Grid-reinforced foam sandwich composite material preform and its forming method

A technology for enhancing foam and foam core materials, applied in the direction of weight reduction, etc., can solve the problems of high manufacturing cost and unsuitability for industrial applications, and achieve the effects of low manufacturing cost, improved convenience of loading and unloading, and easy assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

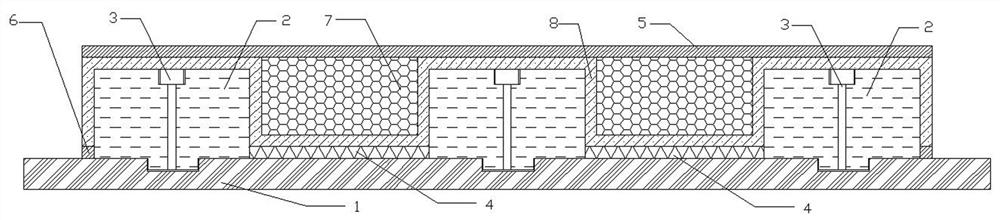

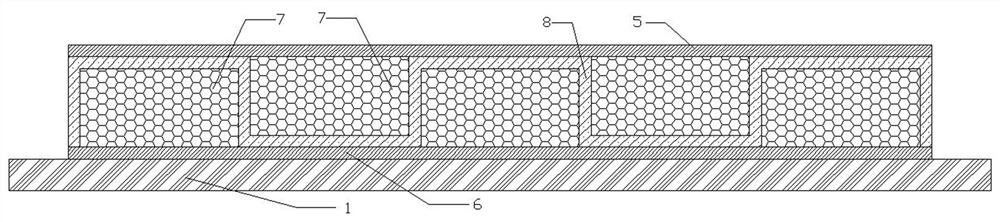

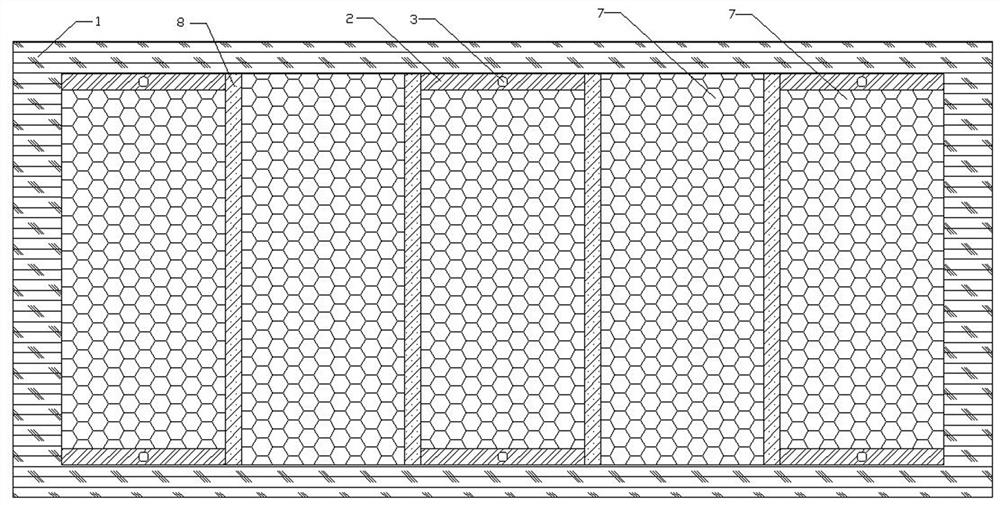

[0059] The preparation of the preform relies on the flat auxiliary mold, including the laying of the upper panel 5 and the lower panel 6, the laying of the foam core strip 7, the dry fiber fabric 8 (after resin infiltration molding is the composite grid). structure), etc. The thickness of the lower panel 6 is the same as that of the silicone gasket 4, which is laid on the metal base plate 1 at a position between the two fence-like structures, and above the lower panel 6, staggered foam core strips 7 and drywalls are arranged. State fiber fabric 8.

[0060] The forming method of the lattice reinforced foam sandwich composite material comprises the following steps:

[0061] (1) Preparation of metal base plate 1

[0062] The metal base plate 1 is placed flat on a horizontal operating table. After that, use alcohol or acetone to clean the upper surface and the card slot of the metal base plate 1. After cleaning and drying, apply mold release wax to the upper surface and the card...

Embodiment 1

[0090] combined with Figure 7 and 8 , the shape of the longitudinal section of the positioning block in the grid-reinforced foam sandwich composite material in this embodiment is a rectangle. Among them, the number of positioning blocks with rectangular longitudinal section is 12 pairs of 24, the length is 40mm, the width is 15mm, and the height is 28.5mm. The adjacent spacing between the positioning blocks is 40.8mm. The type of tightening bolt is M8, and the metal base plate is 1150mm long, 1150mm wide and 20mm thick.

[0091] The upper and lower panels are 929mm long, 920mm wide and 3.5mm thick, the dry fiber fabric in the grid structure is 950mm wide and 0.4mm thick, and the number of foam core strips with a rectangular longitudinal section is 23, with a length of 950mm (11) and 920mm (12) two kinds, width 40mm, height 25mm.

[0092] The metal base plate and positioning block are made of 6061 aluminum alloy, and the locking bolts are made of 12.9 grade high-strength st...

Embodiment 2

[0096] combined with Figure 9 and 10 , the shape of the longitudinal section of the positioning block in the grid-reinforced foam sandwich composite material in this embodiment is an isosceles trapezoid. Among them, the number of positioning blocks whose longitudinal section is an isosceles trapezoid is 15 pairs of 30, the upper bottom is 20 mm, the lower bottom is 66.2 mm, the width is 20 mm, and the height is 42.6 mm. 20mm, thickness 2.6mm, locking bolt type is M10, metal base plate is 1500mm long, 1300mm wide and 25mm thick.

[0097] The length of the upper panel is 1233mm, the length of the lower panel is 1279mm, the width of the upper panel and the lower panel are both 1030mm, and the thickness is 2.6mm. There are 29 pieces, 1070mm long (14 pieces) and 1030mm (15 pieces), the upper base is 20mm, the lower base is 66.2mm, and the height is 40mm.

[0098] The metal base plate and positioning block are made of 45# steel, and the locking bolts are made of 42# chrome-manga...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| surface smoothness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com