Patents

Literature

64results about How to "Guaranteed eligibility" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

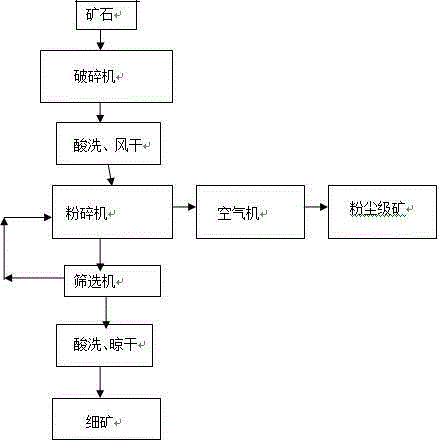

Ore grinding process

The invention discloses an ore grinding process. The ore grinding process comprises the following steps: performing coarse crushing on a raw ore by using a crushing machine; performing two-grade sorting on a coarsely-crushed ore by using a vibration sorting machine to obtain a large crushed ore and a small crushed ore; returning the large crushed ore to the crushing machine, enabling the small crushed ore to enter acid liquid for soaking and air-drying, and enabling the small crushed ore into a grinding machine; collecting a dust-level ore by using an air engine which is connected with the grinding machine; and screening large granular crushed minerals by using a screening machine which is connected with the grinding machine, returning a coarse powder ore into the grinding machine for grinding again, collecting a fine powder ore, and performing acid pickling and airing on the collected fine powder ore for later use. By adopting the ore grinding process, the content of impurities in the collected fine powder ore can be reduced to a highest extent, the purity degree of the minerals can be ensured, the qualification degree of raw materials in a machining process can be ensured, and the use effect of products can be ensured.

Owner:SUZHOU LU LU SHUN ELECTRICAL EQUIP

Environment-friendly waste gas purifying device

PendingCN107596900ATimely replacementAvoid pollutionDispersed particle filtrationLiquid storage tankProduct gas

The invention discloses an environment-friendly waste gas purifying device which comprises a barrel, wherein an inner chamber of the barrel is hollow and an opening is formed at the bottom of the barrel; a gas storage tank is connected to the top of the barrel in a clamped manner; an air quality detector and a pressure sensor are successively connected with the inner wall of the top of the gas storage tank along the horizontal direction; a first exhaust pipe and a second exhaust pipe are successively arranged on the outer wall of the gas storage tank along the vertical direction; a first electric control valve and a second electric control valve are arranged on the inner walls of the first exhaust pipe and the second exhaust pipe, respectively; a liquid storage tank is fixedly connected with one end, away from the gas storage tank, of the second exhaust pipe; one end, away from the gas storage tank, of the second exhaust pipe penetrates through the top wall of the liquid storage tank and extends into the liquid storage tank; a drug feeding box is fixedly connected with the outer wall of the liquid storage tank. The environment-friendly waste gas purifying device has a simple structure, is convenient in operation, is capable of increasing the sufficiency of exhaust gas treatment and guaranteeing the qualification of gas emission and is combined with a conveniently detached filtering structure for realizing energy-saving and environment-protecting functions.

