Patents

Literature

55results about How to "Ensure appearance consistency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

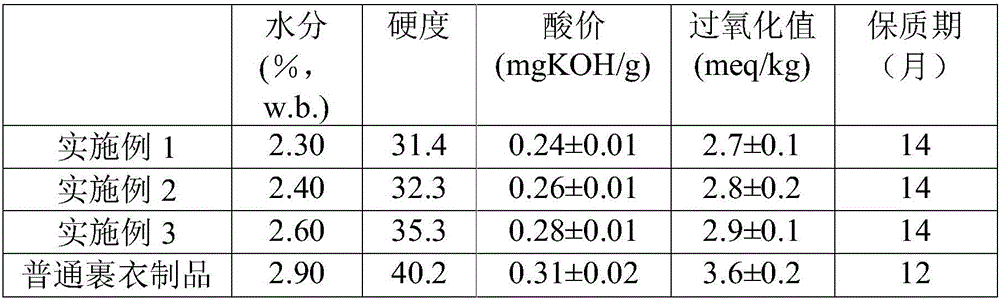

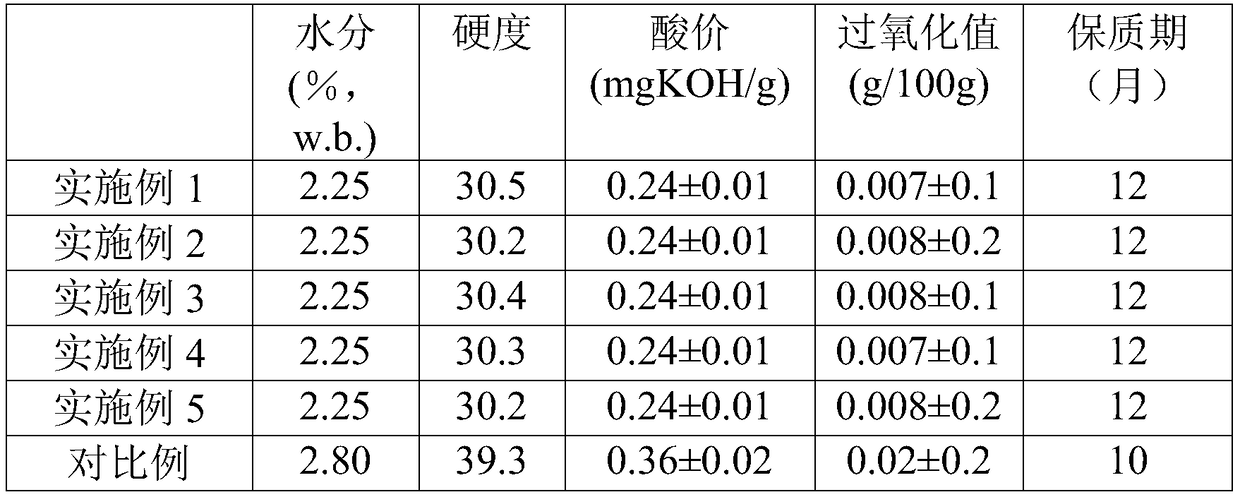

Processing technology of butter honey nuts

InactiveCN106174328AImprove uniformityImprove texture firmnessSugar food ingredientsFood coatingAdhesive materialsNutrient

The present invention discloses a processing technology of butter honey nuts. The processing technology specifically consists of the following steps: (1) wrapping liquid preparing; (2) pre-powder and post-powder preparing; (3) spraying and coating; (4) oil-frying and residue removing; (5) oil blowing; (6) cooling and beating; (7) butter spraying; and (8) nut finished product wrapping. The processing technology enriches the fragrant and sweet mouthfeel of the coated butter honey, effectively improves the uniformity of the powder wrapping, improves the texture tightness of the coating, and effectively prevents the falling of the coating, so that the product appearances, physicochemical indicators and other various performance indicators of the butter honey nuts are more stable. The processing technology effectively prevents the losses of the nuts, honey, butter and other nutrients, the low-temperature oil-frying reduces the destruction of the product nutrients, and the processing technology improves the nutritional values of the products, enables the coating to be translucent in appearances and uniform in color and luster, reduces the defective percentage to be 20-30%, improves the yields, and can well separate the adhesive materials. The oil blowing technology is conducive to the rapid drying of the surfaces of the butter honey nuts and prolongs the shelf life of the products.

Owner:青岛果果爸爸食品有限公司

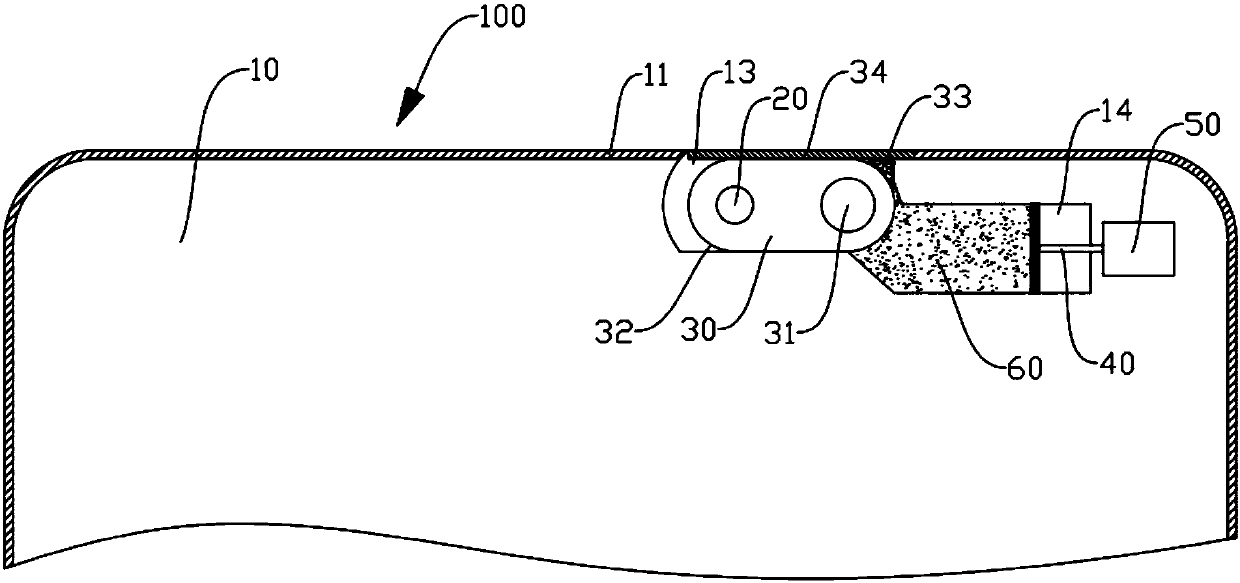

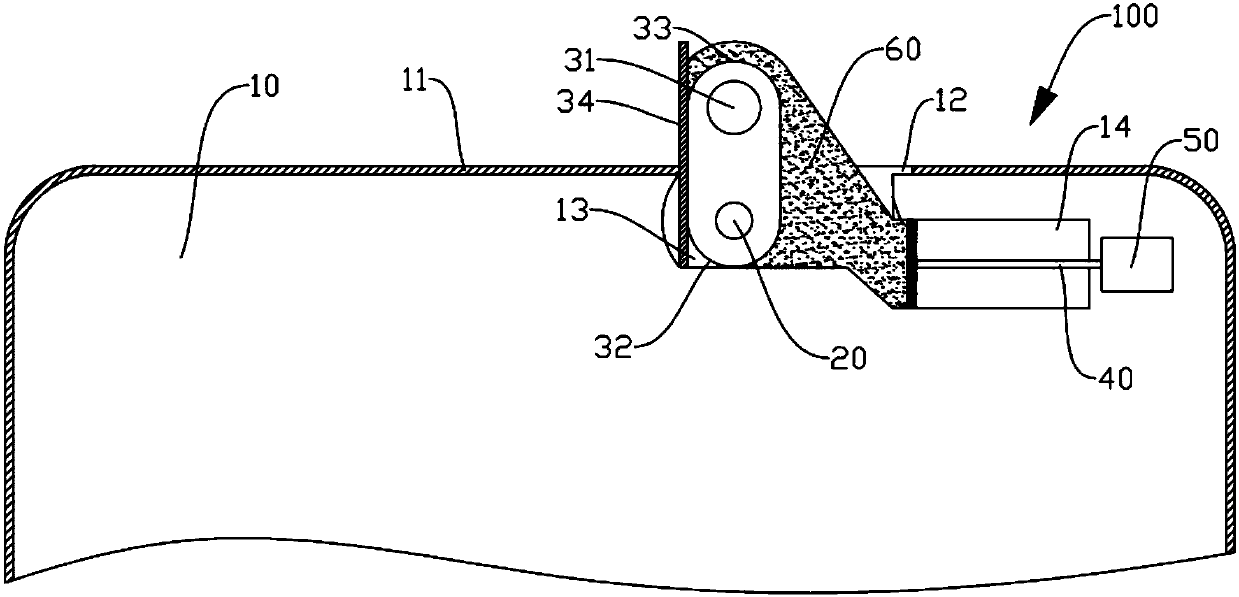

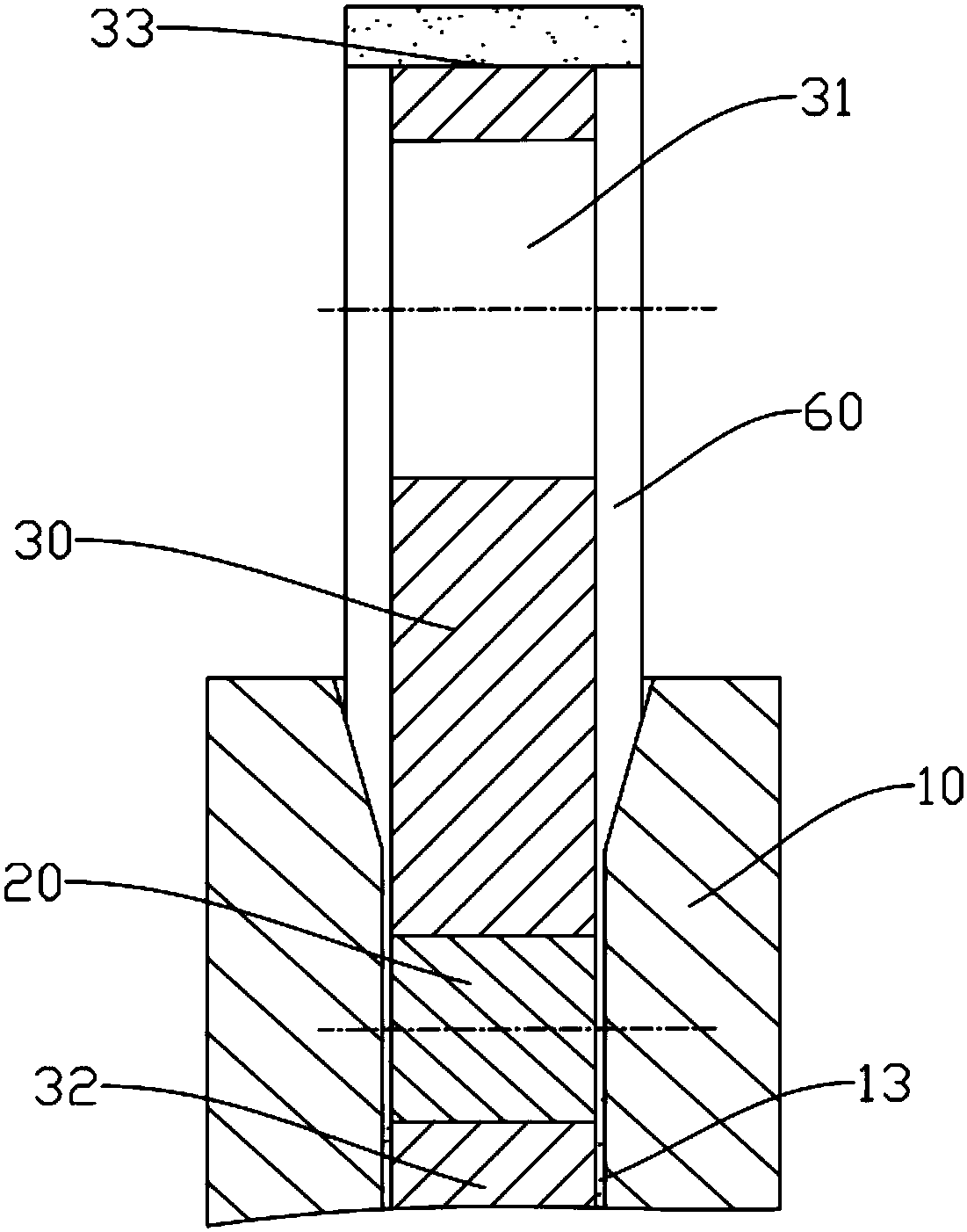

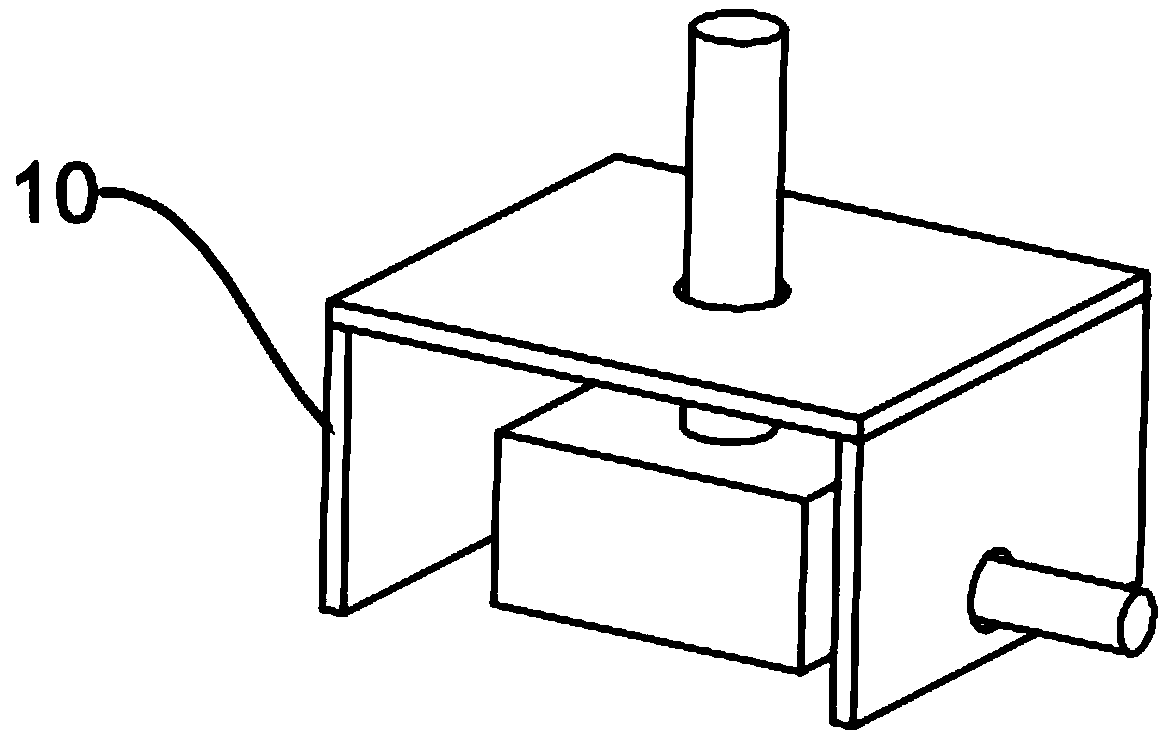

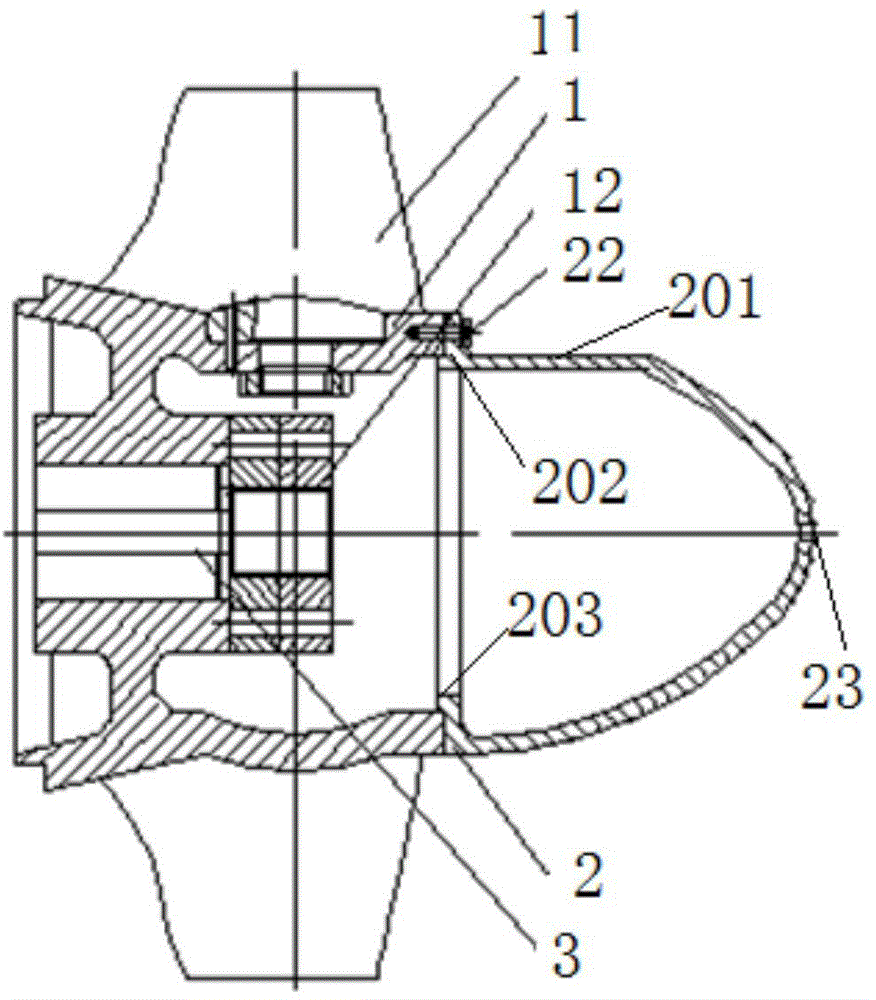

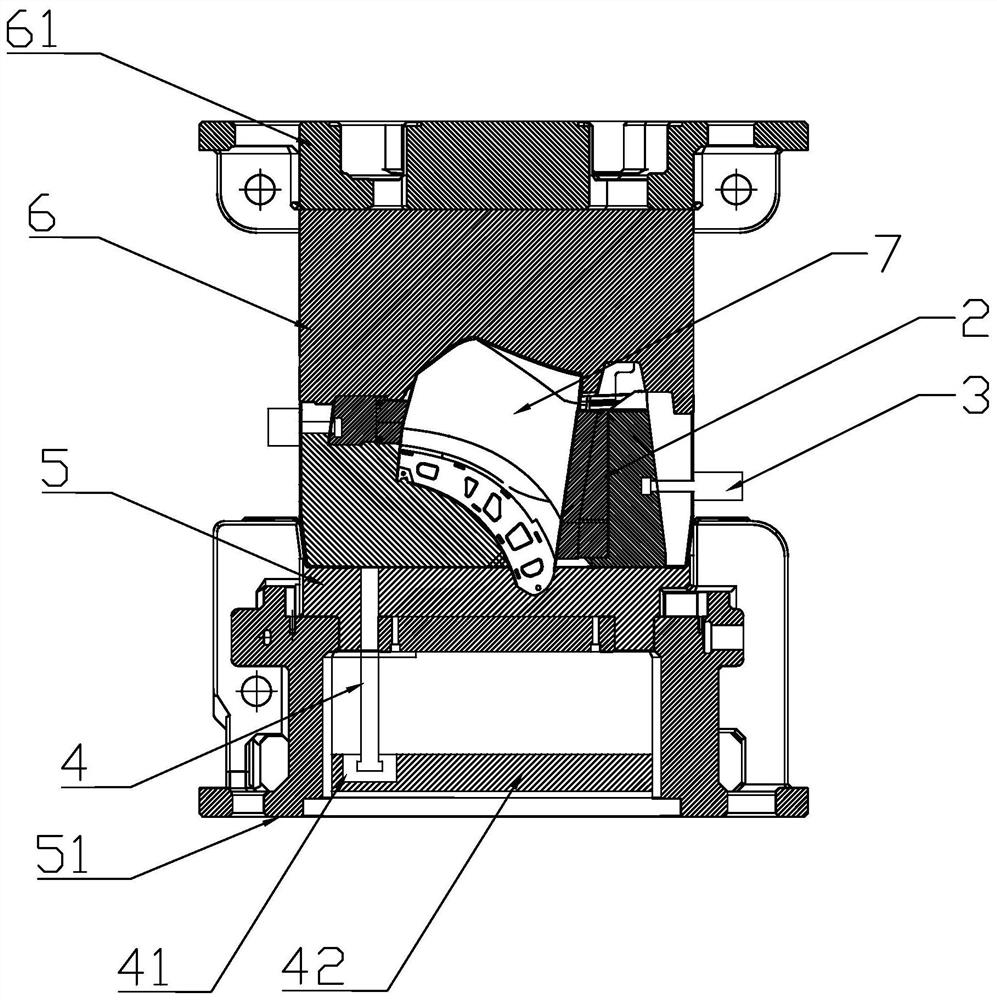

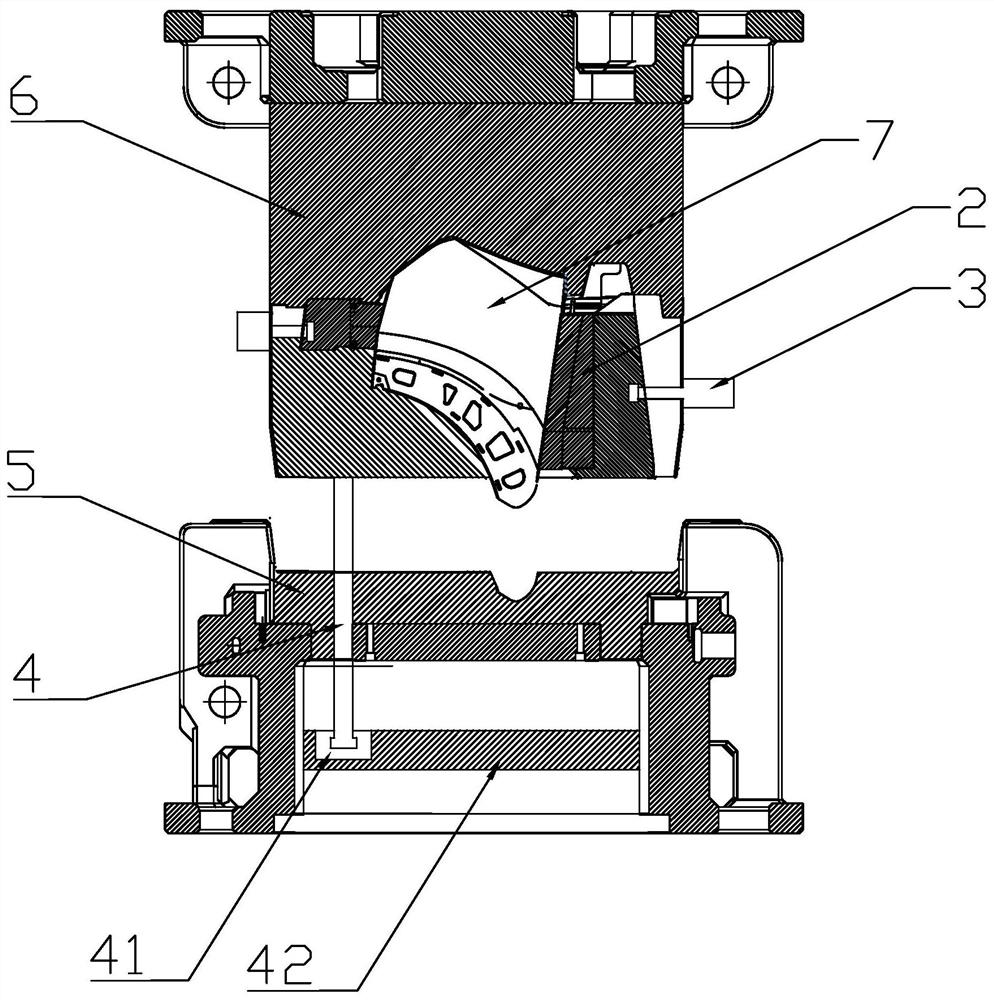

Functional assembly, electronic device and control method thereof

ActiveCN109962996AAvoid damageEnsure appearance consistencyTelephone set constructionsCamera moduleEmbedded system

The invention discloses a functional assembly. The functional assembly comprises a shell, a rotating shaft, a turntable, a pushing piece, a driving assembly and a buffer bag, wherein a first accommodating cavity and a second accommodating cavity are formed in the shell; a camera module is arranged on the turntable; the rotating disc is rotationally connected to the first accommodating cavity through the rotating shaft; the driving assembly drives the pushing piece to push at least part of the buffering bag located in the second containing cavity towards the first containing cavity, the rotating disc is made to rotate relative to the shell through extrusion, and therefore the camera module is driven to rotate out of the shell. The buffer bag serves as an ejection functional part of the functional assembly and also serves as a buffer protection part of the camera module after ejection, so that falling is prevented. The electronic device comprising the functional assembly can hide functional devices in the shell, so that the user experience is improved. The invention further discloses an electronic device and a control method thereof.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

