Patents

Literature

81results about How to "Automatic movement" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method and device for displaying three-dimensional image

ActiveCN103402106AAutomatic movementSolve problems such as not supporting changes in user viewing angles and narrow interaction rangeSteroscopic systemsOptical elementsVirtual cameraVideo camera

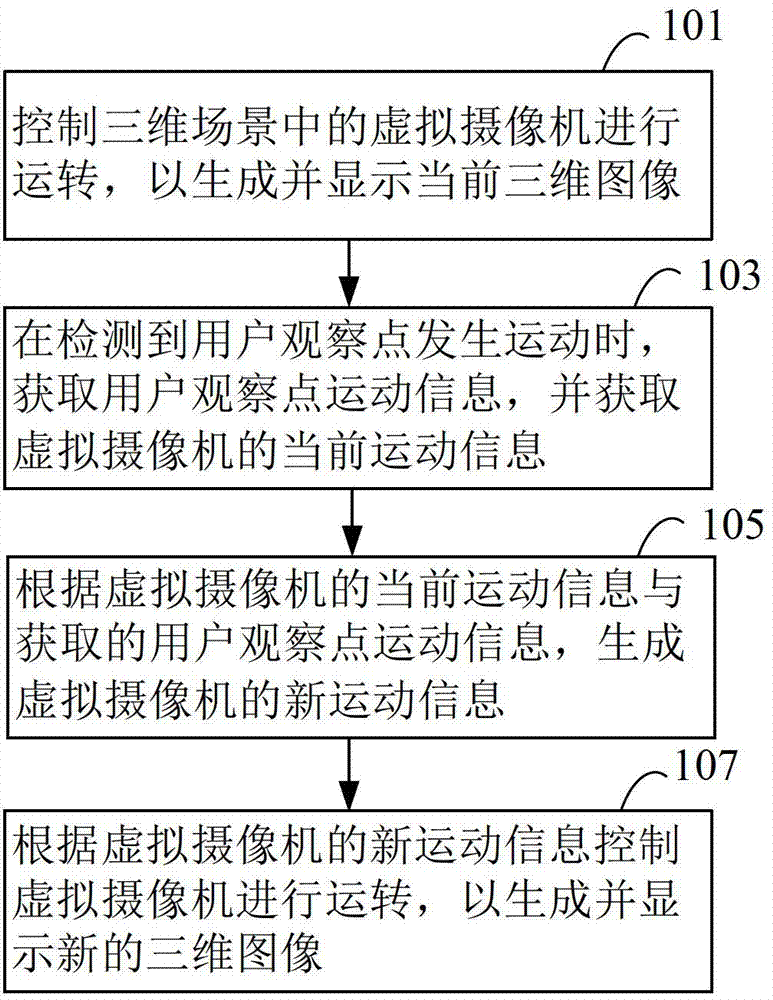

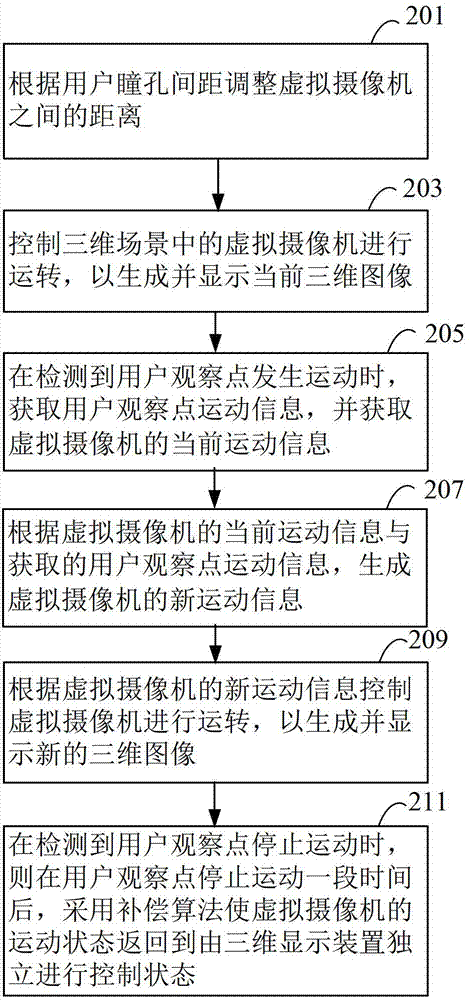

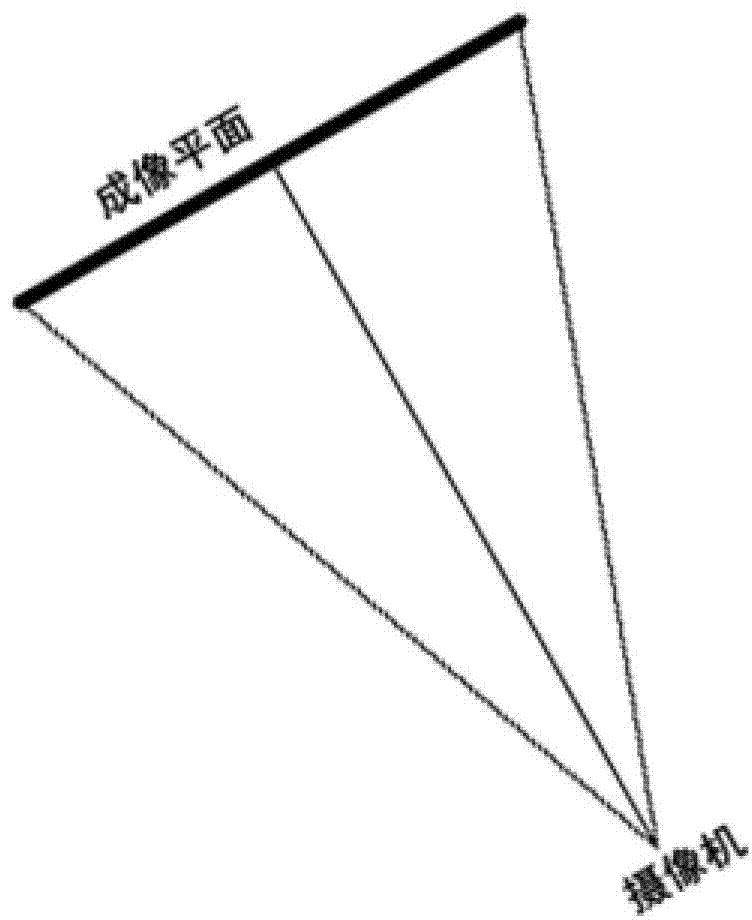

The embodiment of the invention discloses a method and a device for displaying a three-dimensional image, and belongs to the field of display. The method for displaying the three-dimensional image comprises the following steps: controlling a virtual camera on a three-dimensional scene to work so as to generate and display a current three-dimensional image; when motion of a user observation point is detected, obtaining motion information of the user observation point, and obtaining current motion information of the virtual camera, and generating new motion information of the virtual camera according to the current motion information of the virtual camera and the obtained motion information of the user observation point; controlling the virtual camera to work according to the new motion information of the virtual camera so as to generate and display a new three-dimensional image. According to the method and the device for displaying the three-dimensional image, the three-dimensional image dynamically adaptive to user motion is generated in a human-computer interaction manner, so that the motion of the virtual camera on the three-dimensional scene along with the motion of the user can be automatically realized in the displaying process of the three-dimensional image, and the three-dimensional image more similar to the real world is realized.