Owner:ANHUI WANSHANHONG ENVIRONMENTAL PROTECTION TECH CO LTD

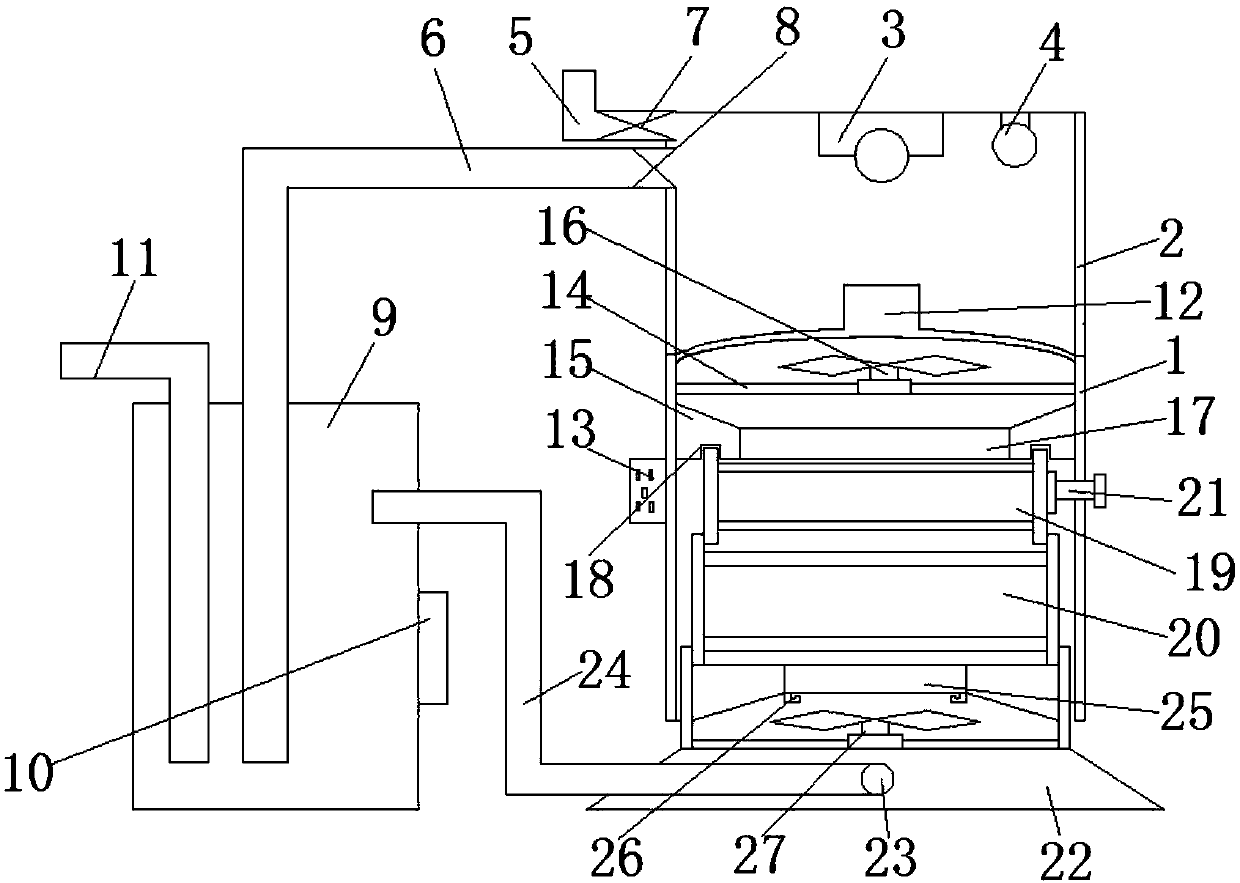

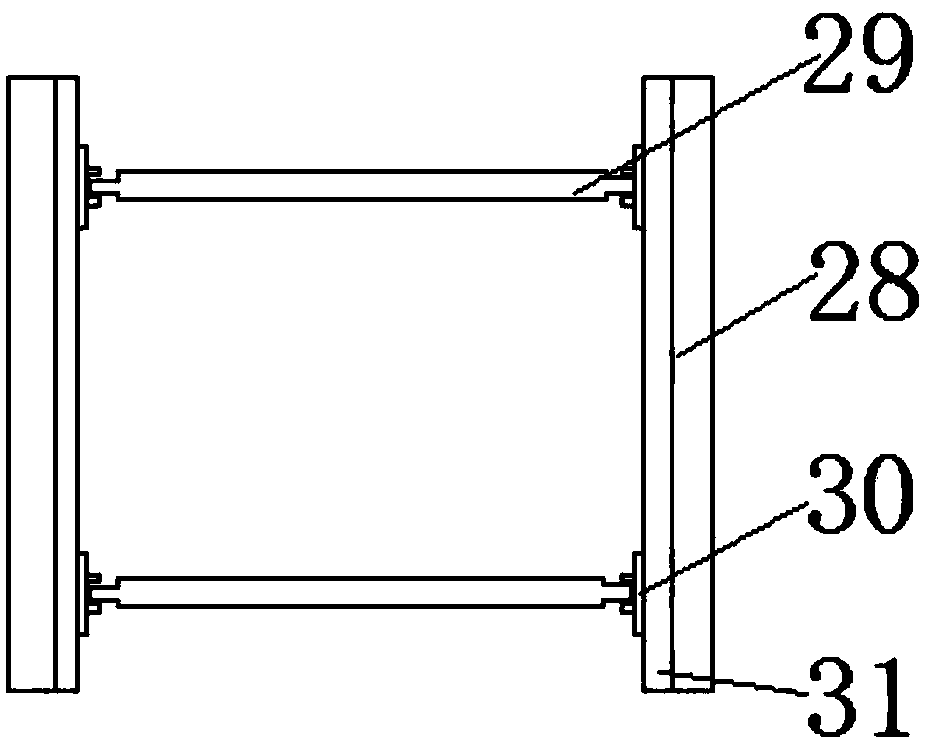

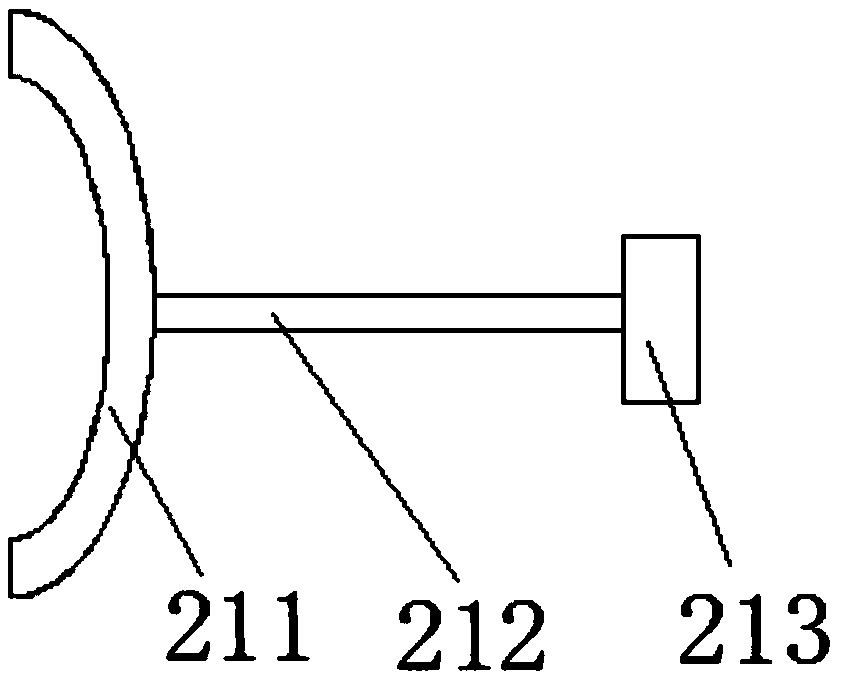

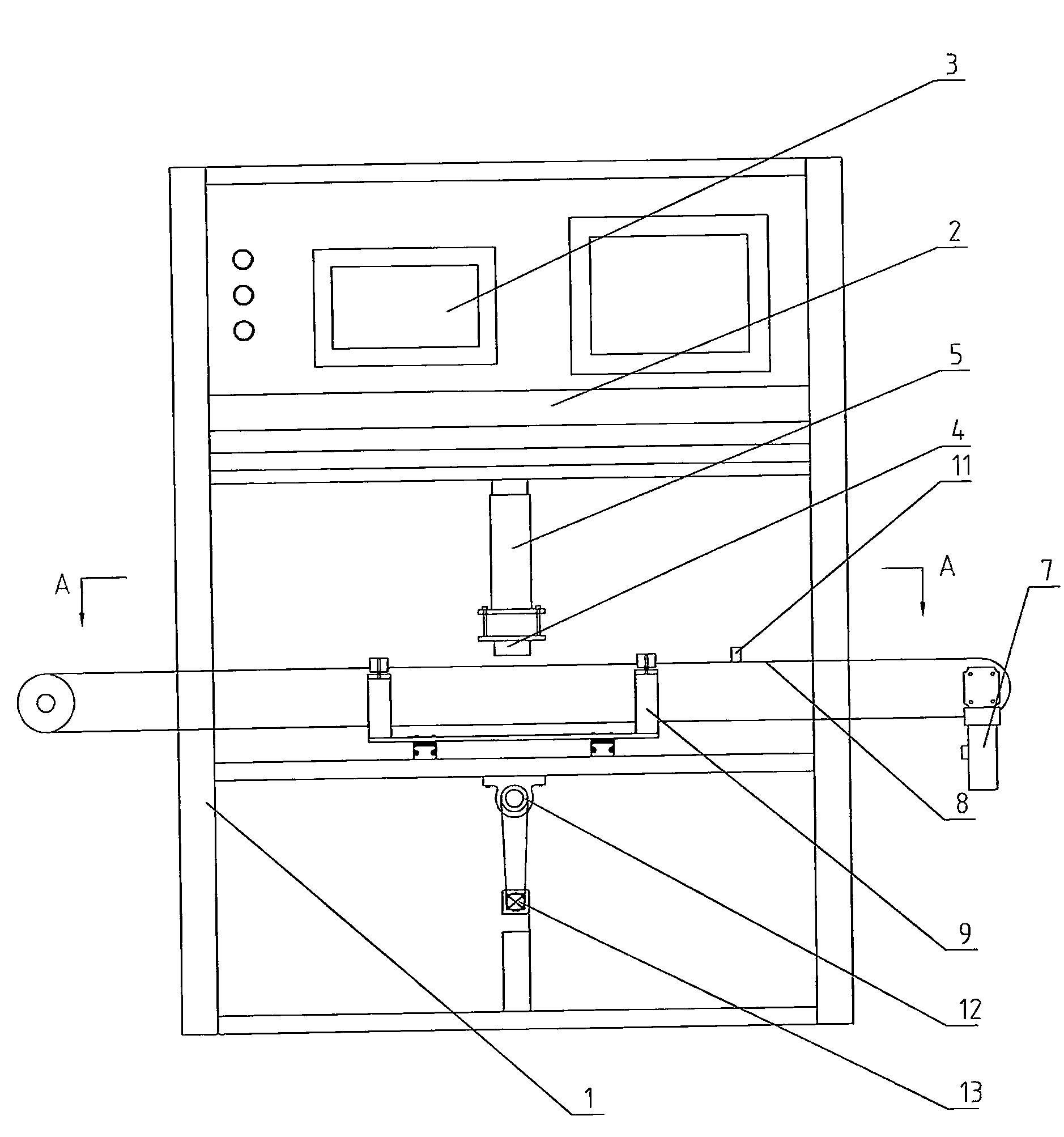

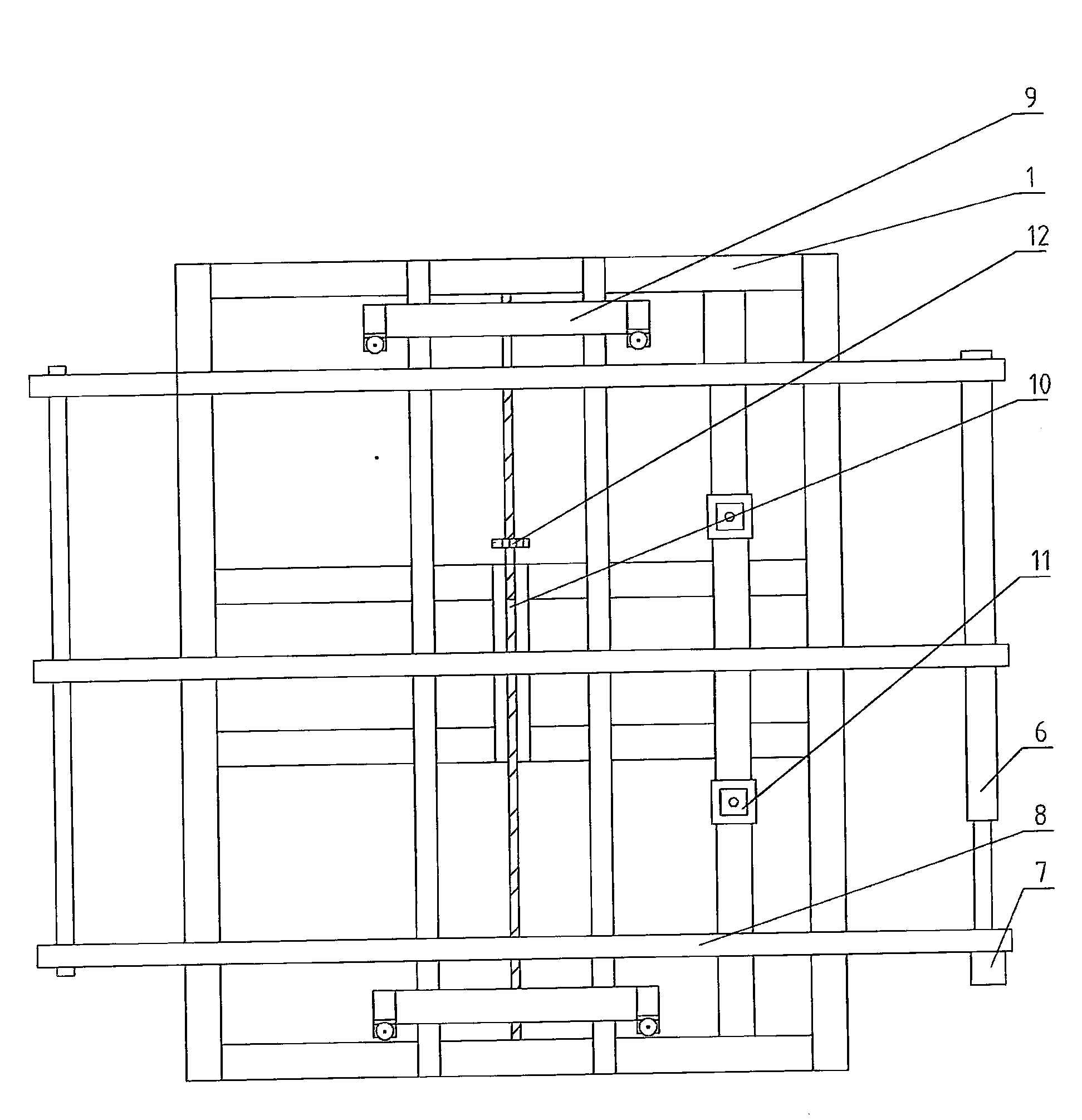

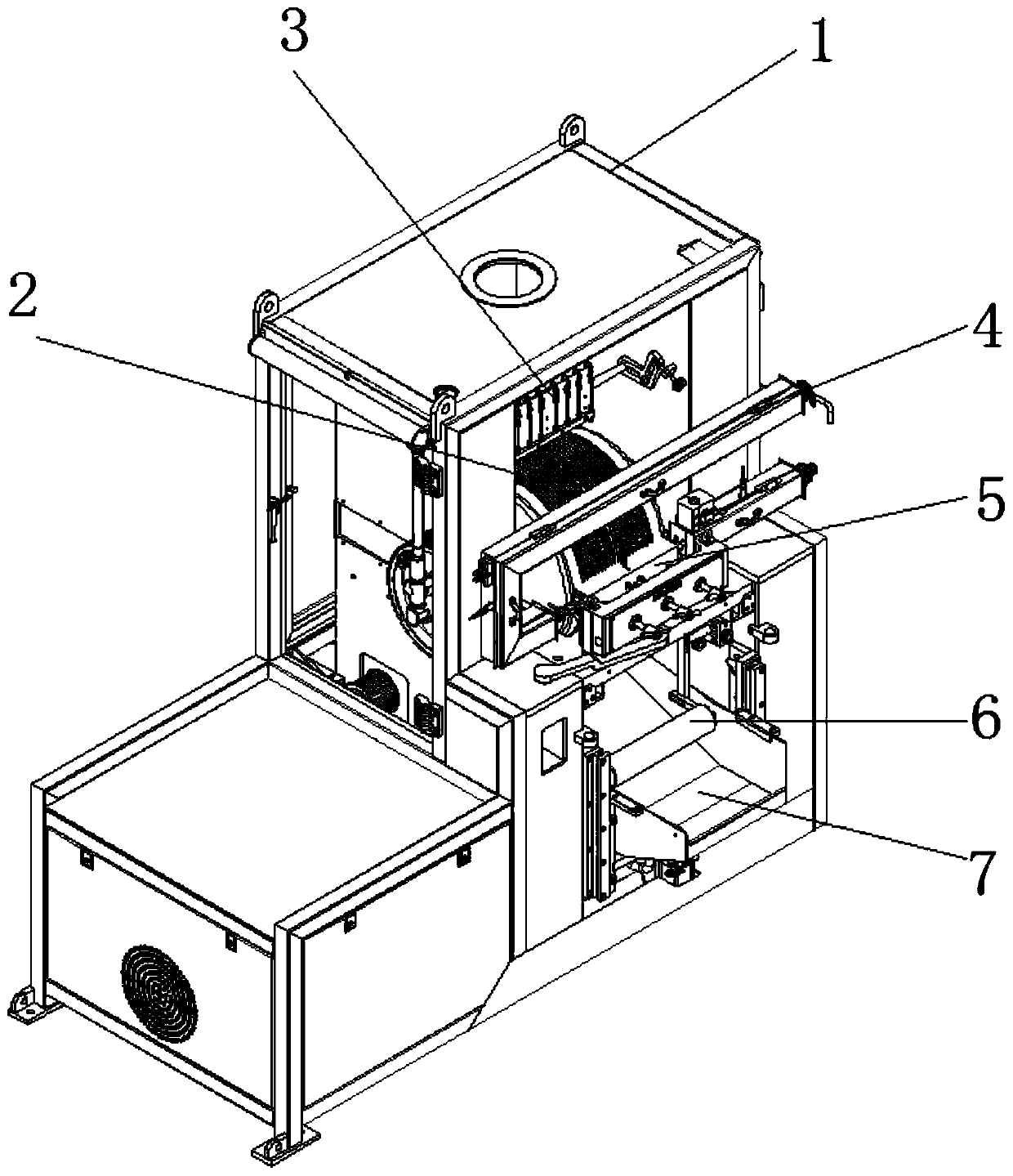

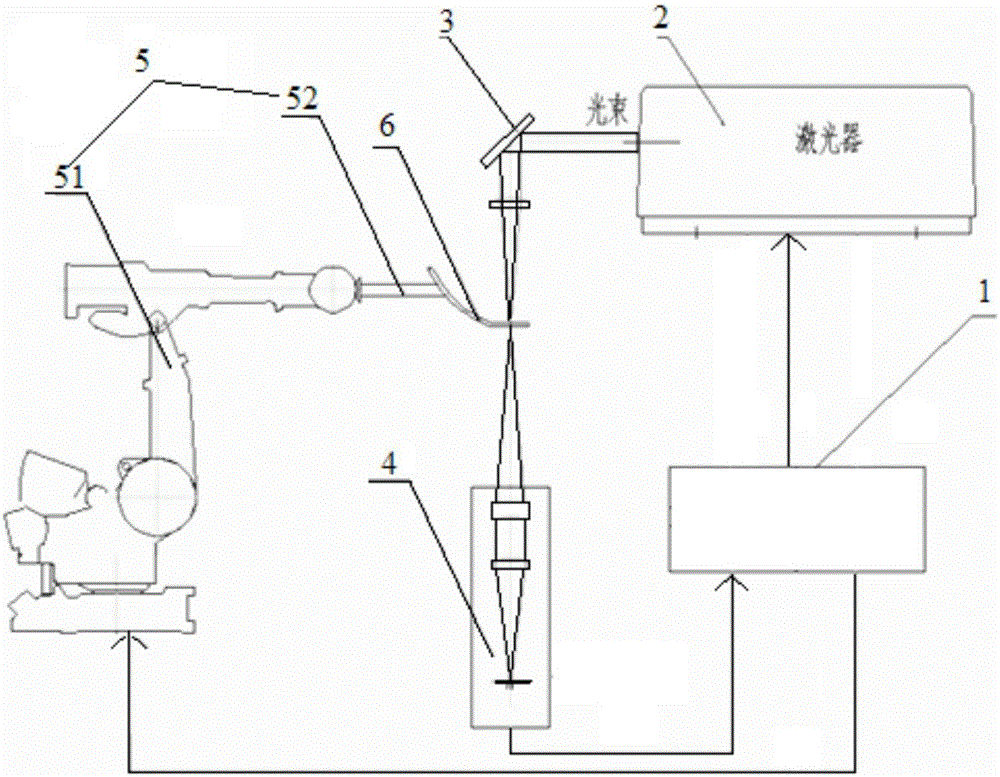

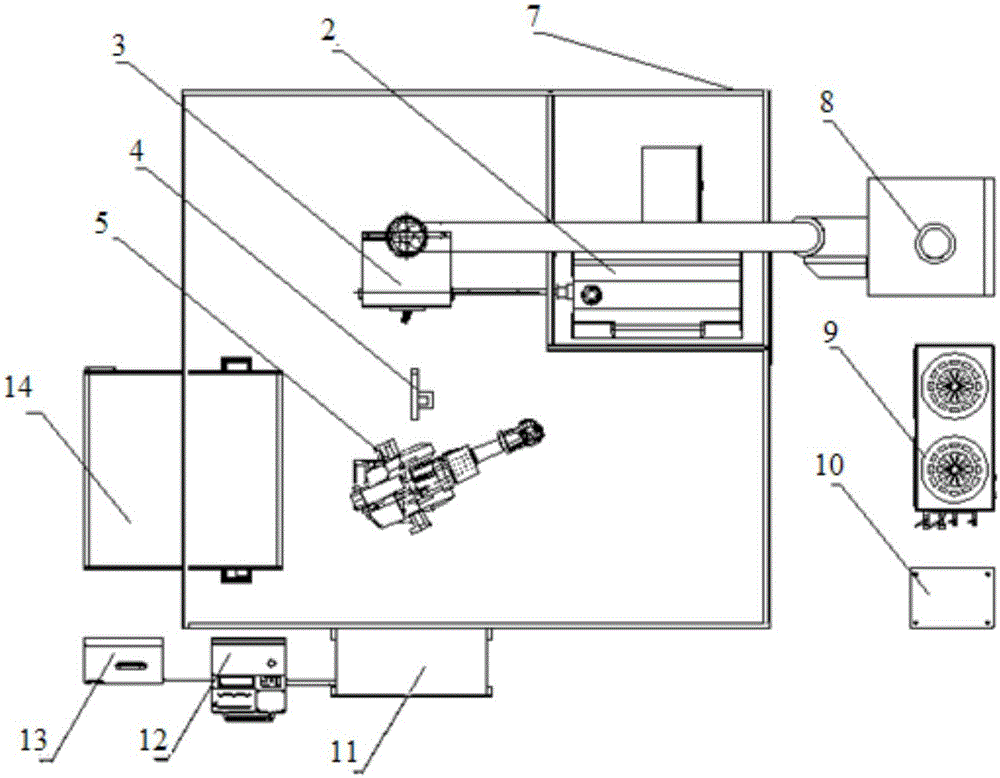

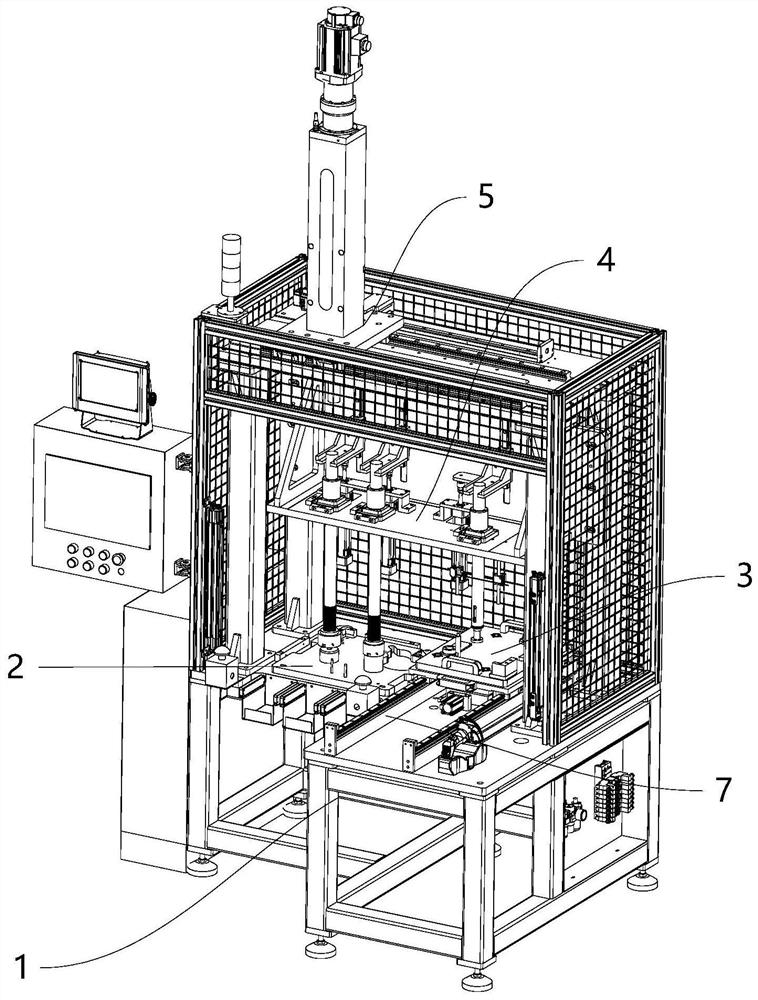

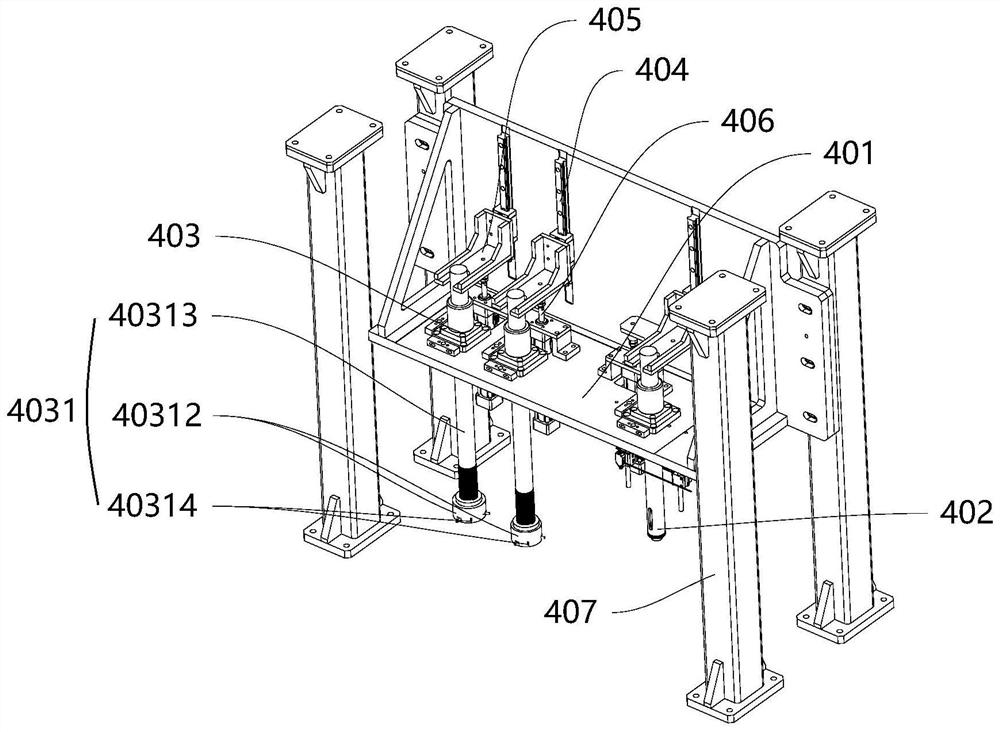

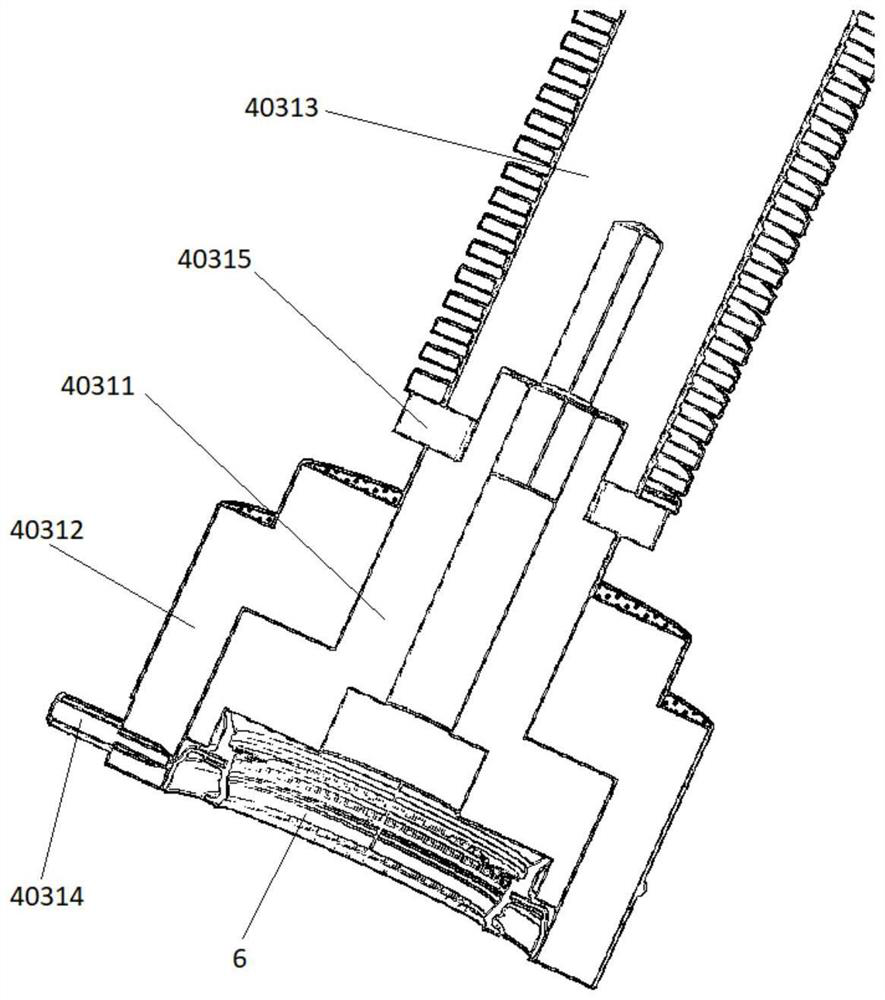

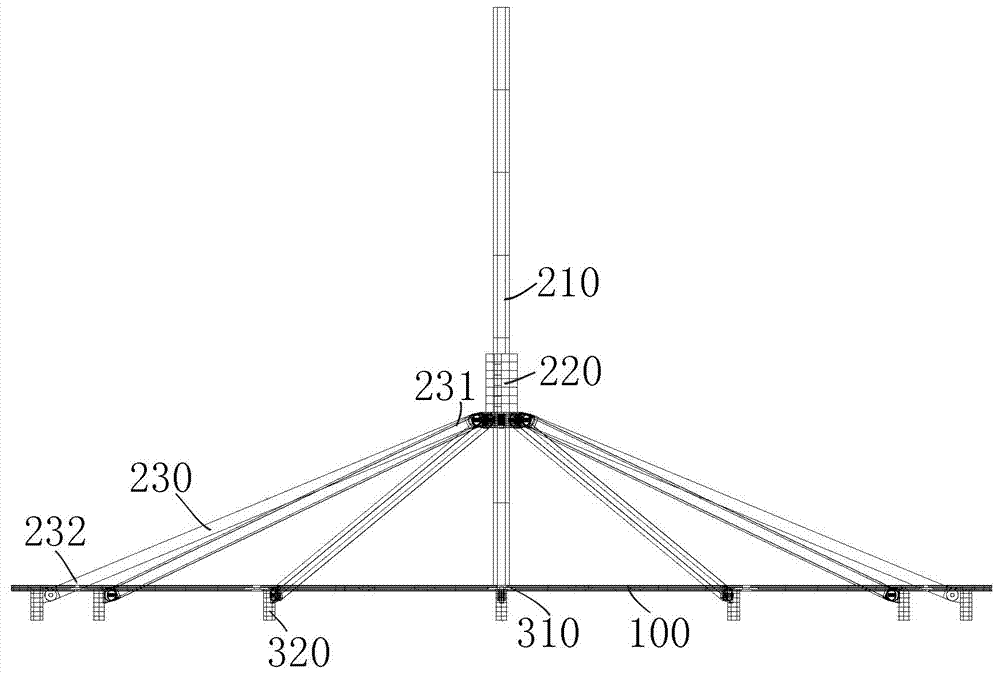

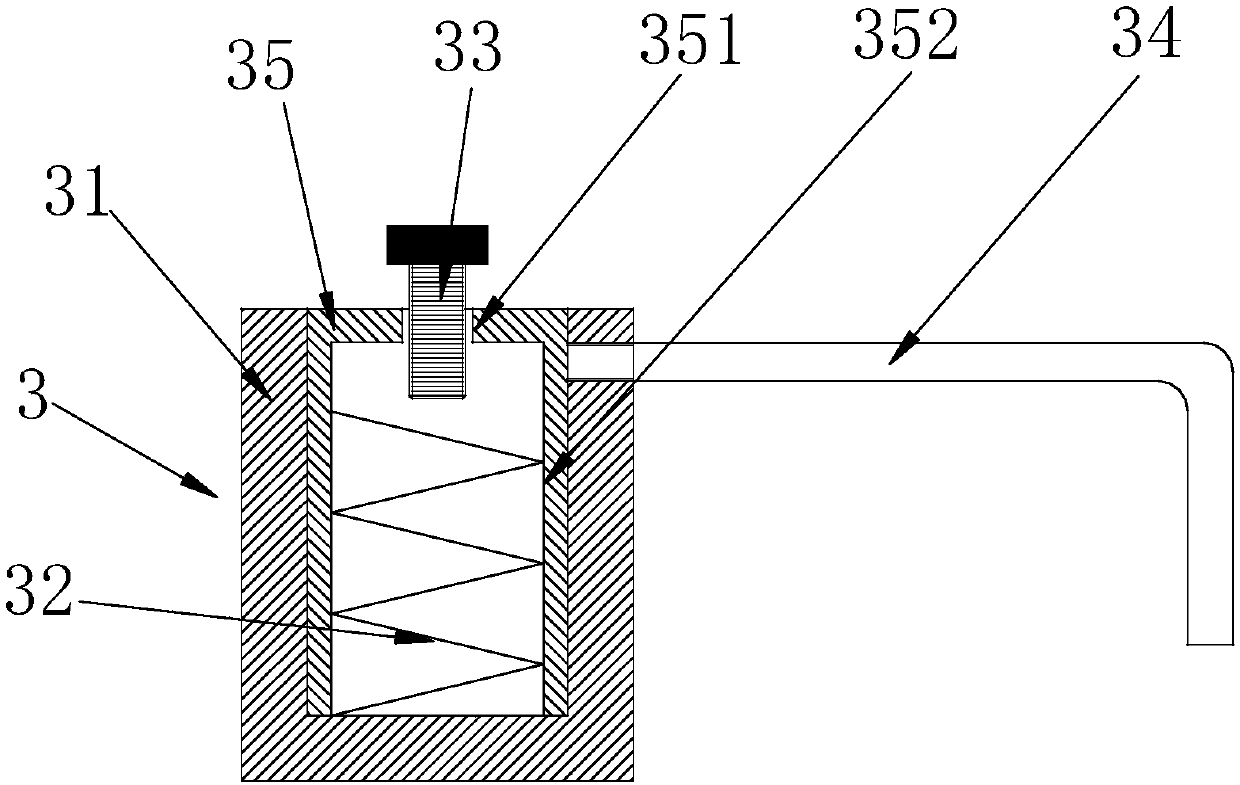

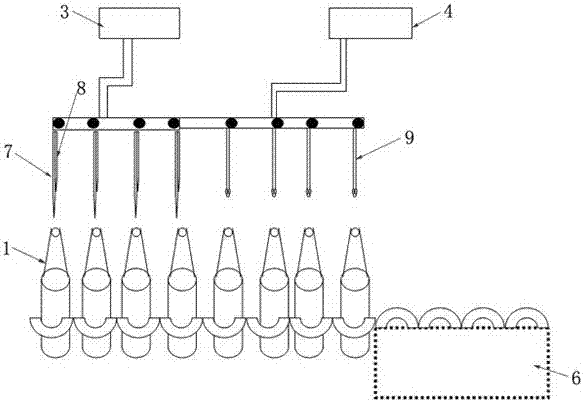

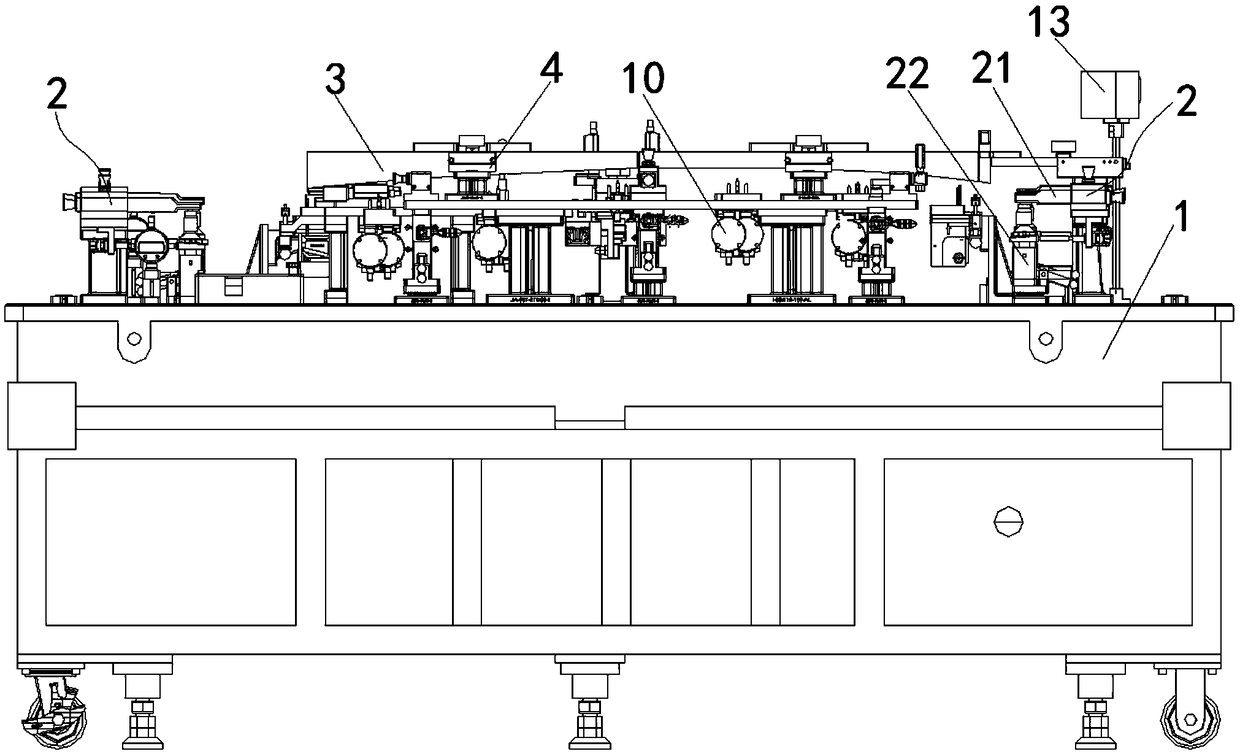

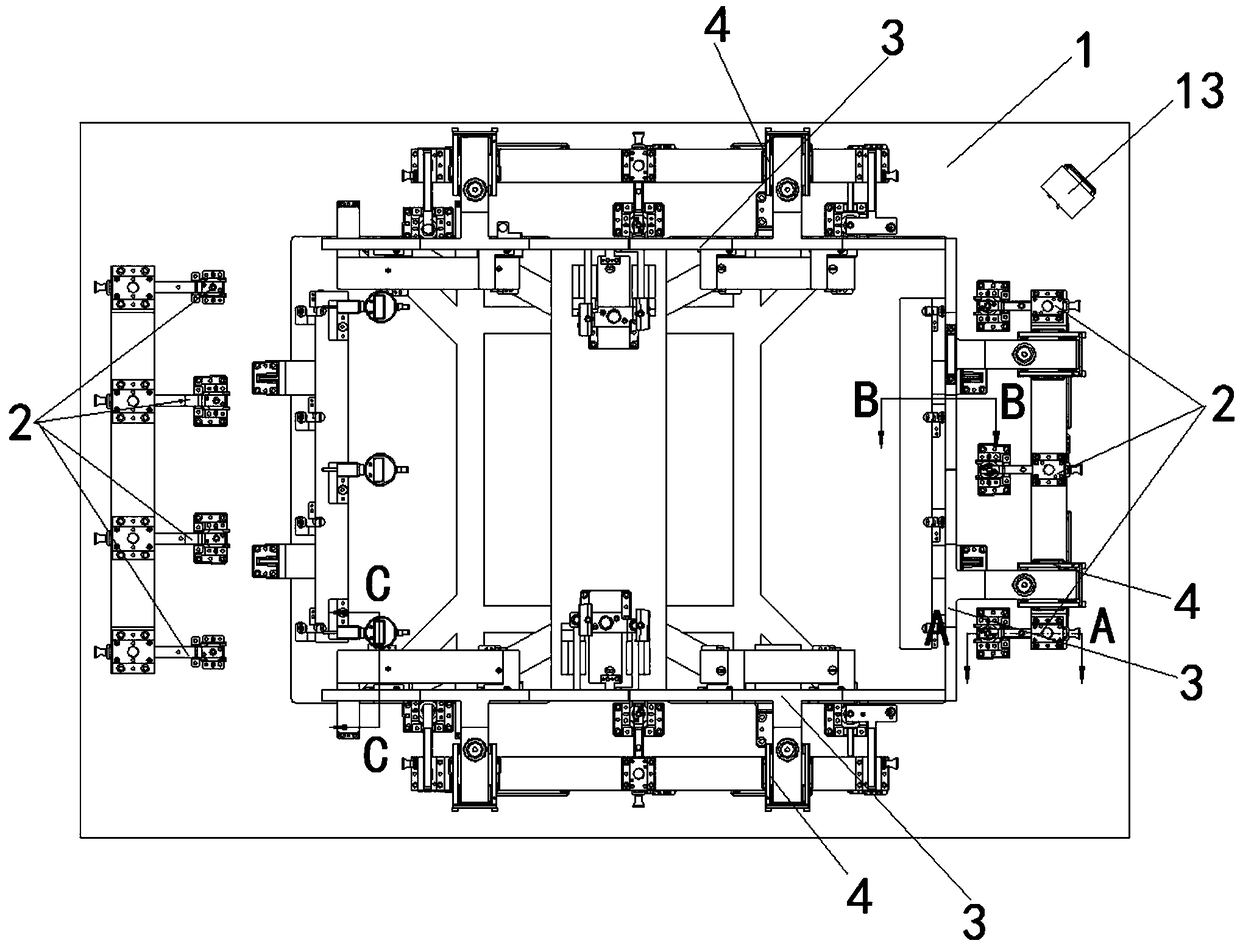

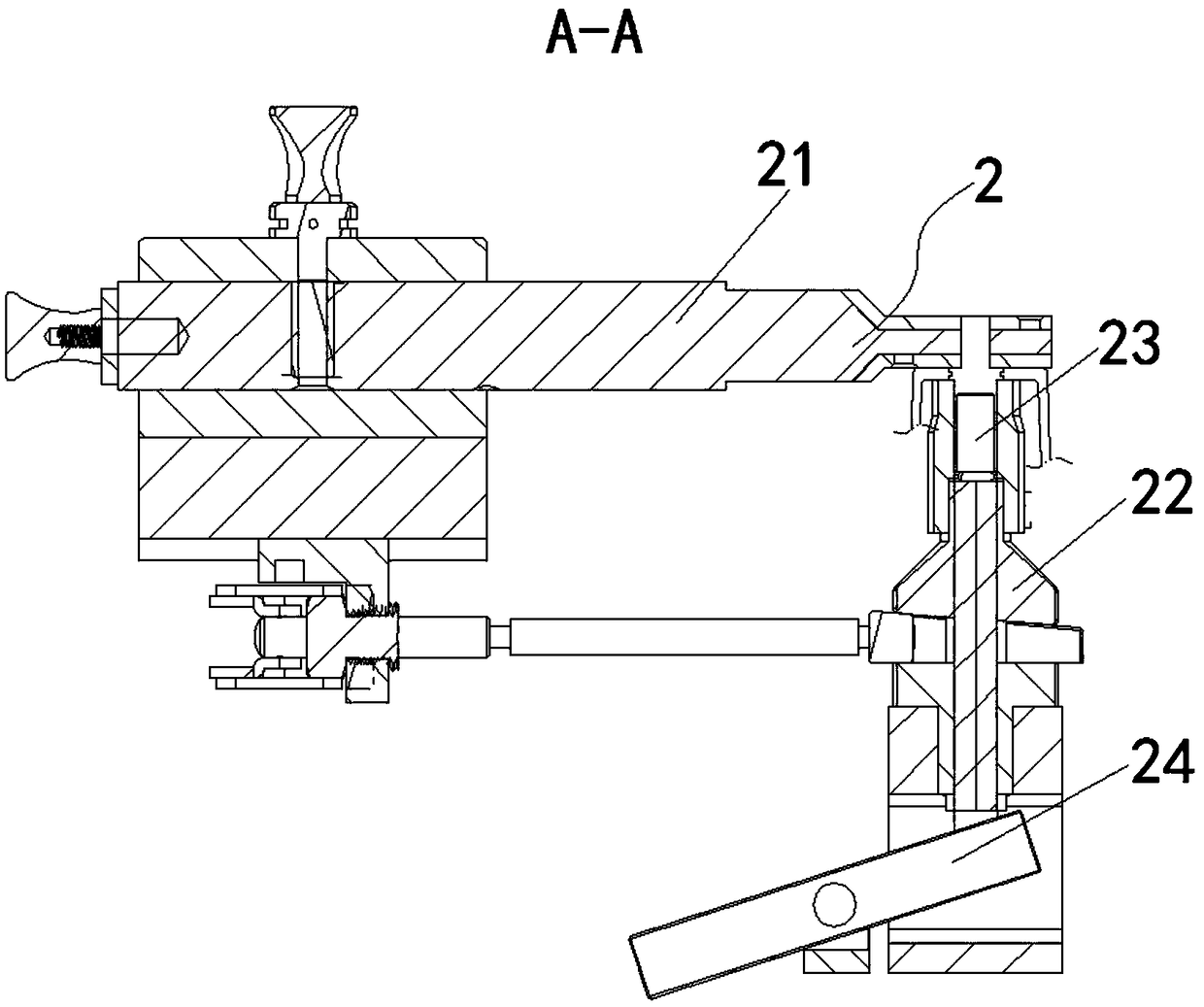

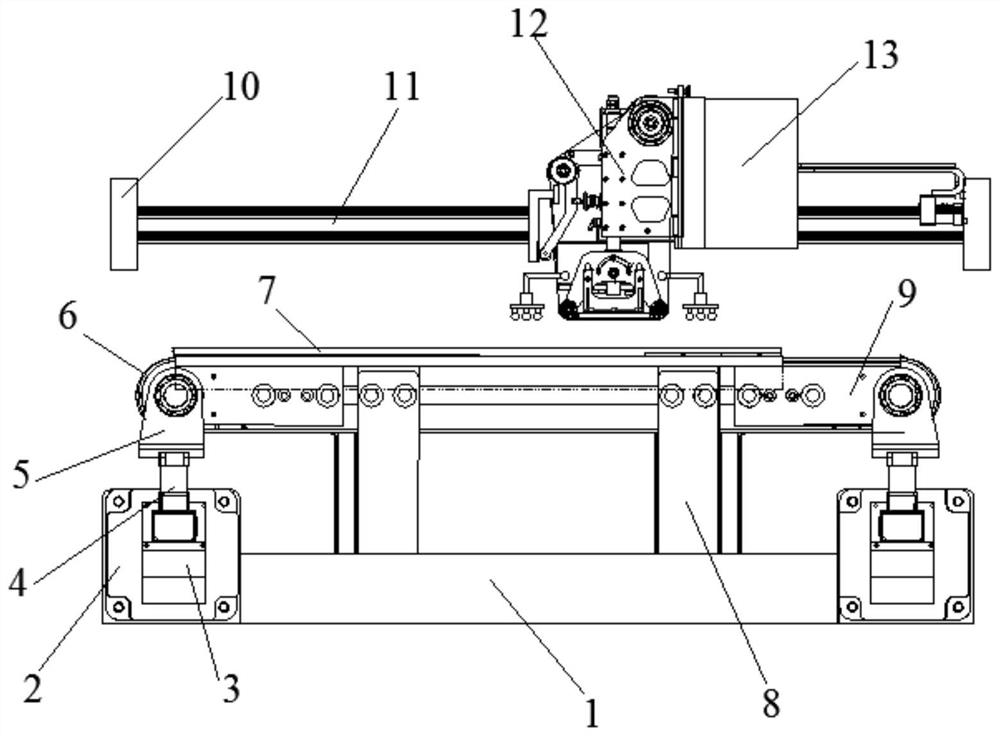

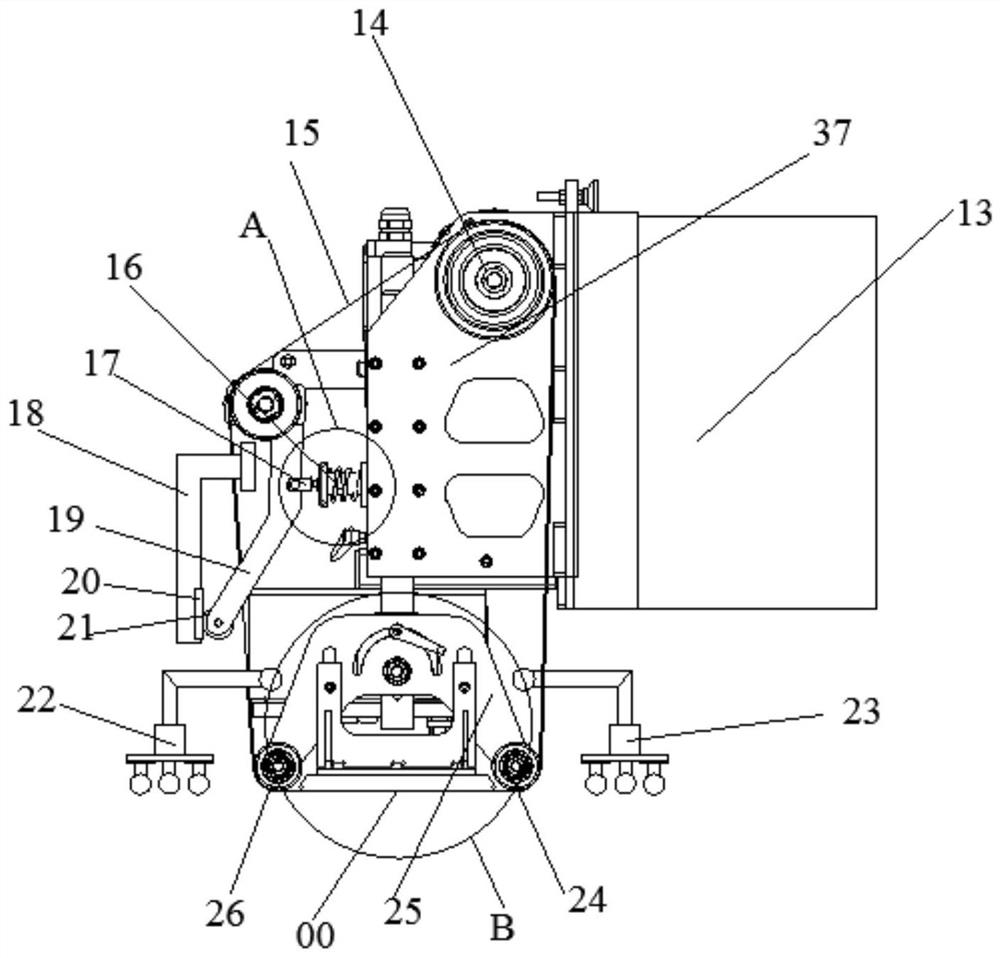

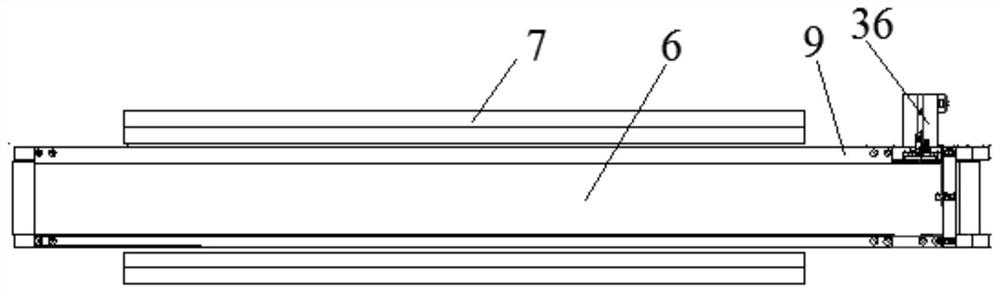

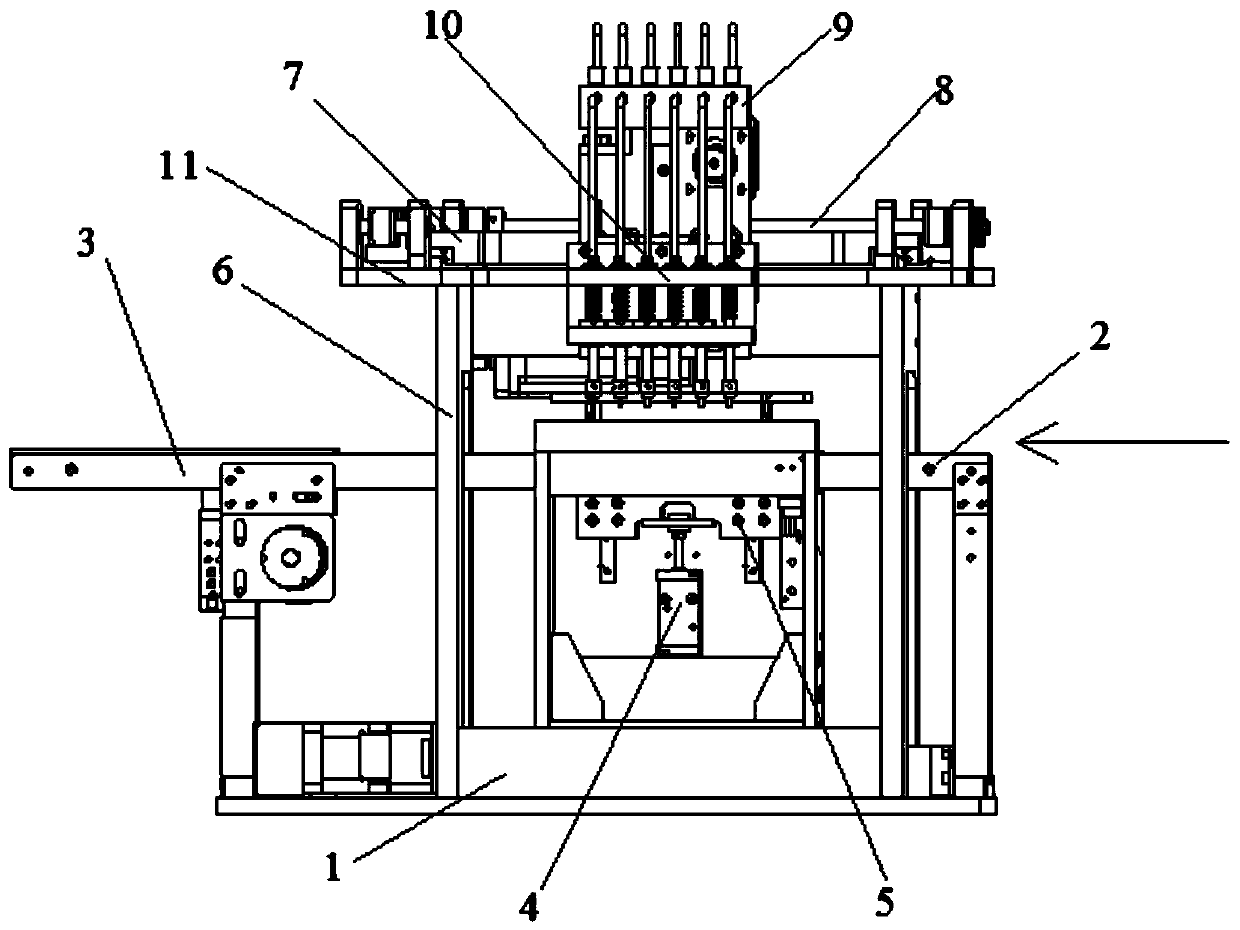

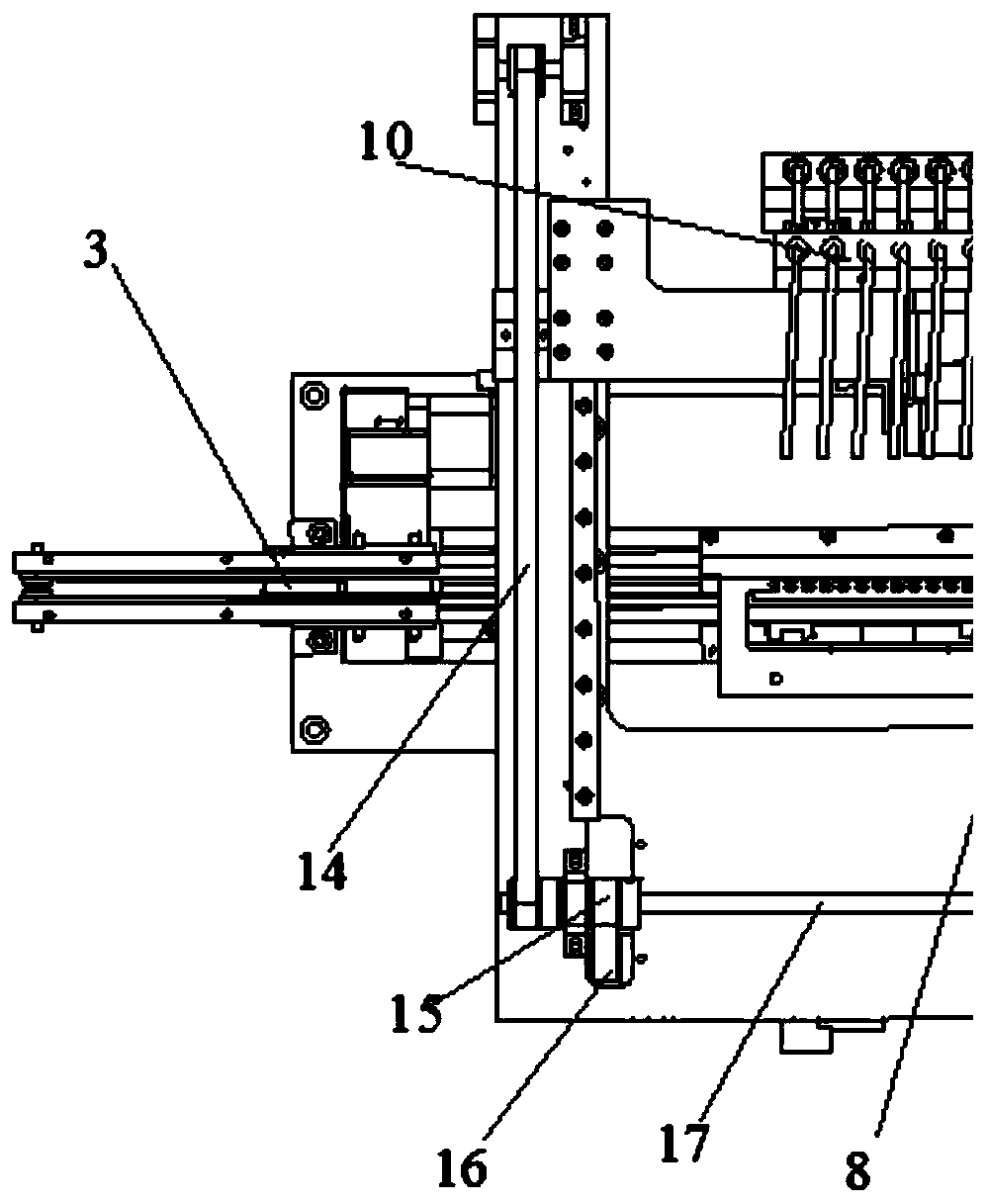

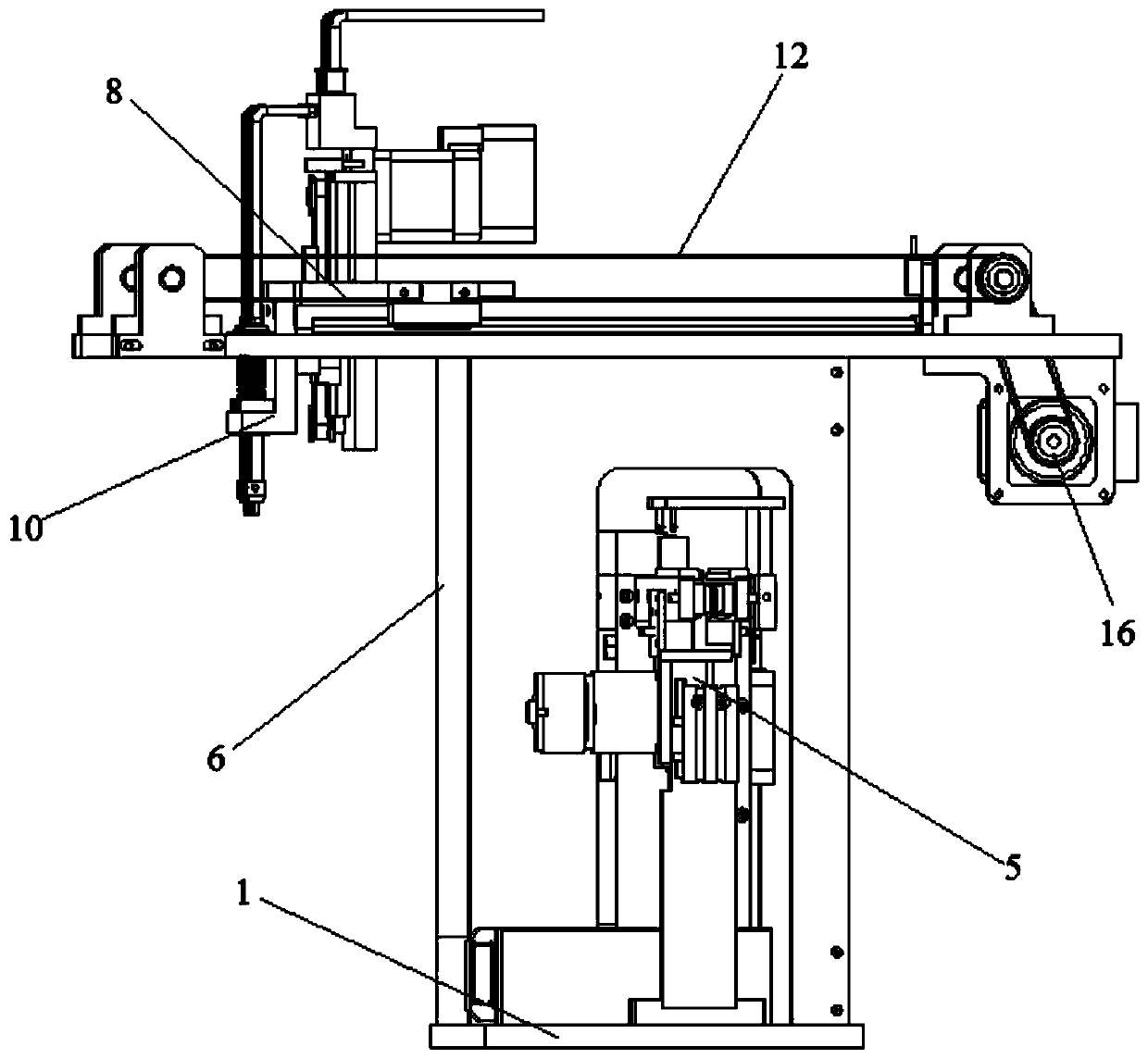

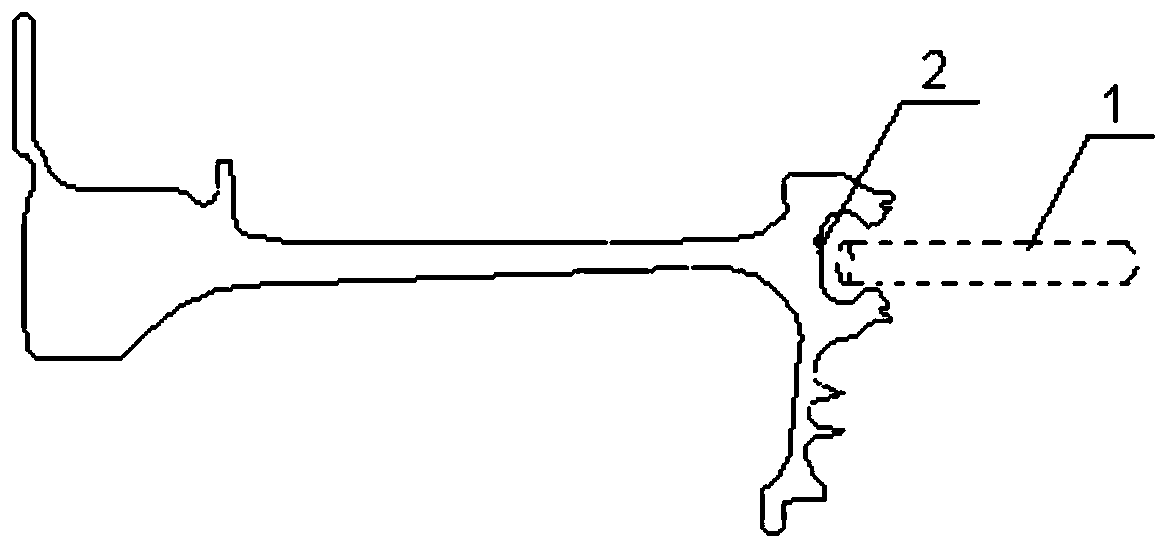

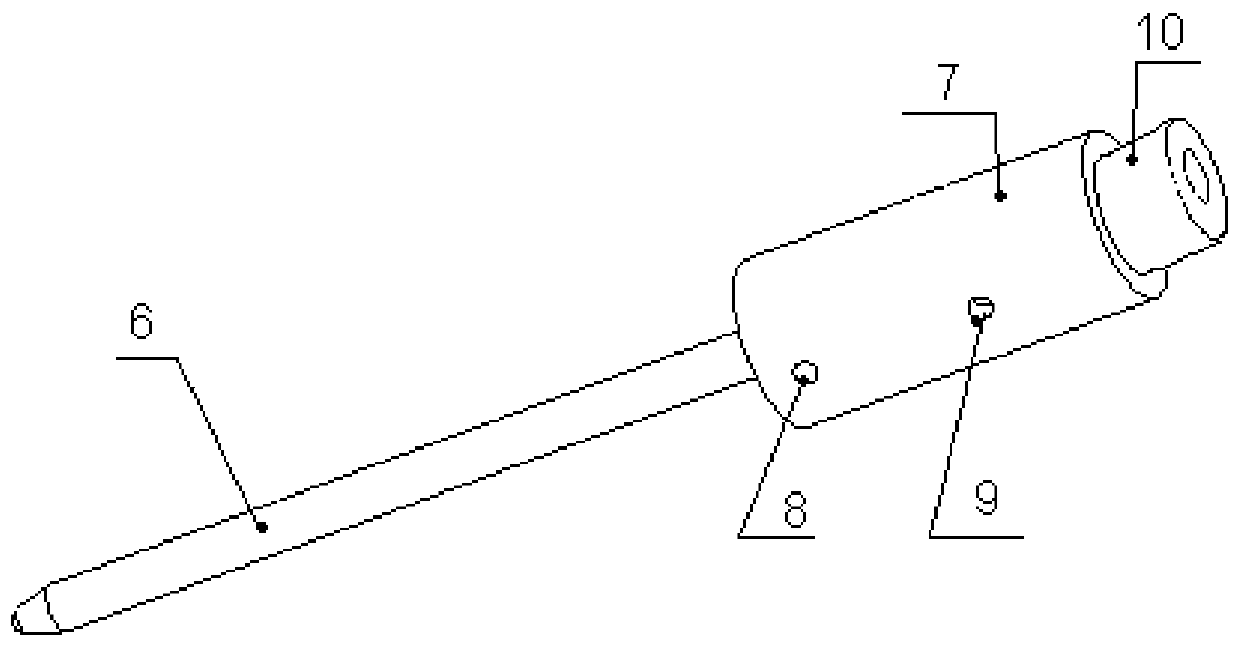

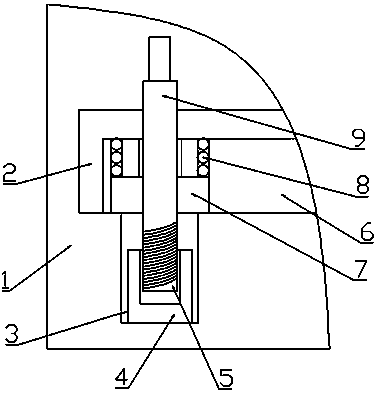

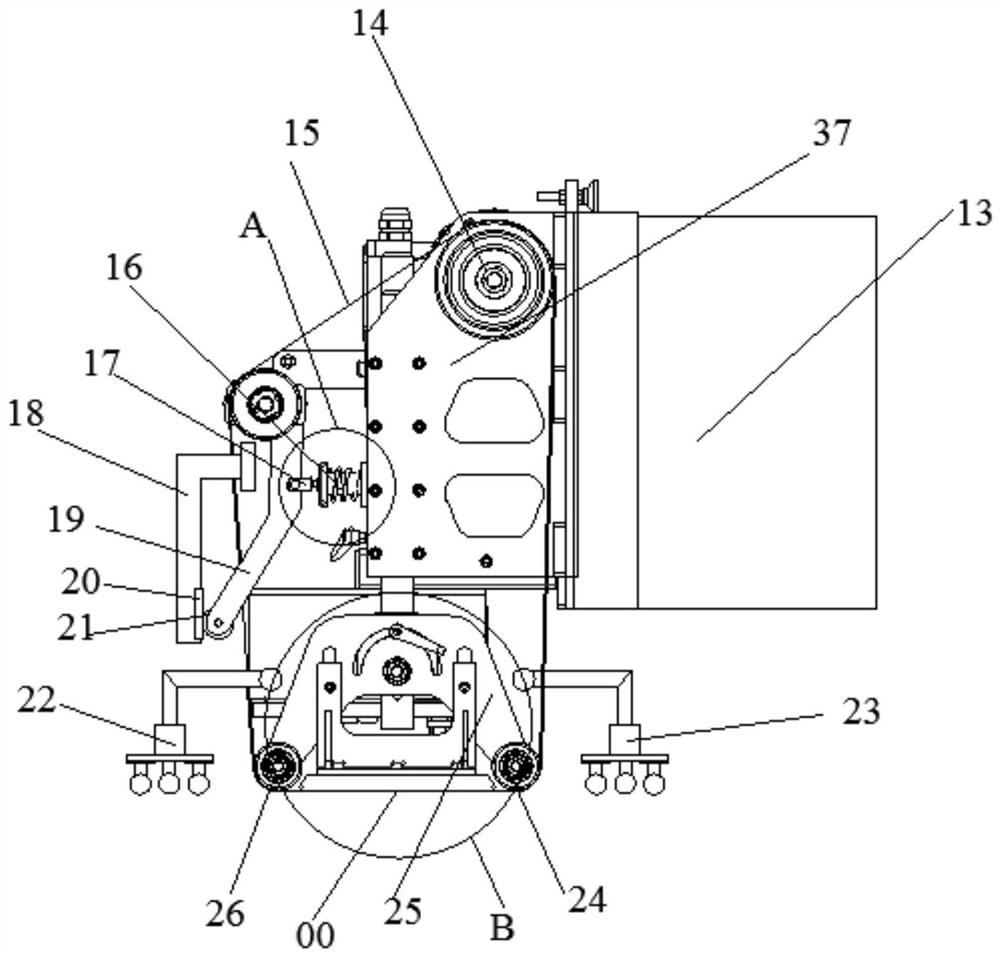

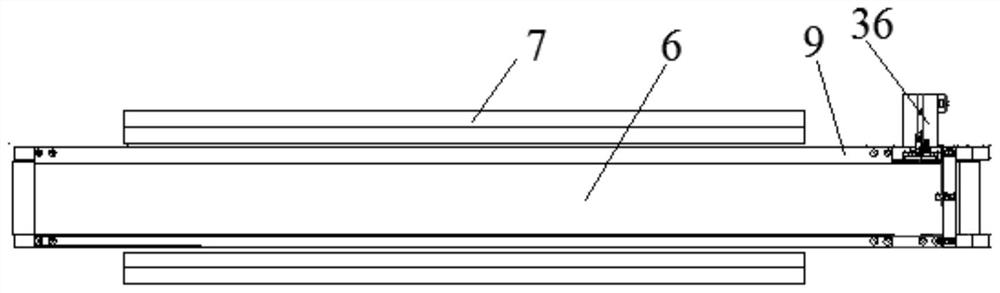

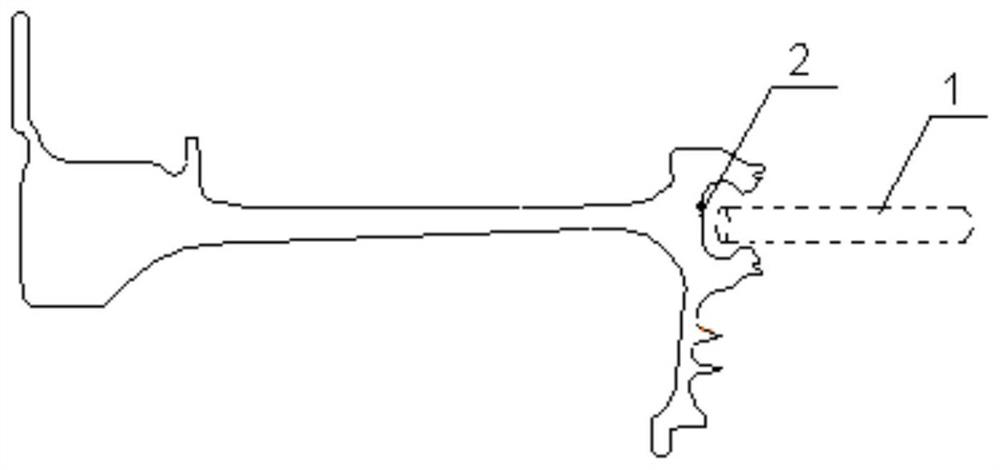

Automatic insulation and voltage resistance testing device for solar photovoltaic module

ActiveCN103018643AGuaranteed eligibilityAvoid the danger of high voltage electric shockTesting dielectric strengthEngineeringElectrical and Electronics engineering

The invention discloses an automatic insulation and voltage resistance testing device for a solar photovoltaic module. The automatic insulation and voltage resistance testing device for the solar photovoltaic module comprises a frame, a sealing and isolating box, an insulation and voltage resistance tester, a contact probe, a probe cylinder and a tri-axial restoration mechanism, the probe cylinder enables the contact probe to automatically extend and retract, the tri-axial restoration mechanism enables the solar photovoltaic module to move and be positioned, the insulation and voltage resistance tester is mounted in the sealing and isolating box which is mounted on the frame, one end of the probe cylinder is fixed on the frame, and the contact probe is fixed at the other end of the probe cylinder, positioned outside the sealing and isolating box and connected with a positive and negative pole leading-out end of the insulation and voltage resistance tester. The device is capable of accurately positioning the solar photovoltaic module and automatically testing insulation and voltage resistance performances thereof, thereby being fast in test, convenient and easy to operate. Besides, misoperation due to human factors is avoided.

Owner:SERAPHIM SOLAR SYST

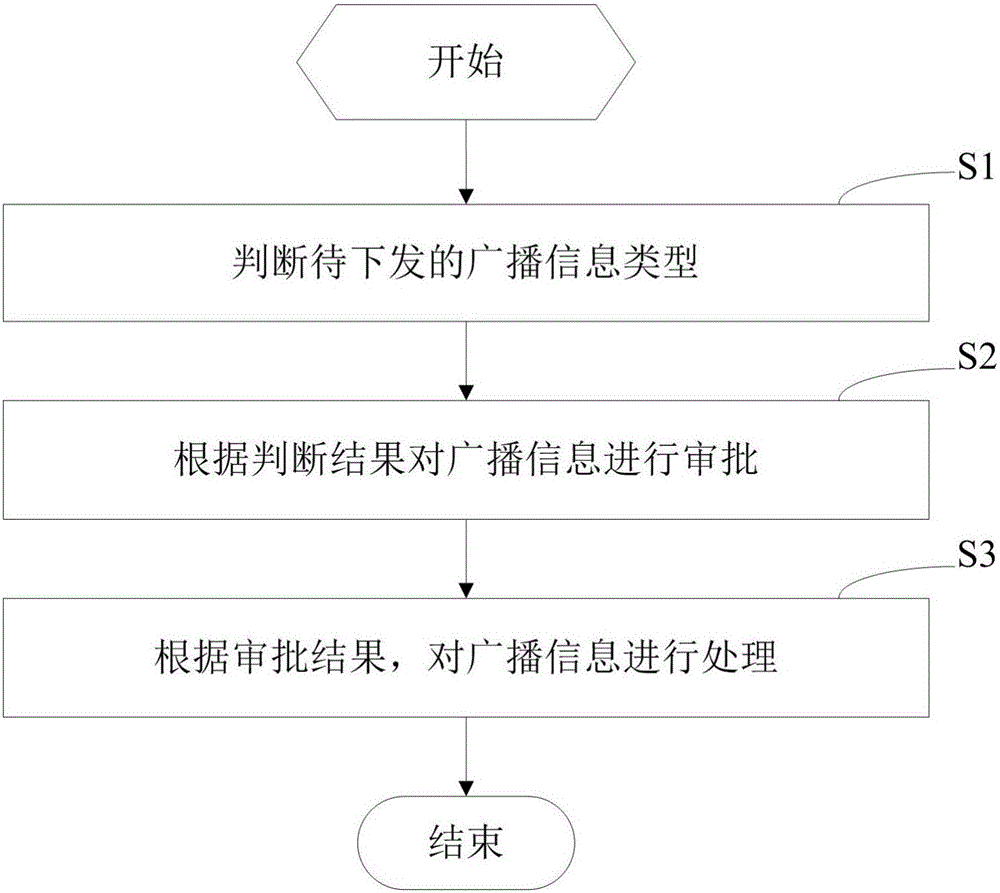

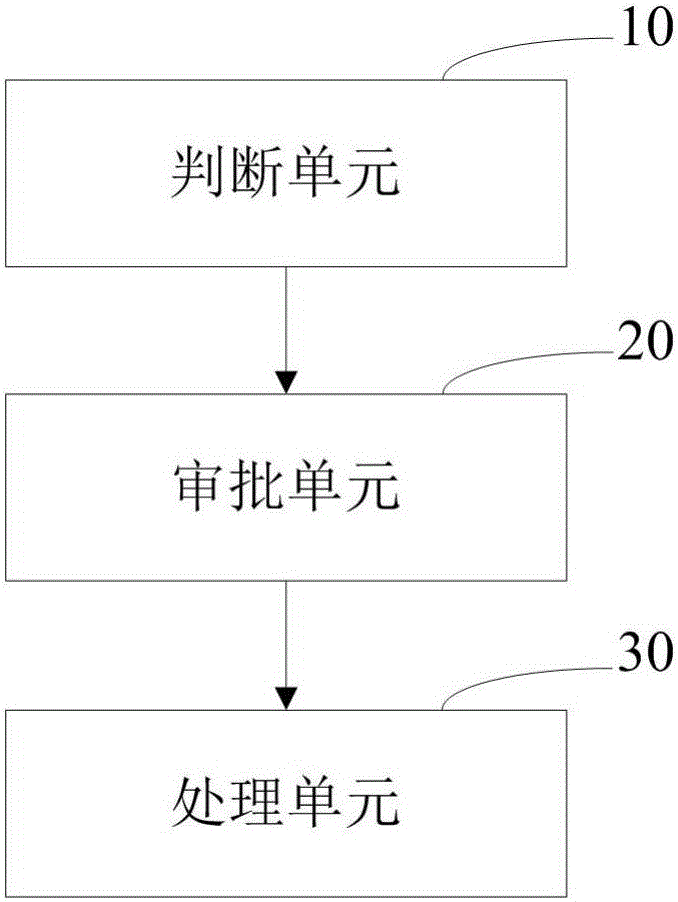

