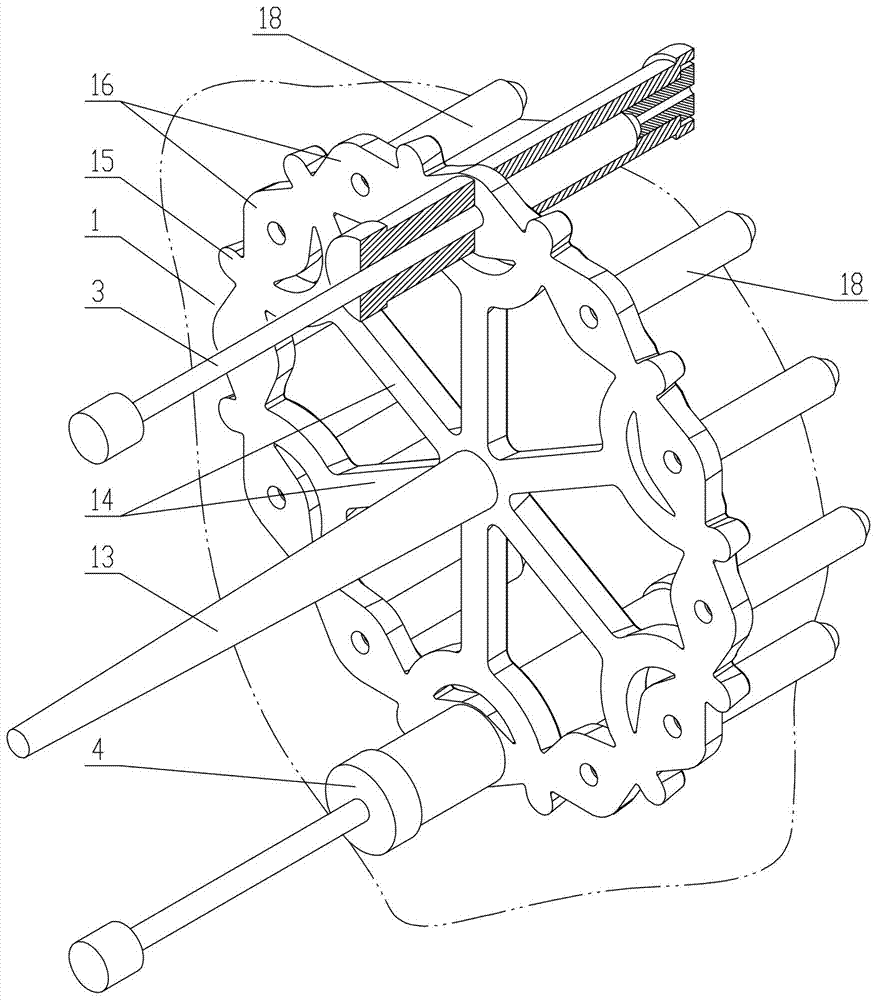

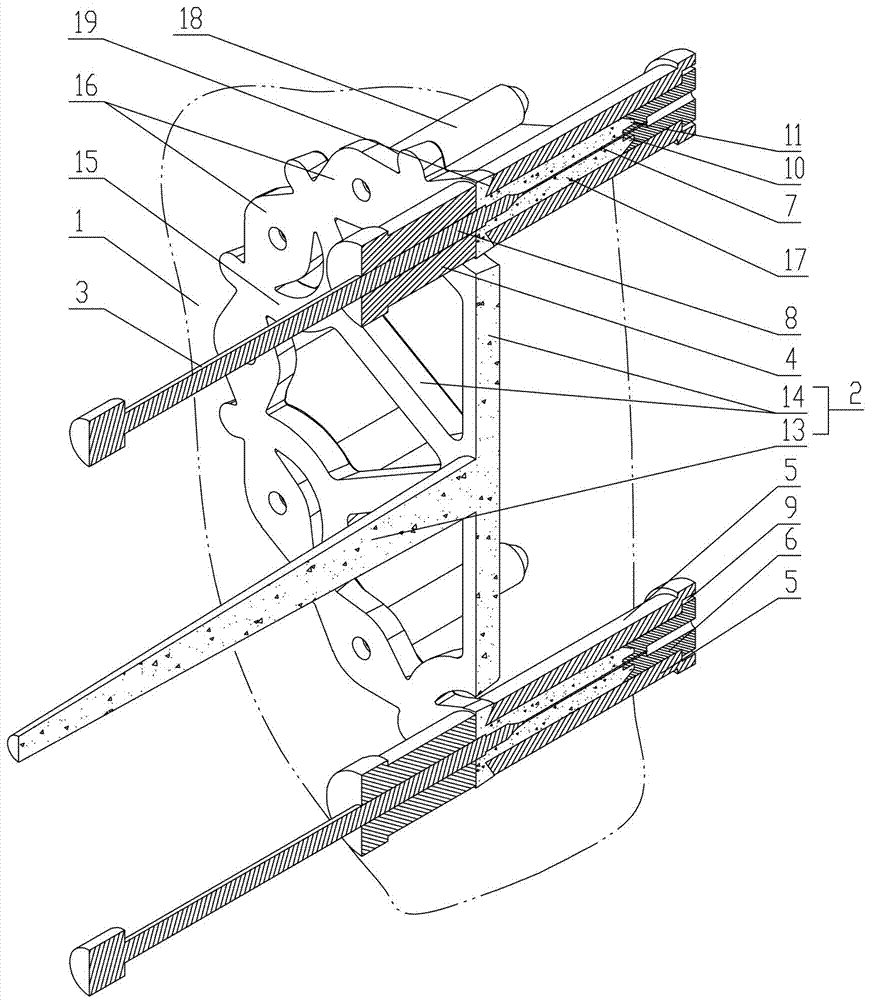

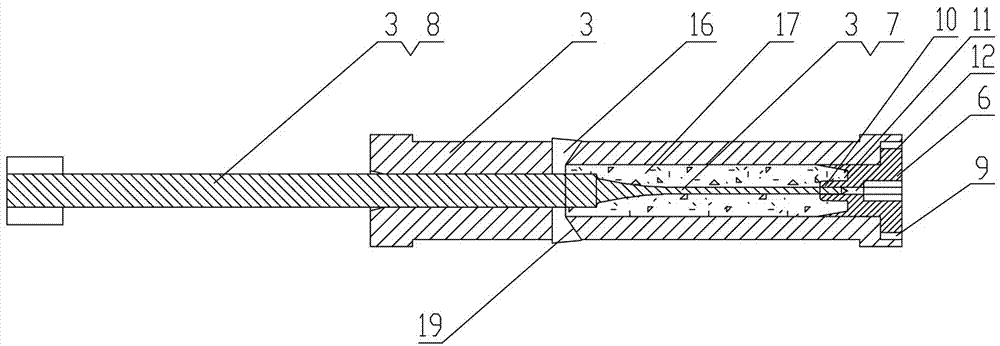

A SMT dispense process for BGA chip

InactiveCN109041420APlay a role in bondingLow costPrinted circuit assemblingPrinted circuit aspectsHot-melt adhesiveMaterials science

The invention discloses a SMT dispensing process of a BGA chip, comprising the following steps: S1, mounting a BGA chip on the SMT board surface of a board card; S2, a hot melt adhesive block is arranged at a preset position of the BGA chip; S3: the board provided with the hot melt adhesive block is reflow heated through a reflow soldering furnace, the hot melt adhesive block is heated to melt tobond the BGA chip and the PCB board, and the board is returned to a solid state after the board is out of the furnace. The SMT dispensing process of the BGA chip provided by the invention can completedispensing and curing operations in the SMT wire body, does not need to install a dispensing machine and a reflow soldering furnace outside the wire body, and reduces the equipment cost. Moreover, the off-line operation flow is not needed, the production circulation flow of the product is reduced, and the production efficiency is improved. The cost of manual operation is reduced, and the operation risk of the product is further reduced.

Owner:ZHENGZHOU YUNHAI INFORMATION TECH CO LTD

Preparation method of graphene-polyurethane composite fiber

InactiveCN109137132AGood effectImprove uniformityMonocomponent synthetic polymer artificial filamentArtifical filament manufactureFiberPolymer science

The invention provides a preparation method of a graphene-polyurethane composite fiber. Low-viscosity liquid dihydric alcohol and liquid diisocyanate are taken as raw materials to prepare a polyurethane prepolymer, and then photosensitive groups are introduced on molecular chains of the polyurethane prepolymer to obtain the modified low-viscosity polyurethane prepolymer; the obtained modified polyurethane prepolymer is mixed with graphene and photoinitiator to be dispersed and stirred so that the graphene is fully impregnated and compounded, then spinning is performed on the impregnated and mixed material, then UV irradiation is utilized, so that the photocurable polyurethane prepolymer on the surface of the fiber reacts and is solidified to obtain the graphene / polyurethane composite fiber. The preparation method of the graphene-polyurethane composite fiber has the advantages that the defect of lower uniformity when the composite fiber is prepared by spinning the graphene and polyurethane is overcome, the bonding strength between the polyurethane and the graphene is improved by photocuring of the polyurethane, the process is continuous and rapid, and the uniformity of the preparedcomposite fiber is high.

Owner:CHENDU NEW KELI CHEM SCI CO LTD

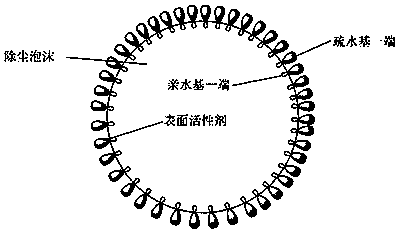

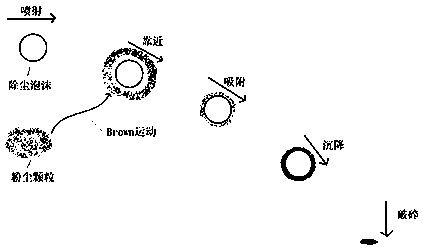

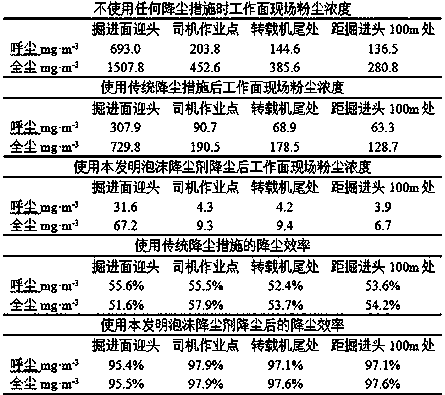

Novel coal mine foam dustfall agent

InactiveCN108285773AReduce surface tensionStrong moistureOther chemical processesChemistryAlkylphenol

The invention discloses a novel coal mine foam dustfall agent. The agent is prepared from, by weight, 0.20-0.45% of forming agent, 0.02-0.03% of foam stabilizer, 0.10-0.15% of wetting agent and 99.37-99.68% of water. Alkylphenol polyoxyethylene ether, polyanionic cellulose, coconut oil diethanolamide and fatty alcohol-polyoxyethylene ether glucoside are fully mixed with water, then the liquid mixture is put into a foam dustfall foamer for mining to generate foam, the foam is conveyed to a dust source to cover the dust source, correspondingly dust generated by the dust source is caught and sedimented, and finally, a great operation environment under a coal mine well is ensured. Hydrophobic groups (also named as lipophilic groups), adsorbed to a water source layer, of wetting agent moleculesare the first ones in contact with coal dust and are composed of long organic carbon chains; the molecular property of the hydrophobic groups is similar to that of the surface of the coal dust, and compared with water molecules, the hydrophobic groups can achieve adsorption more easily, so that the dust catching efficiency of the foam is improved, the dustfall rate is increased to 97.9% or above,and the dustfall efficiency is improved.

