Patents

Literature

63results about How to "Improve safety production efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

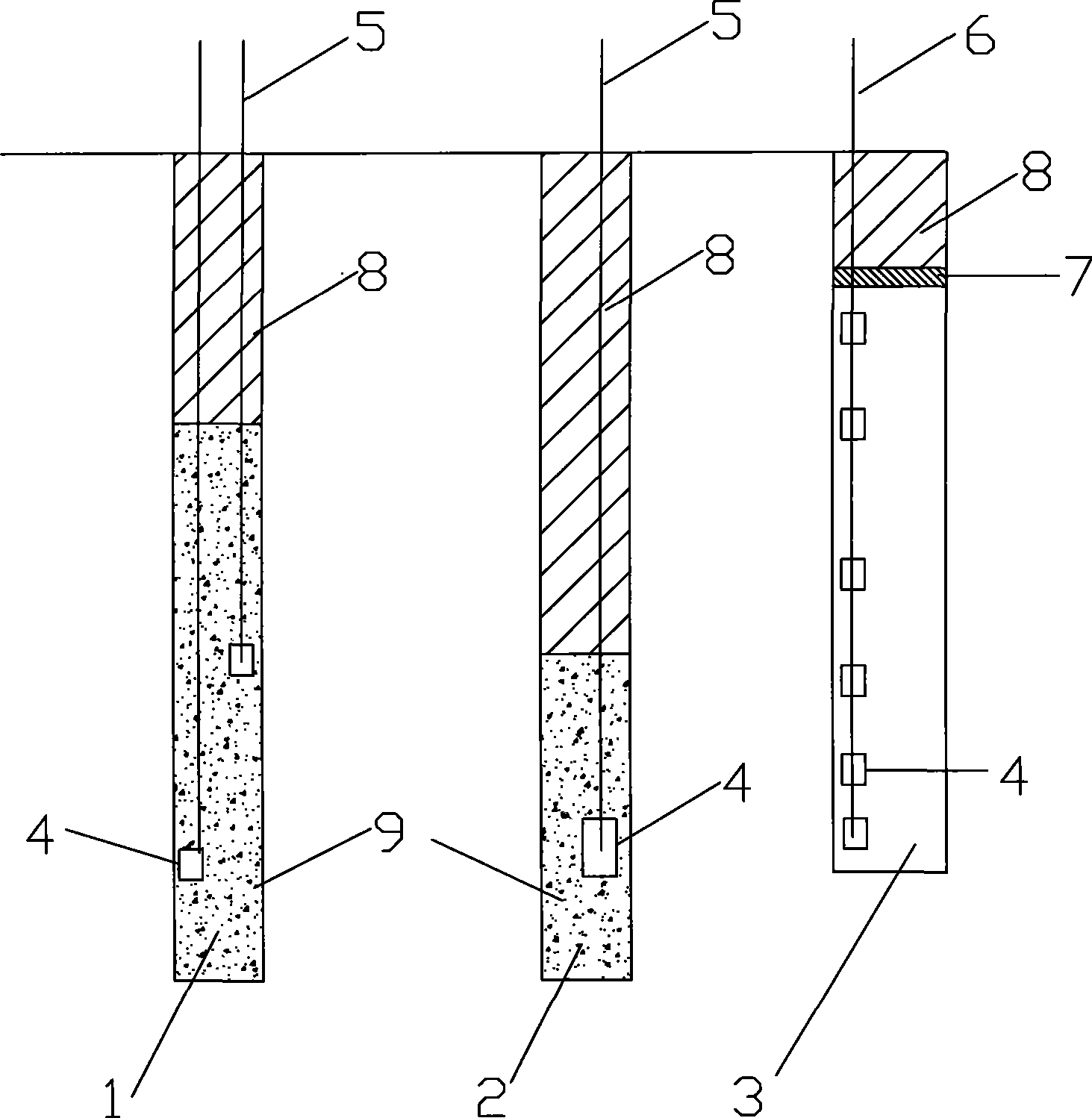

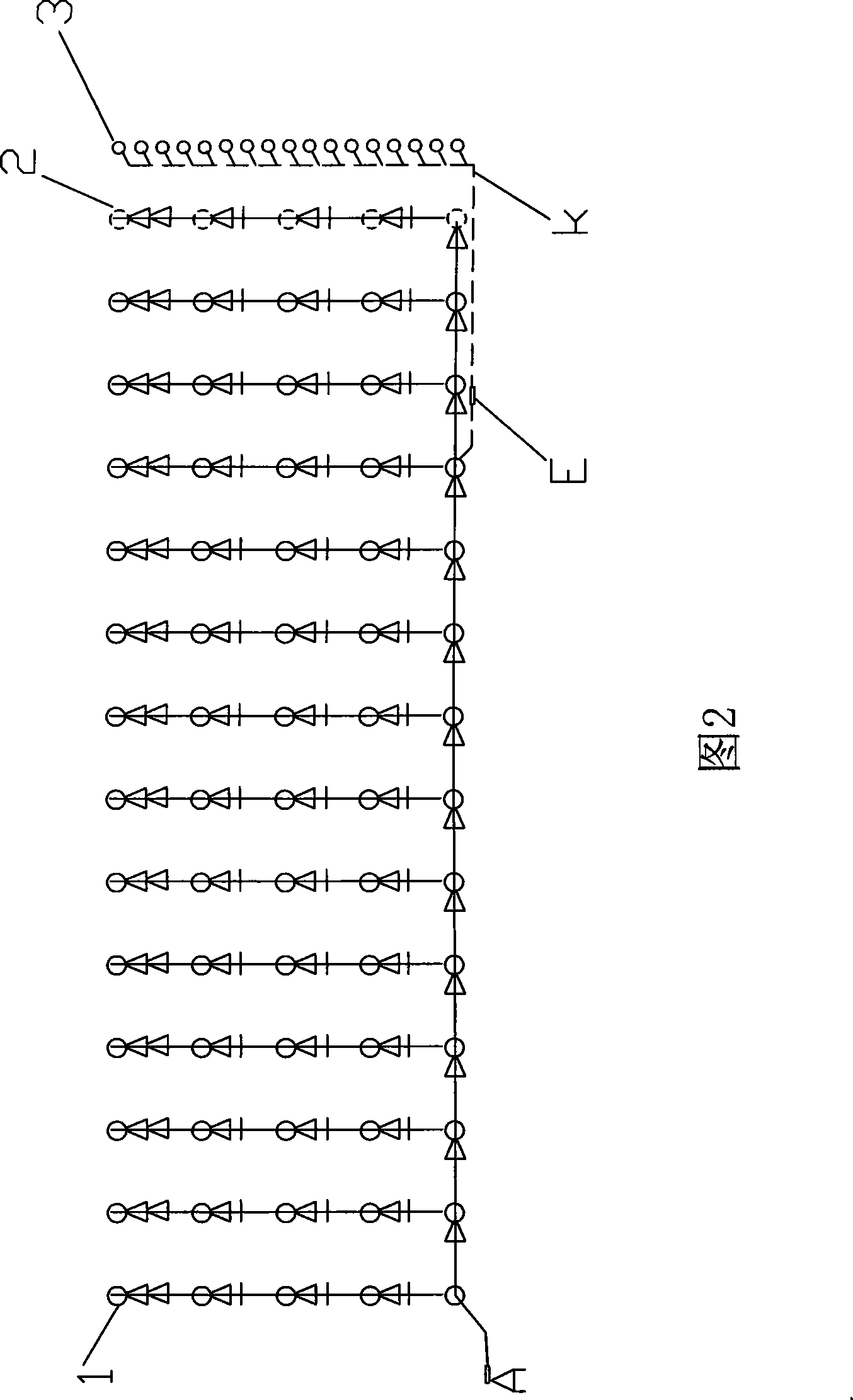

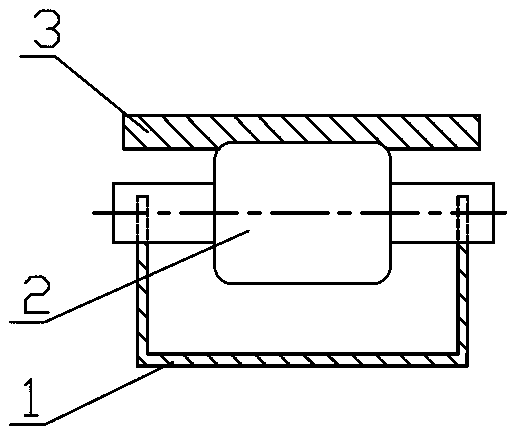

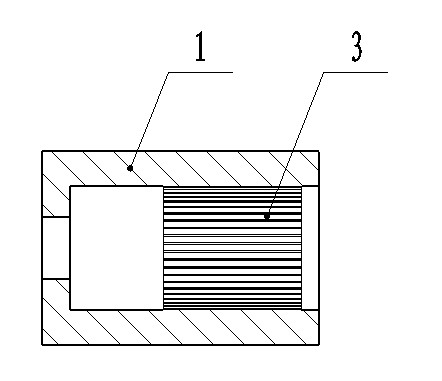

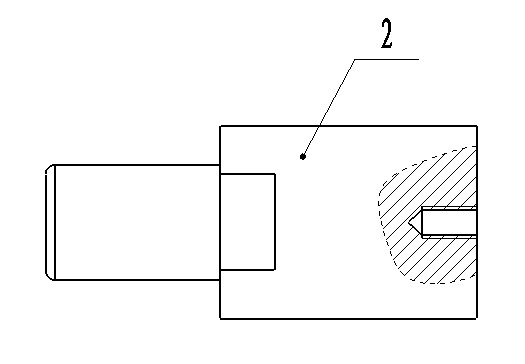

Presplit blasting method

The invention relates to a presplitting explosion method. A row of presplitting holes (3) with small diameters are drilled along designed excavation profile between the exploitation region and the boundary slope. Cushion holes (2) are designed parallel to the presplitting holes (3) and disposed between a main blast hole (1) and presplitting holes (3). The specific steps are as follows: a. determining parameters of the presplitting explosion holes, drilling; b. determining matched explosive load, loaded constitution, loaded ingredients, pack height and explosion initiation manner, implementing explosion. The invention is adaptive to explosion construction of highway cutting, large-scale hydropower station, metal mine exposed for long time. Integrality and stability of boundary rock mass are protected, occurrence of landslip is prevented, good and safe production environment is provided for mine, and good social efficiency and economic efficiency are provided.

Owner:CHINACOAL PINGSHUO GRP

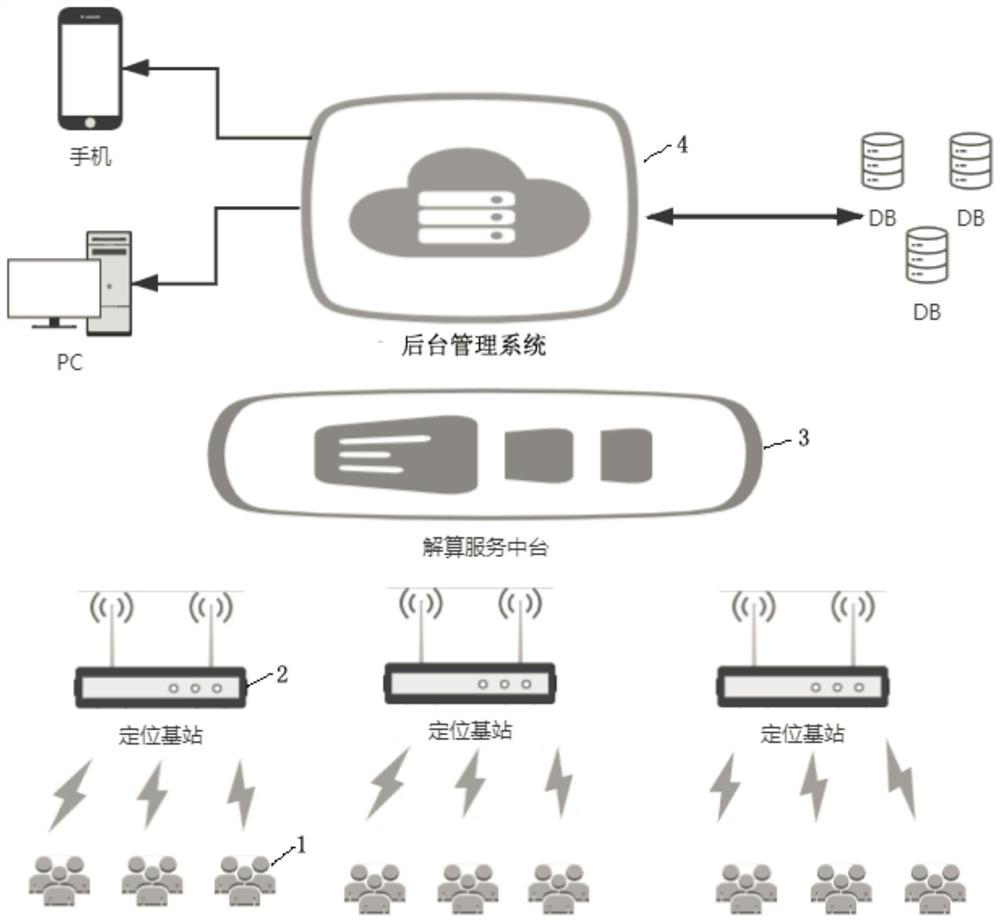

Positioning device and system for real-time monitoring of construction site personnel information

InactiveCN111615059AAvoid safety accidentsReduce frequencyAlarmsTransmissionEmbedded systemElectronic map

The invention relates to a positioning device and system for real-time monitoring of construction site personnel information. The system comprises a positioning label attached to a constructor, a positioning base station, a resolving service center station and a background management system. The positioning label is attached to a safety helmet; the positioning label enters a signal coverage rangeof the positioning base station and automatically establishes connection with the positioning base station, and the positioning base station completes acquisition of positioning data according to a built-in rule, transmits the positioning data to a resolving service center through data message middleware for resolving, calculates an actual position of the positioning label and stores the actual position into an entity database; the background management system displays the positions of all people in the area in real time through an electronic map, monitors the dynamic state of people, and masters the number of people and the real-time distribution condition. Based on equipment information collection and reporting, the functions of personnel positioning, track playback, intelligent uncapping detection, safety helmet unwearing monitoring and the like are achieved, safety accidents caused by personnel retention negligence are effectively eradicated, and the construction site safety accident occurrence frequency is reduced.

Owner:JIANGSU CHINA NUCLEAR IND HUAWEI ENGDESIGN & RES

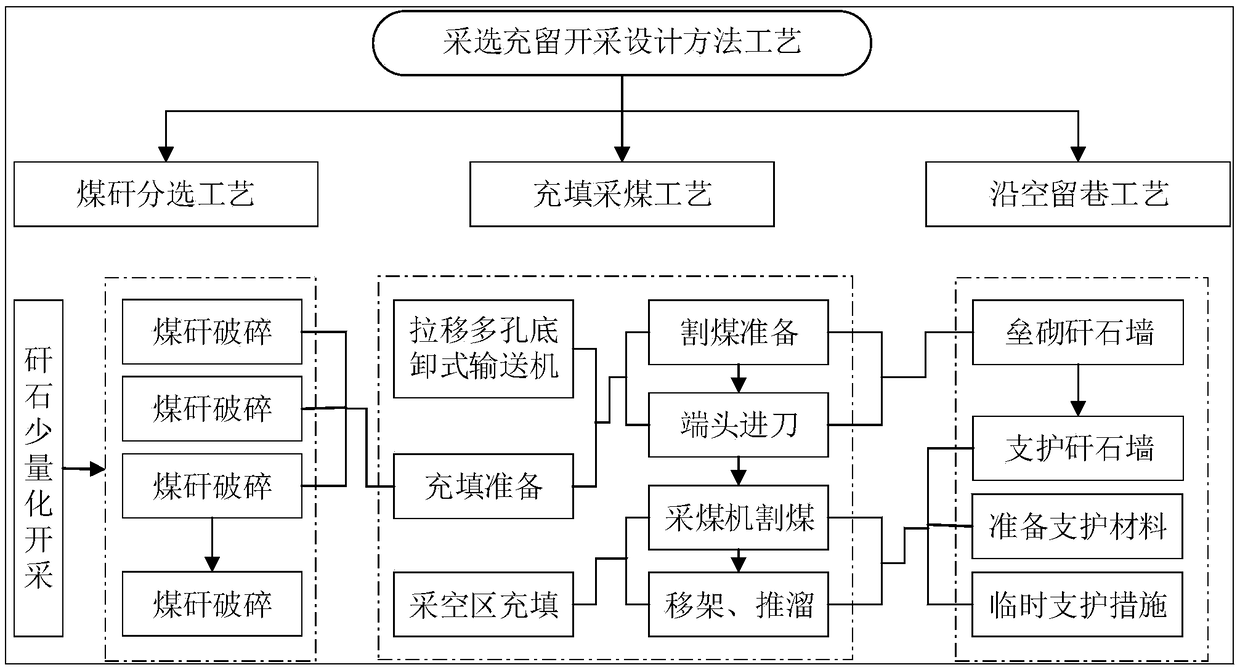

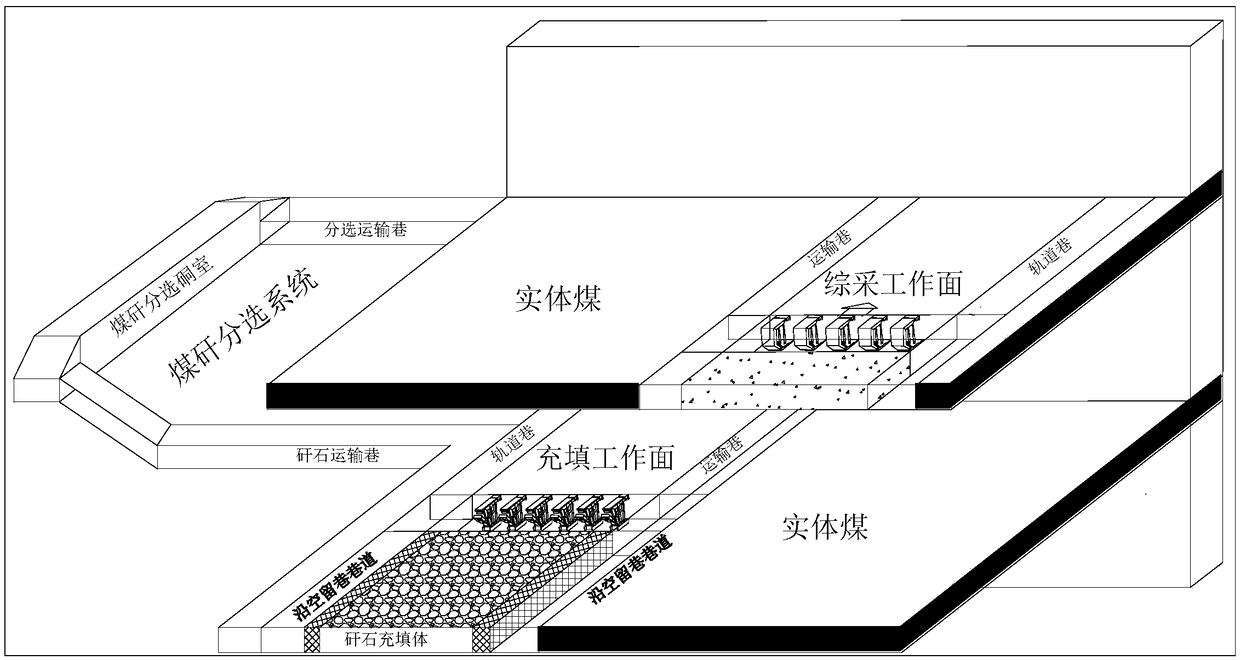

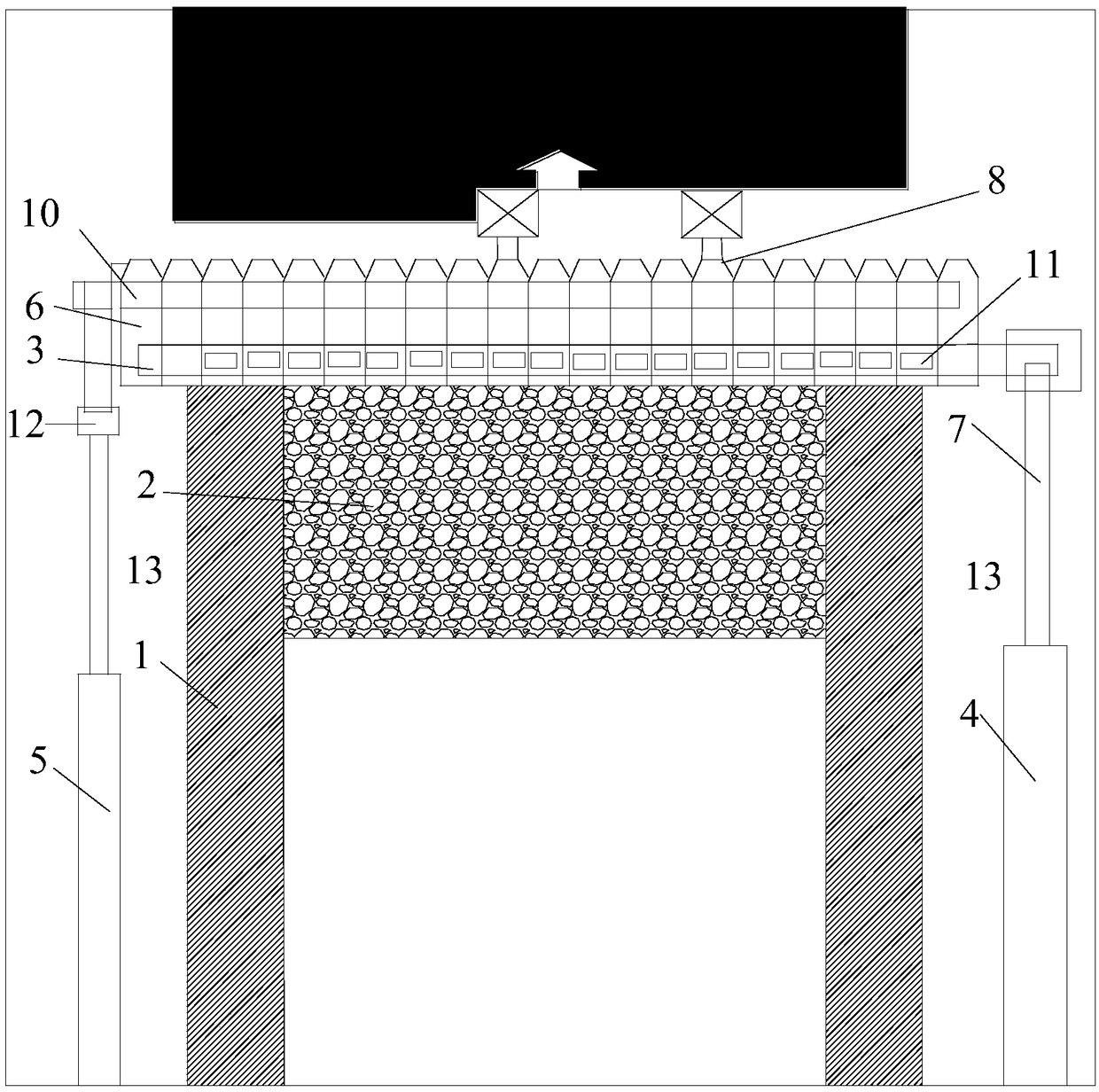

Backstopping-separating-backfilling-roadway retaining mining method for mine mining and beneficiation

InactiveCN109209381AEfficient recyclingHigh recovery rateUnderground miningSurface miningMining engineeringCoal pillar

The invention discloses a backstopping-separating-backfilling-roadway retaining mining method for mine mining and beneficiation. According to the invention, gangue separated from coal gangue is used as a backfilling material for backfilling of a working surface, roadways are retained along the edges of goafs, and gangue walls are built as support bodies for the roadways retained along the goafs toreinforce and support the roadways and to ensure the stability of the roadways; and the roadway retained along the goafs are used as transportation roadways for the backfilling materials and coal, socoal mining without coal pillars is realized in a mining area. Since the gangue separated from coal gangue in the mining area is used as the backfilling material, the requirements of environmental protection are met; through organic combination of three major systems for coal gangue separating, backfilling mining and retaining and supporting of the roadways along the goafs, respectively, a complete cycle of the backstopping-separating-backfilling-roadway retaining mining method is formed; process is simple; the matching between retaining of roadways along goafs and backstopping, separating and backfilling is realized; various coal pillar resources are recovered, and the solid gangue waste in the mining area can be reasonably treated, so the recovery rate of coal resources is improved; andthus, the method effectively solves the problem of shortage of coal resources and difficulties in efficient mining of mines, and improves the safe production efficiency of coal mines.