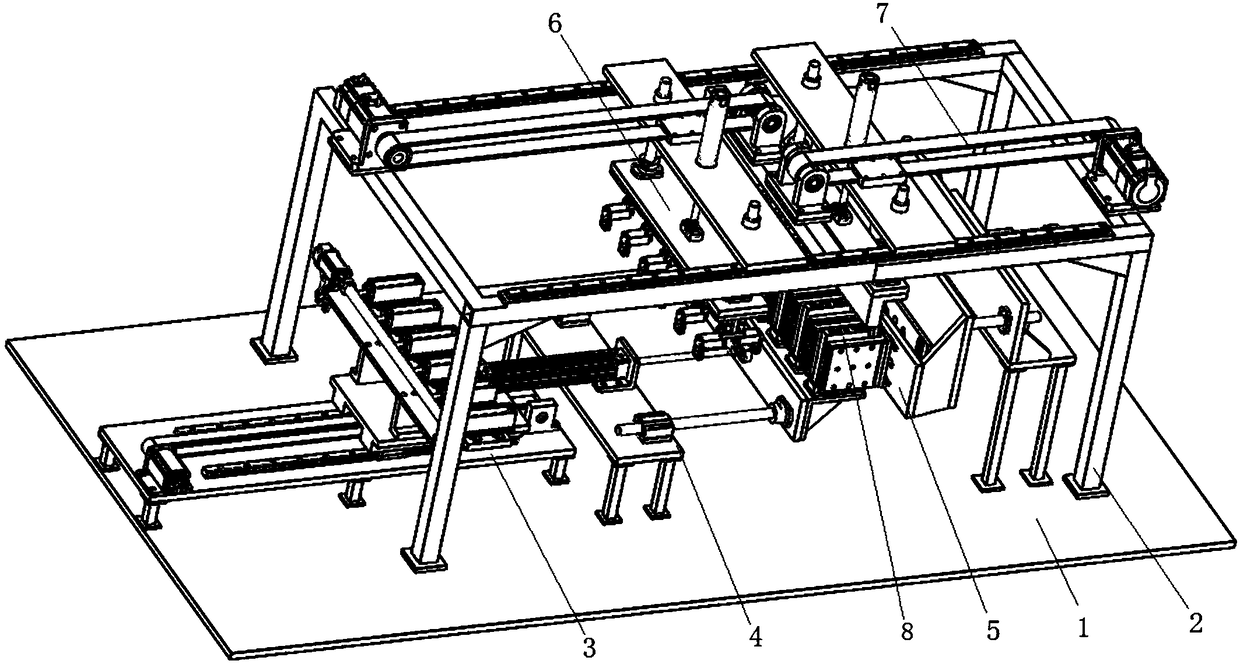

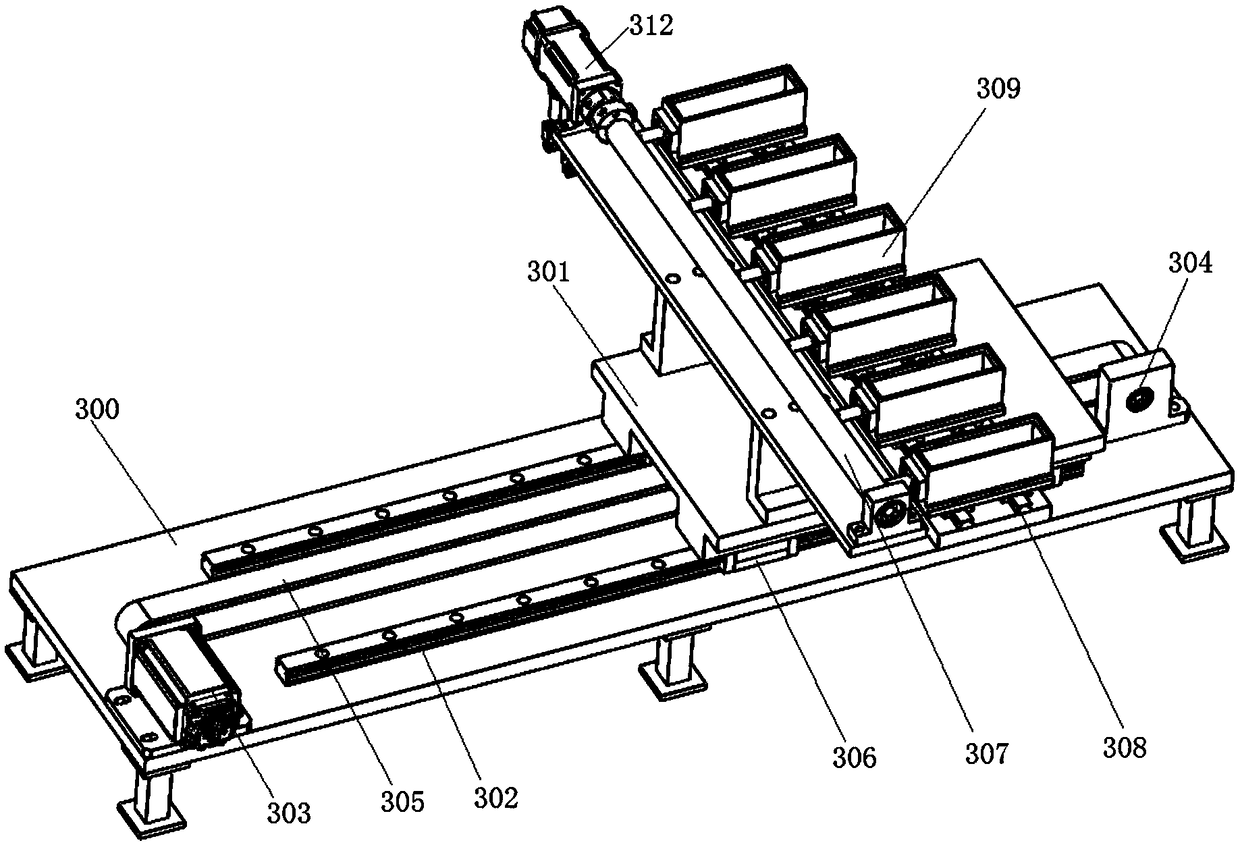

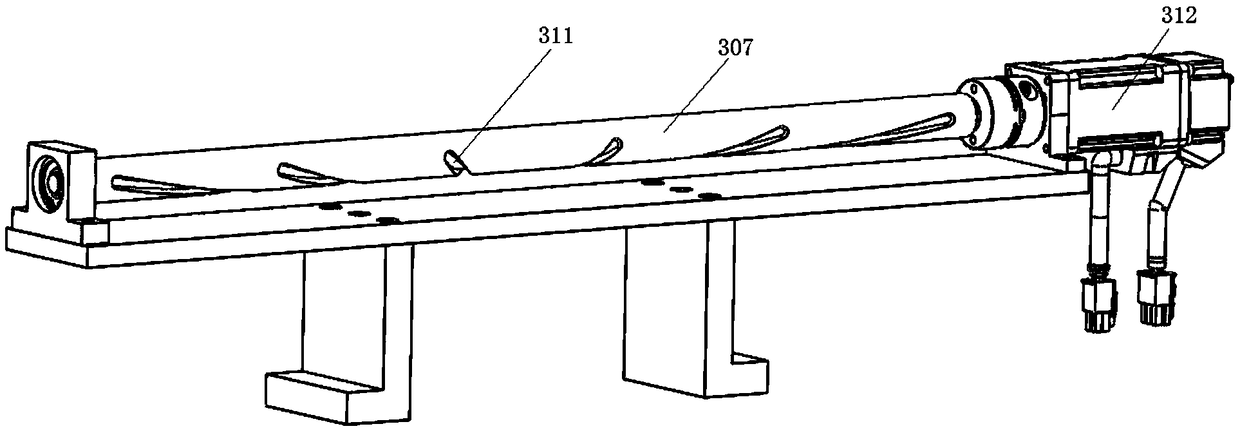

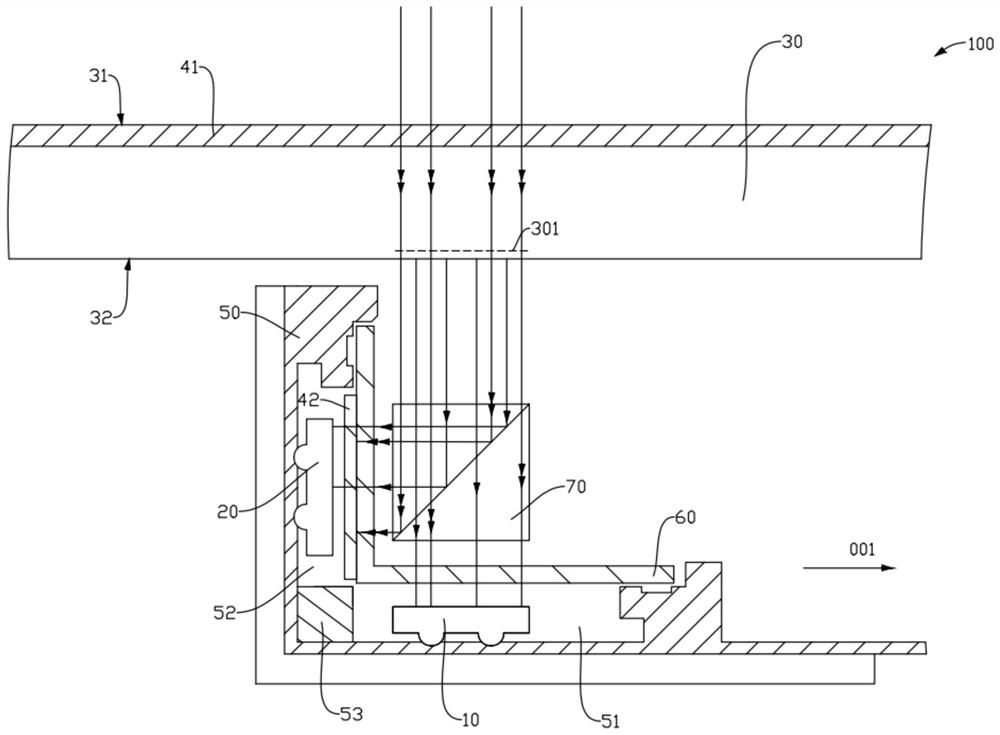

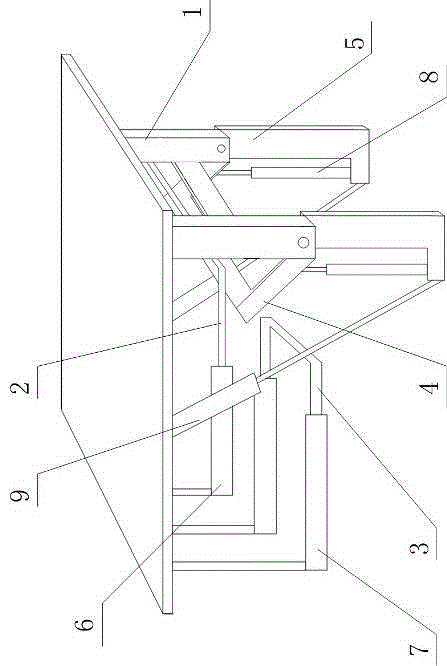

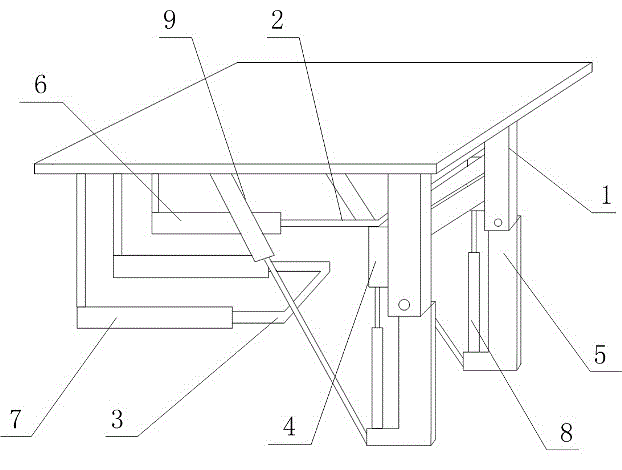

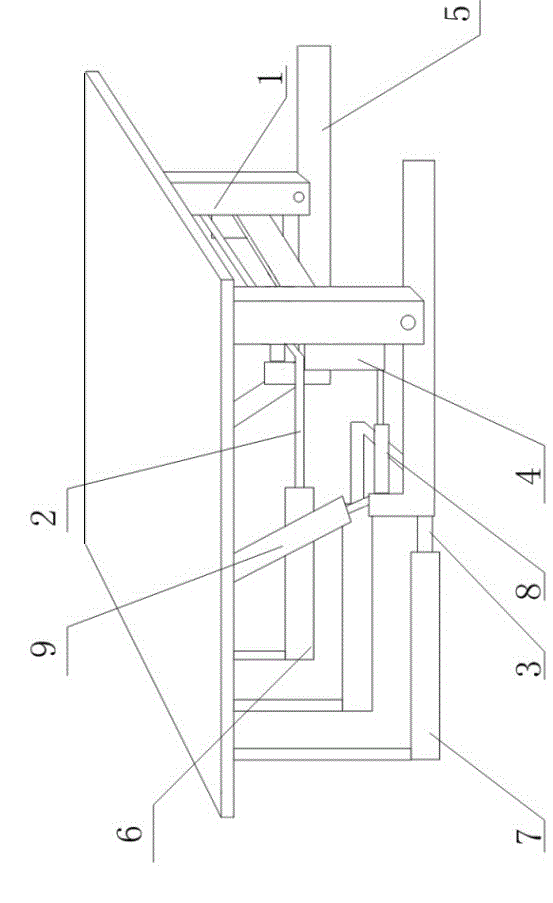

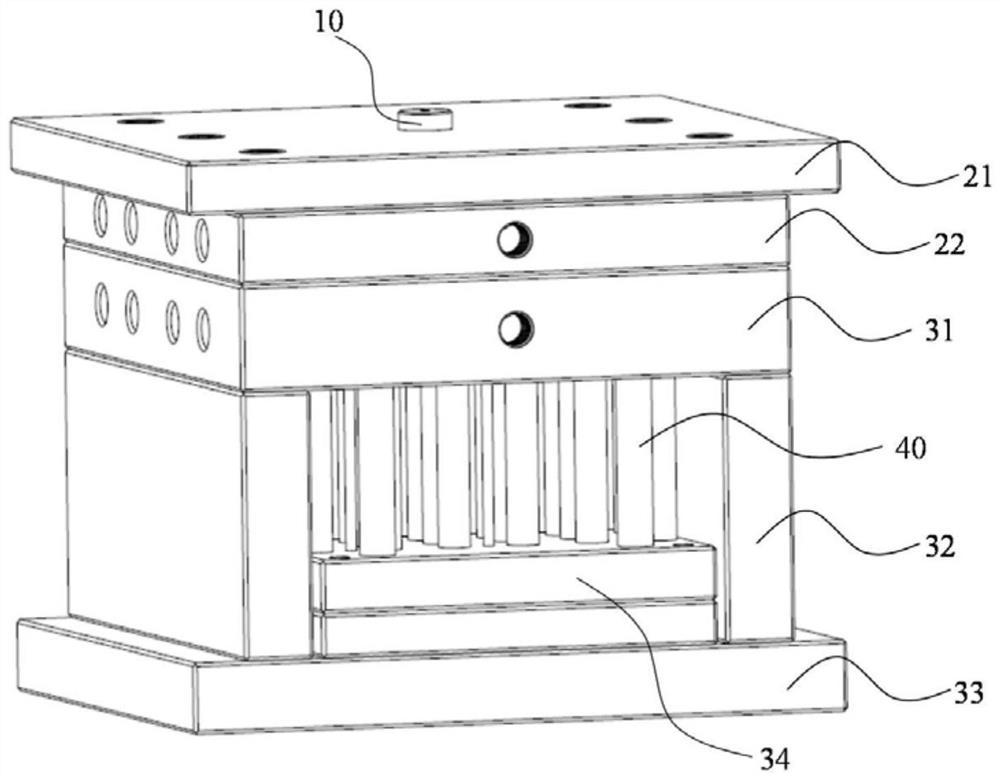

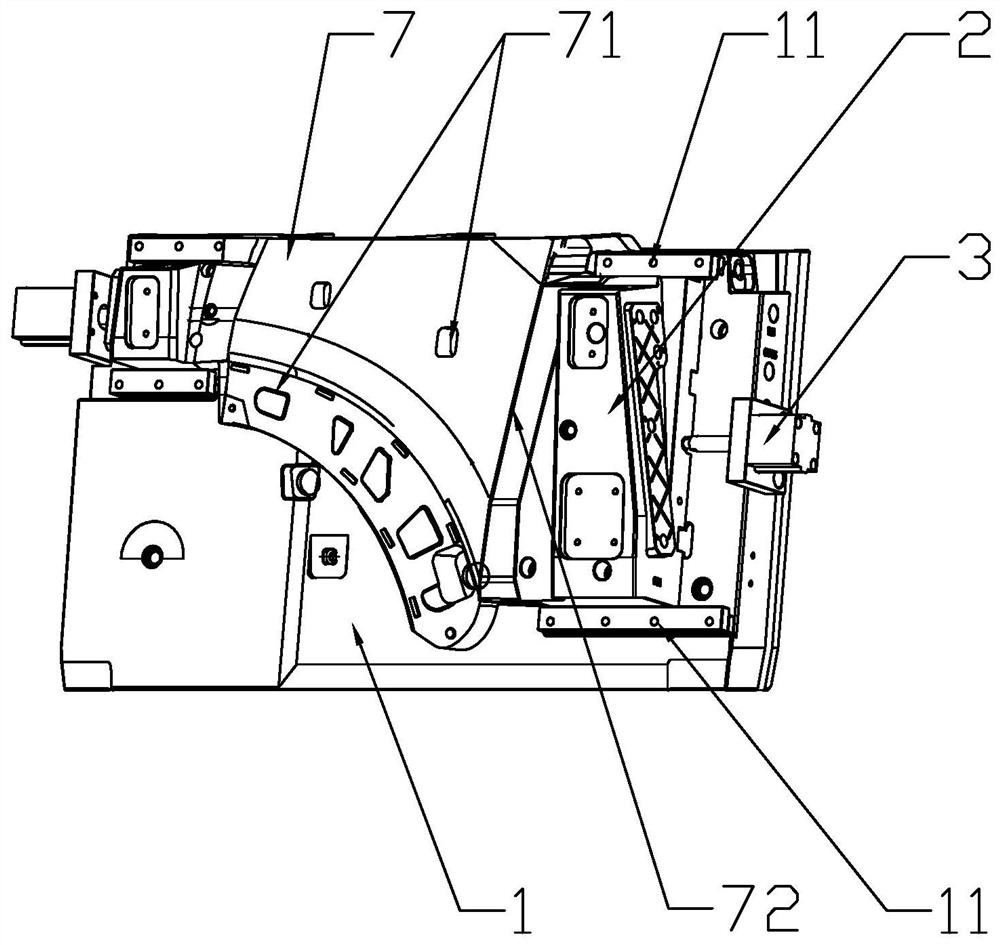

Square lithium ion battery shaping device

ActiveCN109473726AConducive to shaping efficiencyHigh-speed and effective clamping and shapingFinal product manufactureElectrolyte accumulators manufactureElectrical batteryEngineering

The invention relates to a square lithium ion battery shaping device, comprising: a bottom plate, a bracket disposed on the bottom plate, a battery grasping mechanism and a battery vacuuming mechanism, which are sequentially disposed on the bracket from left to right, and a battery turnover mechanism, a battery supporting mechanism and a battery shaping mechanism, which are sequentially disposed below the bracket from left to right. The square lithium ion battery shaping device provided by the invention fully realizes a mechanical automatic operation, realizes automatic turnover after a battery is fed, automatic adjustment of a battery gap, automatic clamping of the battery, automatic placement of the battery on a batter tray, automatic placement of the batter tray in a shaping station, automatic vacuuming of the battery, automatic shaping of the battery, automatic discharge of the shaped battery from the shaping station, automatic turnover mechanism of the battery and other functions;and the utilization rate of various mechanisms of the square lithium ion battery shaping device provided by the invention is high, the operation stability of the mechanisms is high, the maintenance is simple and convenient, and the appearance deformation of the battery due to various reasons before liquid injection is effectively solved, so that the appearance consistency of a square lithium ionbattery is ensured.

Owner:HEFEI GUOXUAN HIGH TECH POWER ENERGY

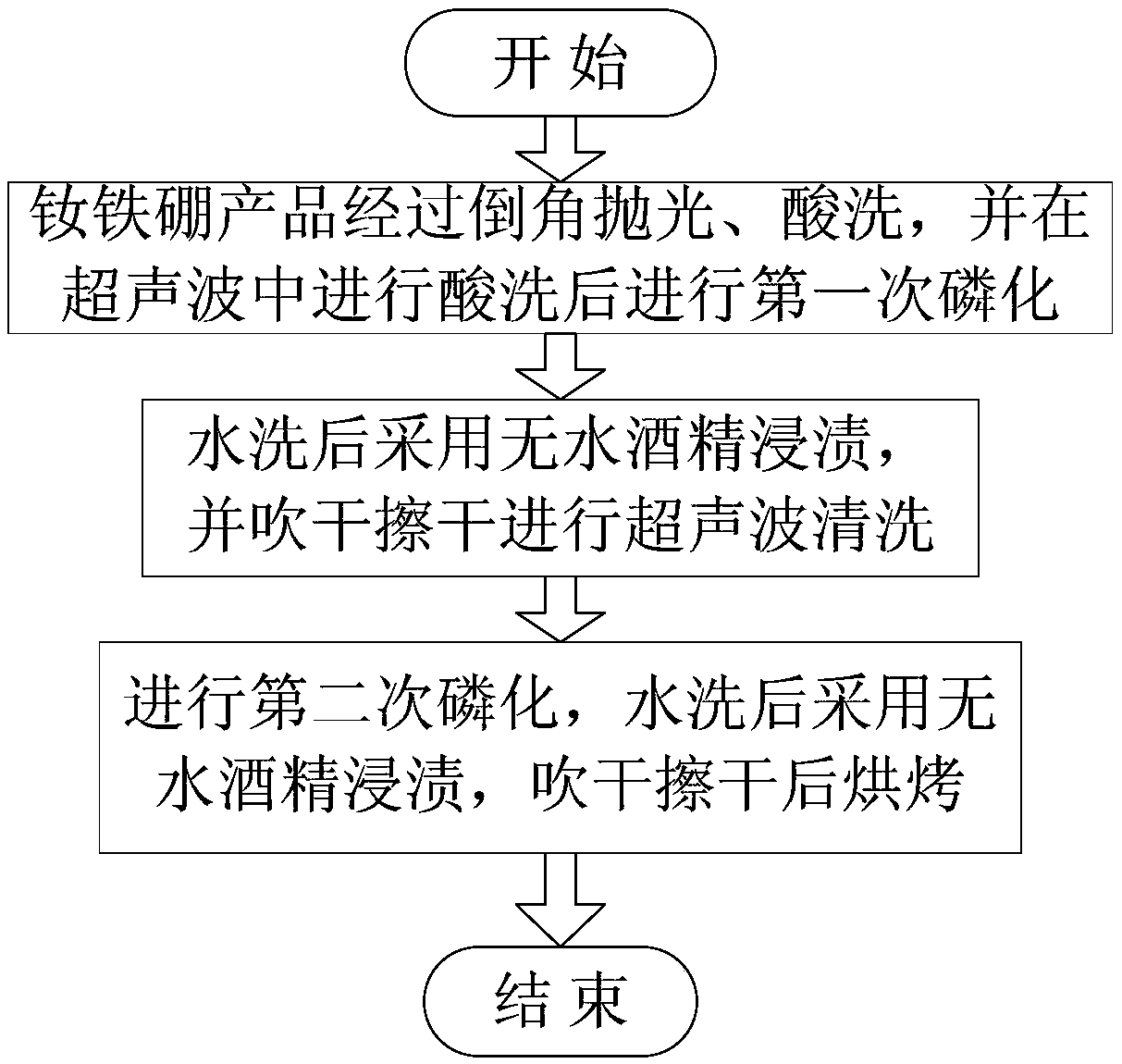

Phosphating technology of neodymium iron boron product

ActiveCN105506611AResolve Appearance ConsistencySolve the problem of surface powderMetallic material coating processesAlcoholMetallurgy

The invention discloses a phosphating technology of a neodymium iron boron product. The phosphating technology comprises the following steps that firstly, after being subjected to chamfer polishing, pickling and pickling in ultrasonic waves, the neodymium iron boron product is subjected to primary phosphating; then, the neodymium iron boron product after the primary phosphating is subjected to water washing and is dipped with absolute alcohol, and the dipped neodymium iron boron product is dried and wiped dry, and is subjected to ultrasonic cleaning; finally, secondary phosphating is carried out, the neodymium iron boron product after the secondary phosphating is subjected to the water washing and is dipped with absolute alcohol, the dipped neodymium iron boron product is dried, wiped dry, and then baked, wherein a phosphating solution adopted in the primary phosphating comprises the components: H2SO4, H3PO4 and Na2SO4, and a phosphating solution adopted in the secondary phosphating comprises the components: Zn(H2PO4)2, Mn(H2PO4)2 and NaNo2. The phosphating technology uses two different phosphating solutions, so that the problems that the appearance of the phosphated product is not consistent and powder exists on the surface of the phosphated product are solved; the problem that magnetic steel aging is affected due to an improper phosphating method is solved; in addition, the phosphating technology can conceal product surface defects; and the product yield is increased.

Owner:SINO MAGNETICS TECH

Honey peanut and production technology thereof

The present invention relates to a honey peanut and a production technology thereof. The honey peanut is produced from peanuts, water, xanthan gum, maltose syrup, white granulated sugar, honey and edible salt. The production technology comprises the following steps: (1) the peanuts, water, xanthan gum, maltose syrup, white granulated sugar, honey and edible salt are separately weighed; (2) coatingliquid is prepared; (3) surface powder is prepared; (4) a coating layer is sprayed; (5) powder wrapping is conducted; (6) baking is conducted; (7) cooling is conducted; and (8) stirring and bag packaging are conducted. The production technology enriches layer senses of fragrant and sweet mouthfeel and taste of the honey in the coating layer of the honey peanut, improves texture tightness of the coating layer and effectively prevents the coating layer from falling off. The low-temperature baking reduces damages of product nutrients. The production technology improves product nutritional values, reduces a defective rate by 25-35% and a half-grain rate by 20%, improves yield, and solves an adhesion problem of the product after being taking out from an oven. The rapid cooling technology is beneficial to quick drying of the surface of the honey peanut and extends a shelf life of the product again.

