Processing technology of butter honey nuts

A processing technology and nut technology, applied in the field of butter honey nut processing technology, can solve the problem of single taste of coated nuts, and achieve the effects of ensuring appearance consistency, convenience and mobilization, and delaying aging.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

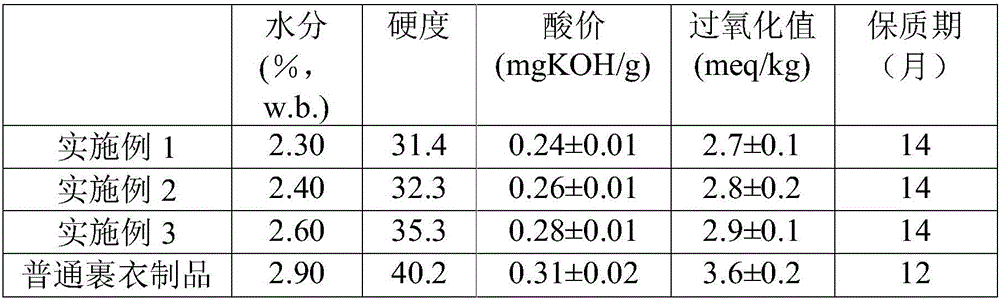

Examples

Embodiment 1

[0033] Nut products use flat almonds, and the processing technology of butter honey flat almonds includes the following steps:

[0034] (1) Prepare coating solution: prepare coating solution according to the mass percentage of nuts at 5%, and the coating solution is composed of 55% hot water with a water temperature of 60°C, 3% xanthan gum, 30% white granulated sugar and 12% honey, after mixing xanthan gum and auxiliary materials, add in a high-shear machine equipped with hot water and stir evenly, and set aside;

[0035] (2) Preparation of pre-powder and post-powder: take 8% white sugar and 4% maltodextrin according to the mass percentage of nuts, mix and stir evenly to prepare the front powder; take 1% salt and 1% white sugar according to the mass percentage of nuts Mix and stir evenly to obtain the back powder;

[0036] (3) Spray coating: The inner wall of the coating cylinder is equidistantly provided with truncated conical protrusions, which are arranged in an S-shape stag...

Embodiment 2

[0044] Almonds are selected as nut products, and the processing technology of butter honey almonds includes the following steps:

[0045] (1) Prepare coating liquid: prepare coating liquid according to the mass percentage of nuts at 5%, and the coating liquid is composed of: 60.5% hot water, 2.5% xanthan gum, 27% white granulated sugar, 10 % honey, after mixing xanthan gum and auxiliary materials, add in the high-shear machine that hot water is housed and stir evenly, stand-by;

[0046] (2) Preparation of pre-powder and post-powder: take 10% white sugar and 5% maltodextrin according to the mass percentage of nuts, mix and stir evenly to prepare the front powder; take 1.5% salt and 1.5% white sugar according to the mass percentage of nuts Mix and stir evenly to obtain the back powder;

[0047] (3) Spray coating: The inner wall of the coating cylinder is equidistantly provided with truncated conical protrusions, which are arranged in an S-shape staggered along the horizontal an...

Embodiment 3

[0055] Nut products use hazelnut kernels, butter honey hazelnut kernel processing technology, specifically including the following steps:

[0056] (1) Preparation of coating solution: prepare coating solution according to the mass percentage of nuts at 5%, and the coating solution is composed of: 65% hot water with a water temperature of 70°C, 2% xanthan gum, 25% white granulated sugar and 8% honey, after mixing xanthan gum and auxiliary materials, add in a high-shear machine equipped with hot water and stir evenly, and set aside;

[0057] (2) Preparation of pre-powder and post-powder: take 12% white sugar and 6% maltodextrin according to the mass percentage of nuts, mix and stir evenly to prepare the front powder; take 2% salt and 3% white sugar according to the mass percentage of nuts Mix and stir evenly to obtain the back powder;

[0058] (3) Spray coating: The inner wall of the coating cylinder is equidistantly provided with truncated conical protrusions, which are arrang...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com