Owner:CHINA UNIV OF MINING & TECH

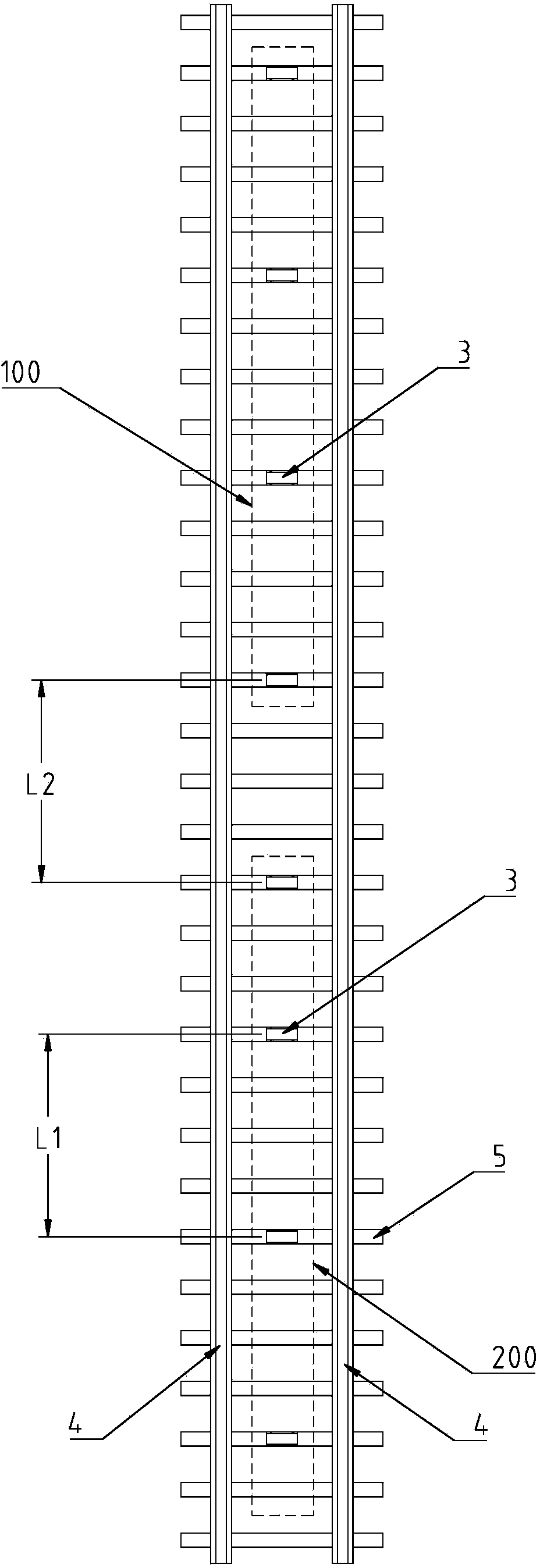

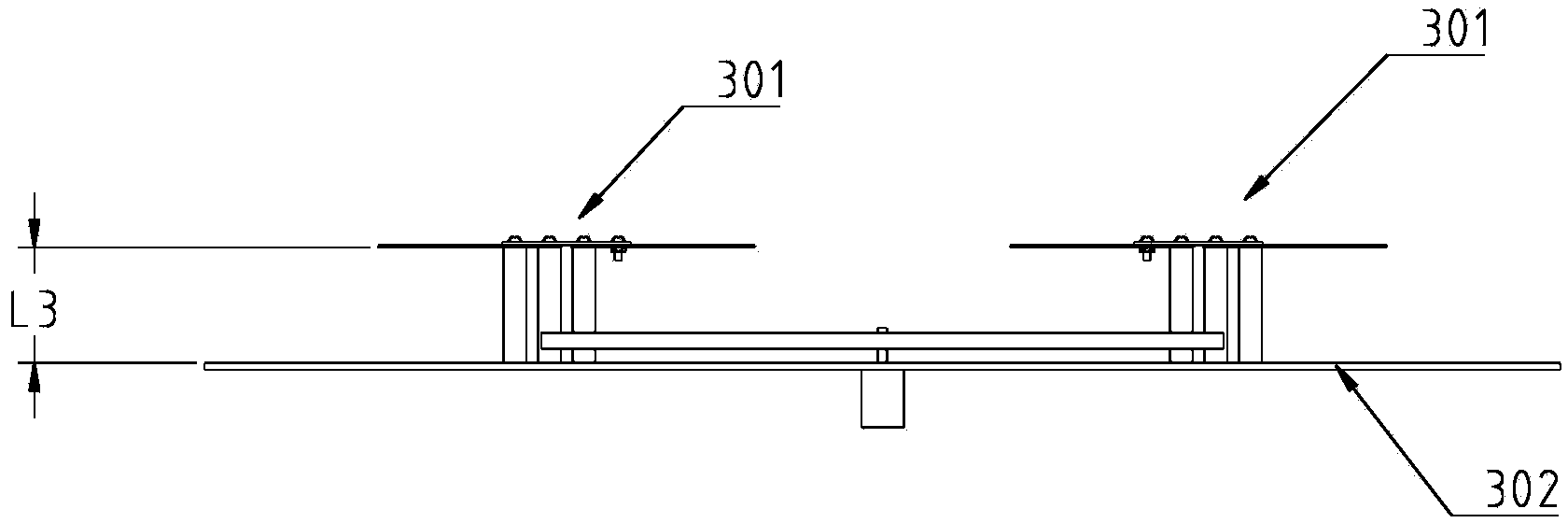

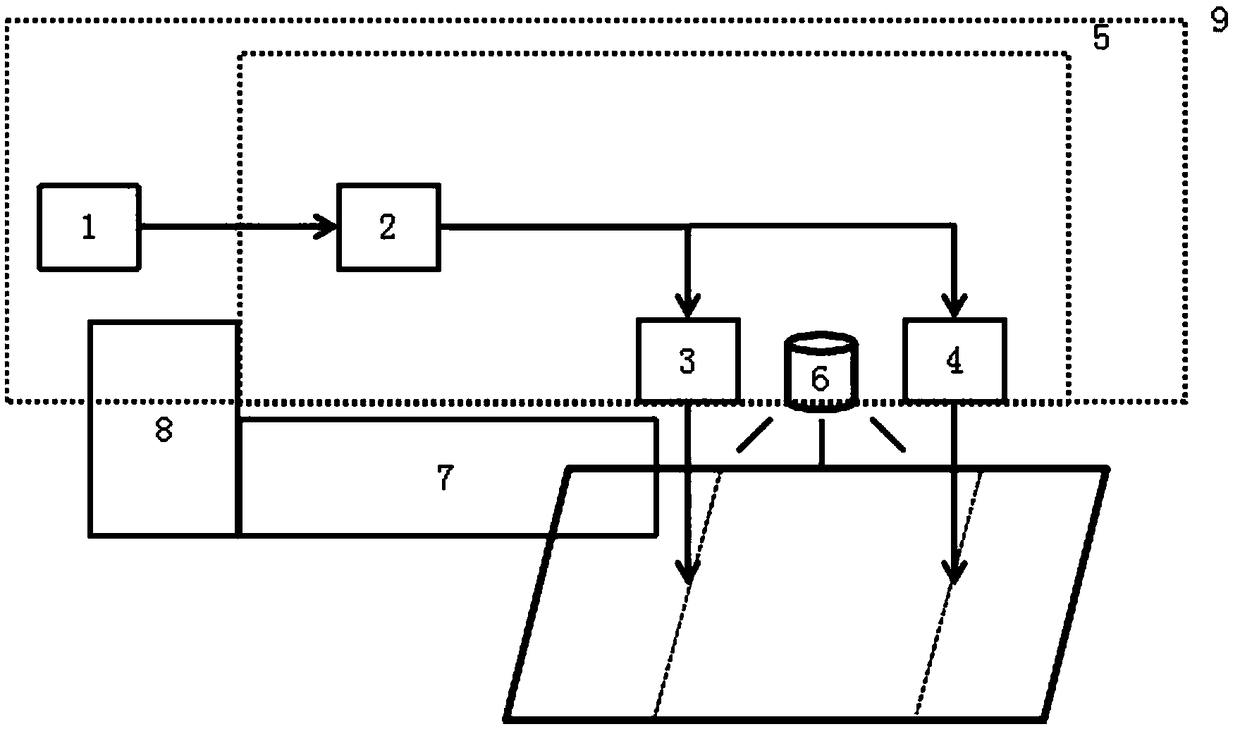

Wheel tracking system for rail vehicles

ActiveCN104143107AGuaranteed uptimeReal-timeCo-operative working arrangementsReal-time dataElectronic tagging

The invention discloses a wheel tracking system for rail vehicles. The wheel tracking system comprises a control system, a ground identification system and a plurality of radio frequency identification tags arranged on wheels of the rail vehicles, wherein the ground identification system comprises a ground identification device and a ground antenna array connected with the ground identification device connected with the control system. Data of the radio frequency identification tags on the running wheels of the rail vehicles can be acquired by means of the ground identification device and the ground antenna array of the ground identification system, real-time data statistics and automatic collection of data including wheel working states and the like can be achieved, production cost is reduced effectively, safety production efficiency is increased, and the reliable statistic basis is provided for safe and stable running of the wheels.

Owner:SHENZHEN MEGMEET ELECTRICAL CO LTD +1

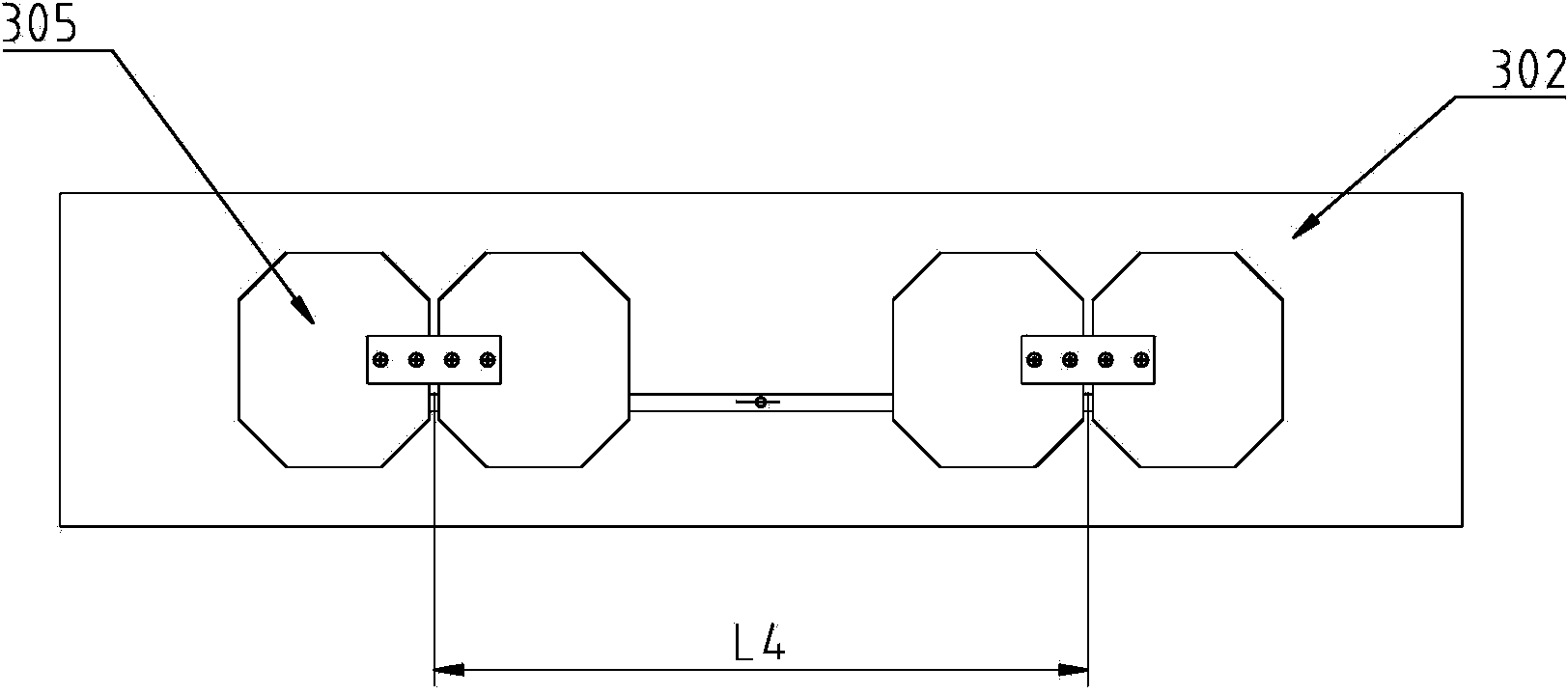

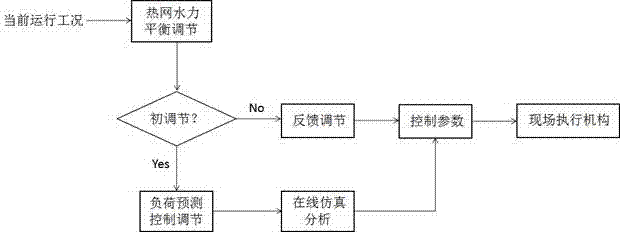

Intelligent control system for centralized heating

InactiveCN107491020AEasy to viewUsage optimizationProgramme controlComputer controlLoad forecastingEngineering

The invention discloses an intelligent control system for centralized heating. The system comprises a centralized control system, a monitoring control system and a heating equipment system. By using a communication network, a heat source factory, a primary network, a plurality of subordinate heat exchange stations and a heat storage device are connected for centralized management, according to actual heating use loads of different user ends of different stages of a heating period, through a prediction control system with a load prediction module and a virtual simulation module, the comprehensive control of the heat source factory, the primary network, the subordinate heat exchange stations and the heat storage device is carried out, the optimization of heating temperature and coal consumption is realized, and an effect of energy saving is achieved while the heating is ensured. The centralized control system established based on GIS system is remotely connected to PC end or a mobile equipment end through a GPRS wireless network, inspection personnel views equipment and parameters of pipeline temperature, repairs and records in real time, convenience is brought to a user to view real-time heating temperature and give a feedback, and the efficiency of production safety is greatly improved.

Owner:ZHONGQINGYUAN ENVIRONMENTAL PROTECTION ENERGY SAVING

Multi-functional intelligent switch controller operating device

ActiveCN104377049AImprove work efficiencyImprove safety production efficiencyContact operating partsWorkloadLED lamp

The invention relates to a multi-functional intelligent switch controller operating device and belongs to the field of power supply units. The device comprises a telescopic main operating rod, wherein a connecting sleeve is arranged on the top of the telescopic main operating rod, a triangular bolt operating head is arranged on the top of the connecting sleeve, a supporting separation blade is fixed between the triangular bolt operating head and the connecting sleeve, the included angle between the supporting separation blade and the connecting sleeve is 90 degrees, the included angle between the supporting separation blade and the triangular bolt operating head is 90 degrees, a U-shaped control knob operating head and an L-shaped auxiliary drag hook piece are arranged on the side face of the connecting sleeve, the U-shaped control knob operating head and the supporting separation blade are oppositely arranged, the included angle between the U-shaped control knob operating head and the L-shaped auxiliary drag hook piece is 90 degrees, an LED lamp is arranged on the top of the connecting sleeve and is connected with a switch arranged on the upper portion of the telescopic main operating rod through a wire and a power supply, and a camera is arranged on the portion, below the connecting sleeve, of the telescopic main operating rod. The device is convenient to use and capable of saving time and labor, workers do not need to climb a rod, the workload of the workers is reduced, and working safety is improved.

Owner:STATE GRID CORP OF CHINA +2

Laser-based road surface cutting device

InactiveCN108620746ASolve efficiency problemsSolve pollutionLaser beam welding apparatusContinuous lightBeam splitting

The invention provides a laser-based road surface cutting device which comprises a laser device, a beam splitting unit, a first output unit, a second output unit and a cutting and translation table; wherein the laser device can emit a light source through a fiber coupling technology; the light source is an adjustable continuous light source or a pulsed light source; the beam splitting unit focusesthe light source transmitted by the laser device and splits the light source into a first light beam and a second light beam; the first output unit outputs the first light beam; the second output unit outputs the second light beam; the first light beam and the second light beam are perpendicular to the ground correspondingly; and the cutting and translation table is movably connected with the first output unit and the second output unit. Through the laser-based road surface cutting device, the technical problems of low road surface cutting efficiency, serious pollution and high cost are solved, and the technical effects of improving the road surface cutting efficiency, shortening basic construction time, saving cost, and reducing pollution and noise are achieved.

Owner:武汉光谷航天三江激光产业技术研究院有限公司

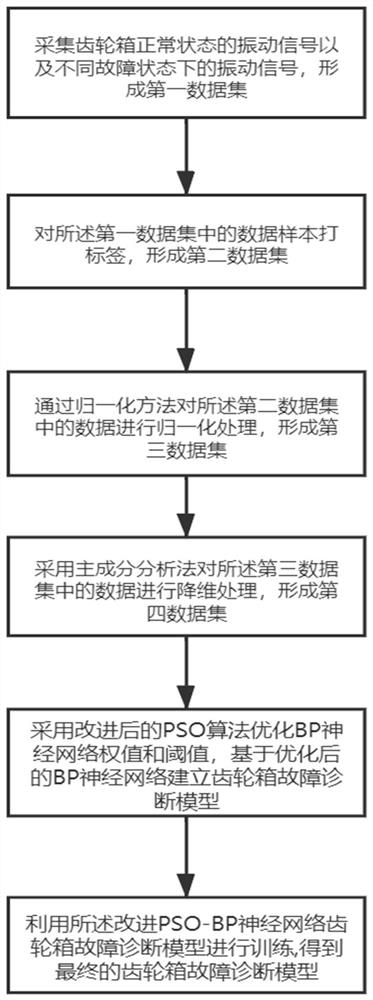

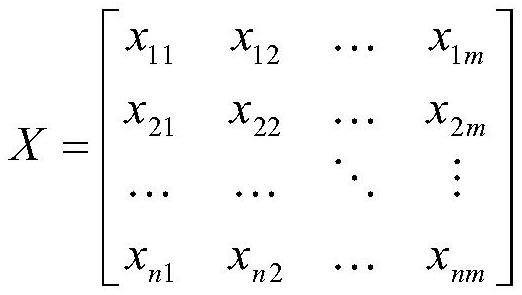

Gearbox fault diagnosis method and device based on improved PSO-BP neural network

ActiveCN113188794ASolve the speed problemResolve accuracyMachine part testingArtificial lifePrincipal component analysisDimensionality reduction

The invention provides a gearbox fault diagnosis method and device based on an improved PSO-BP neural network. The fault diagnosis method specifically comprises the following steps of (1) collecting vibration signals of a gearbox in a normal state and vibration signals in different fault states; (2) labeling the data samples; (3) performing normalization processing on the data through a normalization method; (4) carrying out dimension reduction processing on the data by adopting a principal component analysis method; (5) optimizing the weight and threshold of the BP neural network by adopting an improved PSO algorithm, and establishing a gearbox fault diagnosis model based on the optimized BP neural network; and (6) training by using the optimized BP neural network fault diagnosis model to obtain a final BP neural network fault diagnosis model. According to the fault diagnosis method and device provided by the invention, fault diagnosis accuracy of the gearbox is effectively improved, and the method and device have important practical engineering significance for improving safety production efficiency and reducing economic loss.