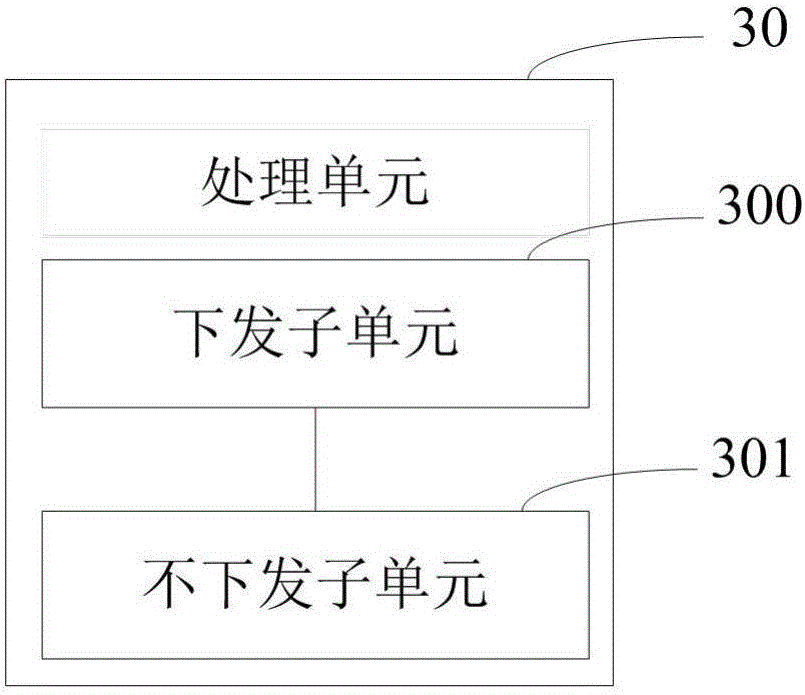

Broadcast message issuing method and system

InactiveCN105872989AGuaranteed validitySecurityBroadcast service distributionTransmissionComputer securityEngineering

The invention puts forward a broadcast message issuing method and system. The broadcast message issuing method comprises the following steps: judging the type of a broadcast message to be issued; according to a judgment judged result, examining and approving the broadcast message; according to an examination and approval result, processing the broadcast message. According to the broadcast message issuing method and system provided by the invention, the type of the broadcast message is judged, different broadcast types can be separately examined and approved, and message transfer effectiveness, eligibility and validity can be guaranteed when the broadcast message is issued.

Owner:TIANJIN BEIHAI COMM TECH

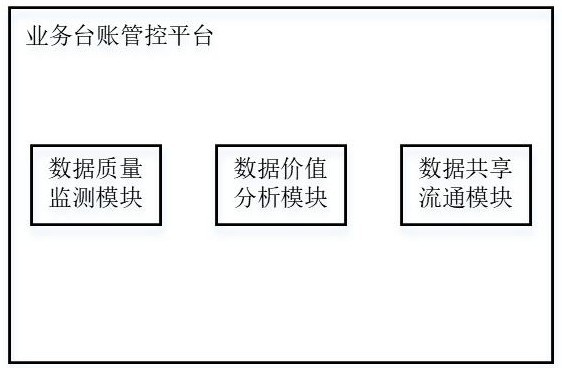

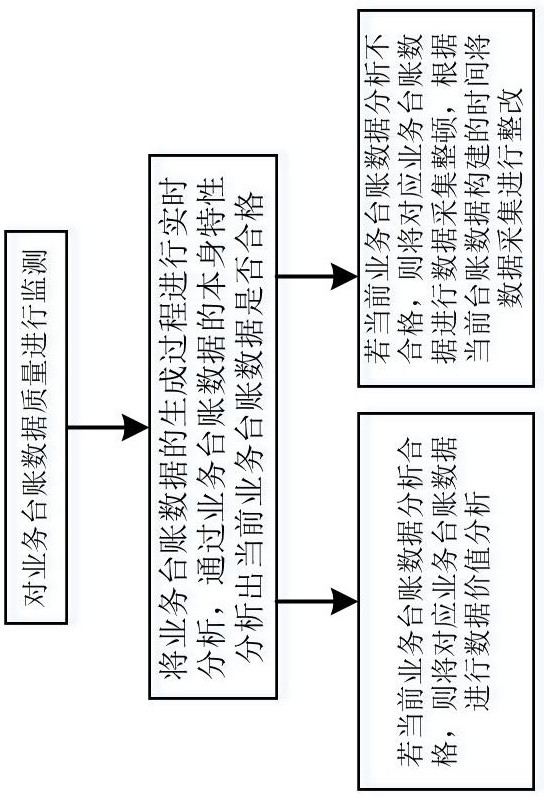

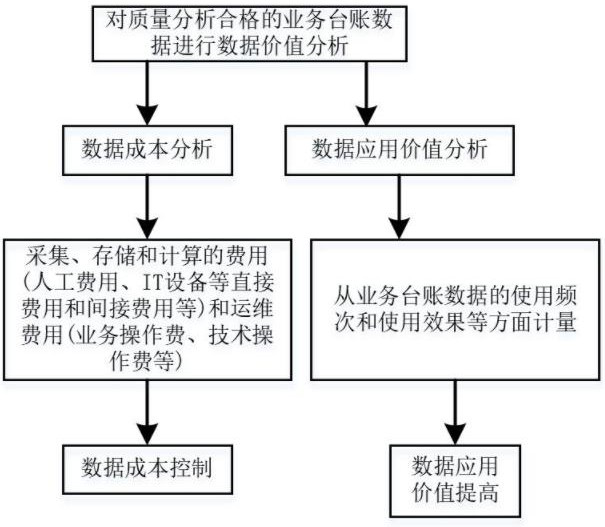

Block chain-based distributed service ledger management method and system

ActiveCN114862373AGuarantee authenticityImprove efficiencyFinanceNatural language data processingData valueData application

The invention discloses a distributed service ledger management method and system based on a block chain, relates to the technical field of service ledger management, and solves the technical problem that in the prior art, data value analysis cannot be performed on service ledger data in an enterprise, so that storage resources of the ledger data cannot be reasonably distributed. Quality monitoring is carried out on business machine account data in an enterprise, the qualification of business machine account data collection in the enterprise is guaranteed, the authenticity of the business machine account is guaranteed, and the enterprise can carry out management in all aspects conveniently; the current situation of the business in the enterprise can be accurately reflected through the qualified business machine account data, and the efficiency of business management in the enterprise is improved; cost control is carried out on each piece of service machine account data through data cost analysis, application value improvement is carried out on each piece of service machine account data through data application value analysis, meanwhile, storage resources are distributed according to real-time service machine account data value analysis, and the service machine account data with low value are prevented from occupying high storage resources.

Owner:JIANGSU RONGZE INFORMATION TECH CO LTD

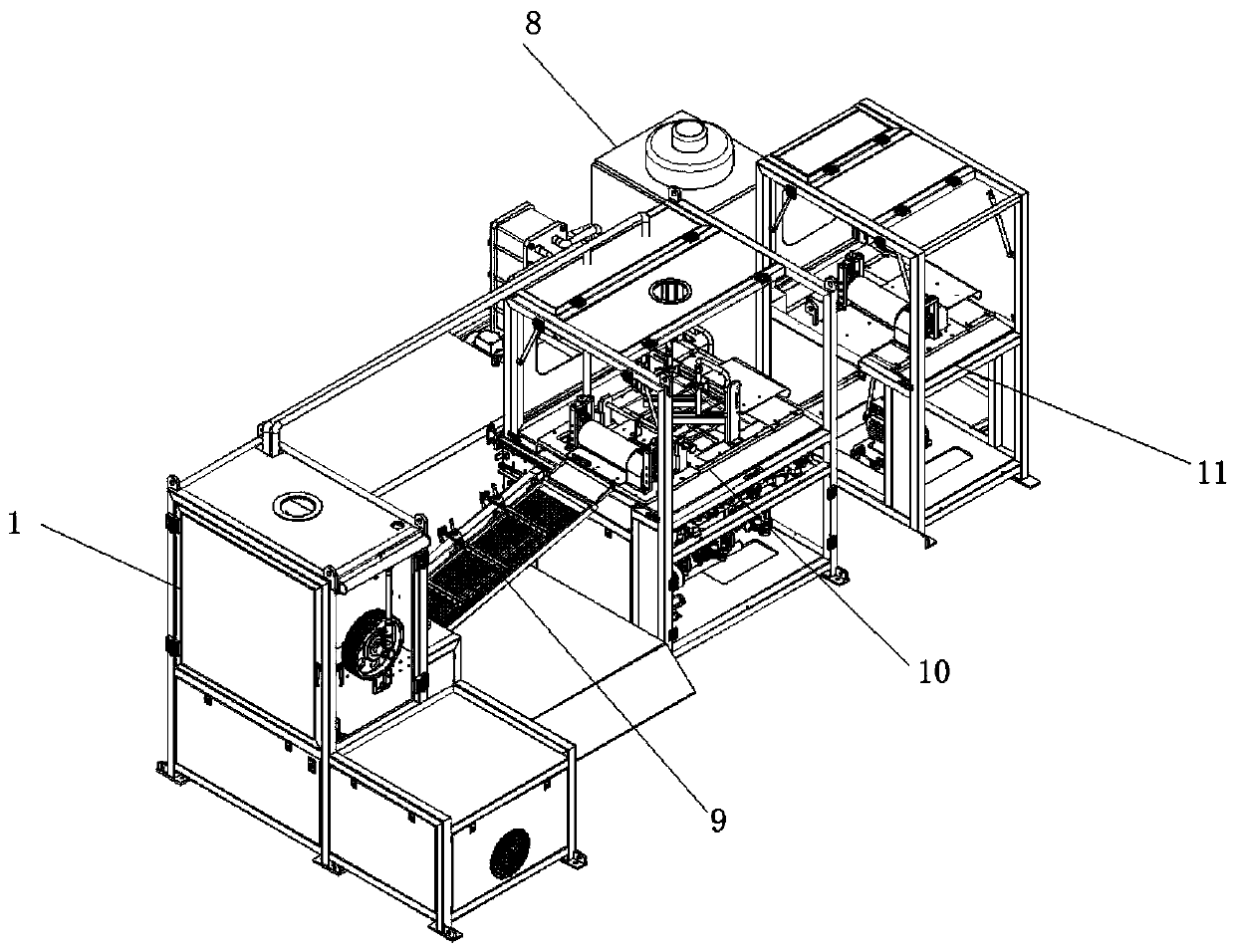

Continuous-casting and continuous-coating production line for plate grid

PendingCN110640121ASolve wear and tearAvoid uneven wearMoulding toolsMolten metal conveying equipmentsOil waterMold removal