Owner:南京阿甘正馔食品有限公司

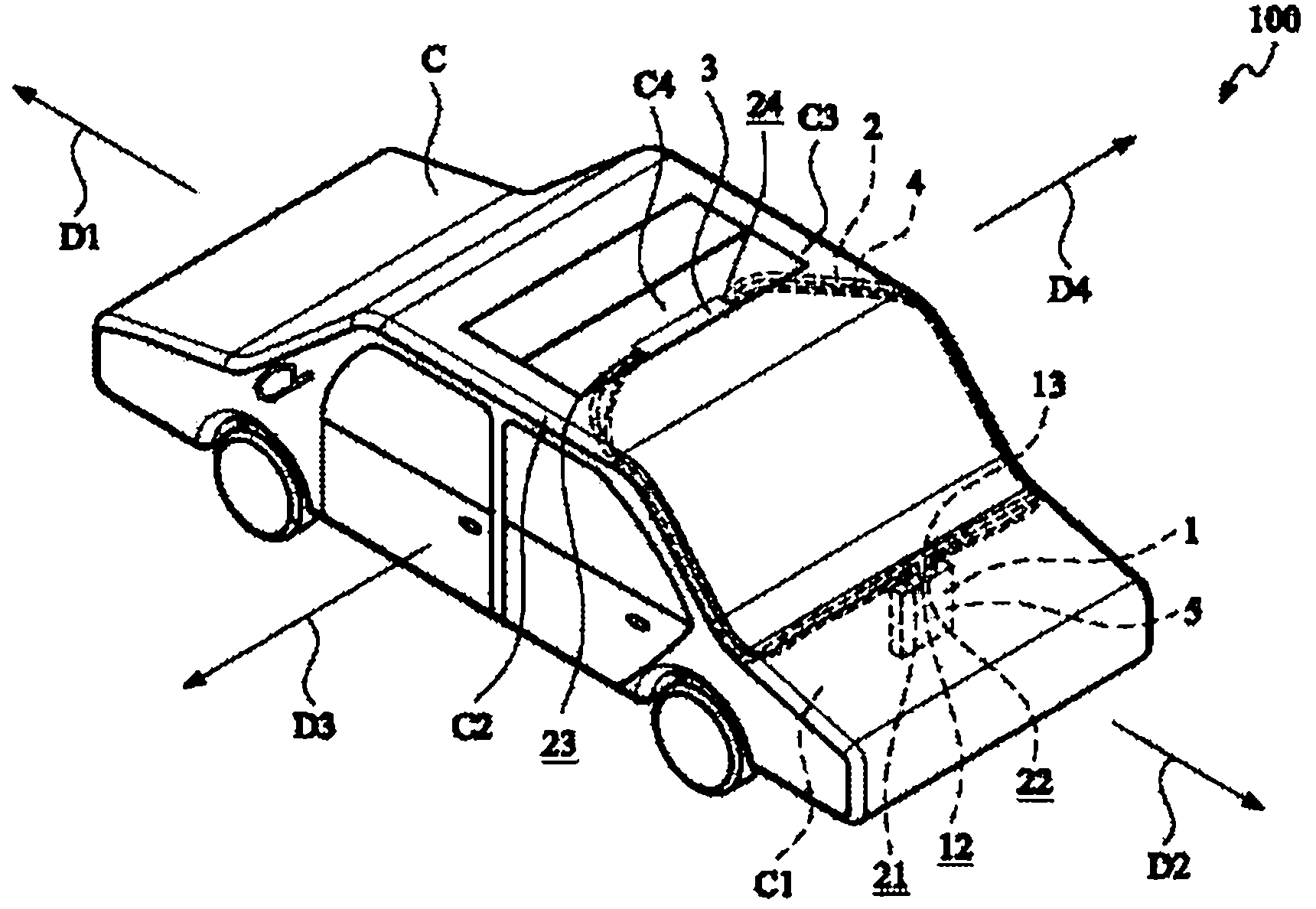

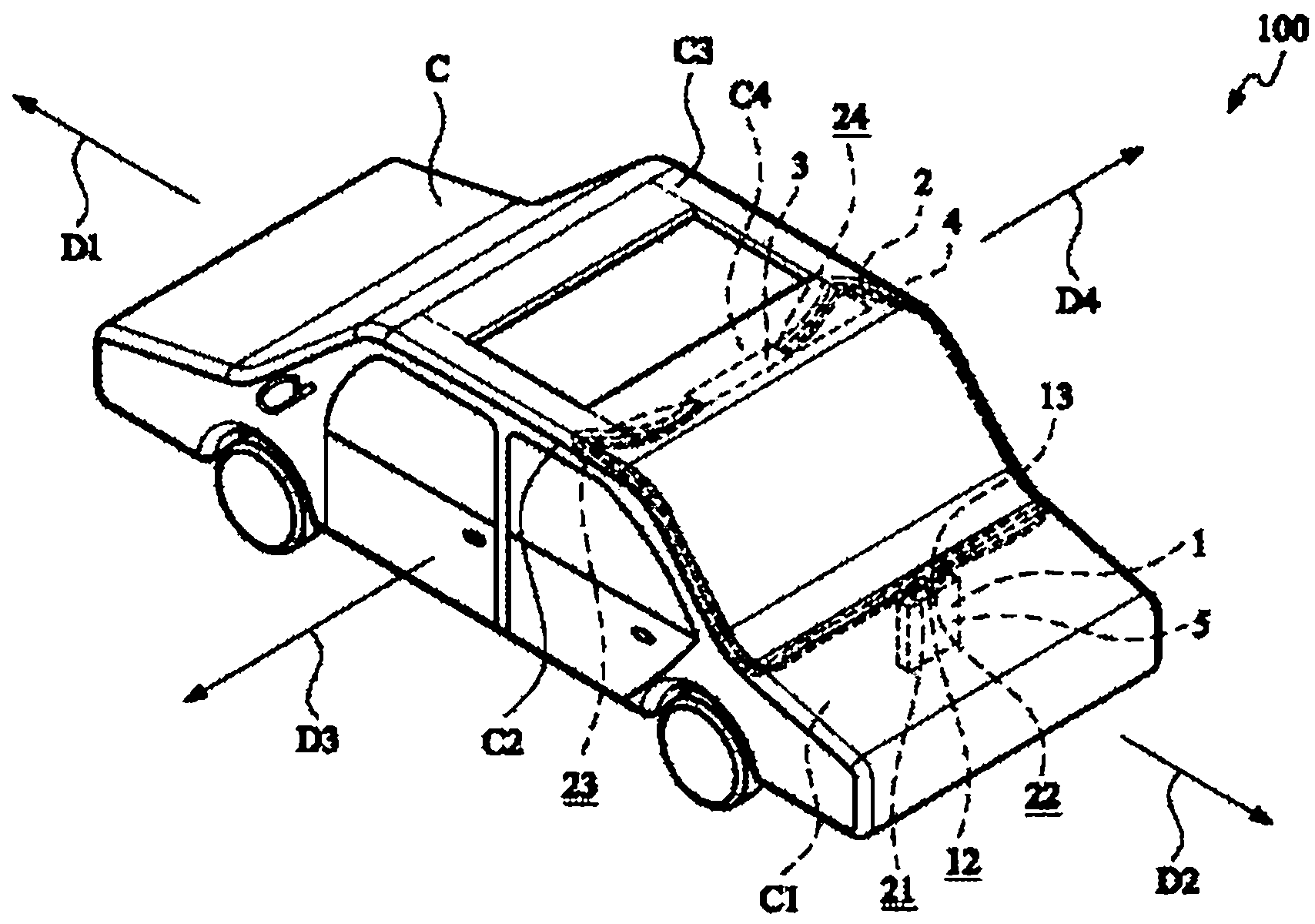

Car cover device

InactiveCN103129356AEasy to useAuto expandRemovable external protective coveringsSunroofAutomotive engineering

Owner:张嘉雯

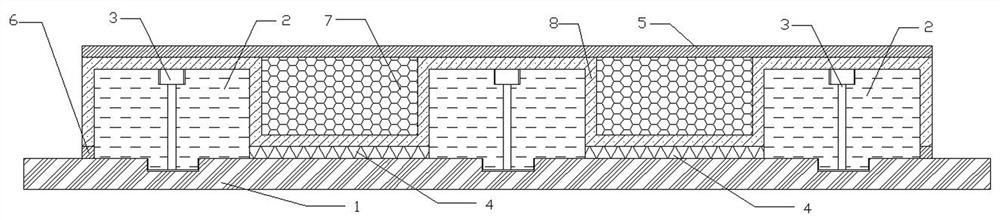

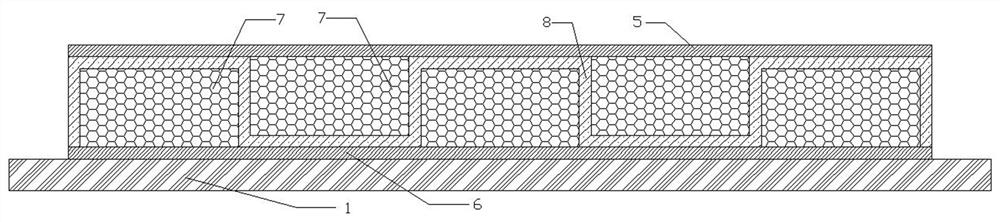

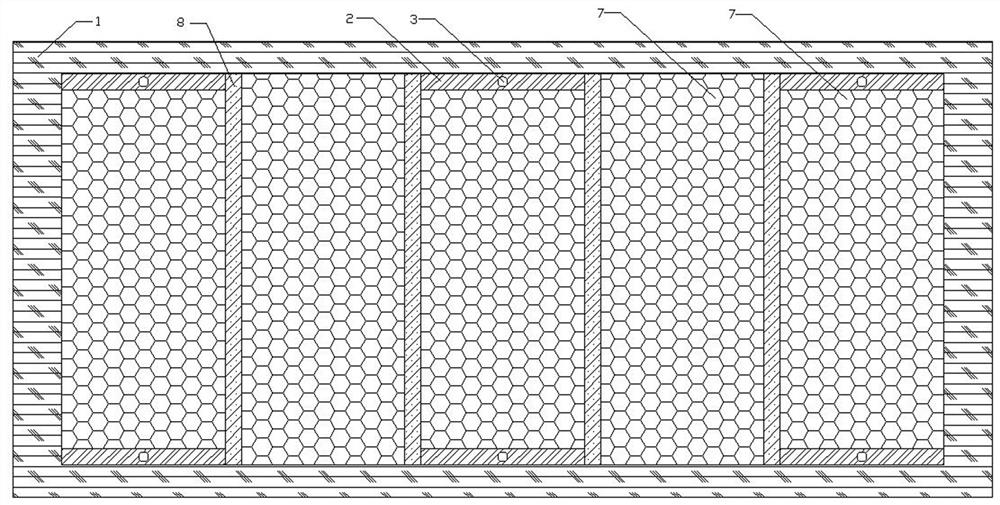

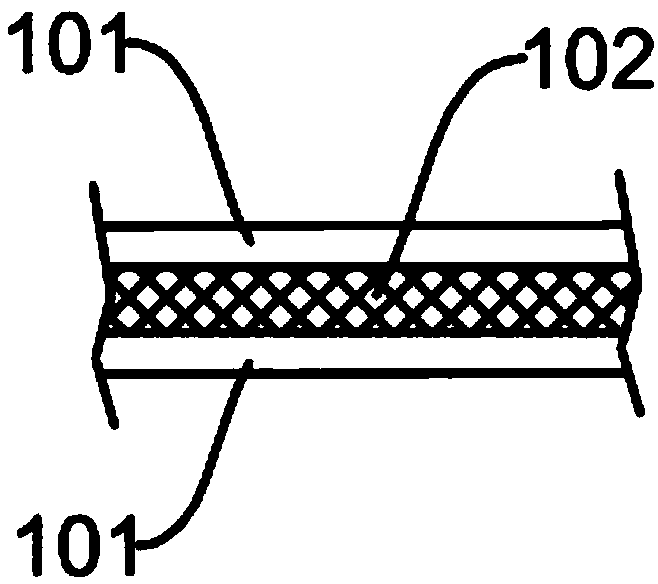

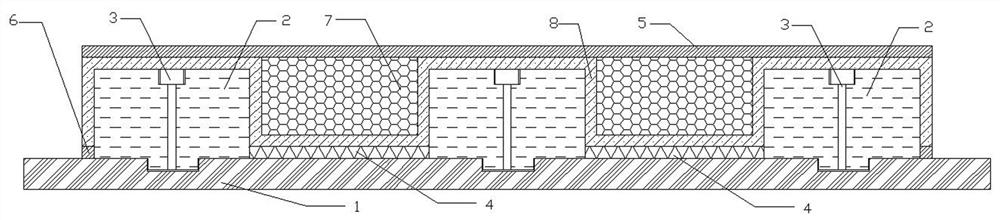

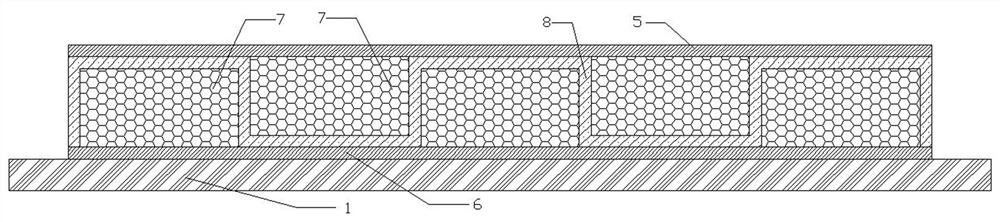

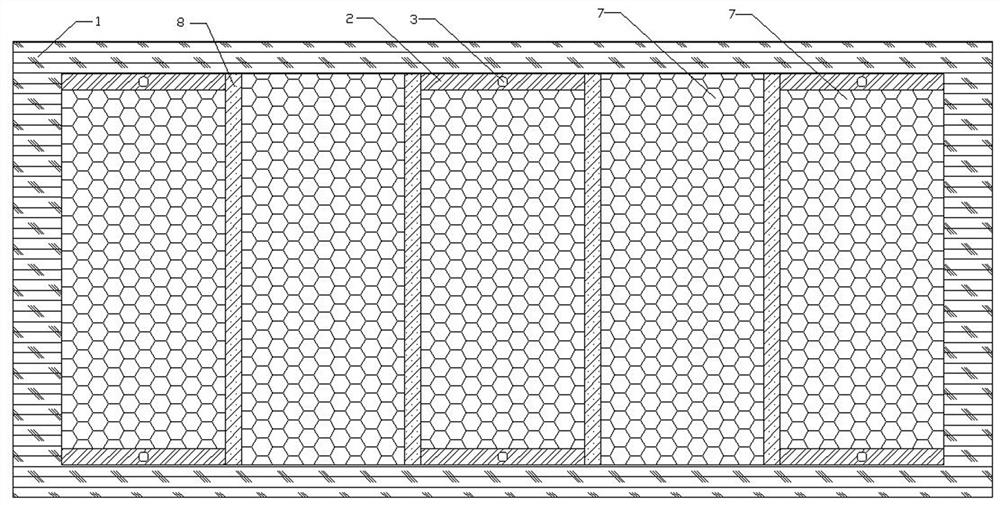

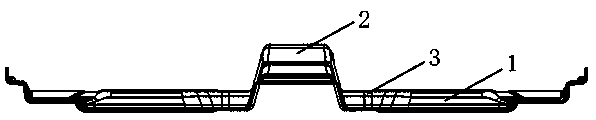

Preform for forming grid reinforced foam sandwich composite material and forming method thereof

ActiveCN112677362APrecise size controlImprove the convenience of loading and unloadingWeight reductionFiberRail transit

The invention discloses a preform for forming a grid reinforced foam sandwich composite material and a forming method thereof. The preform can conveniently and quickly finish staggered interpenetration compounding of a discrete foam core material and dry fiber fabric, and can ensure the dimensional accuracy, the overall stability and the quality consistency of a finished composite material. The forming process is simple in method, convenient to operate and low in cost, integral forming of a large-size grid reinforced foam sandwich composite material with the size not smaller than 1m*1m can be achieved, and the novel composite material sandwich structure can partially replace an existing composite material sandwich structure, can be widely applied to the fields of rail transit, high-speed trains, aerospace, ships, ocean engineering and the like.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

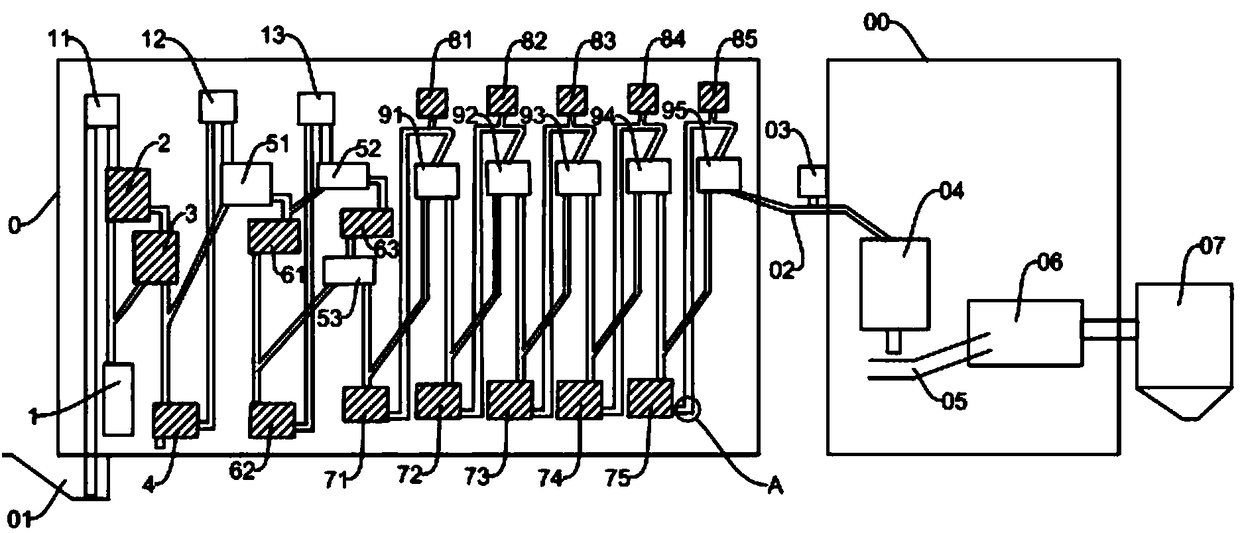

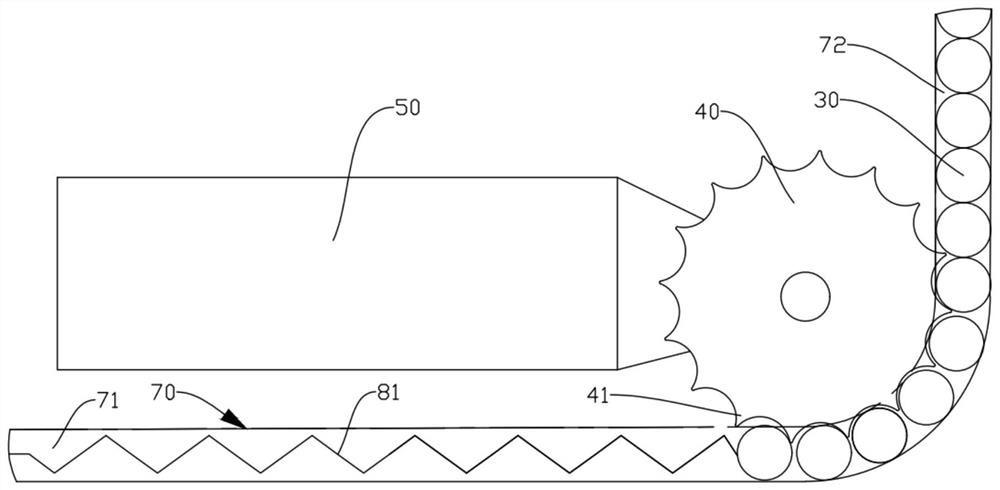

Efficient-type corn niblet powder-making and caking-making system and corn cake preparing method

ActiveCN108283956AReduce impurityGuaranteed finenessGrain huskingGrain polishingMulti linkMagnetic separator

Disclosed are an efficient-type corn niblet powder-making and caking-making system and a corn cake preparing method. The efficient-type corn niblet powder-making and caking-making system comprises a winnowing machine, a magnetic separator, a crushing and skinning machine, a crushing mechanism and a milling mechanism which are arranged in a treatment workshop, further comprises a batching tank anda puffing machine which are arranged in a puffing workshop, and further comprises a feeding channel and a finished product temporary storage tank. The feeding channel is formed in a downward-inclinedmode from the position, located on the outer side of the treatment workshop, of the ground, extends into the treatment workshop, and is connected with the bottom end of a first elevator in the treatment workshop. The refining effect is achieved through multi-link screening and then conveying and a multi-stage grinding and screening mechanism, so that feeding, powder-making, puffing and dischargingare conducted in different workshops, feeding and discharging are convenient to operate, the situation that operators are in the treatment workshop with loud noise is avoided, mutual interference ofpowder-making and puffing processes is avoided, noise reduction treatment is further conducted on key equipment, air pipes and an elevator channel, and the structure of the connecting position of theair pipes is improved to solve the situation of outage retention.

Owner:成都昌盛鸿笙食品有限公司

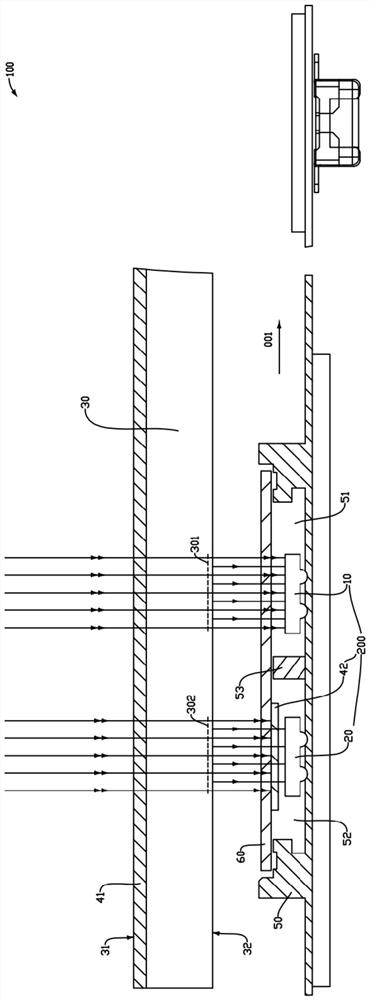

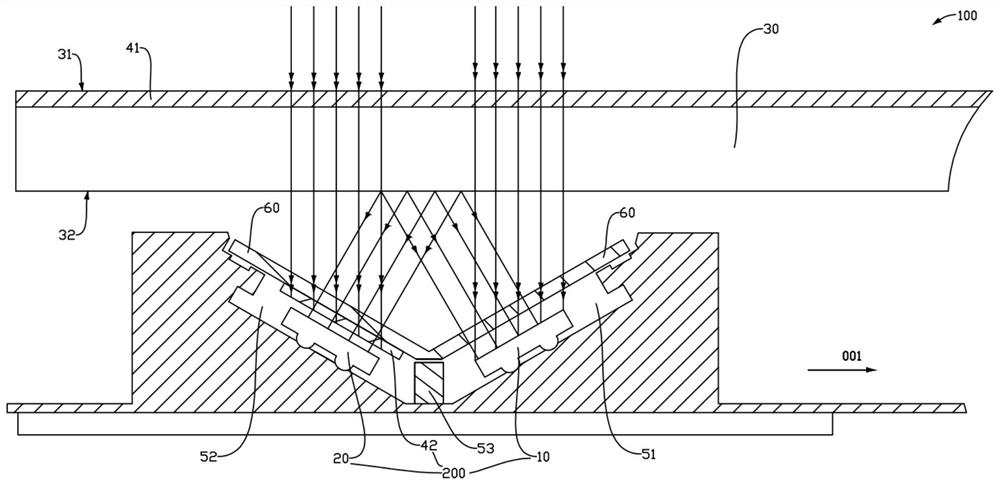

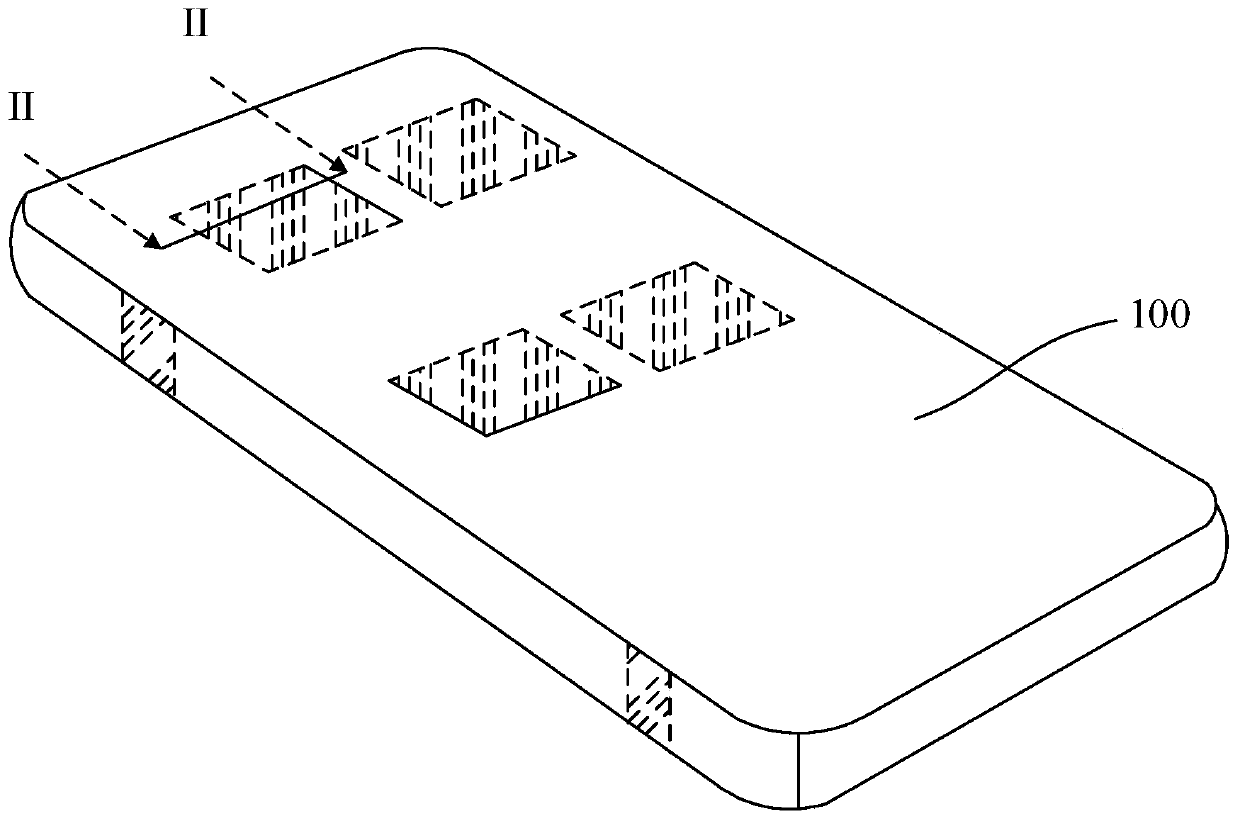

Photosensitive module, display device and electronic equipment

PendingCN112133723AAvoid transmissionEnsure consistencyStatic indicating devicesSolid-state devicesOptical axisEngineering

The invention relates to a photosensitive module which is arranged on one side, far away from a light-emitting surface, of a light-transmitting display panel. The light-emitting surface of the displaypanel comprises a first polaroid, and the photosensitive module comprises a first optical sensor, a second optical sensor and a second polaroid. The optical axis of the first polaroid is perpendicular to the optical axis of the second polaroid, and the second polaroid is arranged between the second optical sensor and the display panel. Therefore, the first light sensor can receive ambient light and light generated by the display panel, and the second light sensor can only receive light generated by the display panel. The current ambient light intensity can be obtained by calculating the lightdifference received by the first light sensor and the second light sensor. The invention further relates to a display device and electronic equipment equipped with the photosensitive module, and since a hole does not need to be formed in the display panel to monitor ambient light, a full screen can be realized, and the use experience of a user is improved.

Owner:NANCHANG OUFEI BIOLOGICAL IDENTIFICATION TECH

Portable multifunctional mortar leveling device

InactiveCN109083377AAccurate shapeAvoid Excessive MoistureBuilding constructionsLeveling effectEngineering

The invention discloses a portable multifunctional mortar leveling device. The top surface of a wiping plate is provided with a handle which can push the wiping plate to move after holding, the innerportion of the wiping plate is of a hollow structure, a cavity is used as a water storage cavity for storing water, the upper surface, near the front side, of the wiping plate is provided with a concave cavity with a concave, and a slurry feeding plate is suspended by a support rod above a drain plate; rectangular-shaped side plates with smooth surfaces are also hinged to the edges of the two sides of the wiping plate in the direction of the length of the wiping plate, the edges in the length direction of the side plates are hinged to the edge of the length direction of the wiping plate, the connected length edges of the side plates and the wiping plate are integrally provided with sleeves with protruding edges, the sleeve on the wiping plate is coaxially located between the two sleeves onthe side plates, the two ends outside the two sleeves of the side plates are coaxially provided with live sleeves, and a hinged shaft penetrates through all the sleeves and the live sleeves to achieve the hinged connection between the side plates and the wiping plate. The portable multifunctional mortar leveling device has good leveling effect, and shaping of edges of a mortar body is flexible and reliable.