Owner:NORTHEAST DIANLI UNIVERSITY

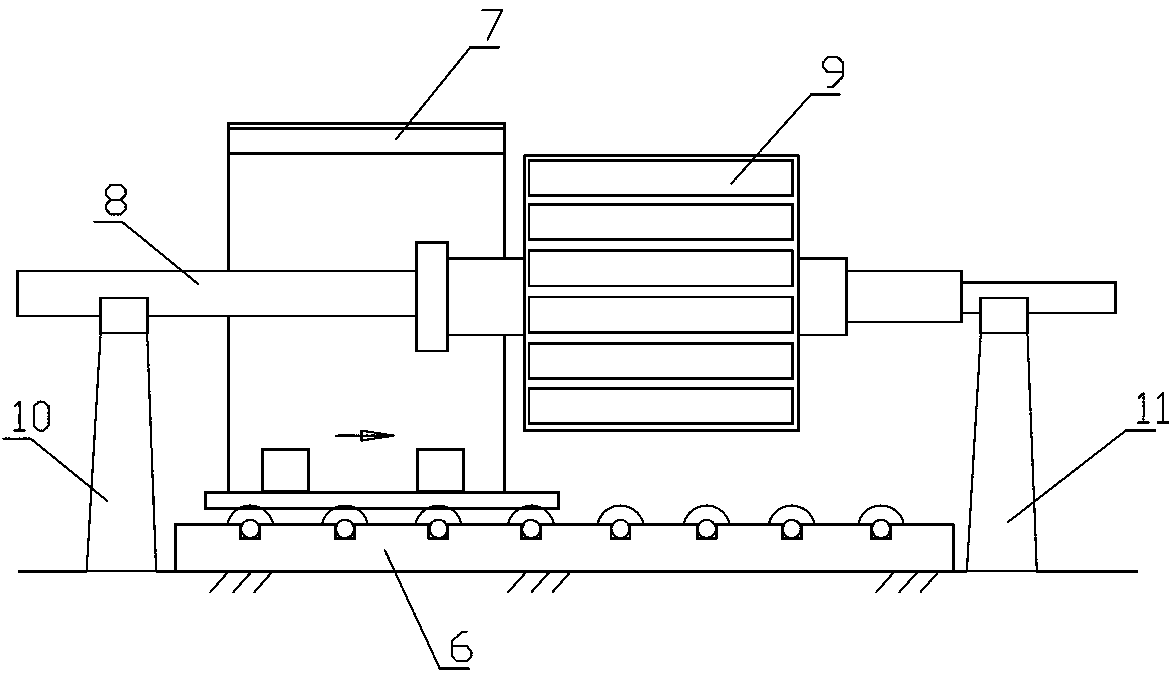

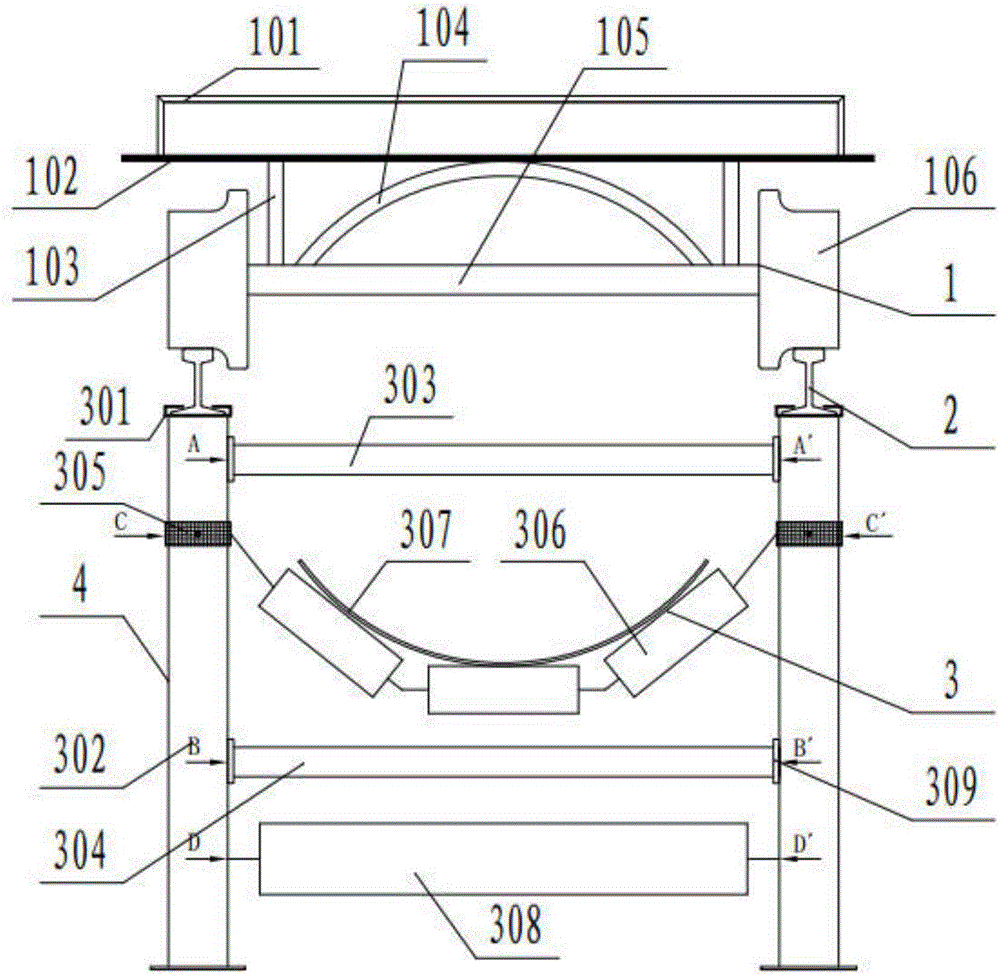

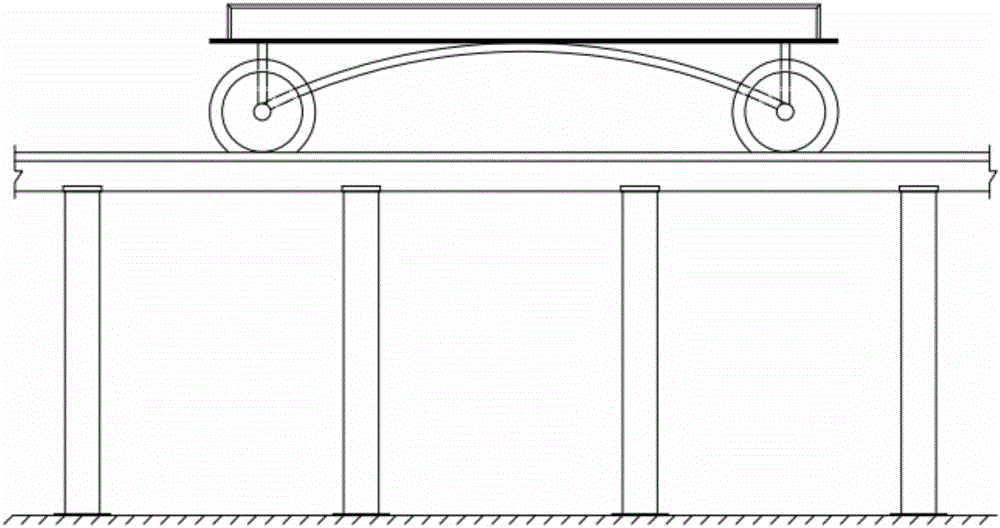

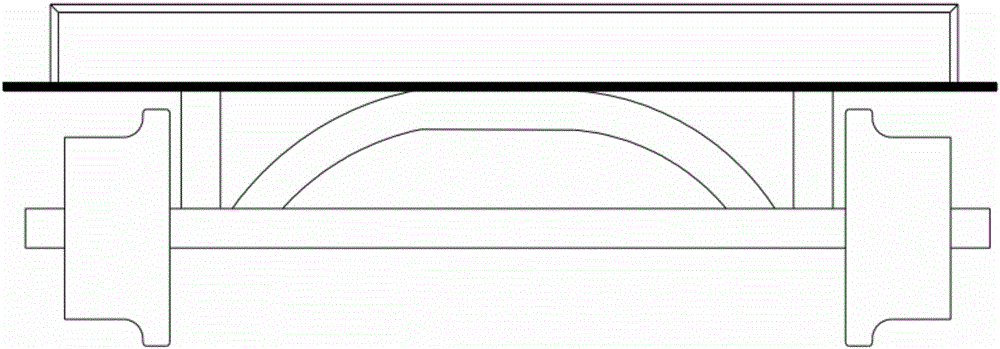

Linear movement core sleeving assembly method of large motor stator

InactiveCN103023229AMeet the general assemblyImprove safety production efficiencyManufacturing dynamo-electric machinesGeneral assemblyElectric machine

The invention relates to the technology of large motor assembly, in particular to a linear movement core sleeving assembly method of a large motor stator. The method is characterized in that the stator is placed on a roller type transferring device, is enabled to be capable of linearly moving along the roller type transferring device, and is pushed so as to complete core sleeving. The method includes the specific steps: 1) lifting the motor stator to be placed on the roller type transferring device; 2) temporarily connecting a rotor with an extended shaft; 3) disposing a first temporary support and a second temporary support; 4) lifting the rotor to penetrate the stator, and after the stator is penetrated, carrying the shaft end of the extended shaft on the first temporary shaft, and carrying the other end of the motor rotor on the second temporary shaft; 5) controlling the coaxiality of the stator and the rotor to be not larger than 5mm; and 6) moving the stator and completing core sleeving assembly. Compared with the prior art, the method has the advantages that general assembly of large motors of various specifications can be met, and vibration, swing and collision generated along with linear movement of the rotor in a core sleeving assembly process of the large motor are eliminated.

Owner:ANGANG CONSTR CONSORTIUM

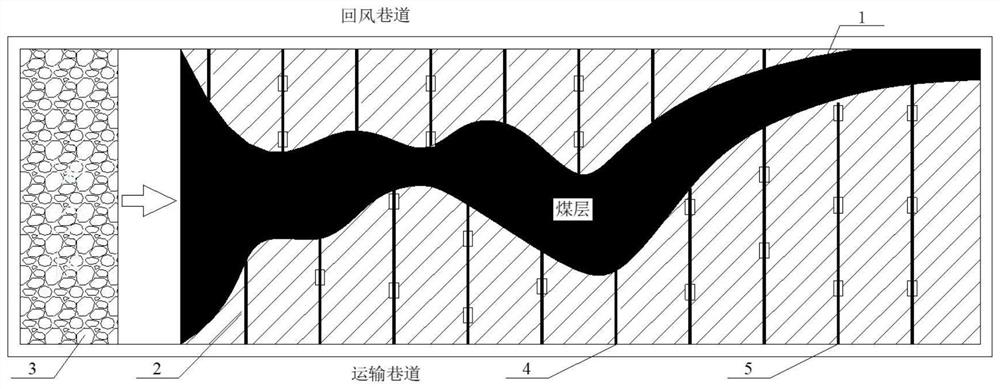

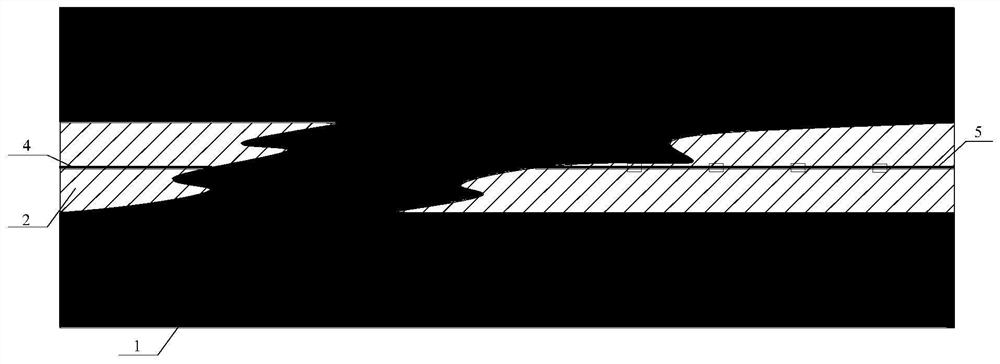

Method for weakening hard waste rock inclusion layer in coal seam through hydraulic presplitting in underground coal mine deep hole

ActiveCN112253114AImprove safety production efficiencyReduced compressive strengthDisloding machinesUnderground miningMining engineeringCoal

The invention discloses a method for weakening a hard waste rock inclusion layer in a coal seam through hydraulic presplitting in an underground coal mine deep hole. The method comprises the followingsteps of Step 1, determining the occurrence form and range of the hard waste rock inclusion layer in a stope face; Step 2, determining drilling hole arrangement parameters and fracturing technical parameters; Step 3, performing drilling construction; and Step 4, performing in-hole conveying of fracturing equipment and fracturing construction. The method can overcome the defects and existing problems of an existing technology for weakening a hard waste rock inclusion layer in a coal seam, the effect of weakening the hard waste rock inclusion layer in more environmental-friendly, safer and moreefficient way is achieved, advanced weakening of the hard waste rock inclusion layer in an underground coal mine stope face is achieved, smooth recovery of a whole set of construction equipment for presplitting in the deep hole is completed, the fracturing construction efficiency is guaranteed, and technical defect problems existing in the prior art are solved.

Owner:XIAN RES INST OF CHINA COAL TECH& ENG GROUP CORP

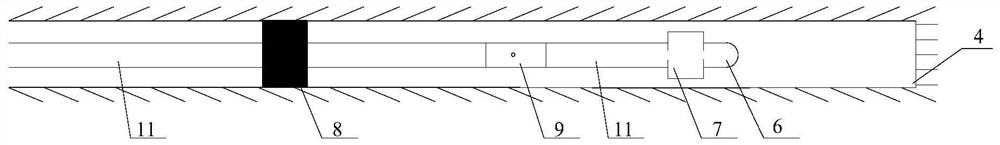

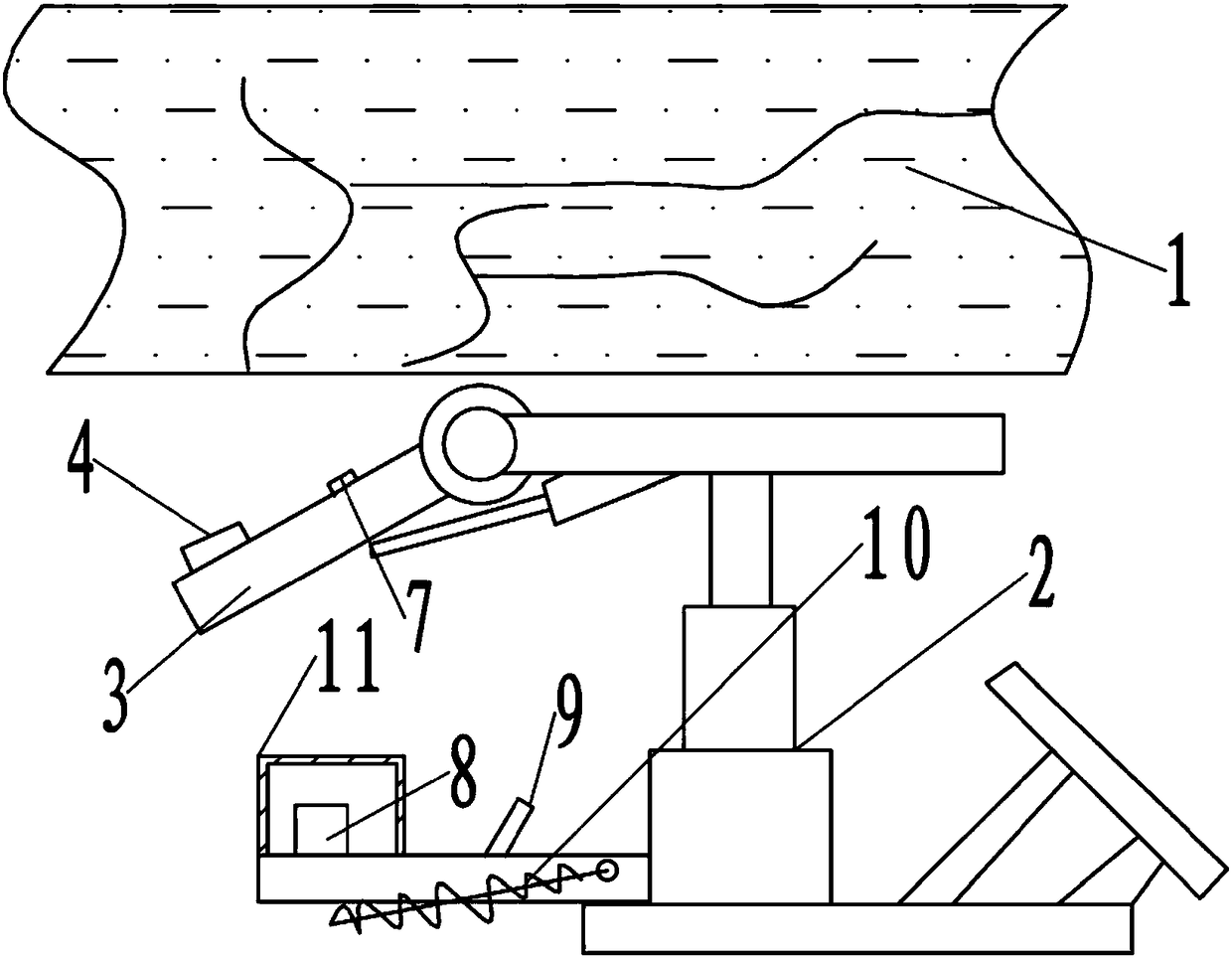

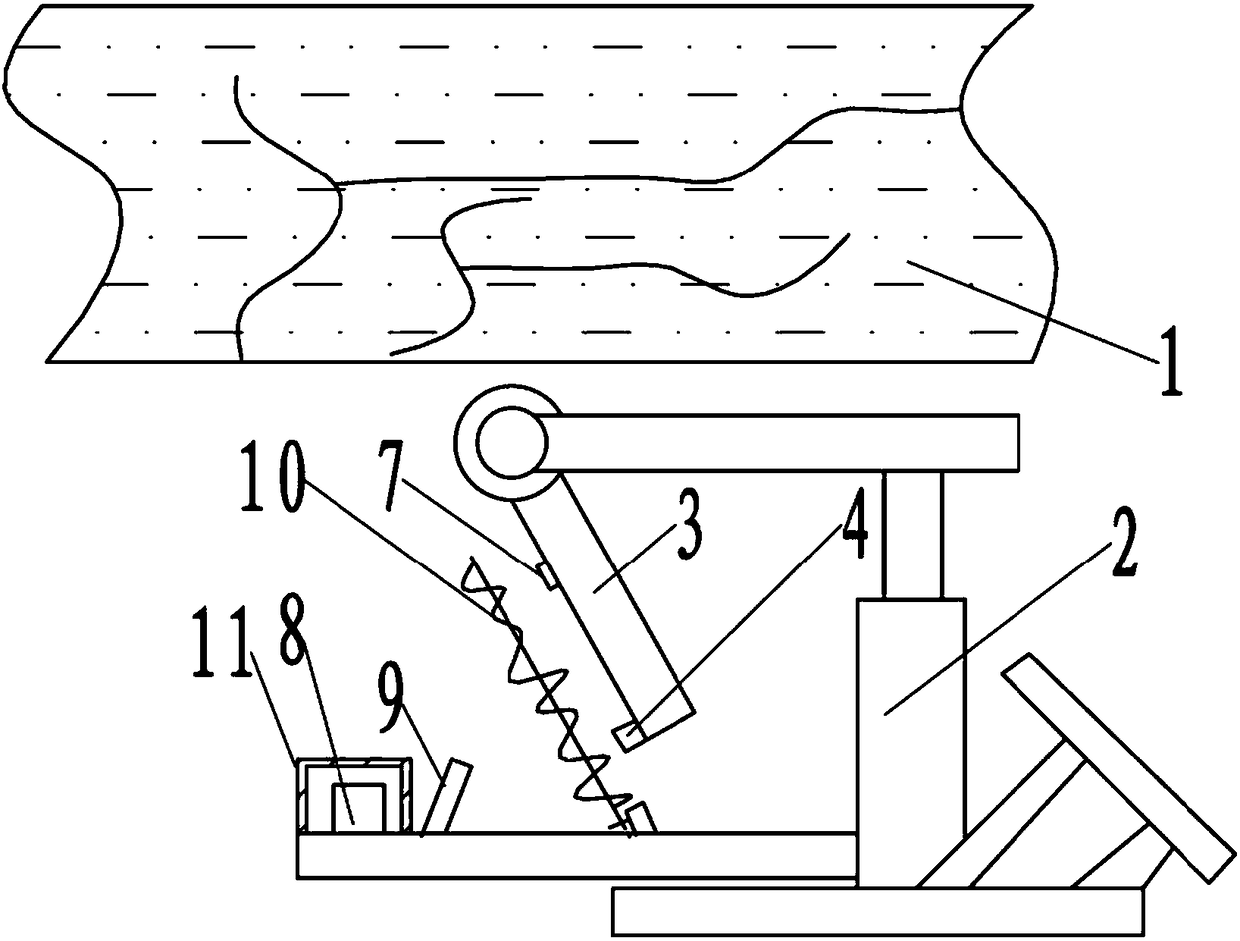

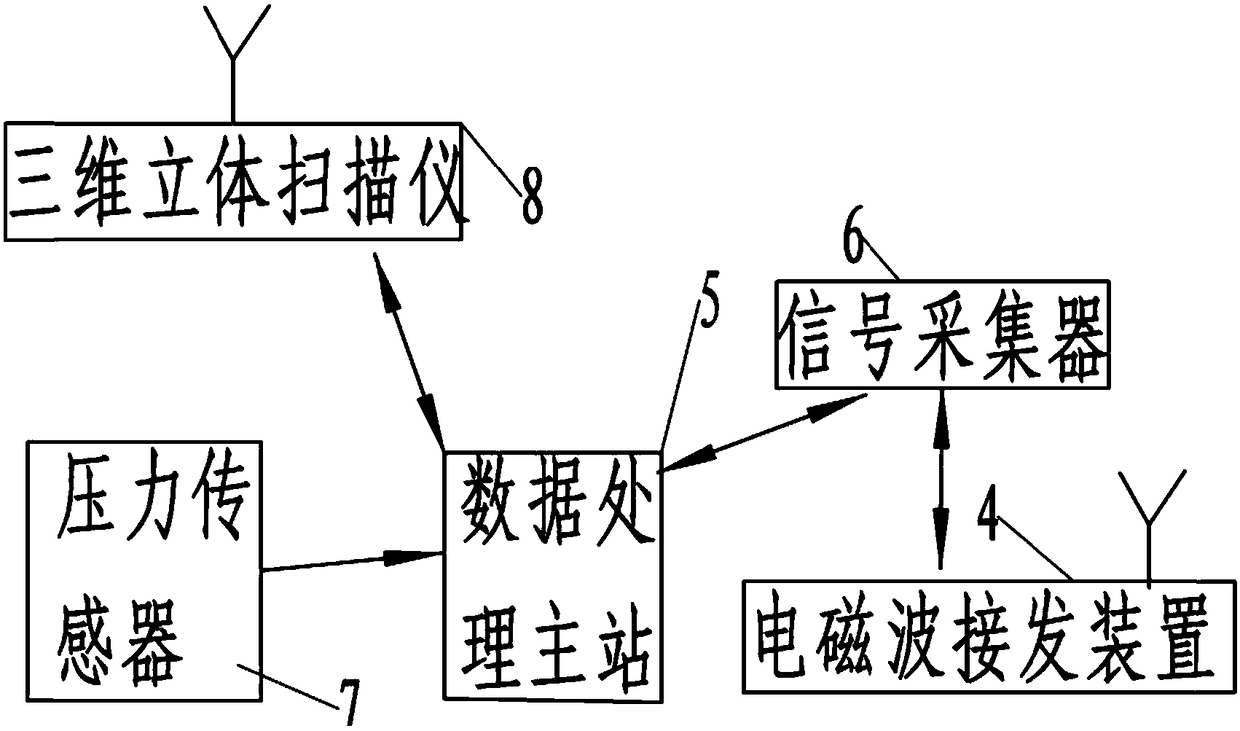

Rib spalling real-time prediction method

ActiveCN108562895AEnables real-time forecastingSolving real-time forecasting problemsMining devicesUsing optical meansElectricityInformation transmission

The present invention relates to a rib spalling real-time prediction method. A data processing main station, an electromagnetic wave receiving and transmitting device, a signal collector and a three-dimensional scanner are provided. The data processing main station is electrically connected with the three-dimensional scanner and the signal collector; the electromagnetic wave receiving and transmitting device is electrically connected with the signal collector; the three-dimensional scanner is configured to perform surface crack scanning and identification of the rib spalling and transmit the surface crack scanning and identification information to the data processing main station, and the data processing main station obtains the surface crack scanning and identification. The rib spalling real-time prediction method is reasonable in design, compact in structure and convenient to use.