Owner:SHANDONG UNIV OF TECH

Adhesive tape with fluorescent effect

InactiveCN103242773AReasonable structural designFunctionalFilm/foil adhesivesLuminescent compositionsWater basedSurface layer

The invention discloses an adhesive tape with a fluorescent effect. The adhesive tape comprises a surface layer, a base layer and an adhesive layer, wherein the surface layer and the adhesive layer are respectively molded at the two sides of the base layer; the base layer is a textile fabric layer; the surface layer is a fluorescent thin film layer; the adhesive layer is a lipid pressure-sensitive adhesive layer; and the surface layer comprises main components of fluorescent powder, a water-based binding agent and relative auxiliary agents. The adhesive tape with the fluorescent effect is reasonable in structural design and outstanding in function; a fluorescent material is added into the surface layer, so that the adhesive tape can release light at daytime and night and can have a good caution effect while having a binding effect. Therefore, the safety of going out on rainy days of people is improved and the practical value of the adhesive tape is improved greatly.

Owner:KUNSHAN HANBAO TAPE TECH

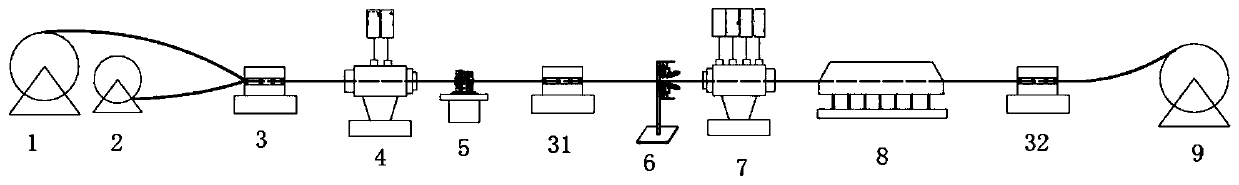

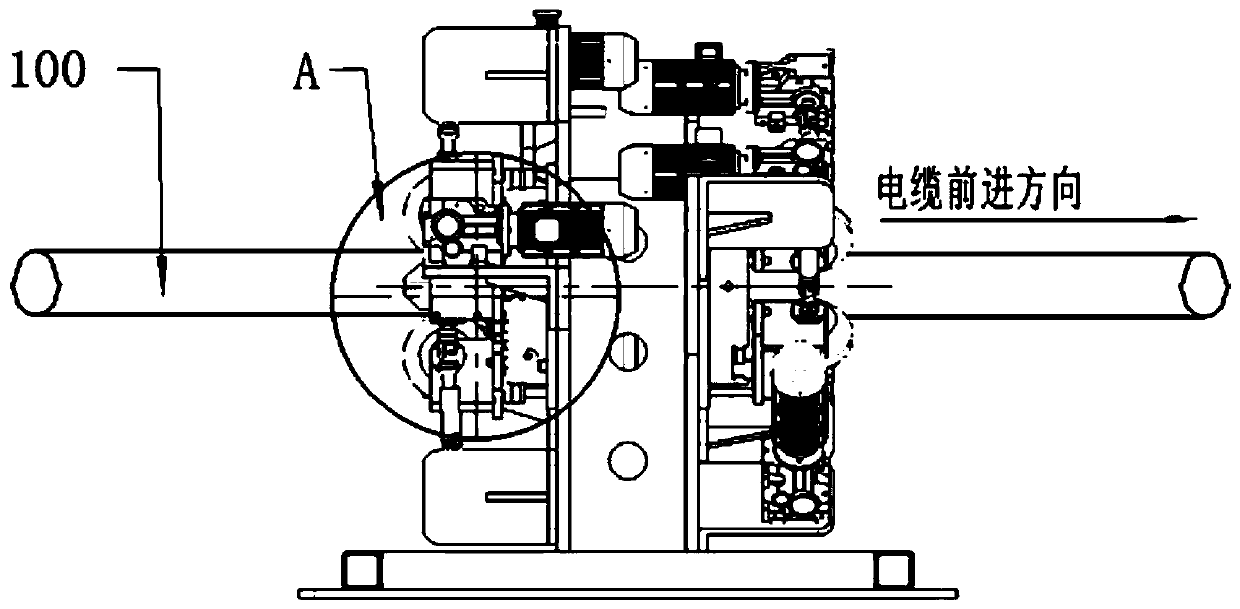

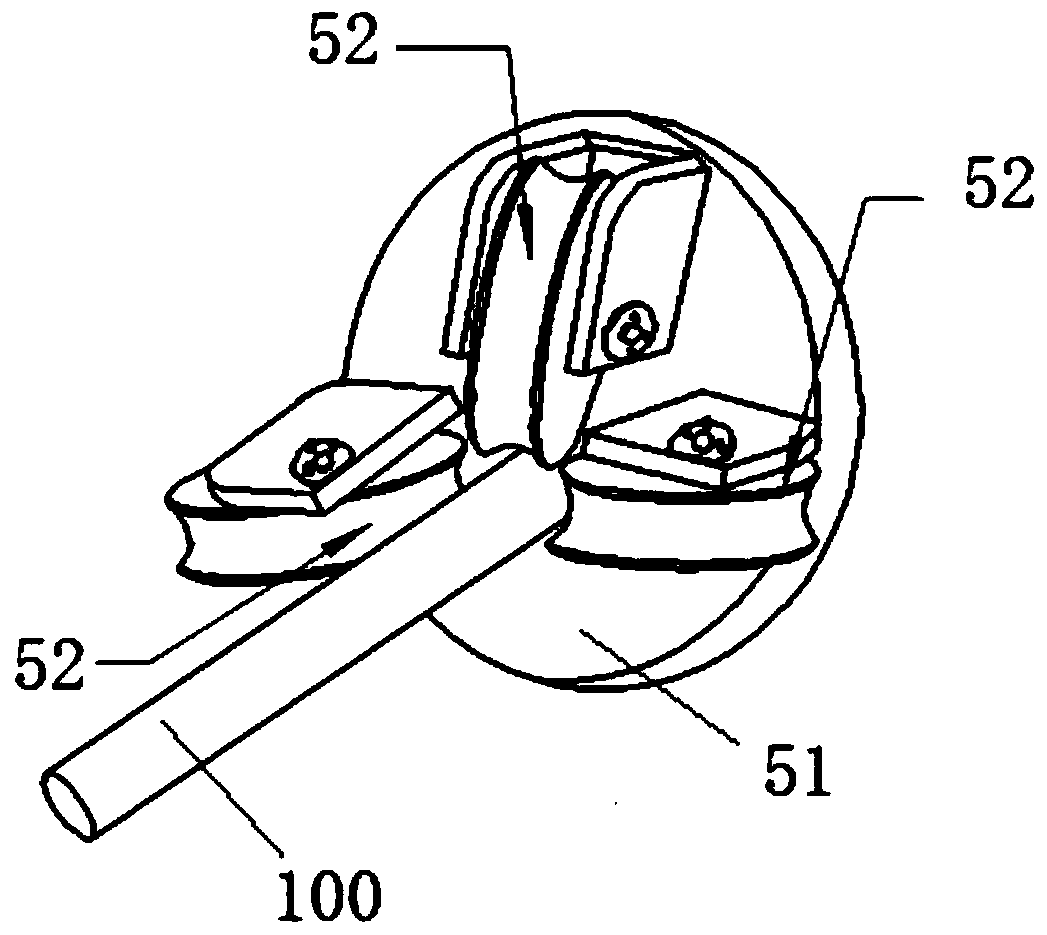

Extruded composite smooth aluminum sleeve cable production equipment and a production method

PendingCN111524657AReduce manufacturing costCompact structureInsulated cablesCable/conductor manufactureEngineeringHot melt

The invention discloses extruded composite smooth aluminum sleeve cable production equipment and a production method. The production equipment comprises an extruded aluminum sleeve device, a wheel type reducing device, a preheating device, a multi-layer co-extrusion device and a cooling water tank, and the extruded aluminum sleeve device continuously extrudes an aluminum sleeve; the cable coated with the aluminum sleeve passes through a shaft hole, and the aluminum sleeve is tightened to the outer diameter designed by the process by the wheel type reducing device, so that the whole aluminum sleeve is coated on the surface of the cable core; the preheating device is used for heating the aluminum sleeve; the multi-layer co-extrusion device is used for compounding the aluminum sleeve with thehot melt adhesive, a PE sheath, a PVC sheath and a conductive layer together and carrying out cooling molding through the cooling water tank. According to the hot melt adhesive extrusion technology designed by the invention, the hot melt adhesive not only achieves an anti-corrosion effect, but also achieves a bonding effect, so that the PE sheath, the PVC sheath, the conductive layer and the smooth aluminum sheath of the cable are firmly bonded together, and the phenomena of arching or wrinkling cannot be generated during bending, take-up and construction of the cable.