Owner:江西干圣建设有限公司

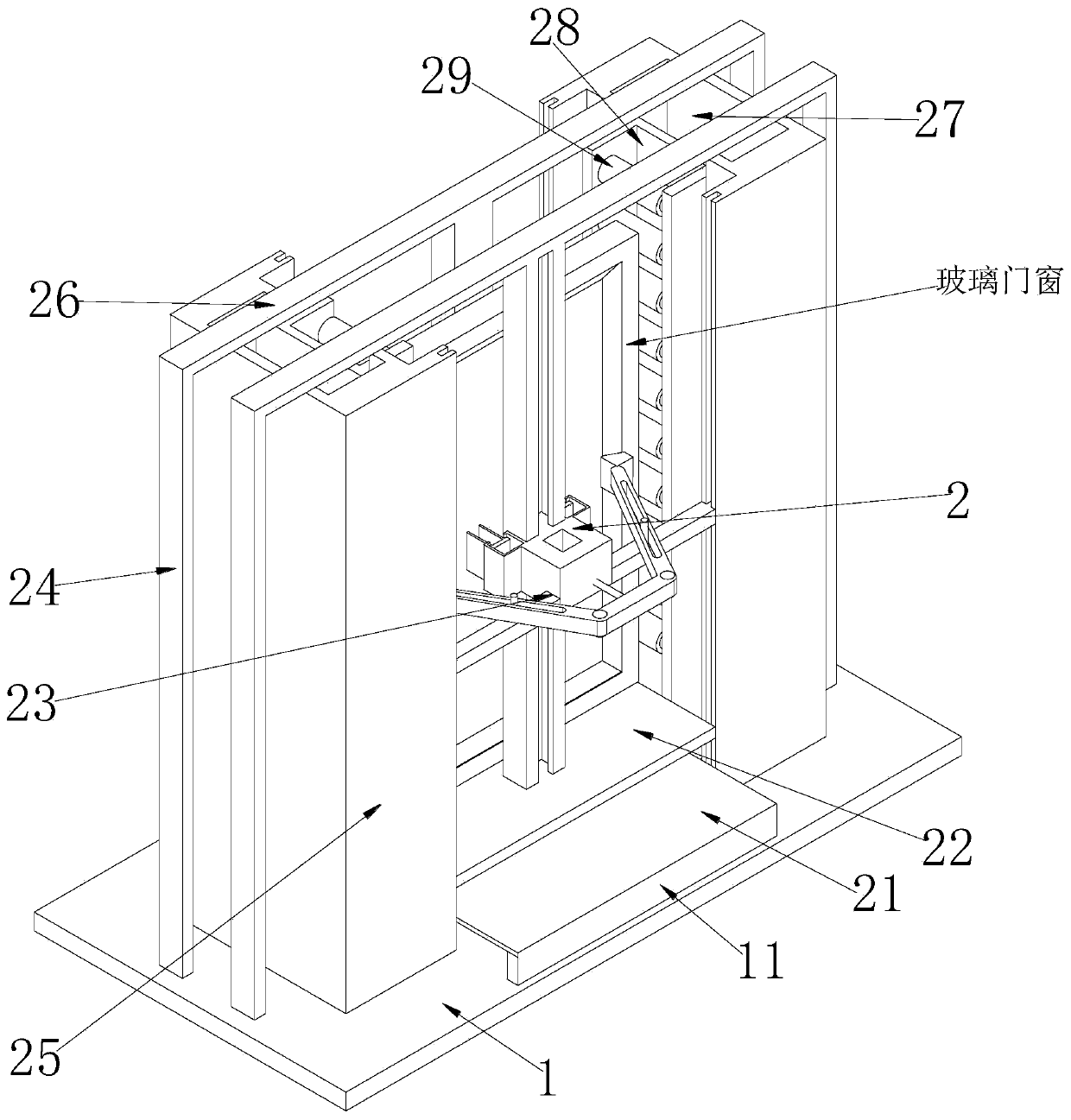

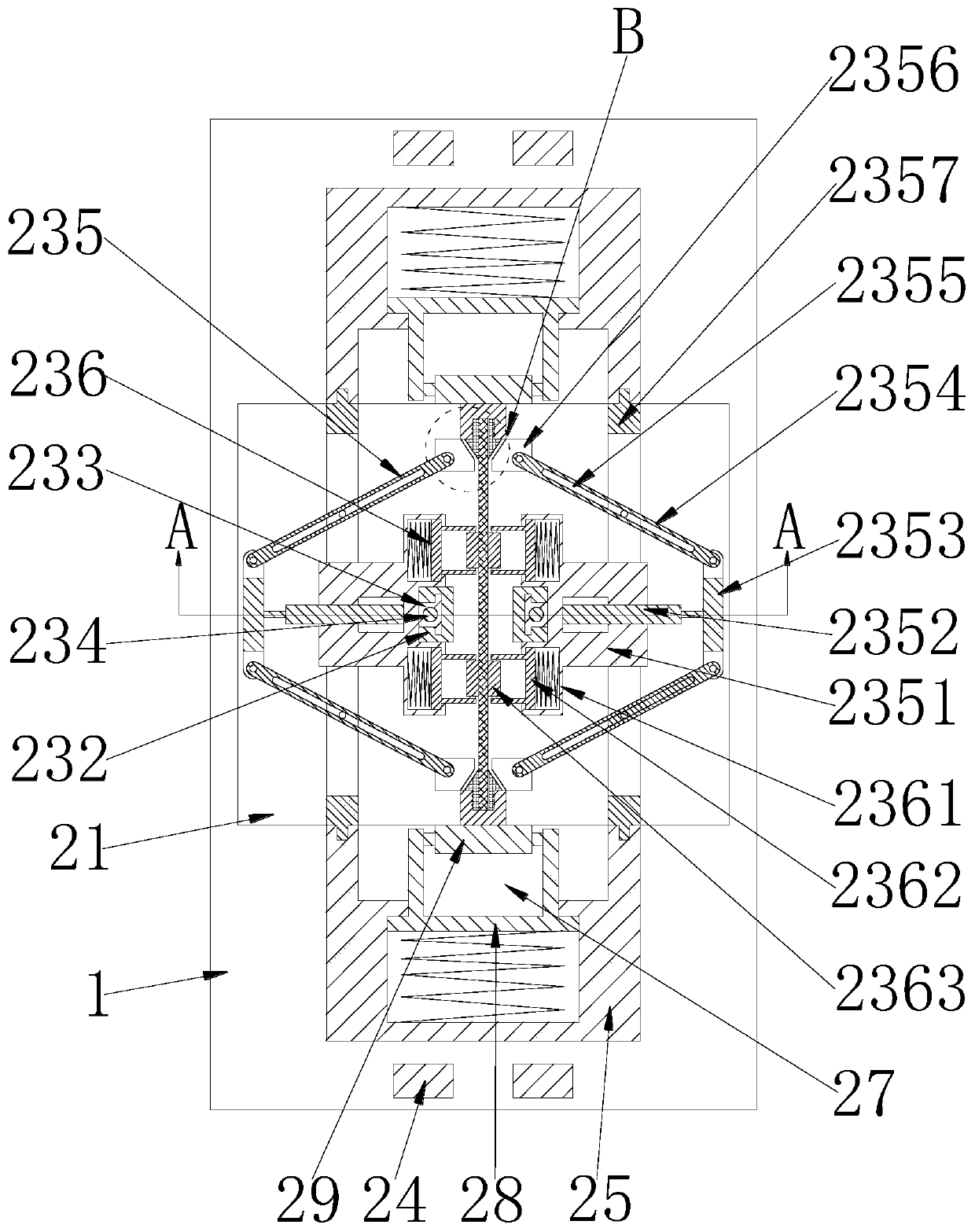

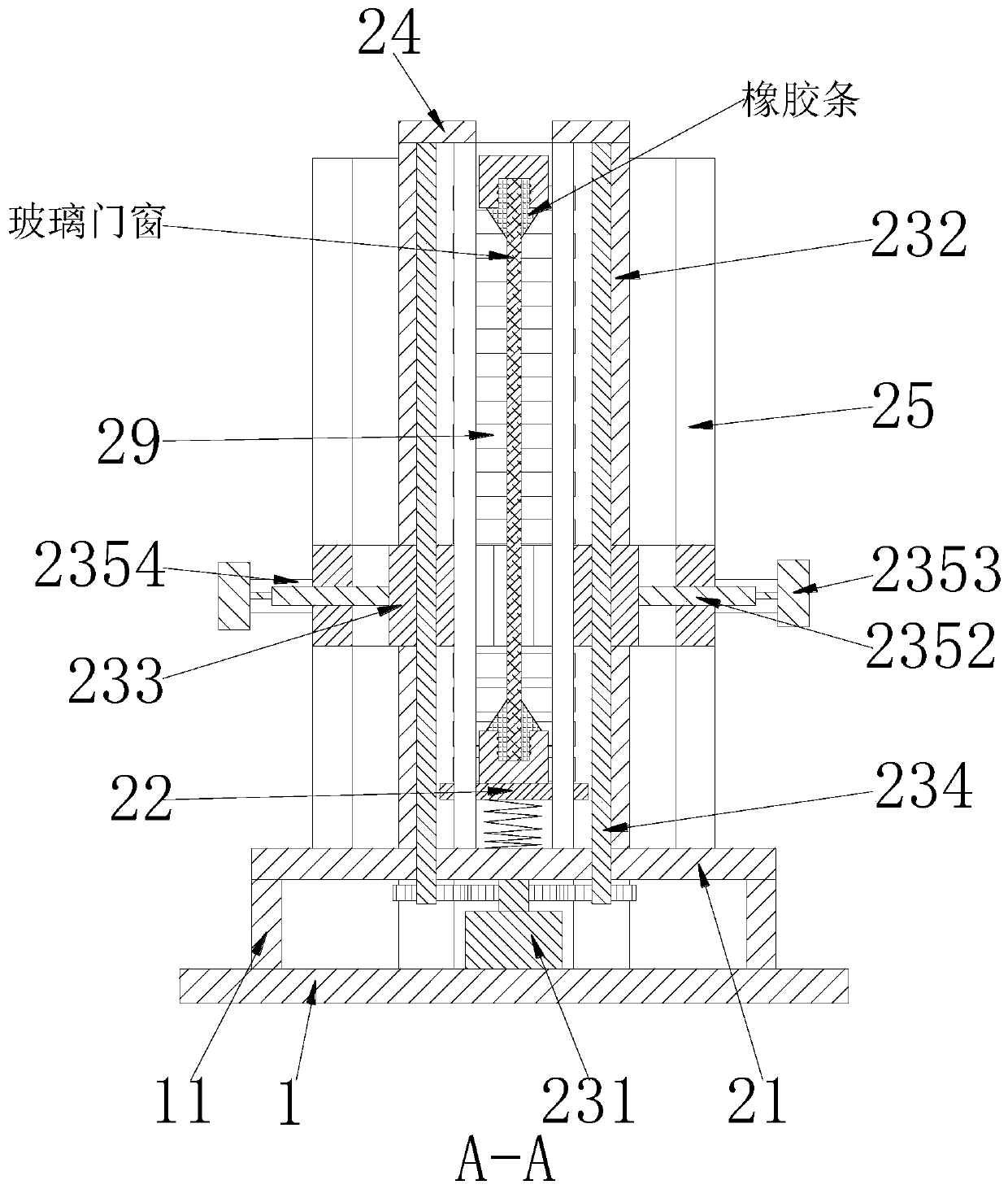

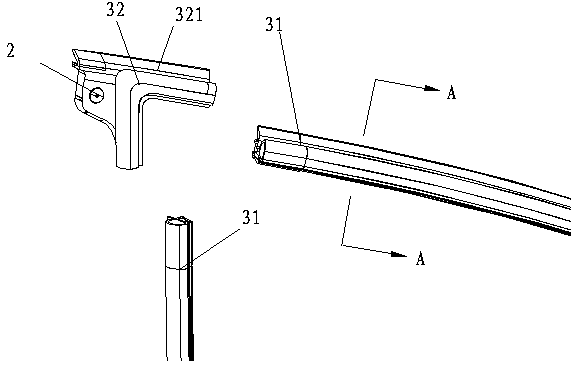

Bridge-cut aluminum glass door and window sealing rubber strip mounting machine and mounting method

ActiveCN111546045AIncrease productivityReduce labor intensityMetal working apparatusMechanical engineering

The invention relates to a bridge-cut aluminum glass door and window sealing rubber strip mounting machine and a mounting method. The mounting machine comprises a base and a mounting device, supporting vertical plates are symmetrically arranged on the upper surface of the base front and back, and the mounting device is arranged on the supporting vertical plates. According to the mounting machine and the mounting method, the following problems existing in installation of a sealing rubber strip in a bridge-cut aluminum door and window at present can be solved, specifically, when the sealing rubber strips are installed in a gap between a bridge-cut aluminum door and window frame and glass, the sealing rubber strips need to be pressed in little by little by hands of a worker, no tool or special equipment is available, the working strength is high, the labor hour is wasted, and fingers of the workers are easily injured; and the bridge-cut aluminum doors and windows are usually produced in batches, so that labor is intensive, the production efficiency is reduced due to the fact that sealing rubber strips are installed manually, and the qualification and attractiveness of manual installation cannot be guaranteed to be consistent.

Owner:上海平易装潢材料有限公司

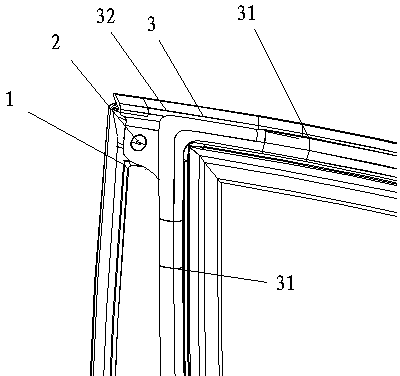

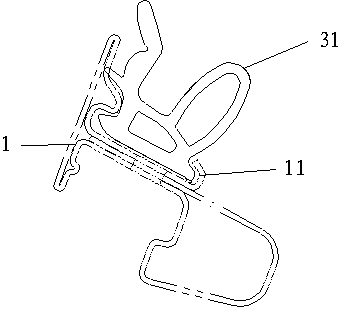

Connection corner structure for automobile window frame sealing bar

InactiveCN104070974ANice appearanceThere will be no appearance defects such as twisted cornersEngine sealsVehicle sealing arrangementsEngineeringCar door

