Automatic grinding device for aluminum alloy parts of high-speed rail overhead line system

A technology for aluminum alloys and parts, which is applied in the field of automatic grinding equipment for aluminum alloy parts of high-speed railway catenary, which can solve the problems of low production efficiency and low safety factor, and achieve the effects of improving efficiency, reducing dust hazards, and improving competitiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0056] The present invention will be described in further detail below in conjunction with specific examples, but the embodiments of the present invention are not limited thereto.

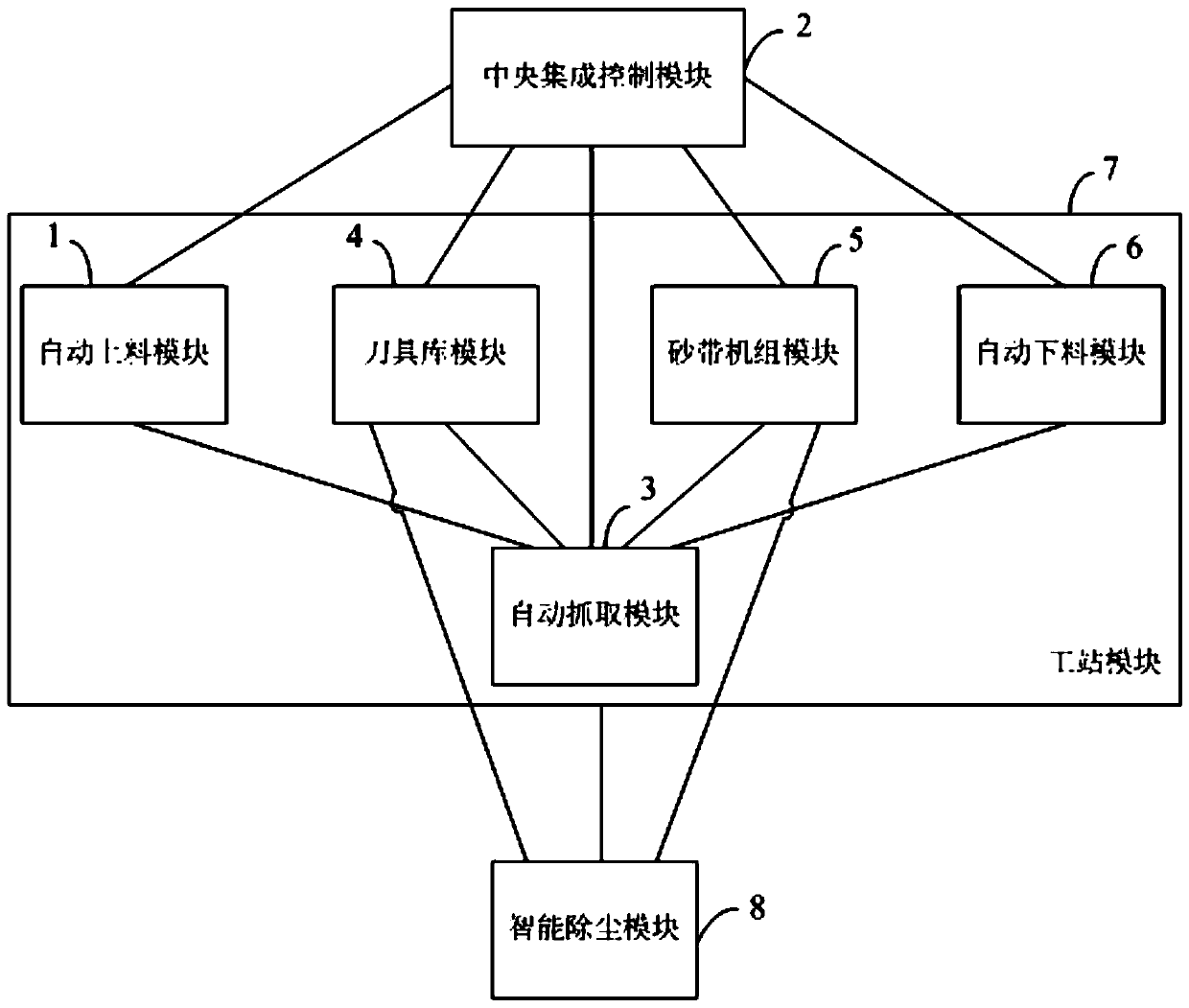

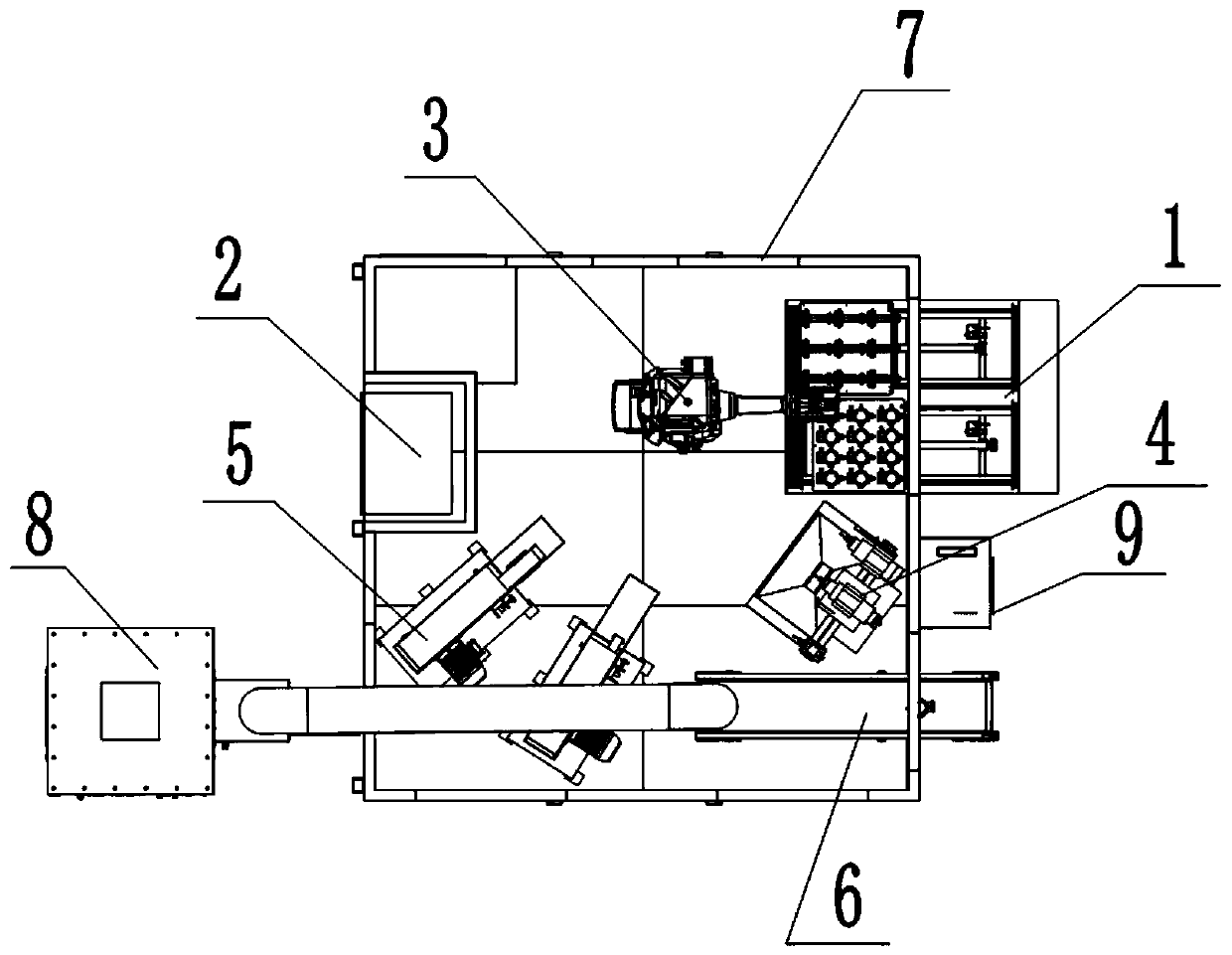

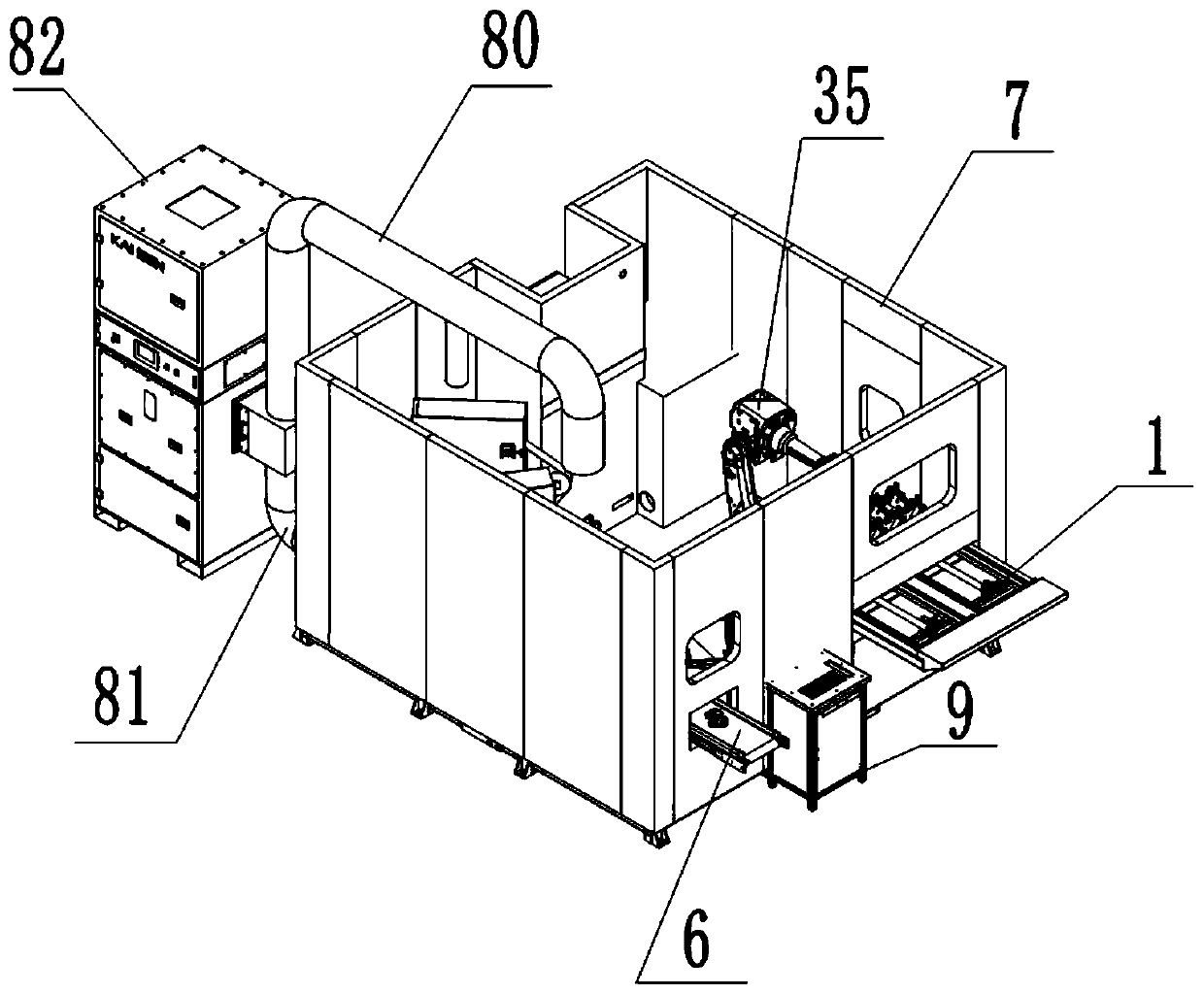

[0057] See also figure 1 , figure 2 and image 3 , the embodiment of the present invention provides a kind of high-speed rail catenary aluminum alloy parts automatic grinding equipment, this equipment comprises:

[0058] Automatic loading module 1, central integrated control module 2, automatic grasping module 3, tool module 4, abrasive belt unit module 5, automatic unloading module 6, workstation module 7 and intelligent dust removal module 8; among them,

[0059] The station module 7 is a rectangular shell structure, the automatic feeding module 1 is located in the front right side of the station module 7, and partially extends out of the station module 7; the automatic grabbing module 3 is located in the station module 7, and is connected with the automatic The loading module 1 is arranged o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com