Rib spalling real-time prediction method

A real-time prediction and coal wall technology, which is applied in measuring devices, earth square drilling, and electromagnetic wave detection, etc., to achieve the effects of identifying large depths, improving the operating rate and recovery rate, and preventing partial side accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

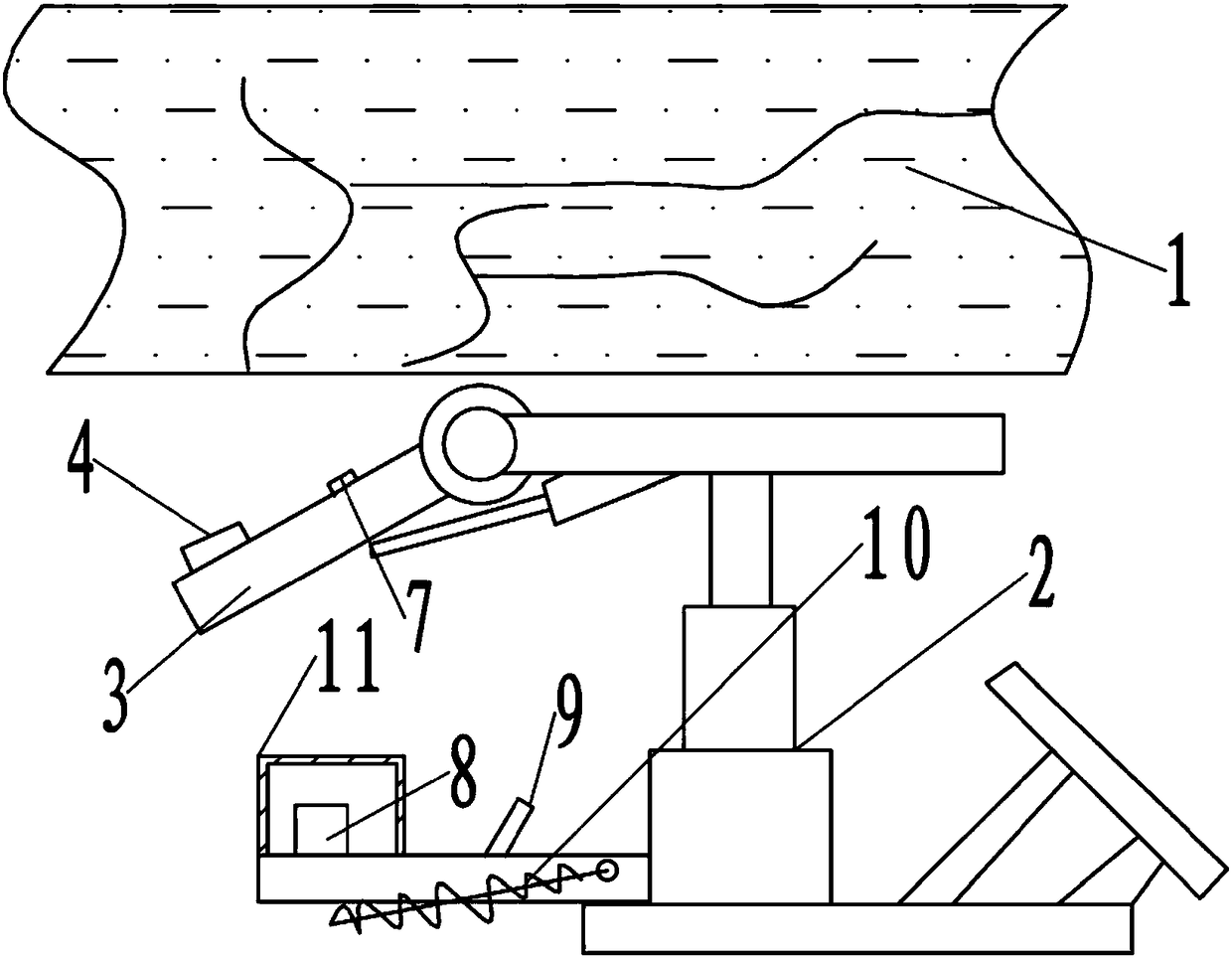

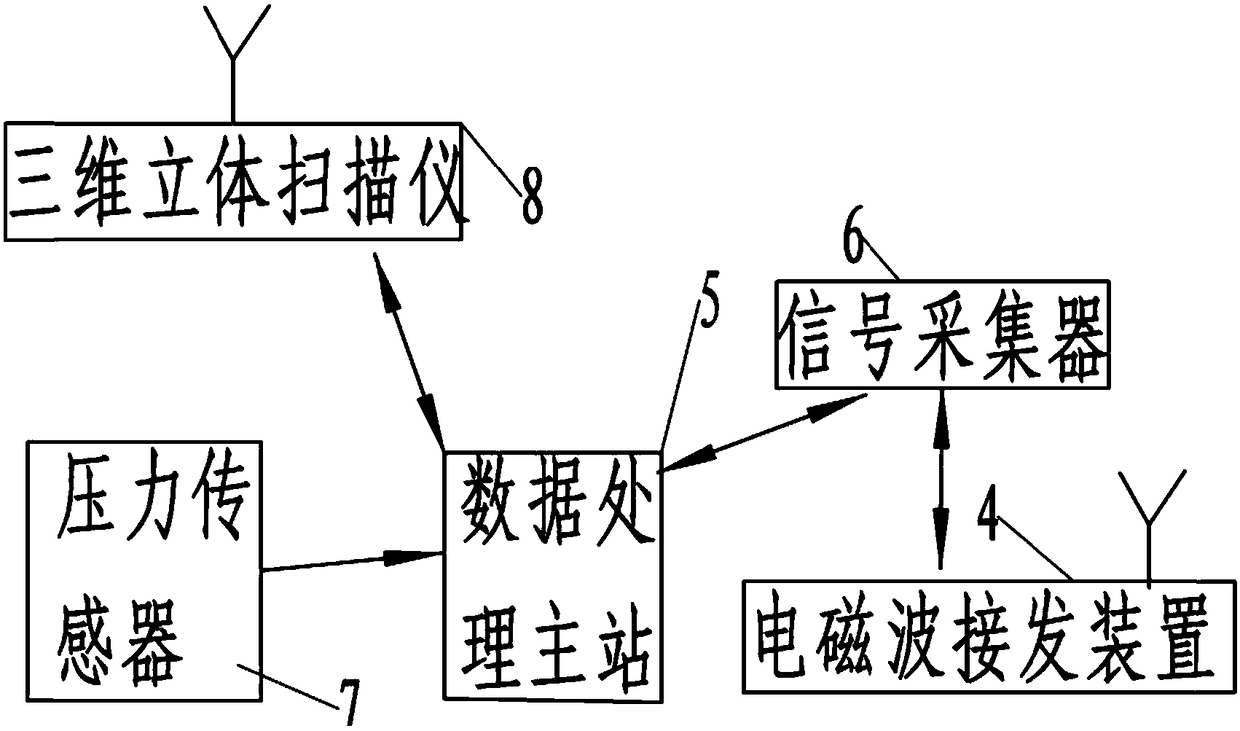

[0054] Example 1, such as Figure 1-3 , also includes a pressure sensor 7 arranged on the upper surface of the side protection board 3; the pressure sensor 7 transmits the positive pressure information of the receiving side coal wall 1 to the data processing master station 5; the electromagnetic wave sending device 4 is arranged on the side protection board 3 On the upper surface or on the frame of the hydraulic support 2; the signal collector 6, the three-dimensional scanner 8 and the data processing master station 5 are arranged on the hydraulic support 2; a swing motor is also arranged on the hydraulic support 2, and the output of the swing motor A rotating telescopic manipulator 10 is connected to the shaft, and a brush for cleaning the upper surface of the side guard 3 is arranged on the rotating telescopic manipulator 10; The water nozzle 9; the three-dimensional scanner 8 is a three-dimensional laser scanner, and the three-dimensional scanner 8 is provided with a protec...

