Injection mold pitched roof vibrating needle linkage mechanism and inverted buckle removing method

An injection mold and linkage mechanism technology, applied in the field of molds, can solve the problems of sticking to the sloping roof, affecting the appearance, affecting the demoulding, etc., and achieves the effect of simple and convenient operation, avoiding the exposure of the clamping line, and effectively tripping the buckle.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

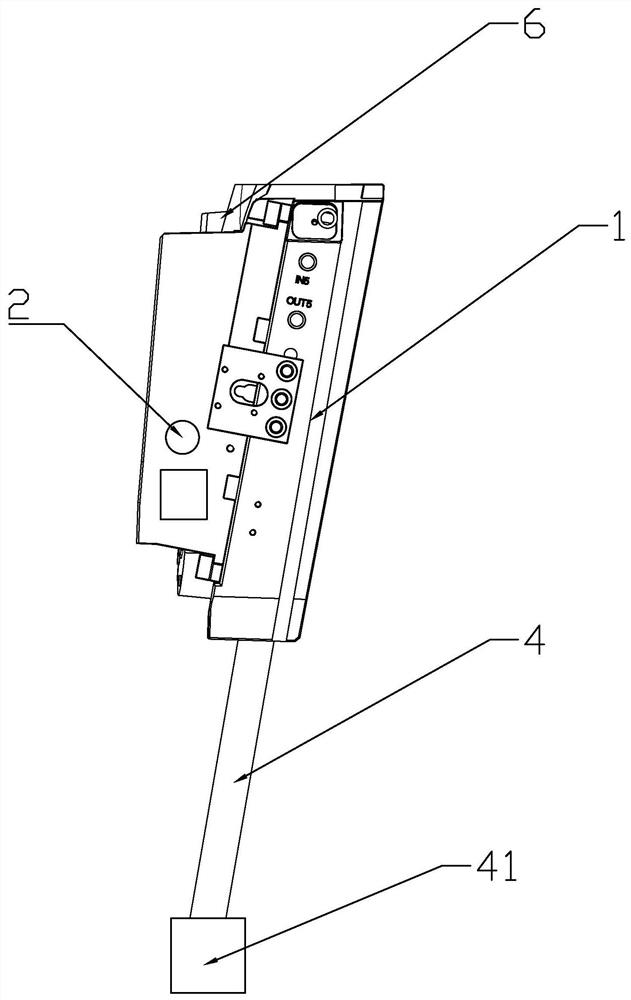

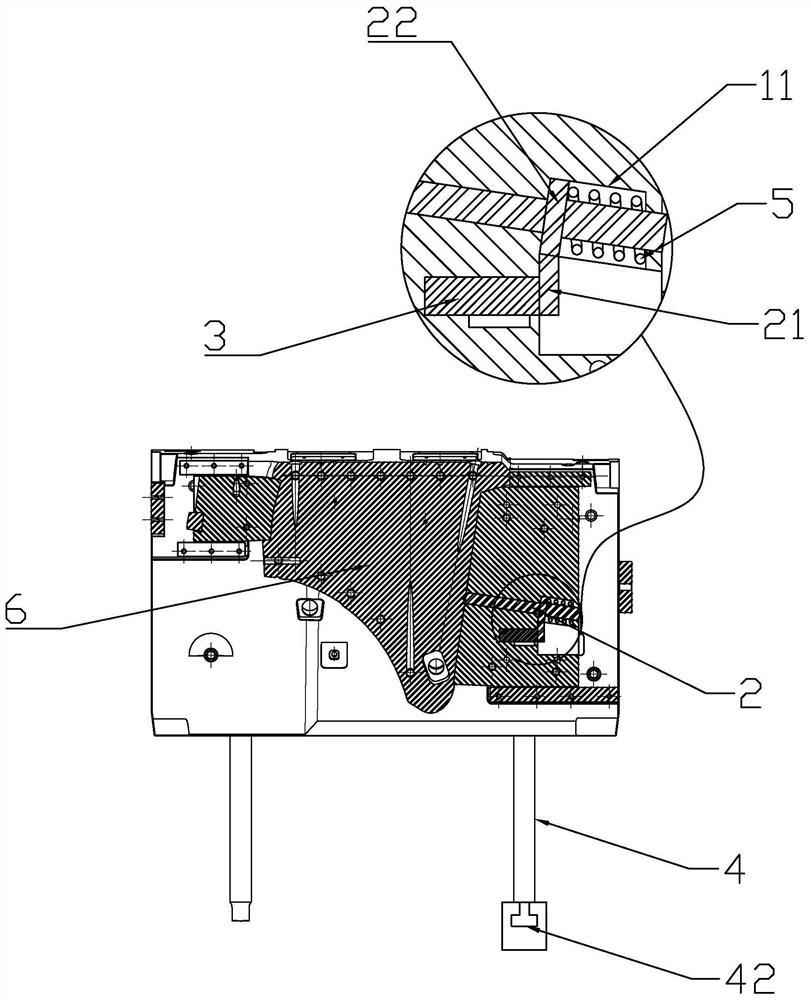

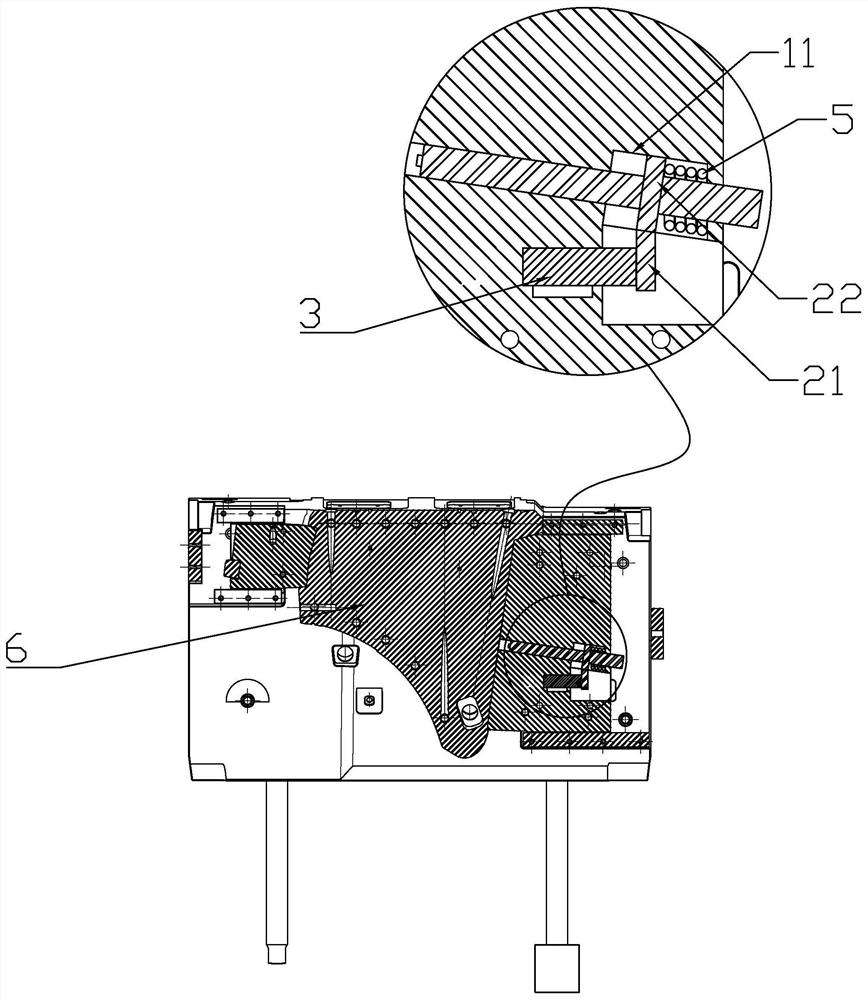

[0028] like figure 1 , figure 2 As shown, an injection mold inclined ejector pin linkage mechanism includes:

[0029] Inclined roof 1, one side of the inclined roof 1 is inclined and slidably arranged on the core, and an injection cavity is formed between the other side of the inclined roof 1 and the cavity. The entire inclined roof 1 has a plate-like structure, such as figure 1 As shown, the inclined top 1 moves to the right while moving along the mold opening direction (upward). Since the product 6 in the figure has an undercut structure on the left side, the first step of undercutting is realized. like figure 2 , image 3 As shown, the inclined top 1 is lateral to the chute 11, and the spring pin 2 is slid in the chute 11, and the top of the spring pin 2 is set corresponding to the undercut structure on the side of the product 6. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com