Owner:HISENSE VISUAL TECH CO LTD

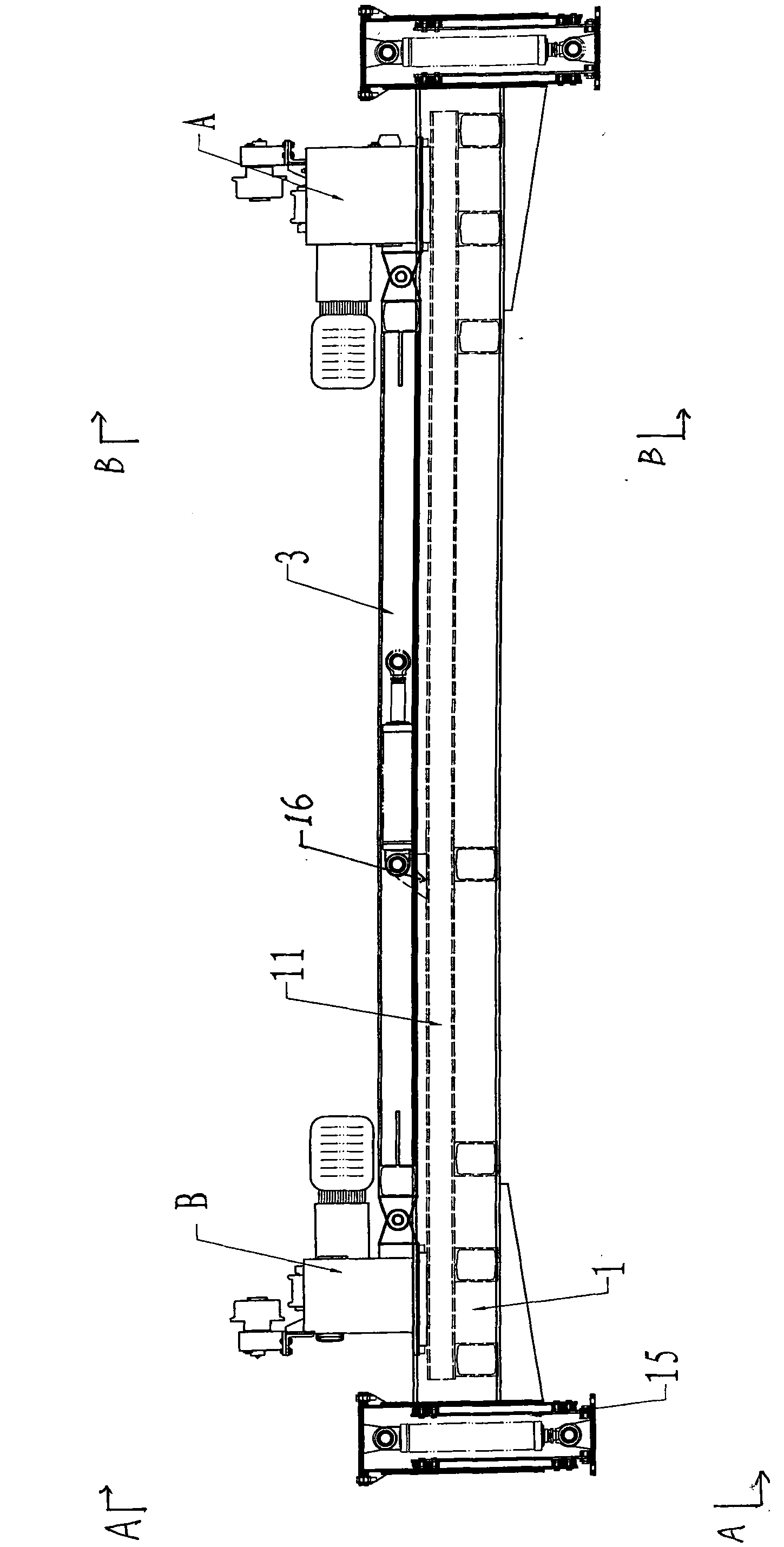

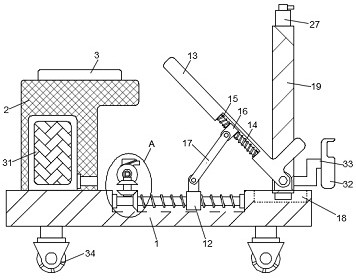

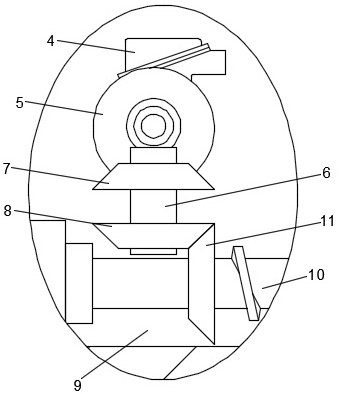

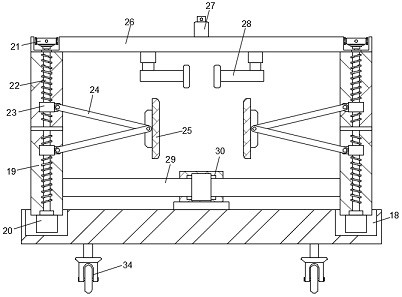

Mobile support device

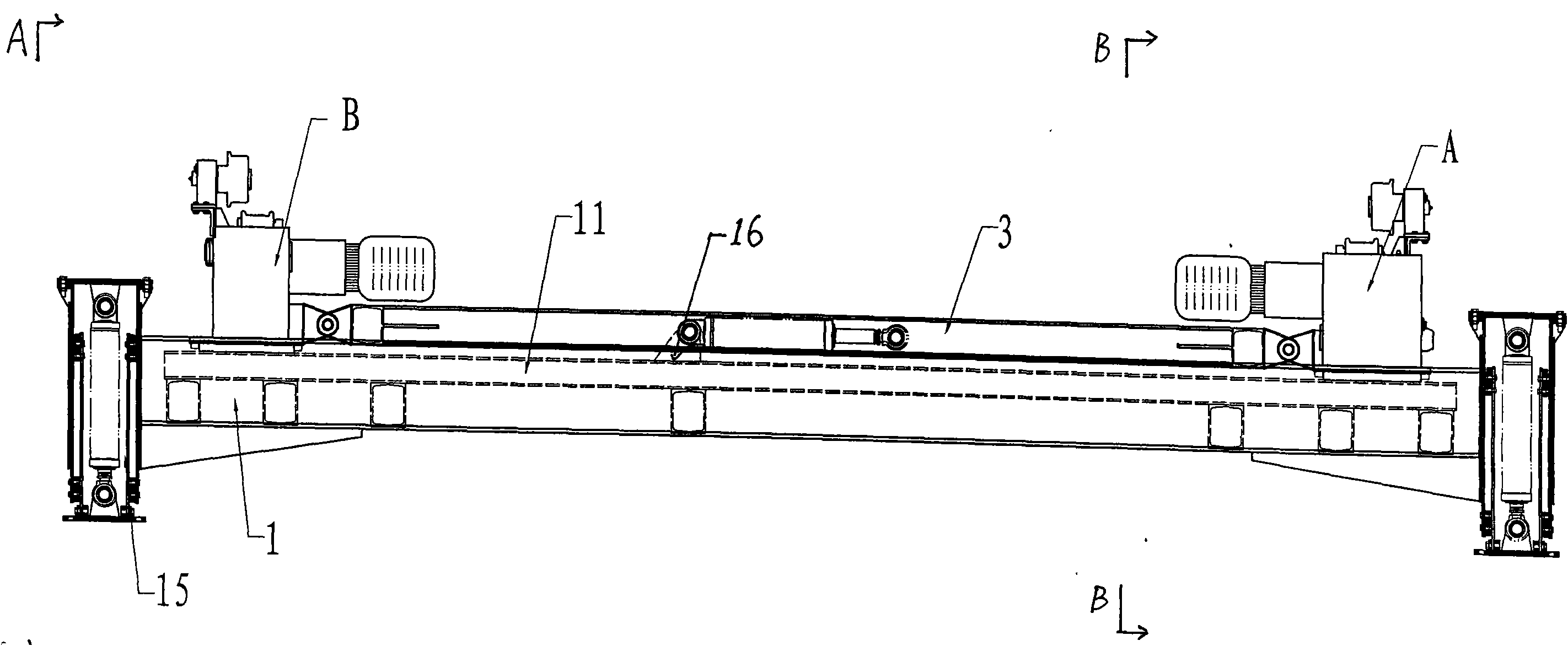

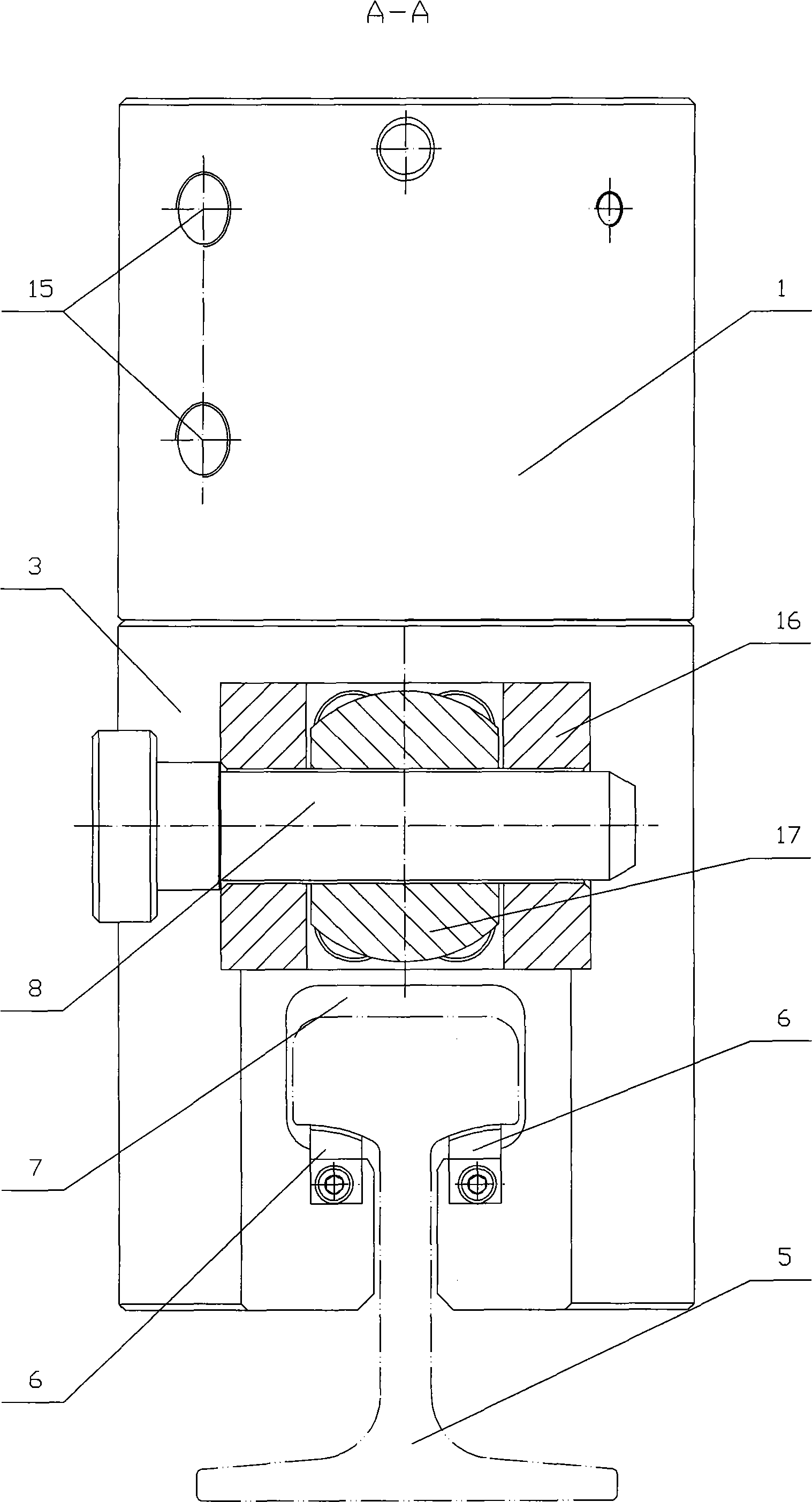

InactiveCN102094648AAutomatic movementGuarantee the need for automatic walkingTunnelsUnderground transportEngineeringMechanical engineering