Embodiment 2

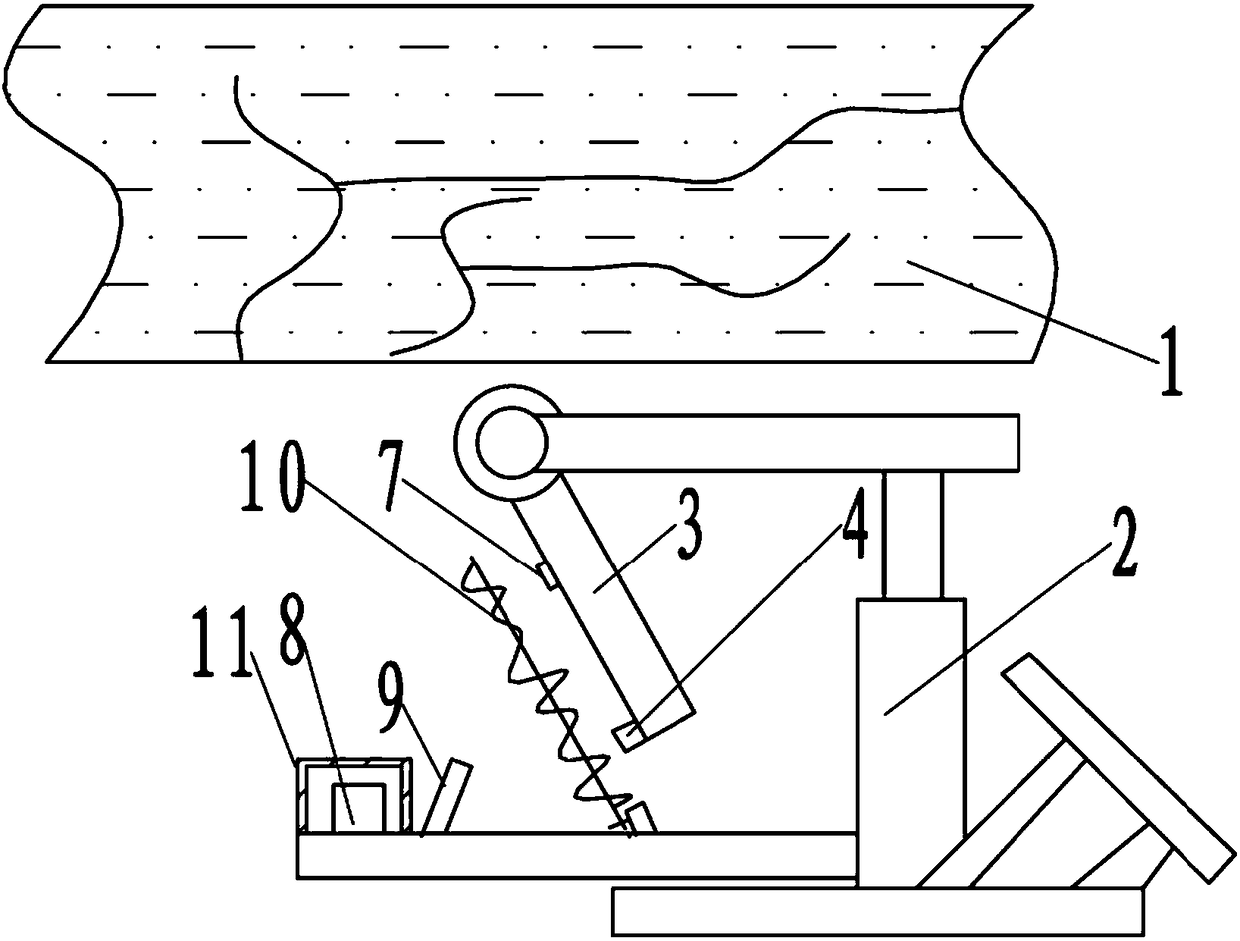

[0060] Embodiment 2: as Figure 4-8 , also includes a pressure sensor 7 arranged on the upper surface of the roof 12 and attached to the lower surface of the side coal wall 1; thereby reducing real-time prediction costs, the number of pressure sensors 7 can be designed according to different coal seam layouts and experience. Realize preliminary rough prediction.

[0061] A lifting screw 13 is arranged on the base of each hydraulic support 2 in the underground working face, and a walking track 14 is arranged on the nut seat of the lifting screw 13, and the walking track 14 is sequentially connected to form a conveying track, and a walking trolley is arranged on the conveying track 15; the signal collector 6 and the three-dimensional scanner 8 are arranged on the walking trolley 15 respectively, and the electric screw rod 16 is vertically arranged on the walking trolley 15, and the electromagnetic wave sending and receiving device 4 is arranged on the screw nut seat of the elect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com