Film blowing industry PLC data acquisition analysis processing system and method based on internet

A data acquisition, analysis, and data processing technology, applied in the field of industrial data analysis and processing, can solve the problems of insufficient specific and detailed understanding of production process parameters and equipment performance, and unsatisfactory early warning effects, so as to achieve the production process monitoring effect and equipment performance early warning effect improvement. , monitoring effect and early warning ability improvement, data compatibility effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

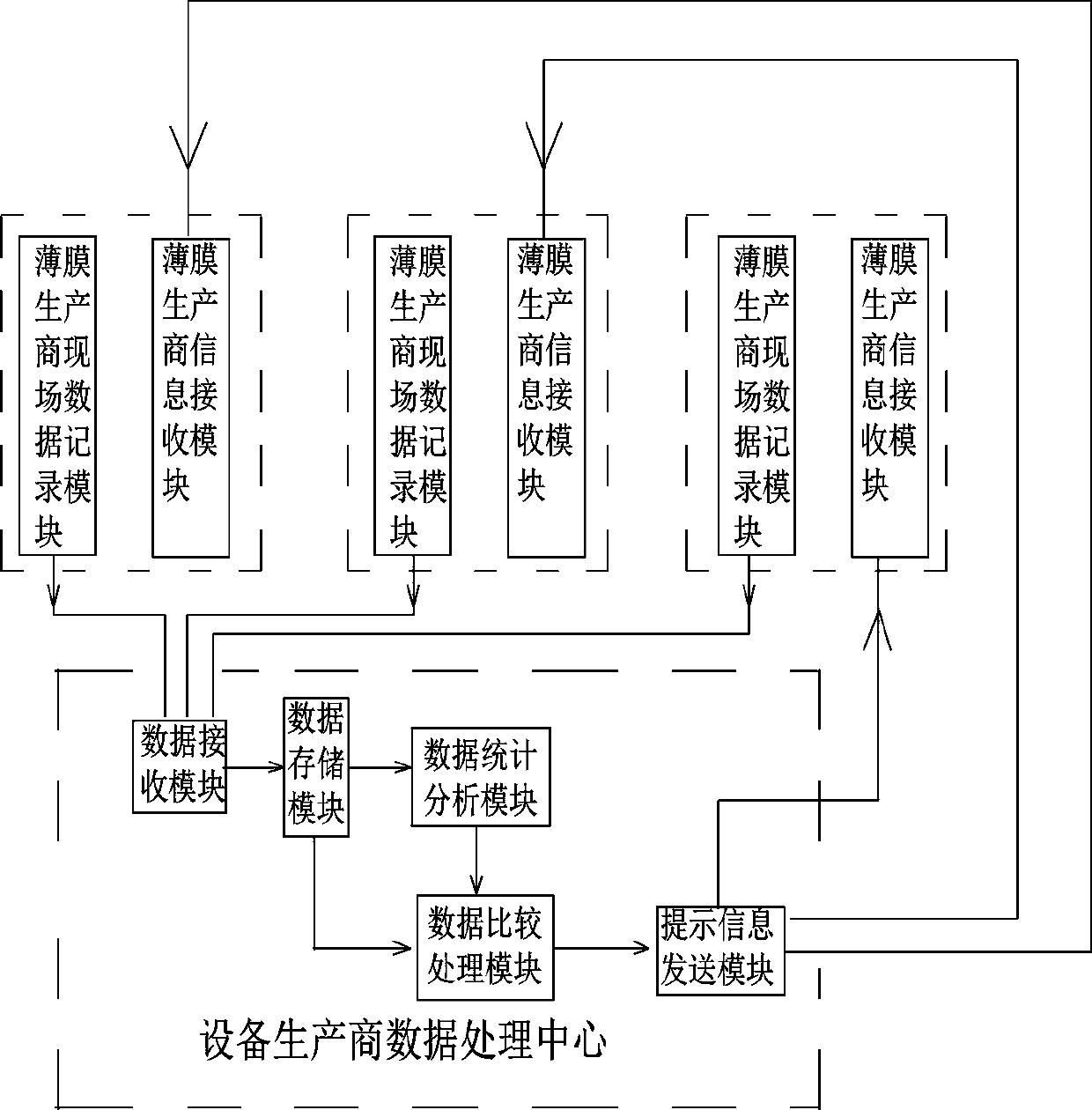

[0023] An Internet-based PLC data acquisition, analysis and processing system for the blown film industry, including multiple blown film production lines of the same structure and type manufactured by the same equipment manufacturer, and each blown film production line is distributed in the production workshops of different film manufacturers. Each blown film production line is equipped with a film manufacturer’s on-site data recording module and a film manufacturer’s information receiving module; it also has an equipment manufacturer’s data processing center, which includes a data receiving module, a data storage module, and a data processing center. Analysis and statistics module, data comparison processing module, prompt information sending module; film manufacturer’s on-site data recording module connects to the data receiving module of the equipment manufacturer’s data processing center through the Internet, and the prompt information sending module of the equipment manufac...

Embodiment 2

[0030] An Internet-based method for collecting, analyzing and processing PLC data in the blown film industry, adopting the Internet-based PLC data collecting, analyzing and processing system for blown film industry of Embodiment 1, comprising the following steps in turn:

[0031] (1) The on-site data recording module of the film manufacturer records the real-time process parameters of the corresponding blown film production line, and transmits the real-time process parameters to the data processing center of the equipment manufacturer through the Internet;

[0032] (2) The data storage module of the data processing center of the equipment manufacturer stores all the data transmitted by each film manufacturer;

[0033] (3) The data analysis and statistics module of the data processing center of the equipment manufacturer conducts statistical analysis on the stored data, calculates the average value of the process parameters of all film manufacturers, and calculates the alarm thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com