The invention discloses a continuous-casting and continuous-coating production line for a plate grid. The continuous-casting and continuous-coating production line comprises a rack; a movable mold isarranged in the rack; a mold-releasing oil spraying component is arranged at a part, in the rack, above the movable mold; a lead transporting pipeline component is arranged on one side of the rack; afixed mold matched with the movable mold is arranged on the lead transporting pipeline component; a pressurizer is arranged on a part, on the rack, on the outer side of the fixed mold; a guide-out roll component is arranged below the inner side of the rack; a cooling groove component is arranged in the rack at the position below the guide-out roll component; and an oil-water cooler is arranged onone side of the rack. The continuous-casting and continuous-coating production line effectively solves the problems existing in the cast plate grid, which is caused by the abrasion of the movable moldand the fixed mold and the use of a mold releasing agent, can enable the plate grid to smoothly fall from a cast cavity in the surface of the movable mold, effectively reduces the abrasion of the movable mold and the fixed mold, ensures the qualification of the cast plate grid, avoids the phenomena of uneven quality, few burrs and rib defects of the plate grid, and correspondingly improves the production efficiency and prolongs the service life of the mold.

Owner:BAODING GOLDEN SUNLIGHT POWER EQUIP TECH

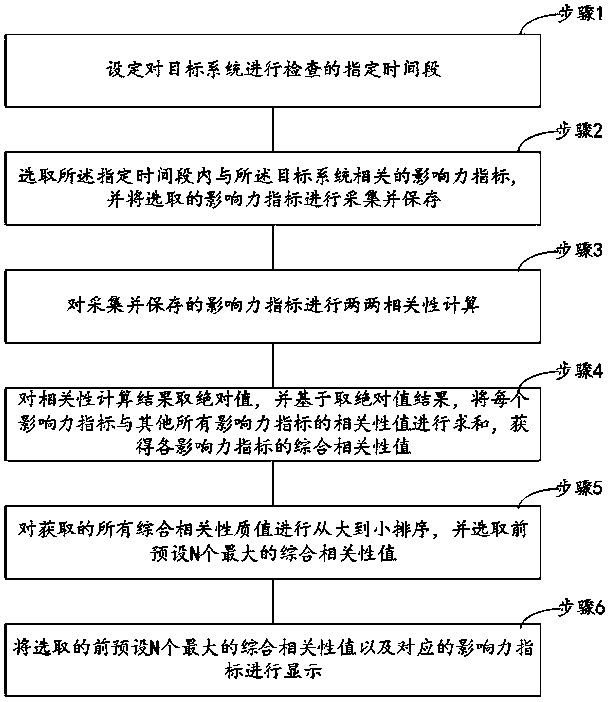

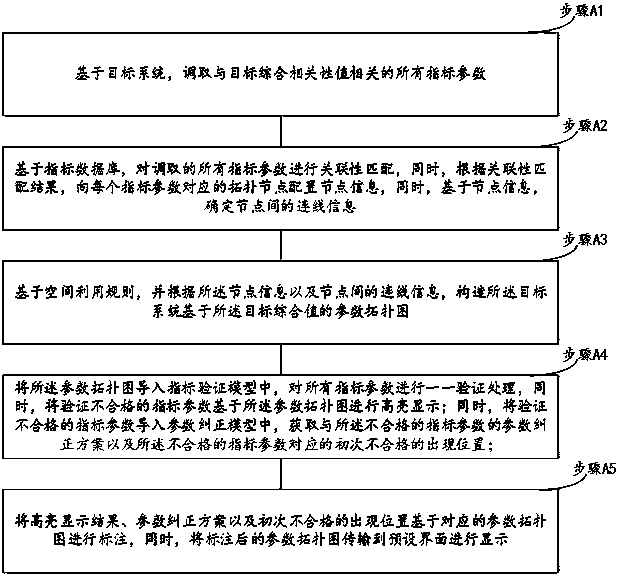

Method for automatically discovering key influence indexes

ActiveCN111444075AAvoid unreasonableImprove performanceHardware monitoringPair correlationData mining

The invention provides a method for automatically discovering key influence indexes. The method comprises the following steps: setting a specified time period for checking a target system; selecting an influence index related to the target system in a specified time period, and collecting and storing the selected influence index; carrying out pairwise correlation calculation on the collected and stored influence indexes; taking the absolute value of the correlation calculation result, and summing the correlation values of each influence index and all the other influence indexes based on the absolute value result to obtain a comprehensive correlation value of each influence index; sorting all the obtained comprehensive correlation values from large to small, and selecting first preset N maximum comprehensive correlation values; and displaying the selected first preset N maximum comprehensive correlation values and the corresponding influence indexes. The indexes which most influence thehealth condition of the system can be automatically screened out from all the indexes without manual intervention.