Owner:ZHEJIANG CHENGUANG CABLE CO LTD

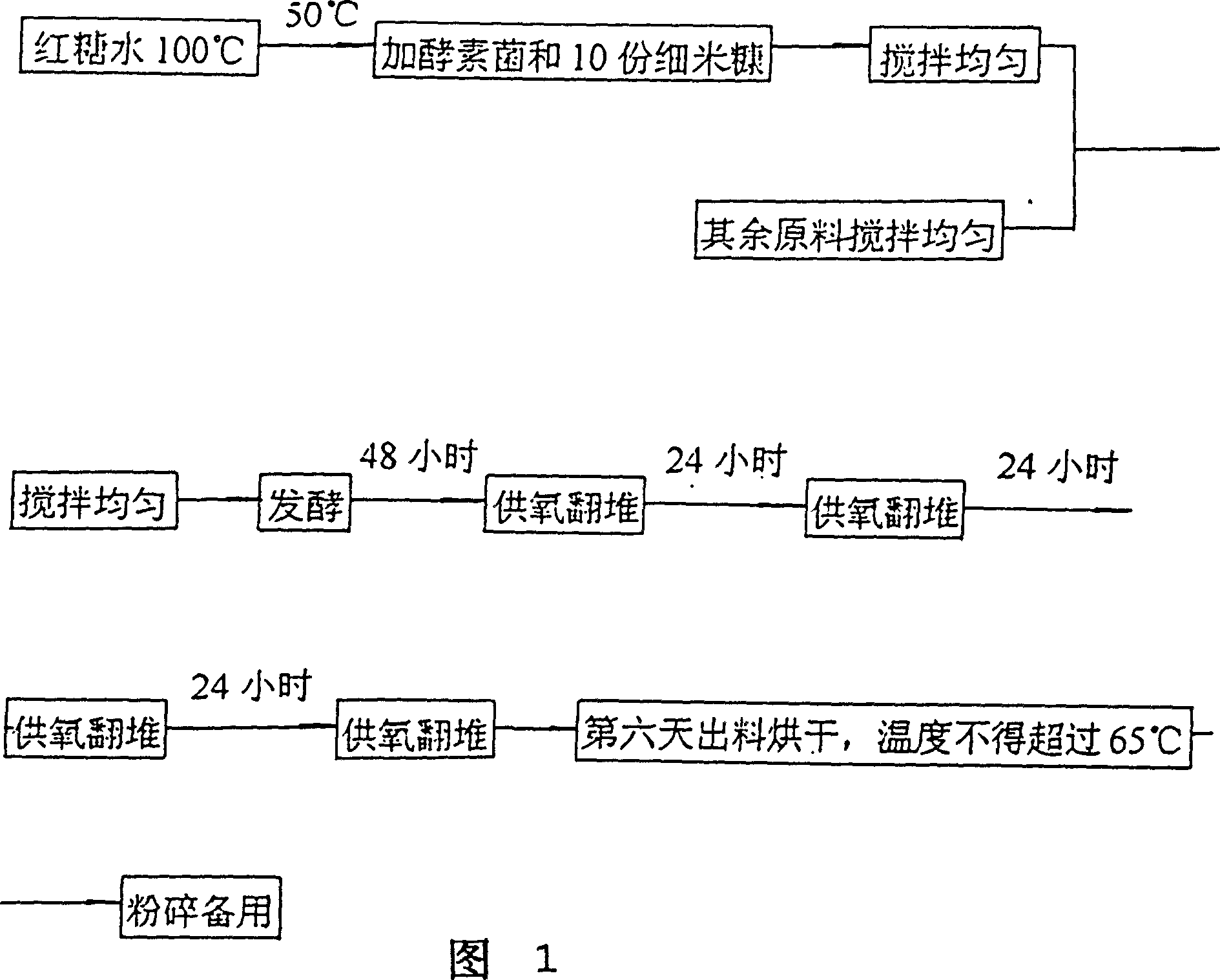

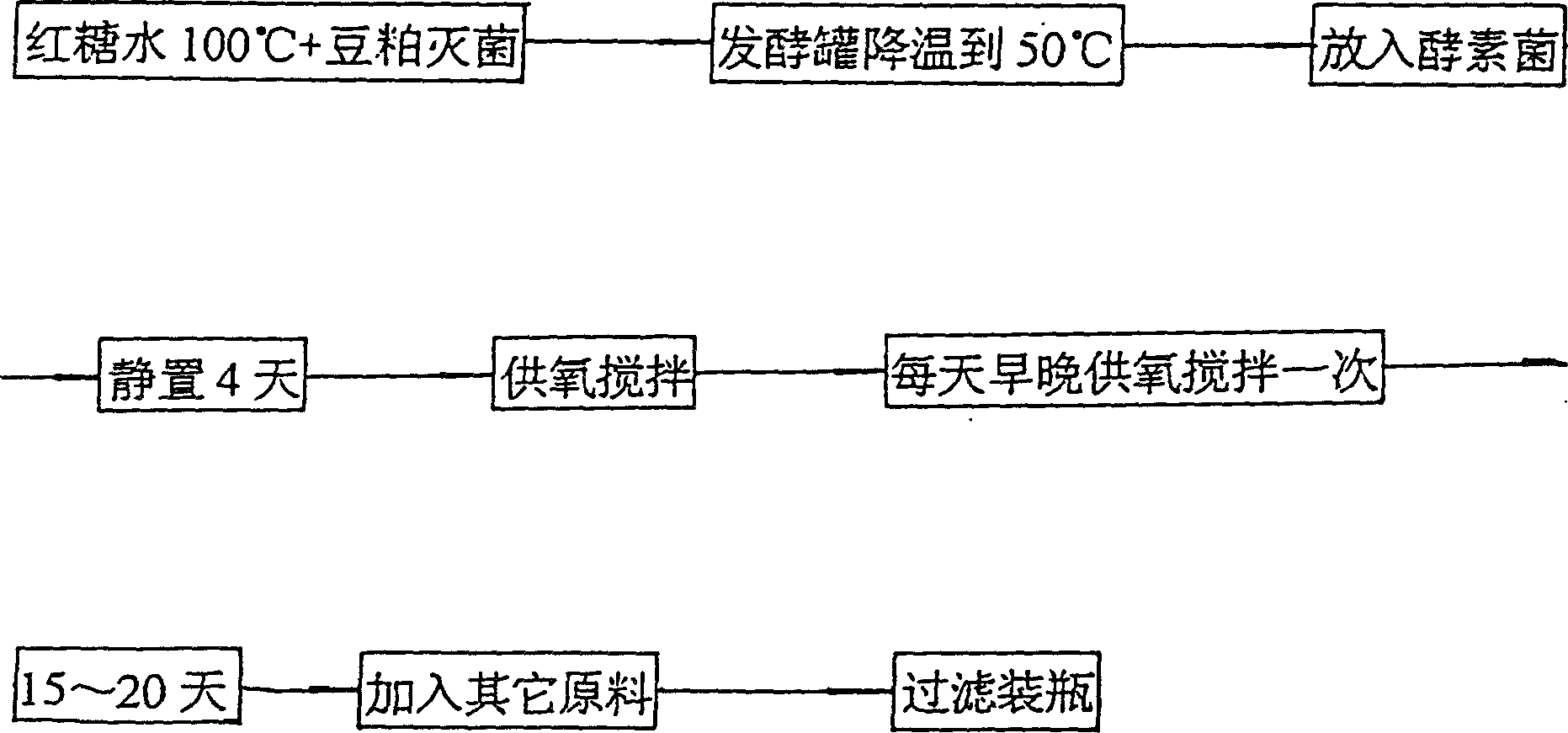

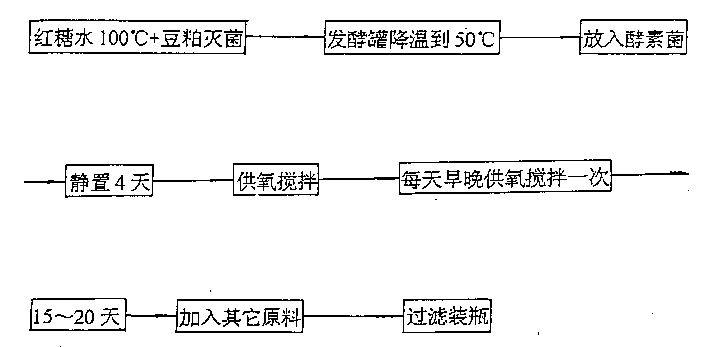

Activated biological breeding feed

InactiveCN1533706AControl hazardsPlay a role in bondingFood processingAnimal feeding stuffBiotechnologyFowl

An active biological additive for the feed of domestic animals and fowls features that it contains a lot of useful bacteria and amino acids.

Owner:张玉华

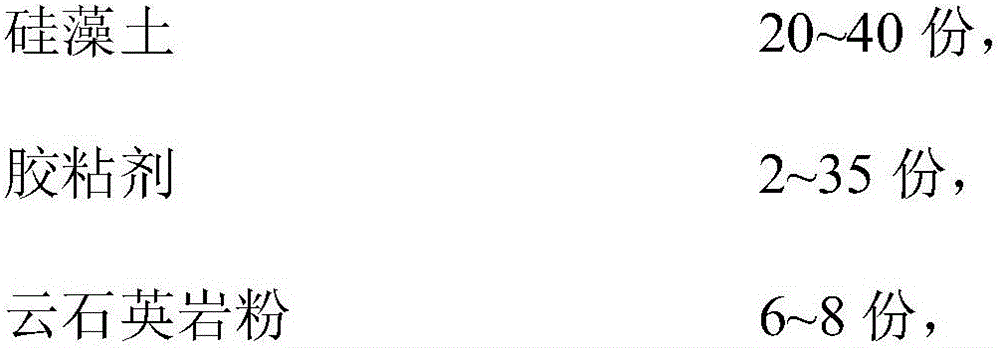

Environment-friendly diatom ooze decorative wall material

InactiveCN106007559AImprove adsorption capacityWith sound and heat insulationHazardous substanceAntibacterial activity

