Belt conveying system capable of conveying material and equipment with upper part and conveying coal with lower part

A belt transportation and equipment technology, applied in transportation and packaging, metal processing equipment, conveyors, etc., can solve problems such as inability to transport materials, achieve the effect of simple structure, safe operation, and improve the transportation capacity of mining face

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

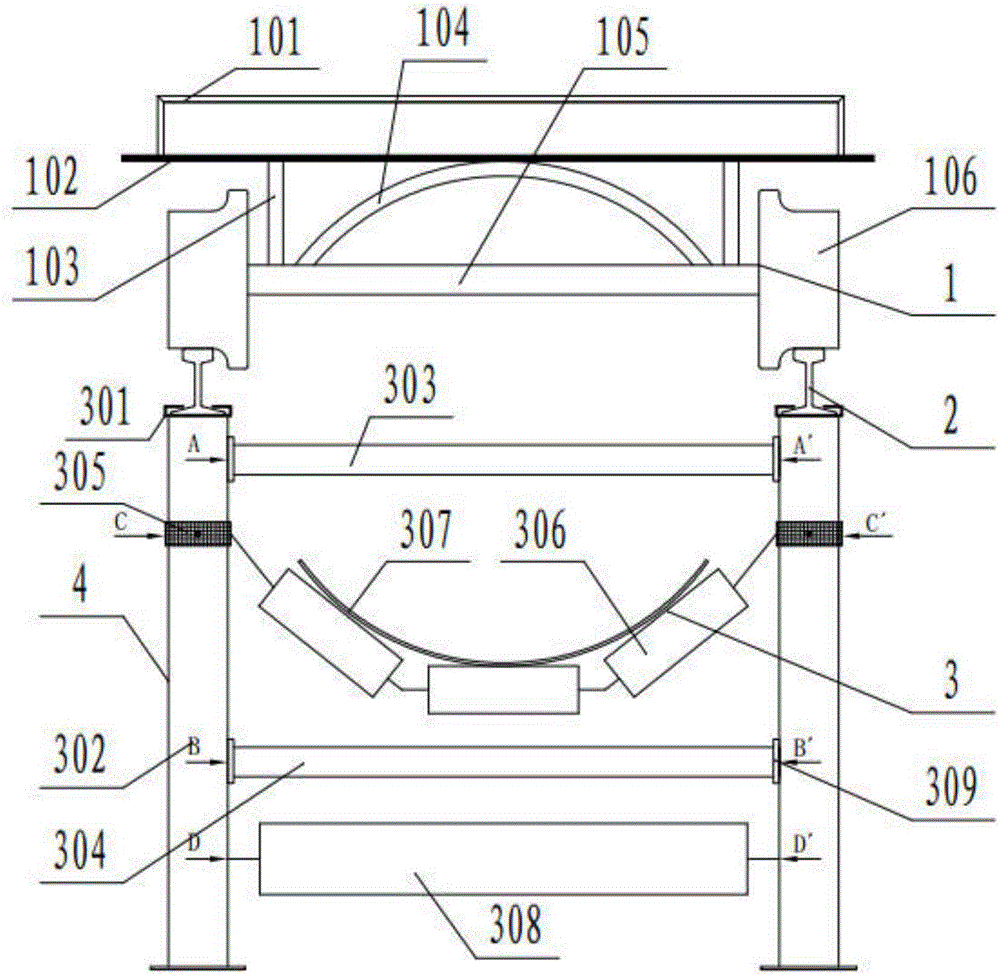

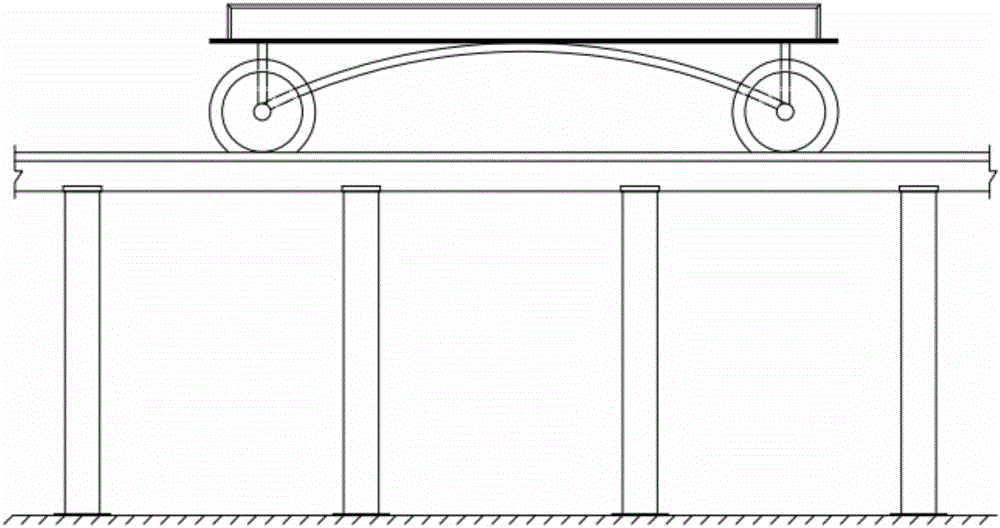

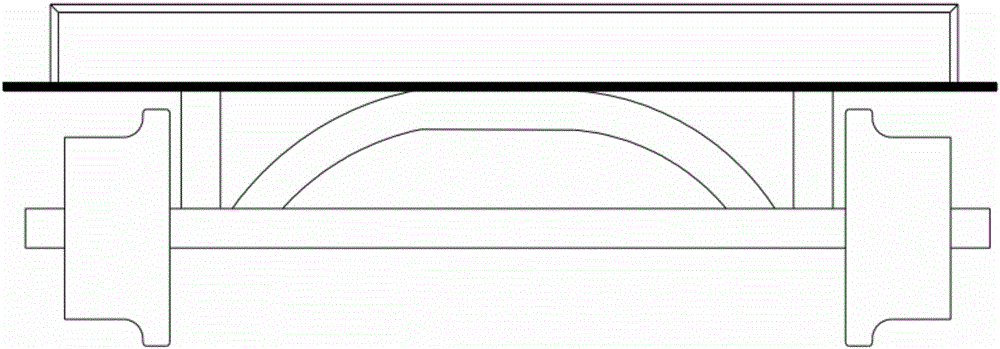

[0026] Embodiment 1: as Figure 1-Figure 10 As shown in the figure, a belt conveying system for conveying coal from above and below the equipment includes an upper material conveying car 1, a running rail 2 and a lower coal conveying belt system 3, and two parallel belt racks 4 are installed on the top of the lower coal conveying belt system 3. The upper material transport vehicle 1 is placed on the upper material transport vehicle 2 and can move along it, the belt rack 4 is fixedly connected to the ground, and the orientation of the lower coal transport belt system 3 is the same as that of the upper material transport vehicle 1. Same, the traveling rail 2 is No. 24 rail for mining, and the length is 1600mm.

[0027] Preferably, the above-mentioned upper material transport vehicle 1 includes a carrying platform 102 and a mining wheel 106, the lower side of the carrying platform 102 is connected with a rotatable wheel shaft 105, and the two ends of the wheel shaft 105 are respe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com