Owner:CHONGQING CHANGAN AUTOMOBILE CO LTD

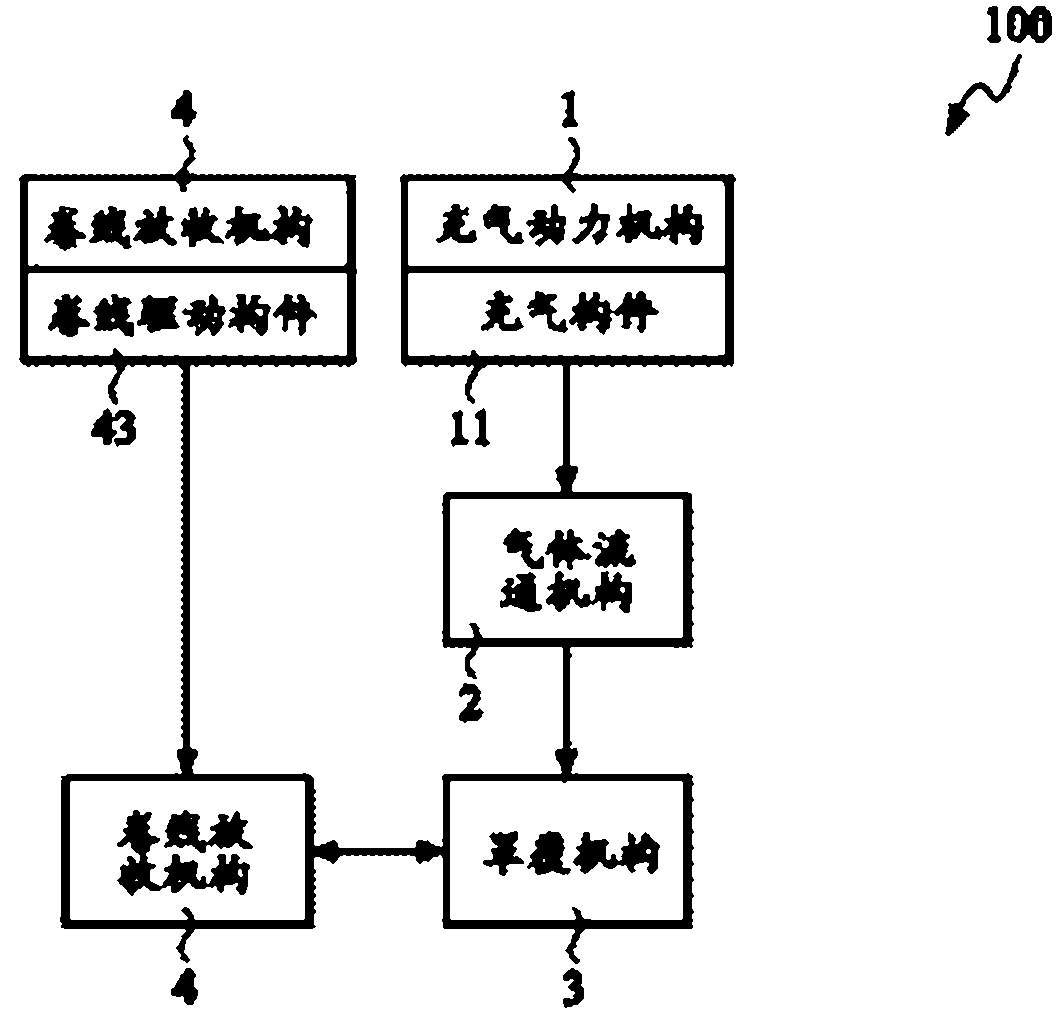

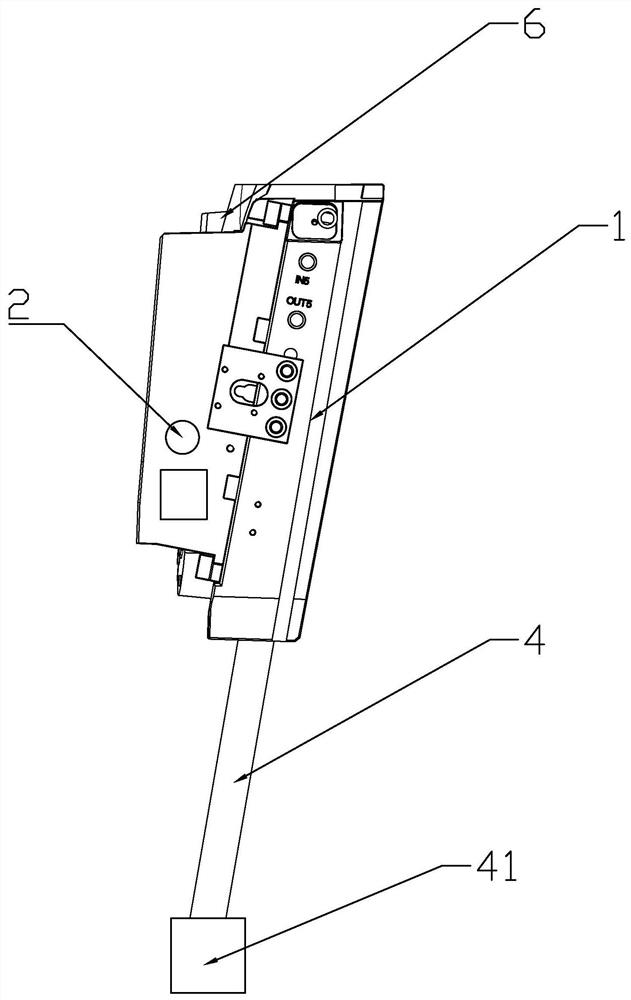

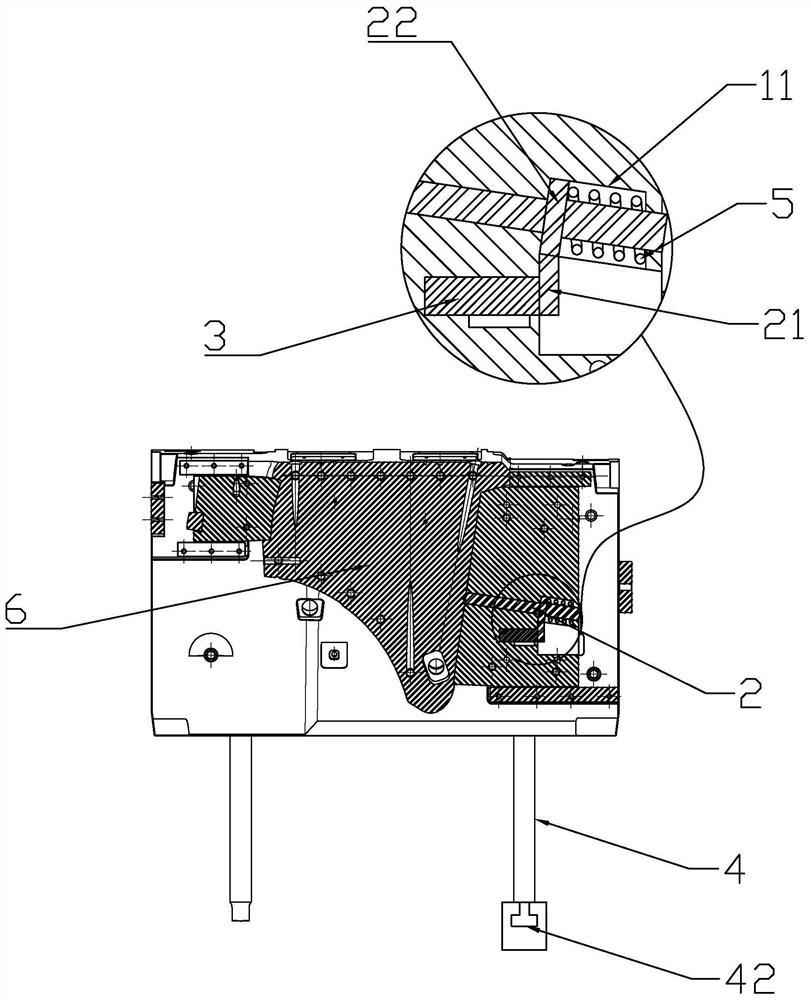

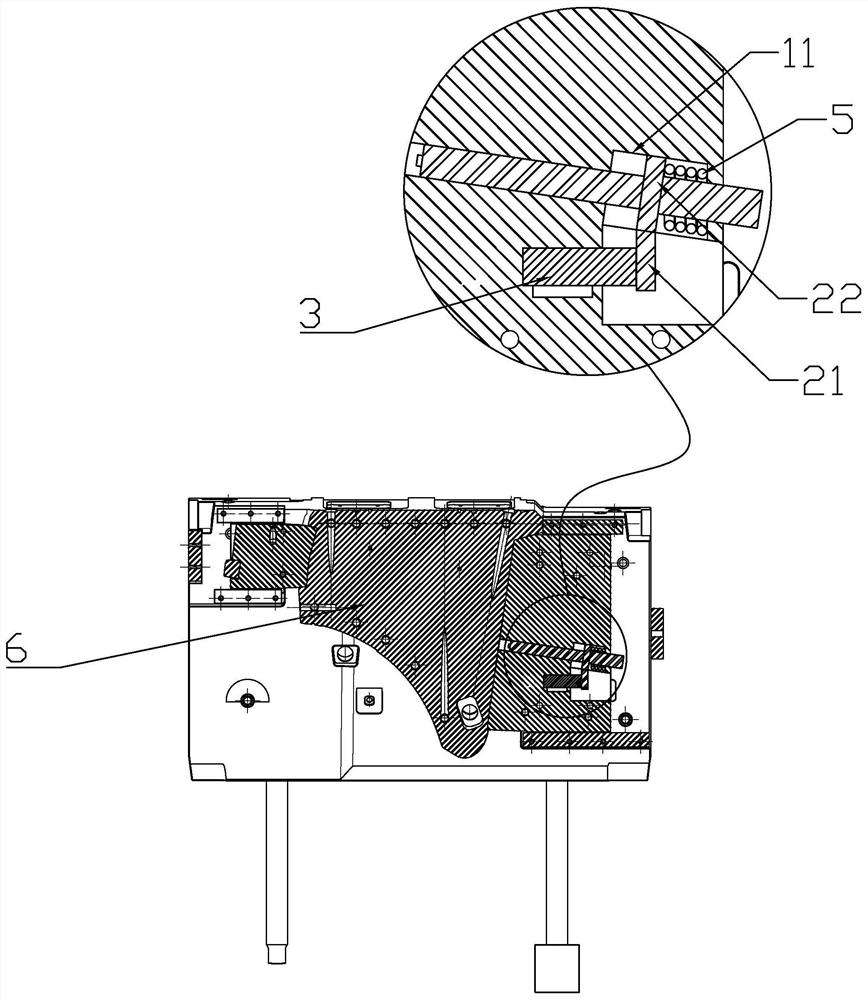

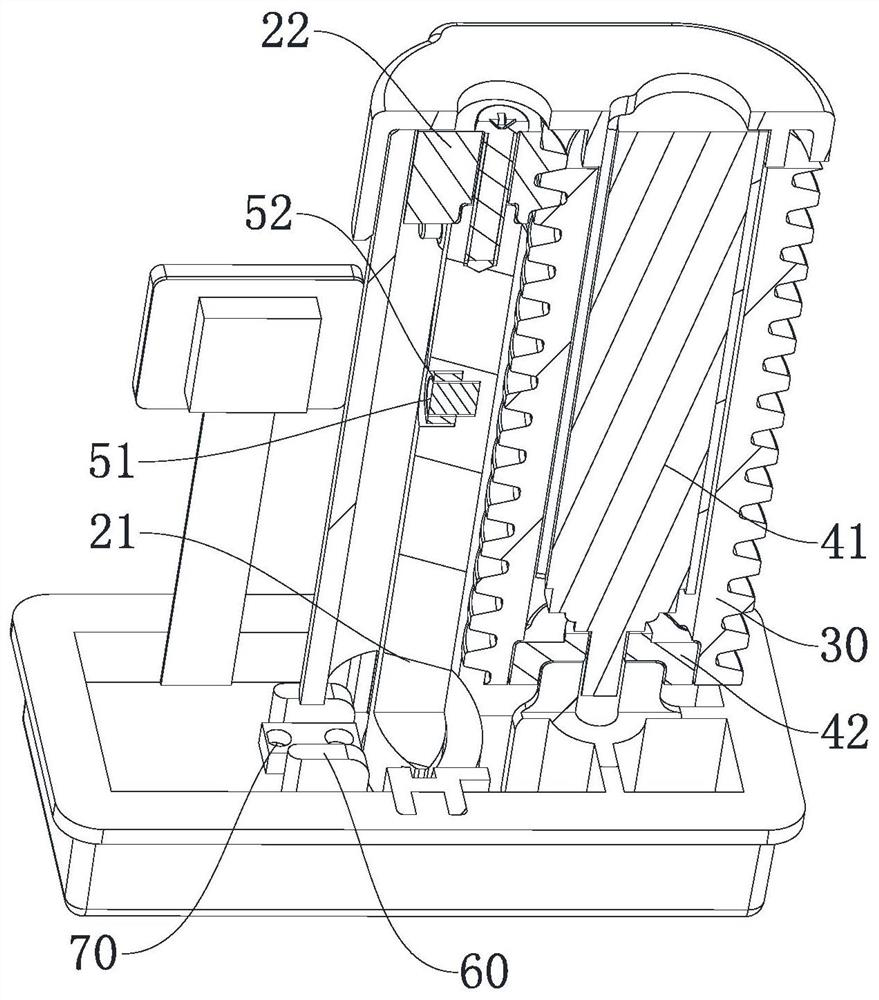

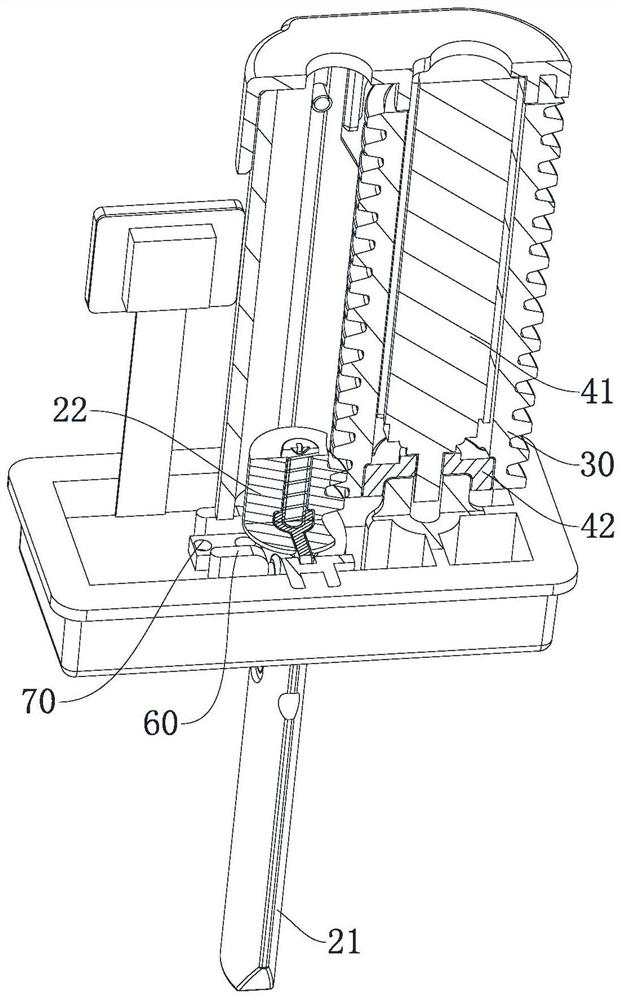

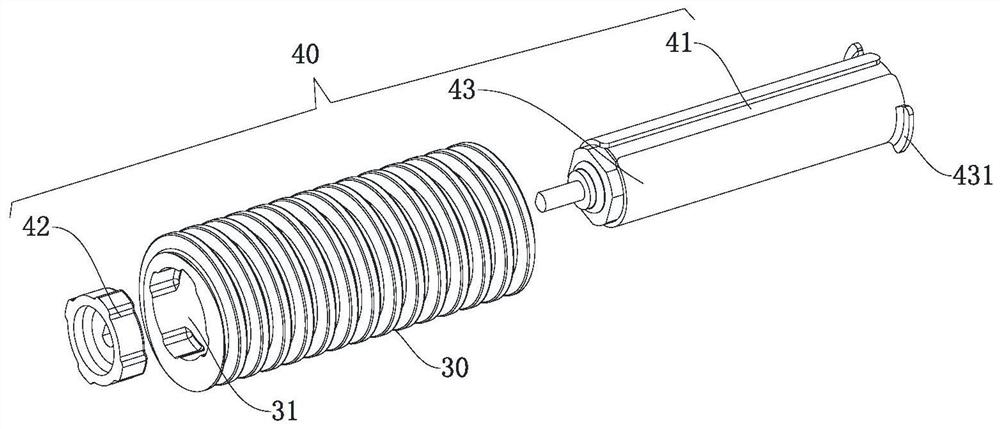

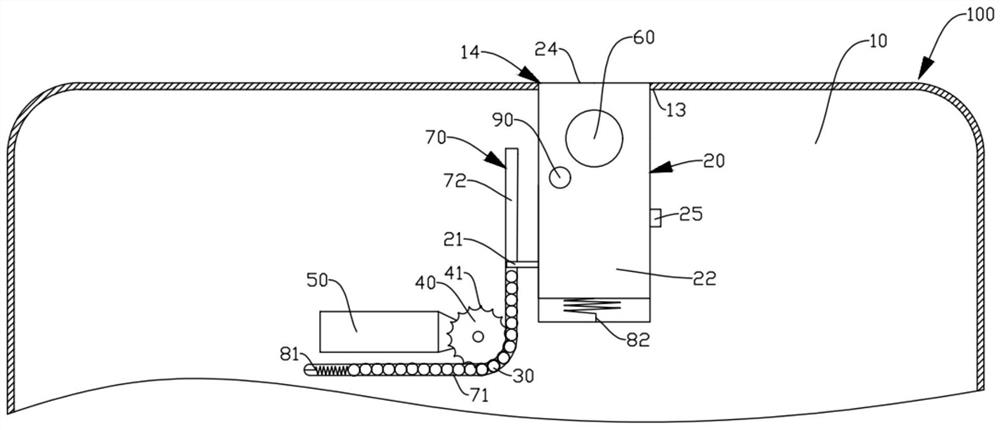

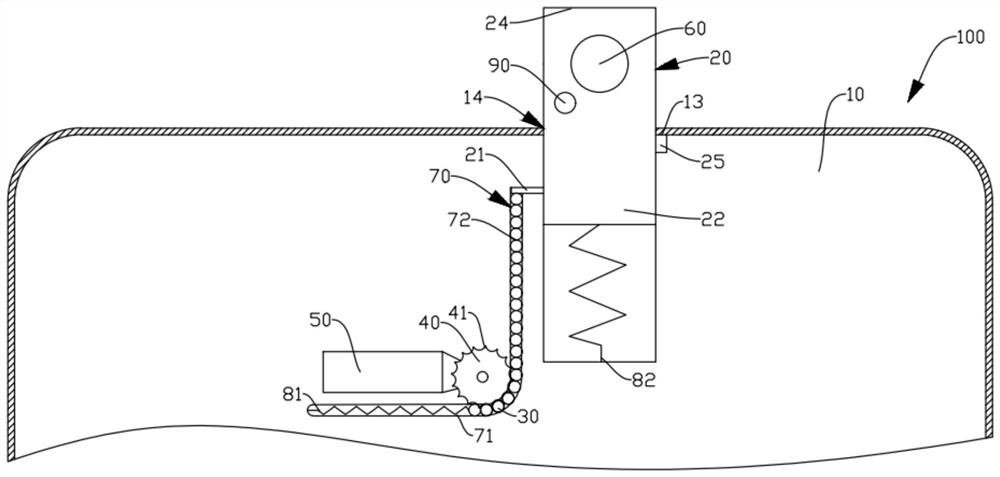

Functional assembly, electronic device and control method thereof

ActiveCN109962999AAvoid damageEnsure appearance consistencyTelephone set constructionsMotor driveCamera module

The invention discloses a functional assembly. The functional assembly comprises a shell, a sliding base, a buffer bag, a shifting wheel and a motor. Wherein the sliding seat is telescopically connected to the shell in a sliding mode, a camera module and supporting legs are arranged on the sliding seat, the sliding way comprises a containing section and an ejection section, and the supporting legsextend into the ejection section. The motor drives the dial wheel to rotate, the dial wheel pushes the buffer bag contained in the containing section into the ejection section, and the buffer bag pushes the supporting legs in an extruded mode, so that the sliding base carries the camera module to stretch out of the shell. The buffer bag serves as an ejection functional part of the functional assembly and also serves as buffer protection of the camera module after ejection, and falling is prevented. The electronic device comprising the functional assembly can hide functional devices in the shell. The invention further discloses an electronic device and a control method thereof, and the user experience is improved.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

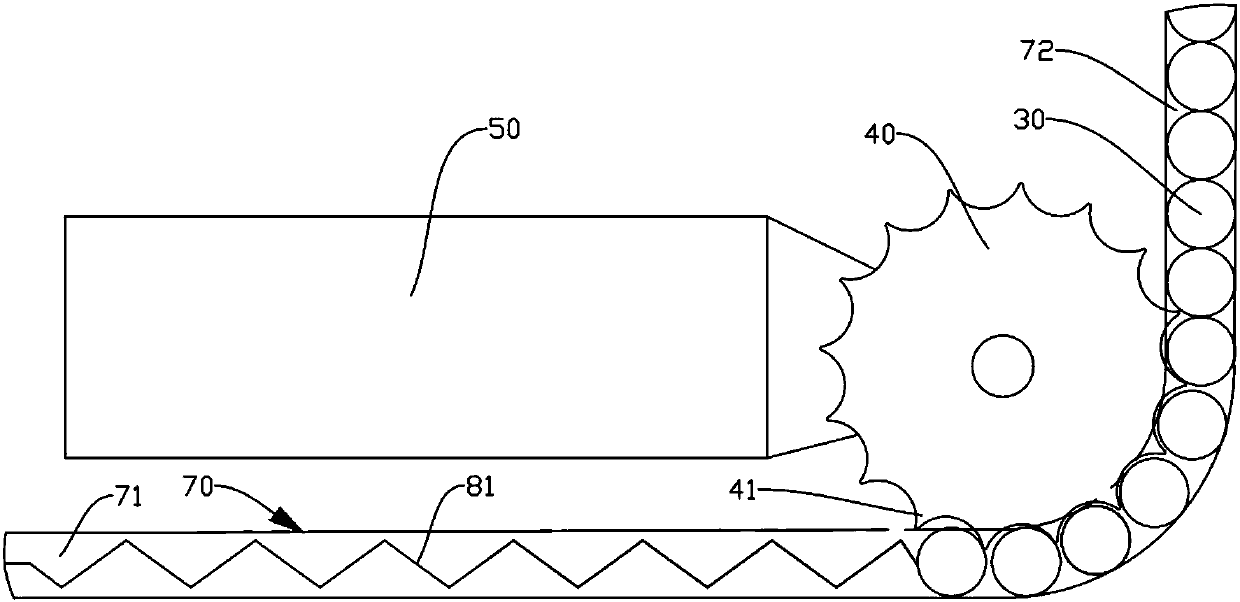

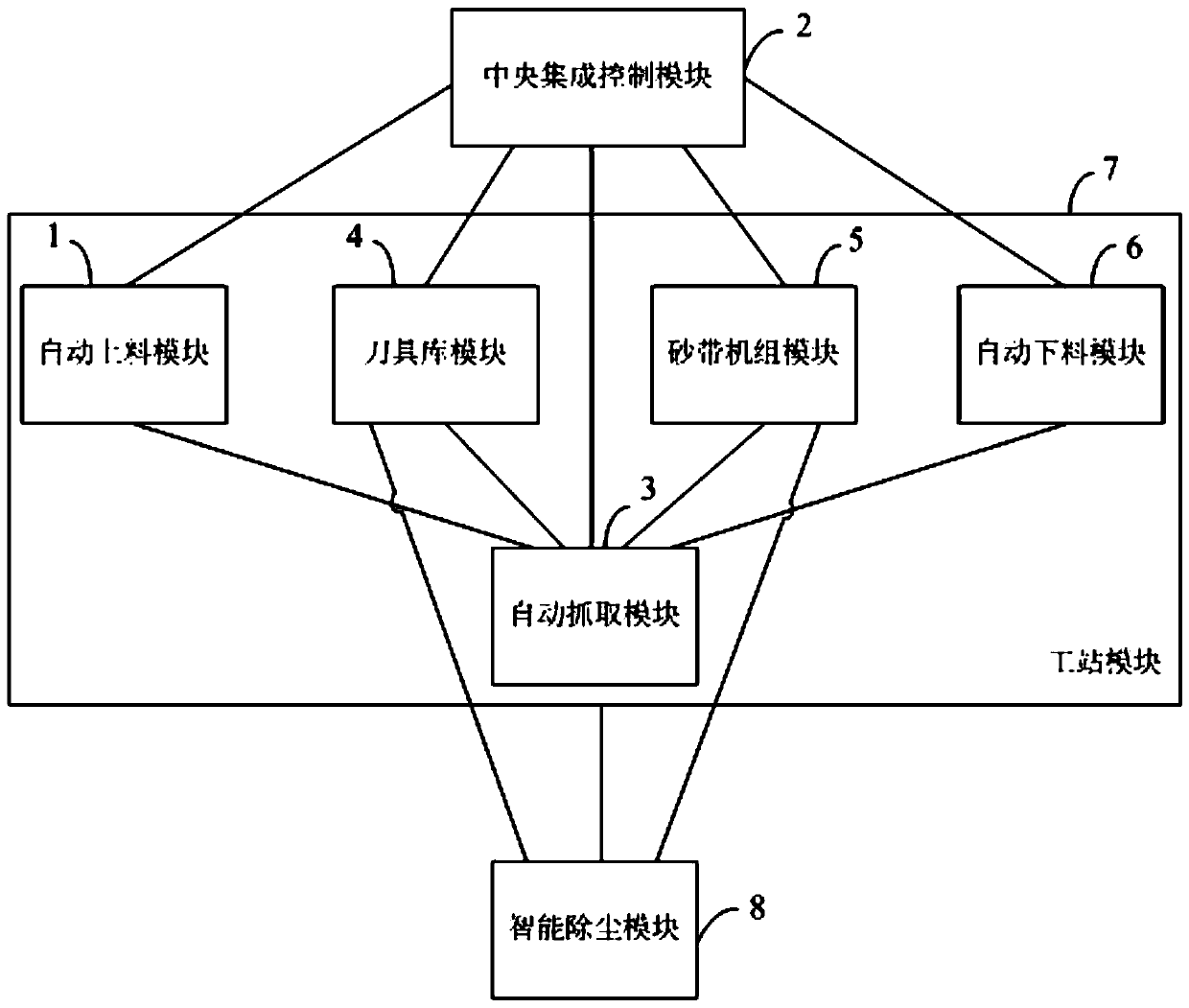

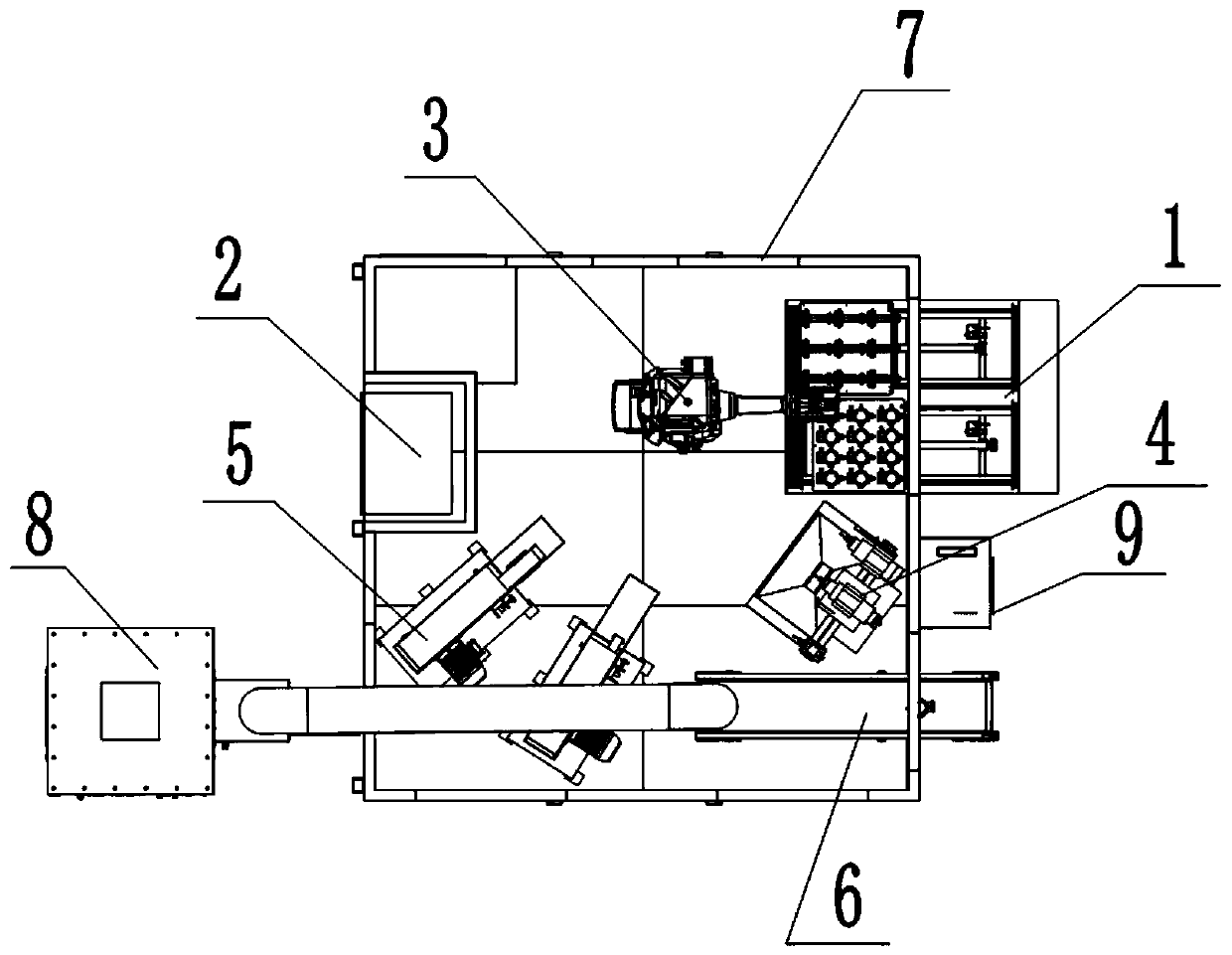

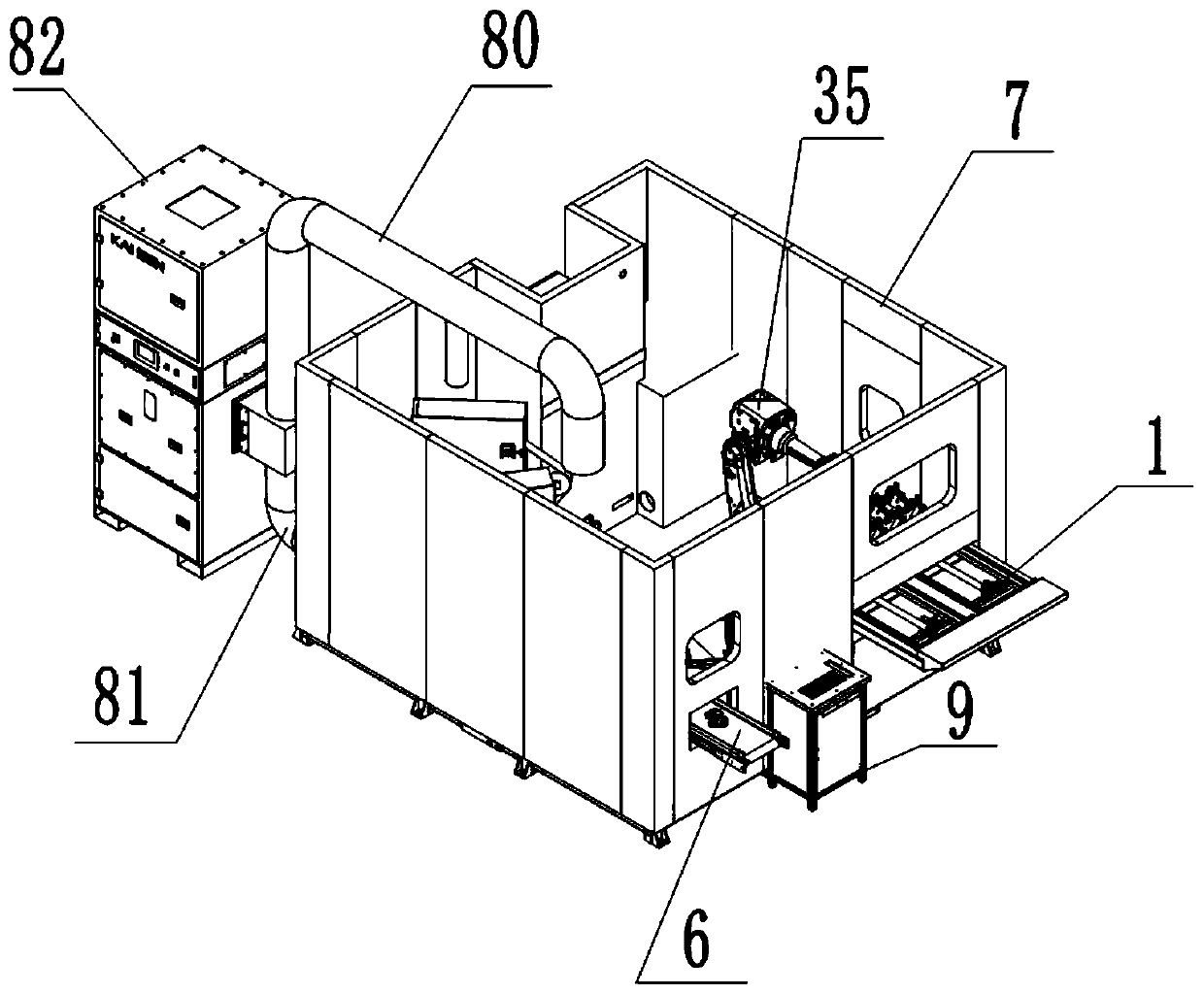

Automatic grinding device for aluminum alloy parts of high-speed rail overhead line system

PendingCN110524253AGuaranteed accuracy consistencyEnsure appearance consistencyDirt cleaningOther manufacturing equipments/toolsEngineeringOverhead line

The invention discloses an automatic grinding device for aluminum alloy parts of a high-speed rail overhead line system. The automatic grinding device is characterized in that a central integrated control module sends different signals to an automatic feeding module, an automatic grabbing module, a cutter module, an abrasive belt unit module and an automatic discharging module, the automatic feeding module feeds the aluminum alloy castings to a grabbing position, and the automatic grabbing module sequentially grabs the grabbed aluminum alloy castings at the grapping position to the cutter module, the abrasive belt unit module and the automatic discharging module; the cutter module and the abrasive belt unit module grind the aluminum alloy castings separately to obtain the aluminum alloy parts, the automatic discharging module conveys the aluminum alloy parts, the automatic feeding and discharging module, the automatic grabbing module, the cutter module and the abrasive belt unit moduleare placed on a work station module, and an intelligent dust removal module is used for removing the dust in the cutter module, the abrasive belt unit module and the work station module. The parts ground by the device are small in die assembly seam and tidy in burrs and seams, and the labor cost is greatly saved.