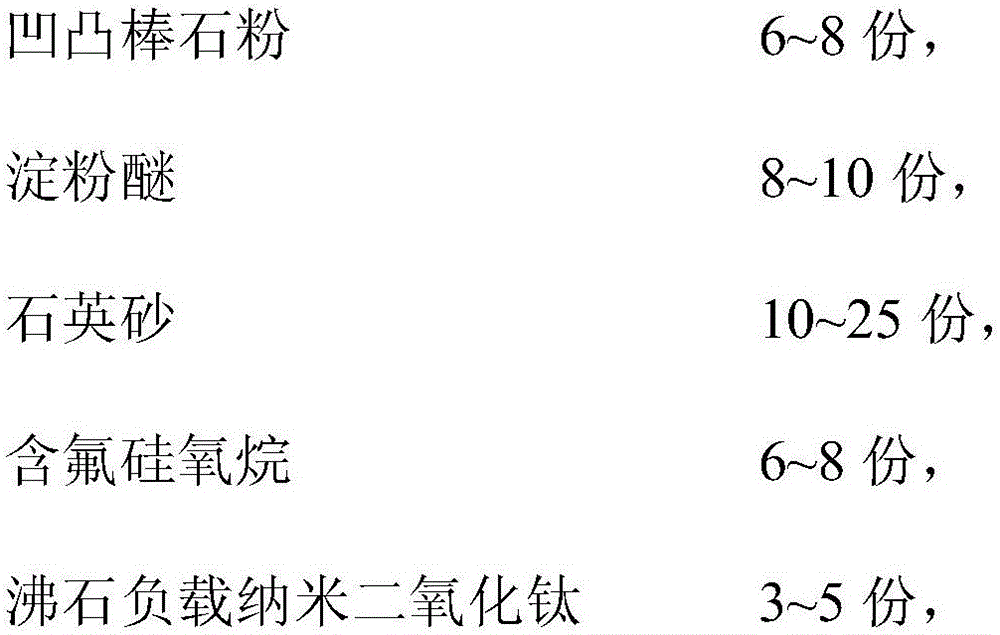

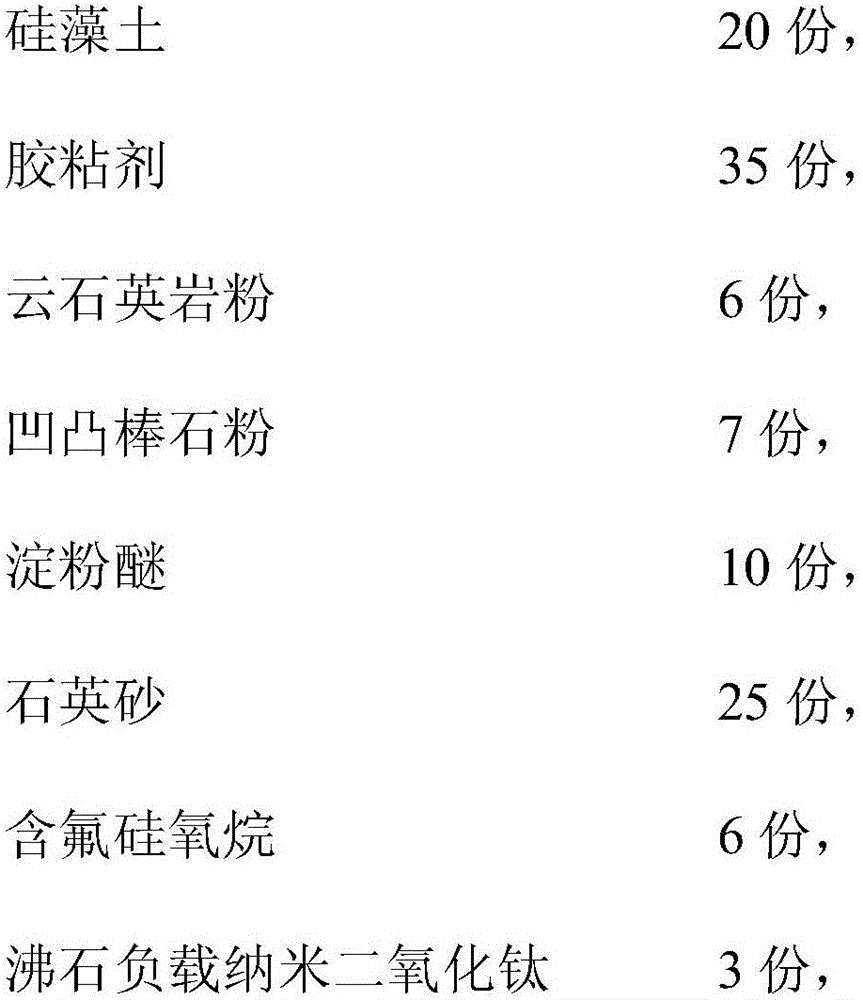

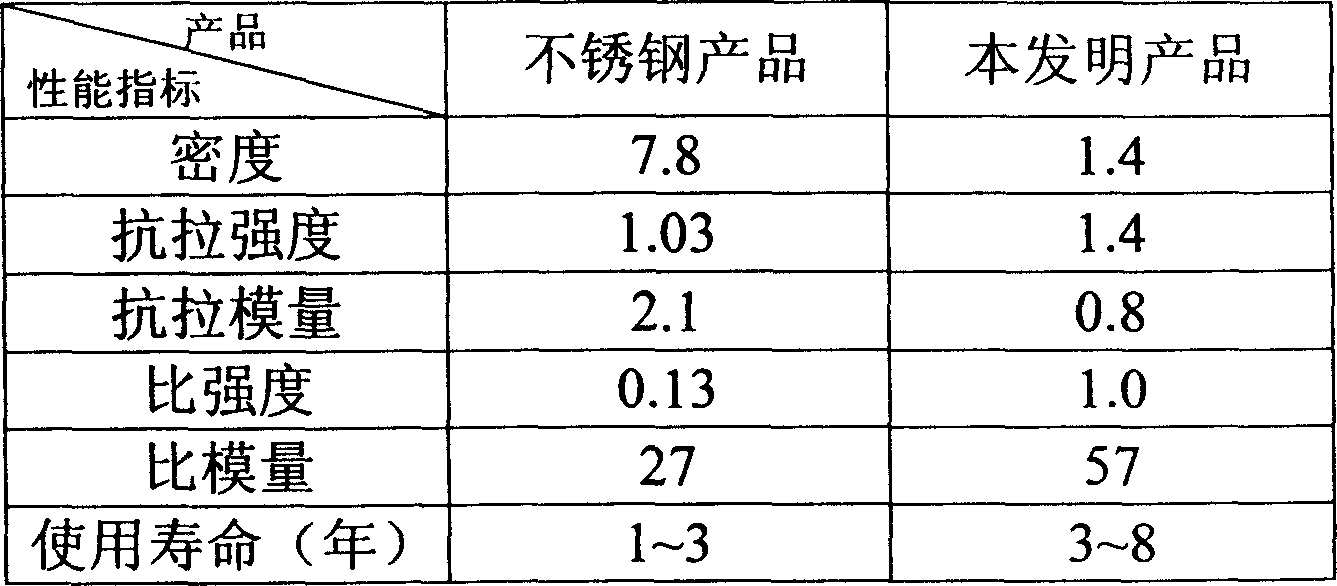

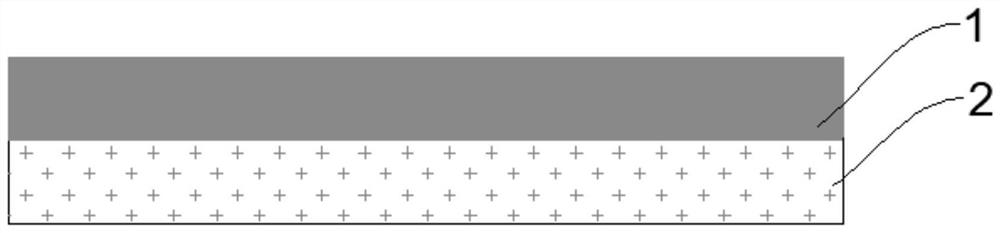

The invention relates to the field of coatings, and discloses an environment-friendly diatom ooze decorative wall material. The environment-friendly diatom ooze decorative wall material is prepared from components in parts by weight as follows: 20-40 parts of diatomite, 2-35 parts of an adhesive, 6-8 parts of marble quartzite powder, 6-8 parts of attapulgite powder, 8-10 parts of starch ether, 10-25 parts of quartz sand, 6-8 parts of fluorine-containing siloxane and 3-5 parts of zeolite-loaded nanometer titania. The energy-saving and environment-friendly diatom ooze decorative wall material contains no harmful substances and has the advantages of good cohesiveness, high formaldehyde removal efficiency, high antibacterial activity and deodorization performance and excellent self-cleaning and purification durability, and the performance index meets requirements specified in the JC / T2177-2013 standard.

Owner:HANGZHOU MAKEDOLLAR ENVIRONMENTAL PROTECTION NEW MATERIAL

Black garlic capsules and preparation method thereof

InactiveCN103445104AImprove distributionPromote absorptionFood shapingFood preparationOctenyl succinateSlurry

The invention discloses black garlic capsules and a preparation method thereof. The black garlic capsules are prepared from the following raw materials in percentage by weight: 5-10g of black garlic, 2-4g of citric acid, 3-6g of sodium citrate, 0.1-0.2g of sodium malate, 3-5g of calcium carboxymethylcellulose and 81.9-86.9g of starch octenyl succinate anhydride. The product disclosed by the invention is prepared by the following steps: adding water to black garlic to grind to slurry by a colloid mill; then, mixing with liquor prepared by from other auxiliary materials; stirring for 80-120 minutes at a rotate speed of 180-220r / m; then, spraying, drying, pelletizing, leveling and uniformly packaging to prepare the black garlic capsule products. With the adoption of the preparation process, the raw materials of the product are small in grain size and smoothfine, and are beneficially distributed and dissolved-out in vivo, so that the absorption and utilization effect of the product is facilitated. The product disclosed by the invention is convenient to carry and take, low in preparation cost and good in market prospect.

Owner:徐州绿之野生物食品有限公司

Parts and component made from Nano plastic alloy for watering apparatus, and preparing method

A nano-class plastic-alloy part for hydraulic machine is prepared through proportionally mixing short aramid fibers, nanoparticles, nylon powder and PTFE powder to obtain powder mixture, proportionally mixing epoxy resin, solidifying agent and diluent to obtain slurry, mixing them together, pouring into mould containing carbon steel skeleton and aramid fiber fabric and pressure solidifying. Its advantages are high resistance to abrasion and cavitation, and low cost.

Owner:重庆新高纳米塑料合金有限公司

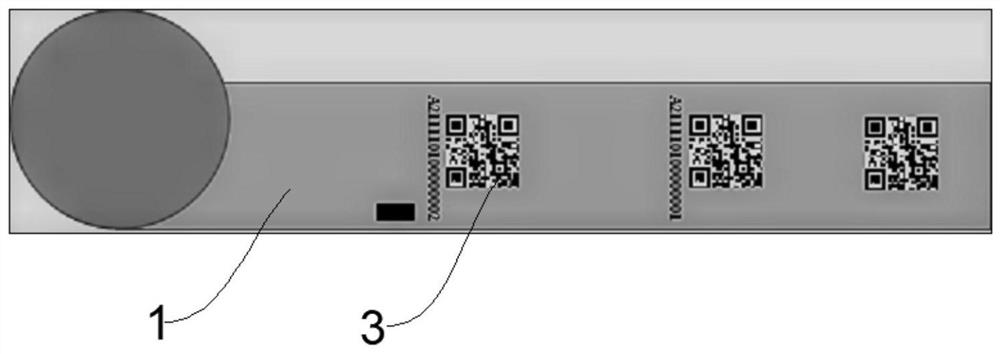

Traceable adhesive tape and preparation method thereof

PendingCN114196345AHigh precisionImprove clarityFilm/foil adhesive primer layersPolyureas/polyurethane adhesivesAdhesive beltEngineering

The invention provides a traceable adhesive tape. The traceable adhesive tape comprises a light-transmitting base material and an adhesive layer which are compounded with each other, the light-permeable base material comprises a first surface and a second surface which are arranged back to back; the first surface is a corona surface, and a digital printing marker is arranged on the corona surface; the first surface of the light-permeable base material is compounded with the adhesive layer. The traceable adhesive tape has the advantages of being high in recognition rate, simple in structure, high in adhesive layer adaptability and high in chemical resistance, and can be applied to industrial production and products, and tracing of production information of the products can be achieved.