Owner:四川坤宇沃达智能科技有限公司

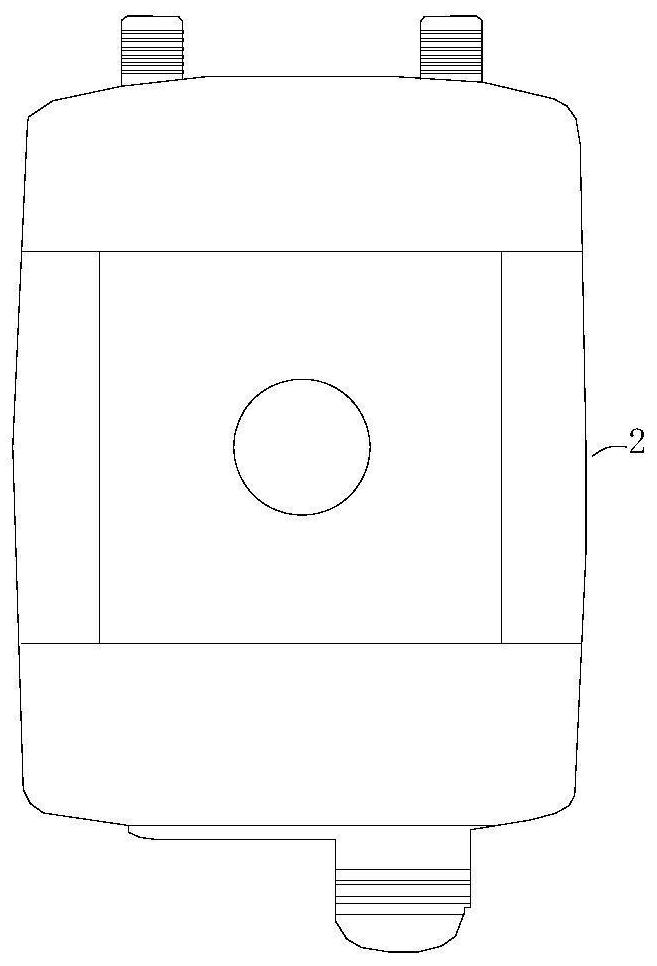

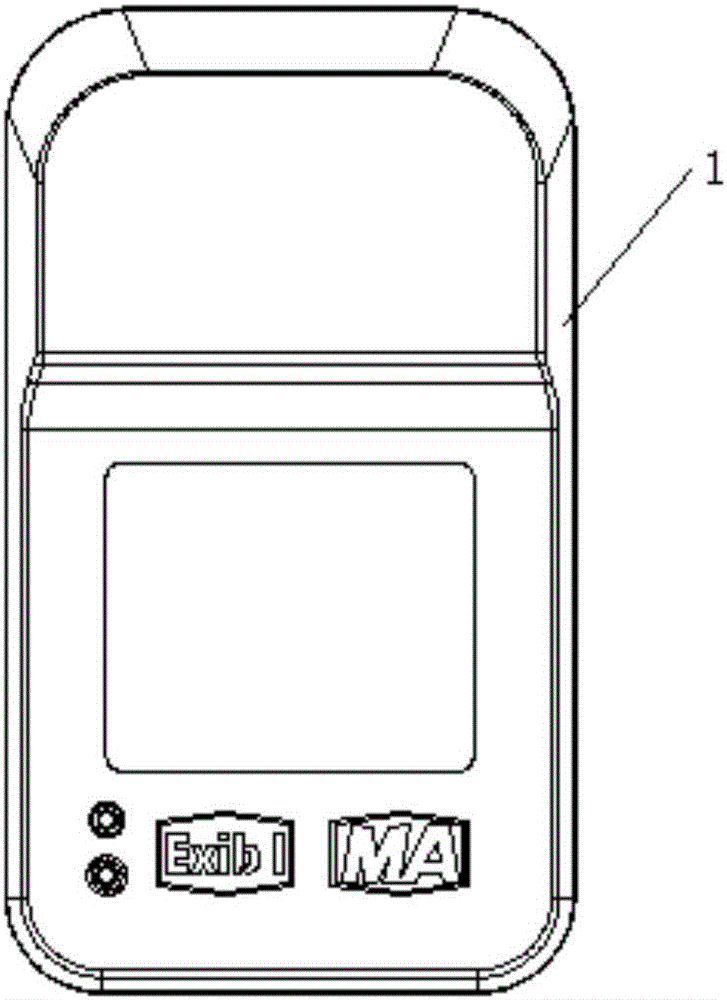

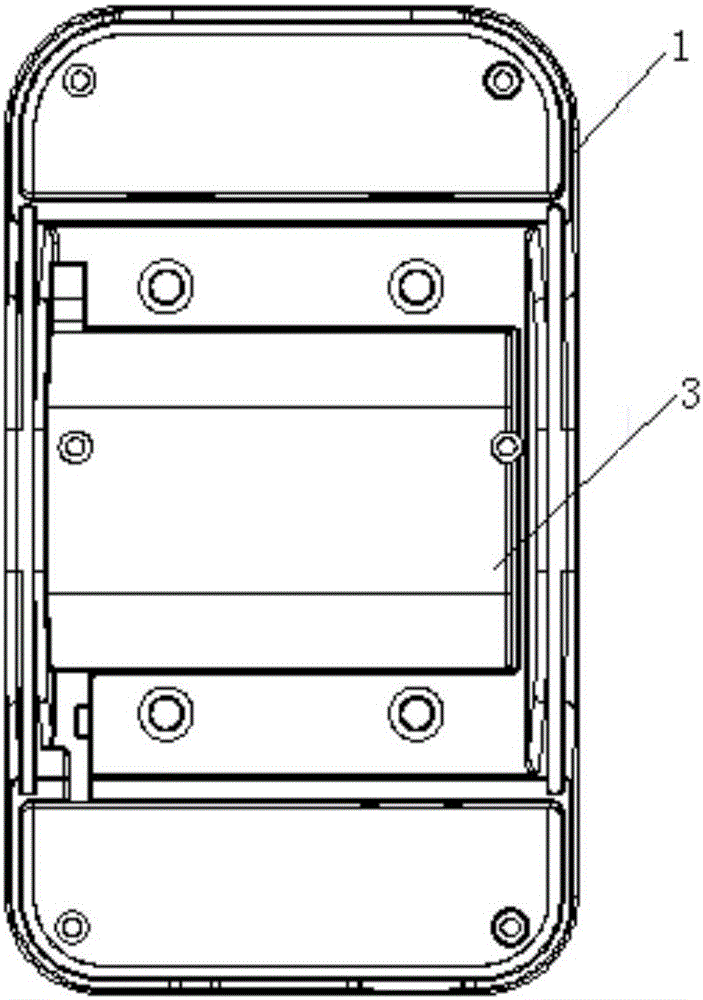

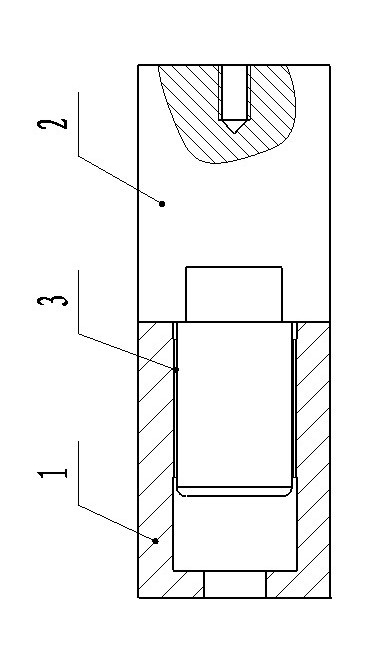

Vehicle-mounted positioner and mining locomotive comprising vehicle-mounted positioner

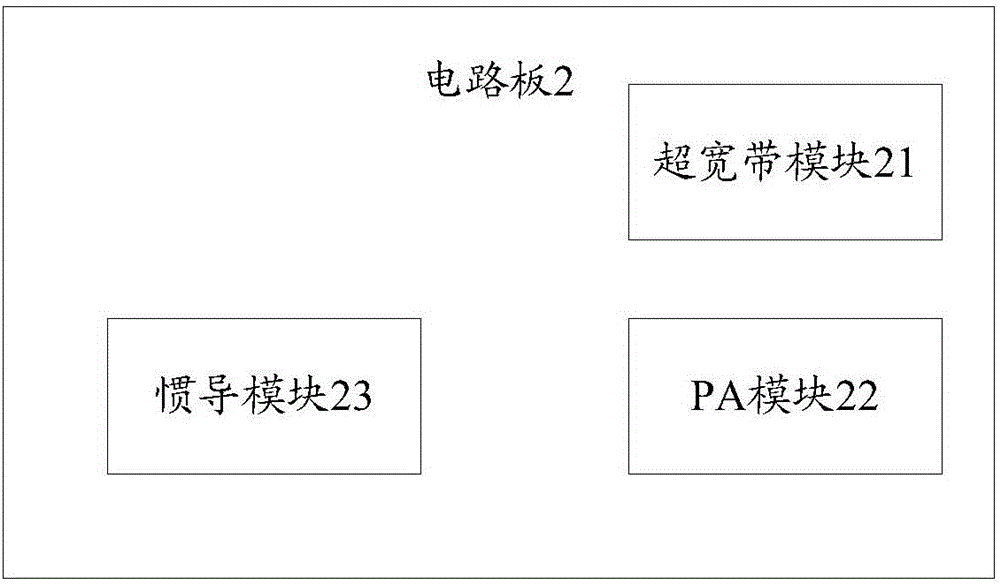

ActiveCN106314484ARealize communicationAchieve positioningSignalling indicators on vehicleNavigation instrumentsUltra-widebandElectrical battery

The invention discloses a vehicle-mounted positioner and a mining locomotive comprising the vehicle-mounted positioner and belongs to the field of positioning of mining locomotives. The vehicle-mounted positioner comprises a shell body, a circuit board and a battery; the circuit board and the battery are arranged in the shell body; the battery is connected with the circuit board and supplies power to the circuit board; the circuit board is provided with an ultra-wideband module; the ultra-wideband module is connected with an antenna; antistatic paint is coated on the shell body; the antenna is packaged in an antenna shell through waterproof glue. The vehicle-mounted positioner has high positioning precision, wide signal coverage range, wide transmission bandwidth and good expandability; safety and good waterproof effect of the locomotive under a coal mine are guaranteed.

Owner:BEIJING YONGANXINTONG TECH CO LTD

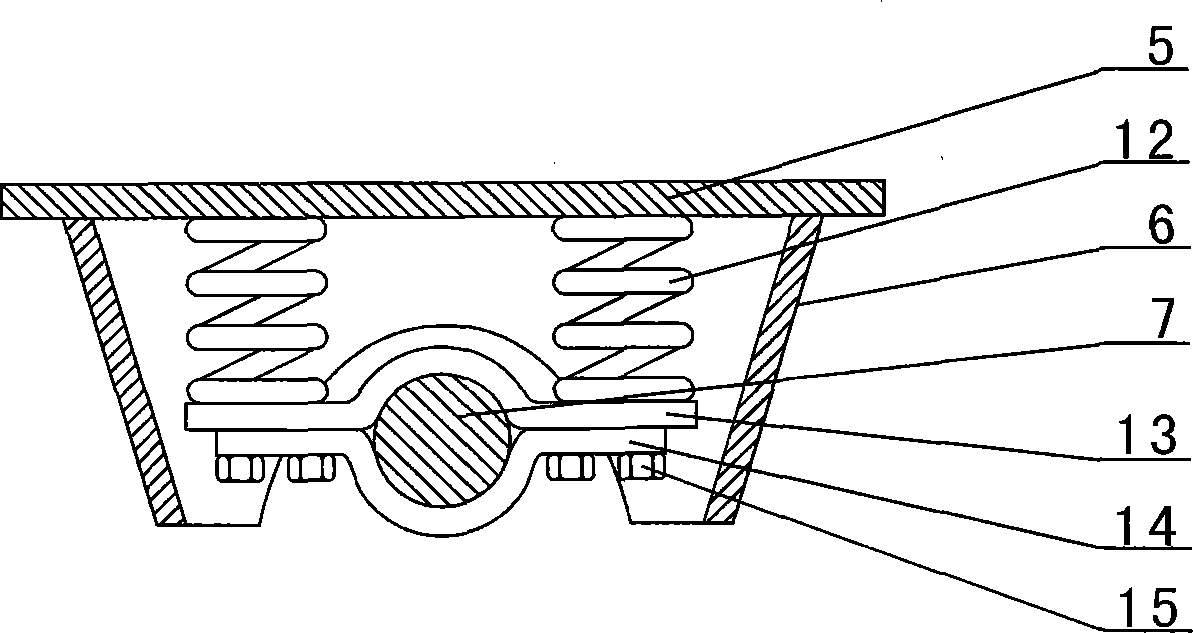

Blade spring type power current inserting-connecting device

InactiveCN102544943AImprove safety production efficiencyIncrease the on-currentCoupling device detailsTwo-part coupling devicesPower cableEngineering

The invention relates to a blade spring type power current inserting-connecting device, which belongs to the technical field of power cable inserting-connecting devices in coal mines and is applied to coal mine electric accessories for power cable quick connection. The adopted technical scheme is that the blade spring type power current inserting-connecting device comprises a female connector and a male connector, the female connector is a hollow cylindrical metal pipe, the hole diameter at the front end of the metal pipe is smaller than that in the middle of the metal pipe, a blade spring is installed on the inner wall of the metal pipe, the blade spring is an elastic metal sheet which is folded in the saw-toothed shape, and the blade spring is installed by being bended into a pipe shape along the inner wall of the metal pipe of the female connector. The male connector is a columnar metal rod, the front end of the male connector is a small cylinder matched with the inner wall of the metal pipe of the female connector, and an axial hole is arranged on the end face at the back end of the male connector. The blade spring type power current inserting-connecting device is suitable for the fields of coal mines, factories and the like.

Owner:刘涛

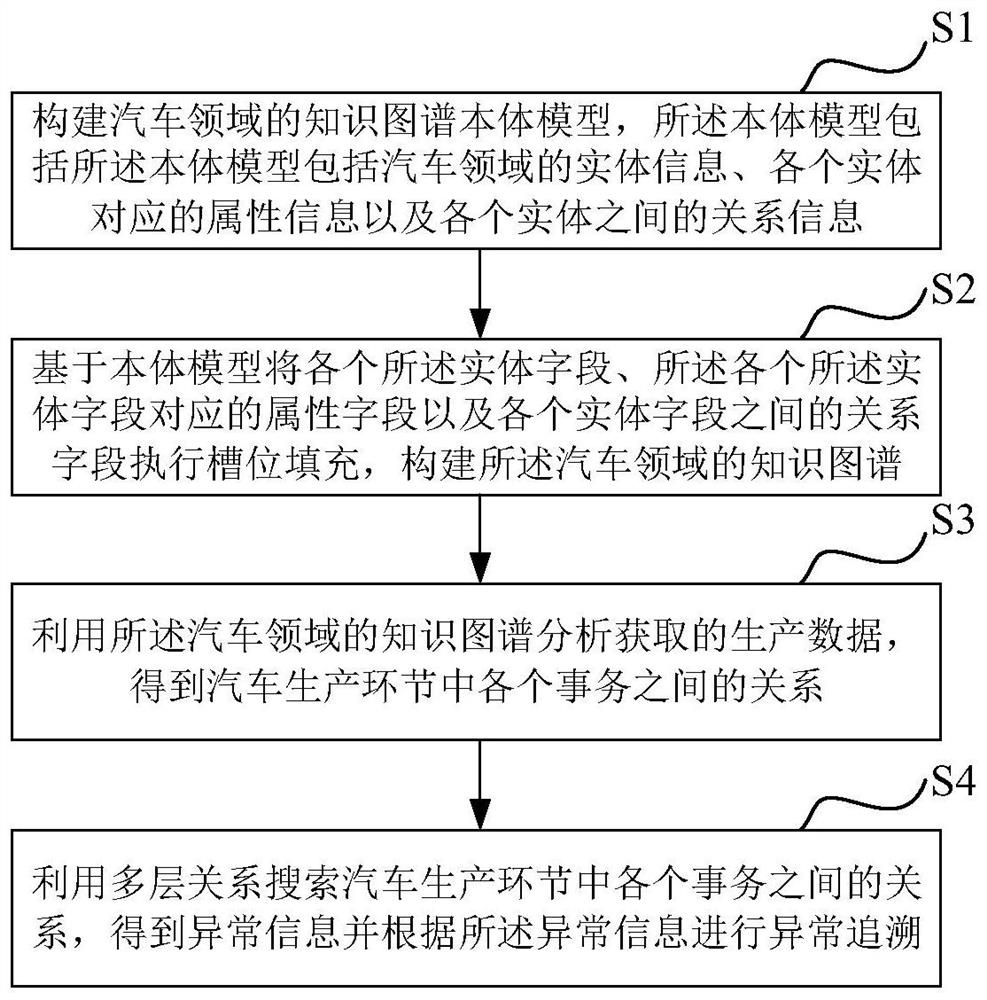

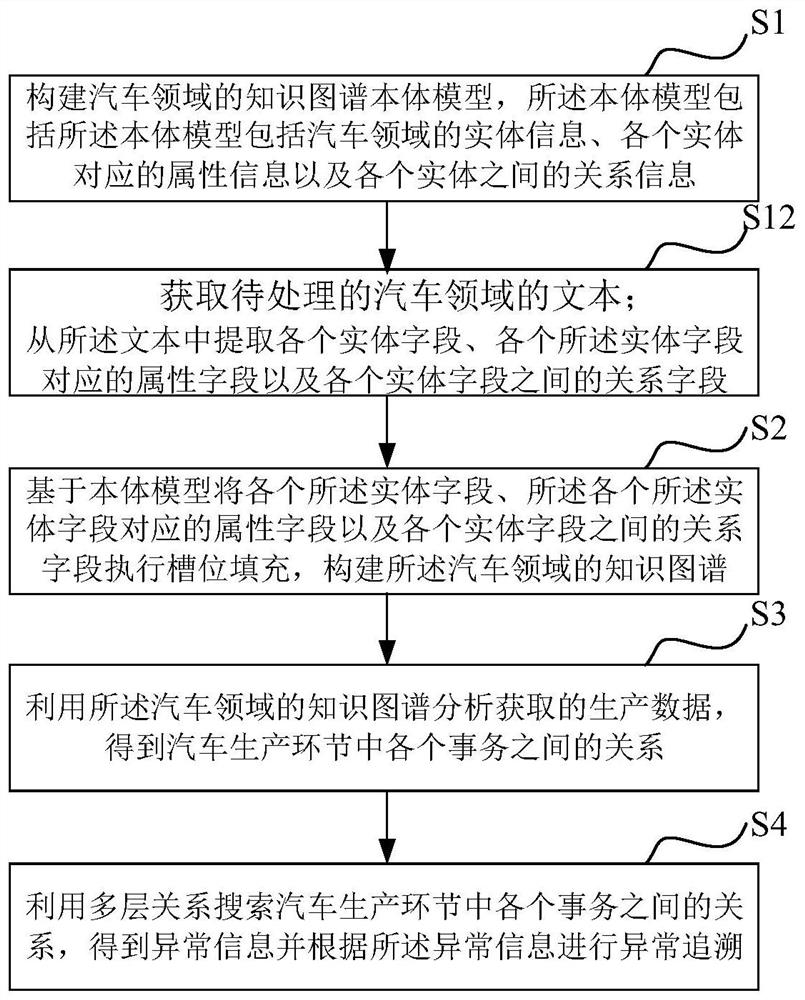

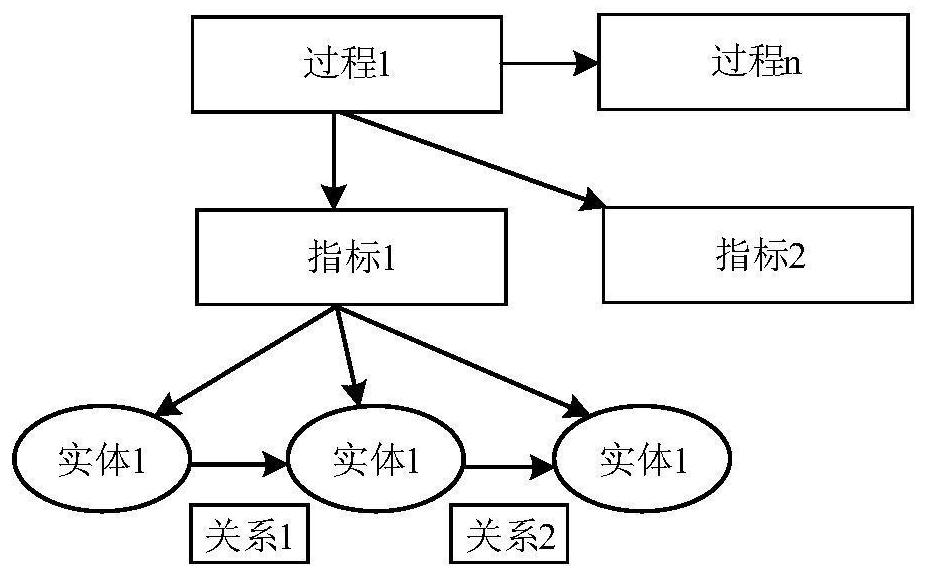

Abnormity prediction and tracing method, system and equipment based on automobile production, and medium

PendingCN113392228AImprove forecastEffective positioningRelational databasesForecastingData miningKnowledge graph

Owner:广域铭岛数字科技有限公司 +1

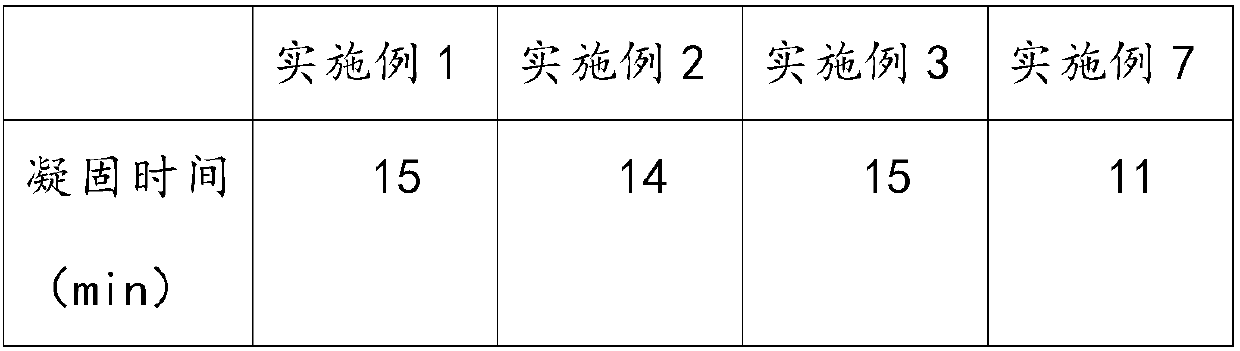

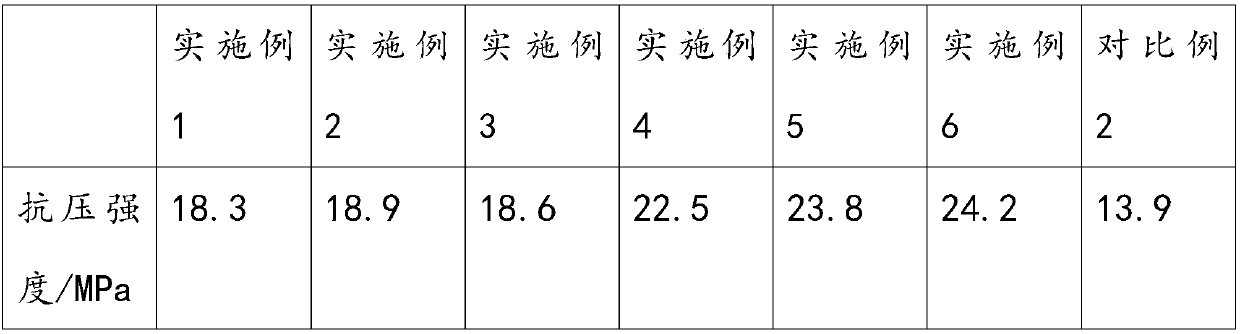

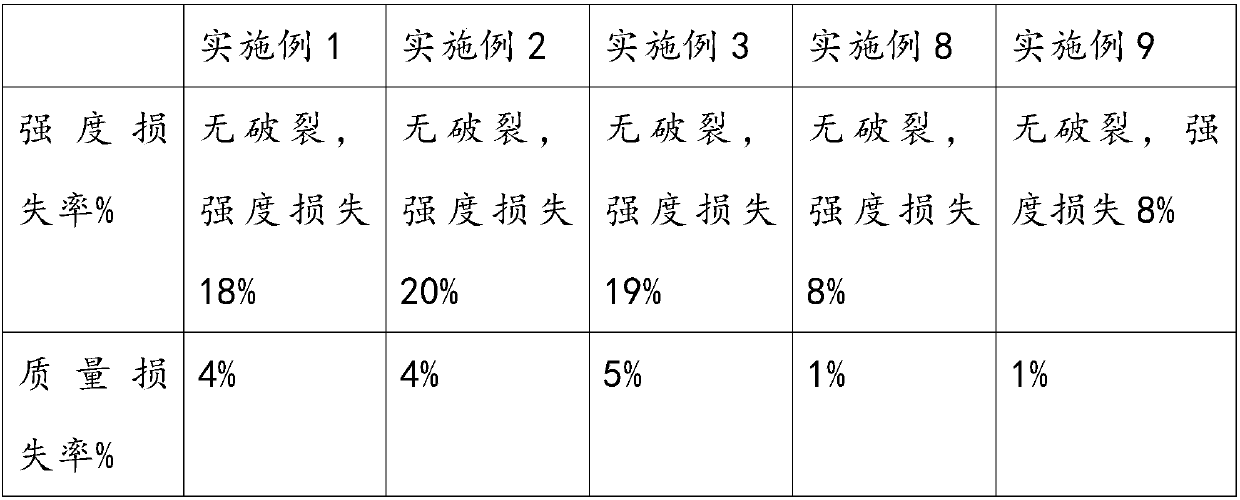

Silicon-calcium inorganic high-strength heat insulation composite wallboard

InactiveCN107857515AHigh compressive strengthAchieving Plastic MobilityWallsHeat proofingFiberCalcium silicate

The invention discloses a silicon-calcium inorganic high-strength heat insulation composite wallboard. A core material of the silicon-calcium inorganic high-strength heat insulation composite wallboard comprises the following components in parts by weight: 100-200 parts of 525 cement, 400-600 parts of calcium silicate, 9-12 parts of quick dry powder, 70-96 parts of silicon calcium powder, 15-18 parts of metal oxide powder, 200-300 parts of neutral mineral powder, 8-15 parts of lithium carbonate, 30-80 parts of gypsum powder, 35-55 parts of a coupling agent, 3-8 parts of fiber, 3-5 parts of a foaming agent and 900-1500 parts of neutral water; a surface layer material comprises 46-55 parts of sodium chloride, 50-67 parts of an adhesive, 72-110 parts of silicon calcium powder, 80-100 parts of525 cement, 5-8 parts of building sand, 10-15 parts of steel wire mesh, 3-8 parts of fiber and 750-780 parts of neutral water. The composite wallboard prepared by a method provided by the invention has the advantages of good heat preservation effect and high strength, can be quickly solidified and dried at a low temperature, and shortens the construction time of construction in the north in autumn and winter.