Owner:宝鸡保德利电气设备有限责任公司

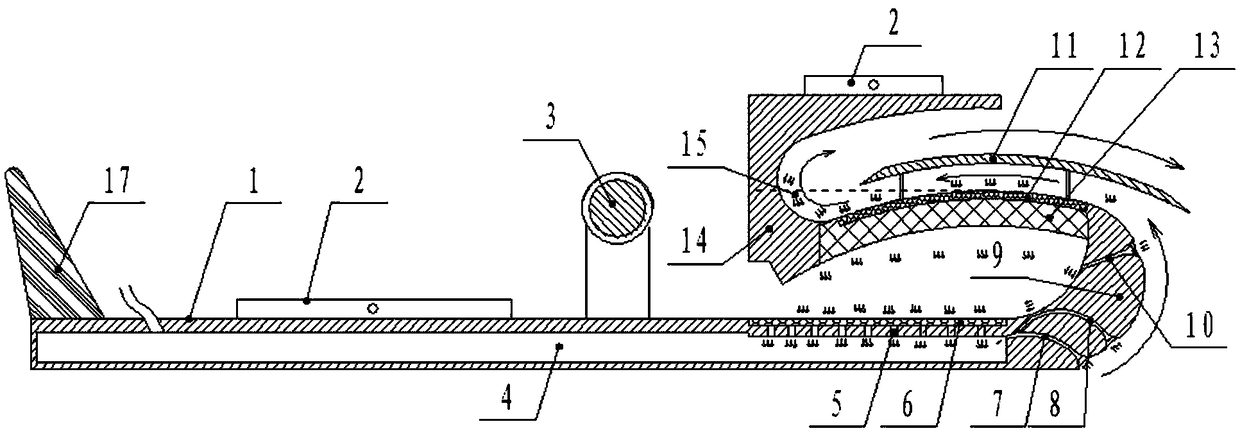

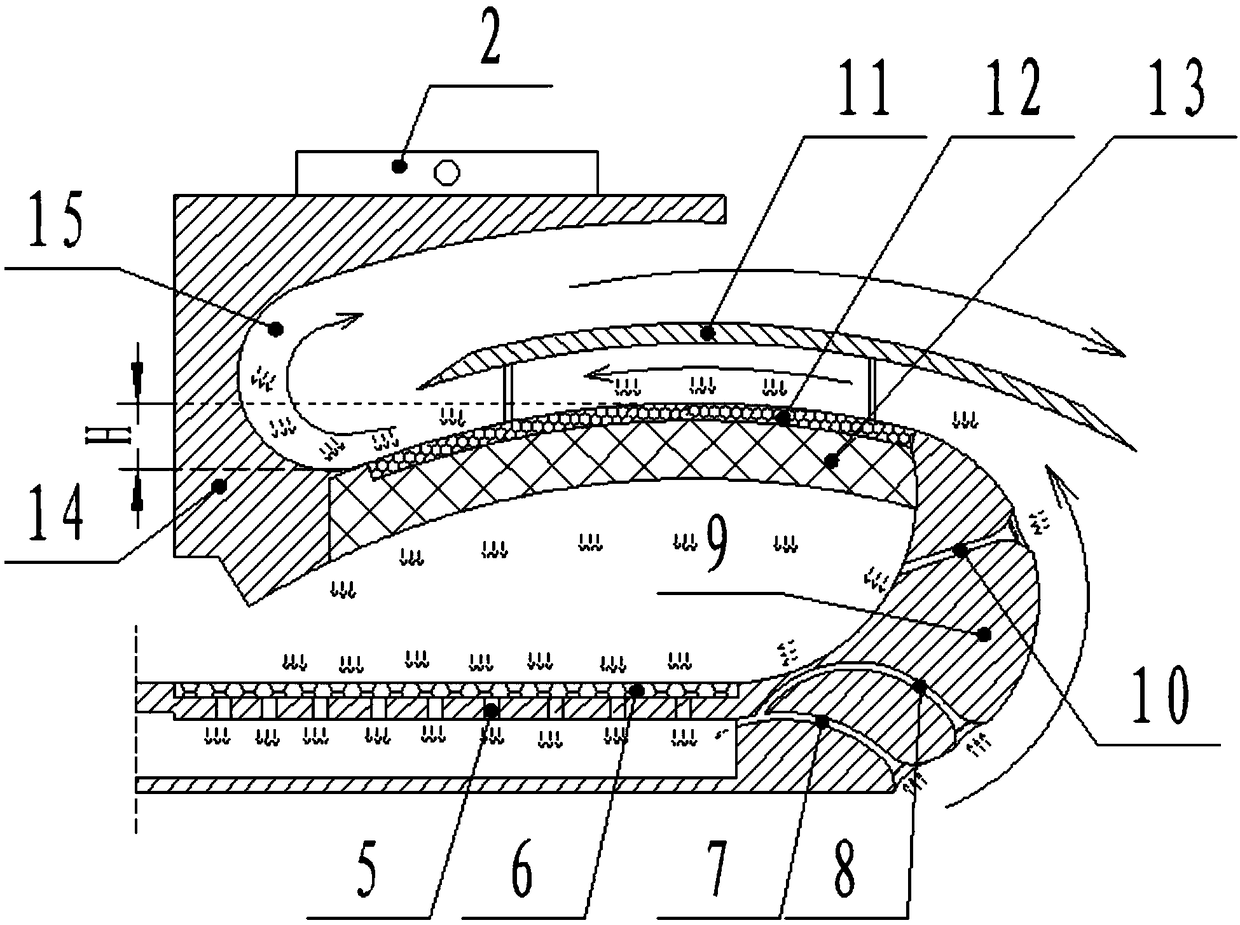

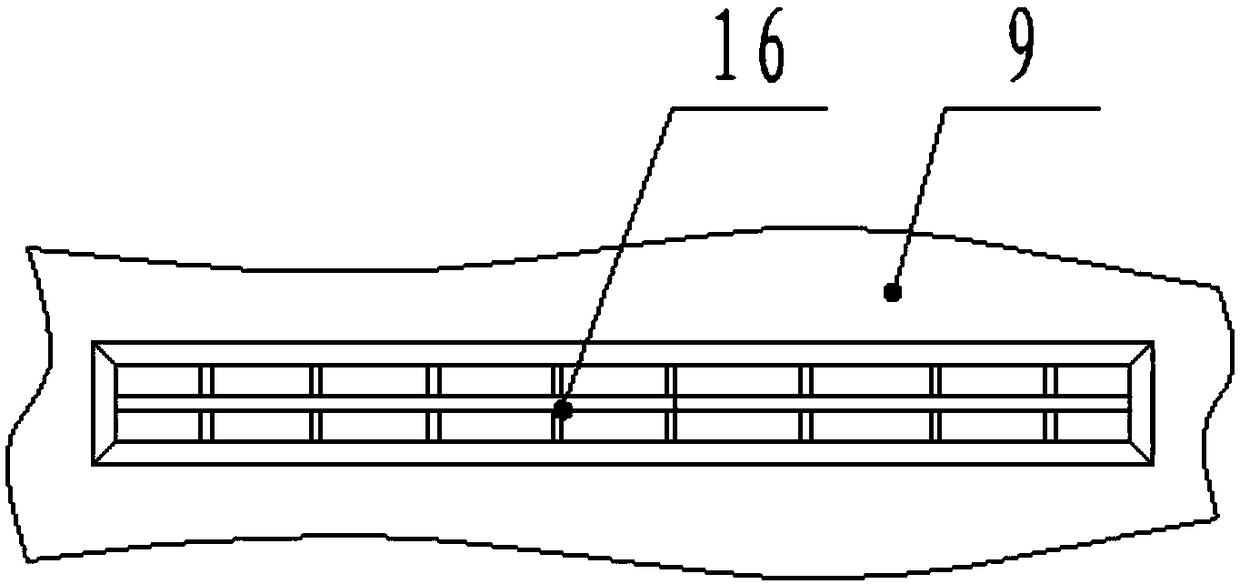

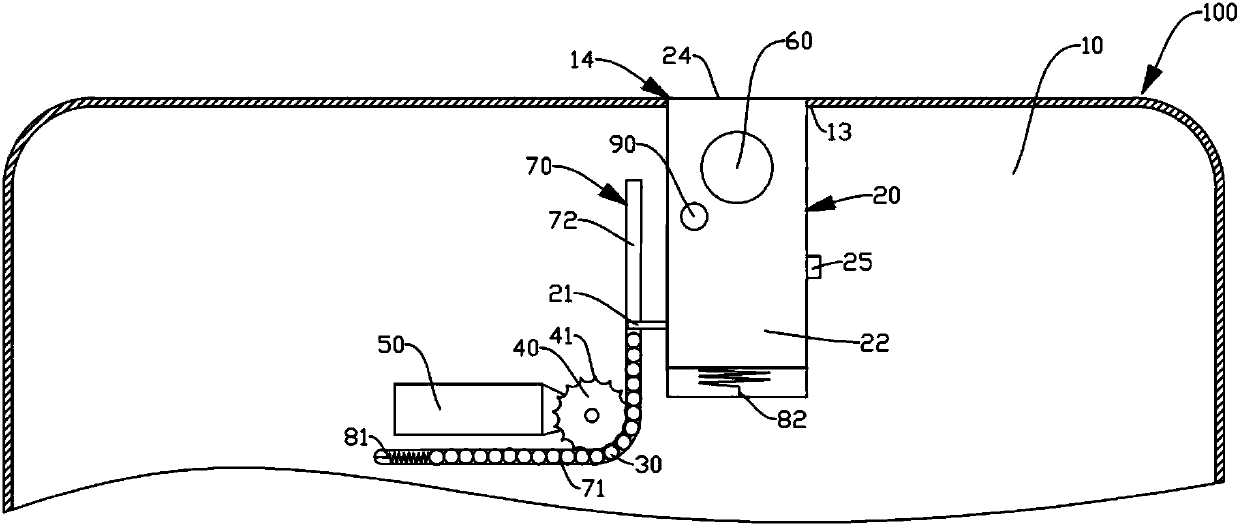

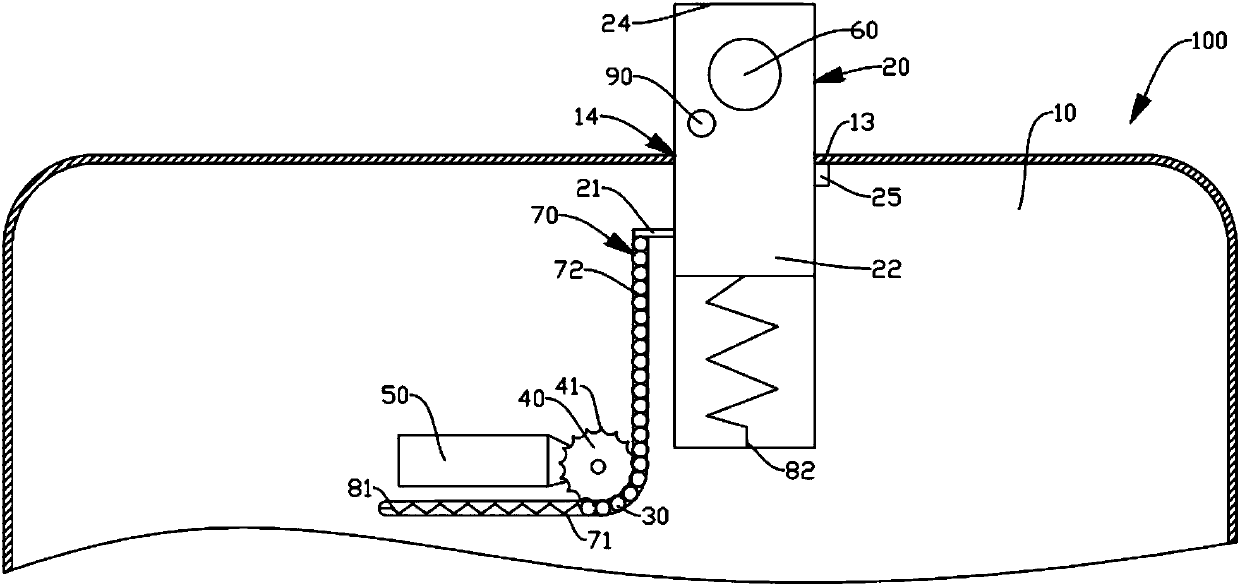

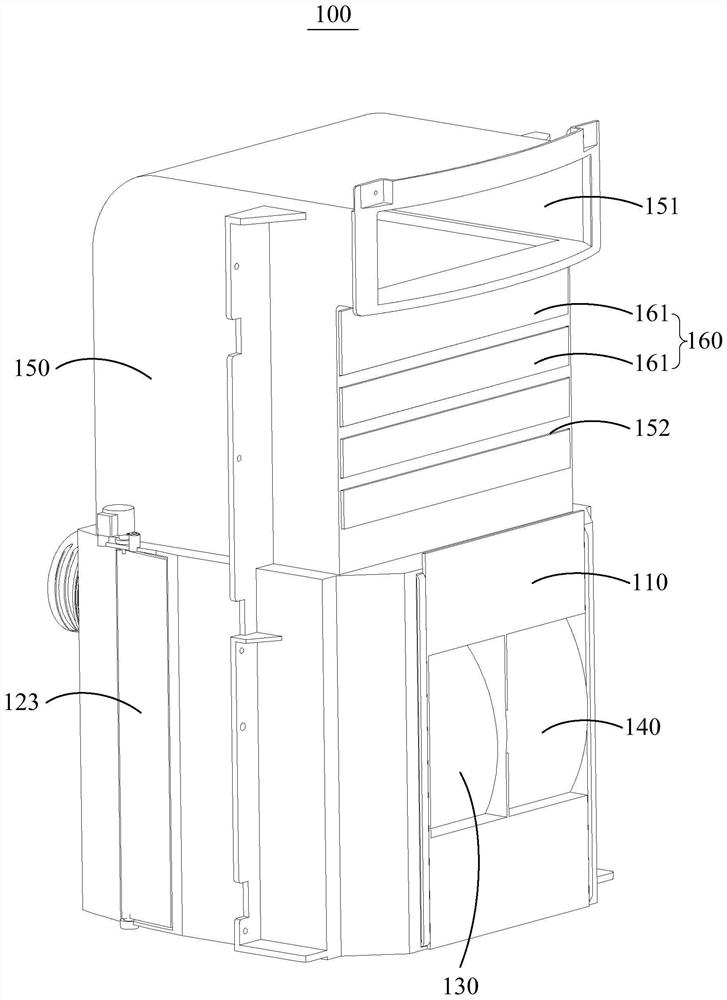

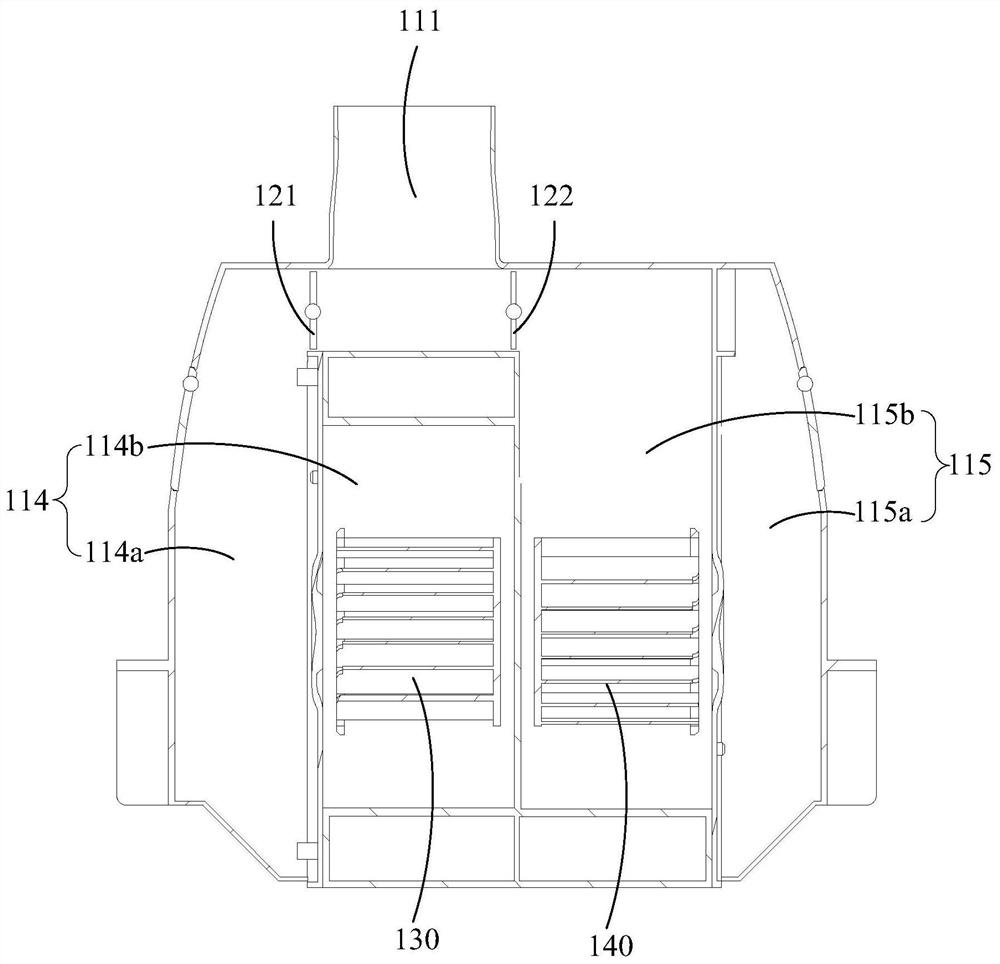

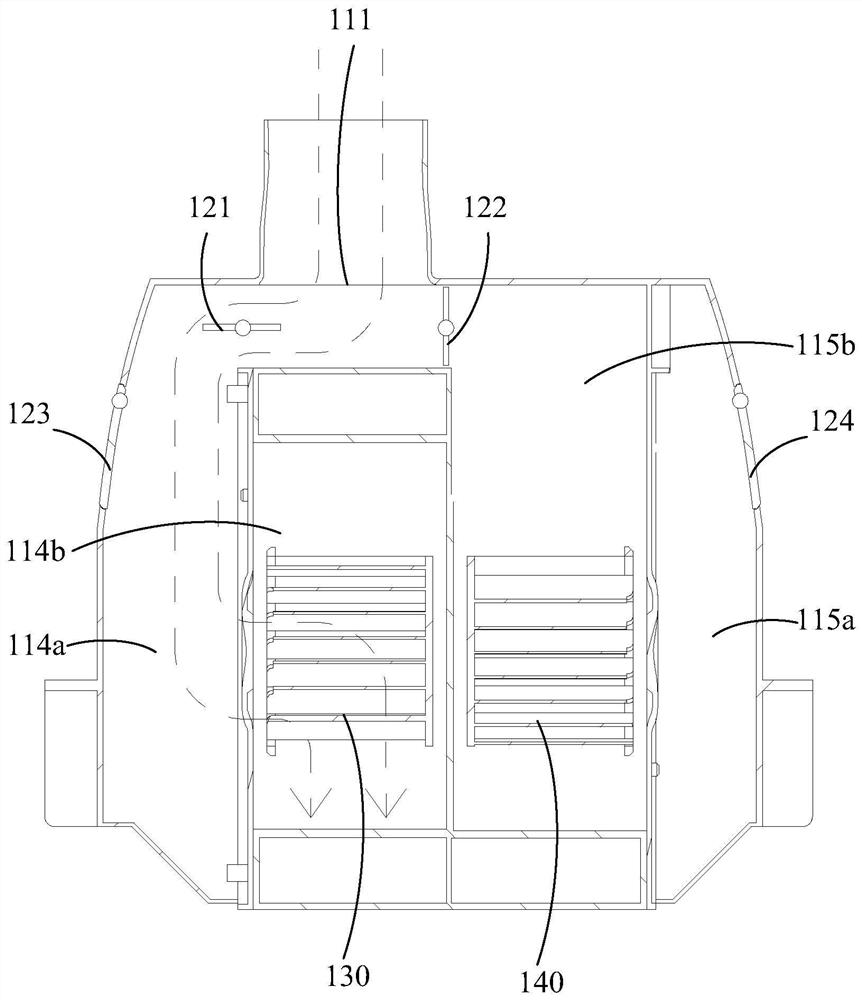

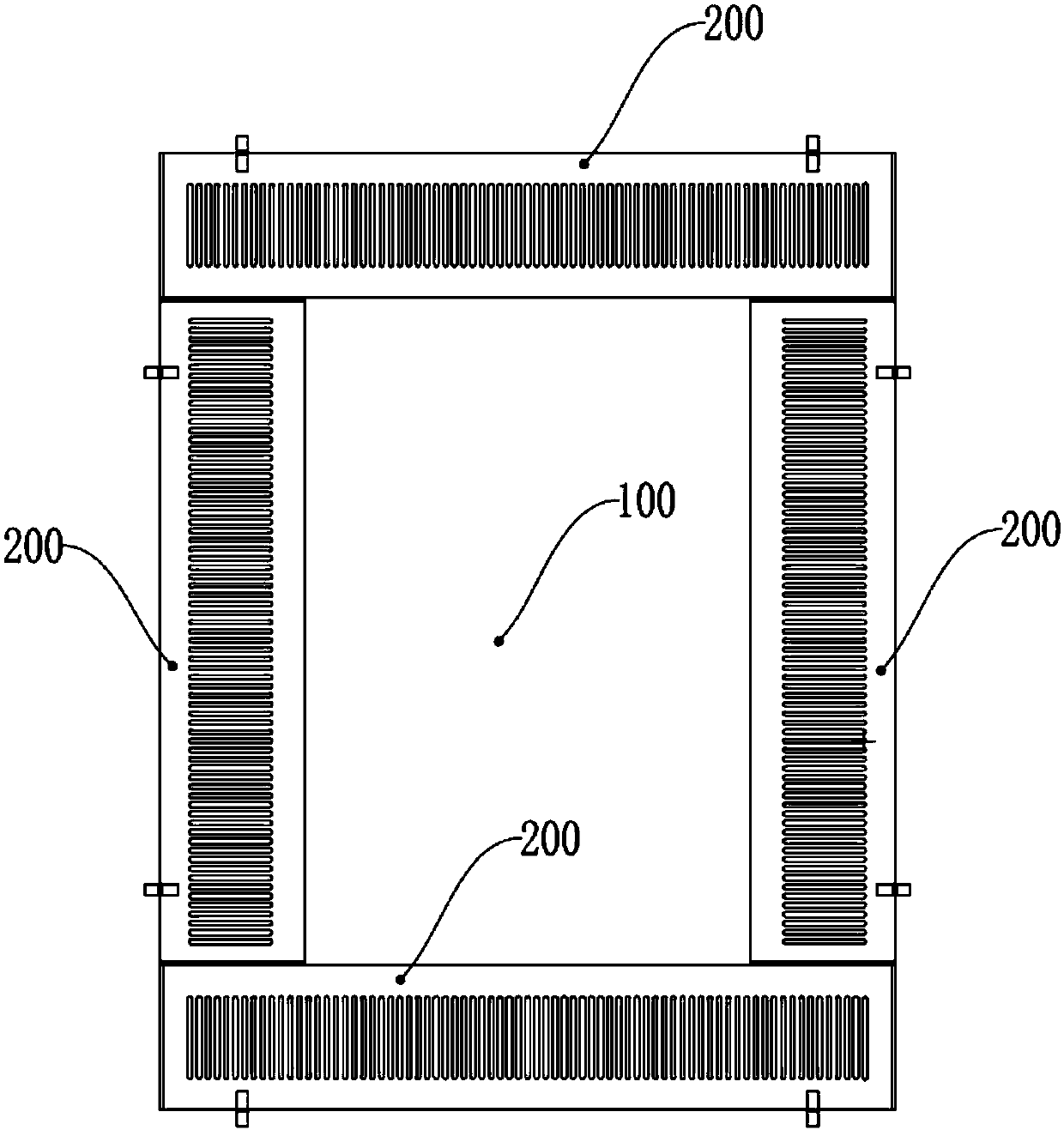

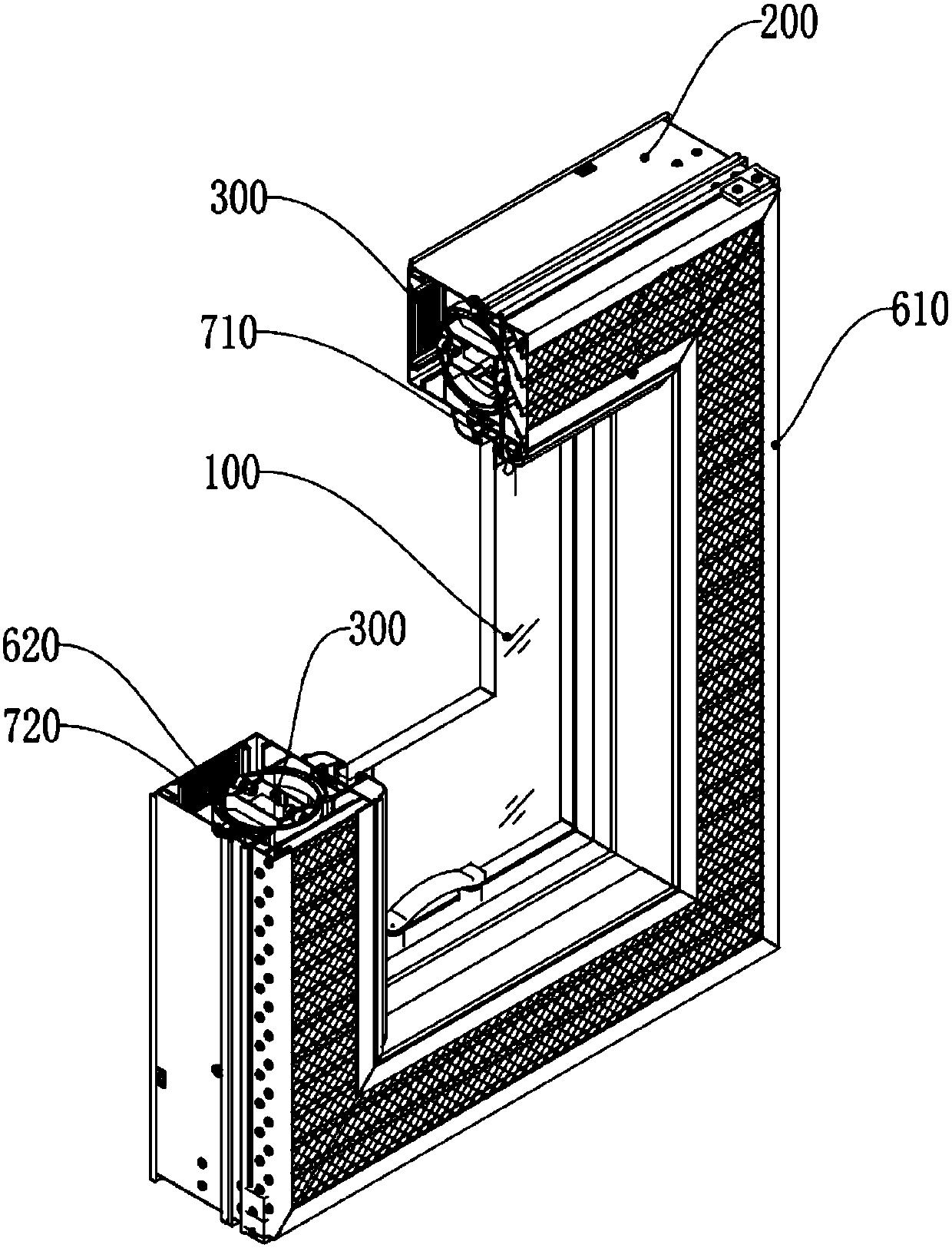

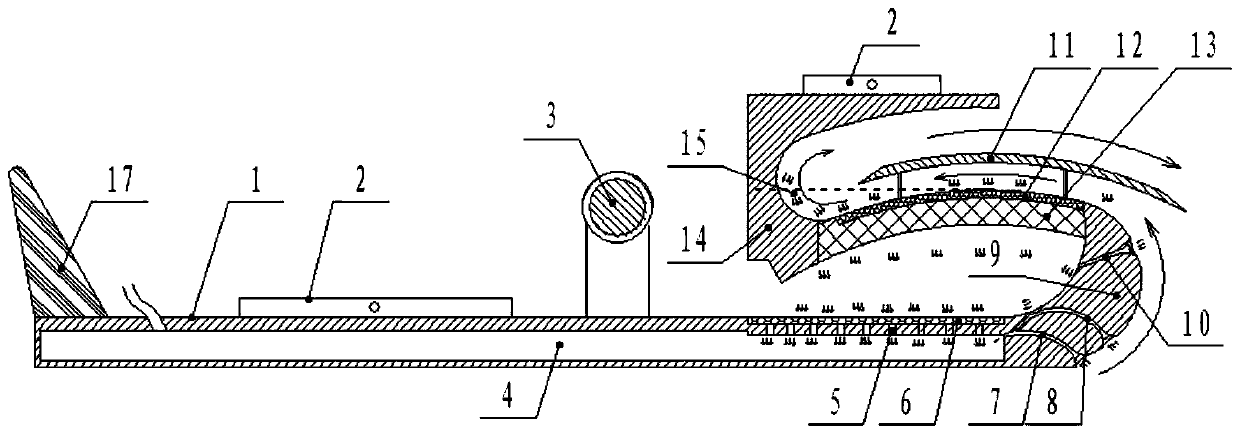

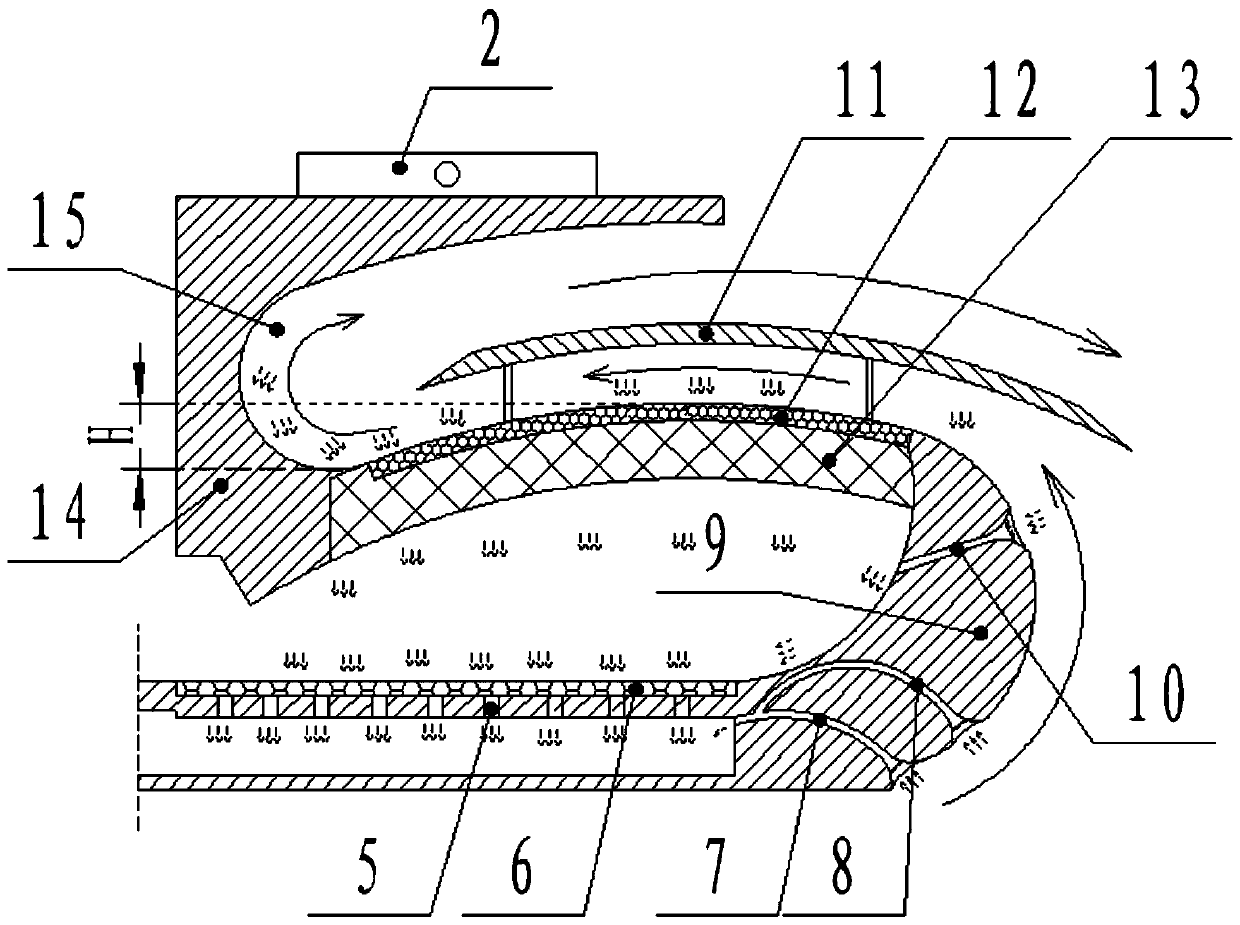

Air treatment device, air conditioner indoor unit and air conditioner

PendingCN114183839ASimple structureEnsure appearance consistencyDucting arrangementsLighting and heating apparatusAir treatmentFresh air

The invention discloses an air treatment device, an air conditioner indoor unit and an air conditioner, and the air treatment device comprises a shell, a valve assembly, a fresh air fan and an exhaust fan; a fresh air opening, an air outlet and a return air opening are formed in the shell, a first circulating cavity communicating with the fresh air opening and the air outlet and a second circulating cavity communicating with the fresh air opening and the return air opening are defined in the shell, and the first circulating cavity and the second circulating cavity are isolated from each other and intersect at the fresh air opening; the valve assembly is installed on the shell so that one of the first circulation cavity and the second circulation cavity can be selected to be communicated with the fresh air opening. The fresh air fan is mounted in the first circulating cavity; and the exhaust fan is mounted in the second circulating cavity. According to the air treatment device, the connecting pipe structure and the mounting process can be simplified, and the appearance consistency of the air treatment device is guaranteed. In addition, the air exchange efficiency of the whole air treatment device can be improved, the structure is simple, and implementation and control are easy.