Owner:DONGGUAN AOZON ELECTRONICS MATERIAL

Ramsbottom carbon powder molding adhesive

InactiveCN101781531APlay a role in bondingHigh strengthNon-macromolecular adhesive additivesStarch adhesivesAdhesiveSodium hydroxide

The invention discloses ramsbottom carbon powder molding adhesive. The ramsbottom carbon powder molding adhesive is prepared by mixing 20 to 30 percent of caustic soda sodium hydroxide solution, 20 to 30 percent of urea solution and 40 to 60 percent of corn starch and adding hot water at the temperature of between 60 and 80 DEG C into the mixture with mixing, wherein the concentration of the sodium hydroxide solution is 0.1 to 5 percent and the concentration of the urea solution is 0.1 to 5 percent. The formula is simple and practical; the materials are easy to obtain; and after the adhesive is used, the ramsbottom carbon powder has good molding, low ash content, good adhesive performance and good chemical activity, has consistent using effect of ramsbottom carbon, reduces the energy waste, avoids environment pollution and provides a guarantee for reducing production cost and promoting benefit.

Owner:丹江口福安运输有限责任公司

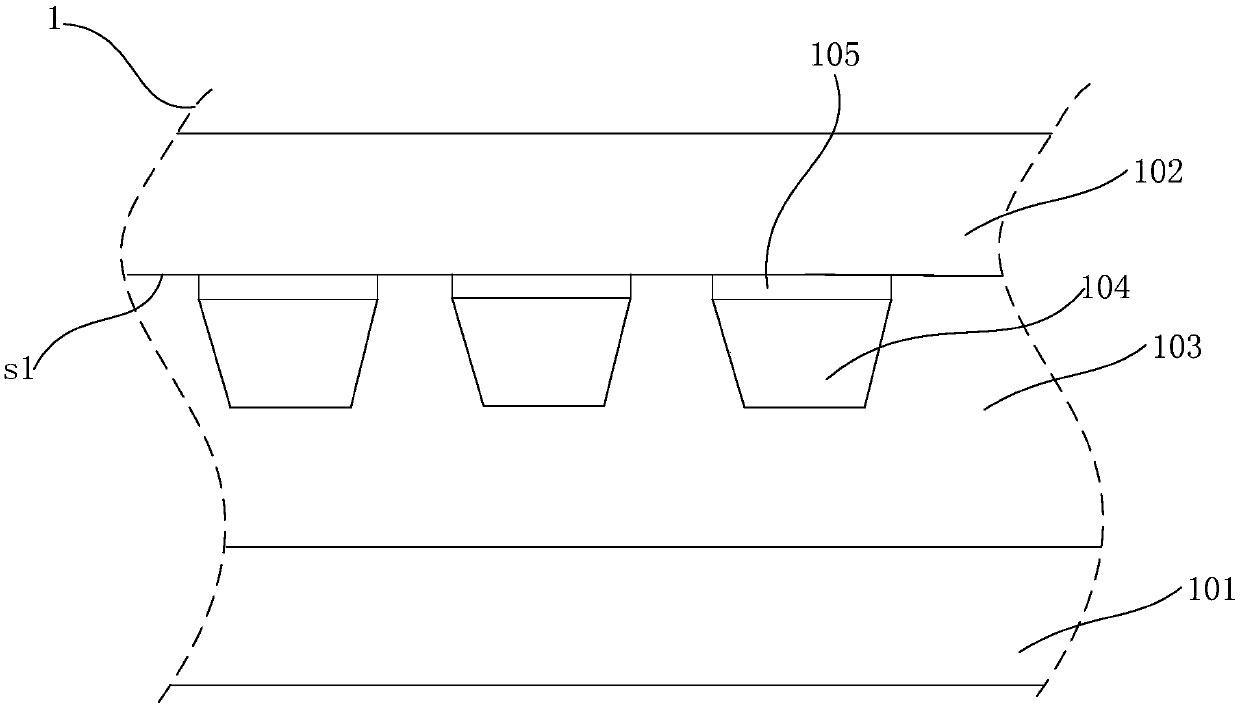

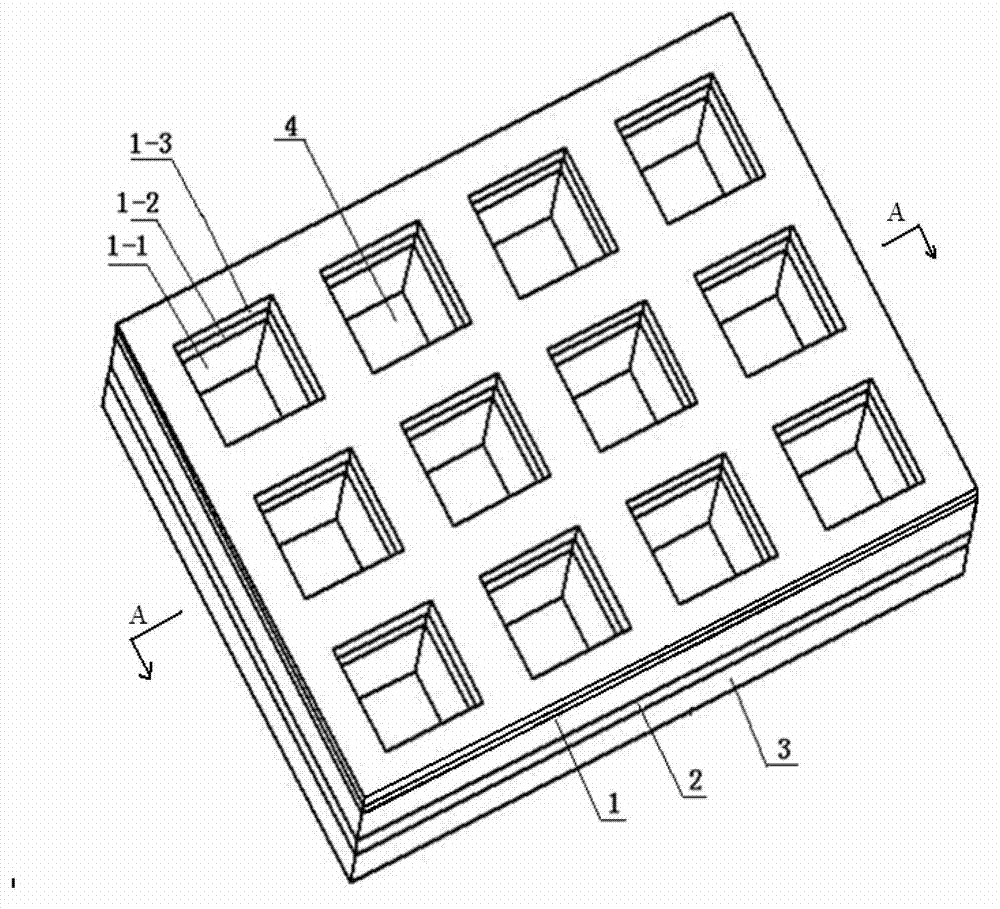

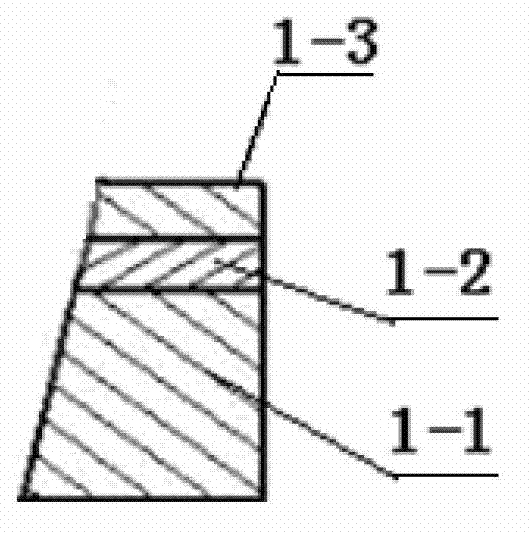

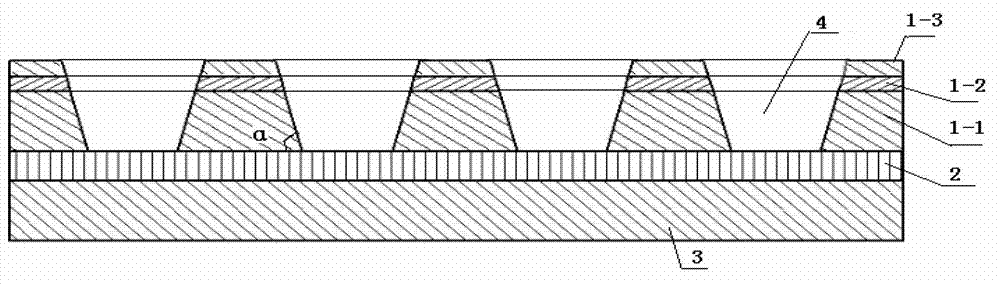

Biochip with constant volume and preparation method thereof

InactiveCN102879556APlay a role in bondingReduce stepsBiological testingChemical vapor deposition coatingEpoxySpray coating

A biochip with a constant volume and a preparation method thereof relate to a biochip and a preparation method thereof. The invention solves the problems of inaccurate detection results and complicated preparation methods for current biochips. The biochip with a constant volume is formed by a porous silicon wafer layer, an epoxy resin layer and a glass substrate. The preparation method comprises the following steps: firstly, preparing the porous silicon wafer layer; secondly, coating epoxy resin on the glass substrate by spin coating or spray coating to obtain the epoxy resin layer, putting the porous silicon wafer layer on the epoxy resin layer to obtain a primary biochip, wherein a monocrystalline silicon layer of the porous silicon wafer layer contacts the epoxy resin layer; thirdly, curing the primary biochip to obtain the biochip with a constant volume. The biochip of the invention can accurately detect the concentration of a target molecule in a biological sample, and the method of the invention is simple. The invention is applicable to the crossing field of biotechnology and micromachining.

Owner:NO 49 INST CHINESE ELECTRONICS SCI & TECH GRP

Preparation method of heteromorphic microporous ceramic capillary

ActiveCN107324802AGuaranteed positionAppearance dimensionally stable and uniformMouldsCoupling light guidesMicrometerVolumetric Mass Density

The invention provides a preparation method of a heteromorphic microporous ceramic capillary. The preparation method comprises the steps of designing a special heteromorphic microporous ceramic capillary forming die, preparing special zirconia ceramic particles, matching a unique sintering forming technology to achieve primary sintering forming of a heteromorphic inner hole of the ceramic capillary without secondary processing, and designing a thimble positioning hole during forming green body preparation according to a product property of the heteromorphic microporous ceramic capillary to allow that an outside diameter grinding technology of the ceramic capillary is greatly simplified. For the ceramic capillary prepared by the method, the density reaches 6.0-6.10g / cm<3>; the hardness is greater than 1200HV; the bending strength is greater than 1200MPa; the dimensional tolerance of the inner hole is within 3 micrometers; the outside diameter grinding precision can reach 1-micrometer position precision; a glass capillary in a multi-core optical fiber collimator can be completely replaced; the matching precision with an optical fiber is high; the reliability meets a requirement of an optical passive device standard GR1209 / 1221.

