Carbon fiber composite material automobile front floor, manufacturing method thereof, and automobile

An automobile front floor and composite material technology, which is applied in the field of carbon fiber composite automobile front floors, can solve the performance requirements and layability requirements of parts that cannot support the front floor, and does not mention the overall layup and reinforcement layup design and other problems , to achieve the effect of improving the process coverage, ensuring the process coverage and reducing the mold

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Embodiment 1, a method for manufacturing a carbon fiber composite car front floor, which includes the following steps:

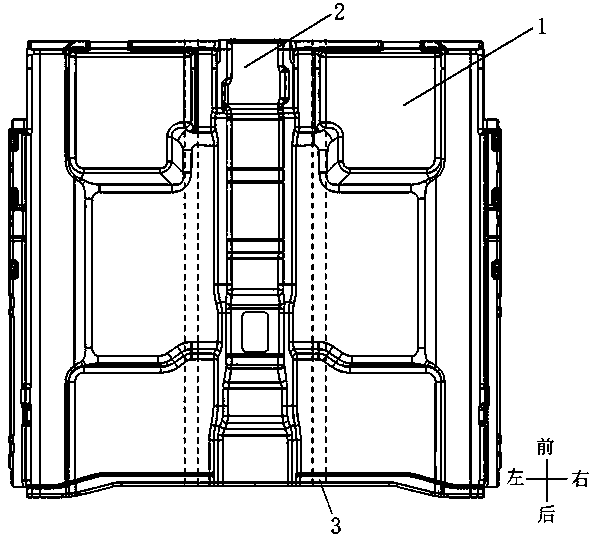

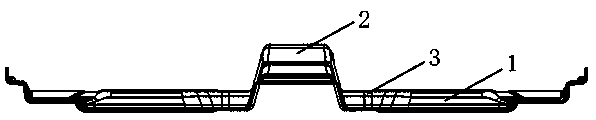

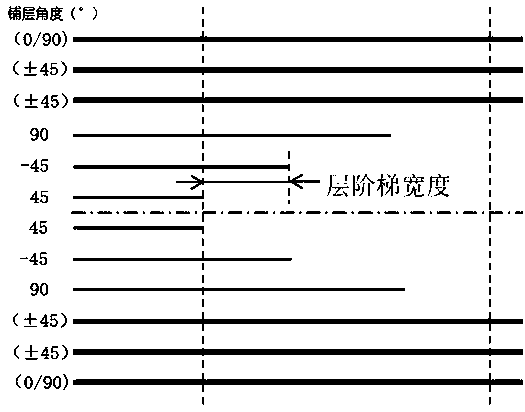

[0034] S1, cutting carbon fiber fabrics and carbon fiber unidirectional fabrics according to the shape of the front floor of the car and different lay-up areas, wherein the front floor body 1 is an integral lay-up, and multiple reinforcements are interposed in the overall lay-up corresponding to the central passage 2 area As for the laying layer, the edges of the plurality of reinforcing laying layers in the width direction of the vehicle body are in a step transition. Taking the direction of the front of the car as the direction of 0°, the overall layup is made of carbon fiber fabric, and the layup angle is [(0 / 90) / (±45) / (±45) / (±45) / (±45) / ( 0 / 90)]. The reinforced layup is made of carbon fiber unidirectional fabric, and the layup angle is [90 / -45 / 45 / 45 / -45 / 90].

[0035] S2, laying the cut carbon fiber fabric and carbon fiber unidirectional fabric in...

Embodiment 2

[0039] Embodiment 2, a method for manufacturing a carbon fiber composite automobile front floor, which includes the following steps:

[0040] S1, cutting carbon fiber fabrics and carbon fiber unidirectional fabrics according to the shape of the front floor of the car and different lay-up areas, wherein the front floor body 1 is an integral lay-up, and multiple reinforcements are interposed in the overall lay-up corresponding to the central passage 2 area As for the laying layer, the edges of the plurality of reinforcing laying layers in the width direction of the vehicle body are in a step transition. Taking the direction of the front of the car as the direction of 0°, the overall lay-up is made of carbon fiber fabric, and the lay-up angle is [(±45) / (0 / 90) / (0 / 90) / (0 / 90) / (0 / 90 ) / (±45)]. The reinforced layer is made of carbon fiber unidirectional fabric, and the angle of the layer is [-45 / 0 / 45 / 45 / 0 / -45].

[0041] S2, laying the cut carbon fiber fabric and carbon fiber unidirec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com