Owner:南京开特信息科技有限公司

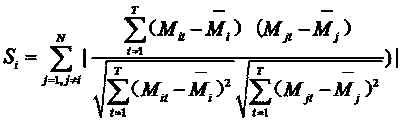

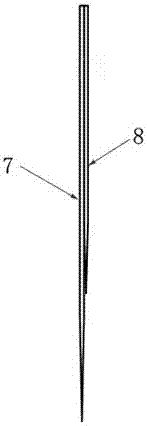

Laser weakening machining equipment

InactiveCN105033471AGuaranteed eligibilityHigh precisionLaser beam welding apparatusControl systemEngineering

The invention belongs to the technical field of automobile industrial laser machining and provides laser weakening machining equipment. The laser weakening machining equipment comprises a technological control system, a laser device, a reflection focusing module, a sensor system and a workpiece fixing device. The technological control system is in control connection with the laser device, the sensor system and the workpiece fixing device. The workpiece fixing device is used for fixing and positioning a workpiece. The reflection focusing module is located on the horizontal side of a laser outlet of the laser device. The workpiece and the sensor system are sequentially located below the reflection focusing module. Lasers emitted by the laser device in the horizontal direction are reflected and focused through the reflection focusing module to be downward so as to machine the workpiece. The sensor system below the workpiece comprises a focus lens and a sensor. Due to the fact that the sensor is arranged below the workpiece, laser signals penetrating the workpiece are detected when the workpiece is machined, the system can monitor and store machining data of each hole on a weakening line in an on-line manner, and judge whether each hole is qualified or not, and the residual thickness precision of the weakening line is improved.

Owner:WUHAN FARLEY LASERLAB CUTTING WELDING SYST ENG CO LTD

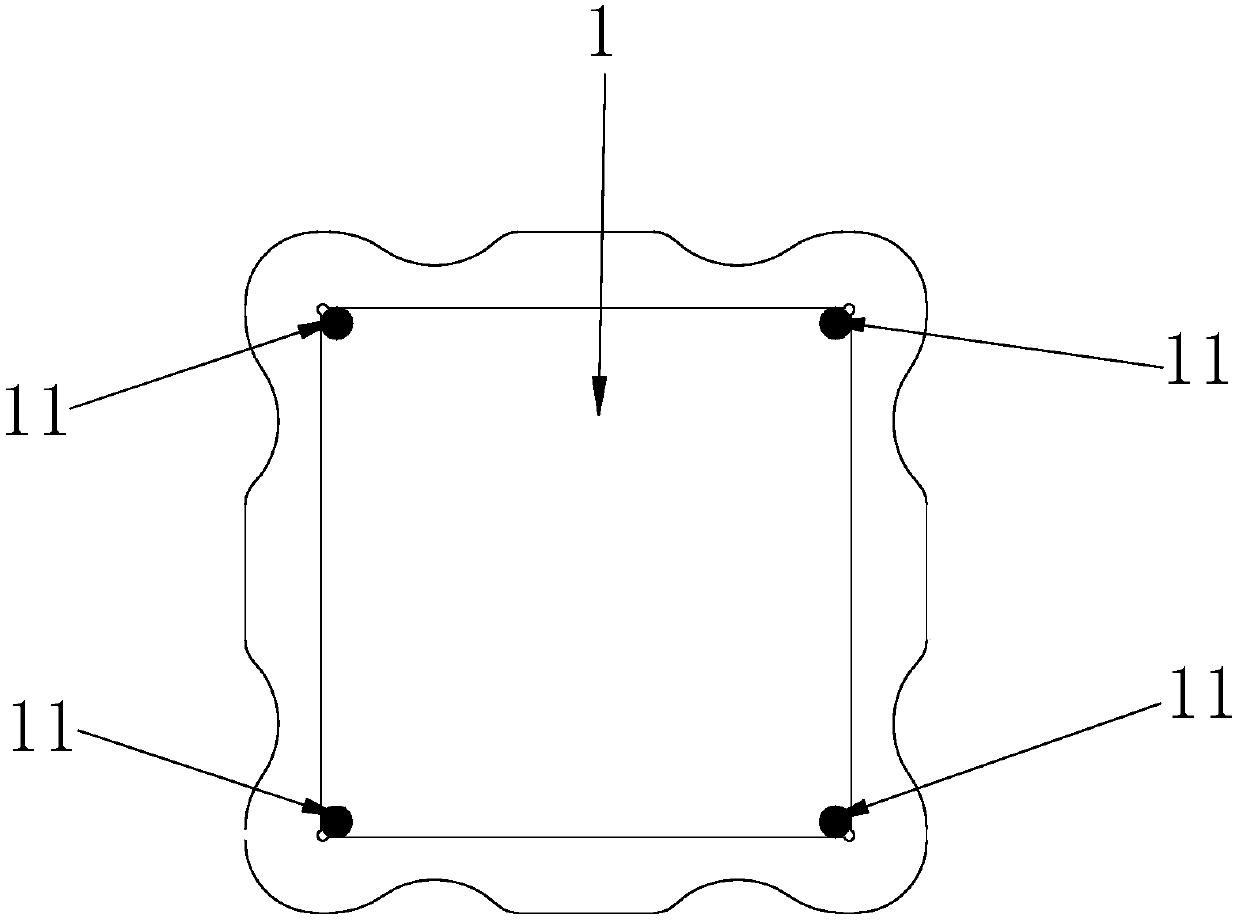

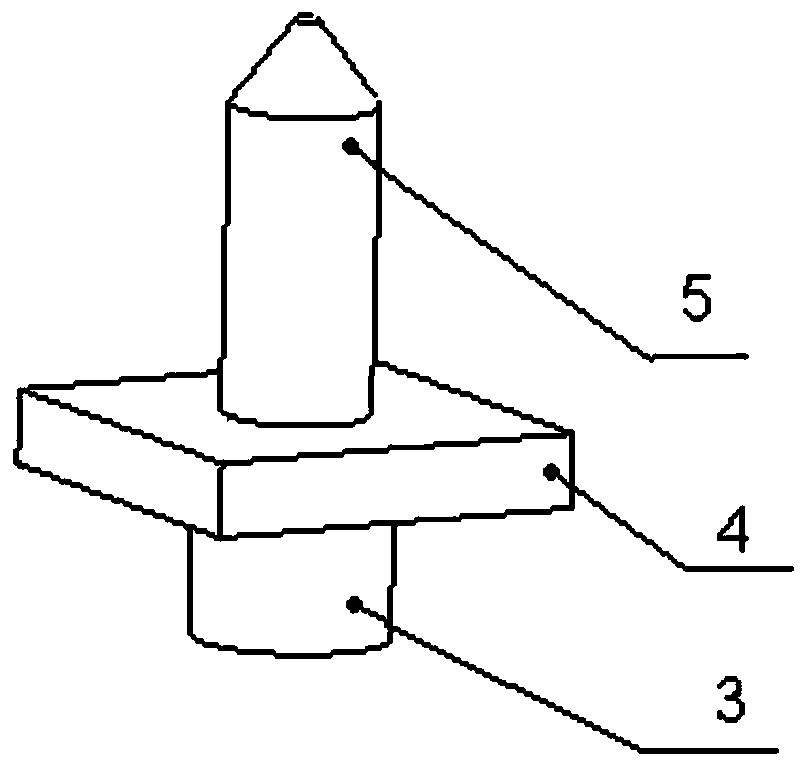

In-hole mechanical pile construction technology for metro construction

InactiveCN110847159AGuaranteed uniformityGuaranteed eligibilityArtificial islandsFoundation testingSlurryRebar

The invention discloses an in-hole mechanical pile construction technology for metro construction, and relates to the technical field of mechanical pile construction. The in-hole mechanical pile construction technology mainly solves the problems that a mechanical pile is low in construction efficiency and poor in stability. The construction technology comprises the following steps of S1, slurry mixing, wherein after a slurry sample is collected, the slurry sample is stored in pile casings, and stored slurry is stirred once every 8 hours; S2, drilling; S3, hole cleaning, wherein after a drill arrives at a designed elevation, a drilling machine stops footage, and is kept rotating at a slow gear in situ to constantly smash soil blocks at a pile tip; S4, installation of the steel pile casings,wherein the steel pile casings are installed after hole forming and adopt multiple sections; S5, making and installation of reinforcement cages; S6, grouting of underwater concrete; and S7, field test and pile body detection. According to the construction technology, the slurry is stirred every 8 hours, specific gravity and other data of the stirred slurry are measured, and the homogeneity and qualification degree of the slurry can be effectively guaranteed; and meanwhile, a quadrangle pile is adopted for control, the drill is aligned with the cross intersection point, and thus the positioning accuracy of drilling can be guaranteed.

Owner:CHINA RAILWAY 16TH BUREAU GRP CO LTD

Speed reducer oil seal press-fitting monitoring device

ActiveCN113814698AGuaranteed eligibilityIncrease profitOptical detectionMetal working apparatusGratingReduction drive

According to a speed reducer oil seal press-fitting monitoring device designed by the invention, multi-station time-phased press-fitting is adopted, and one set of press-fitting monitoring system is shared; a sensor is arranged on a tray for bearing a workpiece and used for detecting whether the workpiece exists; a light beam sensor is arranged in a guide sleeve and used for detecting whether an oil seal is placed in place; stations are provided with gratings for protection, so that damage to personnel, equipment or workpieces caused by misoperation is avoided; the press-fitting depth of the oil seal adopts double guarantees of mechanical limiting and pressure feedback, so that the qualification of press-fitting products is guaranteed; and pressure displacement real-time monitoring is adopted in the oil seal press-fitting process, and original defects of products or process tools can be recognized. According to the device, the utilization rate of a key mechanism is improved, the problems of low efficiency and low product percent of pass caused by manual knocking installation are eliminated, and the production efficiency and the product quality are greatly improved.

Owner:智新科技股份有限公司

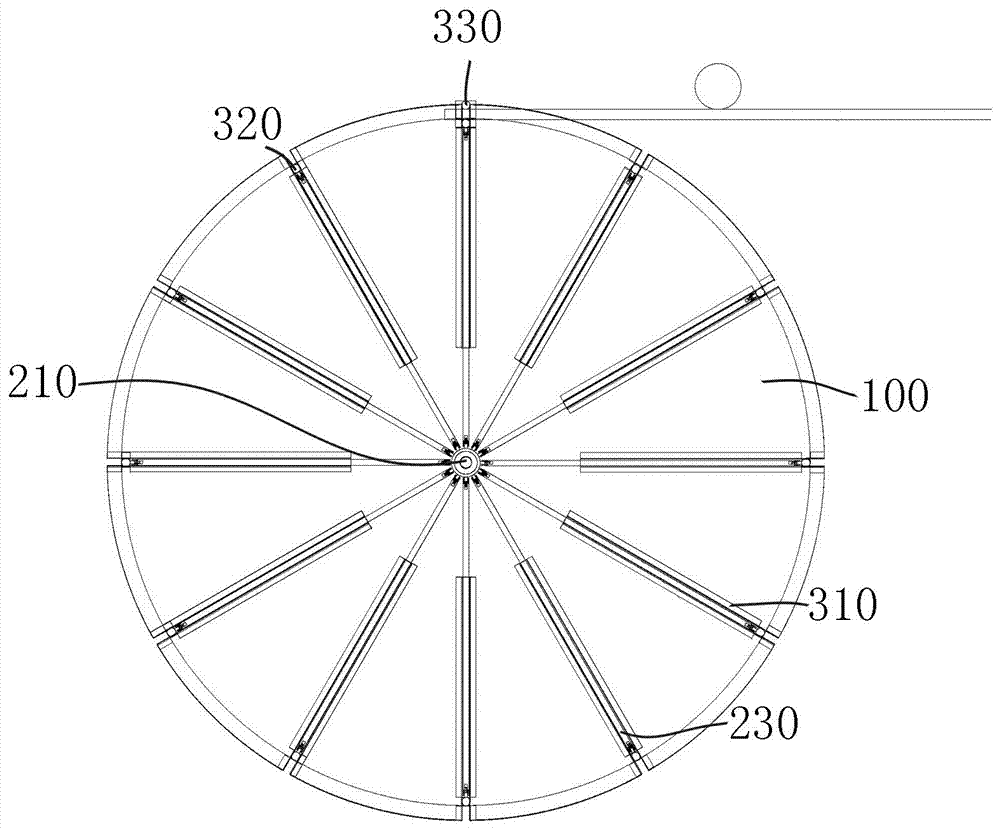

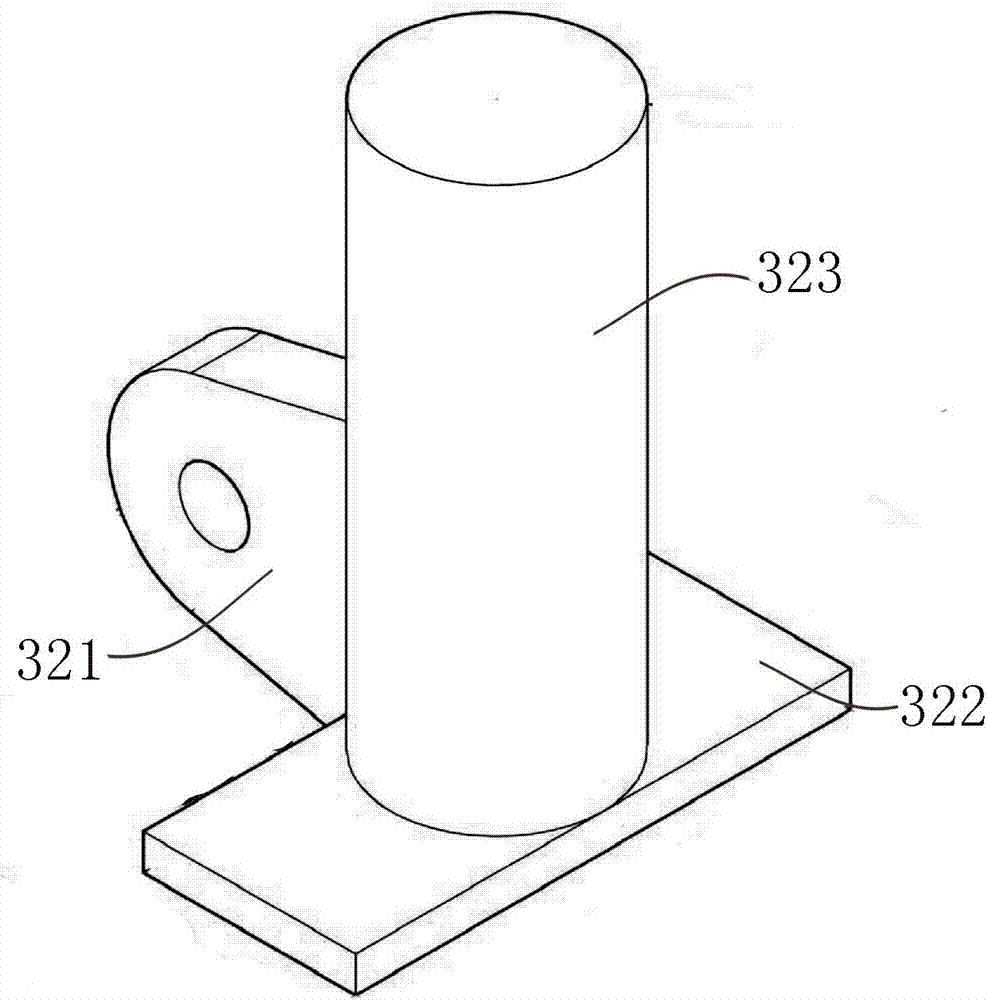

Radius-adjustable steel bar bending and rounding machine

The invention relates to the technical field of steel bar machining, in particular to a radius-adjustable steel bar welding, bending and rounding machine. The radius-adjustable steel bar bending and rounding machine comprises a rotatable operation table, a radius adjusting locking assembly arranged on the operation table and a connecting assembly. The radius-adjustable steel bar bending and rounding machine is characterized in that the connecting assembly comprises multiple radial guide parts arranged on the operation table in a radial shape and corresponding parts of the radial guide parts; the radius adjusting locking assembly comprises a main shaft rod, a sleeve and multiple supporting rods with the number corresponding to that of the radial guide parts; and each supporting rod is provided with a connecting end and a moving end, the connecting ends the hinged to the sleeve, and the moving ends are hinged to the corresponding parts. The radius-adjustable steel bar bending and rounding machine has the advantages of being simple in operation, fast, accurate and high in practicality.

Owner:THE 3RD ENG CO LTD OF CHINA RAILWAY 16TH BUREAU GRP CO LTD +1

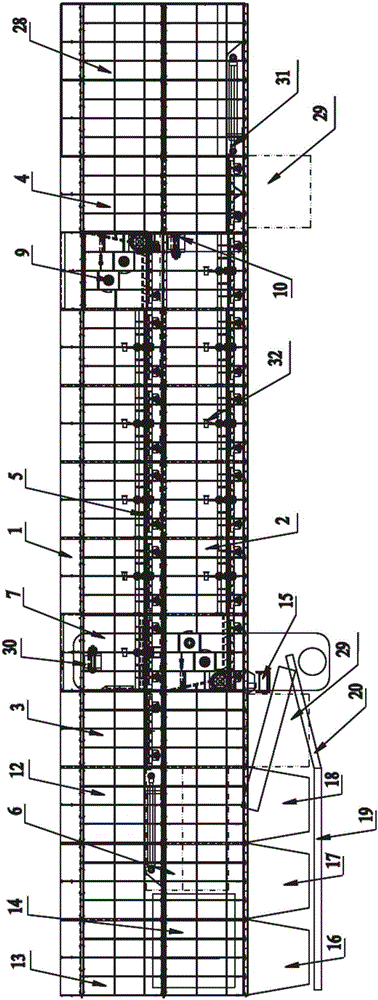

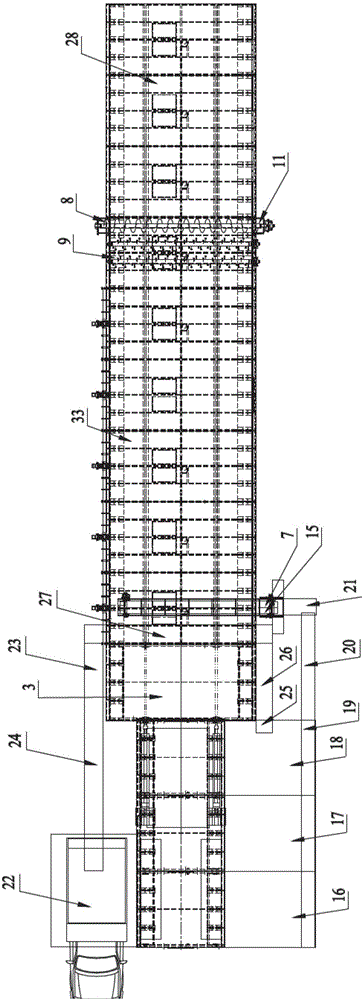

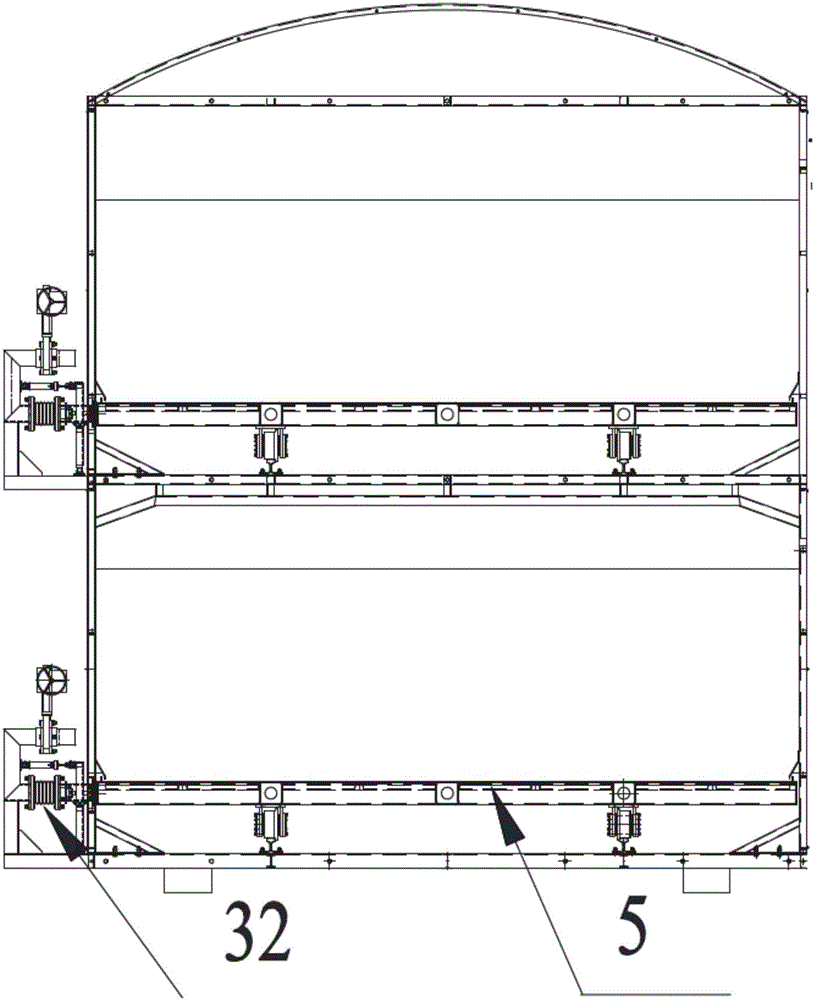

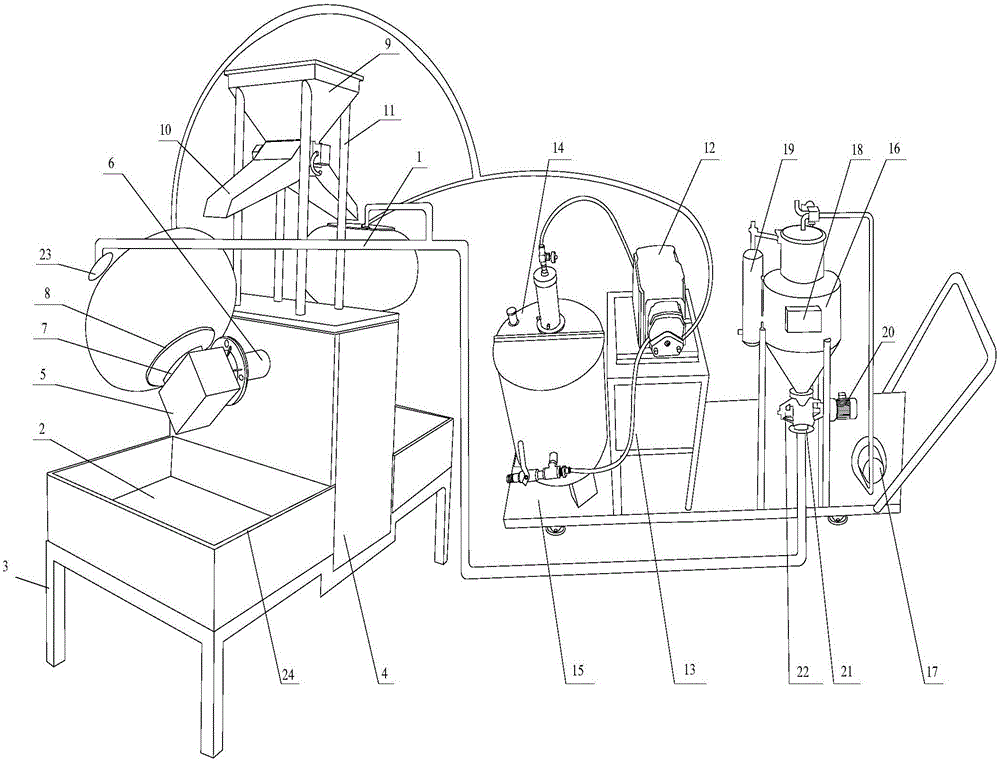

Integrated aerobic fermentation system with double-layer structure

PendingCN106746427ASimple structureSmall footprintSludge processingBiological sludge treatmentMobile vehicleFermentation system

The invention relates to an integrated aerobic fermentation system with a double-layer structure. The integrated aerobic fermentation system with the double-layer structure comprises a primary fermentation chamber and a secondary fermentation chamber which are distributed in upper and lower double layers; an empty vehicle lifting chamber is arranged on one side of the primary fermentation chamber and the secondary fermentation chamber, and an empty vehicle landing chamber is arranged on the other side of the primary fermentation chamber and the secondary fermentation chamber; driving devices of fermented material moving vehicles are arranged on one side of the upper layer of the empty vehicle lifting chamber and one side of the lower layer of the empty vehicle landing chamber correspondingly; a plurality of fermented material moving vehicle strings, which are connected end to end and form an integrated flat plate, are arranged on the middle part of each of the primary fermentation chamber and the secondary fermentation chamber; a material lifting machine for conveying to-be-fermented materials to the starting end of the fermented material moving vehicle strings as well as screw conveying machines for outputting the fermented materials arranged on the other side of the empty vehicle lifting chamber; the screw conveying machines are arranged on one side of an upper overturning machine and one side of a lower overturning machine correspondingly; the upper overturning machine is arranged on the upper part of the primary fermentation chamber; the lower overturning machine is arranged on the upper part of the secondary fermentation chamber; and a material conveying channel is arranged between the upper overturning machine and the lower overturning machine.

