Cooling/heating floor connected by clamp pieces

A connection type and floor technology, which is applied in the direction of floors, insulation layers, buildings, etc., can solve the problems that the technology cannot meet the demand, the damage of buried pipelines, and the temperature rise lag.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

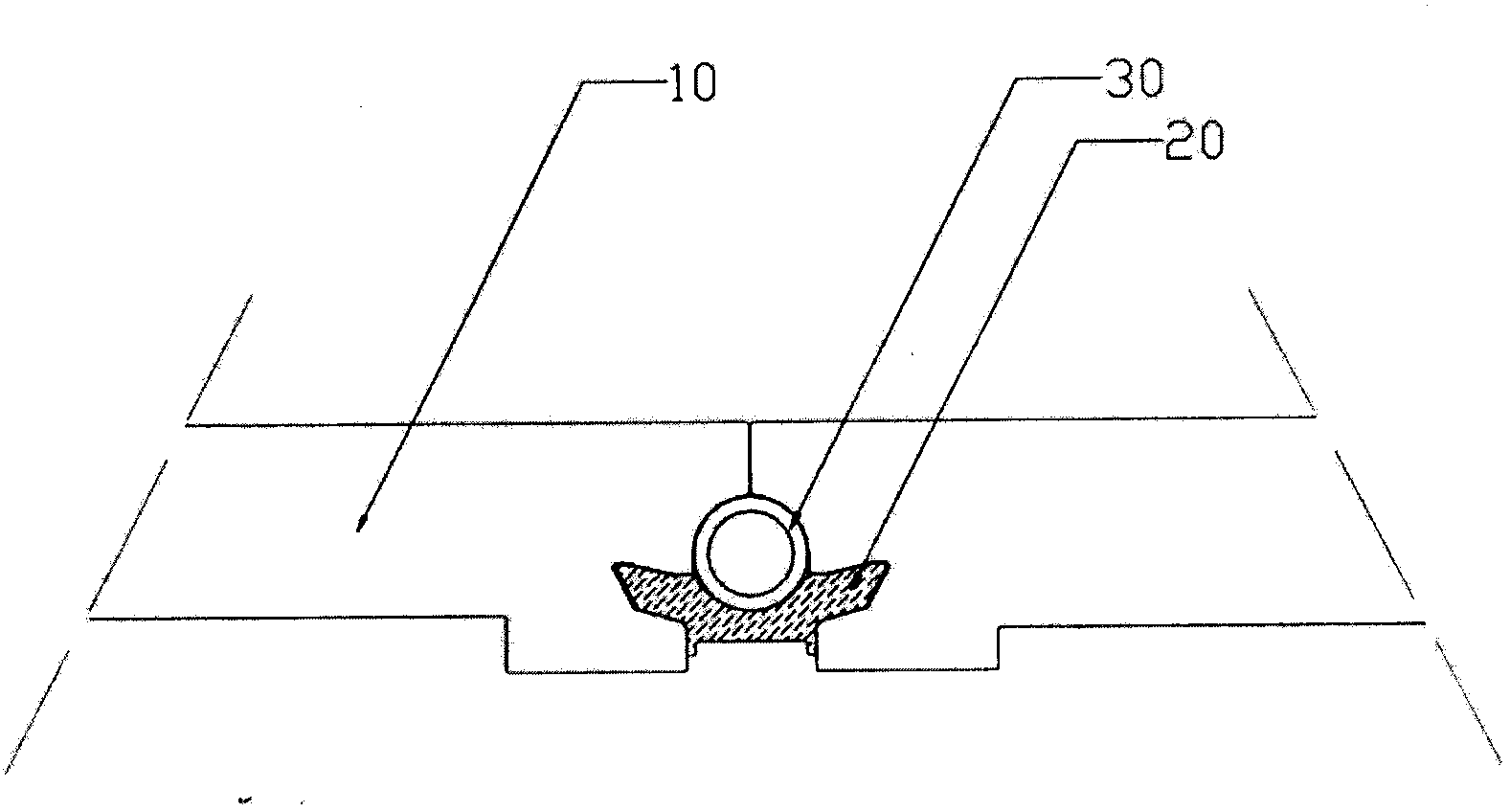

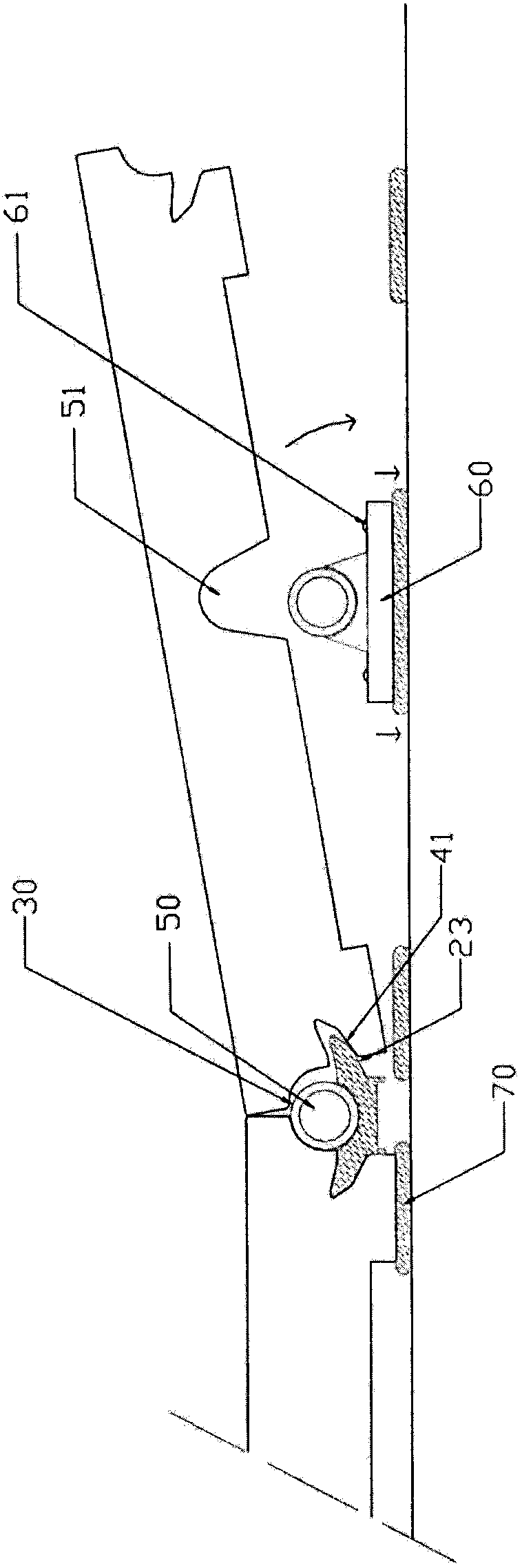

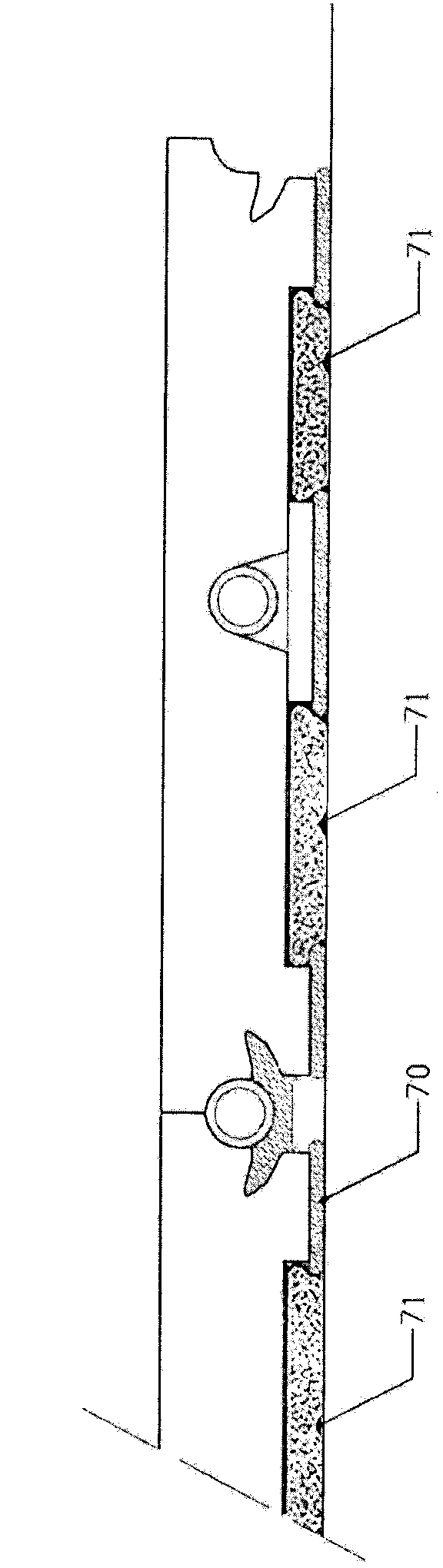

[0023] Such as Figures 1 to 3 As shown, a preferred embodiment of a clamp connection type heating and cooling floor is described. The floor includes a floor body 10, an arc-shaped notch 50 of the floor body, an opening in the middle of the floor body to accommodate a cavity 51 downward, a concave groove 40 of the floor body, and a bottom overlapping surface 41 of the concave groove of the floor body. A groove 11 at the bottom of the floor body, a heating pipe 30, a connecting latch 20, a vertical edge 21 of the connecting latch, a groove 22 for connecting the latch, and a bottom overlapping surface 23 of the connecting latch , a heating pipe supporting plate 60, a supporting plate adhesive 61, a thermal insulation cushion layer 70, a thermal insulation grouting layer 71.

[0024] There are arc-shaped notches 50 and accommodating chambers 51 on both sides and in the middle of the floor body 10, and the connecting latch 20 is located below the arc-shaped notches 50 of the floo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com