Multiple-point gas sensing detection system

A technology of gas sensing and detection system, which is applied in the field of multi-point gas sensing and detection system to achieve the effect of reducing labor intensity and improving safety production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

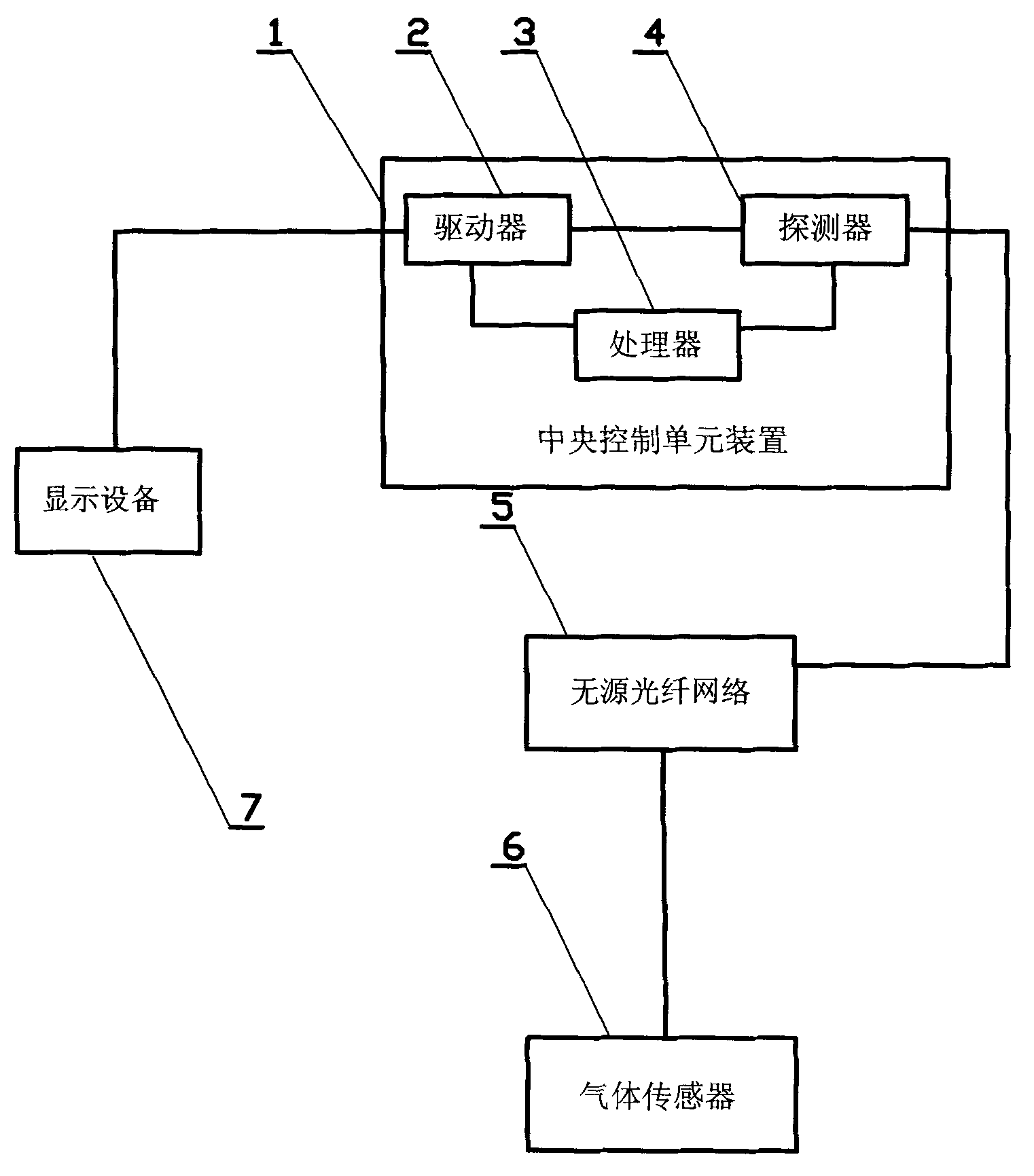

[0009] In the figure, the multi-point gas sensing detection system includes a central control unit device 1, a driver 2, a processor 3, a detector 4, a passive optical fiber network 5, a gas sensor 6, and a display device 7. The sense detection system is provided with a central control unit device 1, the central control unit device 1 is internally provided with a driver 2, a processor 3 and a detector 4, and the driver 2, processor 3 and detector 4 are electrically connected to each other, The central control unit device 1 is electrically connected to the display device 7 to transmit data. This kind of multi-point gas sensing detection system is provided with a gas sensor 6, and the gas sensor 6 is installed on the roadway wall, and through the passive optical fiber network 5, Connect with the central control unit device 1 to transmit data, and the downhole gas status can be displayed on the display device 7 in real time for warning.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com