Owner:BEIJING ZHONGKE BOLIAN ENVIRONMENT ENG

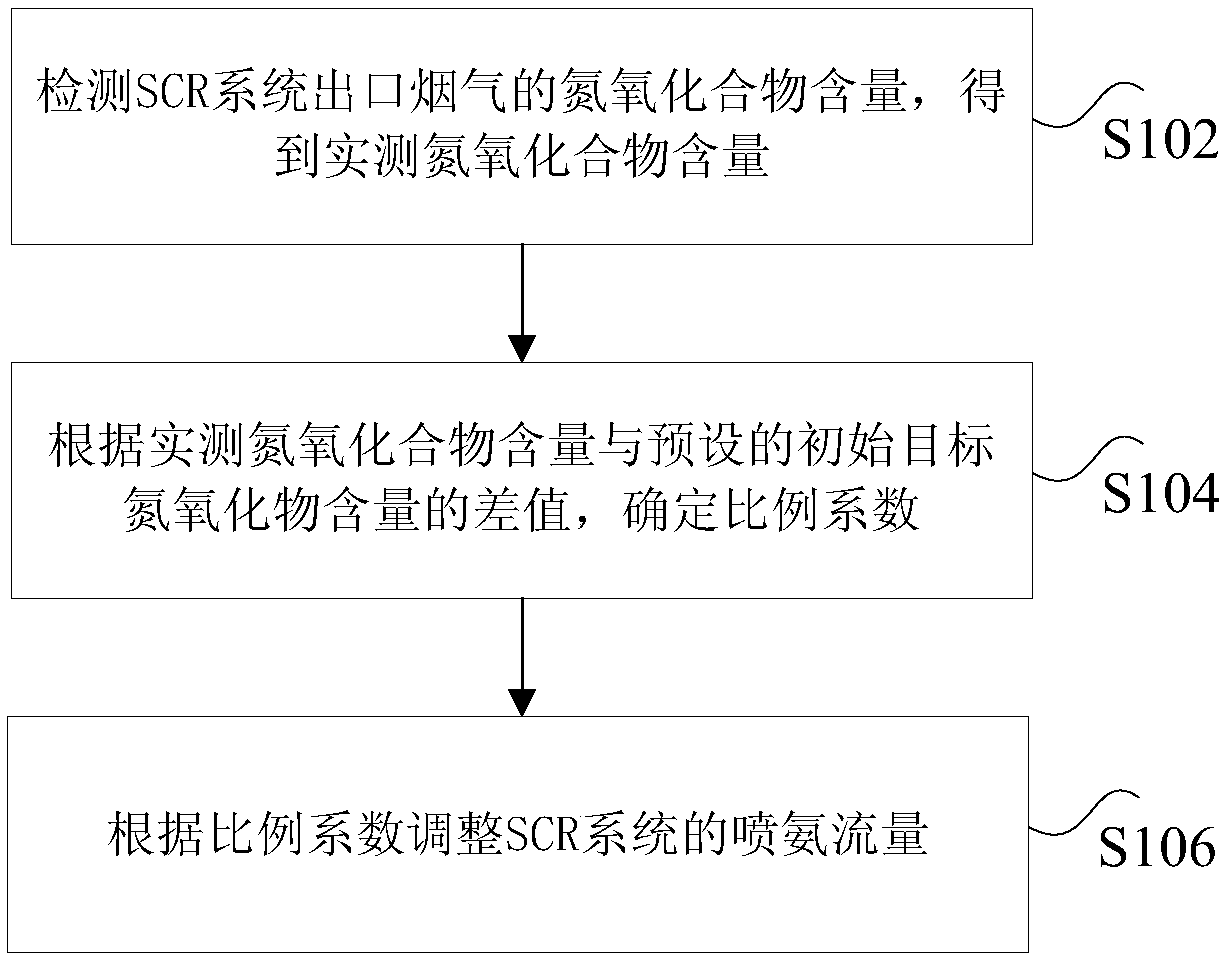

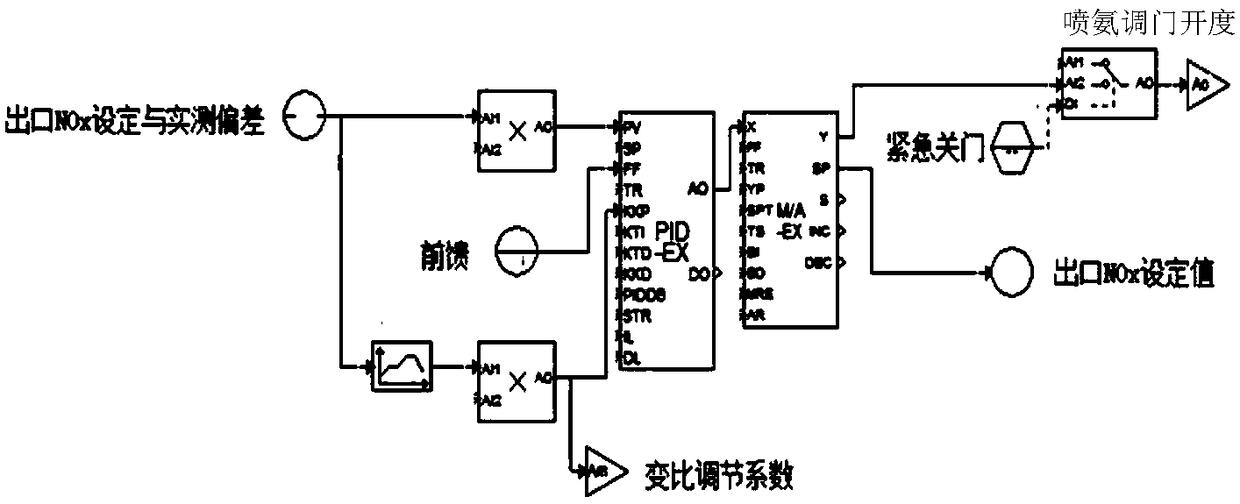

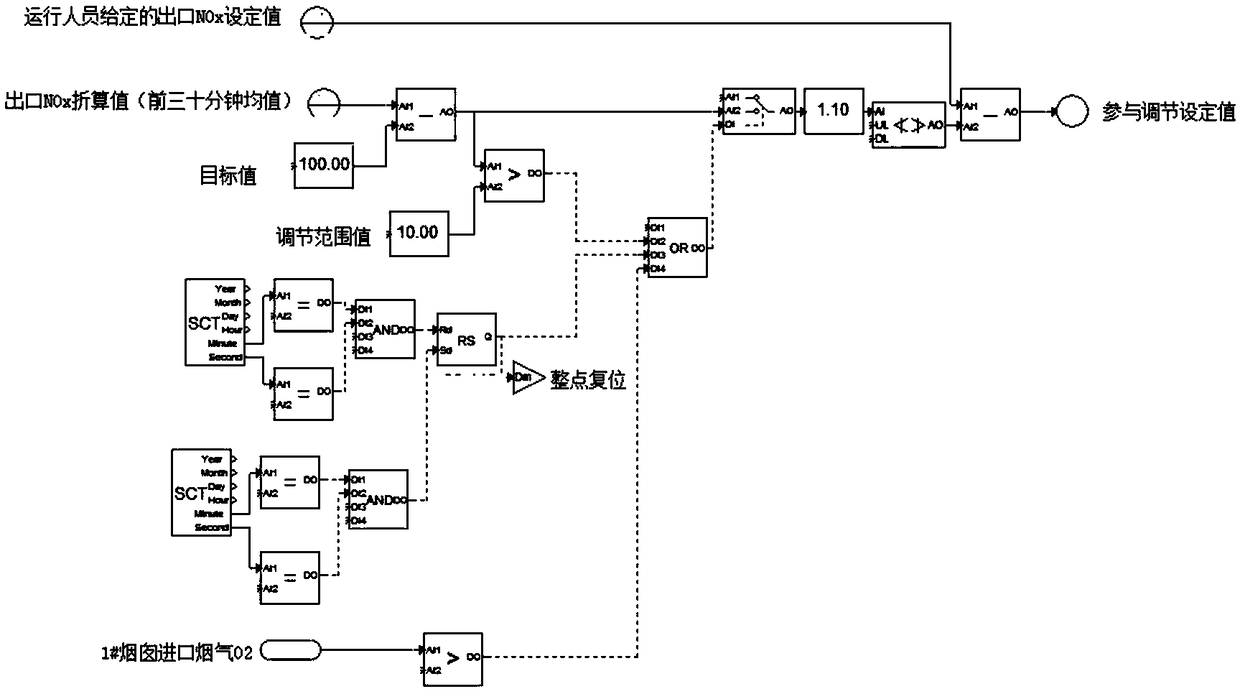

Ammonia spraying control method and device of SCR system

ActiveCN109236427ASolve the technical problem of inaccurate spray volume controlImprove economyInternal combustion piston enginesExhaust apparatusNitrogen oxidesFlue gas

The invention discloses an ammonia spraying control method and device of an SCR system. The method comprises the steps that the nitrogen oxide content of flue gas at an outlet of the SCR system is detected, and the actually measured nitrogen oxide content is obtained; according to the difference between the actually measured nitrogen oxide content and preset initial target nitrogen oxide content,a proportion coefficient is determined, wherein the proportion coefficient is used for adjusting the ammonia spraying flow of the SCR system; the ammonia spraying flow of the SCR system is adjusted according to the proportion coefficient. The method and device solve the technical problem that control over the ammonia spraying amount of the SCR system in the prior art is not accurate.

Owner:CHNA ENERGY INVESTMENT CORP LTD +2

Method for rectifying cushion block for supporting asphalt tank, and measuring tool

PendingCN107796347AIncrease contactFully contactedMeasurement devicesEconomic benefitsStructural engineering

The invention provides a method for rectifying a cushion block for supporting an asphalt tank. The method comprises the following steps: marking at least one position at each of four corners of the first surface of the cushion block as a measuring point; placing the cushion block on the bottom of the asphalt tank, and maintaining the distance between the cushion block and the bottom plate of the asphalt tank at a basic value H1; placing measuring tools at respective measuring points, and obtaining, by the measuring tools, the vertical distances H2 between the cushion block and the bottom plateof the tank at respective measuring points; subtracting the basic value H1 from the measured vertical distances H2 to obtain the thicknesses H required to be machined at the corresponding positions on the cushion block; milling the four corners of the cushion block according to the thicknesses H and inspecting the quality of the milled cushion block. The method can rapidly inspect the cushion block for supporting the asphalt tank, improves the labor efficiency of workers, shortens shipbuilding period, improves the technical level of the construction of a asphalt ship, and can reduce the rejection rate of the cushion block, reduces cost loss, and creates economic benefits.

Owner:GUANGZHOU WENCHONG SHIPYARD CO LTD

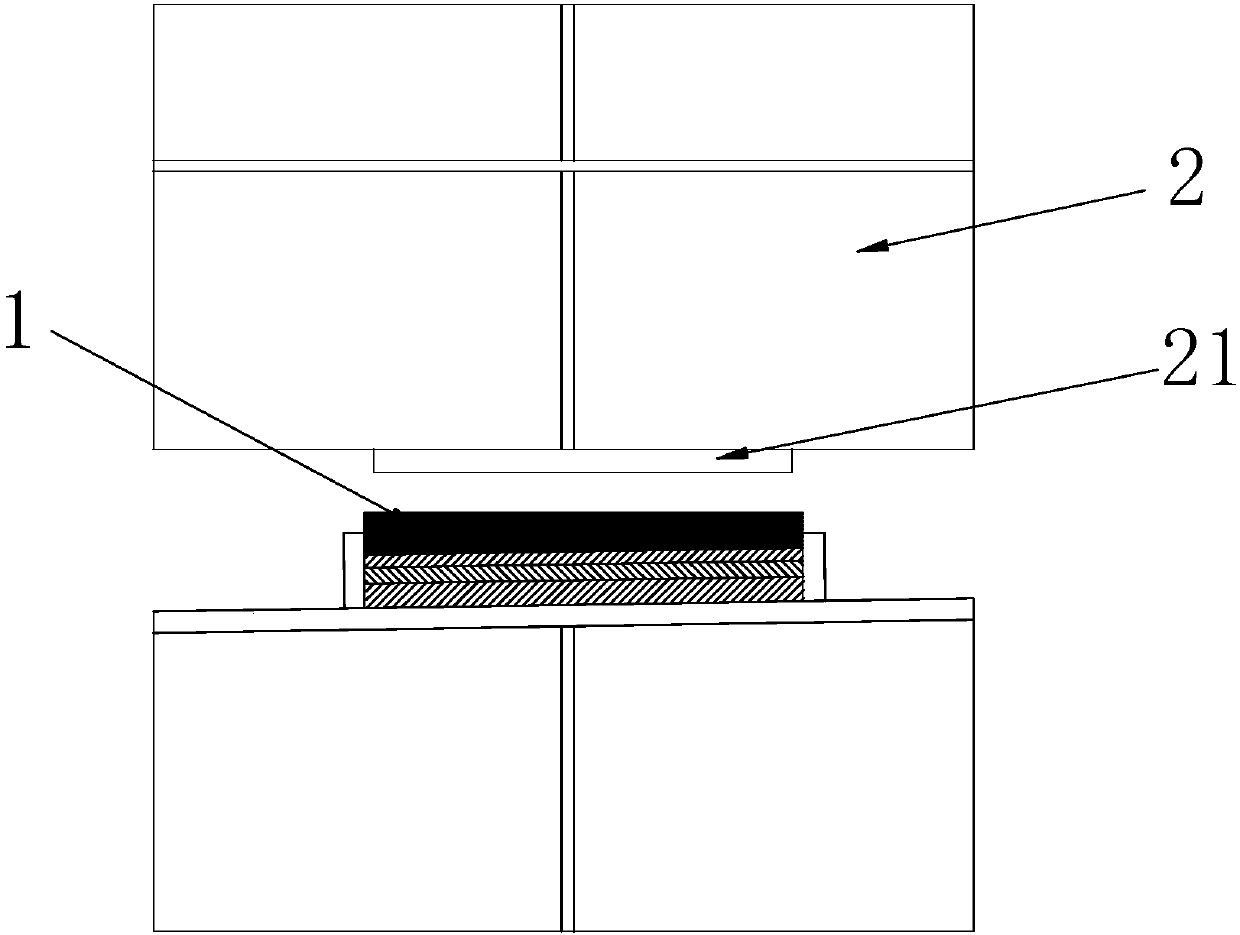

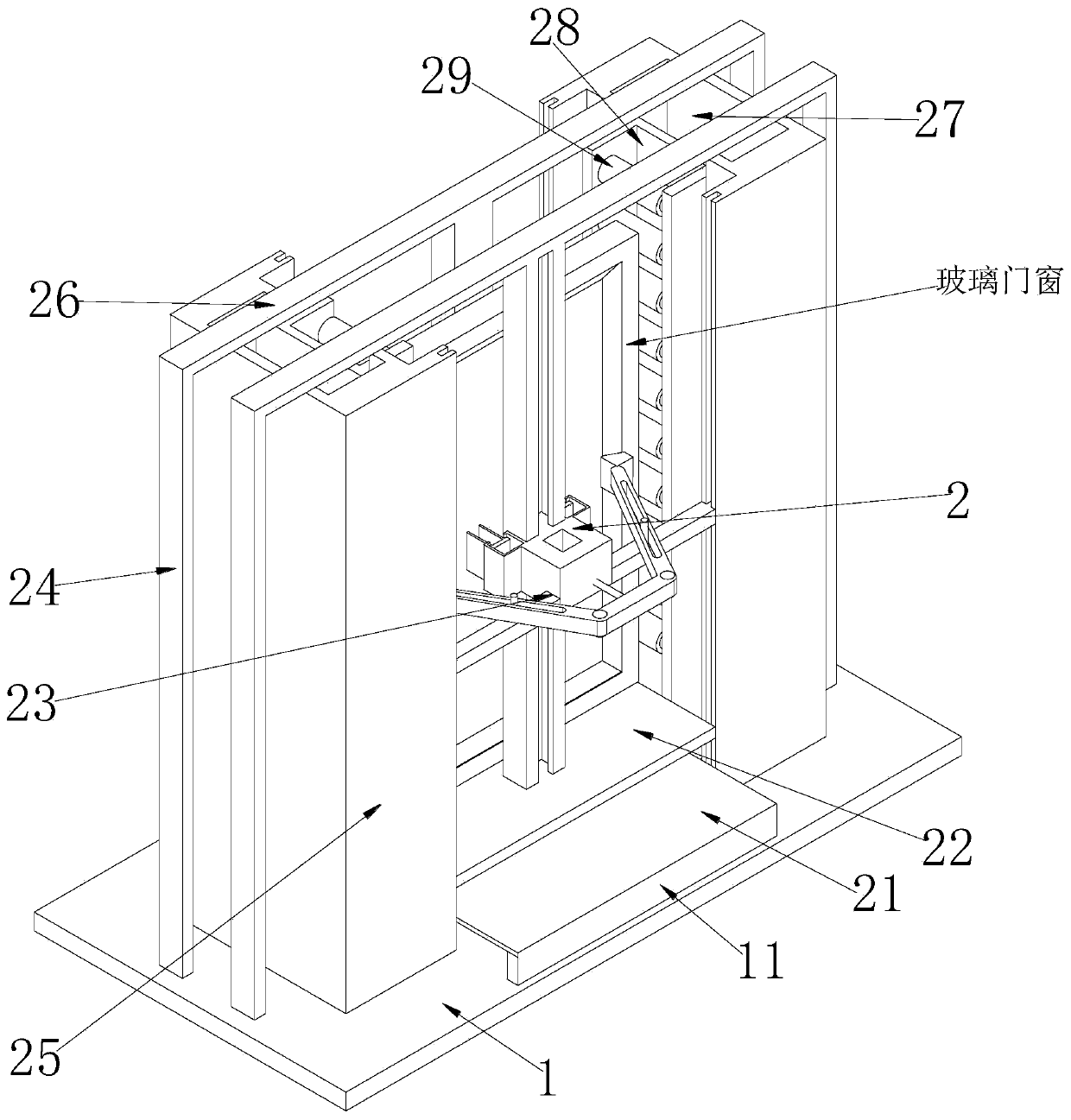

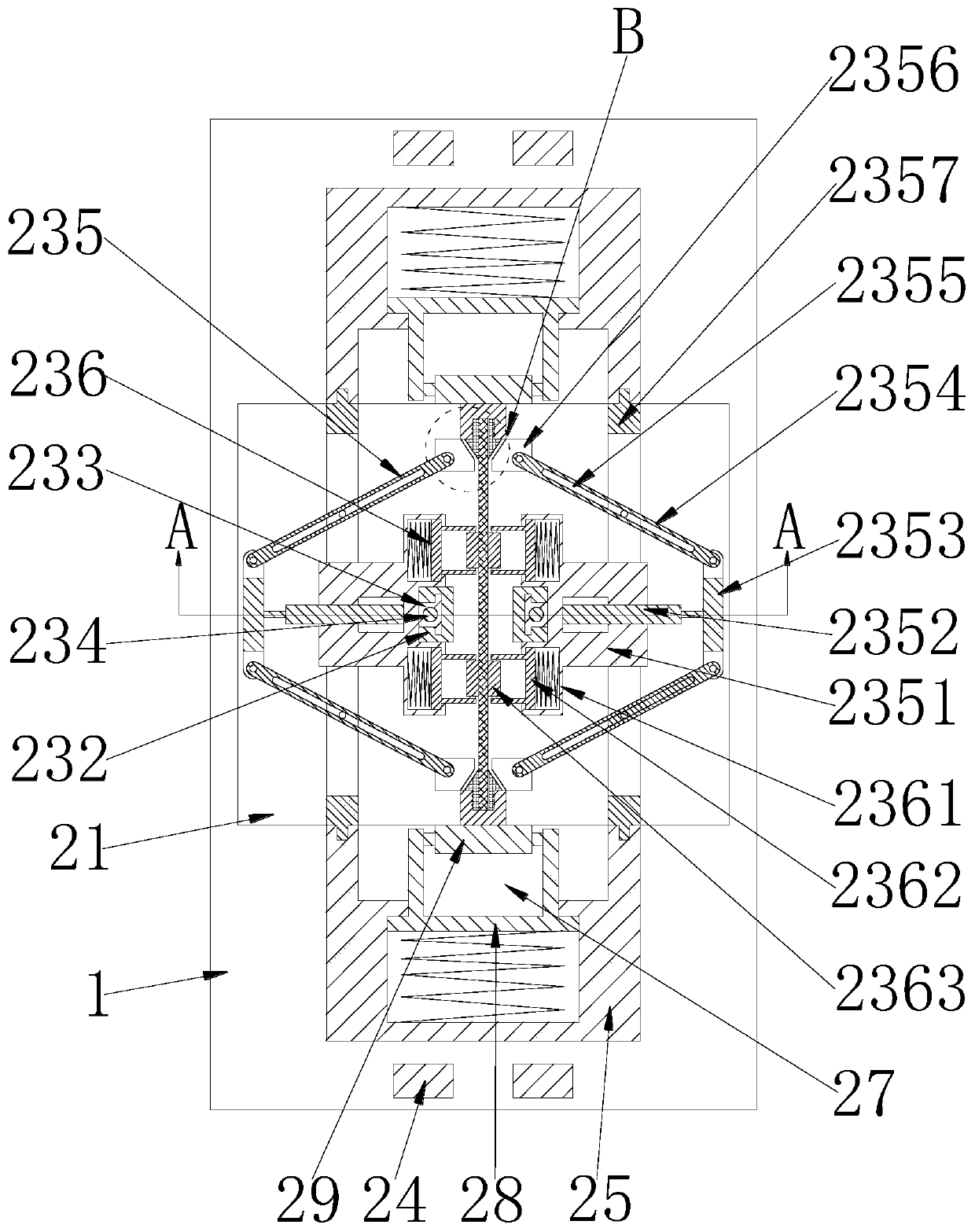

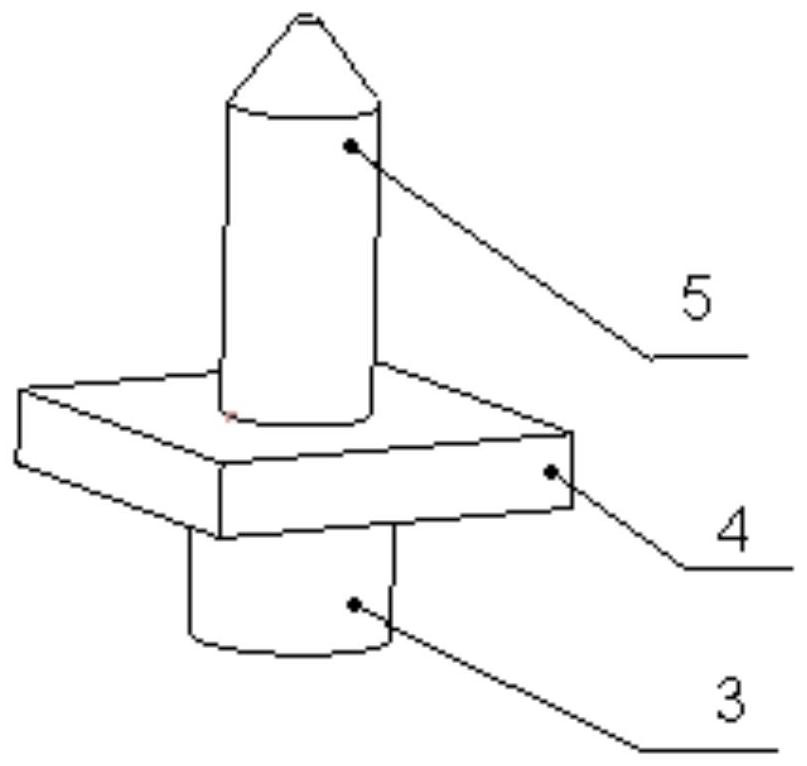

Bridge-cut aluminum glass door and window sealing rubber strip mounting machine and mounting method

ActiveCN111546045AIncrease productivityReduce labor intensityMetal working apparatusMechanical engineering

The invention relates to a bridge-cut aluminum glass door and window sealing rubber strip mounting machine and a mounting method. The mounting machine comprises a base and a mounting device, supporting vertical plates are symmetrically arranged on the upper surface of the base front and back, and the mounting device is arranged on the supporting vertical plates. According to the mounting machine and the mounting method, the following problems existing in installation of a sealing rubber strip in a bridge-cut aluminum door and window at present can be solved, specifically, when the sealing rubber strips are installed in a gap between a bridge-cut aluminum door and window frame and glass, the sealing rubber strips need to be pressed in little by little by hands of a worker, no tool or special equipment is available, the working strength is high, the labor hour is wasted, and fingers of the workers are easily injured; and the bridge-cut aluminum doors and windows are usually produced in batches, so that labor is intensive, the production efficiency is reduced due to the fact that sealing rubber strips are installed manually, and the qualification and attractiveness of manual installation cannot be guaranteed to be consistent.