Owner:GD MIDEA AIR-CONDITIONING EQUIP CO LTD +1

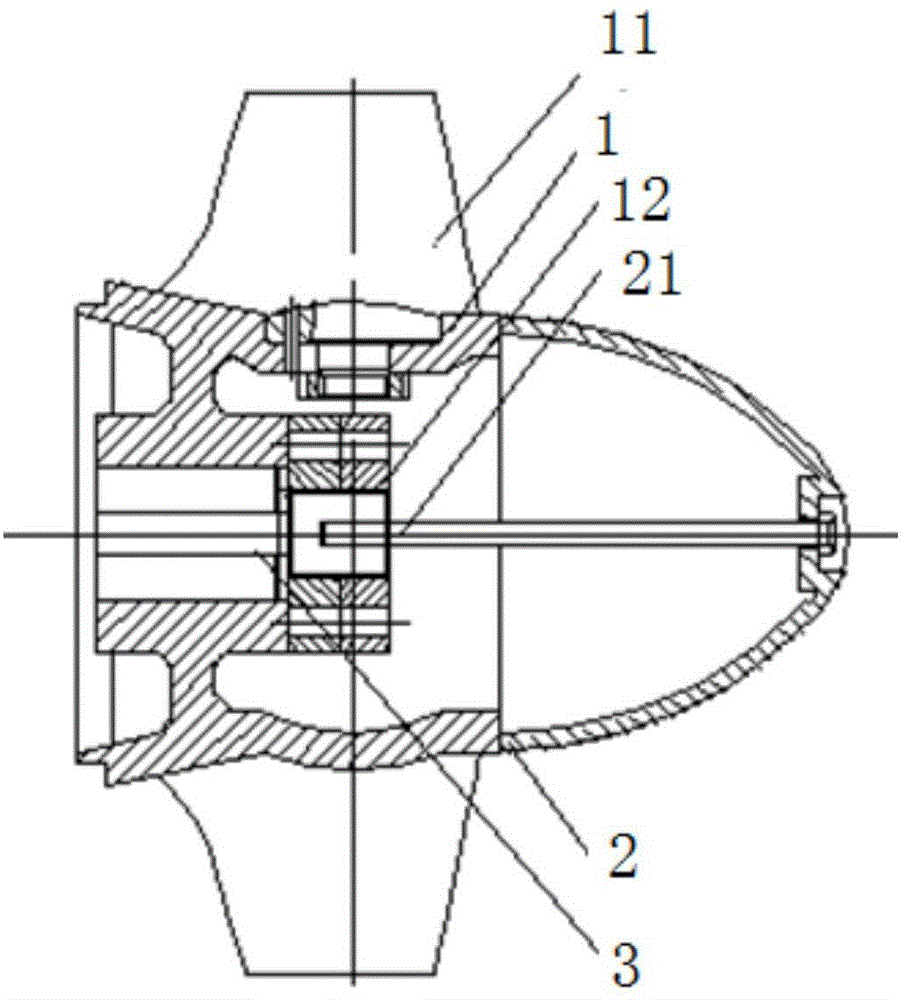

Water guide cone and impeller hub connecting structure

InactiveCN104819171AEnsure appearance consistencyEnsure consistencyPump componentsPumpsImpellerEngineering

The invention discloses a water guide cone and impeller hub connecting structure. The connecting structure comprises an impeller hub, wherein one end of the impeller hub is connected with a submersible pump main shaft through an impeller nut, and the other end is connected with a water guide cone; an axial plane is arranged at the outer side of a cone port part of the water guide cone; an extension connecting part overlapped with the end surface of the impeller hub is arranged at the connected side of the axial plane with the impeller hub; and the extension connecting part and the end surface of the impeller hub are fixed through a screw. The water guide cone and impeller hub connecting structure is simple in structure, is convenient to be installed, and prolongs the service life of a pump.

Owner:川源(中国)机械有限公司

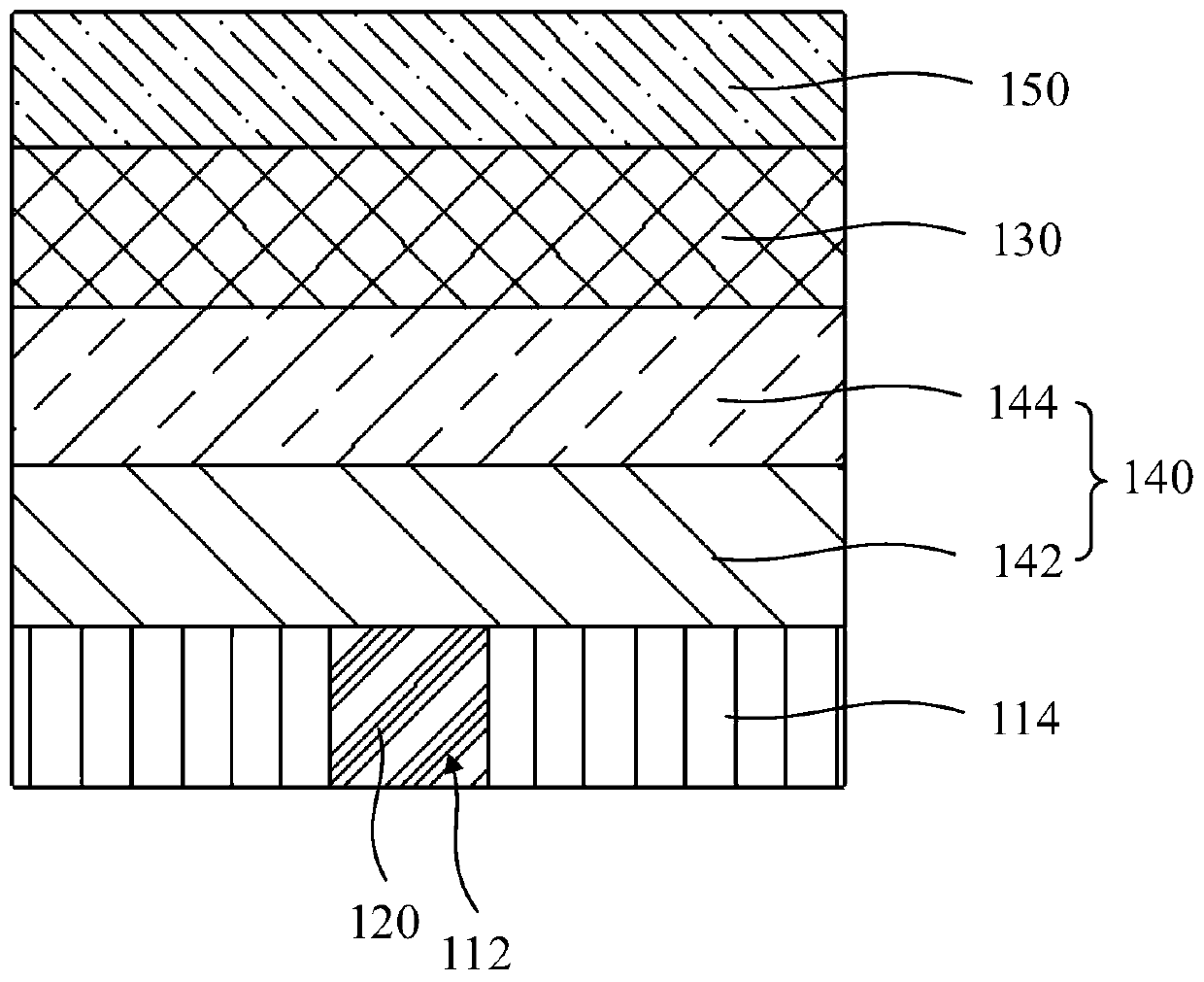

Shell assembly and preparation method thereof and electronic equipment

InactiveCN110650605AGood appearance consistencyEnsure appearance consistencySynthetic resin layered productsVacuum evaporation coatingEngineeringMechanical engineering

The invention relates to a shell assembly and a preparation method thereof and electronic equipment. The shell assembly comprises a substrate, a plastic part and a covering layer. The substrate is provided with a display surface. A through containing hole is formed in the substrate, and one opening of the containing hole is located in the display surface. The plastic part is arranged in the containing hole and fixedly connected with the substrate. The covering layer completely covers the display surface and completely shields the containing hole. The appearance consistency effect of the shellassembly is good.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

Automatic cloth spreading machine

ActiveCN103029876BReduce labor costsIncrease productivityFolding thin materialsPackagingPulp and paper industryTextile

The invention discloses an automatic cloth spreading machine. The automatic cloth spreading machine comprises a cloth spreading device, wherein the cloth spreading device comprises a support; a cloth arranging rod is arranged at the position rightly facing to the upper end of the support; a cloth pushing rod is arranged at the position rightly facing to the lower end of the support; a cloth clamping clamp and a cloth turning frame capable of rotating along the support are arranged at the lower end of the support; the cloth arranging rod, the cloth pushing rod, the cloth clamping clamp and the cloth turning frame are respectively connected with a cloth arranging cylinder, a cloth pushing cylinder, a cloth clamping cylinder and a turning cylinder; the cloth arranging cylinder and the cloth pushing cylinder respectively drive the cloth arranging rod and the cloth pushing rod to horizontally reciprocate; and the cloth clamping cylinder and the turning cylinder respectively drive the cloth clamping clamp and the cloth turning frame to rotate along the support. The automatic cloth spreading machine finishes cloth spreading procedures in matched with the cloth arranging cylinder, the cloth arranging cylinder, the turning cylinder and the cloth pushing cylinder. By the automatic cloth spreading machine, the labor cost is reduced, the production efficiency and the production stability are improved, and the appearances of products can be enabled to be accordant.

Owner:SUZHOU TA&A ULTRA CLEAN TECH CO LTD

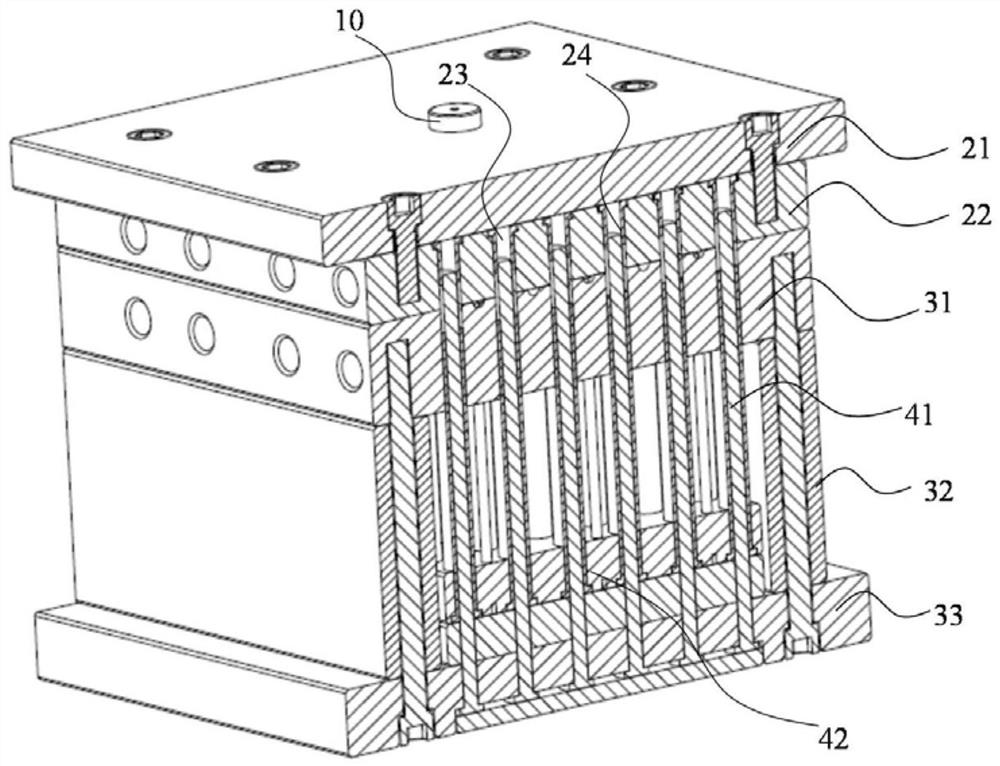

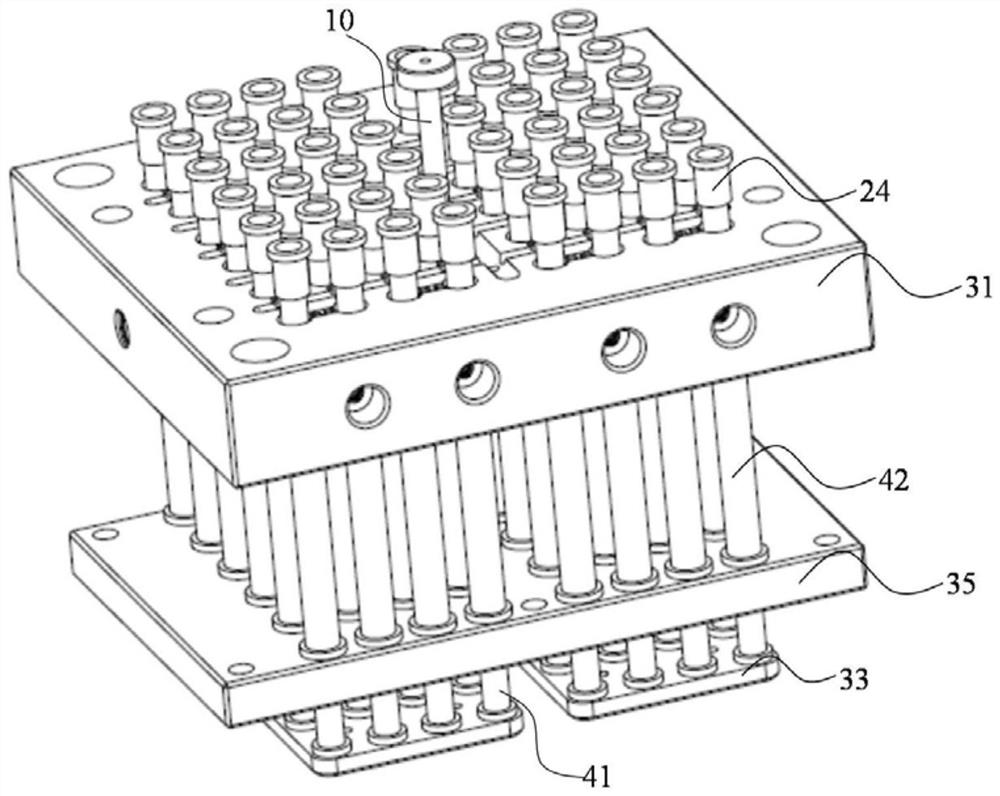

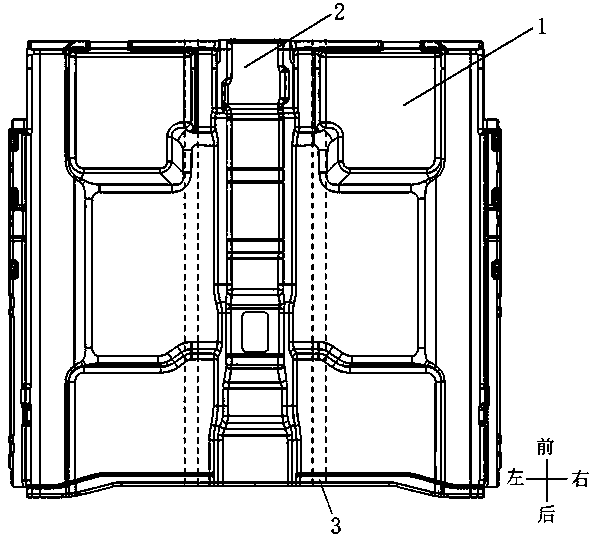

Injection mold pitched roof vibrating needle linkage mechanism and inverted buckle removing method

The invention discloses an injection mold pitched roof and vibrating needle linkage mechanism and an inverted buckle removing method. The injection mold pitched roof and vibrating needle linkage mechanism comprises a pitched roof, a pitched roof rod arranged on the pitched roof, a vibrating needle and a transmission mechanism, the vibrating needle is elastically connected with the pitched roof and is slidably arranged in the pitched roof, the pitched roof rod is rotationally arranged on the pitched roof, and the pitched roof rod drives the vibrating needle to stretch on the pitched roof through the transmission mechanism. The injection mold pitched roof and vibrating needle linkage mechanism has the following beneficial effects that (1), the reverse buckle removal in the cavity direction is realized by arranging the pitched roof, and an external parting mold does not need to be arranged on the cavity, so that the exposure of a clamping wire is avoided, and the appearance consistency is ensured; (2), by arranging the vibrating needle, a product is locked and driven when the first section is opened, and the inverted buckle is efficiently removed when the second section is opened; (3), two-section demolding and reverse buckle removal are realized through two moving modes of an inclined ejector rod structure; and (4), the mold is simple in structure and simple and convenient to use and operate.