Owner:黄石晨信光电股份有限公司

Conductive adhesive structure and display device

ActiveCN111409326AImprove adhesionWith longitudinal conductivityConductive layers on insulating-supportsSynthetic resin layered productsPhysicsEngineering

The invention relates to the technical field of display, and discloses a conductive adhesive structure and a display device. The conductive adhesive structure comprises a first adhesive layer, a conductive layer and a second adhesive layer which are sequentially arranged in a stacked mode, a plurality of conductive particle filling areas distributed at intervals are arranged in the first adhesivelayer, conductive particles are arranged in the conductive particle filling areas, and the conductive particles are electrically connected with the conductive layer. Based on the conductive adhesive structure, display panel backside, inductive charges generated on the back face of the display panel can be guided and dispersed evenly in the whole face of the back face of the display panel, the situation that the inductive charges are gathered is avoided, the problem that a fingerprint unlocking area becomes dark is solved, it is guaranteed that the display brightness of the unlocking area is uniform and consistent with that of other display areas, and the overall brightness of the display panel is displayed evenly.

Owner:BOE TECH GRP CO LTD +1

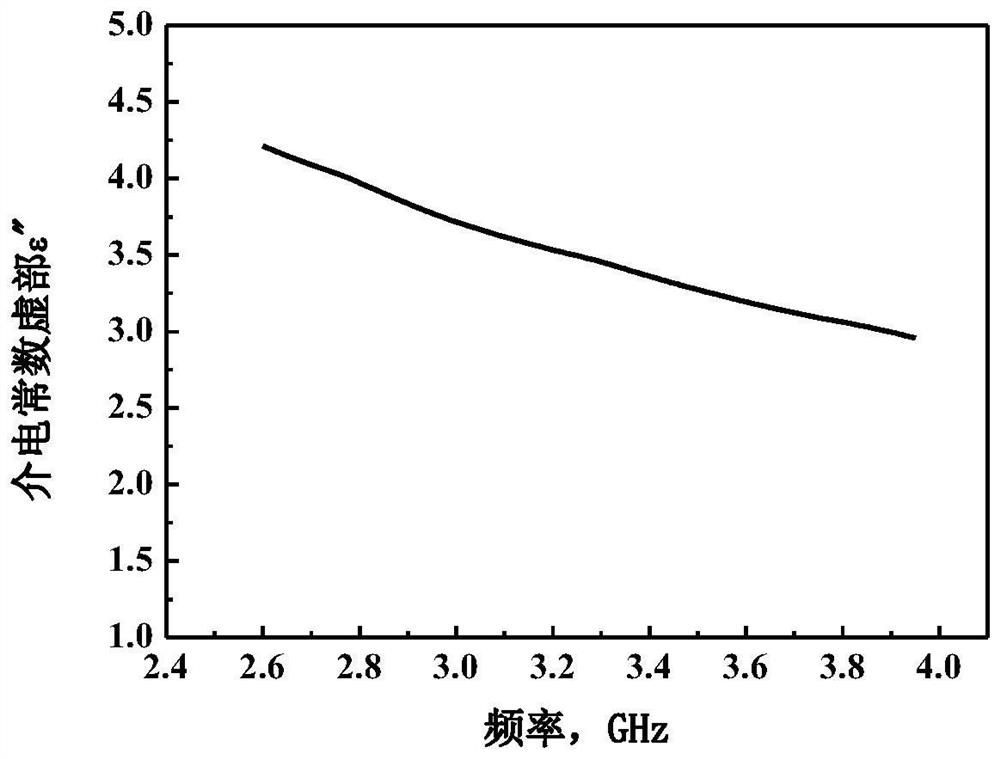

Coating type wave-absorbing aramid paper, wave-absorbing honeycomb and preparation method