Owner:HUNAN WUXIN MACHINERY

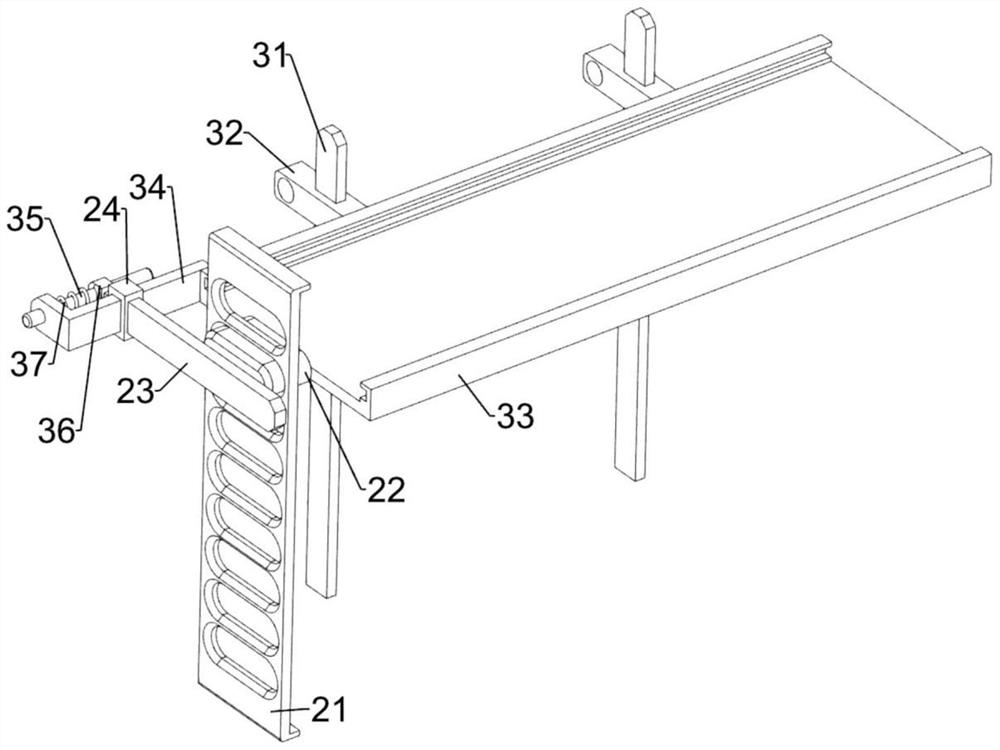

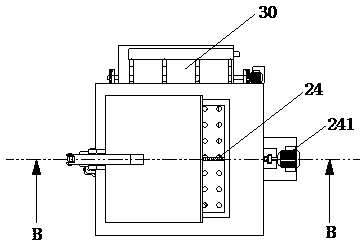

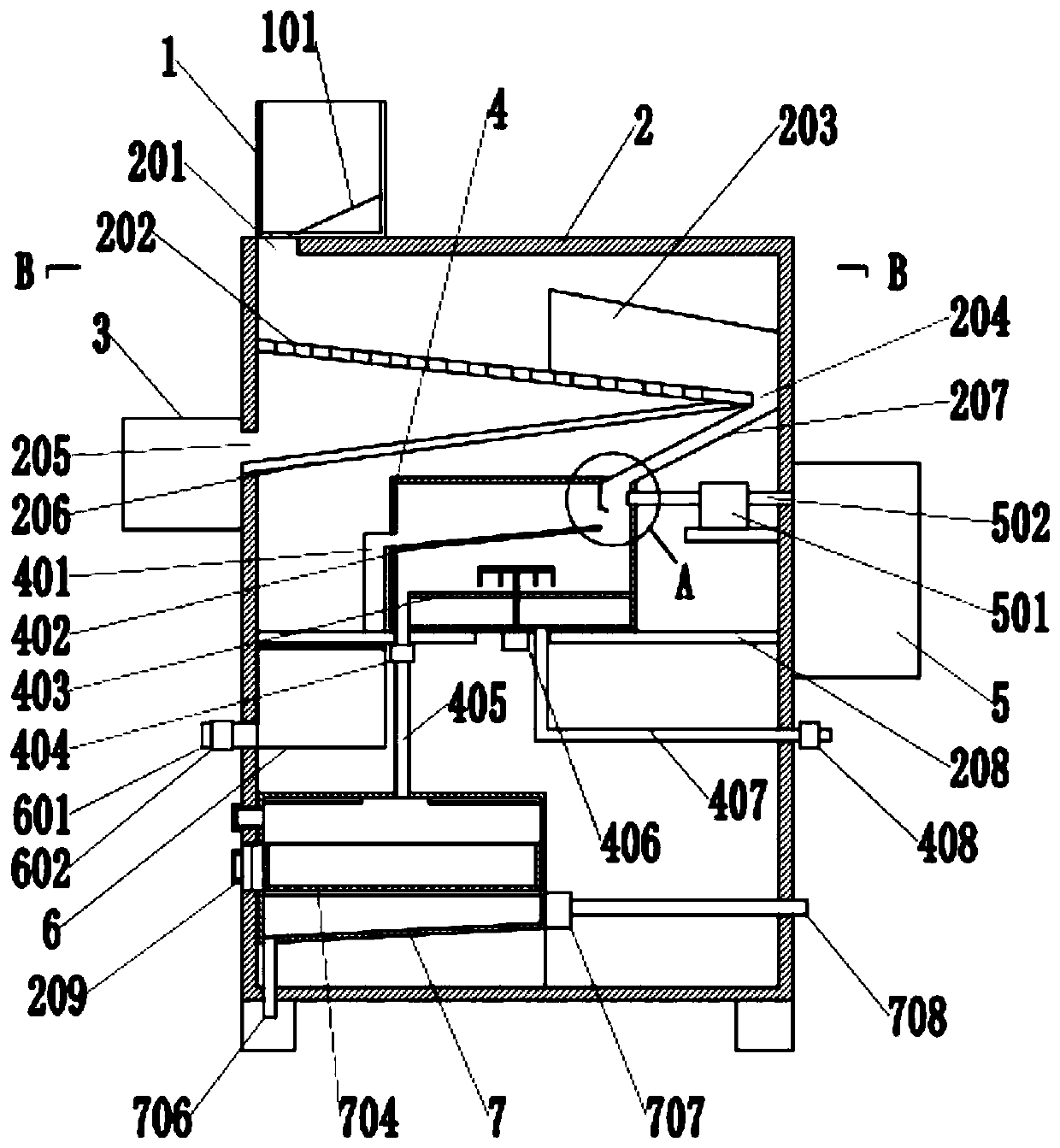

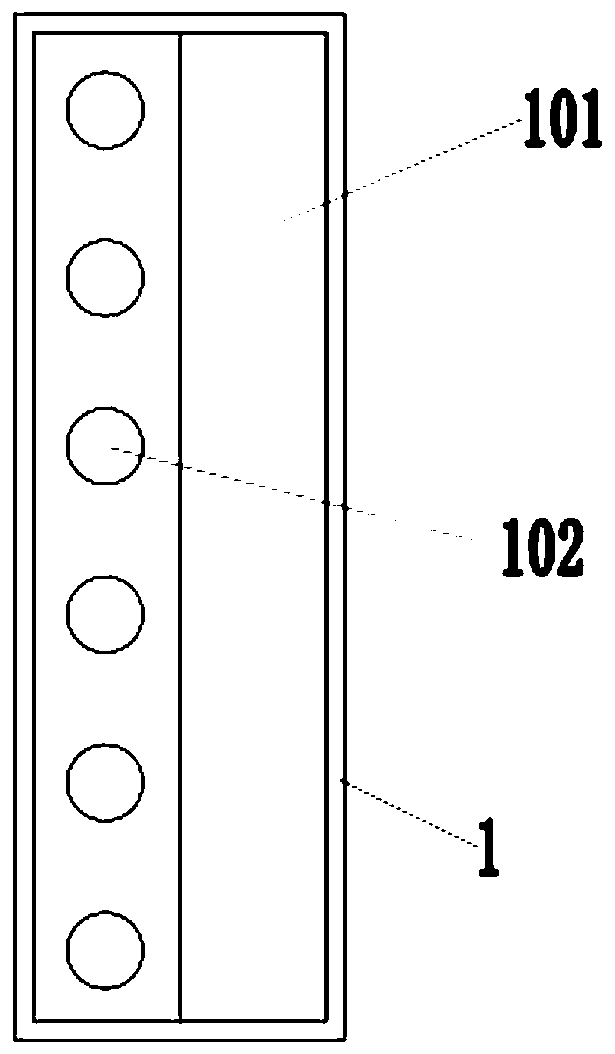

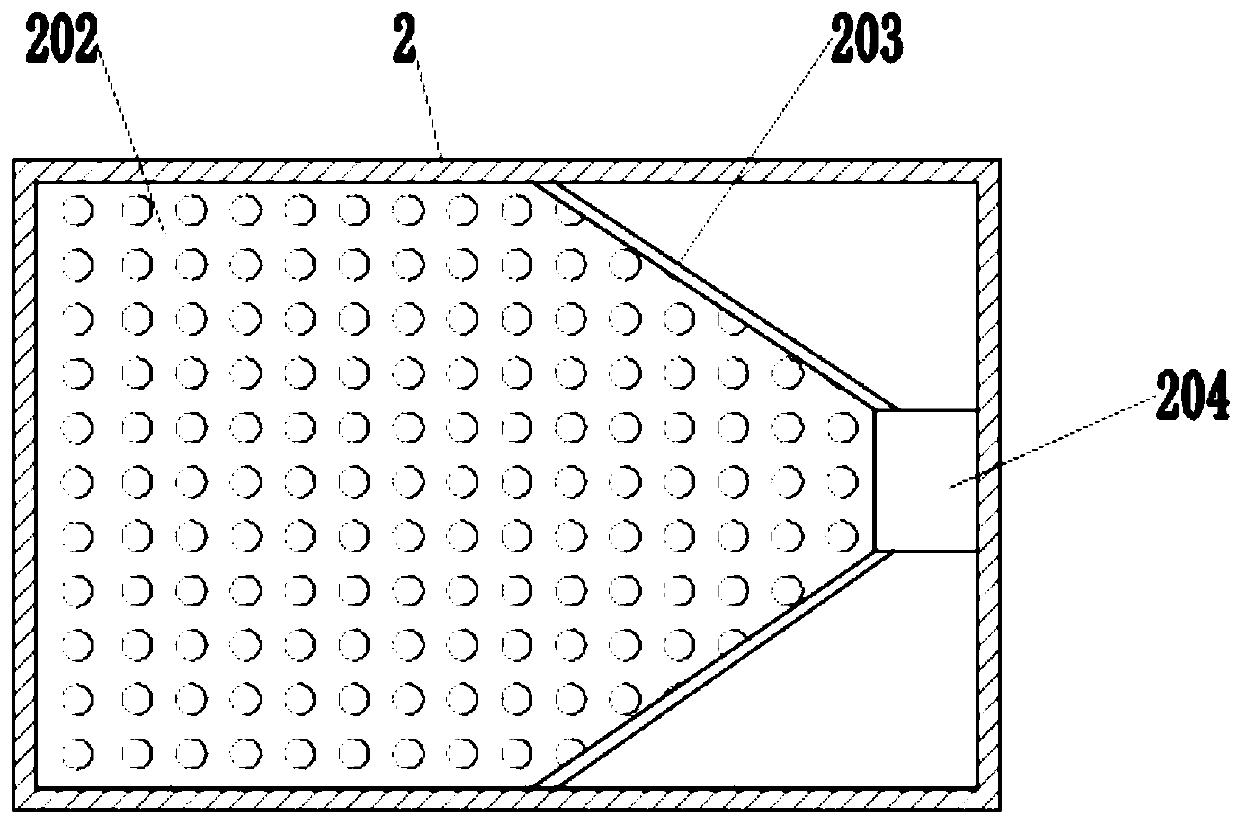

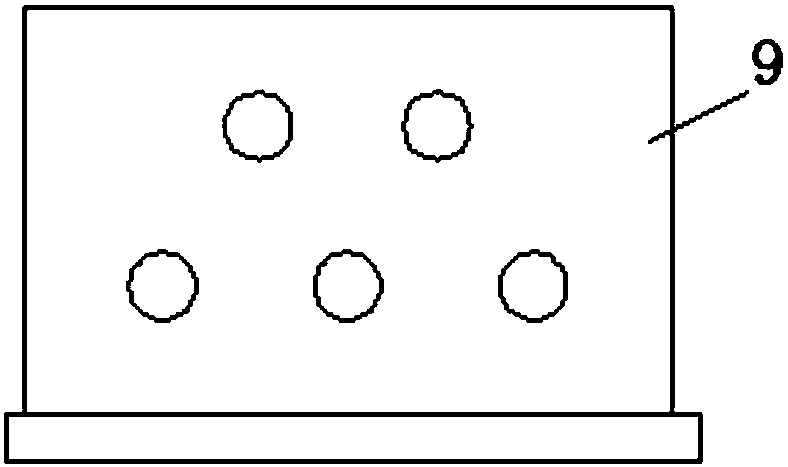

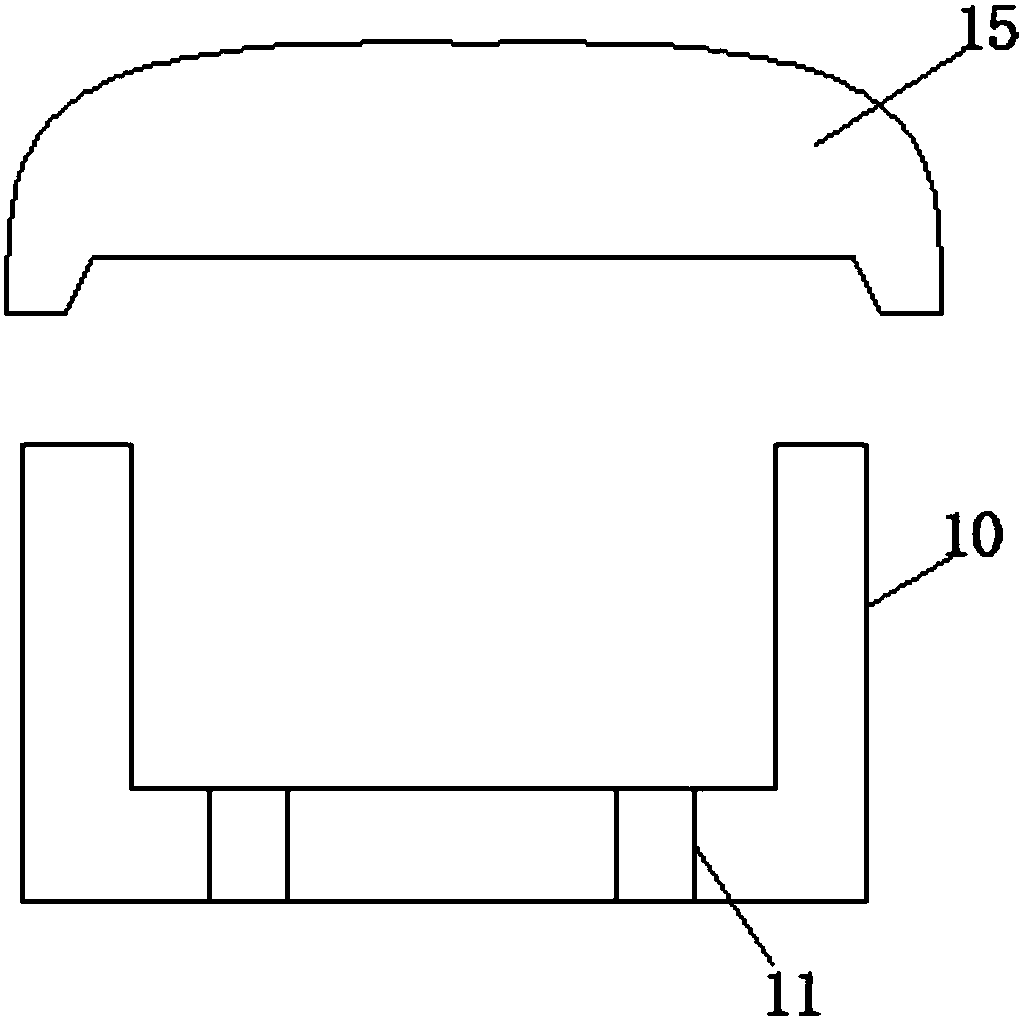

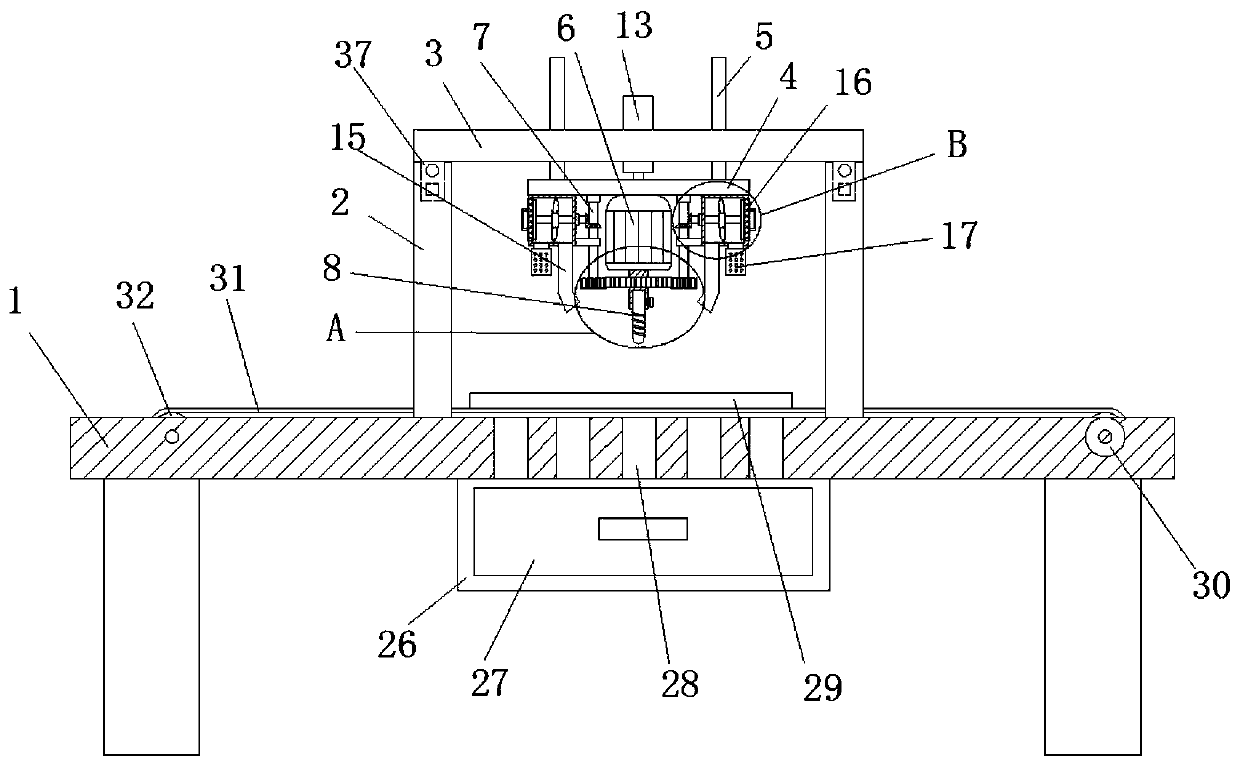

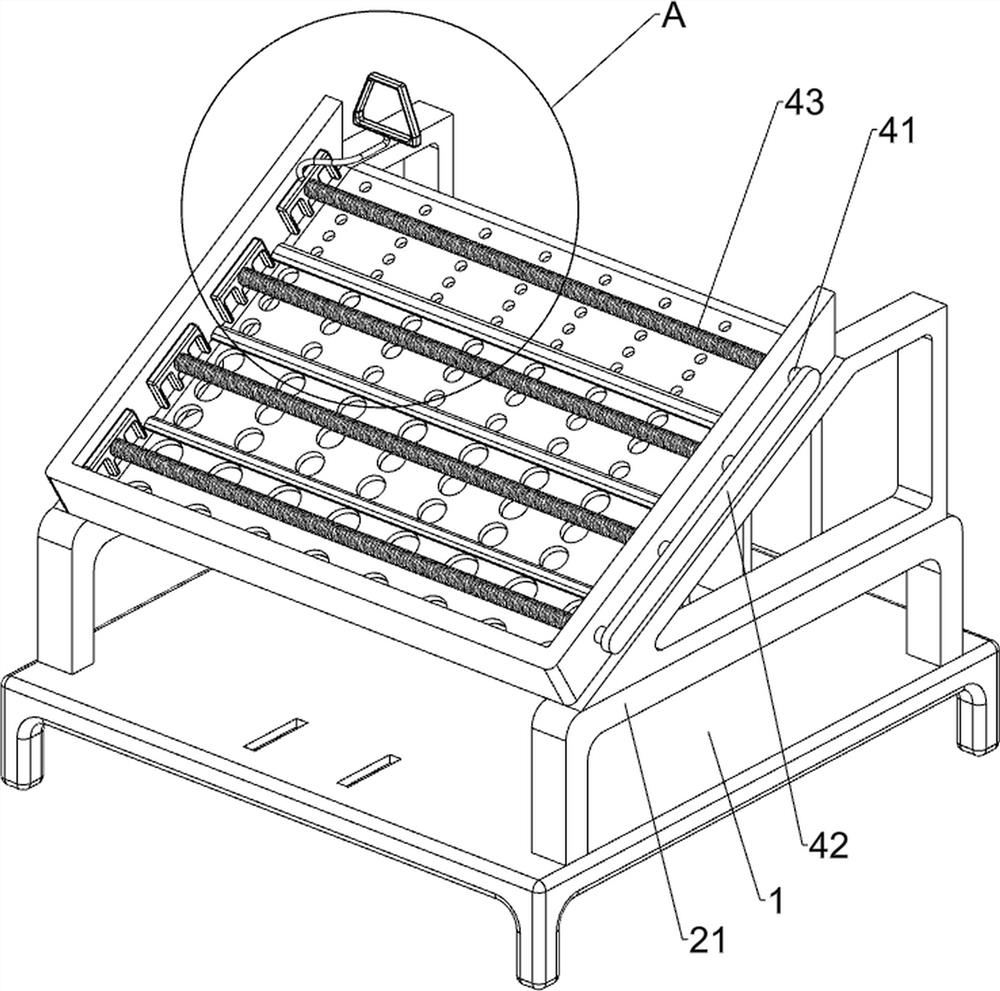

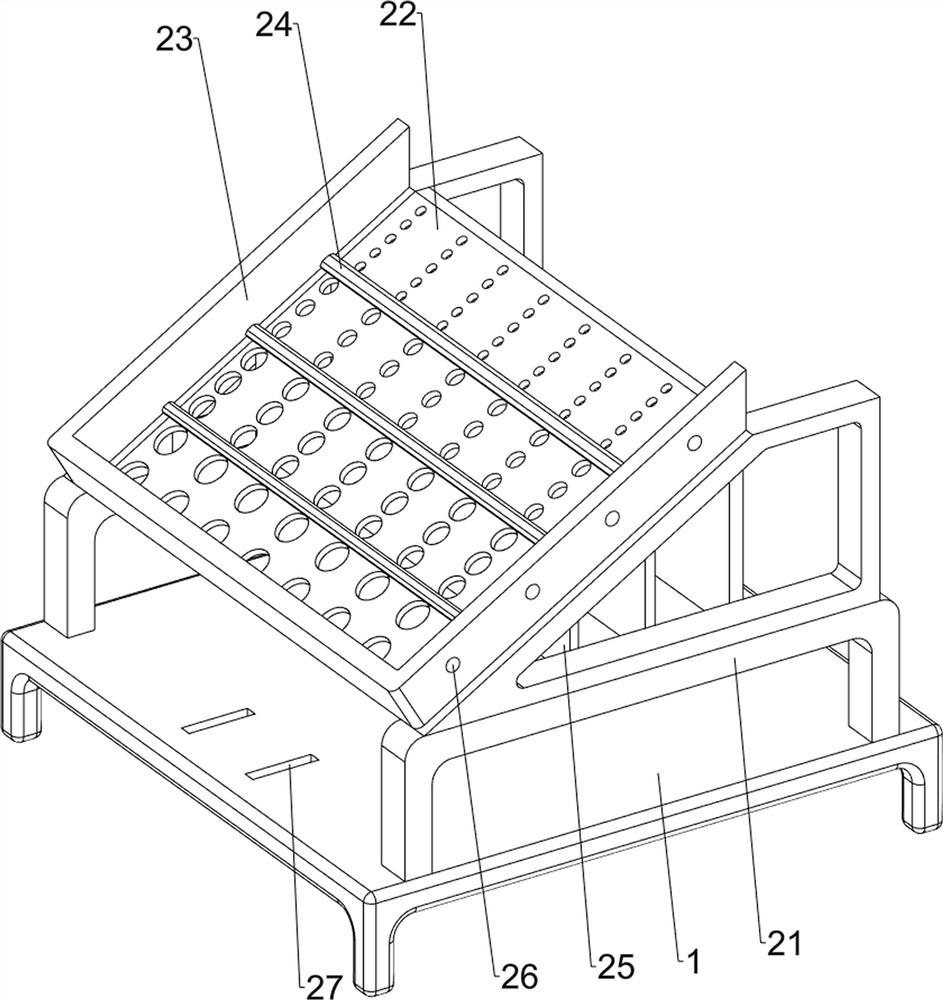

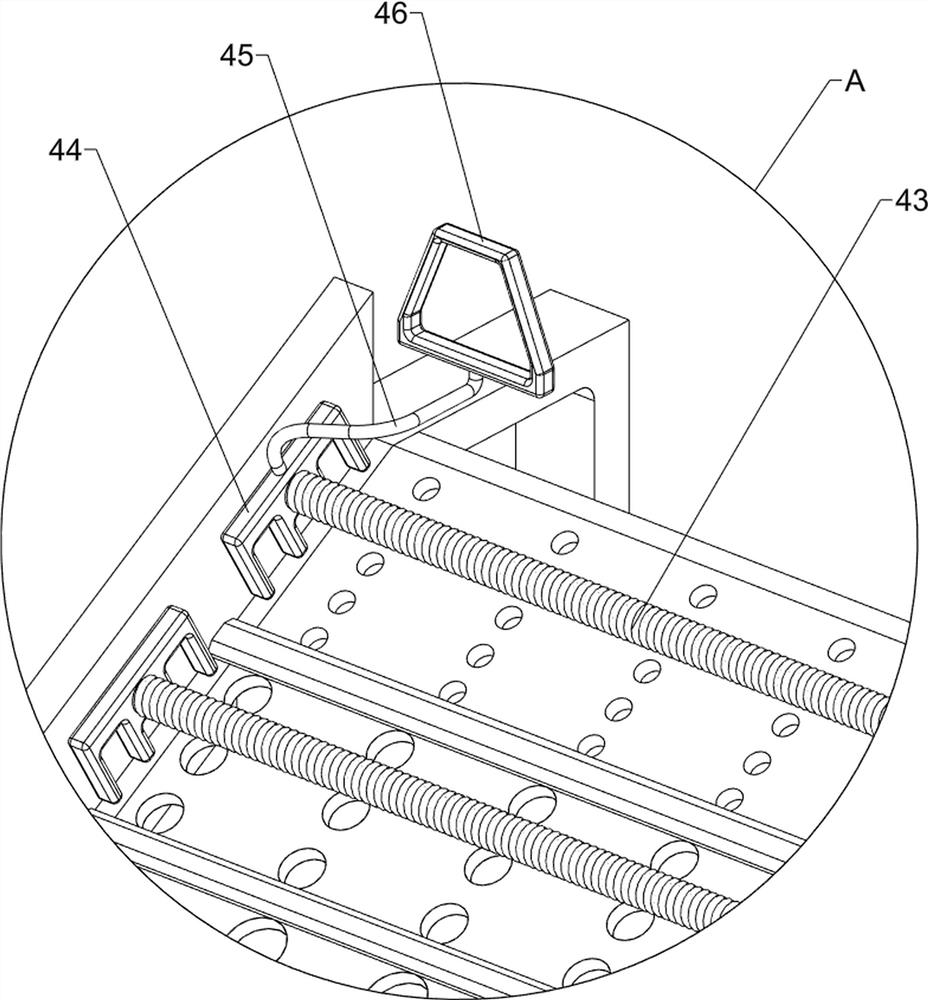

