Plastic crushed material vermicelli separation equipment

A technology for separating equipment and crushing materials, which is used in solid separation, plastic recycling, and separation of solids from solids by air flow. It can solve problems such as quality equipment failure, avoid material performance loss, avoid pipe quality problems, and solve Effects of quality and equipment failure issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

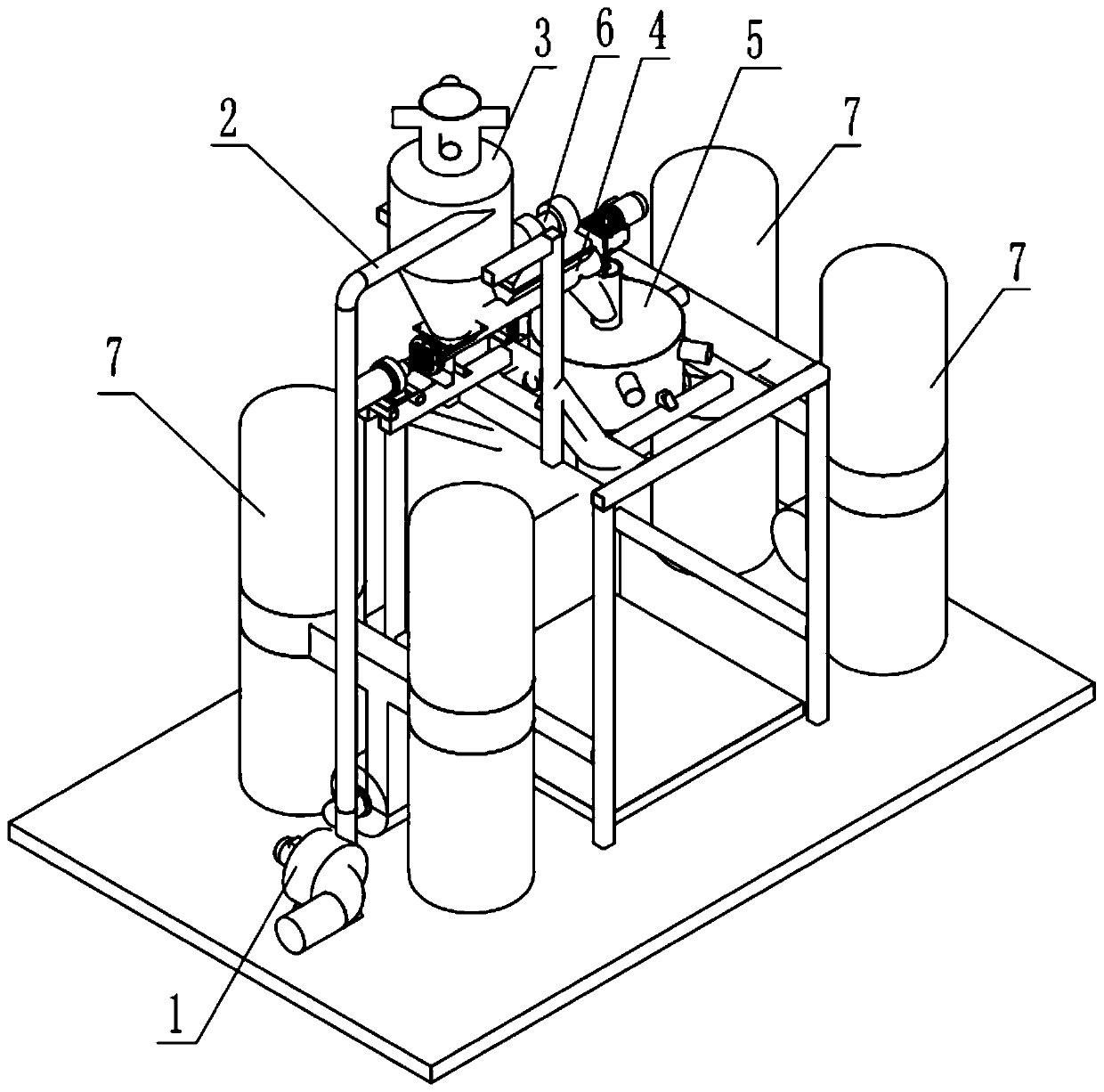

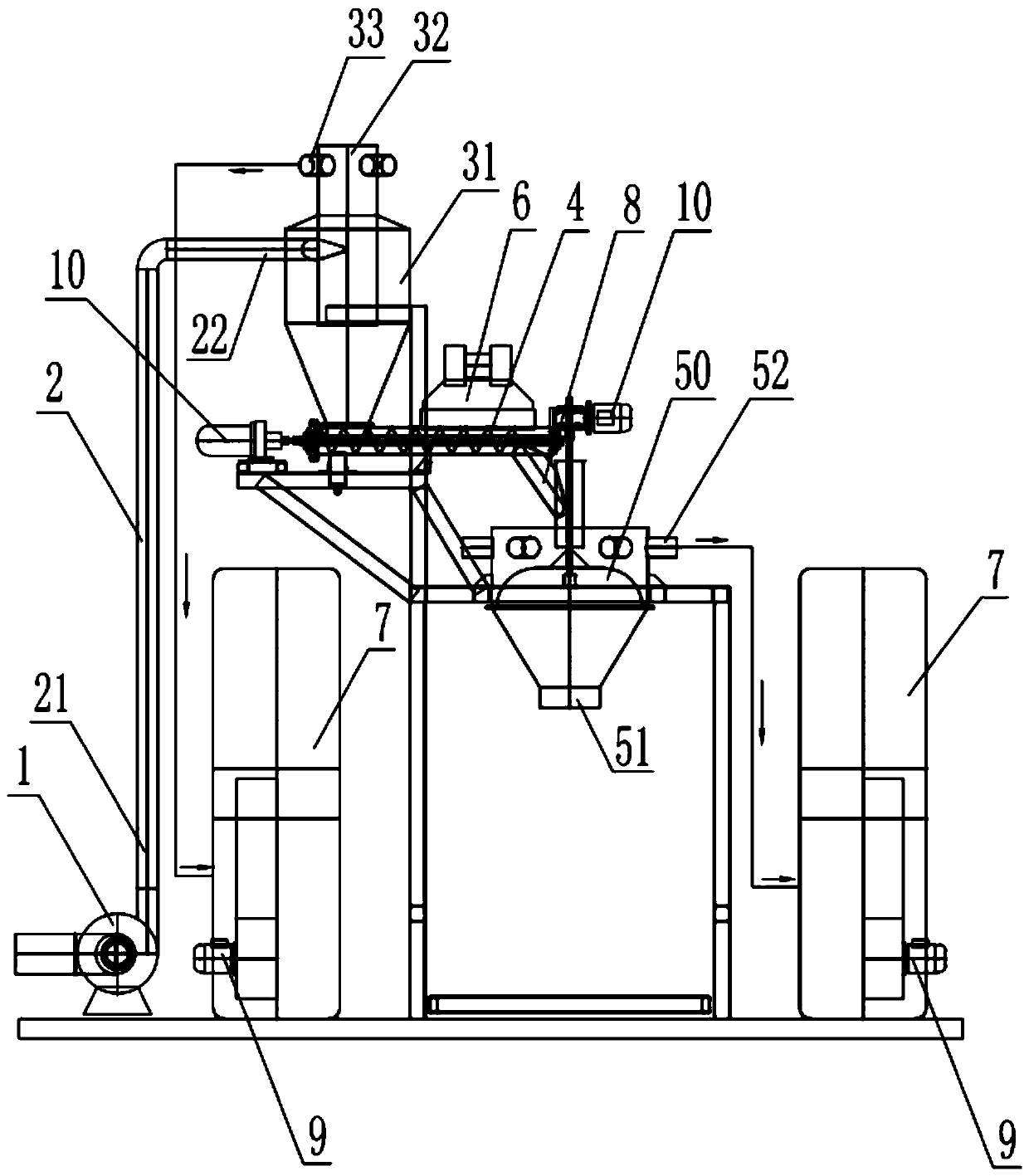

[0026] Embodiment one, with reference to Figure 1 to Figure 2 , The separation equipment for plastic crushed material and vermicelli provided by the present invention includes a suction pump 1, a suction pipe 2, a primary cyclone separation tank 3, a primary dust collection device, a rotary dispersion secondary separation tank 5 and a secondary dust collection device.

[0027] The primary cyclone separation tank 3 includes an outer tank 31 and an inner tank 32, and the outer tank 31 and the inner tank 32 are arranged coaxially. The inner tank 32 runs through the top of the outer tank 31 and is fixed on the outer tank 31, and the bottom of the outer tank 31 is provided with a discharge port.

[0028] The inner tank 32 is a cylinder structure with the upper end closed and the lower end open, and the side wall of the inner tank 32 is provided with a feed port.

[0029] The input end 21 of the suction pipe 2 is connected with the discharge port of the suction pump 1, and the out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com