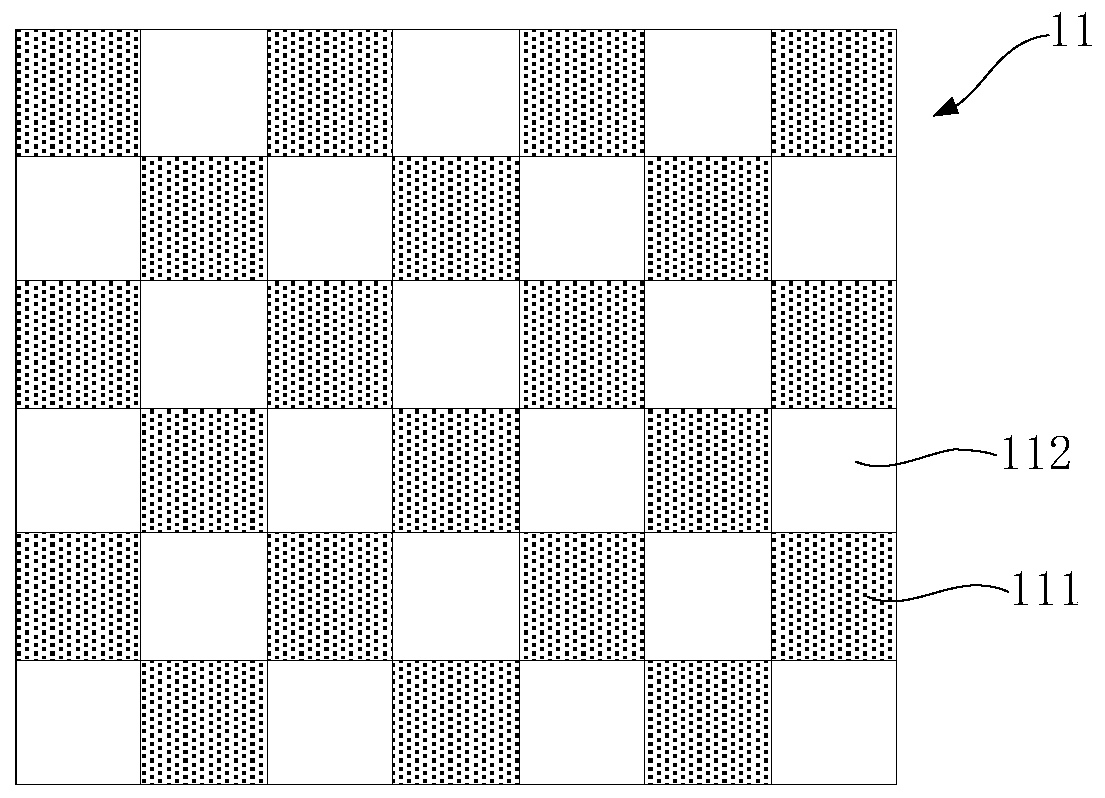

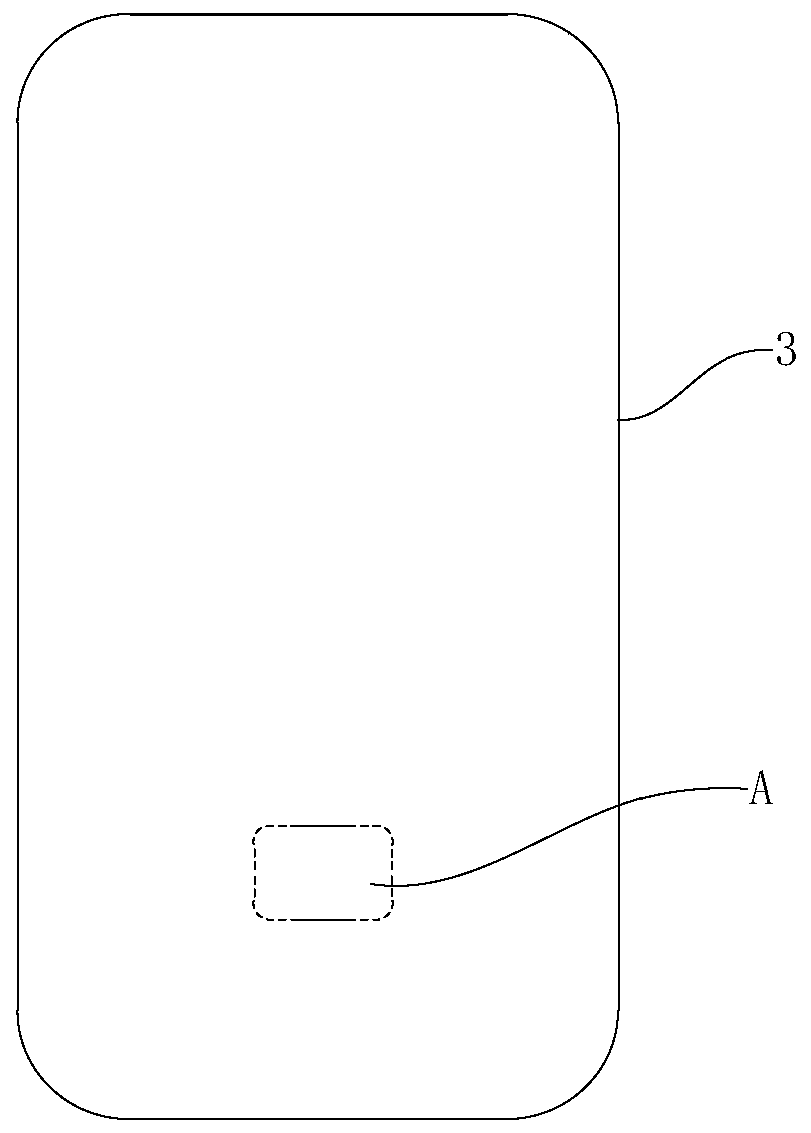

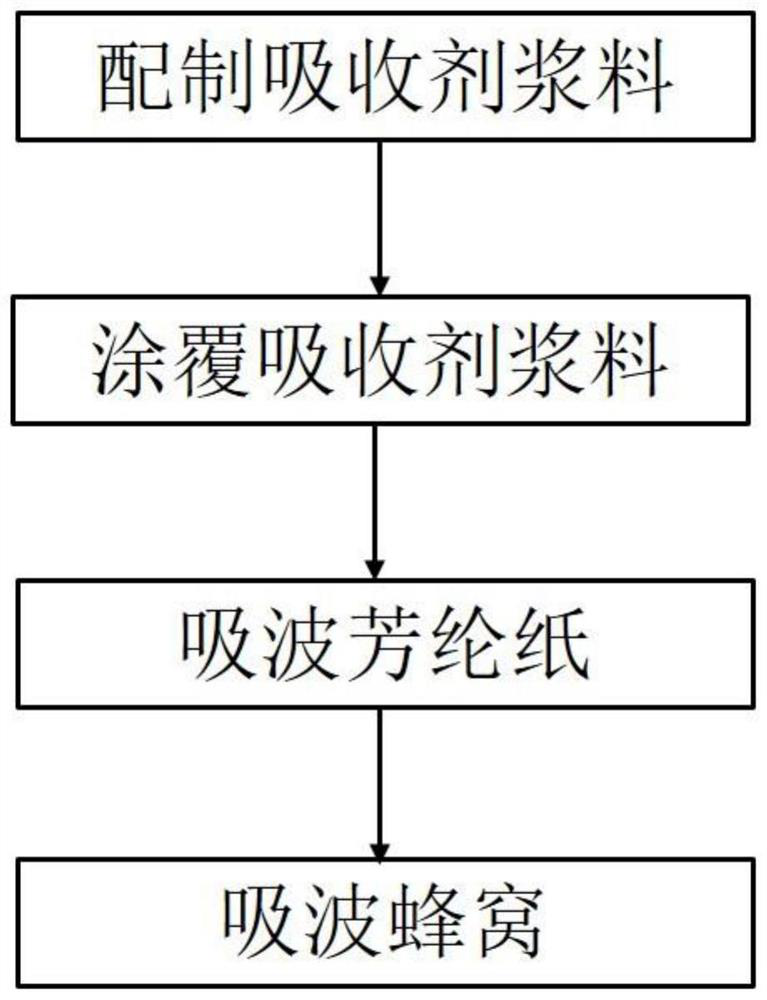

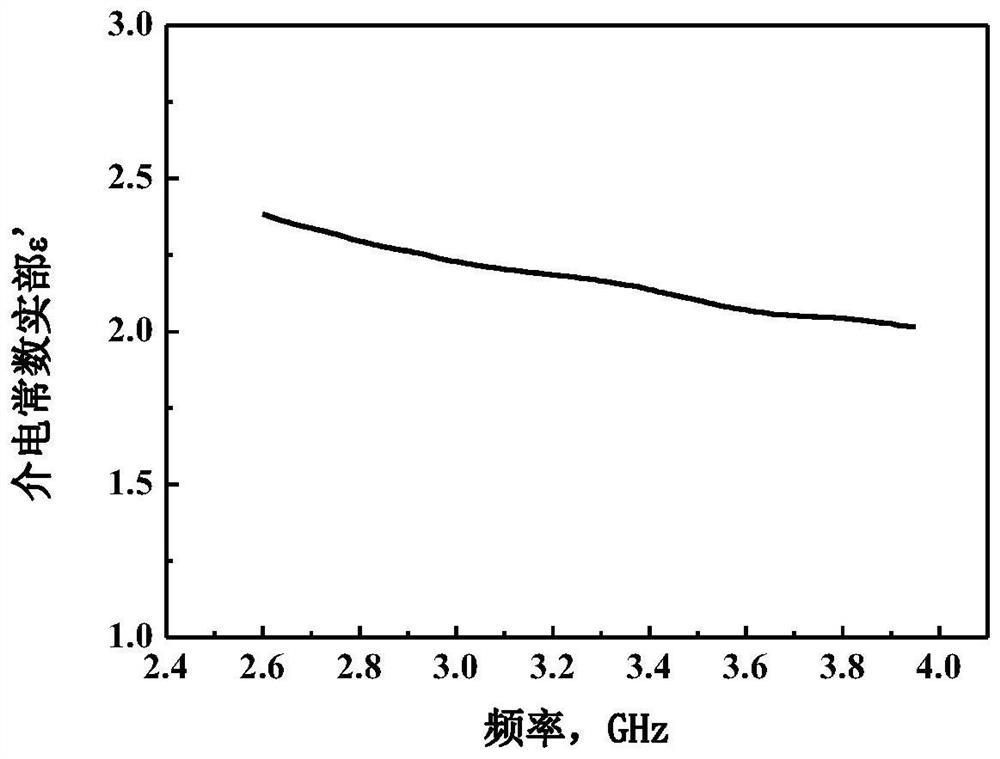

PendingCN114214871APlay a role in absorbing wavesEvenly dispersedNon-fibrous pulp additionCoatings with pigmentsPolymer scienceAramid

The invention discloses coating type wave-absorbing aramid paper, a wave-absorbing honeycomb and a preparation method, and belongs to the technical field of functional materials, the coating type wave-absorbing aramid paper comprises aramid paper and a wave-absorbing layer coated on the surface of the aramid paper, the components of the wave-absorbing layer comprise an absorbent and a resin system, the thickness of the wave-absorbing layer is 0.02-0.1 mm, and the volume ratio of the absorbent to the resin system is 1: 1-1: 5. The coating type wave-absorbing aramid paper not only has high electromagnetic loss, stable electromagnetic parameters and large electromagnetic parameter regulation range, but also has good mechanical properties.

Owner:AEROSPACE INST OF ADVANCED MATERIALS & PROCESSING TECH

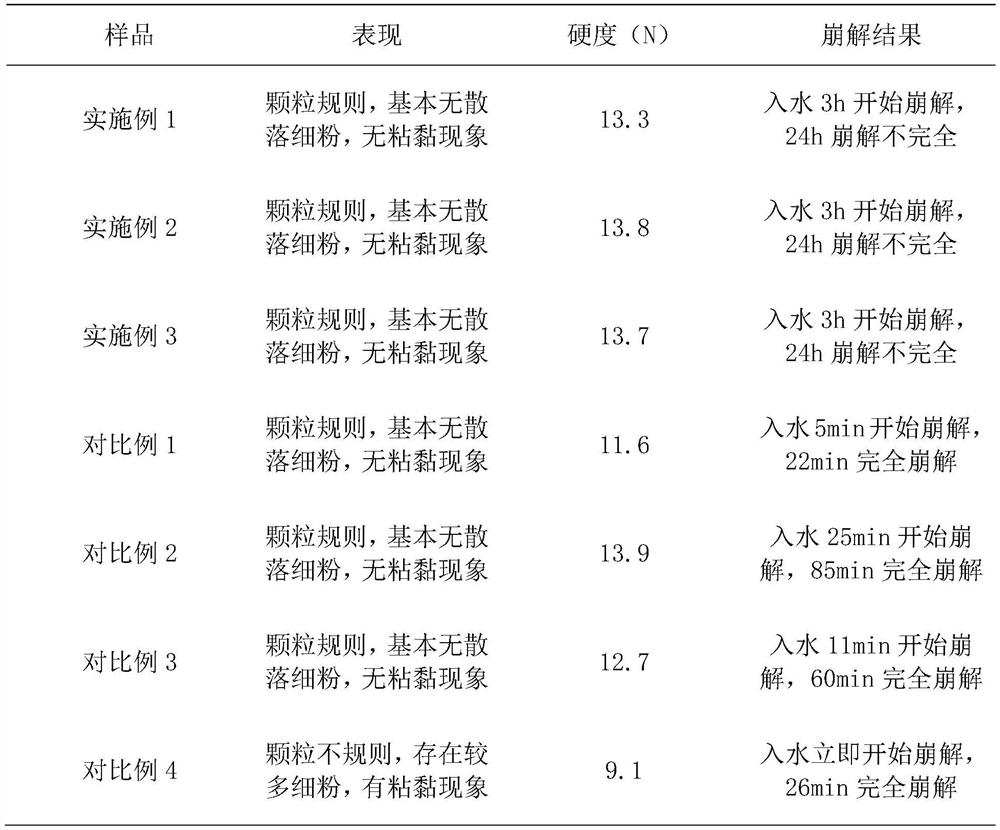

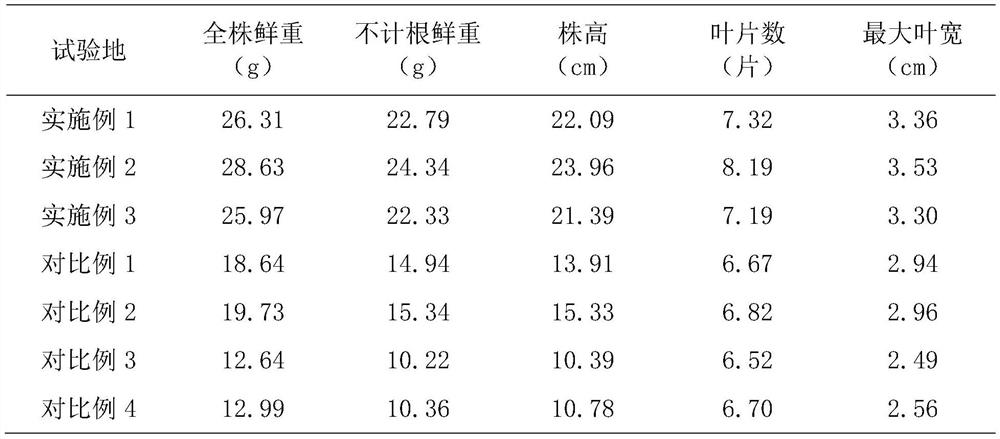

Granulation method of microbial fertilizer

PendingCN113307698AHigh environmental toleranceGuaranteed long-term stabilityBio-organic fraction processingExcrement fertilisersFertilizerEnvironmental chemistry

The invention discloses a granulation method of a microbial fertilizer. The method comprises: carrying out solid fermentation on an organic material containing microbial bacteria to obtain a bacterial fertilizer, and carrying out molding granulation on the bacterial fertilizer to obtain bacterial fertilizer particles; carrying out surface mechanical activation treatment on the bacterial fertilizer particles; respectively preparing modified starch with the particle size of 0.01-5 microns and aerated concrete powder with the particle size of 50-200 microns, mixing the modified starch with the aerated concrete powder, adding a dispersing solvent, and stirring to obtain coating slurry; and carrying out coating treatment on the bacterial fertilizer particles by using the coating slurry, and drying to obtain the microbial fertilizer. In the granulation process of the biological bacterial fertilizer, the surfaces of fertilizer particles are firstly activated and then coated with the coating film prepared from the aerated concrete powder and the modified starch, so that fertilizer efficiency components are fully fixed and cannot be directly and completely collapsed, dissolved and lost when meeting water, and stable dissolution and emission of the fertilizer efficiency can be always kept by the microporous structure; therefore, the slow-release effect is achieved, the environmental tolerance of the biological bacterial fertilizer is improved, and the long-term stability of the fertilizer efficiency is ensured.

