Milling device for laptop case

A notebook computer and shell technology, which is applied in the field of notebook computer shell milling device, can solve problems such as worker injury, waste can not be cleaned in time, equipment failure, etc., to avoid the loss of parts, the cleaning method is timely, and the cleaning effect is good.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

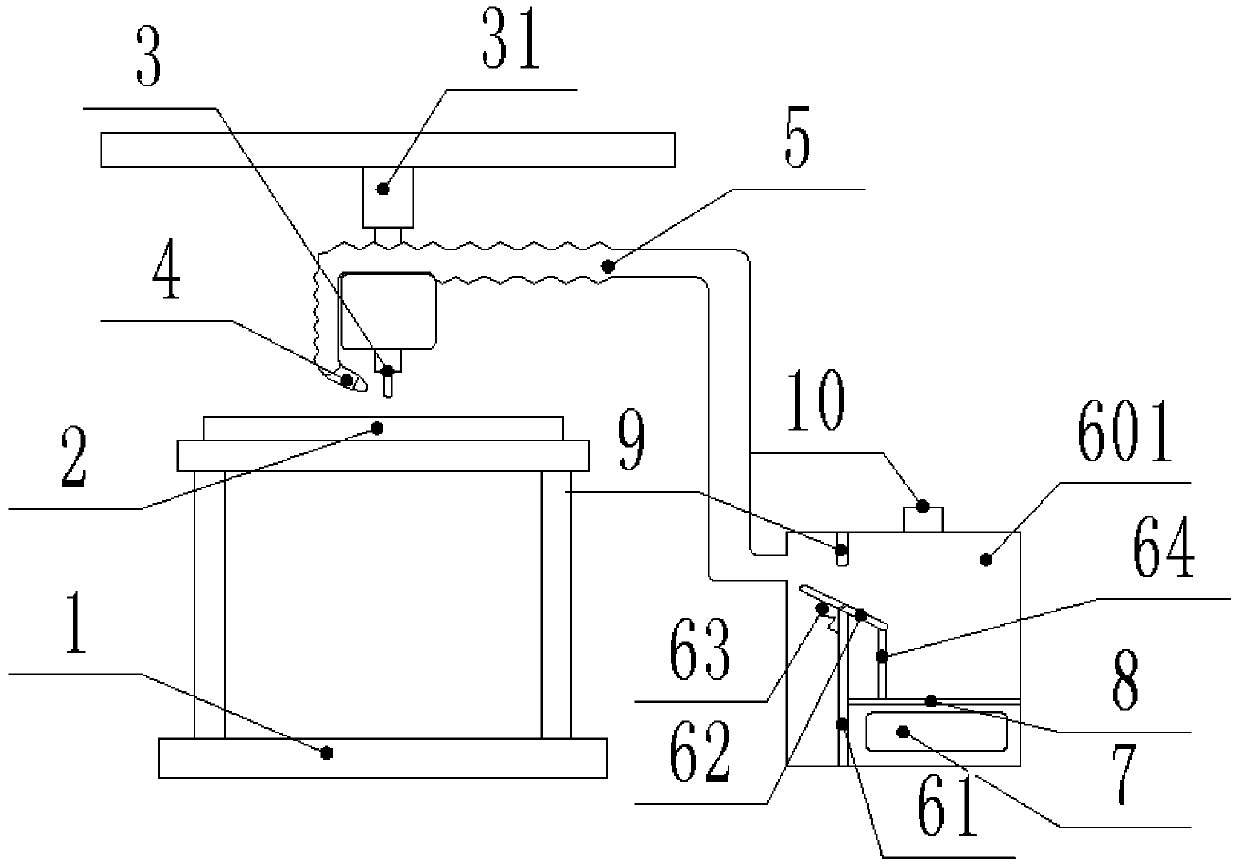

[0030] Such as figure 1 Shown: a notebook computer casing milling device, including a base 1, a placement table 2 for placing a notebook computer casing, a milling cutter device 3 for milling material heads, a mechanical arm 31 that drives the milling cutter device 3 to move, and a control milling cutter device 3, A control unit for the action of the mechanical arm 31. In this embodiment, the control unit can adopt OMRON's CP1H-XA40DR-A programmable controller, which is easy to program and stable in performance.