Owner:河北坐城建材科技有限公司

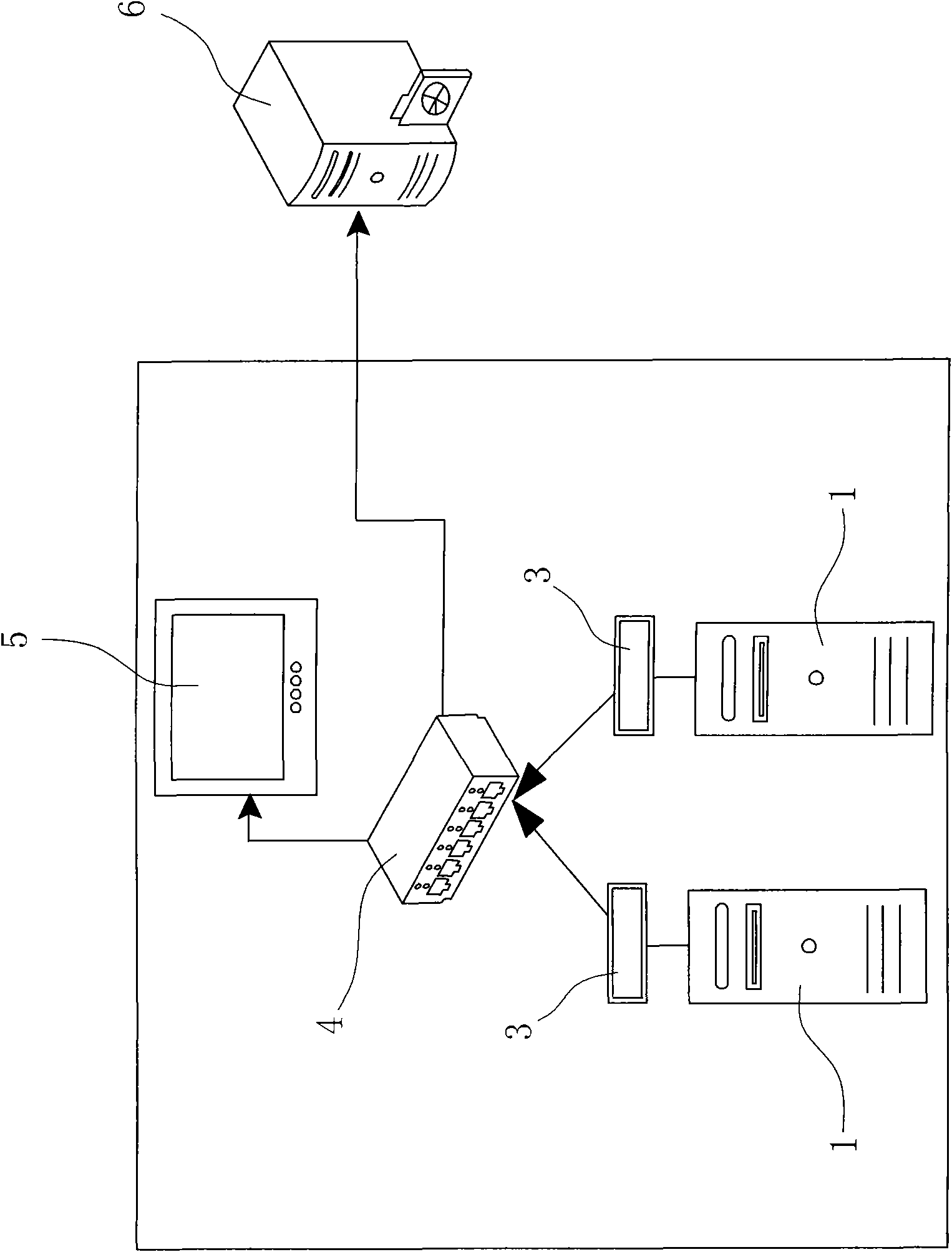

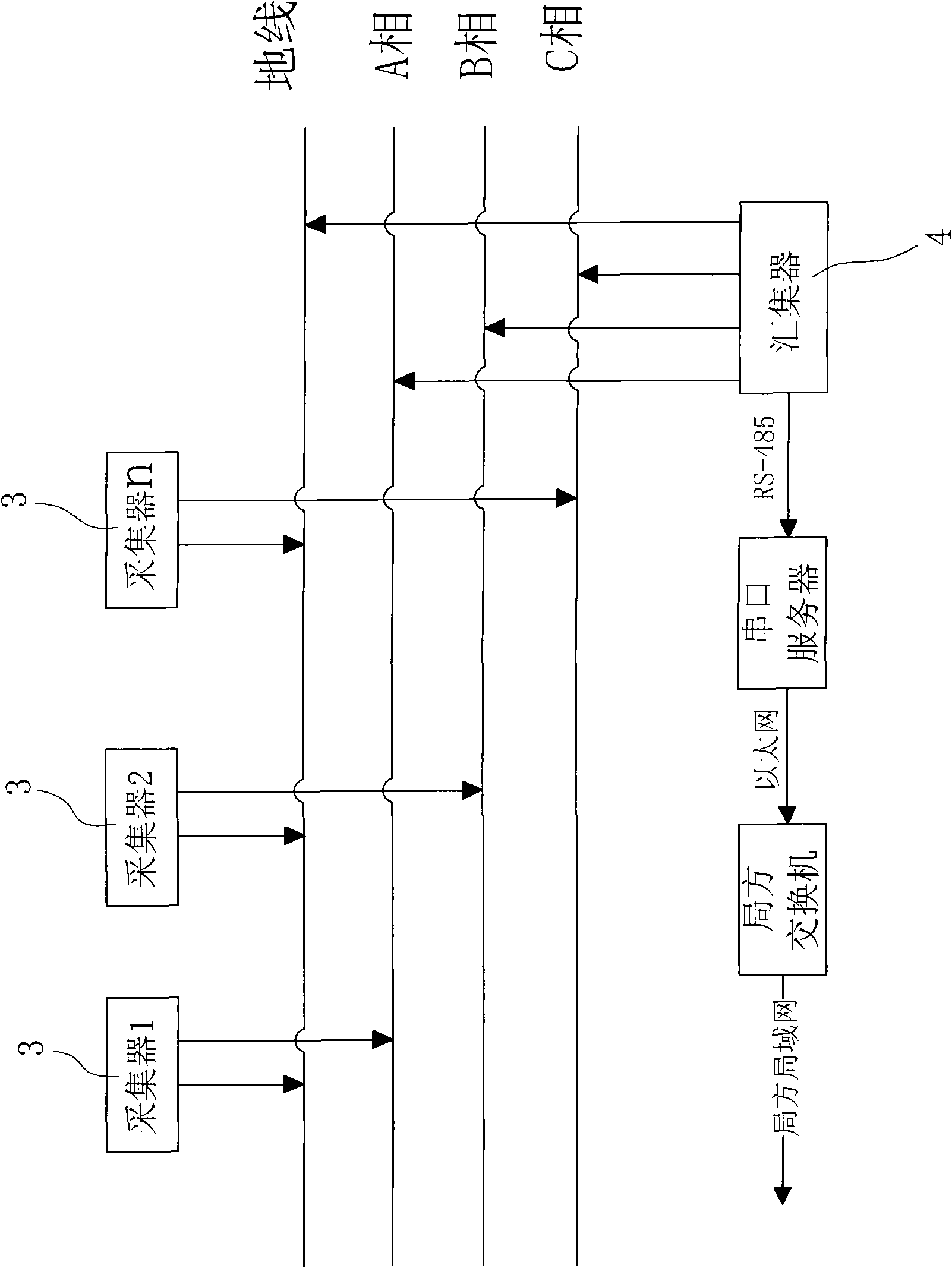

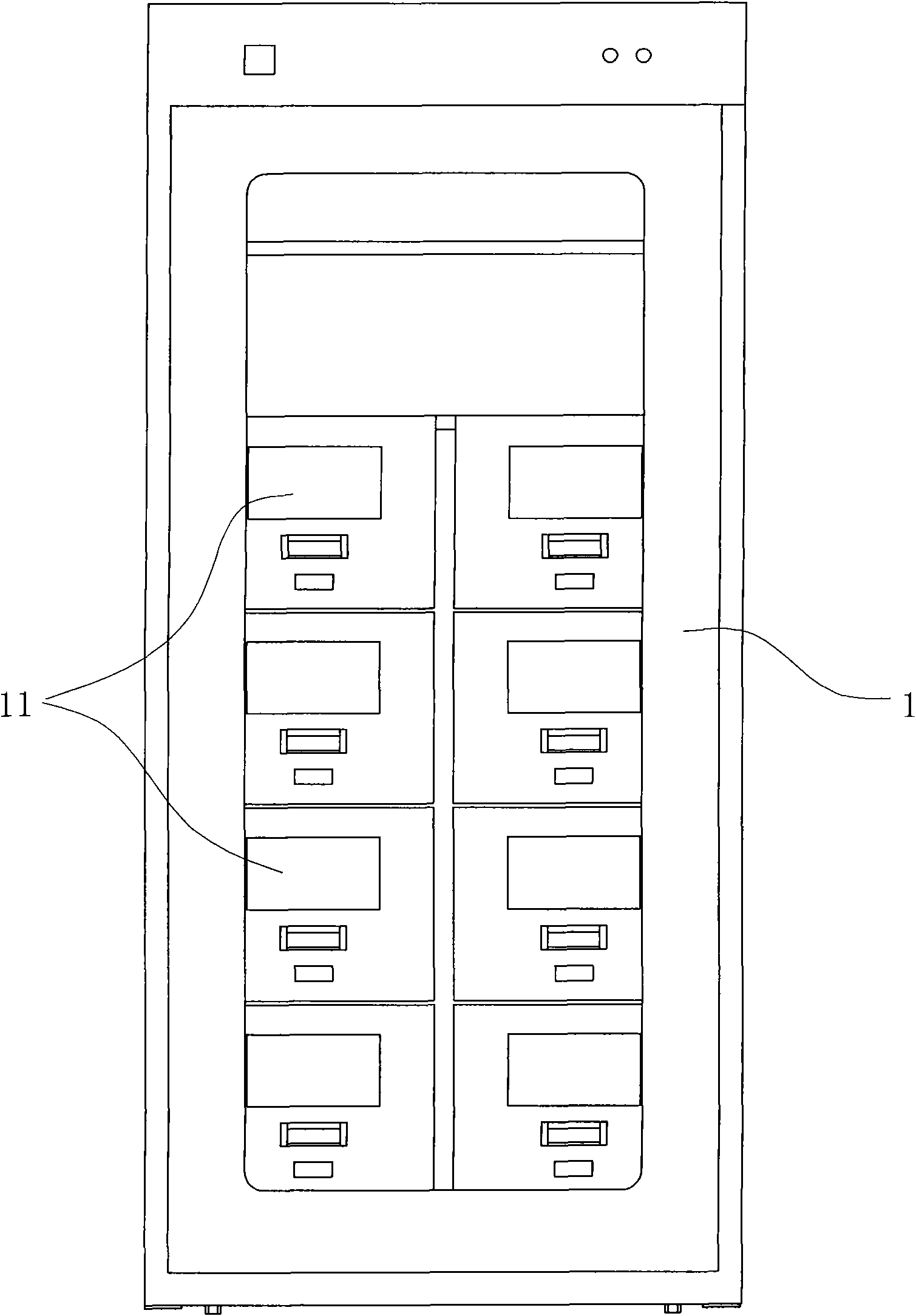

Transformer substation grounding wire monitoring device and monitoring method thereof

ActiveCN101820139AAdaptableSimple structureSupervisory desks/panelsBoards/switchyards circuit arrangementsNetwork connectionEngineering

The invention relates to a transformer substation grounding wire monitoring device which comprises a grounding wire cabinet with a plurality of independent drawers. The monitoring device is characterized in that each drawer is internally provided with a laminate plate, and an elastic piece is arranged below the laminate plate; a sensor for sensing the deformation quantity of the elastic piece and sending switching signals is arranged below the laminate plate of each drawer; the monitoring device also comprises a collector, a concentrator, a display screen and a server, wherein the collector is arranged in the grounding wire cabinet, electrically connected with the sensors and used for collecting and storing switching signals sent by each sensor; the concentrator is electrically connected with the collector and used for realizing the information transmission with the collector; the display screen is electrically connected with the concentrator and used for realizing the information transmission with the concentrator; and the server is provided with a database and background management software and connected with a concentrator network through an electric power local area network. Compared with the prior art, the invention has the advantages of simple structure of the whole set of equipment, low cost and higher promotional value and can truly realize the informationization management, improve the safe production efficiency and effectively stop the occurrence of power transmission accidents caused by switching on with grounding wires.

Owner:NINGBO POWER SUPPLY COMPANY STATE GRID ZHEJIANG ELECTRIC POWER +1

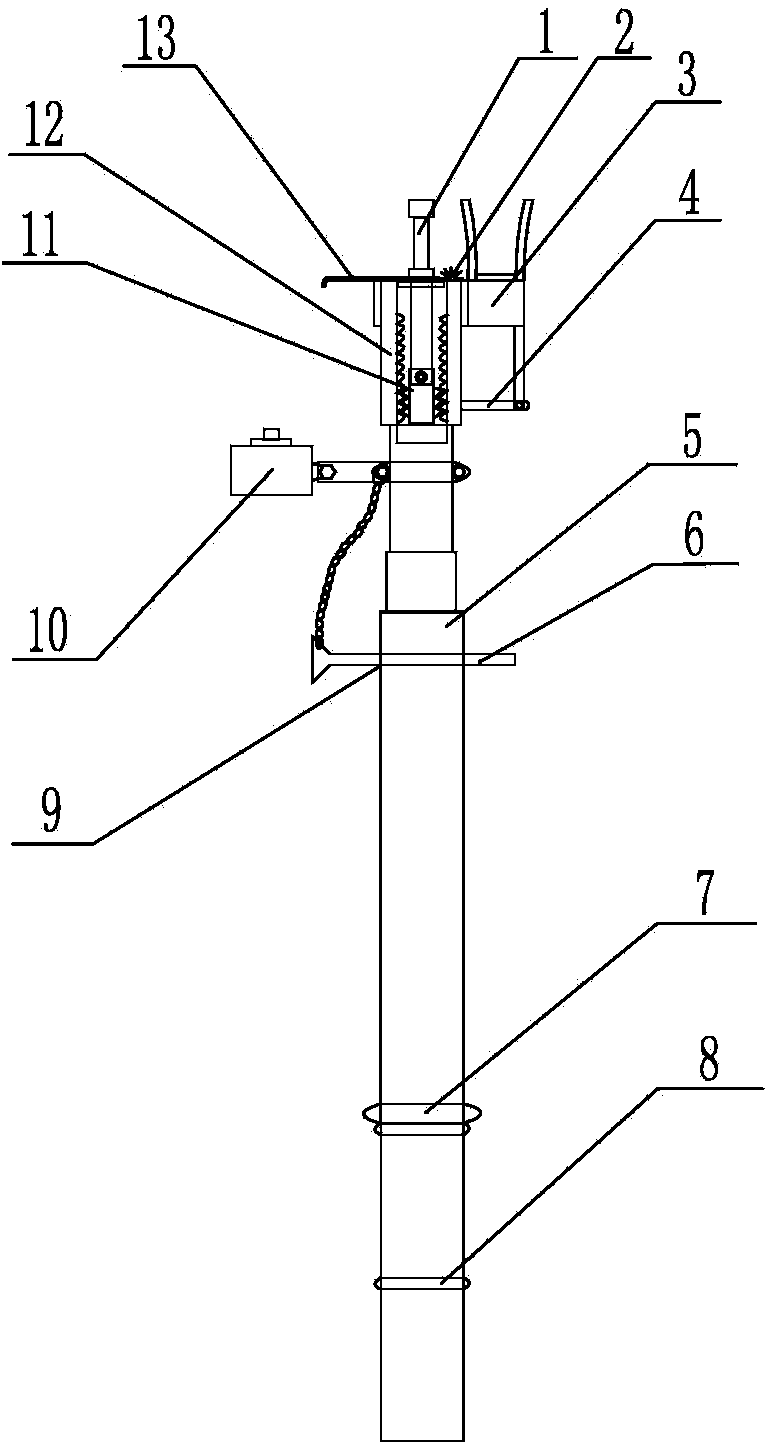

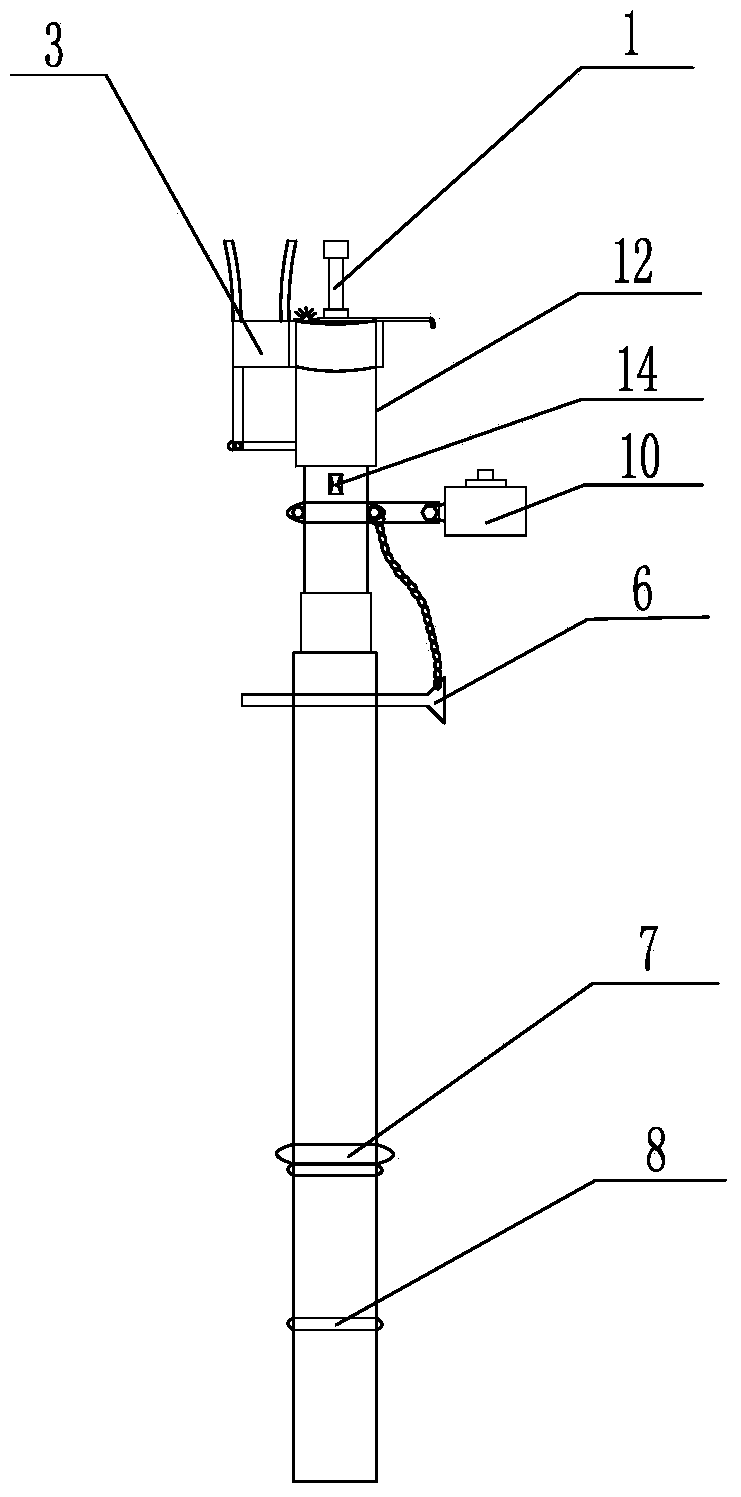

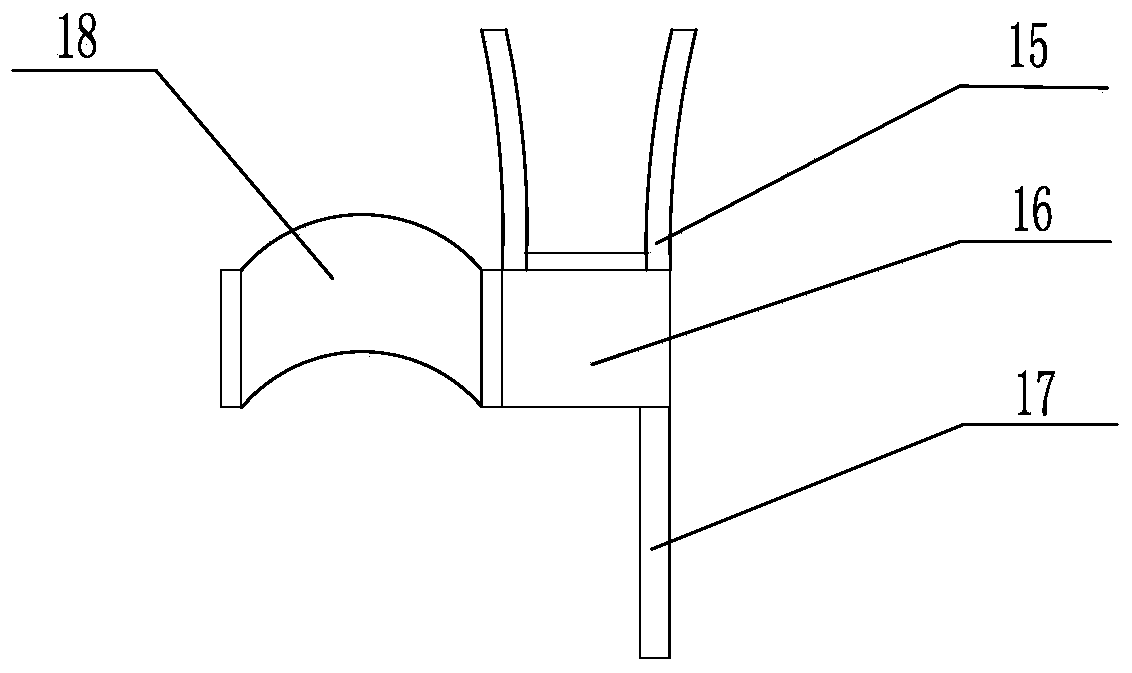

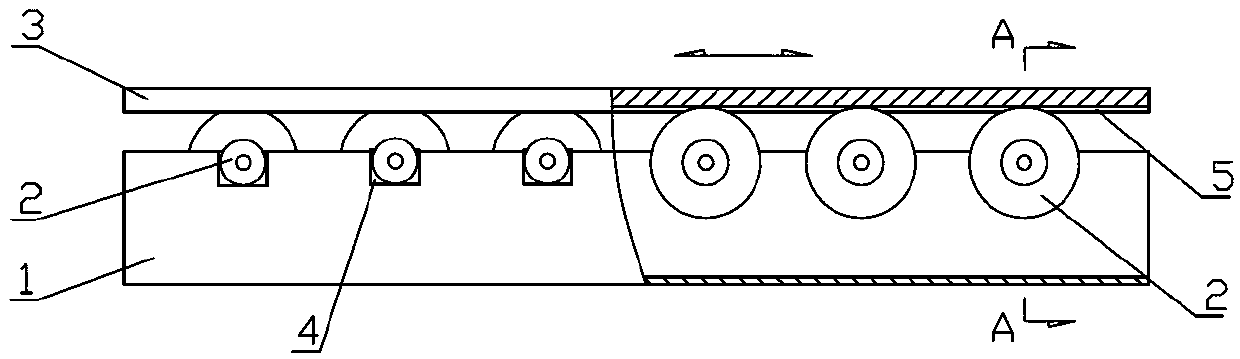

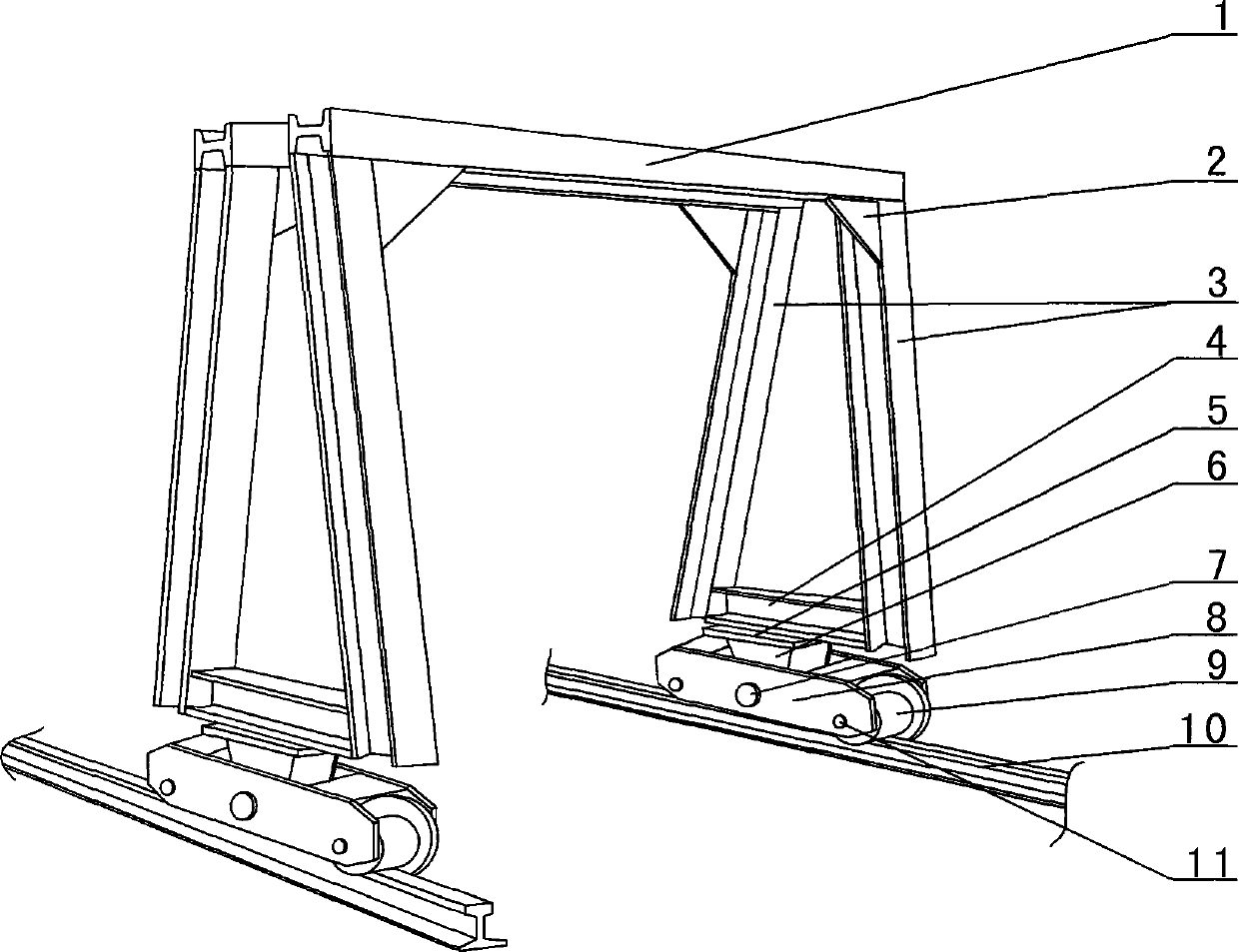

Follow-up device of coal mine fully-mechanized coal winning machine belt support

InactiveCN103216229APromote safe productionImprove safety production efficiencySlitting machinesCoalEngineering

