Bridge-cut aluminum glass door and window sealing rubber strip mounting machine and mounting method

A technology of sealing rubber strips and broken bridge aluminum, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of manual installation qualification, inability to guarantee the appearance, injured fingers of staff, and decreased production efficiency. , to achieve the effect of reducing the risk of finger injury for workers, high work intensity, and reduced labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

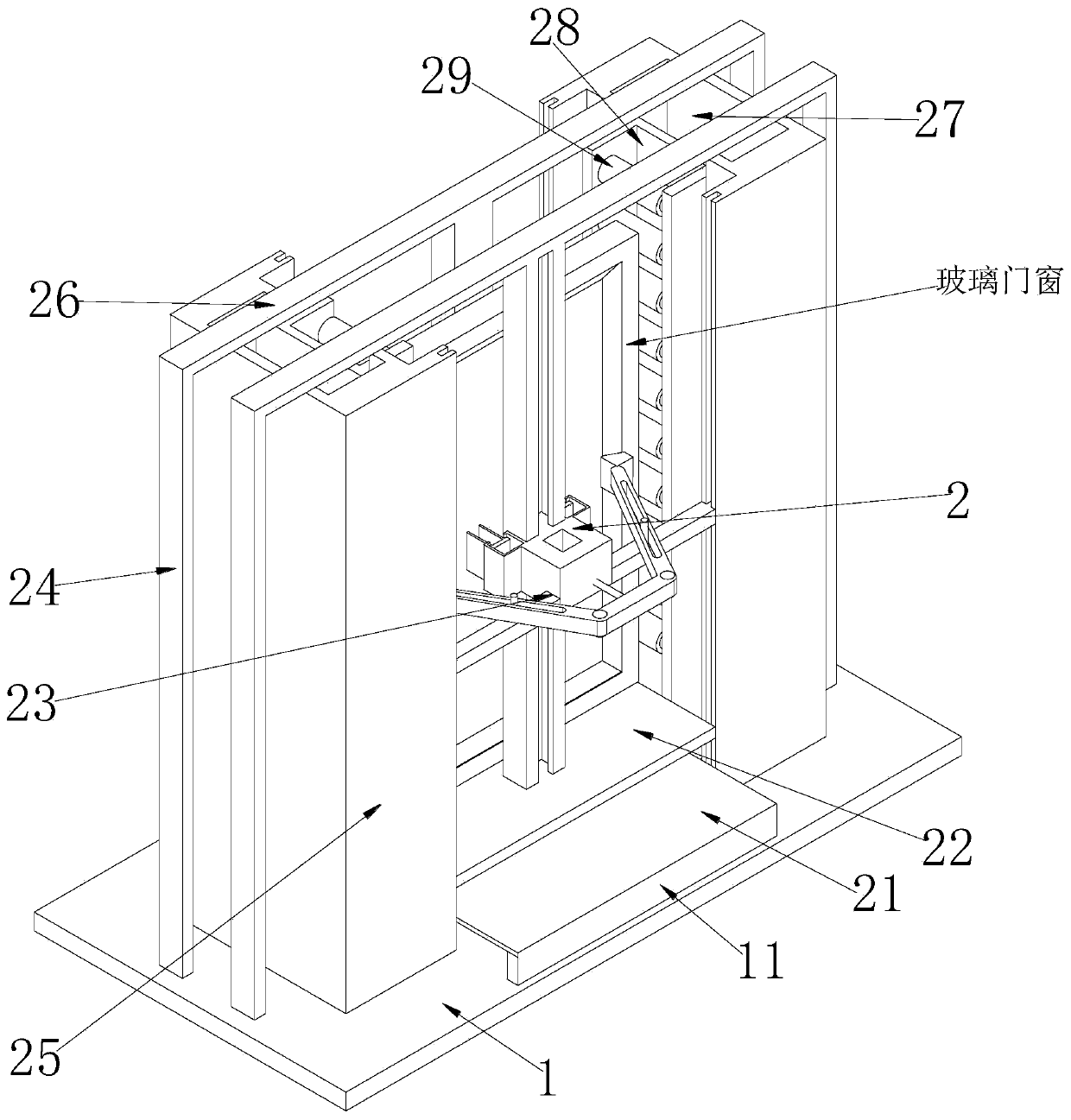