Owner:ZHEJIANG KAIHUA MOLDS

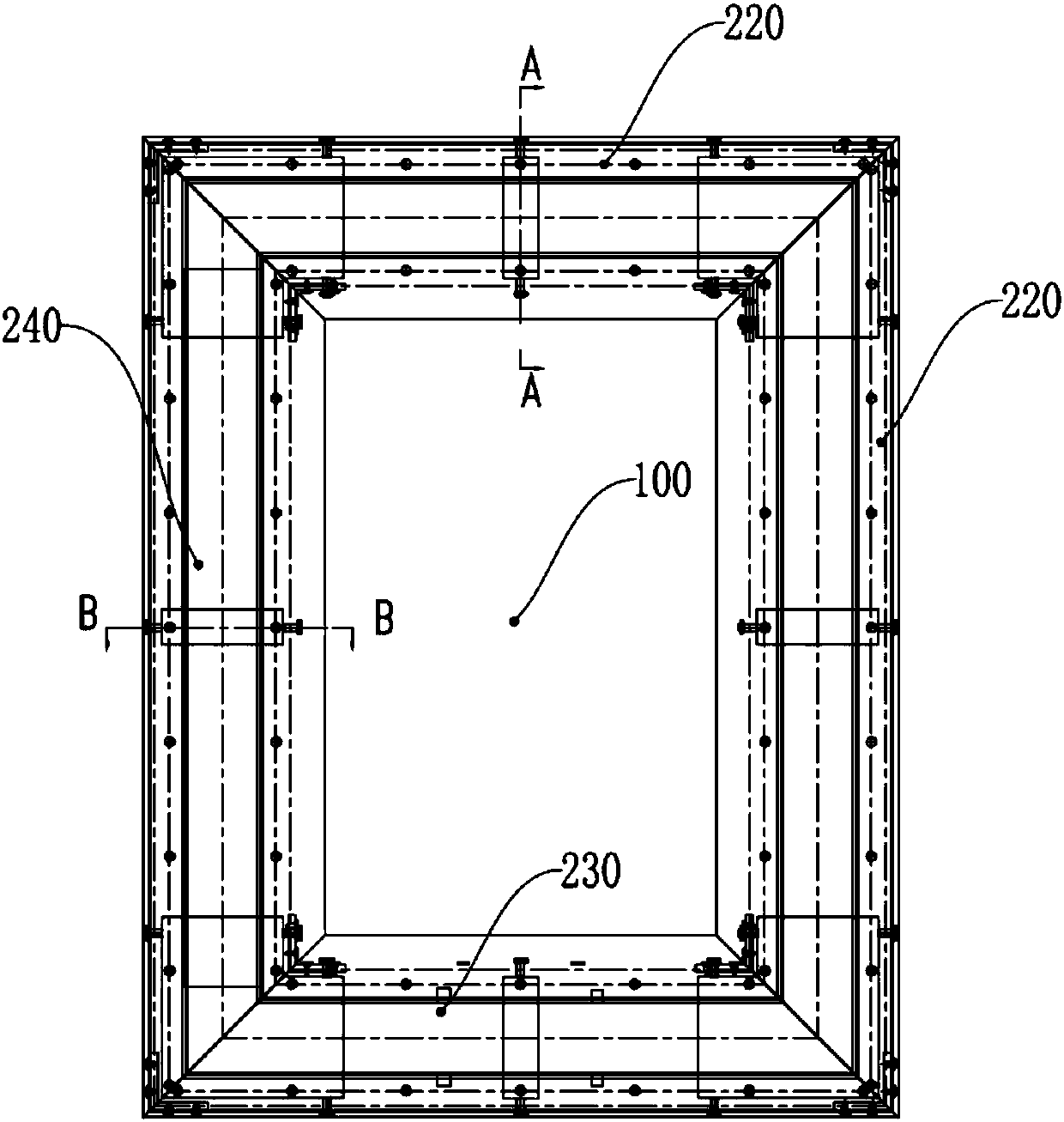

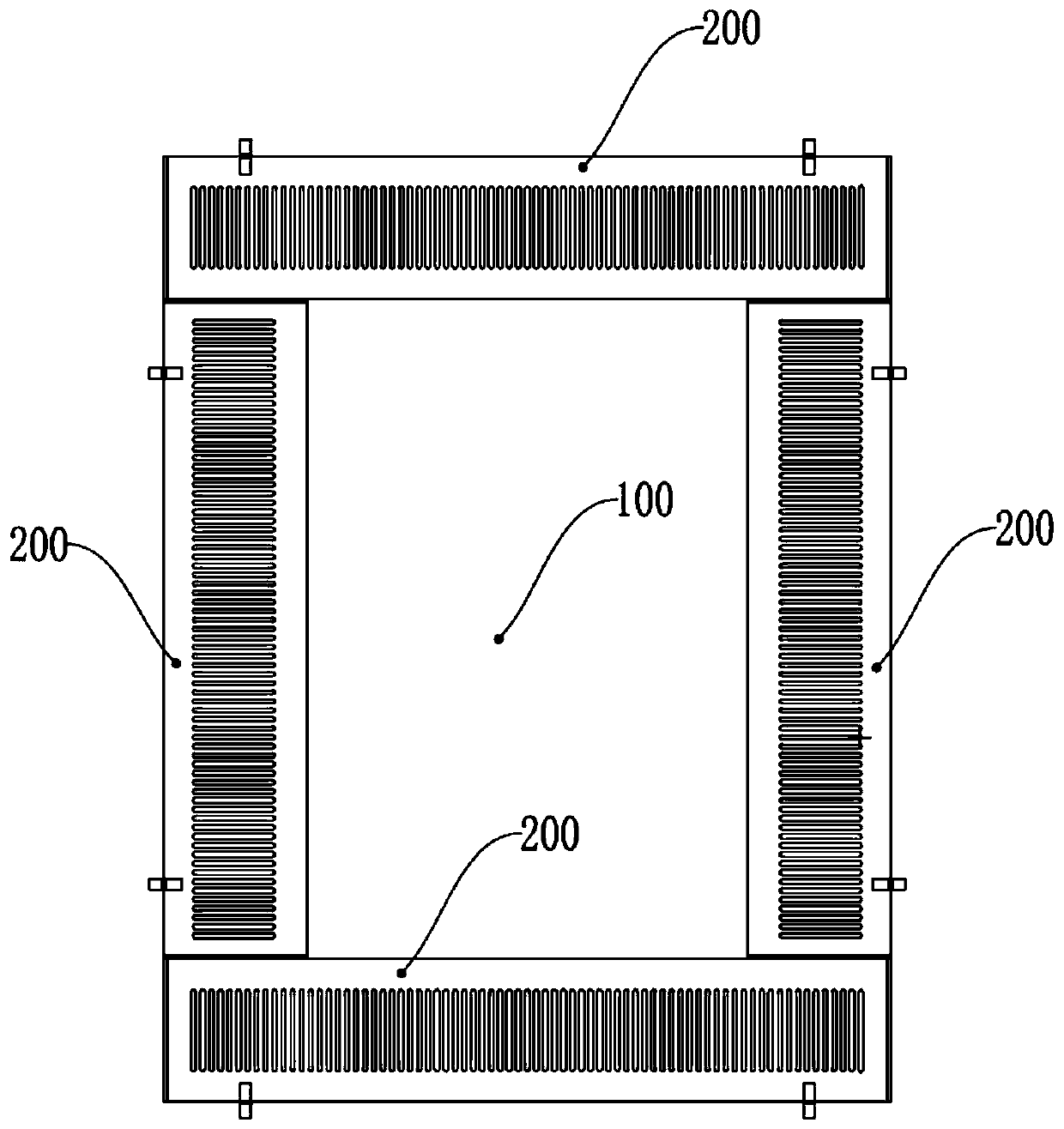

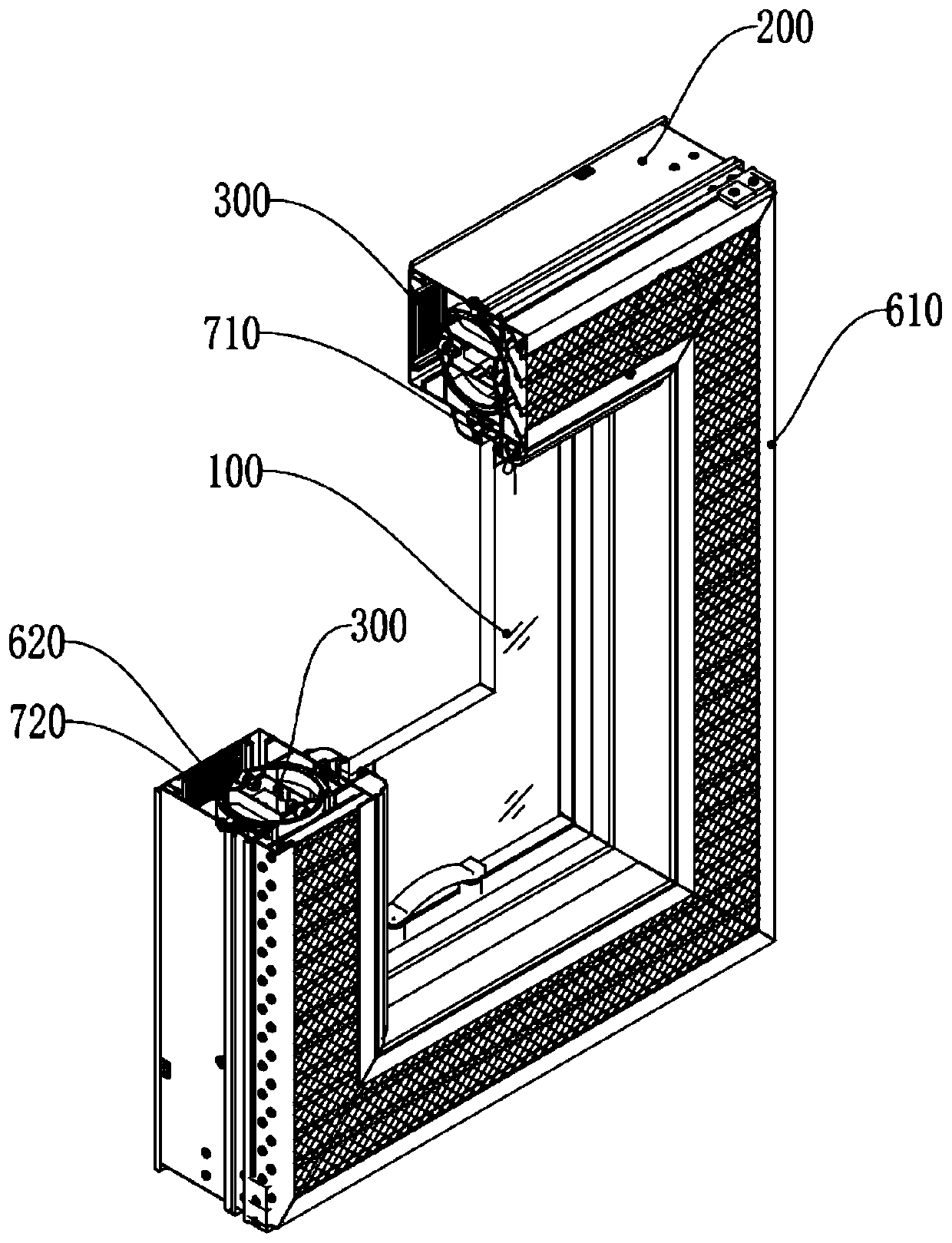

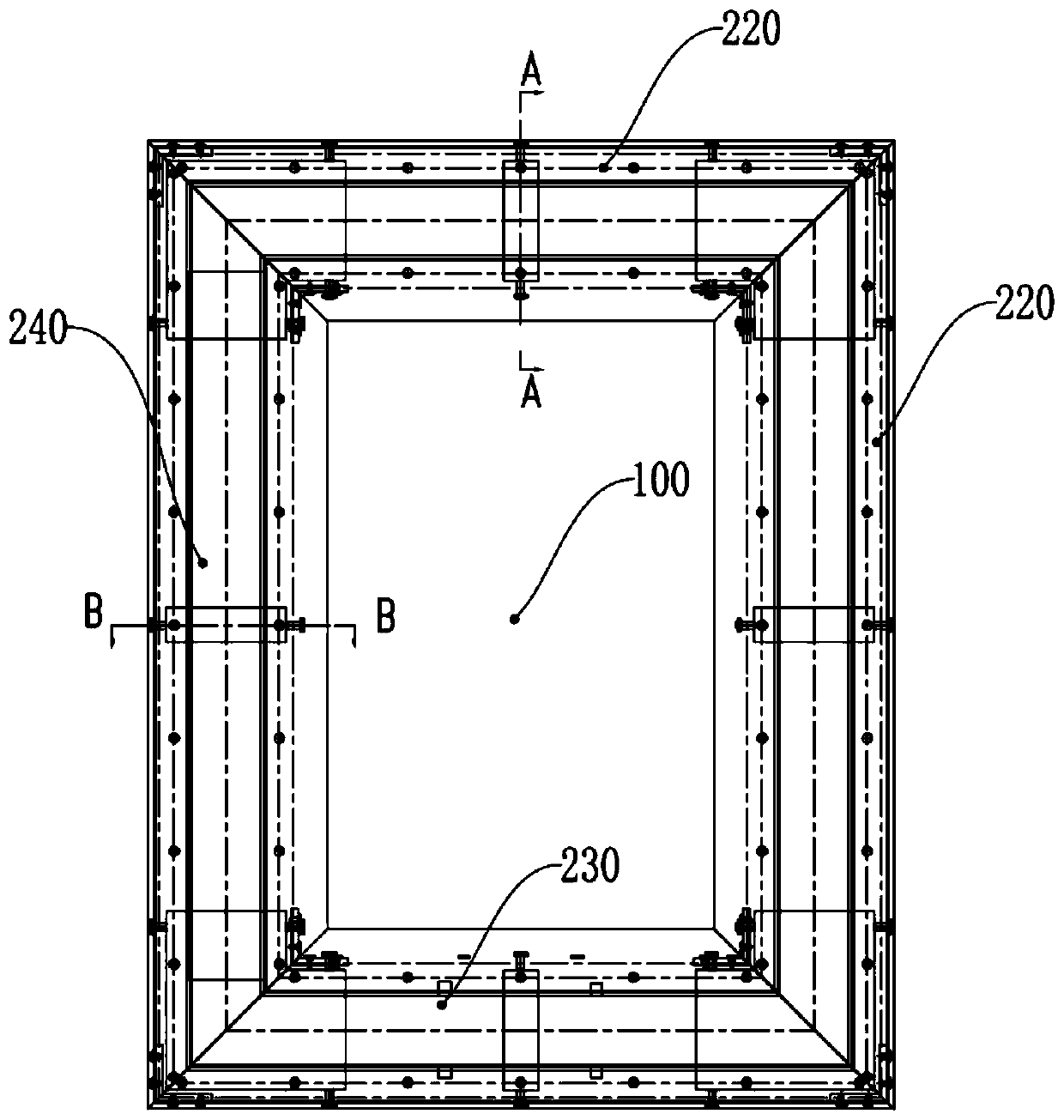

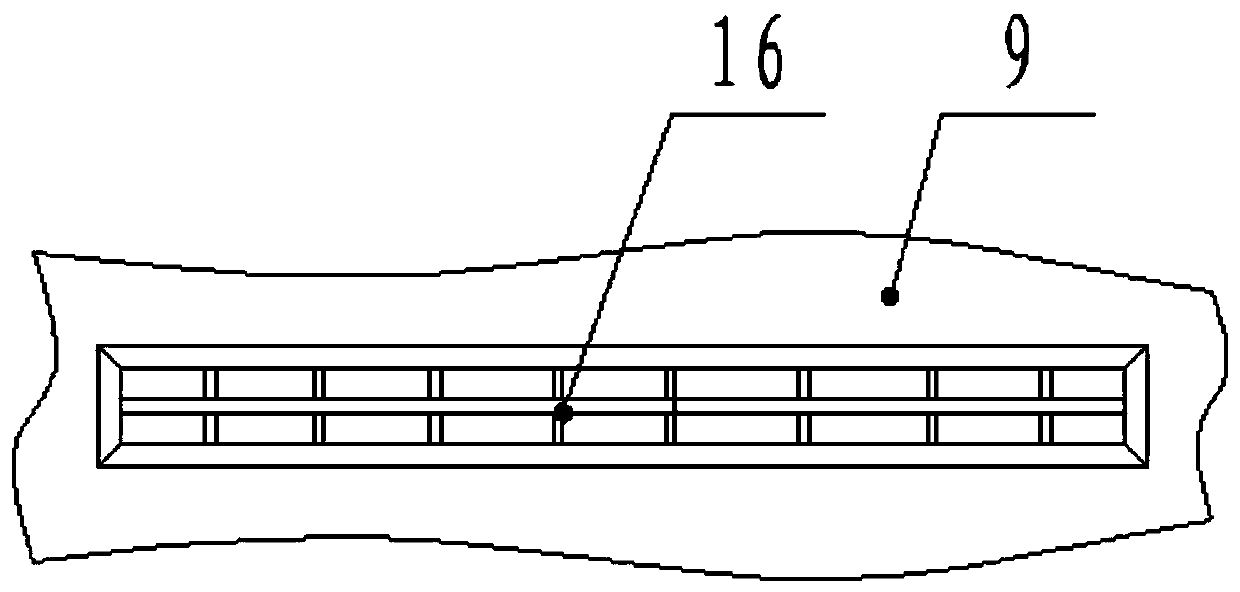

Multifunctional concealed ventilation window

InactiveCN108049761AEnsure appearance consistencyIncrease light transmission areaVentilation arrangementElectrical and Electronics engineeringLight transmission

The invention relates to the field of building windows, in particular to a multifunctional concealed ventilation window which comprises a light transmission region and ventilation window frames. The ventilation window frames are arranged on the periphery of the light transmission region; the light transmission region is provided with barriers made of transparent materials; the ventilation window frames comprise window frame bodies and drum mechanisms; the drum mechanisms comprise drum bodies and transmission mechanisms, and the transmission mechanisms are arranged between the drum bodies in atransmission connection manner; drums can be driven by the transmission mechanisms to rotate, so that drums of ventilation surfaces of the window frames can be blocked or opened. Compared with existing windows, the multifunctional concealed ventilation window has the advantages that the multifunctional concealed ventilation window has large light transmission areas under the condition of identicalareas, and is simple and attractive; the light transmission region of the multifunctional concealed ventilation window and ventilation regions are separated from one another, accordingly, interference can be structurally complementary in ventilation and light transmission use procedures, and the problem of inconvenience in use and the problems in the aspect of safety due to the fact that ventilation only can be carried out if the existing windows are opened can be solved; all ventilation structures are completely concealed, smooth ventilation can be carried out, noise can be reduced, internalstructures of the ventilation window frames can be protected to a great extent, and accordingly the service life of the multifunctional concealed ventilation window can be prolonged.

Owner:王再荣

Grid-reinforced foam sandwich composite material preform and its forming method

ActiveCN112677362BPrecise size controlImprove the convenience of loading and unloadingWeight reductionFiberRail transit

A preform for forming a lattice-reinforced foam sandwich composite material and a forming method thereof. The preform can conveniently and quickly complete the interleaved composite of the discrete foam core material and the dry fiber fabric, and can ensure the dimensional accuracy, overall stability and quality consistency of the finished composite material. The molding process itself is simple in method, convenient in operation, and low in cost, and can realize the integral molding of large-sized grid-reinforced foam sandwich composite materials of not less than 1m*1m. The new composite material sandwich structure can partially replace the existing composite material sandwich structure. , can be widely used in rail transportation, high-speed trains, aerospace, shipbuilding and marine engineering and other fields.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

A multifunctional concealed ventilation window

InactiveCN108049761BEnsure appearance consistencyIncrease light transmission areaVentilation arrangementEngineeringLight transmission

The invention relates to the field of building windows, in particular to a multifunctional concealed ventilation window which comprises a light transmission region and ventilation window frames. The ventilation window frames are arranged on the periphery of the light transmission region; the light transmission region is provided with barriers made of transparent materials; the ventilation window frames comprise window frame bodies and drum mechanisms; the drum mechanisms comprise drum bodies and transmission mechanisms, and the transmission mechanisms are arranged between the drum bodies in atransmission connection manner; drums can be driven by the transmission mechanisms to rotate, so that drums of ventilation surfaces of the window frames can be blocked or opened. Compared with existing windows, the multifunctional concealed ventilation window has the advantages that the multifunctional concealed ventilation window has large light transmission areas under the condition of identicalareas, and is simple and attractive; the light transmission region of the multifunctional concealed ventilation window and ventilation regions are separated from one another, accordingly, interference can be structurally complementary in ventilation and light transmission use procedures, and the problem of inconvenience in use and the problems in the aspect of safety due to the fact that ventilation only can be carried out if the existing windows are opened can be solved; all ventilation structures are completely concealed, smooth ventilation can be carried out, noise can be reduced, internalstructures of the ventilation window frames can be protected to a great extent, and accordingly the service life of the multifunctional concealed ventilation window can be prolonged.

Owner:王再荣

Dumbbell full-buckle mold

The invention discloses a dumbbell full-buckle mold. The dumbbell full-buckle mold comprises a sprue bush, a lower mold, an upper mold and a sleeve type ejector pin; the upper mold is arranged above the lower mold and can move up and down relative to the lower mold, the sleeve type ejector pin comprises an ejector pin body and an ejector sleeve, the ejector sleeve is arranged on the ejector pin body in a sleeving mode and can move up and down relative to the ejector pin body, the ejector pin body is arranged on the lower mold, and the ejector sleeve is used for ejecting a dumbbell full buckle,the lower mold comprises a lower forming plate, the lower forming plate comprises a forming plate body, a runner and a pouring channel, the pouring channel comprises a first pouring gate and a secondpouring gate, the pouring channel is used for communicating a branch runner with a cavity, the sprue bush is arranged on the upper mold, and a discharging port of the sprue bush is located above a main runner. According to the dumbbell full-buckle mold, due to the design of the pouring channel, cutting of the pouring gates is completed during dumbbell full-buckle demolding, the appearance consistency of the pouring gate separation position is guaranteed through automation of pouring gate separation, and the problem that the appearance consistency of the pouring gate separation position cannotbe guaranteed through a traditional manual pouring gate separation technology is solved.

Owner:NANTONG BAIHAI MUNICIPAL FACILITIES

A portable multifunctional mortar troweling device

Owner:江西干圣建设有限公司

Adjustable angle ejector reverse buckle removing mechanism for injection mold and reverse buckle removing method

PendingCN114103019AAvoid pinch wire exposureEnsure appearance consistencyEngineeringStructural engineering

The invention discloses an injection mold adjustable inclined top reverse buckle removing mechanism and a reverse buckle removing method.The reverse buckle removing mechanism comprises a mold core and a mold cavity and further comprises an adjustable reverse buckle removing assembly, the adjustable reverse buckle removing assembly is arranged on the mold core in a sliding mode, and an injection molding cavity with a plurality of reverse buckle structures is formed between the adjustable reverse buckle removing assembly and the mold cavity; and the reverse buckle removing directions of the reverse buckle structures are different, and the adjustable reverse buckle removing assembly moves towards one of the reverse buckle removing directions while moving in the mold opening direction. The clamping wire is prevented from being exposed, and the appearance consistency is guaranteed; the product is locked and driven when the first section is opened, and the inverted buckle is removed when the second section is opened; a two-section mold opening mode is adopted, the first section of mold opening realizes reverse buckle removal of the mold cavity, and the second section of mold opening can simultaneously realize complete opening of the mold cavity and reverse buckle removal of the sliding block, so that the efficiency is improved; the die is simple in structure and easy and convenient to use and operate.

Owner:ZHEJIANG KAIHUA MOLDS

Unlocking mechanism and unlocking key

PendingCN114550347AAvoid interferenceImprove securityKeysElectric permutation locksLocking mechanismEngineering

The invention provides an unlocking mechanism and an unlocking key. The unlocking mechanism comprises a shell and a locking mechanism, the unlocking piece assembly is provided with a working position extending out of the shell and a retracting position retracting into the shell; the screw rod is in threaded transmission fit with the unlocking piece assembly and can drive the unlocking piece assembly to move between a working position and a withdrawing position; the driving assembly is in driving connection with the screw rod and can drive the screw rod to rotate; the authorization assembly and the unlocking piece assembly move synchronously, and the authorization assembly can unlock the lock cylinder through magnetic force; the fixed electrode is arranged in the shell and can be electrically connected with or separated from the authorization assembly, when the unlocking piece assembly is located at the withdrawing position, the authorization assembly is separated from the fixed electrode, and the authorization assembly is not electrified, and when the unlocking piece assembly is located at the working position, the authorization assembly is electrically connected with the fixed electrode, and magnetic force is generated after the authorization assembly is electrified. The computer key solves the problem of low safety of a computer key in the prior art.

Owner:ZHUHAI UNITECH POWER TECH CO LTD

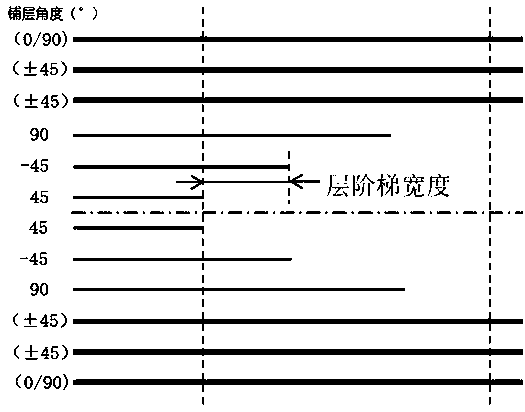

Carbon fiber composite material automobile front floor, manufacturing method thereof, and automobile

ActiveCN111516761ARealize integrated designGuaranteed accuracySuperstructure subunitsDomestic articlesEngineeringFibrous composites

The invention discloses a carbon fiber composite material automobile front floor. The front floor comprises a front floor body integrally made of a carbon fiber composite material, the front floor body is an integral paving layer, a plurality of reinforcing paving layers are clamped in the integral paving layer corresponding to a central channel area, and the edges of the plurality of reinforcingpaving layers in the width direction of an automobile body are in stepped transition; the whole paving layer is made of carbon fiber fabric, each reinforcing paving layer is made of carbon fiber one-way cloth, the process paving performance of the carbon fiber composite material and the light weight of the automobile front floor can be coordinated, and the weight reduction effect is more obvious on the premise that the performance is guaranteed. The invention further discloses a manufacturing method of the carbon fiber composite material automobile front floor. The manufacturing method comprises the following steps: S1, the carbon fiber fabric and the carbon fiber one-way cloth are cut; S2, paving is carried out in a mold according to a designed paving area and a paving angle; S3, die assembly and pressurization are conducted, and then heating and curing are conducted; and S4, after curing is completed, demolding is conducted. The invention further discloses a vehicle comprising the carbon fiber composite material automobile front floor.

Owner:CHONGQING CHANGAN AUTOMOBILE CO LTD

Functional component, electronic device and control method thereof

ActiveCN109962999BAvoid damageEnsure appearance consistencyTelephone set constructionsMotor driveElectric machinery

The invention discloses a functional assembly. The functional assembly comprises a shell, a sliding base, a buffer bag, a shifting wheel and a motor. Wherein the sliding seat is telescopically connected to the shell in a sliding mode, a camera module and supporting legs are arranged on the sliding seat, the sliding way comprises a containing section and an ejection section, and the supporting legsextend into the ejection section. The motor drives the dial wheel to rotate, the dial wheel pushes the buffer bag contained in the containing section into the ejection section, and the buffer bag pushes the supporting legs in an extruded mode, so that the sliding base carries the camera module to stretch out of the shell. The buffer bag serves as an ejection functional part of the functional assembly and also serves as buffer protection of the camera module after ejection, and falling is prevented. The electronic device comprising the functional assembly can hide functional devices in the shell. The invention further discloses an electronic device and a control method thereof, and the user experience is improved.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

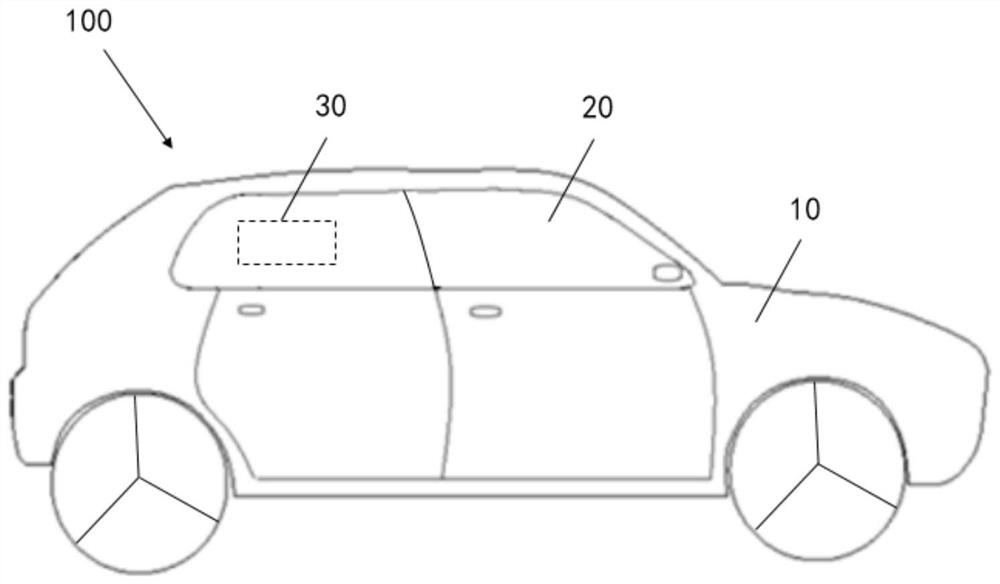

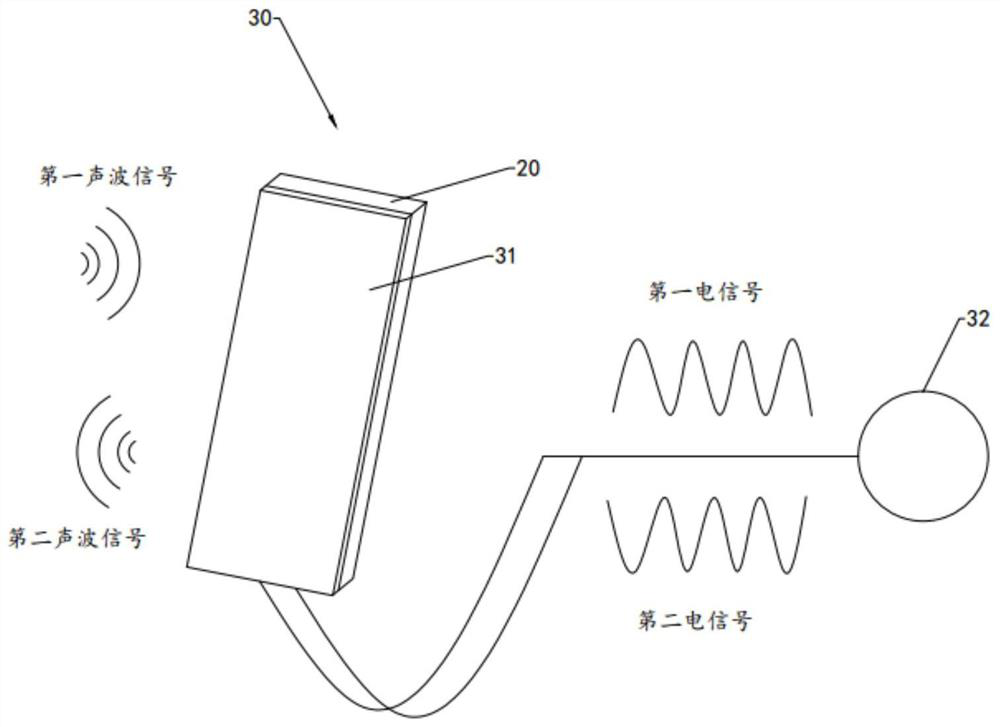

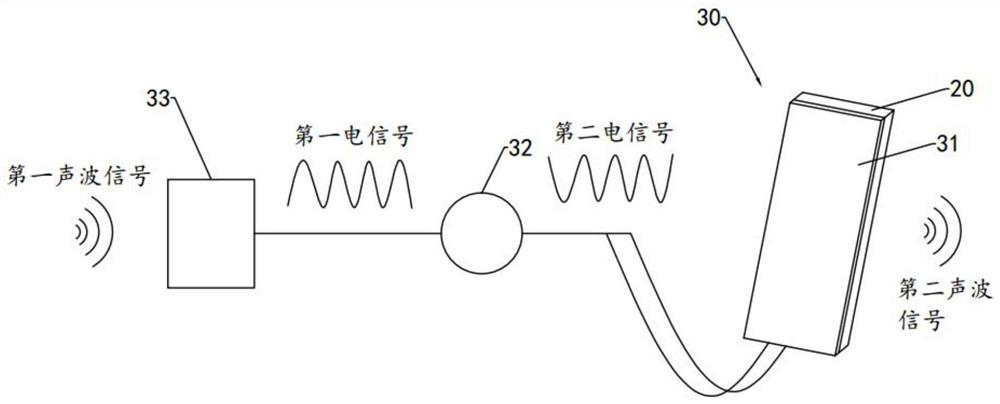

Noise reduction device and vehicle

The invention discloses a noise reduction device and a vehicle. The noise reduction device comprises a piezoelectric film and a circuit module. The circuit module is electrically connected to the piezoelectric film. The circuit module is used for receiving a first electric signal converted from a first sound wave signal, converting the first electric signal into a second electric signal and transmitting the second electric signal to the piezoelectric film, and the first sound wave signal is an external sound wave signal of the noise reduction device. The piezoelectric film is used for forminga second sound wave signal according to the second electric signal and transmitting the second sound wave signal out of the noise reduction device, and the phase of the second sound wave signal is opposite to that of the first sound wave signal. The noise reduction device is small in size and small in occupied space. When the noise reduction device is applied to the vehicle, the space utilizationrate of the vehicle is high.

Owner:ANHUI JINGZHUO OPTICAL DISPLAY TECH CO LTD

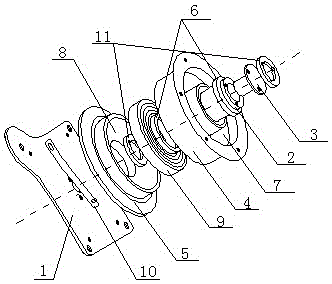

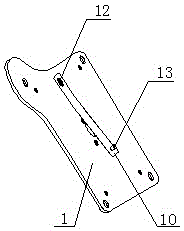

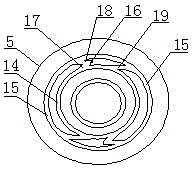

Cable telescoping mechanism with segmentally stopping function

The invention discloses a cable telescoping mechanism with a segmentally stopping function, and belongs to the field of mechanical structure design. A structure of the cable telescoping mechanism comprises a fixing plate, a connecting piece, an upper cable-winding rotary plate and a lower cable-winding rotary plate, wherein the connecting piece is fixedly connected with the fixing plate; the upper cable-winding rotary plate and the lower cable-winding rotary plate are fixedly connected with the connecting piece respectively through a bearing, so that relatively smooth rotation between the connecting piece and the upper cable-winding rotary plate and between the connecting piece and the lower cable-winding rotary plate is achieved; a cable is wound around the upper cable-winding rotary plate; a spiral spring is arranged between the upper cable-winding rotary plate and the lower cable-winding rotary plate, the inner end of the spiral spring is connected with the connecting piece, and the outer end of the spiral spring is partially connected with the upper cable-winding rotary plate and the lower cable-winding rotary plate; besides, a spring pin is arranged on the fixing plate, one end of the spring pin is rotatably connected with the fixing plate, and the other end of the spring pin is in mutual movement matching with the lower cable-winding rotary plate, so that free switching between self locking and back rotation in a cable rotation process is achieved. According to the cable telescoping mechanism with the segmentally stopping function, the free switching between the self locking and the back rotation in the cable rotation process can be achieved; besides, the quality of electrical signals is effectively ensured; the cable telescoping mechanism has the advantages of reasonable structural design, novel conception, firmness in connection and convenience in use.

Owner:INSPUR QILU SOFTWARE IND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com