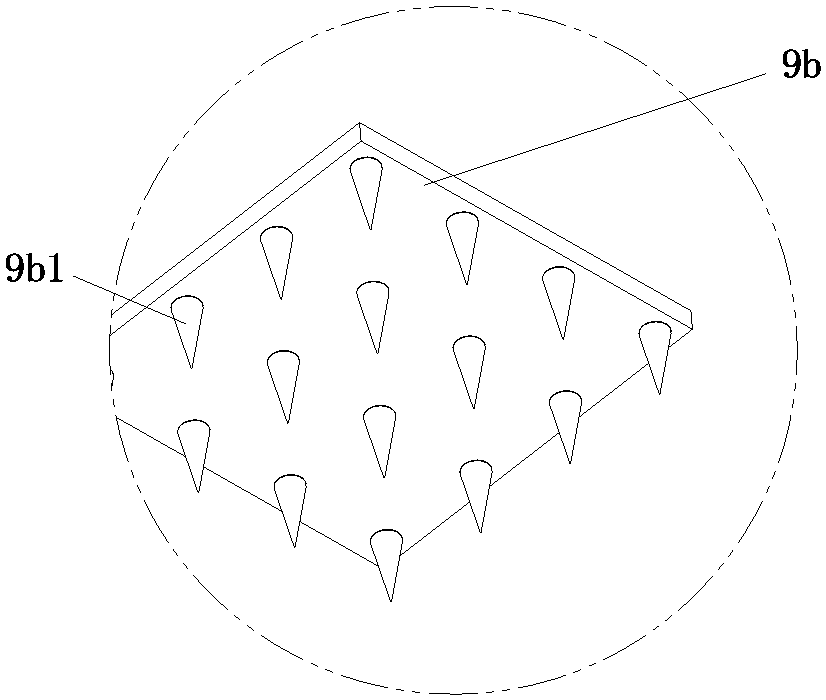

Wood board stamping and punching equipment for building materials

PendingCN112092109AAutomatic movementHole position specificationStationary drilling machinesBark-zones/chip/dust/waste removalPunchingArchitectural engineering

The invention relates to punching equipment, in particular to wood board stamping and punching equipment for building materials. According to the wood board stamping and punching equipment for the building materials, the wood strip punching precision can be improved, and the risk of workers is reduced. The wood board stamping and punching equipment for the building materials comprises a bottom plate, a servo motor, a mounting plate, a discharging box, a pushing and blocking mechanism and a punching mechanism; the servo motor is installed at one side of the bottom plate; the mounting plate is arranged on the bottom plate; the discharging box is arranged at the side, close to the servo motor, of the mounting plate; the pushing and blocking mechanism is arranged at the side, close to the mounting plate, of the bottom plate; and the punching mechanism is arranged on the mounting plate. According to the wood board stamping and punching equipment, by means of the design of the pushing and blocking mechanism, wood boards are pushed leftwards, the wood boards are automatically moved so as to be matched with operation of the punching mechanism, the wood boards do not need to be moved manually, and the punching position of each wood board is more standard.

