Laser-based road surface cutting device

A cutting device and laser technology, applied in the field of infrastructure construction, can solve the problems of high cost, large pollution, low road cutting efficiency, etc., and achieve the effects of reducing pollution and noise, reducing pollution, and improving production safety efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

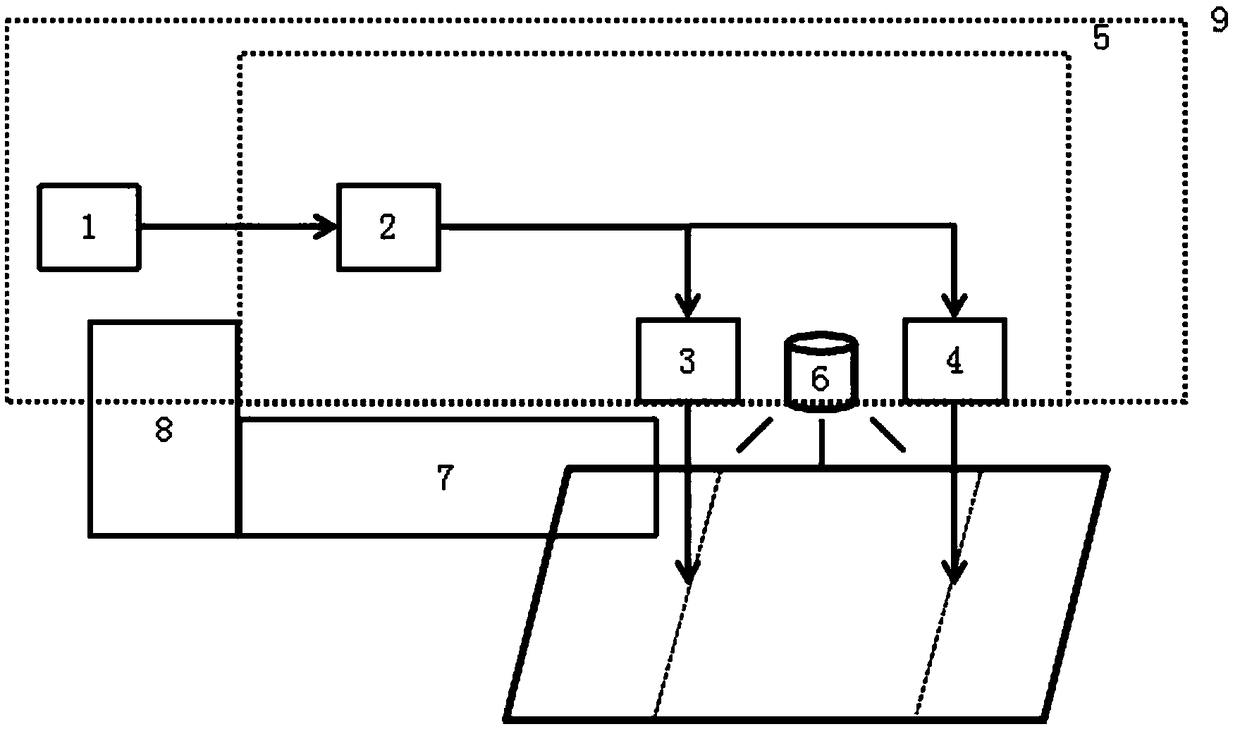

[0023] Such as figure 1 As shown, the present invention provides a laser-based pavement cutting device, said device comprising:

[0024] A laser 1, the laser 1 can transmit a light source through optical fiber coupling, wherein the light source is an adjustable continuous light source or pulsed light source;

[0025] Specifically, such as figure 1 As shown, the laser 1 is a device capable of emitting laser light. According to the working medium, the laser 1 can be divided into four categories: gas laser, solid laser, semiconductor laser and dye laser. Free electron lasers have also been developed recently, and high-power lasers are usually pulsed or continuous. Said laser 1 transmits adjustable continuous or pulsed light source through fiber coupling.

[0026] A beam splitting unit 2, the beam splitting unit 2 focuses the light source emitted by the laser 1, and splits the light source into a first beam and a second beam; further, the beam splitting unit 2 can adjust the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com