A follow-up device of a coal mine fully-mechanized coal winning machine belt support is characterized in that: the number of upper supports is two, both ends of an i-steel support beam (1) are fixed on two upper ends of the two upper supports, lower ends of the upper supports are provided with a connecting plate (5), the lower part of the connecting plate (5) is connected with the middle part of a shaft (7) through a damping mechanism, both ends of the shaft (7) are fixedly connected with the middle part of two fender plates (8), a follow-up of a wheel (9)-formed support is respectively arranged between two ends of each fender plate (8), and automatic adjustment shock absorption of the support is formed by the shaft (7), a damping mechanism and two wheels (9). The upper support body is manufactured by i-steel, a strong and stable support structure is formed, the damping mechanism effectively prevents the vibration phenomenon at rail joints during marching of the machine, and through the follow-up of the wheel (9)-formed support between the two fender plates, safety production of fully-mechanized coal winning machine belt support is improved.

Owner:HENAN YONGHUA ENERGY

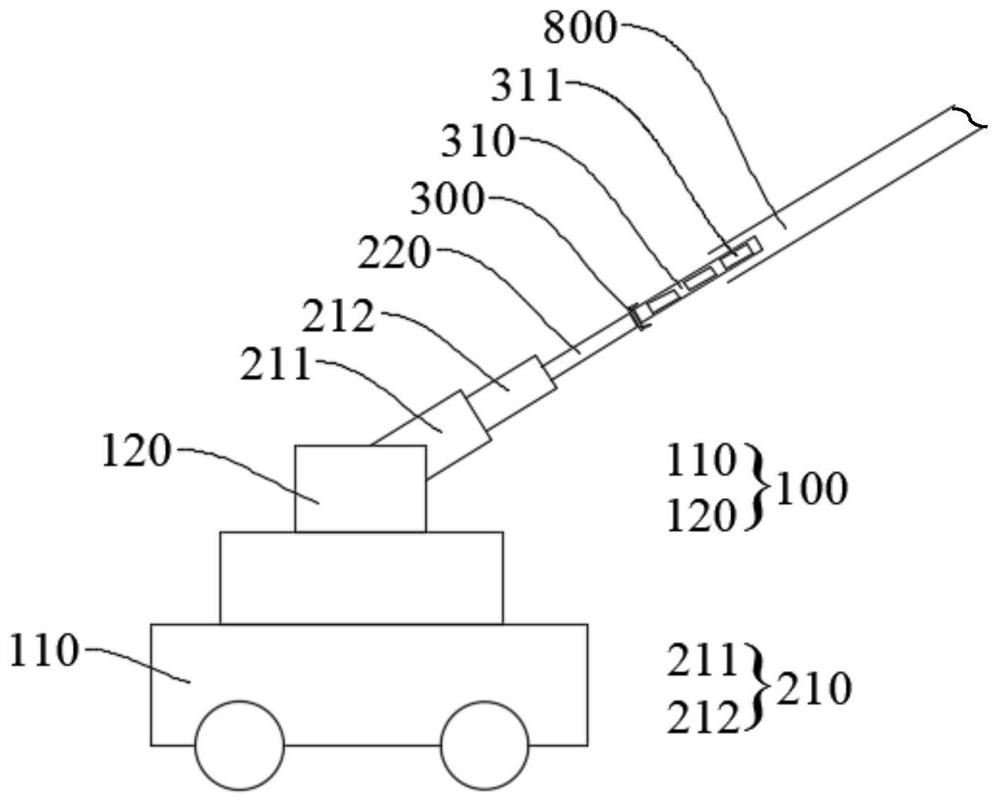

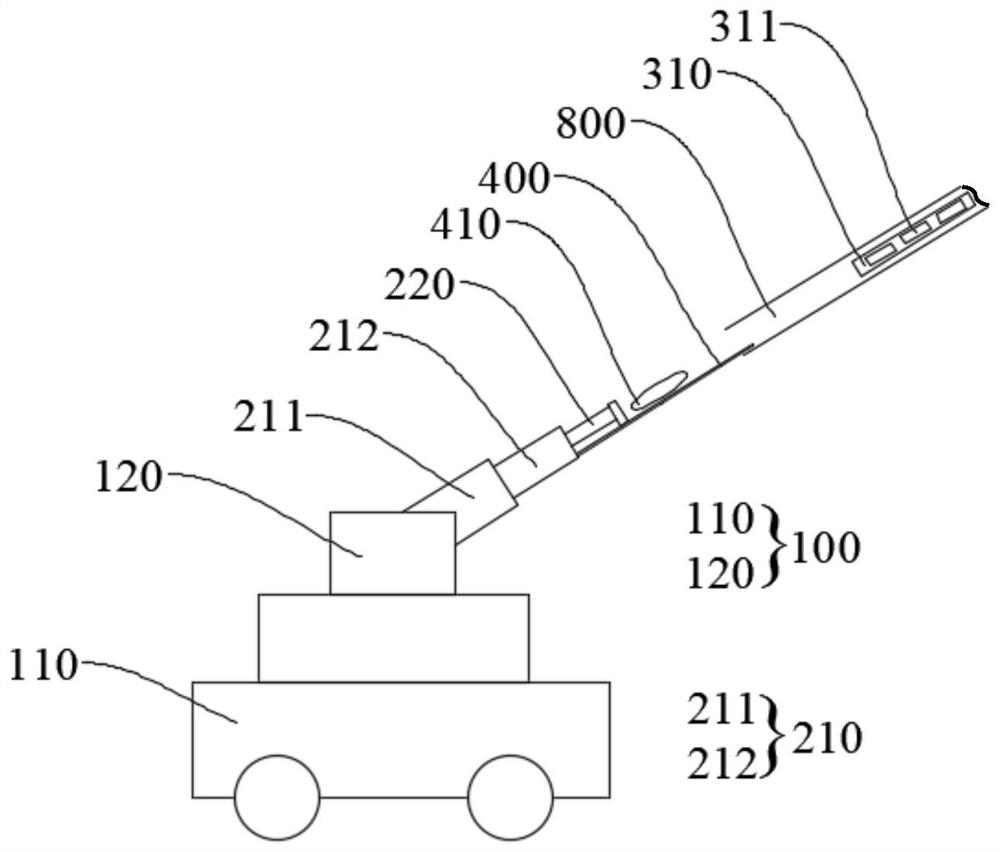

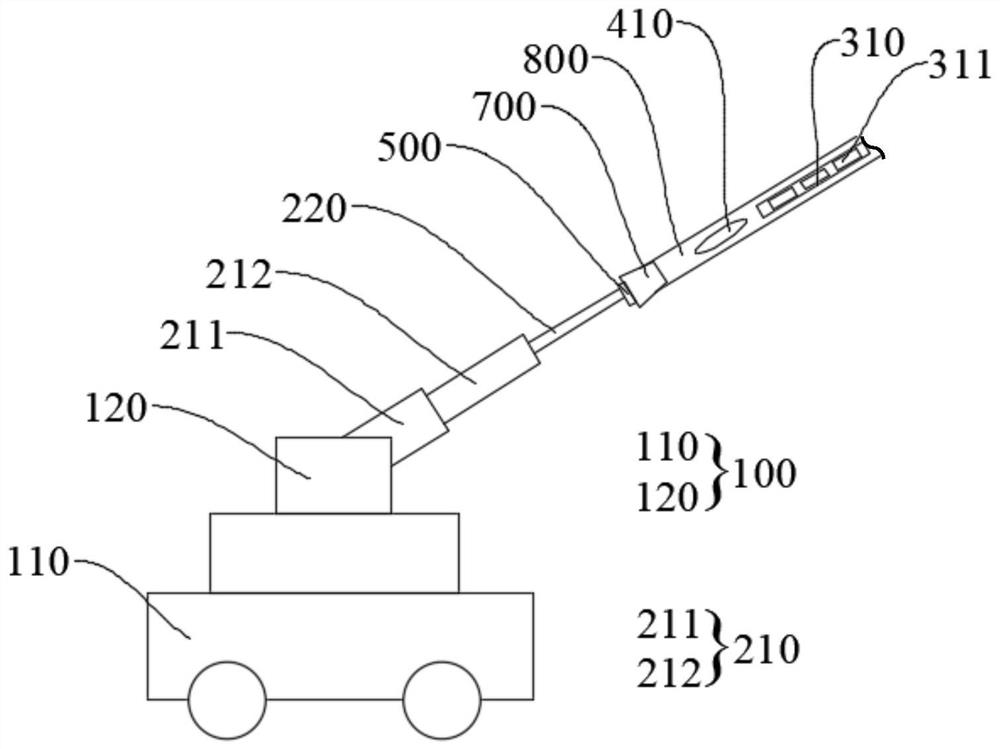

Explosive loading truck

PendingCN113418424AImprove safety production efficiencySave human effortUnderground miningBlastingExplosive AgentsTruck

The invention provides an explosive loading truck, and belongs to the technical field of coal mining. The explosive loading truck is used for filling a blast hole with a carrier containing explosives. The explosive loading truck can comprise a movable chassis, a power mechanism and a fixing claw, wherein the power mechanism can be fixed to the movable chassis, and the power mechanism can be provided with a push rod extending in the direction away from the movable chassis; and the fixing claw can be fixed to the top end of the push rod and can fix the carrier. When deep hole blasting loading is conducted, the movable chassis controls the explosive loading truck to move to a preset position; then the carrier containing the explosives can be fixed by using the fixing claw; and the power mechanism drives the push rod to push the carrier containing the explosives into the blast hole, and the purpose of loading the explosives into the blast hole is achieved by continuously filling the blast hole with the explosives. According to the explosive loading truck, manpower is greatly reduced in a mechanical explosive loading mode, so that the purposes of rapid explosive loading and safe explosive loading are achieved, and the safety production efficiency of a coal mine is improved.

Owner:SHAANXI COAL CAOJIATAN MINING CO LTD +1

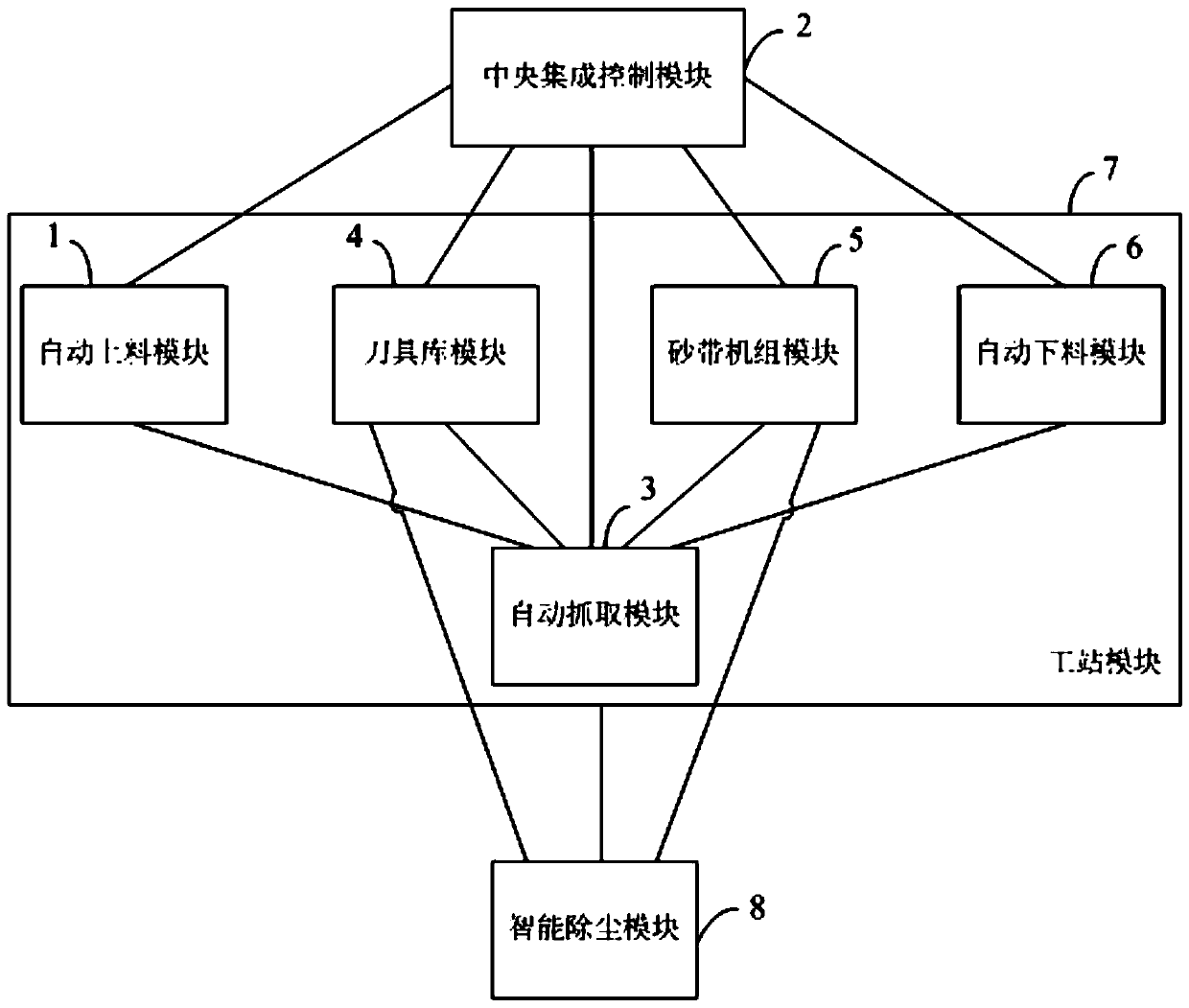

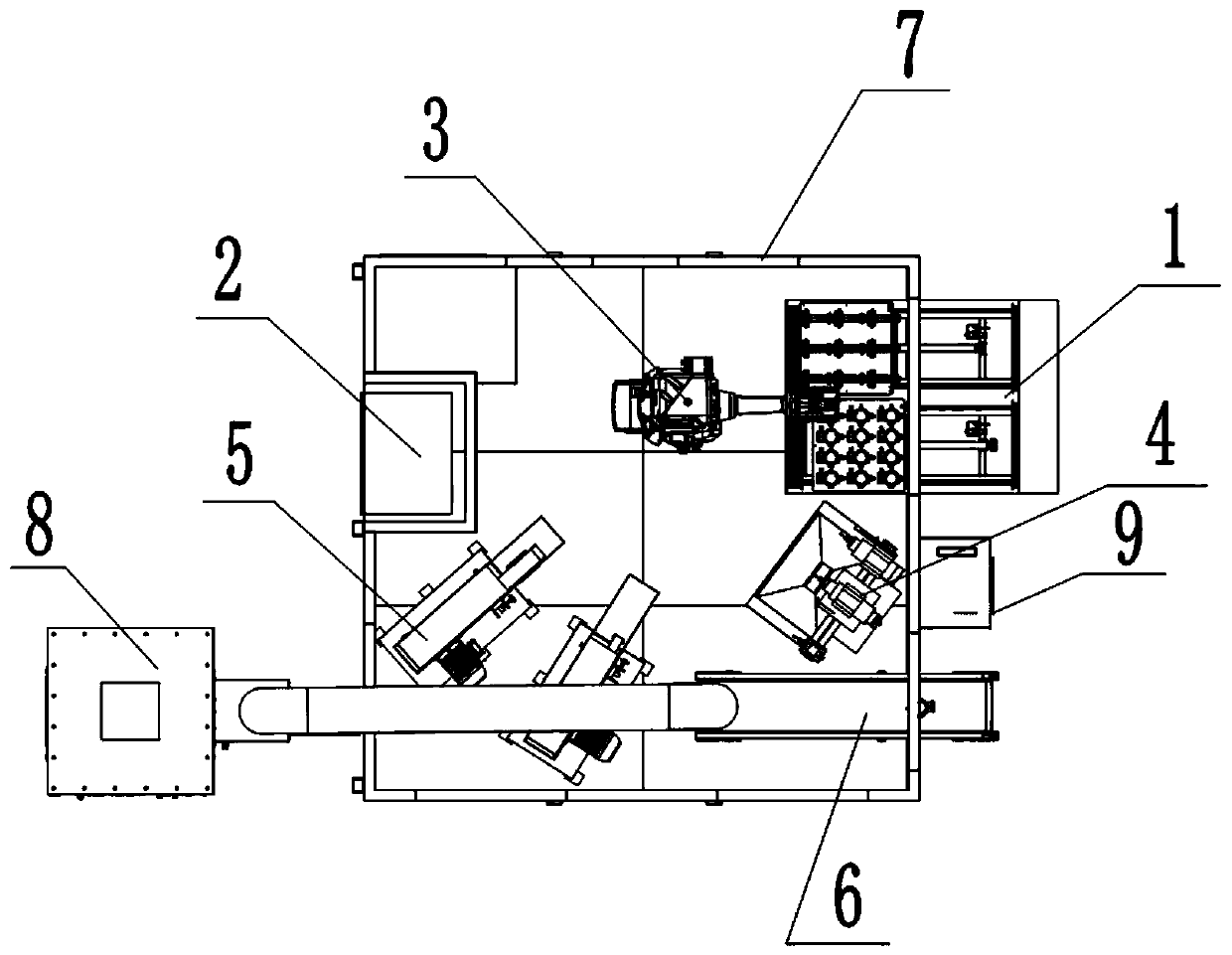

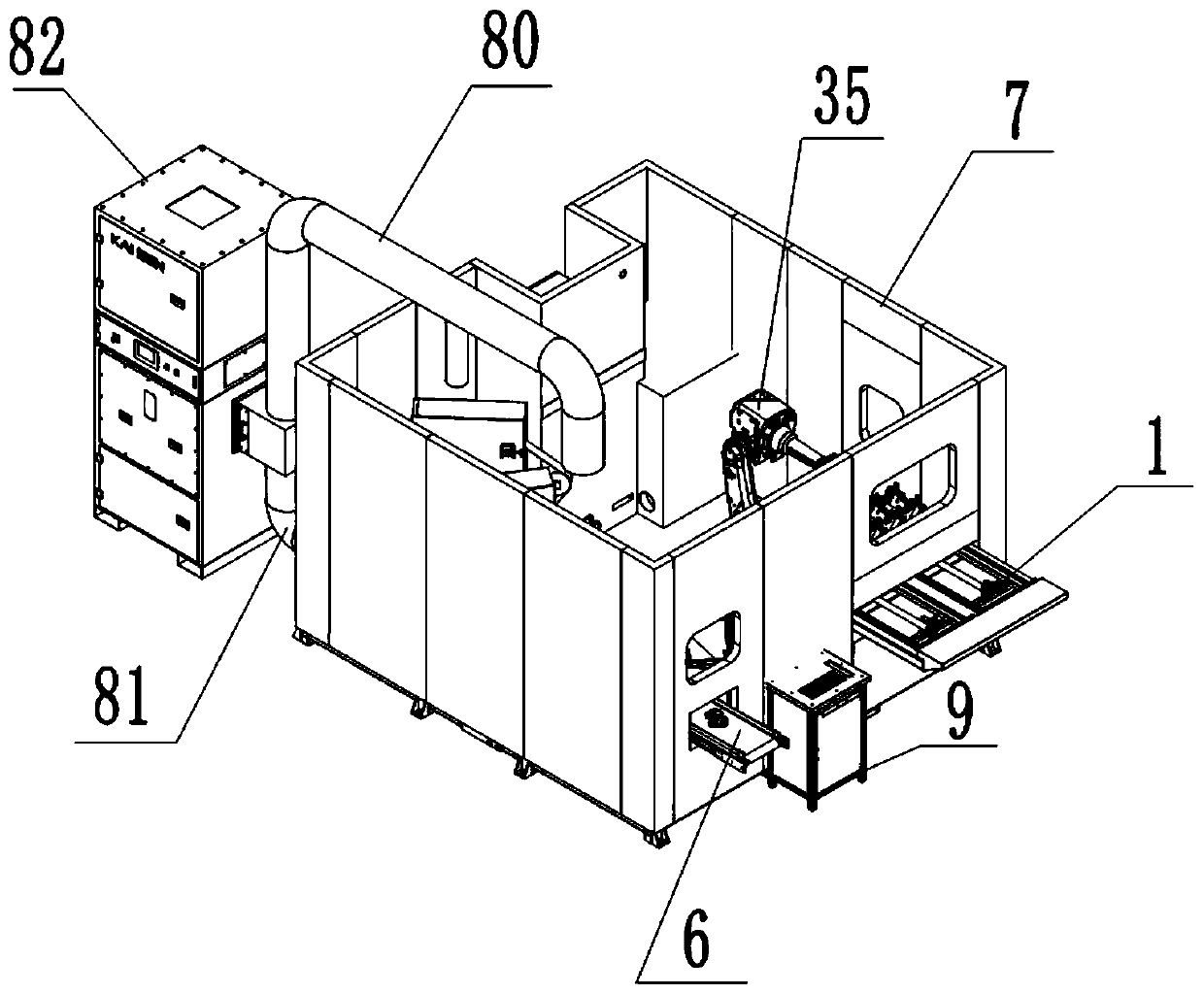

Automatic grinding device for aluminum alloy parts of high-speed rail overhead line system

PendingCN110524253AGuaranteed accuracy consistencyEnsure appearance consistencyDirt cleaningOther manufacturing equipments/toolsEngineeringOverhead line

The invention discloses an automatic grinding device for aluminum alloy parts of a high-speed rail overhead line system. The automatic grinding device is characterized in that a central integrated control module sends different signals to an automatic feeding module, an automatic grabbing module, a cutter module, an abrasive belt unit module and an automatic discharging module, the automatic feeding module feeds the aluminum alloy castings to a grabbing position, and the automatic grabbing module sequentially grabs the grabbed aluminum alloy castings at the grapping position to the cutter module, the abrasive belt unit module and the automatic discharging module; the cutter module and the abrasive belt unit module grind the aluminum alloy castings separately to obtain the aluminum alloy parts, the automatic discharging module conveys the aluminum alloy parts, the automatic feeding and discharging module, the automatic grabbing module, the cutter module and the abrasive belt unit moduleare placed on a work station module, and an intelligent dust removal module is used for removing the dust in the cutter module, the abrasive belt unit module and the work station module. The parts ground by the device are small in die assembly seam and tidy in burrs and seams, and the labor cost is greatly saved.