Owner:邹自强

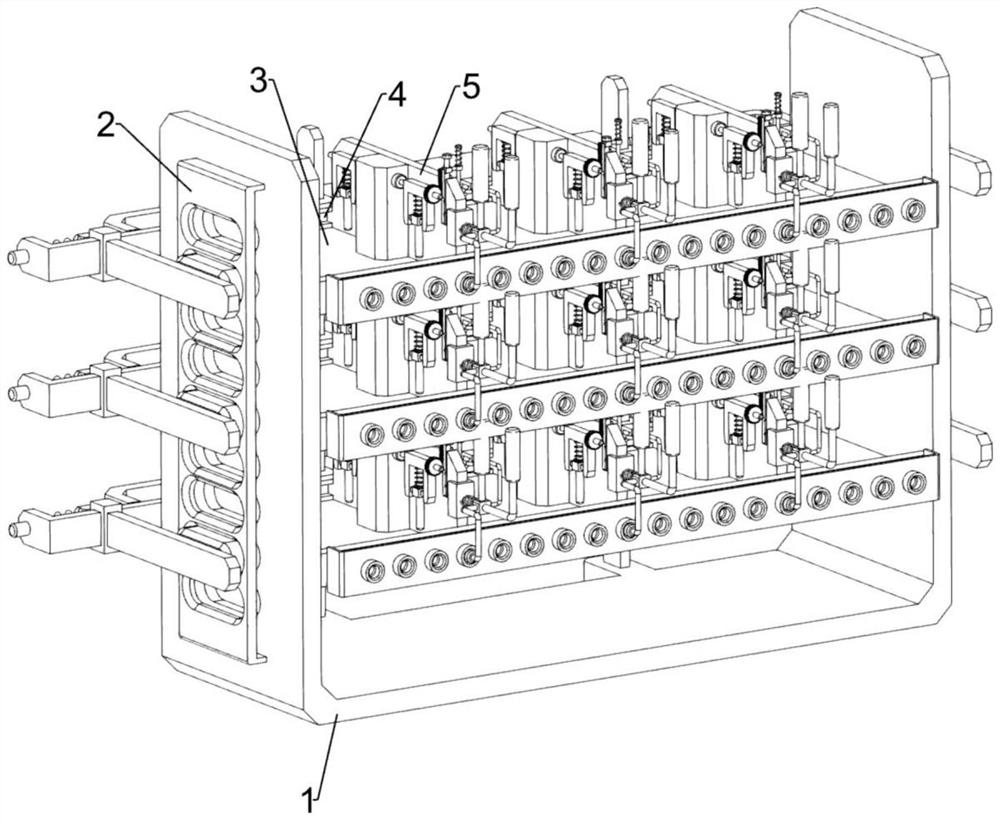

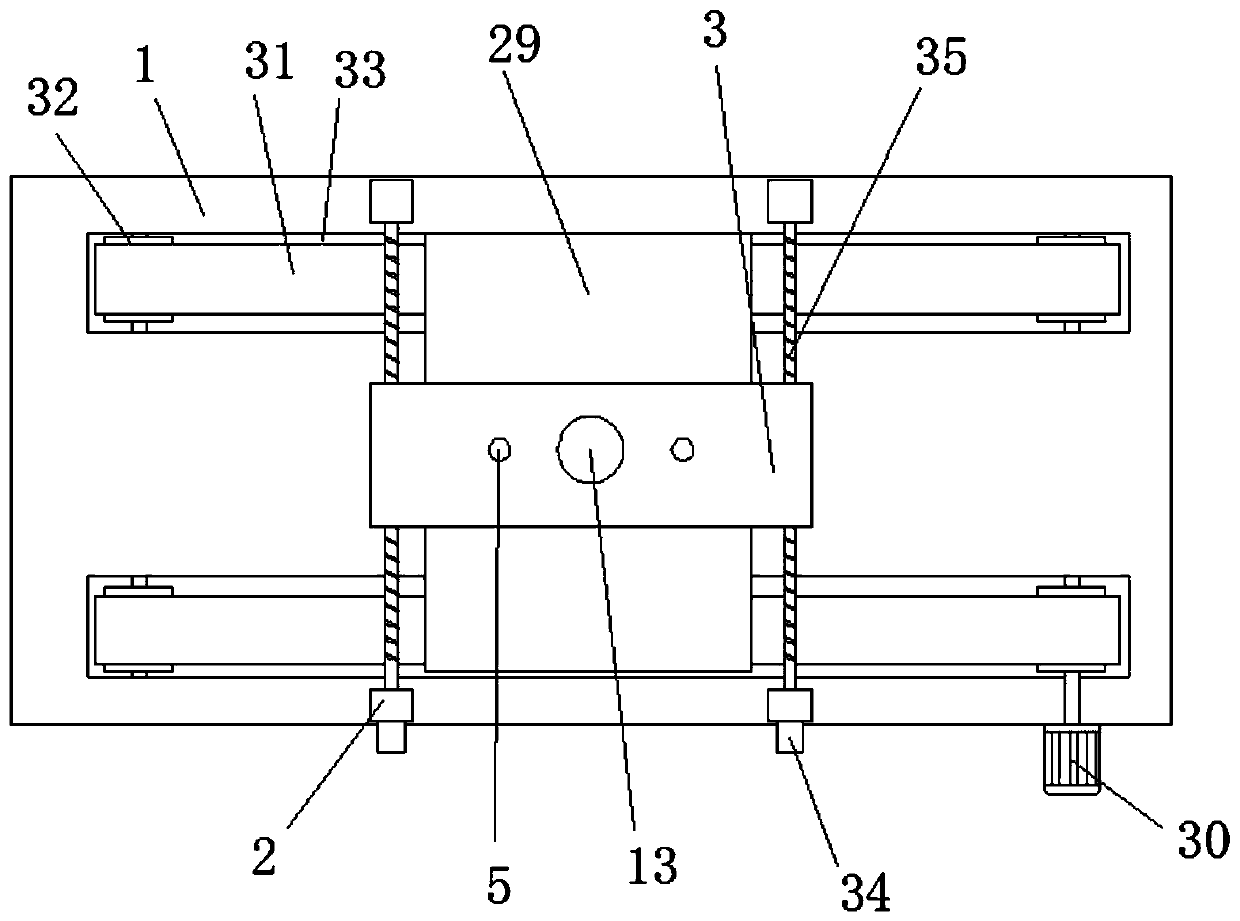

Partitioned adjustable file compact shelf

ActiveCN112869403AImprove placement efficiencyAutomatic movementBook cabinetsFurniture partsComputer hardwareClassical mechanics

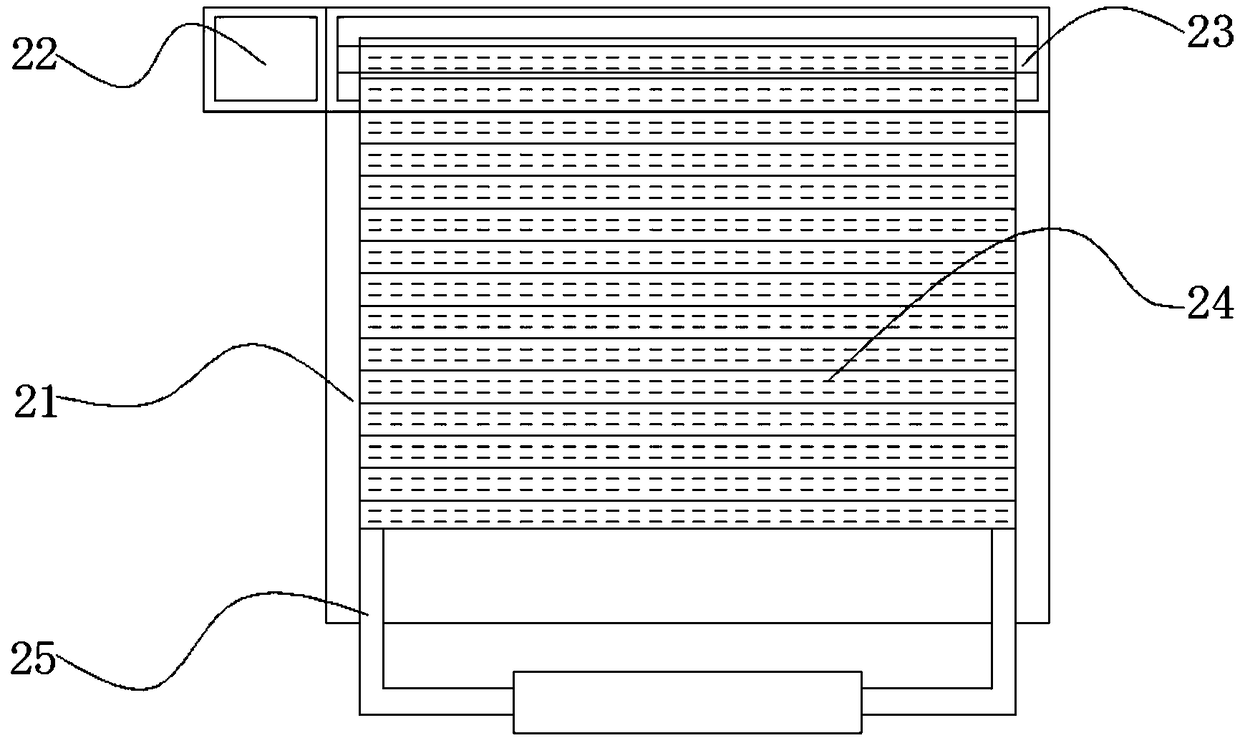

The invention relates to a compact shelf, in particular to a partitioned adjustable file compact shelf. The technical problem to be solved by the invention is to provide the partitioned adjustable file compact shelf capable of freely adjusting partition spaces in a compact cabinet. The partitioned adjustable file compact shelf comprises a frame body; a clamping assembly mounted on the frame body; a placing assembly mounted between the clamping assembly and the frame body; a placing assembly which comprises vertical plates which are installed on the two sides of the frame body; at least two first sliding blocks mounted on the vertical plate in a sliding manner; a placing frame mounted between the first sliding blocks on the same side; second sliding frames installed on the two sides of the containing frame, and connected with the clamping assemblies in a sliding mode; and a first sliding rod installed on the second sliding frame in a sliding mode. The shelf is provided with the partition plates, so that the storage width on the storage rack can be adjusted by controlling the partition plates to move, and the storage efficiency on the storage rack is higher.