[0031] The upper end of the base 1 is welded and fixed with a bracket, and the top of the bracket is welded and fixed with the placement table 2 . The mechanical arm 31 is realized by the mechanical arm 31 in the prior art, and the milling cutter device 3 adopts the milling cutter device in the automatic milling device disclosed by the Chinese patent whose publication number is CN106273202A.

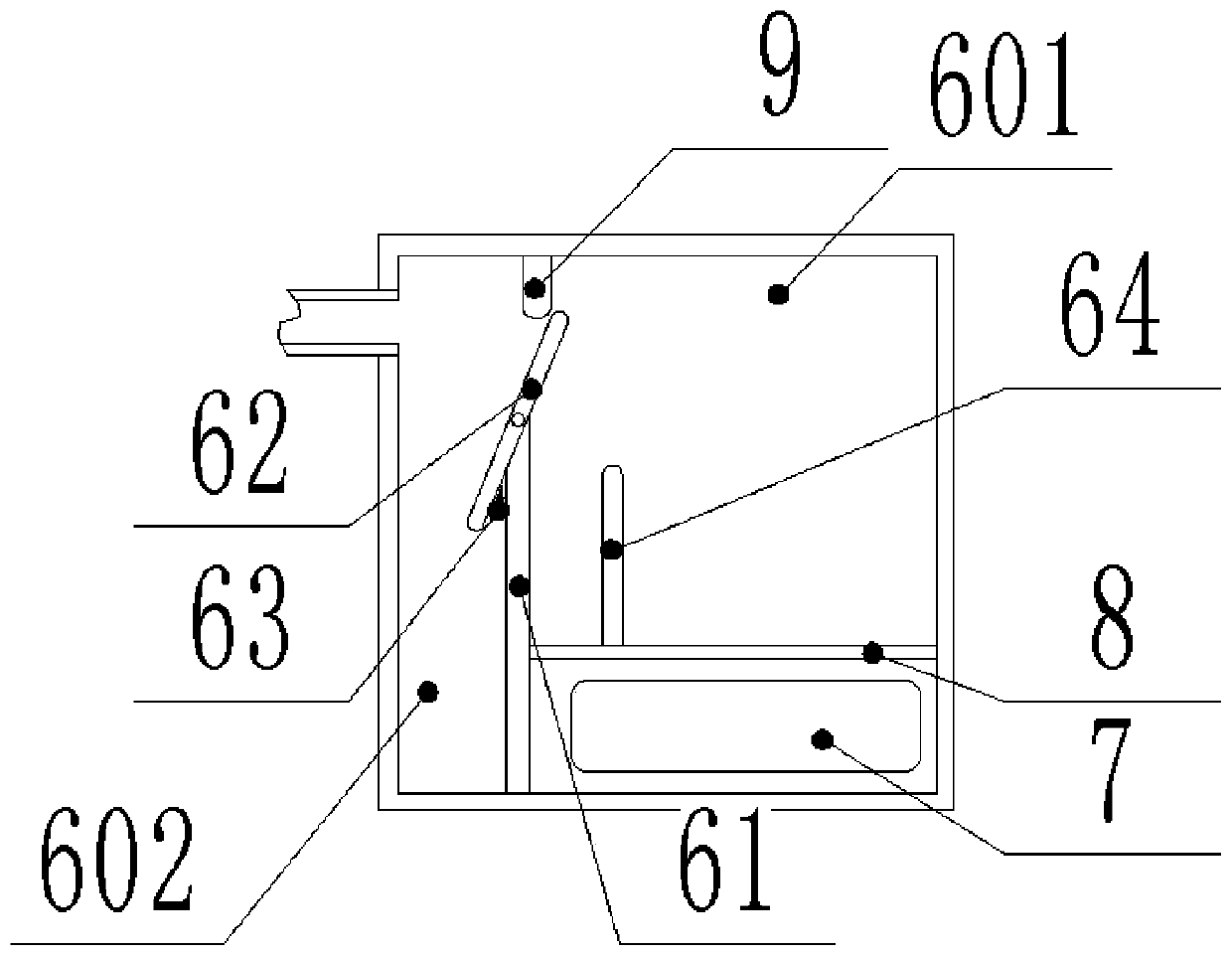

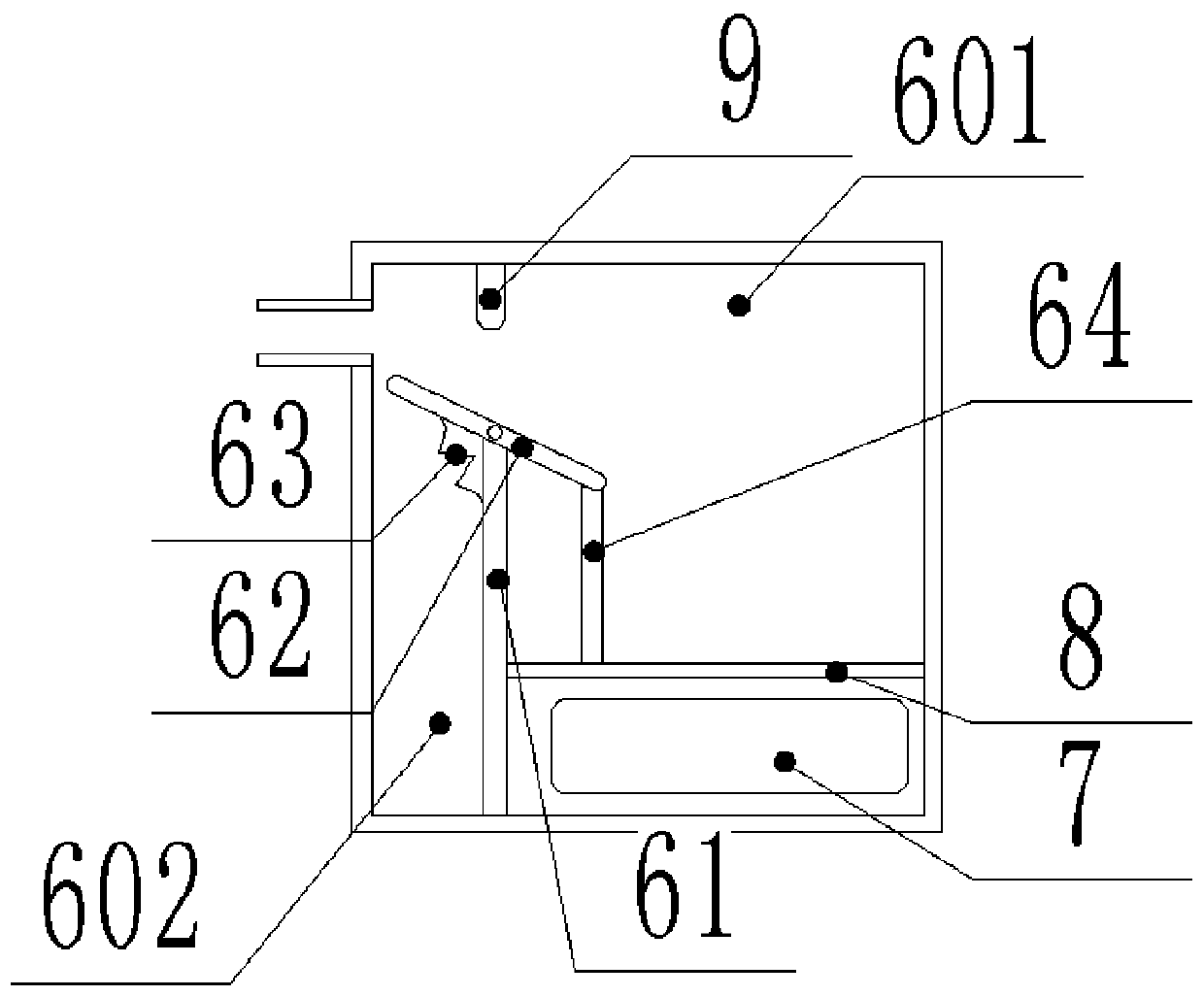

[0032] The notebook computer casing milling device in this embodiment al...

Embodiment 2

[0041] The only difference between this embodiment and the first embodiment is that the waste bin in this embodiment can classify waste materials and metals.

[0042] In modern industrial production, milling devices are mostly automatic devices, and the inspection of milling devices by maintenance personnel is generally a regular inspection. For industrial equipment, every component is critical, and most components are made of metal. In daily production, on the one hand, it is difficult for maintenance personnel to find the falling parts of the device, which leads to failures that cannot be eliminated; on the other hand, the dropped parts are mixed with waste and thrown away, which is also an economic loss.

[0043] In this embodiment, a metal sensor capable of detecting the metal target of the adsorption head 4 is provided in the adsorption head 4, and the metal sensor is connected with the control unit signal; a prompt device 10 controlled by the control unit is fixed on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com