Owner:宝鸡保德利电气设备有限责任公司

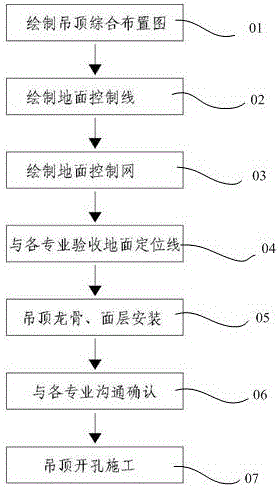

Suspended ceiling installation method

ActiveCN105672657AHigh positioning accuracyImprove stabilityBuilding material handlingKeelControl line

The invention provides a suspended ceiling installation method which comprises the following steps: drawing ground control lines on the ground in a room requiring for a suspended ceiling; setting wires along a suspended ceiling layout according to a designed comprehensive layout graph of the suspended ceiling using the drawn ground control lines, and forming a complete suspended ceiling control net on the ground; determining the positions of components to be installed on the suspended ceiling control net; projecting the positions of the components to be installed to the roof for roof position marking using a measuring tool; performing suspended ceiling installation. The suspended ceiling installation method has the benefits that the suspended ceiling installation method has the advantages of environment-friendly construction, safety, fastness, economy and reliability. Compared with an installation method for a common light steel keel gypsum board suspended ceiling, the installation method disclosed by the invention has the advantages of small workload, short construction period, and reduction of waste of a large quantity of materials and artificial rework and repair expenses and has the characteristics that the repair cost for a large number of mis-perforated holes is reduced compared with that of the common light steel keel gypsum board suspended ceiling and the problem of reduction of the integral stability of a light steel keel skeleton due to mis-perforation is solved.

Owner:湖南省第五工程有限公司

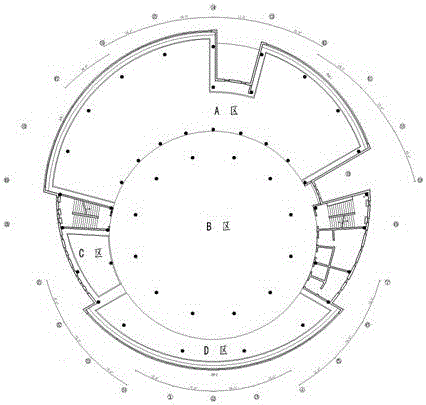

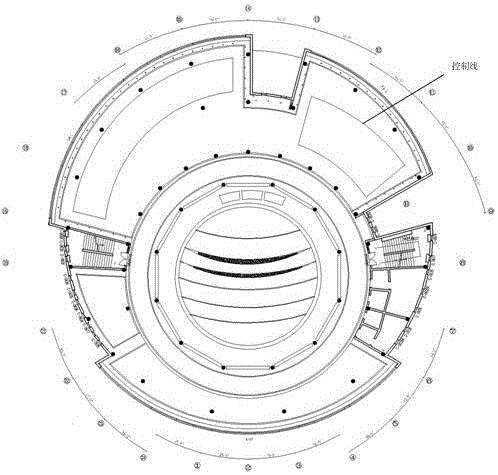

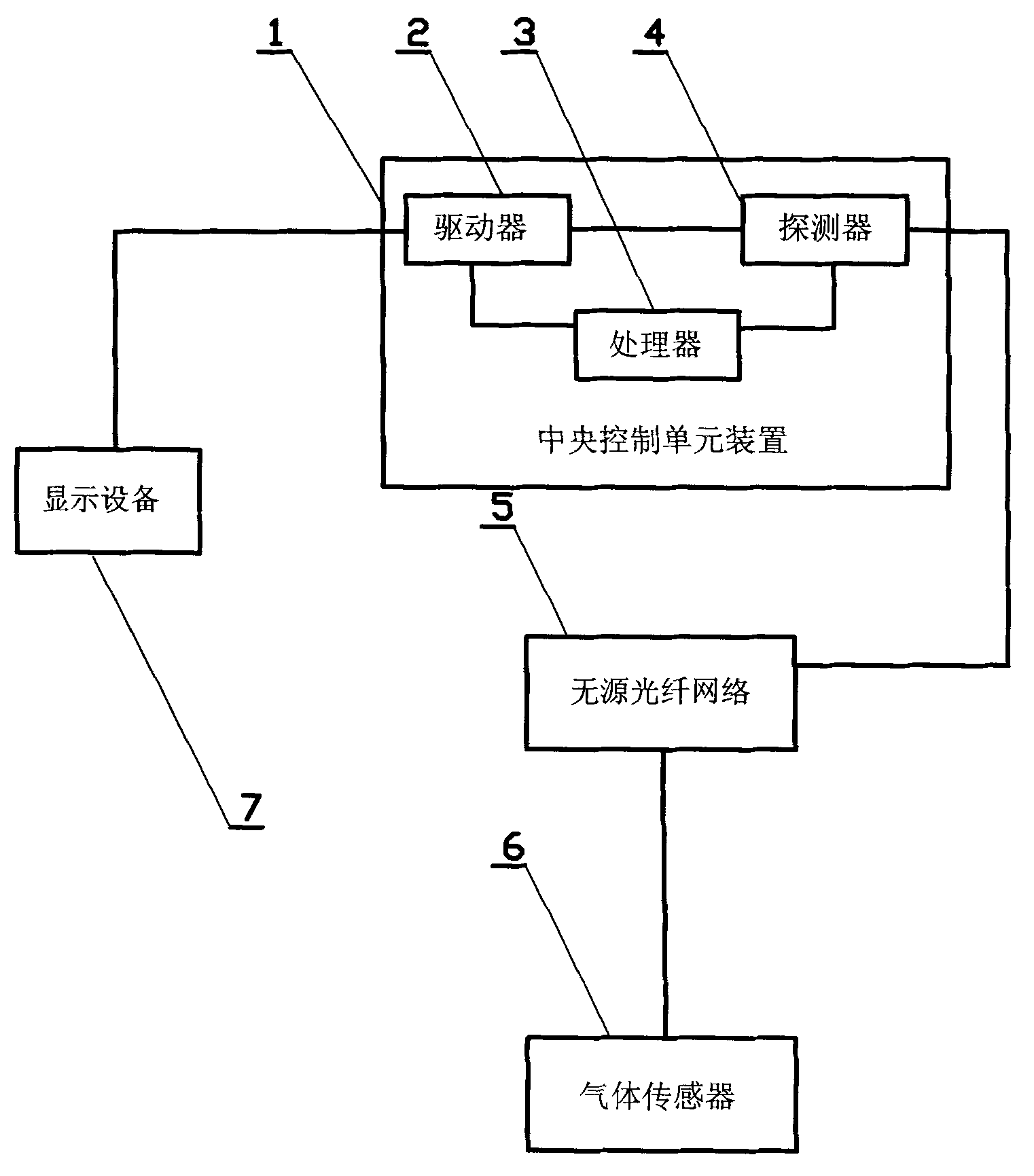

Multiple-point gas sensing detection system

InactiveCN102003212AReduce labor intensityComply with dynamic mobile characteristicsMining devicesElectricityDisplay device

The invention relates to a multiple-point gas sensing detection system. The multiple-point gas sensing detection system is provided with a central control unit device, the inner part of the central control unit device is provided with a driver, a processor and a detector, the driver, the processor and the detector are mutually electrically connected, and the central control unit device is electrically connected with a display device to transmit data. The multiple-point gas sensing detection system is provided with a gas sensor, and the gas sensor is arranged on the lane wall and connected with the central control unit device through a passive optical network tor transmit data. The multiple-point gas sensing detection system is in line with dynamic mobile features of the working face, analyses data so as to predict failure in advance, greatly reduces labor intensity, saves time and labor, improves the efficiency of safety in production, and has promotion value.

Owner:徐州翔和电气设备有限公司

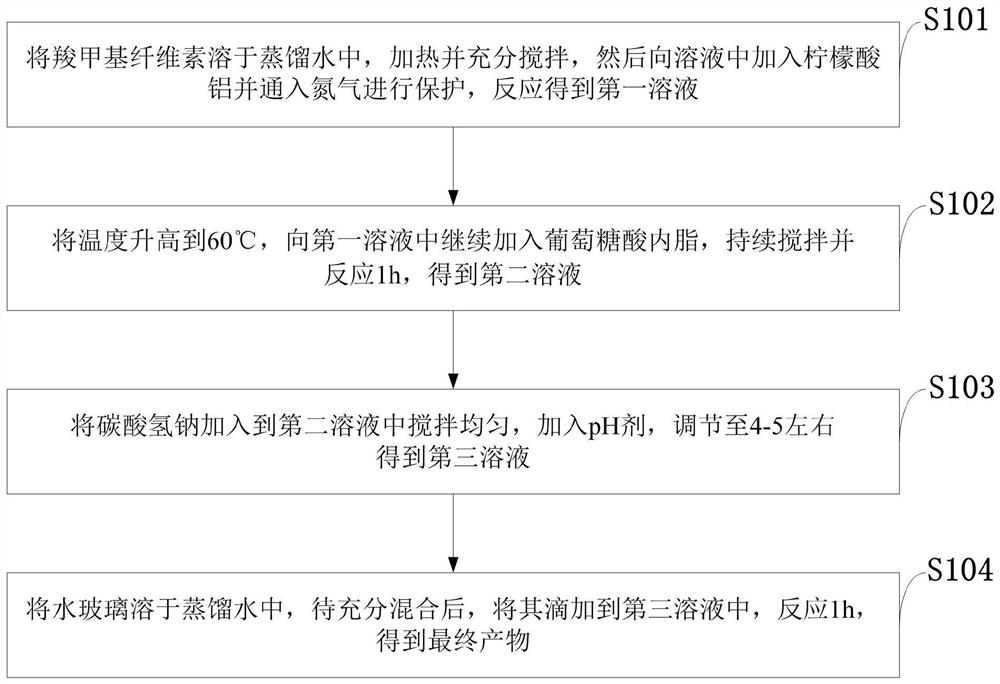

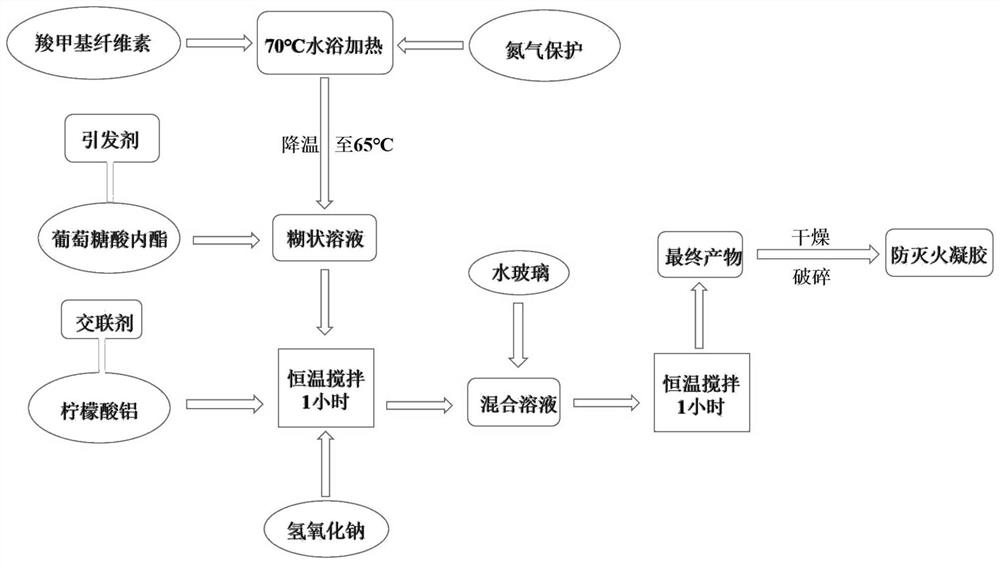

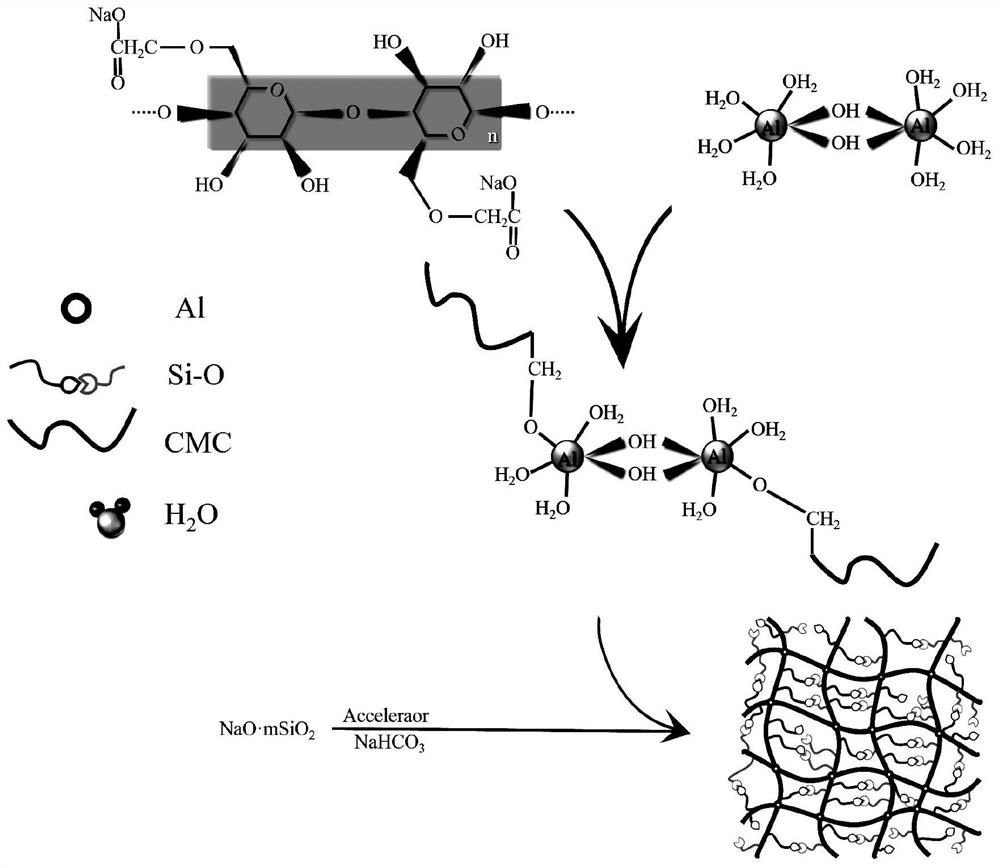

Fire preventing and extinguishing gel preparation method and coal mine fire preventing and extinguishing method

InactiveCN113058193APromote degradationWith reusable effectDust removalFire preventionSodium bicarbonateCellulose

The invention belongs to the technical field of coal mine fire prevention and extinguishment, and discloses a fire preventing and extinguishing gel preparation method and a coal mine fire preventing and extinguishing method. The fire preventing and extinguishing gel is prepared from, by mass, 1%-2% of carboxymethyl cellulose, 4%-5% of a cross-linking agent, 4%-5% of sodium bicarbonate, 4%-5% of a water glass diluted solution, 0.1%-0.3% of a pH regulator and water. The preparation method comprises the following steps: dissolving carboxymethyl cellulose in distilled water, heating and fully stirring, then adding aluminum citrate into a solution, introducing nitrogen for protection, and reacting to obtain a first solution; raising the temperature, continuously adding glucolactone into the first solution, and continuously stirring and reacting to obtain a second solution; adding sodium bicarbonate into the second solution, uniformly stirring, adding the pH regulator, and adjusting to obtain a third solution; dissolving water glass in distilled water, mixing, dropwise adding into the third solution, and reacting to obtain a final product. The coal storage time is prolonged, and the safety production efficiency of a coal mine is improved.

Owner:SHANDONG UNIV OF SCI & TECH

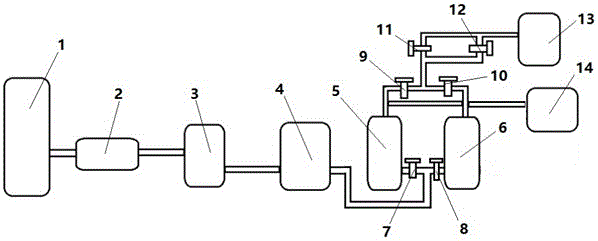

Device for preparing nitrogen and control method thereof

InactiveCN106082144AReduce congestionPrevent affecting stabilityNitrogen purification/separationSpecific gas purification/separationNitrogenEngineering

The invention provides a device for preparing nitrogen. The device comprises an air compressor, a filter, a dryer, a separator and an air storage, wherein the air compressor, the filter, the dryer, the separator and the air storage are sequentially connected; the filter comprises a liquid filter body and a dust filter body; the device further comprises a voltage stabilizer and a pressure sensor. The voltage stabilizer is communicated with the separator through a first loop; a second loop is further arranged on the first loop; the first loop is provided with a first control valve; the second loop is provided with a second control valve; the pressure sensor is respectively arranged on the separator and the first loop. By means of the technical scheme, the production efficiency of preparing nitrogen can be effectively improved, and the influence of pressure floating on stabilization of the device is prevented; the nitrogen preparing device can be simplified, the flow-path plugging condition is reduced; the safety production efficiency is improved, the volume is also relatively small, and disassembling and repairing are convenient.

Owner:宁德盈德气体有限公司

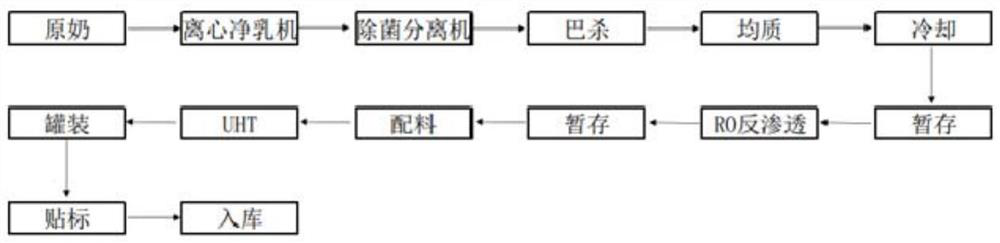

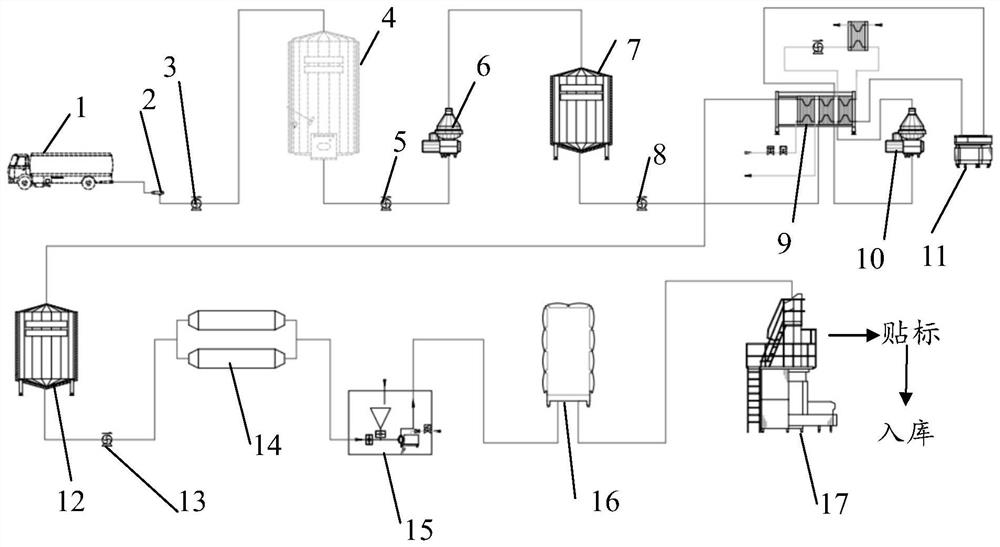

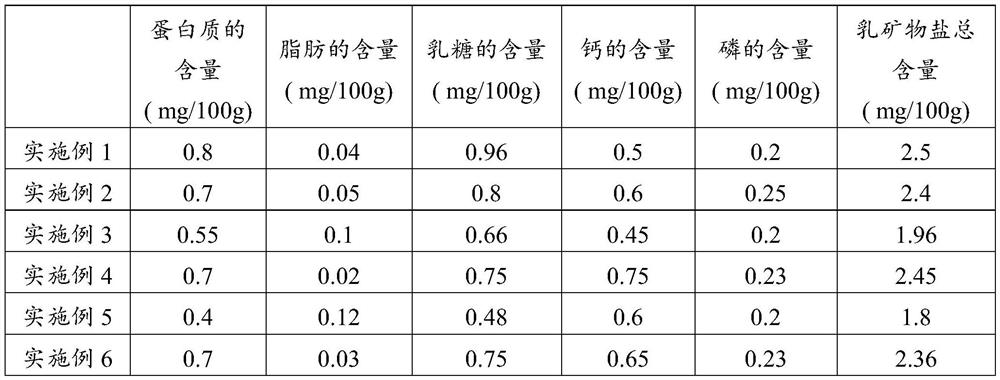

Application of permeate liquid generated in production of concentrated milk, electrolyte beverage and preparation method of electrolyte beverage

PendingCN113016883AIncrease contentImprove the problem of poor powder stabilityMilk preparationBiotechnologyOrganic chemistry

The invention belongs to the technical field of preparation of functional beverages, and particularly relates to application of a permeate liquid generated in production of concentrated milk, an electrolyte beverage and a preparation method of the electrolyte beverage. According to the application of the permeate liquid generated in the production of the concentrated milk in the preparation of the electrolyte beverage, the permeate liquid generated in the production process of the concentrated milk is initiatively applied to the preparation of the electrolyte beverage instead of water, and the permeate liquid is rich in milk mineral salt and protein, so the use amount of the milk mineral salt in the preparation process of the electrolyte beverage can be reduced, and the influence caused by using the milk mineral salt raw material powder is reduced; meanwhile, as the permeate is rich in protein and has natural milk flavor, and additives do not need to be additionally used in the preparation process of the electrolyte beverage, so the electrolyte beverage is greener and more environmentally friendly; and effective supplement of body protein can be realized without adding protein peptide, so that the beverage is deeply welcomed by the majority of consumers. In addition, the electrolyte beverage is prepared by adopting the penetrating fluid instead of water, so that recycling of resources is realized, and water is saved.