Owner:ANHUI GUMEI ECOLOGICAL AGRI TECH CO LTD

Activated carbon fiber paper and preparation method thereof

ActiveCN104233903AGood paperHigh dry and wet strengthSynthetic cellulose/non-cellulose material pulp/paperActivated carbon filtrationUltimate tensile strength

The invention discloses activated carbon fiber paper and a preparation method thereof. The activated carbon fiber paper adopts aramid fibrids as carriers, and the carriers are loaded with activated carbon fibers, wherein the lengths of the activated carbon fibers are within 1-8mm, and the aramid fibrids account for 10-50% of the activated carbon fiber paper in oven-dry mass. Compared with traditional activated carbon fiber paper, the prepared activated carbon fiber paper has the high adsorptive property and high strength.

Owner:南通大学技术转移中心有限公司

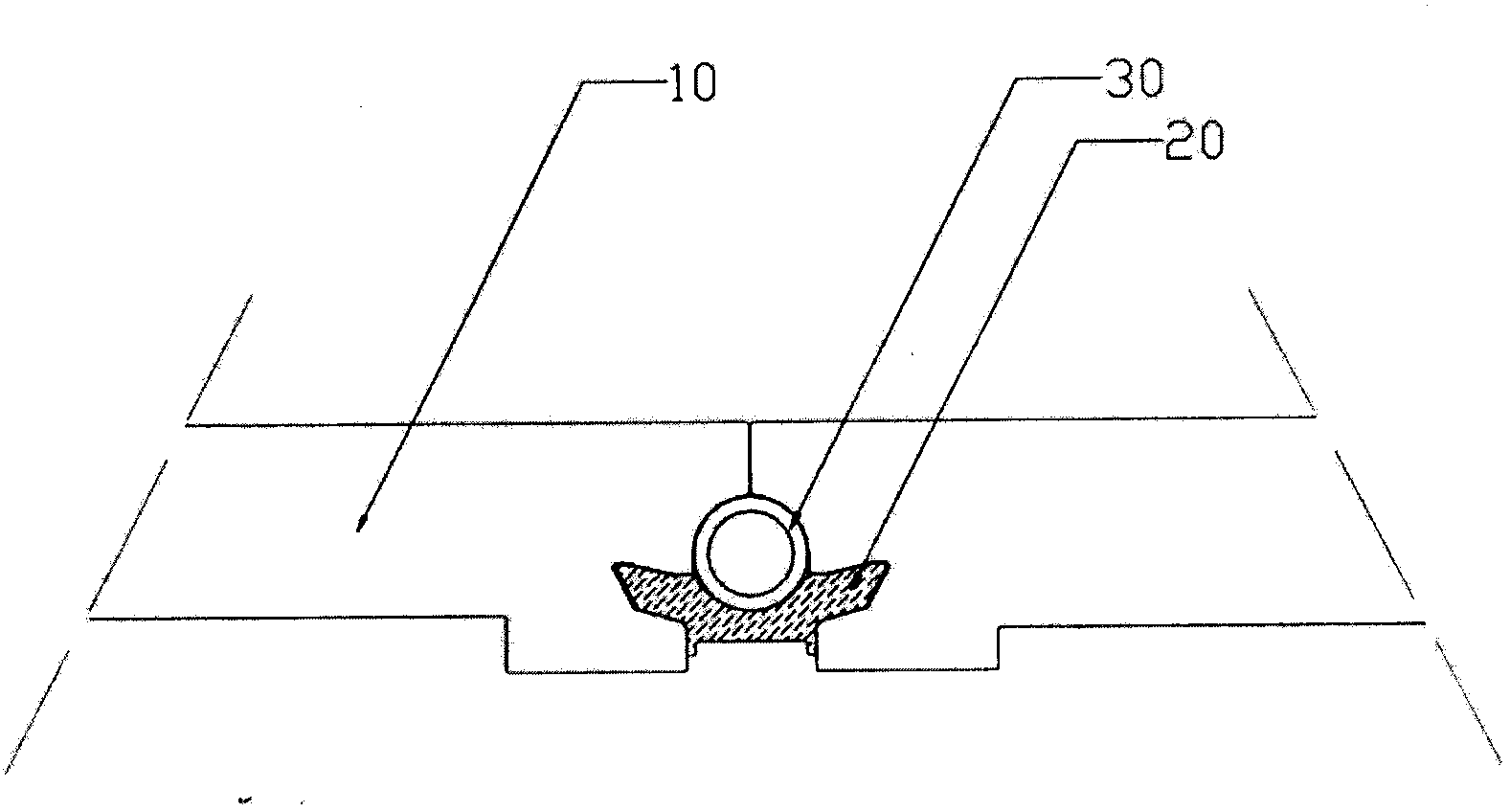

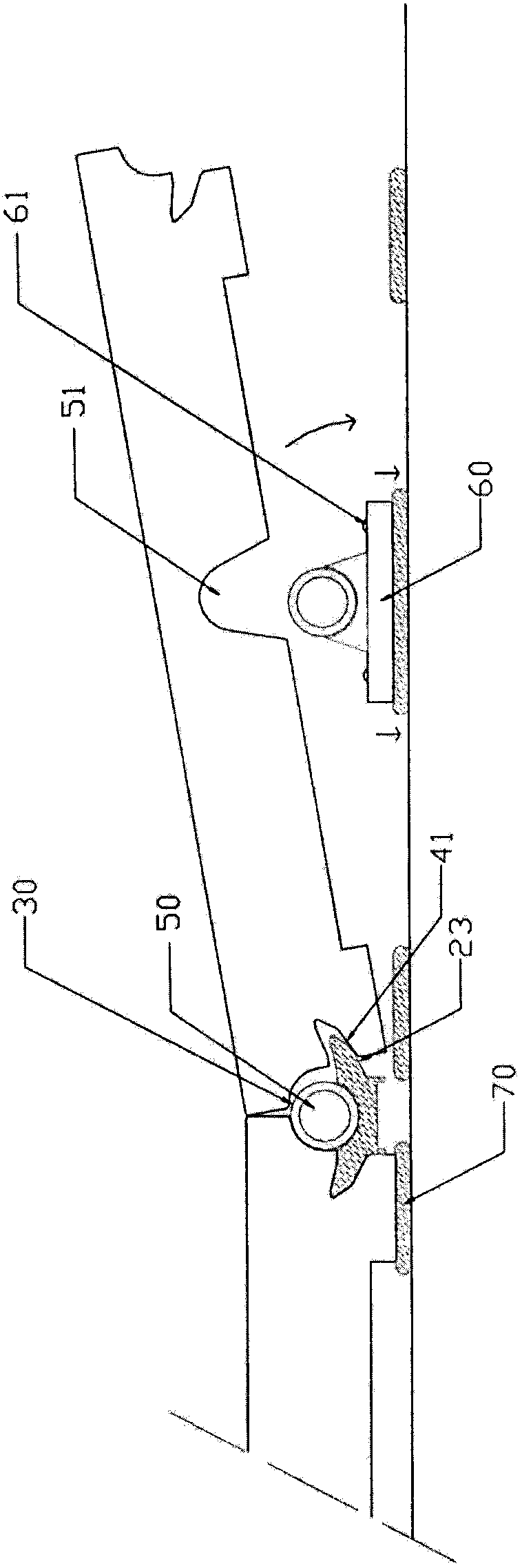

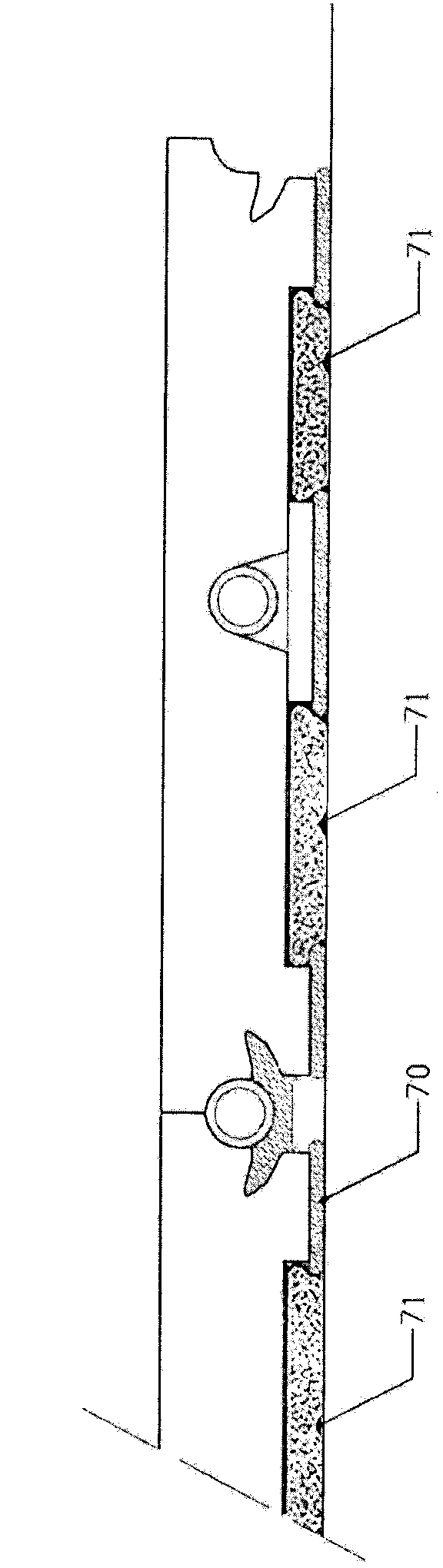

Cooling/heating floor connected by clamp pieces

InactiveCN103912106AHigh heating thermal efficiencyConsistent installation heightFlooring insulationsEngineeringHOLDING CHAMBER

The invention discloses a cooling / heating floor connected by clamp pieces. The cooling / heating floor connected by clamp pieces comprises a floor body, a connection locking piece and a heating pipe. The connection locking piece is located at the side of the floor body, the cross section of the end of the connection locking piece is flying bat-shaped, the wing of one side is inserted in a longitudinal groove of the side of the floor, the wing of the other side is inserted in a longitudinal groove of the side of a floor to be connected with the connection locking piece, the connecting part of the middle of the wing of each side is formed with a downward groove under an arc-shaped nick edge of one side of the floor body, the downward groove and the nick of one side of the floor body define a longitudinal slot, the heating pipe is horizontally mounted in the longitudinal slot, when the connection locking piece is engaged to the floor, an inside holding chamber is formed in the lower part of the floor connecting part, the heating pipe is held in the inside holding chamber, and then the connection locking piece and the heating pipe are firmly integrated with the floor. The cooling / heating floor connected by clamp pieces is more convenient to mount; and moreover, the heat is directly transmitted to the floor through the heating pipe, so that the cold and heat are more effectively emitted to the room.

Owner:郭兆军

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com