Owner:上海平易装潢材料有限公司

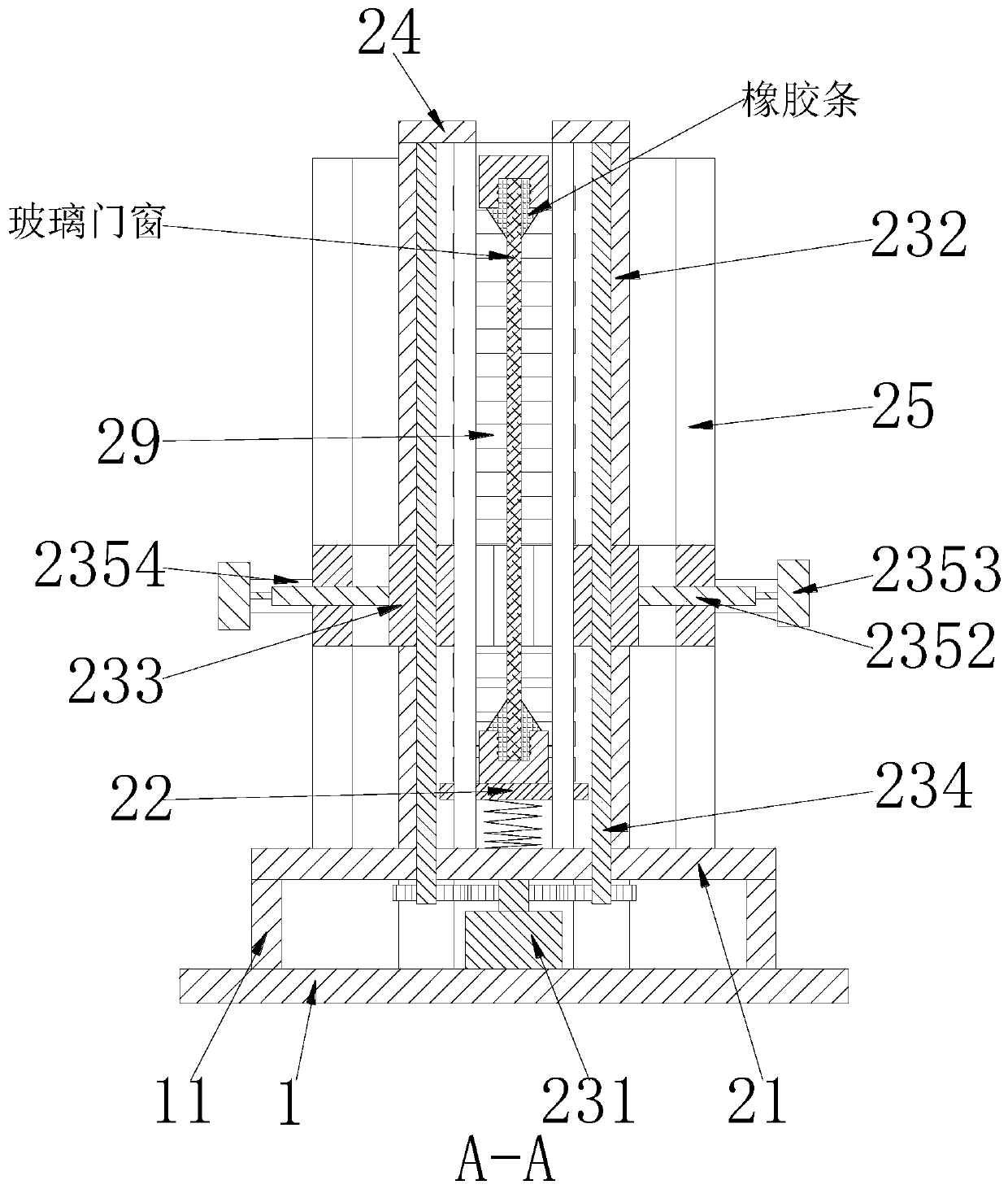

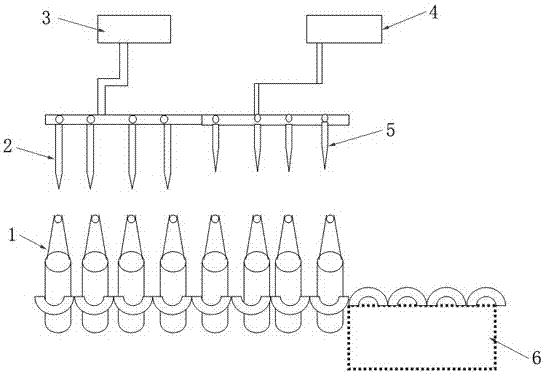

Three-needle-head-group type liquid filling and sealing machine

The invention proposes a three-needle group liquid filling and sealing machine, which includes a filling needle and an inflation needle fixed on a support, the liquid medicine is connected to the filling needle through a pipeline, the gas storage tank is connected to the inflation needle through a pipeline, and the packaging bottle Located on the conveyor chain below the filling needle and inflation needle, a material tray is provided at the end of the conveyor chain, and a group of short suction needles are arranged side by side at the filling needle; the lower end of the inflation needle is closed at the bottom, and the lower end of the inflation needle A plurality of transverse air-filling holes are arranged along the circumferential direction. The use of the present invention can effectively solve the problem of foam overflow generated in the liquid medicine subpackaging process, reduce the loss of medicine, and also reduce the packaging failure rate caused by the foam overflow of the liquid medicine, and improve the quality of production operation.

Owner:张银华

Detecting method for automobile panoramic sunshade curtain skylight

ActiveCN109059709AAccurate detection of tightnessGuaranteed eligibilityMechanical counters/curvatures measurementsOptical detectionEngineeringSunroof

The invention relates to the technical field of automobile skylight detecting and particularly discloses a detecting method for an automobile panoramic sunshade curtain skylight. The detecting methodcomprises the steps that a roof imitation block is used for conducting simulation detection on the matching relation of the automobile panoramic sunshade curtain skylight and a sealing strip; a detecting block and a go-no-go gauge are adopted to conduct flatness detection on a skylight mounting hole; the mounting position of the skylight mounting hole is detected through a detecting pin; the height of a sunshade curtain slideway is detected through the T-shaped detecting pin, the detecting block and the go-no-go gauge, and the width of the slideway is detected through the T-shaped detecting pin; the edges of the slideway are subjected to dotting detection through a dial indicator; and the mounting position of a sunshade curtain is subjected to dotting detection through an infrared sensor.According to the detecting method, the detecting pin and the dial indicator are adopted to detect the slideway, the sunshade curtain is soft, thus the infrared sensor is adopted for detecting, and theoverall qualified degree of the skylight is ensured; and the mounting tightness degree of the sunshade curtain can be detected accurately, meanwhile it is further endured that the phenomenon that theskylight cannot be mounted during mounting is avoided, the detecting efficiency is high, and the labor intensity of a worker is reduced.

Owner:SHENMO NANTONG MACHINERY TECH CO LTD

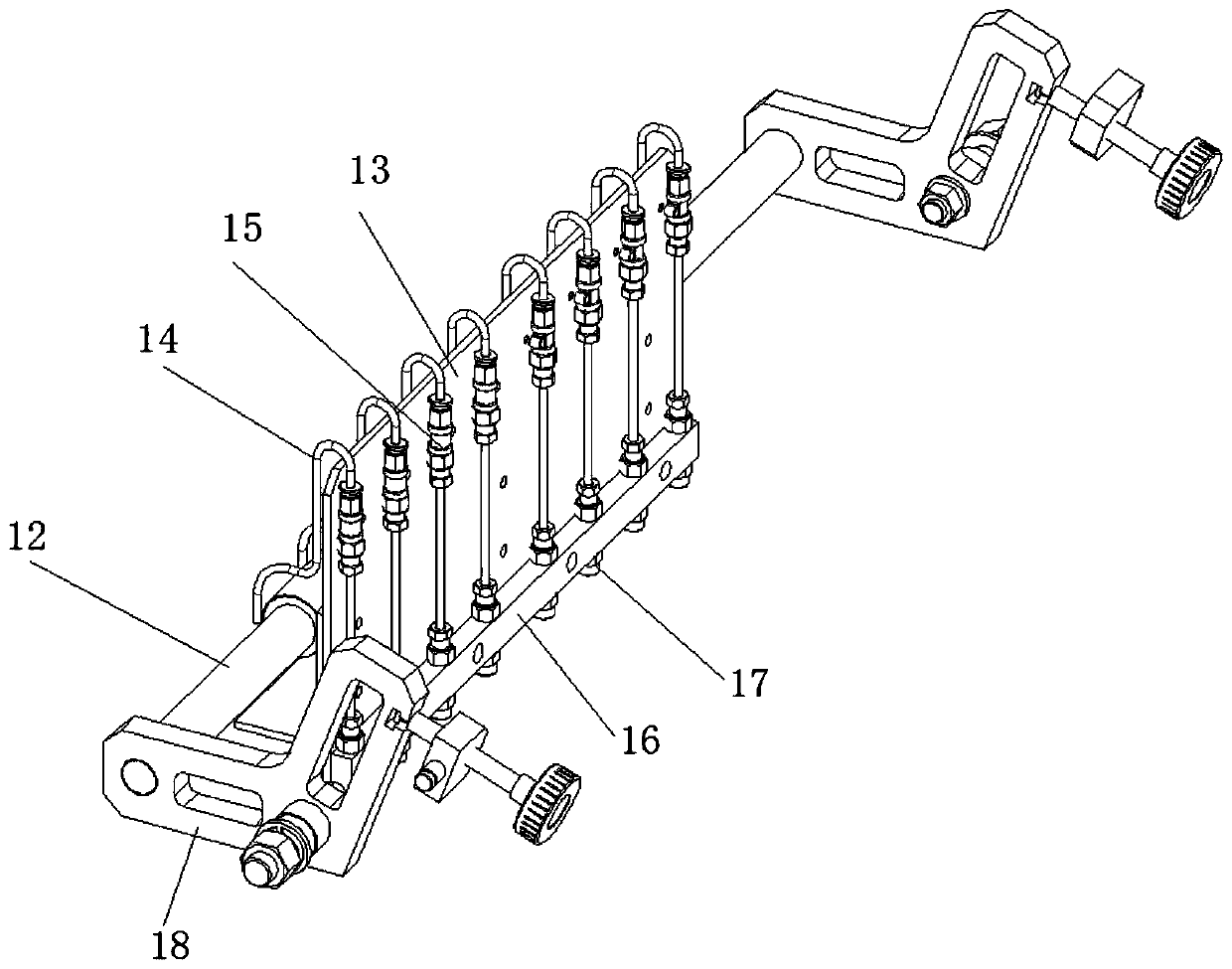

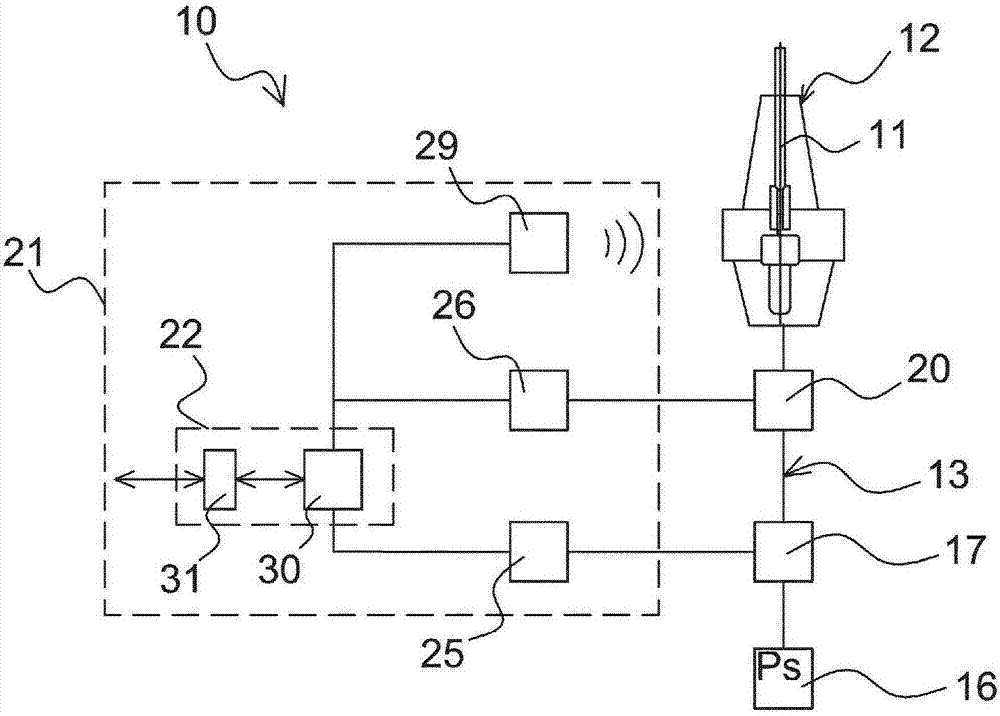

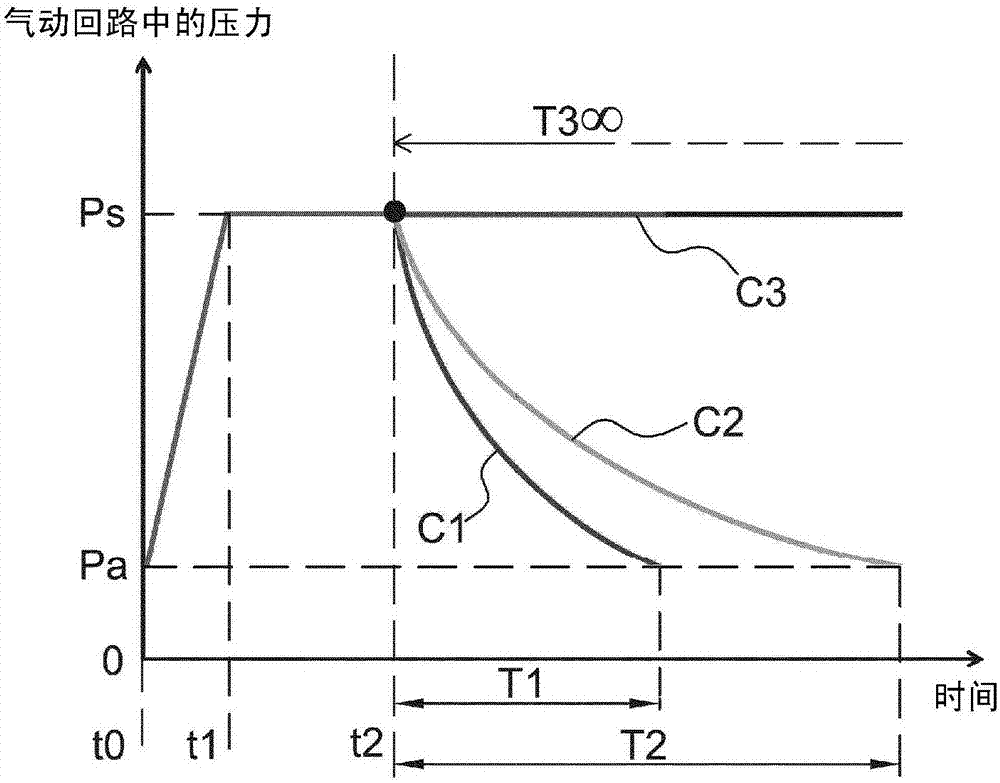

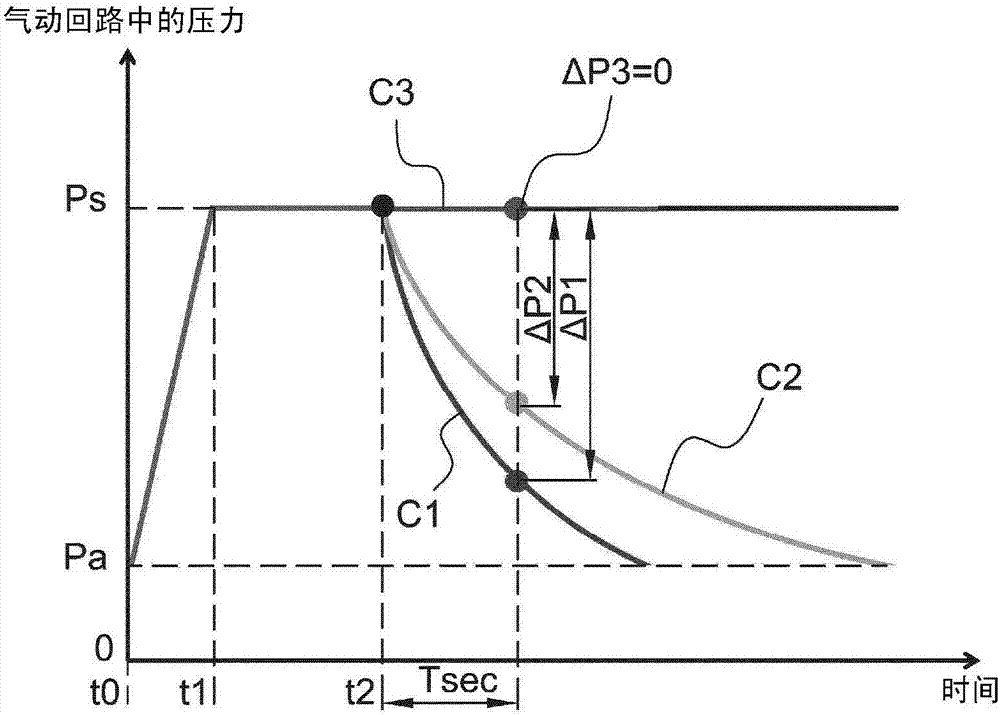

System for detecting a partial or total obstruction of at least one internal pipe of a tool

ActiveCN107405744AGuaranteed eligibilityNo blockingStatic/dynamic balance measurementMeasurement/indication equipmentsPneumatic circuitSolenoid valve

The invention primarily relates to a system (10) for detecting a total or partial obstruction of at least one internal fluid pipe (11) of a tool (12), characterised in that said system (10) comprises: a pneumatic system (13) that is intended to be connected upstream of said internal pipe (11) of said tool (12), a pressure source (16) that is connected to said pneumatic system (13) by means of a solenoid valve (17), and a control unit (22) that is configured to open said solenoid valve (17) so as to pressurise said pneumatic system (13), and then to close said solenoid valve (17) so as to let said pneumatic system (13) be emptied freely by means of said internal pipe (11), and to detect an obstruction state of said internal pipe (11) depending on an analysis over time of a change in the pressure in said pneumatic system (13).

Owner:机械设备建设公司

High-precision sanding machine for furniture plates

ActiveCN111633522AGuaranteed flatnessGuaranteed efficiencyGrinding carriagesBelt grinding machinesSanderEngineering

The invention discloses a high-precision sanding machine for furniture plates. When sanding is performed, especially when rough sanding is performed on the furniture plates, a sanding surface inclination adjusting mechanism and a plate surface detecting mechanism are arranged; and when rough sanding is performed, flatness or inclination of the plates is detected by the plate surface detecting mechanism and fed back to a controller in real time, so that the controller can adjust the inclination angle of the sanding surface through the sanding surface inclination adjusting mechanism according todetection results in real time. Therefore, while sanding efficiency can be ensured, the problems of blocking or failure to sanding certain parts can be solved, and rough sanding efficiency is guaranteed; and during finish sanding, the sanding surface inclination adjusting mechanism can be leveled to make the sanding surface a horizontal plane, sanding flatness is guaranteed, and the plate surfacedetecting mechanism is used for detection to ensure sanding quality and qualification after sanding.