Owner:INNER MONGOLIA MENGNIU DAIRY IND (GRP) CO LTD

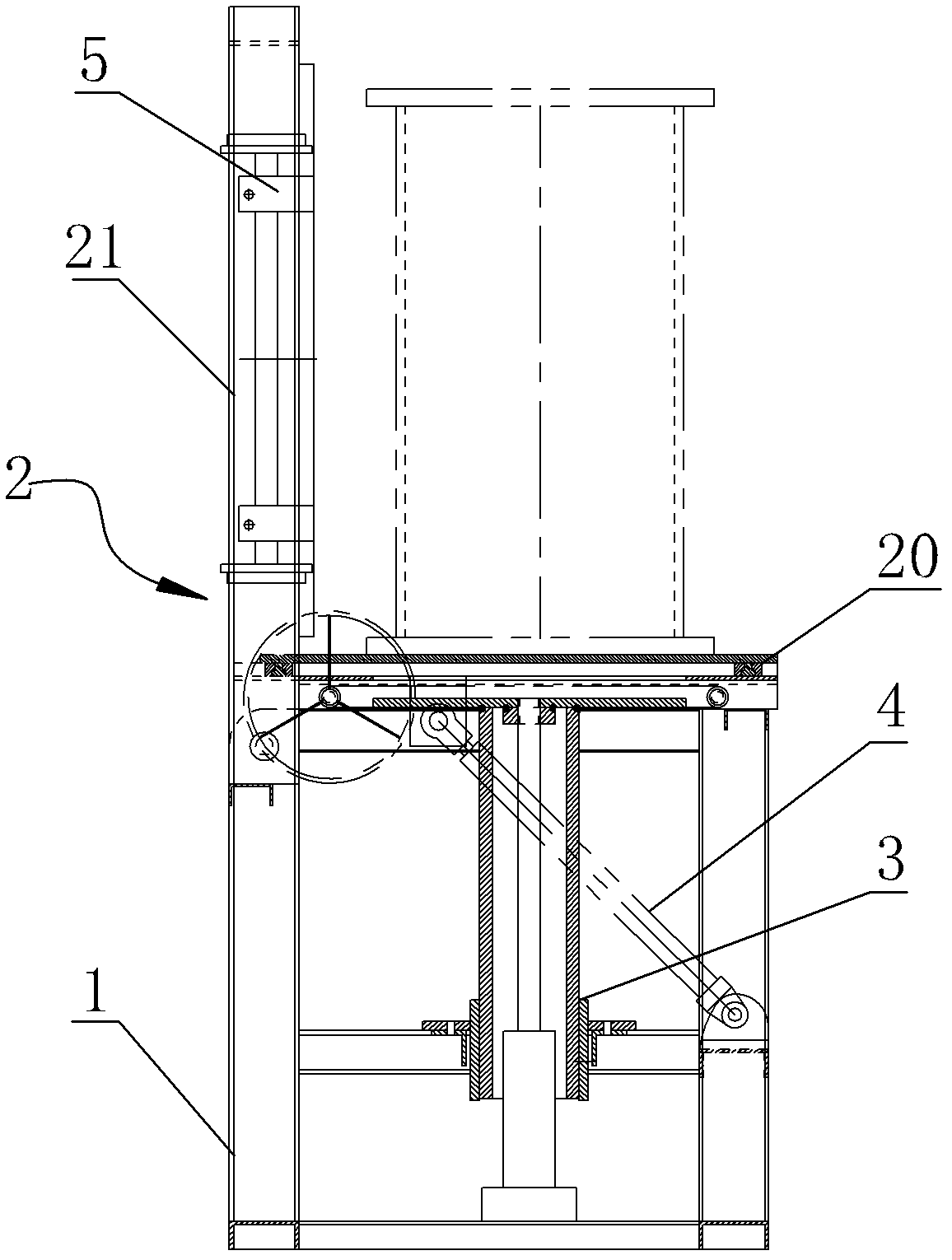

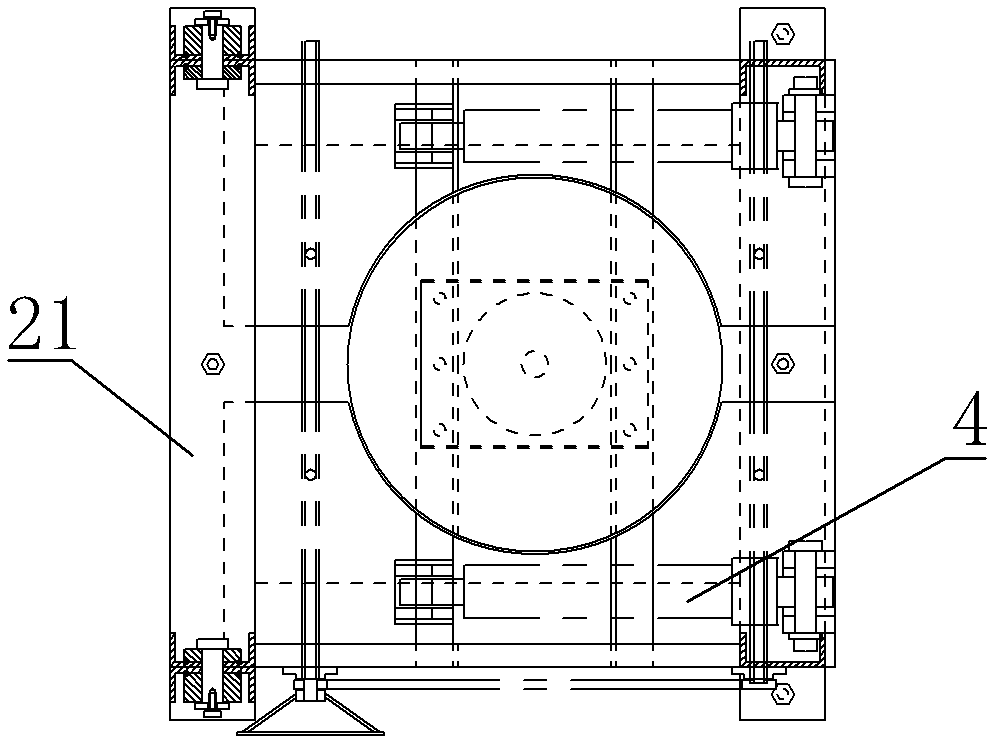

Motor stator casing turnover device

ActiveCN103138512AReduce labor intensityEasy to operateManufacturing dynamo-electric machinesElectric machineControl engineering

The invention relates to a motor stator casing turnover device. The motor stator casing turnover device comprises a machine frame, a casing mould platform arranged on the machine frame, a turnover assembly arranged at the lower portion of the casing mould platform, a lifting drive mechanism connected to the lower portion of the casing mould platform and a turnover drive mechanism connected to the lower portion of the turnover assembly. The turnover assembly comprises a first turnover panel and a second turnover panel which are arranged vertically. When a motor casing is in a vertical state, the first turnover panel is located at the horizontal position. When the motor casing is in a horizontal state, the second turnover panel is located at the horizontal position. The motor stator casing turnover device is simple in operation, can reduce the labor intensity of workers and improve the safety production efficiency and guarantees production safety.

Owner:SUZHOU BETTER TECH

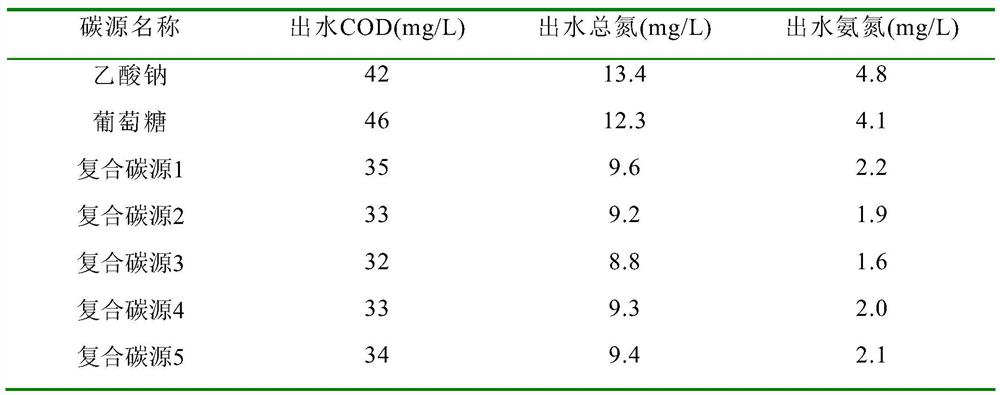

Production process of sewage biological denitrification composite carbon source with low C/N ratio

PendingCN113788536AImprove efficiencyReduce security risksWater treatment compoundsSpecific water treatment objectivesAcetic acidPropanoic acid

The invention discloses a production process of a sewage biological denitrification composite carbon source with a low C / N ratio, which specifically comprises the following steps: (1) taking half of water prepared in proportion, and heating to 35-50 DEG C; (2) sequentially and rapidly dissolving glucose, polyethylene glycol and molasses into the warm water in the step (1) according to a mass ratio, uniformly stirring and mixing for 10 minutes, and filtering to form a solution A; (3) taking a proper amount of water, sequentially adding a proper amount of acetic acid and propionic acid, adding a sodium hydroxide solution until the pH value is 6.5-7.5, uniformly stirring and mixing for 5 minutes, adding glycerol according to a mass ratio, and uniformly stirring and mixing for 5 minutes to form a solution B; and (4) slowly adding the solution A into the solution B, adding the residual water to complement the water, and continuously stirring for 5 minutes to obtain a composite carbon source. The process has the characteristics of simple production process, short time, few bubbles and the like, is convenient to store, transport and use, and is particularly suitable for the production of biological denitrification external carbon sources in sewage treatment plants.

Owner:NANJING RONGZHONG ENVIRONMENTAL ENG RES INST CO LTD

Negative pressure deslagging dredging core pipe valve

InactiveCN108612871ASimple structureEasy to manufactureOperating means/releasing devices for valvesMultiple way valvesSludgeEngineering

The invention discloses a negative pressure deslagging dredging core pipe valve, which is one of self-operated control valves of conventional core pipe valve plates in an original core pipe valve parent series. A valve core pipe is a fixed piece which is perpendicular to the ground surface, and coaxially penetrates through a sleeve I of a valve body, an inner cavity of the valve body and a sleeveII of the valve body from top to bottom; an axial partition layer is arranged in the middle of the valve core pipe; at least one radial circulating hole of each of an input section and an output section is formed in each of the two sides of the axial direction of the partition layer; an upper axial annular valve core and a lower axial annular valve core which surround the partition layer respectively form sealing pairs with annular valve seats at a throat part of each of the sleeve I and the sleeve II; the input section and the sleeve I as well as the output section and the sleeve II are in axial hole type fit, and at least one combination part is arranged in a sealed manner; a driving element which drives the valve body to travel upwards in the axial direction is arranged out of the valvebody; and under the action of liquid gravity and the driving element, the valve body moves reciprocally in the axial direction relative to the valve core pipe so as to realize discharging and closingof sludge and accumulated water. The negative pressure deslagging dredging core pipe valve is simple in structure, small in size, high in cost performance, large in discharging aperture and long in service life, and is flexible and reliable.

Owner:卢星霖

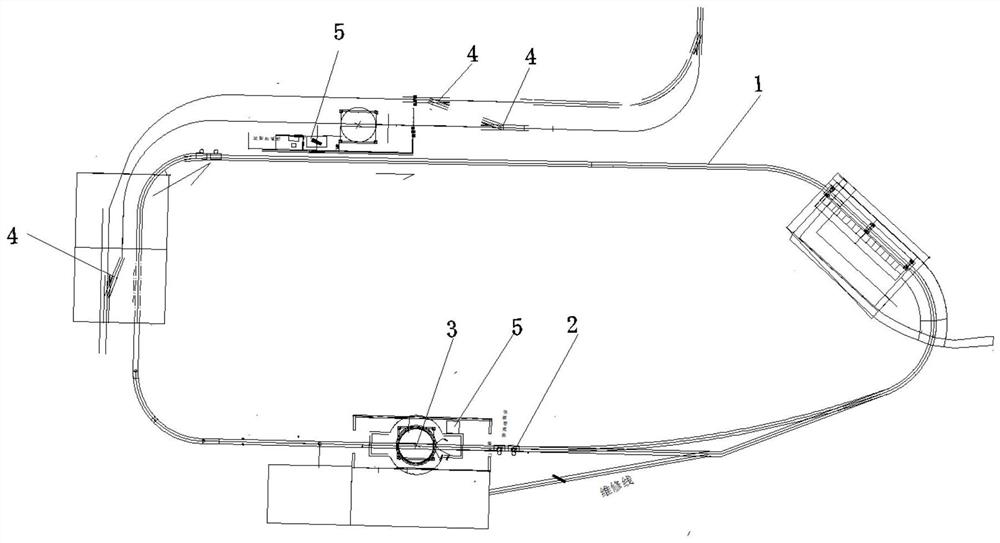

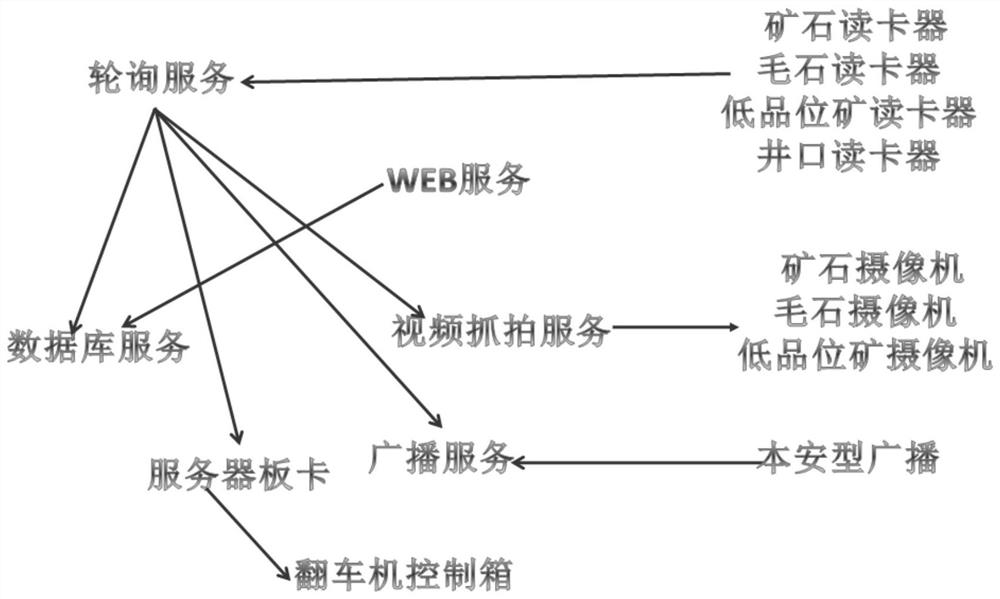

Transportation automatic control system

PendingCN112686347APut an end to violationsReduce the phenomenon of falling off the roadCo-operative working arrangementsClosed circuit television systemsVideo monitoringAutomatic control

The invention discloses an automatic transportation control system. The system comprises a precise positioning base station, a transportation track, an identification card, a turnover device and an automatic management system, and is characterized in that the automatic management system comprises an industrial personal computer, a wheel training service module, a database, a video monitoring system and a broadcasting system, wherein each mine car is provided with a corresponding identification card, and mine car information is written into the identification card; when the tramcar arrives at the accurate positioning base station, the base station reads the information of the tramcar identification card, writes the information into the database, and sends the information to the industrial personal computer to control the corresponding turnover device to unload; and meanwhile, the information is sent to a video monitoring system and a broadcasting system for video snapshot and voice broadcasting. The system is advantaged in that automatic control is adopted, production efficiency is improved, manual participation is reduced, and a safety coefficient of mining and material transportation is increased.

Owner:烟台金曼投资有限公司

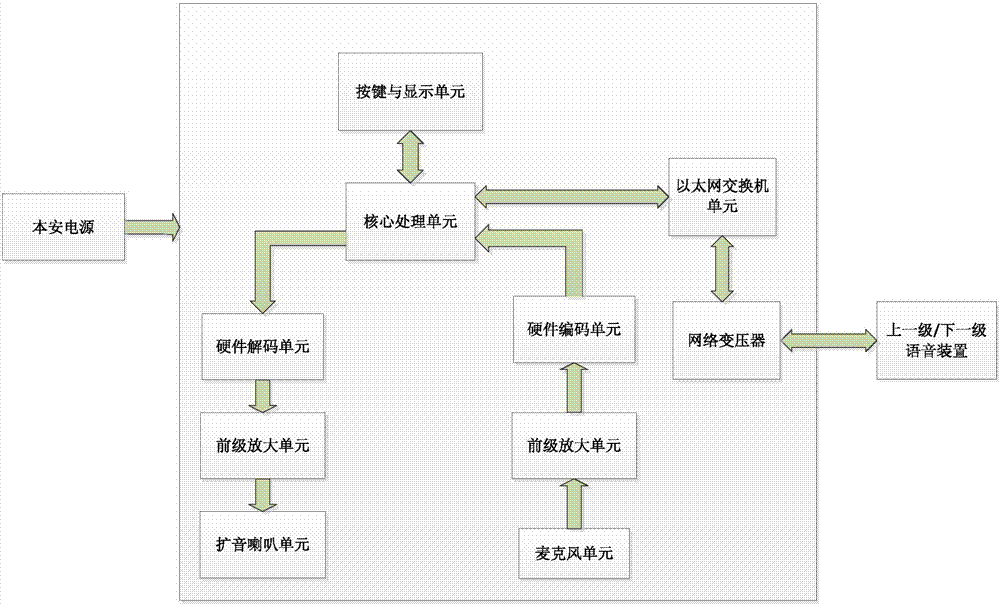

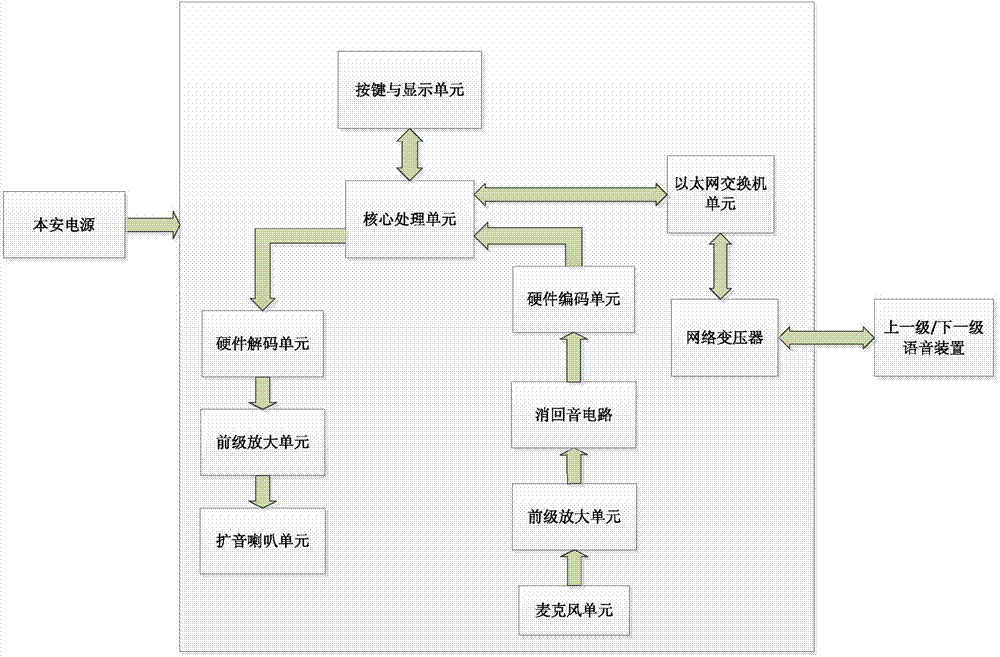

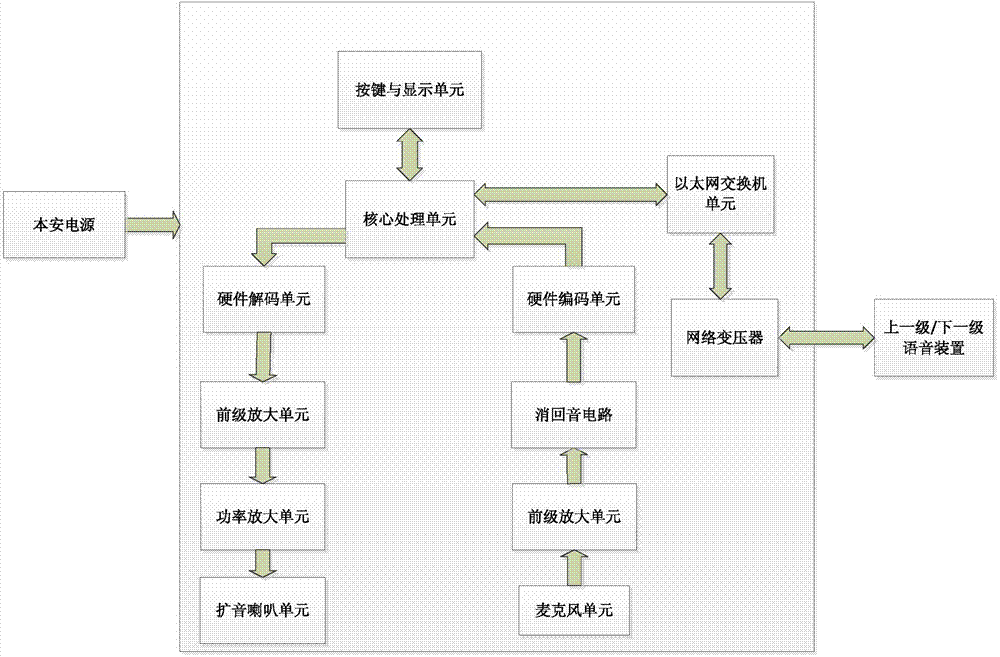

Mining intrinsic safety type voice system and voice device thereof

ActiveCN104104804BImprove safety production efficiencyImplement schedulingInterconnection arrangementsStations for two-party-line systemsKey pressingIp address

The invention relates to a voice conversation system and a voice device, and particularly relates to a mining intrinsic safety type voice system and a voice device thereof. The system comprises an intrinsic safety power supply, a communication data transmission medium, a data processing unit, an ethernet switch unit and voice devices. The data processing unit is provided with a core processing unit, a microphone unit, a pre-amplification unit, a hardware encoding unit, a hardware decoding unit, a power amplification unit, a loudspeaker unit and a button and display unit. The voice devices are communicated via an ethernet, and each voice device is allocated with one IP address. The switch unit supports a full duplex working mode. The mining intrinsic safety type voice device is the voice device adopting the system. A full duplex conversation between any two voice devices or the full duplex conversation with ground dispatching can be realized by the system and the voice device so that dispatching of working personnel under mines can be conveniently realized, and thus coal mine safety production efficiency can be enhanced.

Owner:苏州优米康通信技术有限公司

Belt conveying system capable of conveying material and equipment with upper part and conveying coal with lower part

InactiveCN106494819ASolve the inability to transport materialsTroubleshoot equipmentSupporting framesMetal working apparatusEngineeringCoal

The invention discloses a belt conveying system capable of conveying a material and equipment with an upper part and conveying coal with a lower part. The belt conveying system comprises an upper material conveying trolley, running rails and a lower coal conveying belt system, wherein two parallel running rails are mounted on the top part of a belt rack of the lower coal conveying belt system; the upper material conveying trolley is arranged on the upper running rail and can move along the running rail; the belt rack is fixedly connected to the ground. According to the belt conveying system, the running rails and the upper material conveying trolley are arranged on the belt rack so as to achieve the function of conveying the material and equipment with the upper part and conveying coal with the lower part, and an upper conveying system and a lower coal conveying system are not interfered by each other during the conveying process; meanwhile, a subsequent belt rack assembly is conveyed by the upper material conveying trolley, so that the belt system can be quickly mounted, the labor intensity in material and equipment conveying on a coal face can be greatly reduced, the safe production efficiency of the coal mine can be improved, and the conveying capacity at the coal face can be effectively improved; the personal casualties caused by conveying the material and equipment with the belt without following the rules in a traditional belt conveying system can be prevented.

Owner:GUIZHOU PANJIANG REFINED COAL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com