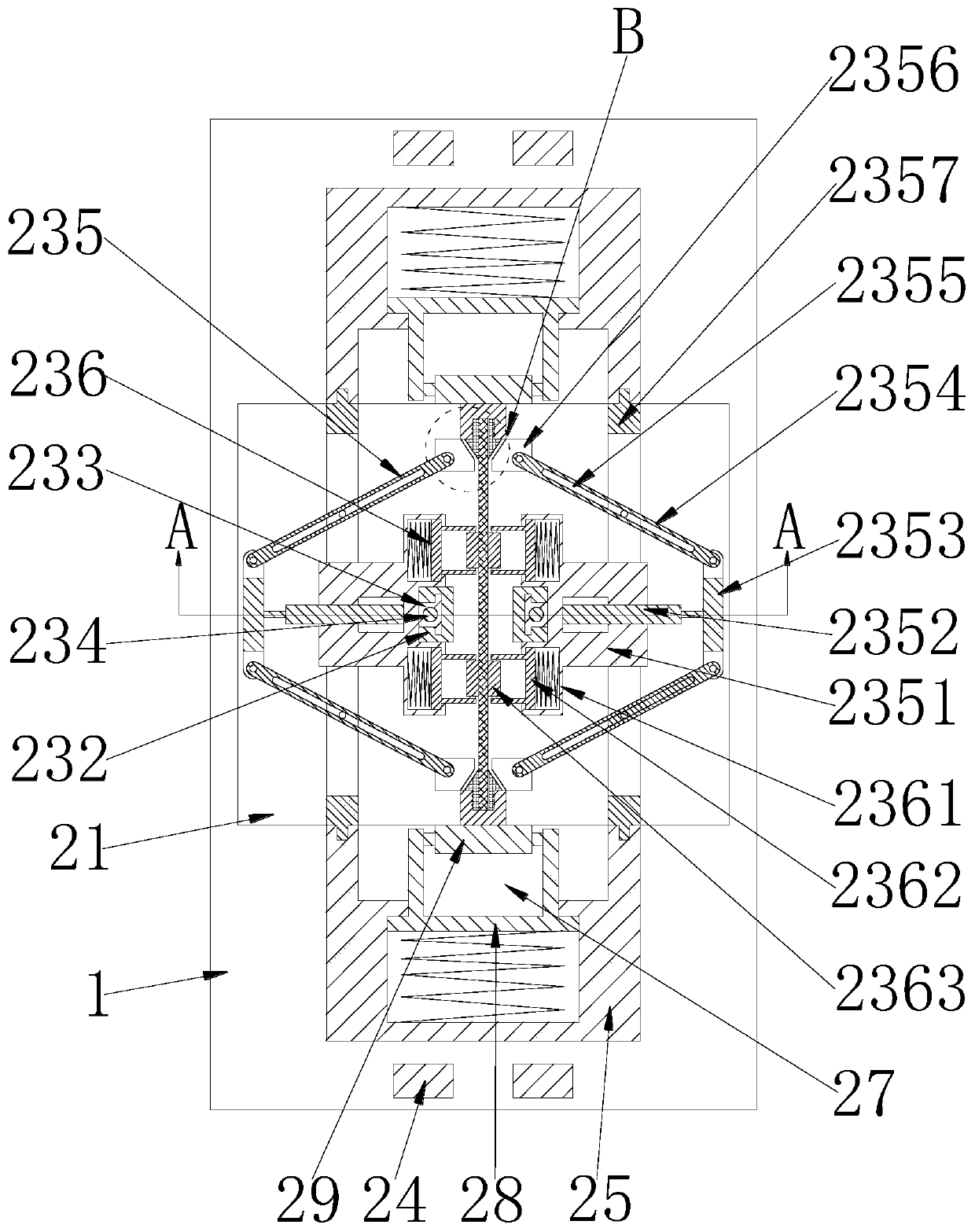

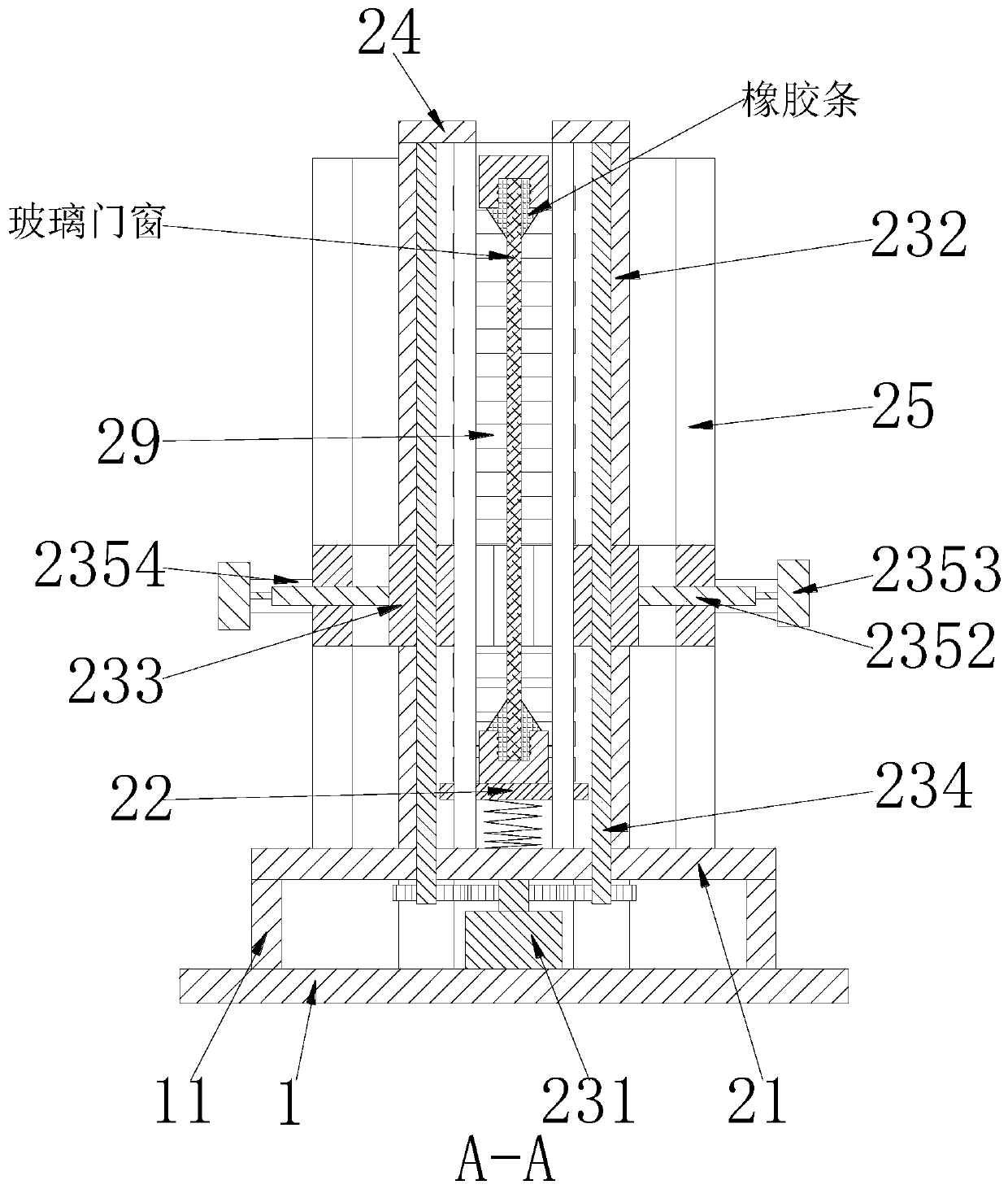

[0025] In order to make the technical means realized by the present invention, creative features, goals and effects easy to understand, the following combination Figure 1 to Figure 4 , to further elaborate the present invention.

[0026] A machine for installing rubber strips for aluminum glass doors and windows on broken bridges, comprising a base 1 and an installation device 2, the upper surface of the base 1 is symmetrically provided with support vertical plates 11 front and rear, and the support vertical plate 11 is provided with an installation device 2; wherein:

[0027] The installation device 2 includes a support horizontal plate 21, a support base plate 22, a mounting mechanism 23, a support vertical bar 24, a support side bar 25, a support cross bar 26, a support card slot 27, a support card frame 28 and a support roller 29. A support horizontal plate 21 is installed on the plate 11, and a support base plate 22 is installed on the support plate 21 by a support sprin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com