Owner:湖北益亚家居有限公司

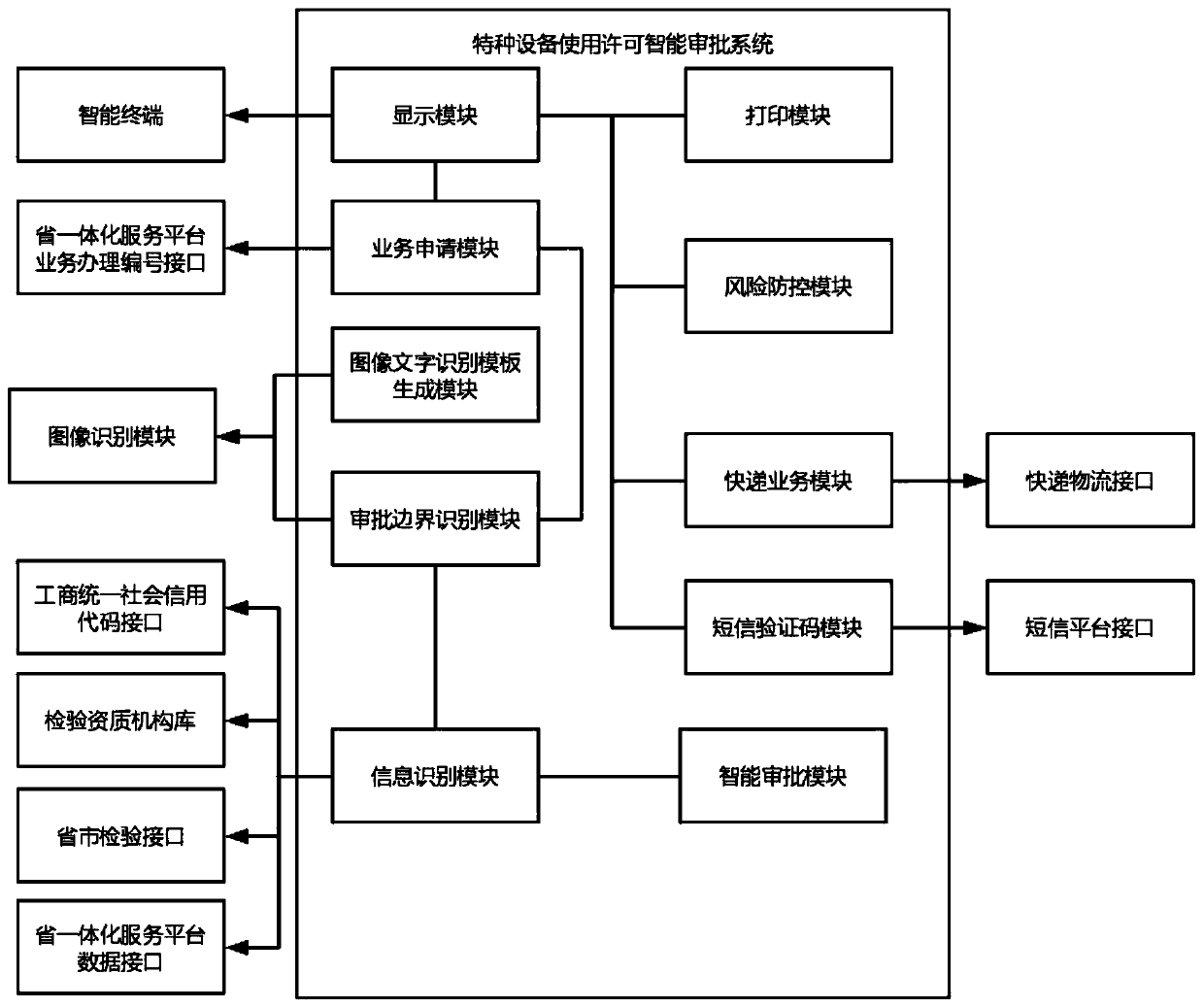

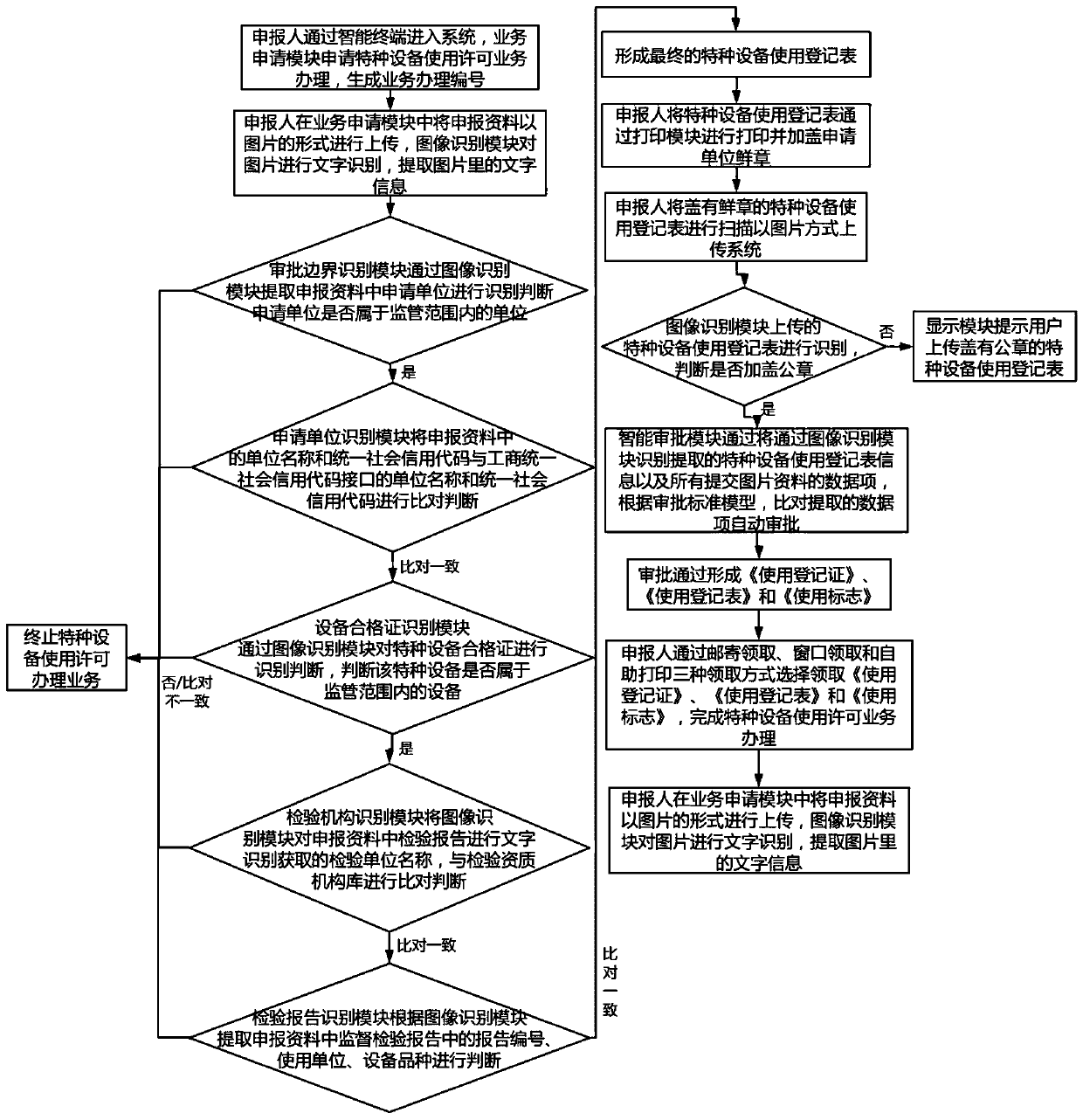

Intelligent approval system for usage license of special equipment

InactiveCN110147978AGuaranteed eligibilityPrevent counterfeitingOffice automationLogistics managementSoftware engineering

The invention discloses an intelligent approval system for usage license of special equipment. The intelligent approval system includes an image recognition module, a province integrated service platform data interface, a province integrated service platform business handling number interface, a business unified social credit code interface; an inspection qualification mechanism library, a province and city inspection interface, an express logistics interface, and a short message platform interface thereof, and also includes a display module, a business application module, an approval boundaryidentification module, an information identification module, a printing module, an image character identification template generation module and an intelligent approval module, wherein the business application module is respectively connected with the province integrated service platform business handling number interface and the image identification module; the approval boundary identification module is connected with the image identification module; and the image character identification template generation module is connected with the image identification module. According to the invention, intelligent approval of usage license of the special equipment is realized, and the approval efficiency is improved.

Owner:成都科鸿智信科技有限公司

Strong-flavor oil enzymatic-process degumming process

The invention discloses a strong-flavor oil enzymatic-process degumming process, is used for solving the problems of relatively large oil product loss, relatively high water content, relatively long degumming time, non-thorough degumming, relatively high phosphorus content, not easy long-term preservation and the like in the prior art, and is characterized in that trace active phospholipase is added in crude oil for degumming, and the process comprises the following specific process steps: measuring the quantity of oil products in a hydration tank with a ruler, calculating the mass of an enzyme required to be added and the mass of soft water required to be added, measuring the temperature of the crude oil, then adding the soft water and the active phospholipase in a stirring heating-up process, stopping stirring, then naturally settling for 2-4 hours, discharging oil foots, starting up a refrigerating unit for cooling hydration oil, starting to filter oil when the temperature is dropped to about 25 DEG C, and completing the process after the oil filtration is completed. The process has the advantages of advanced process, thorough degumming, resource saving, quality improving and the like, and can be widely applied for degumming in a strong-flavor oil production workshop.

Owner:中粮粮油工业(黄冈)有限公司

SMT surface mounting process for PCBA mainboard processing

InactiveCN113163620AGuaranteed eligibilityAvoid non-conformitiesPrinted circuit assemblingSurface mountingSolder paste

The invention discloses an SMT surface mounting process for PCBA mainboard processing. The SMT surface mounting process specifically comprises the steps of solder paste printing, element mounting, inspection after element mounting, reflow soldering, inspection after reflow soldering, cleaning, performance testing and packaging. According to the SMT surface mounting process for PCBA main board processing, the qualification of the PCBA main board is guaranteed by inspecting, cleaning and testing the surface mounting process, the problem can be found out through inspecting and detecting once the problem occurs in the part, the problem can be solved in time, the phenomenon that a large number of PCBA main board patches are unqualified is prevented, and the process is suitable for application and popularization.

Owner:深圳市科美通科技有限公司

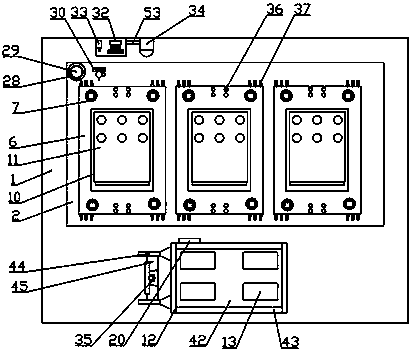

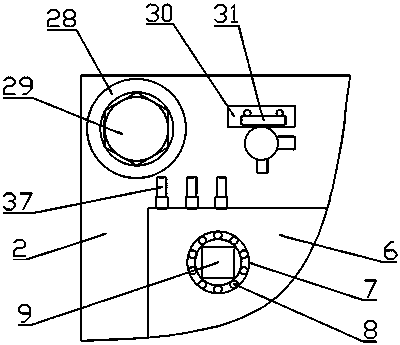

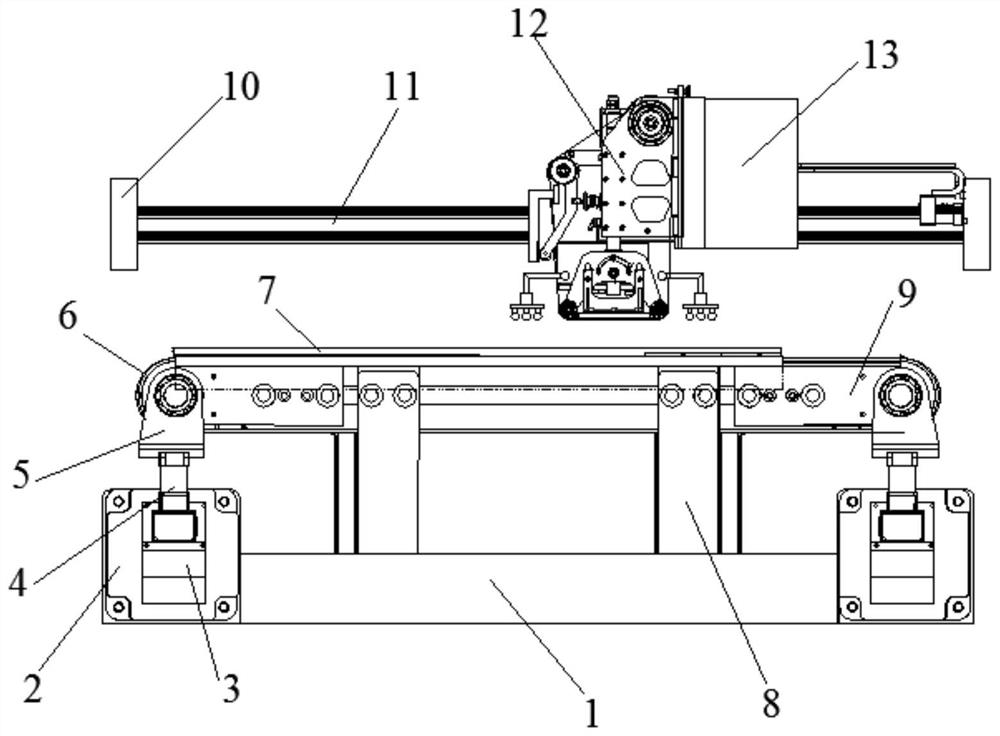

Detection device of power distribution equipment for low-voltage line equipment distribution network

PendingCN111413576AImprove efficiency and reliabilityGuaranteed detection accuracyElectrical testingMeasurement instrument housingAutomotive engineeringAssembly line

The invention discloses a detection device of power distribution equipment for a low-voltage line equipment distribution network. Assembly line type detection of the power distribution equipment can be realized. When the power distribution equipment is detected; to-be-detected power distribution equipment is input by the to-be-detected power distribution equipment conveying mechanism. After beingpositioned and locked by the detection positioning mechanism, the workpiece is jacked up by the jacking mechanism; then, the detection mechanism is used for detecting; the jacking mechanism descends and is loosened by the detection positioning mechanism; a conveying mechanism of the power distribution equipment to be detected outputs; the identification mechanism identifies whether the detected power distribution equipment is qualified or not; effectively ensuring detection precision, according to the detection positioning mechanism, the conveying direction of the power distribution equipmentcan be clamped and positioned; the detection mechanism is simple in structure and convenient to use, clamping and positioning are conducted in the width direction, the clamping reliability and precision are effectively improved, the ex-factory qualified performance of the power distribution equipment is guaranteed, the detection mechanism has a buffering function, and adverse effects on matched equipment during detection are reduced.

Owner:NANJING G LENS INFORMATION TECH CO LTD

Device and method for calibrating shot blasting position of shot blasting machine

ActiveCN110815066AImprove pass rateGuaranteed accuracyBlast gunsAbrasive machine appurtenancesStructural engineeringControl theory

The invention discloses a device and method for calibrating the shot blasting position of a shot blasting machine. The device comprises a calibration block and a calibration simulation gun used for simulating a shot blasting path. Connection ends and calibration ends are arranged on the calibration block and the calibration simulation gun. The connection end of the calibration block is connected with a center positioning hole of a machine tool, and the connection end of the calibration simulation gun is connected with a nozzle of the shot blasting machine. When the shot blasting position of the shot blasting machine is calibrated, the calibration end of the calibration block and the calibration end of the calibration simulation gun are aligned. A conventional spray gun calibration manner is changed, a spray gun position calibration device is adopted for calibrating the position of the nozzle before shot blasting, thus, the quality defect that the shot blasting coverage rate is insufficient as the position of the nozzle is not precise during shot blasting is avoided, the movement track of the nozzle in the shot blasting process is precisely calibrated, and the one-time percent of pass of the shot blasting coverage rate is increased. Meanwhile, the device is simple in structure, convenient to produce and machine, low in cost and suitable for being used and popularized.

Owner:AECC AVIATION POWER CO LTD

Height adjust device of distribution cabinet

InactiveCN109066407AConsistent installation heightGuaranteed eligibilitySubstation/switching arrangement casingsFixed bearingLiquid level sensor

The invention discloses a height regulate device of a distribution cabinet including an installation site, A mount groove is arranged on the mounting site, A mounting mechanism is arranged in the mounting groove, the mounting mechanism is provided with a square groove, a square support column, a threaded hole, a circular through hole, a fixed bearing, a Connecting shaft, a holding groove, a distribution cabinet, a connecting mechanism, A regulating mechanism is arranged in the installation site, the adjusting mechanism is provided with a tool car, a Tool box, an L-shaped adjusting plate, an Angle sensor, An infrared rangefinder, a limiting post, a rechargeable battery, an electric plug board, a connecting piece, a connecting hole, a fastening nut, an electric nut fastening gun, a sleeve, and a protective shield cover; an early warning power-off mechanism is arranged in the mounting groove; the early warning power-off mechanism is provided with a drain pipe, a one-way valve, a liquid level sensor, a circuit main switch, and an electric alarm; and a controller is arranged on the tool vehicle. The invention has the advantages of simple structure and strong practicability.

Owner:苏州智多搭智能科技有限公司

Inclinable dual-pot wrapping device and process with multiple feed assemblies

The invention discloses an inclinable dual-pot wrapping device and process with multiple feed assemblies. The device comprises a powder inlet assembly, a liquid inlet assembly and a driving assembly. The driving assembly comprises a shell. A button is arranged on the surface of the shell. A motor is arranged in the shell. Two output shafts are arranged on the two sides of the outer portion of the shell respectively. Speed reducers are arranged outside the output shafts and can do half-circular motion around the output shafts. Linkage shafts are arranged at the upper portions of the speed reducers and connected with wrapping pots through connecting plates. The wrapping pots can do circular motion around the linkage shafts. Feed devices are arranged on the top of the shell. A support is arranged at the bottom of the shell. A discharge hopper is arranged above the support. Dual pots alternately work, and therefore production efficiency is high; through the mode that pot heads automatically turn to discharge materials and the mode that liquid, powder and other wrapping materials are automatically added, labor intensity is lowered, and the product quality of pills and tablets is ensured.

Owner:江苏库克机械有限公司

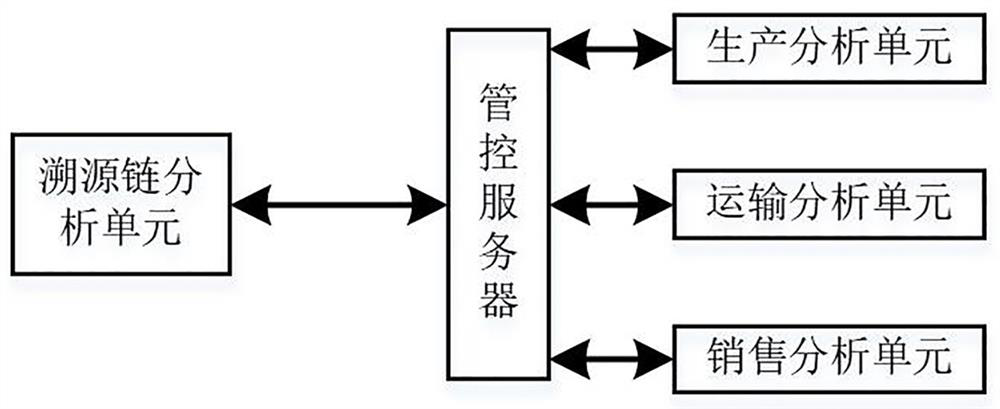

Liquor product grading traceability management system based on data analysis

PendingCN114708005AImprove accuracyImprove product qualityResourcesLogisticsProcess engineeringAlcohol products

The invention discloses an alcohol product grading traceability management system based on data analysis, relates to the technical field of grading traceability management, and solves the technical problems that in the prior art, grading data analysis and acquisition cannot be performed on alcohol products, and qualified circulation of the alcohol products cannot be ensured. Data of each link of the wine products are obtained through grading analysis of the wine products, and a tracing chain is constructed according to the data, so that the accuracy of grading tracing of the wine products is improved; whether the production process of the analysis object is qualified or not is judged, when the production process is qualified, the analysis object is subjected to production data collection, and the production data serves as a traceability basis, so that the quality qualification of the analysis object is improved, and the traceability accuracy of the analysis object is enhanced; and whether the transportation of the analysis object is qualified or not is judged, so that the qualification of the analysis object in the transportation process is ensured, and the product quality of the analysis object is improved.

Owner:SHANDONG TAIBAO PREVENTING COUNTERFEIT

A high-precision sander for furniture panels

ActiveCN111633522BGuaranteed flatnessGuaranteed efficiencyGrinding carriagesBelt grinding machinesSanderIndustrial engineering

The invention discloses a high-precision sander for furniture boards. When performing sanding, especially rough sanding on furniture boards, a sanding surface inclination adjustment mechanism and a board surface detection mechanism are provided to perform rough sanding. When sanding, the planarity or inclination of the plate is detected by the plate surface detection mechanism, and is fed back to the controller in real time, so that the controller adjusts the sanding surface in real time through the sanding surface inclination adjustment mechanism according to the detection result In this way, the sanding efficiency can be guaranteed, and at the same time, there will be no problems of sticking or sanding not reaching certain parts, so as to ensure the efficiency of coarse sanding, and when fine sanding, the sanding surface can be The tilt adjustment mechanism is leveled so that the sanding surface is a horizontal plane to ensure the flatness of the sanding, and the plate surface detection mechanism is used for detection to ensure the quality of the sanding and the qualification after sanding.

Owner:湖北益亚家居有限公司

A device and method for calibrating the shot blasting position of a shot blasting machine

ActiveCN110815066BImprove pass rateGuaranteed accuracyBlast gunsAbrasive machine appurtenancesEngineeringMachine tool

The invention discloses a shot peening position calibration device and method of a shot blasting machine. The device includes a calibration block and a calibration simulation gun for simulating the shot blasting path; the calibration block and the calibration simulation gun are both provided with a connection end and a calibration end; the calibration block The connection end is connected with the central positioning hole of the machine tool, and the connection end of the calibration simulation gun is connected with the nozzle of the shot blasting machine; when the shot blasting position of the shot blasting machine is calibrated, the calibration end of the calibration block is aligned with the calibration end of the calibration simulation gun. The present invention changes the conventional spray gun calibration method, and uses the spray gun position calibration device to check the nozzle position before shot peening, thus avoiding the quality defect of insufficient shot peening coverage caused by inaccurate nozzle position during shot peening, and accurate calibration The trajectory of the nozzle during the shot peening process is clearly defined, and the first pass rate of shot peening coverage is improved. Simultaneously, the device of the invention has a simple structure, is convenient for production and processing, has low cost, and is suitable for popularization and use.

Owner:AECC AVIATION POWER CO LTD

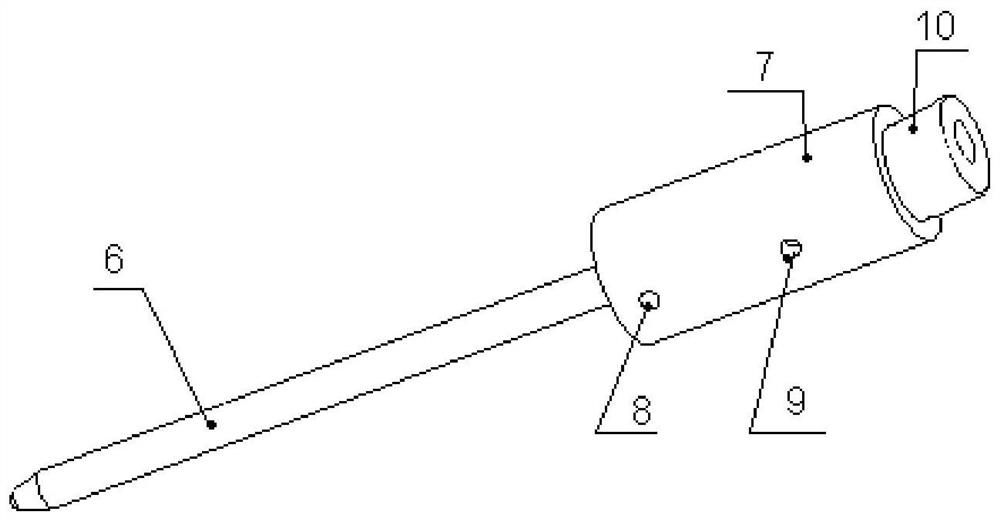

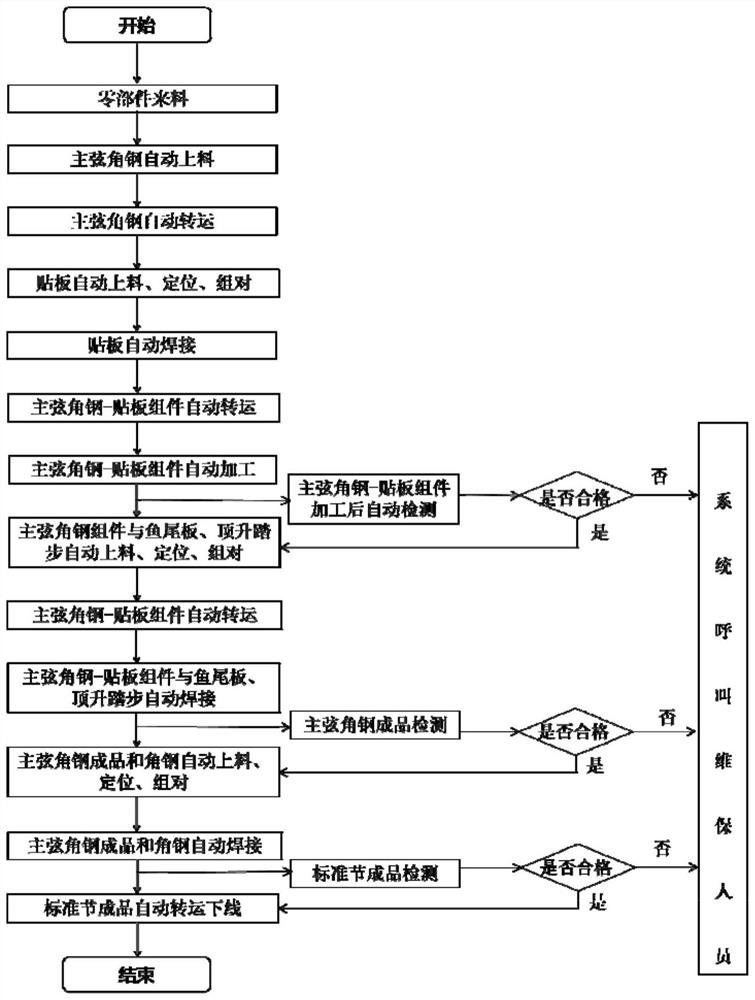

Intelligent automatic production method for standard sections of tower crane

ActiveCN113319548AGuaranteed eligibilityReduce detectionSortingMetal working apparatusSmart controlStructural engineering

The invention discloses an intelligent automatic production method for standard sections of a tower crane, and relates to the field of crane structural part production. The method comprises the following steps that main chord angle steel and flitch plates are respectively subjected to automatic feeding, positioning, pairing and welding operation to form a main chord angle steel-flitch plate assembly, and the main chord angle steel-flitch plate assembly is conveyed to a combined machine tool to be firstly machined; a first detection platform is automatically detected to conduct automatic quality detection; after detection is completed, the main chord angle steel-flitch assembly, a fishplate and a jacking step are subjected to automatic feeding, positioning, assembling and welding operation to form a main chord angle steel finished product; The main chord angle steel finished product is transferred to a second detection platform for automatic quality detection; after the detection is completed, the main chord angle steel finished product and the angle steel are subjected to automatic feeding, positioning, assembling and welding operation to form standard sections; and the standard sections are transferred to a third detection platform for automatic quality detection, and the standard sections are automatically grabbed to be off line after detection is completed. The method has the advantages of intelligent control, unattended operation, reliable quality, complete functions and the like.

Owner:无锡恒久安泰智能制造有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com