Owner:JIANGXI SUNSHINE SAFETY EQUIP GRP CO LTD

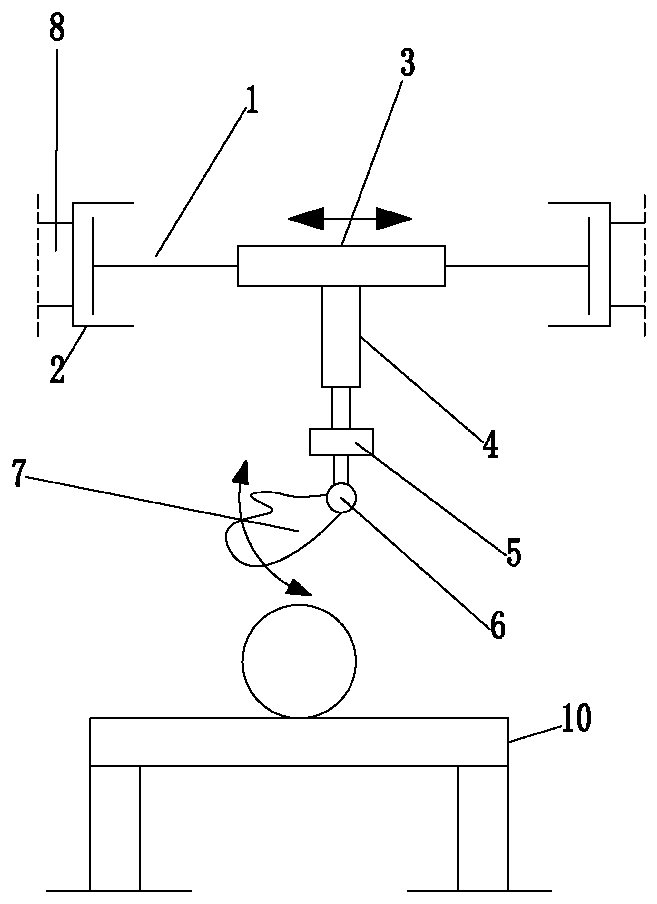

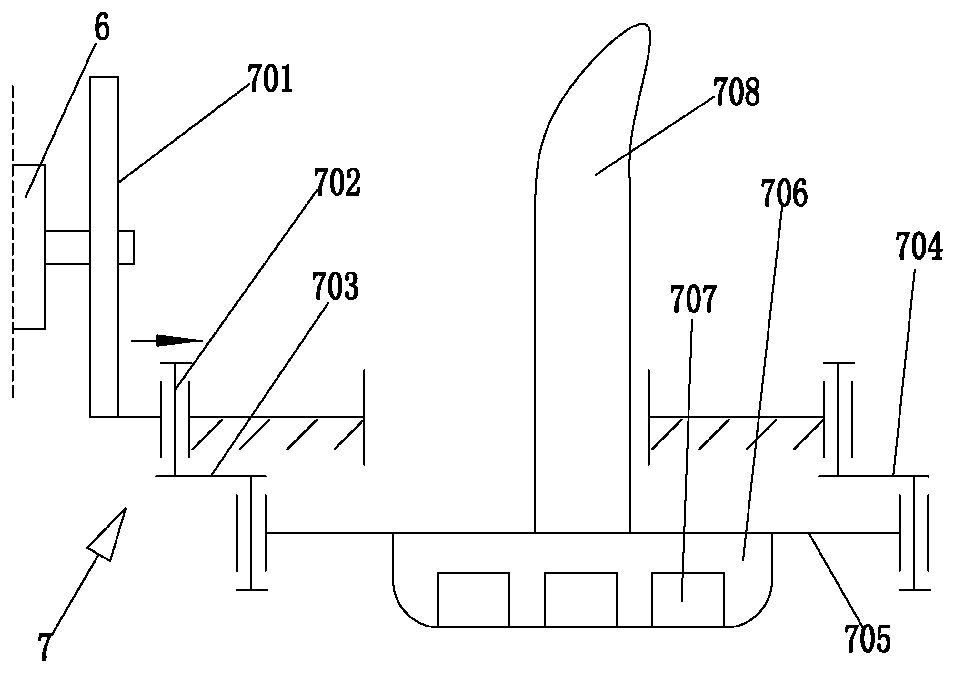

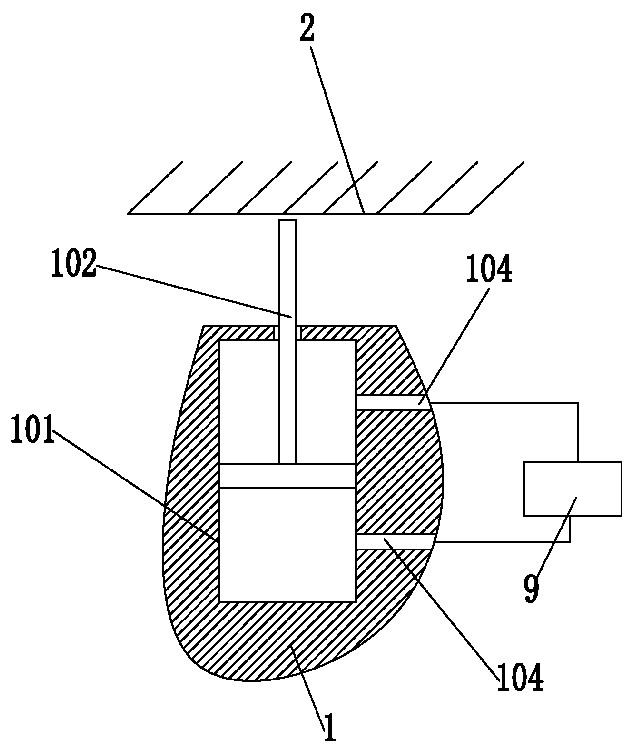

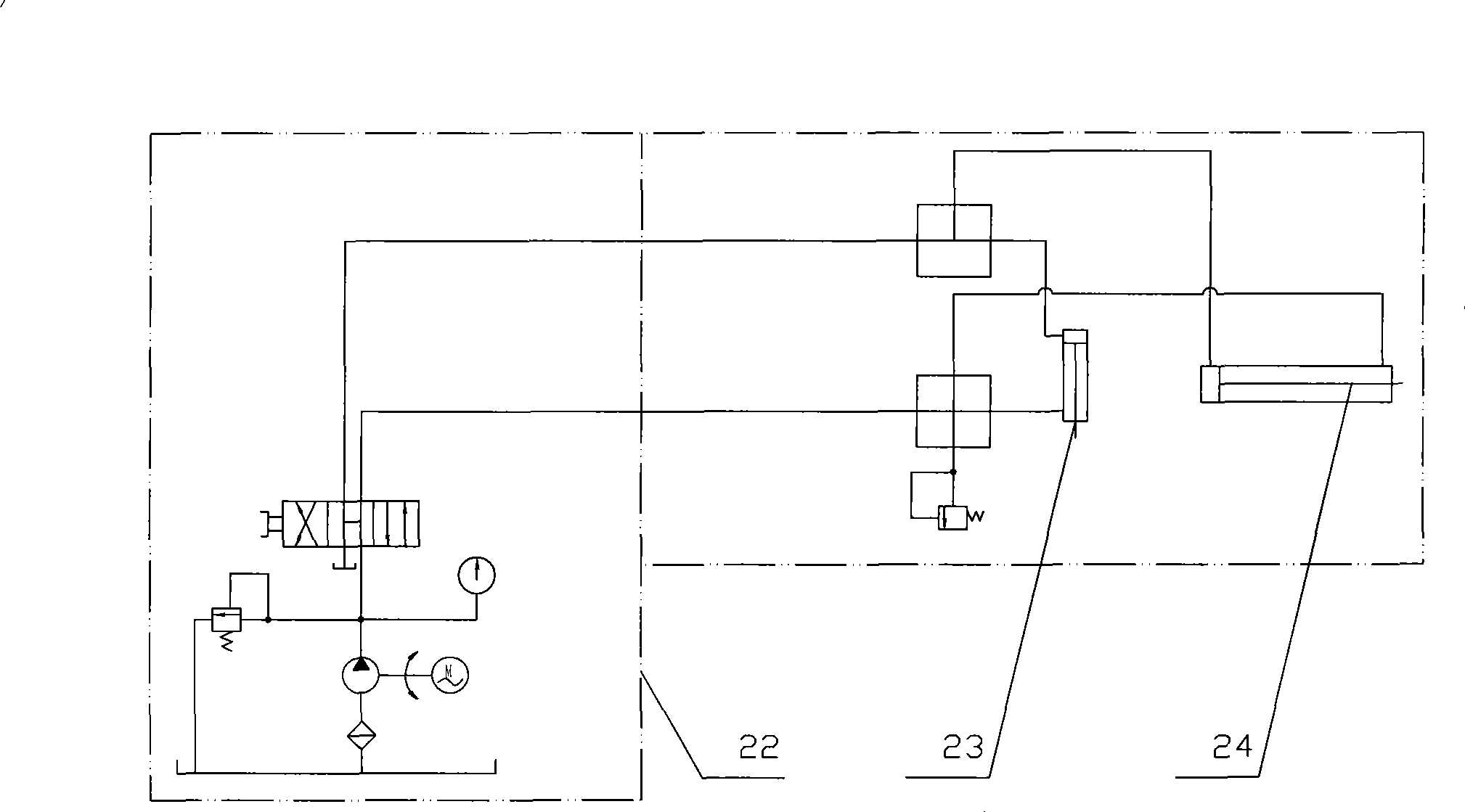

Pneumatic drive active and passive joint hybrid type Chinese massage robot

PendingCN107582348AEasy to operateRealize acupressureDevices for pressing relfex pointsVibration massageElectric machineryHybrid type

The invention discloses a pneumatic drive active and passive joint hybrid type Chinese massage robot in the technical field of medical robots. The pneumatic drive active and passive joint hybrid typeChinese massage robot comprises a main controller, a bed body, a pair of upper fixed tracks, a traverse shift seat, a longitudinal shift seat, a massage executing mechanism, a pitch drive mechanism, aflat turn mechanism and a lifting mechanism. The massage executing mechanism includes a massage head machine frame, a driving connecting rod, a driven connecting rod and an intermediate connecting rod, further comprises a rotary drive mechanism controlled by the main controller, further comprises a palm for massaging the human body, further comprises a finger for acupressure, and further comprises a vibration motor arranged in the palm and controlled by the main controller. The palm is fixed to one side of the intermediate connecting rod, and the finger is fixed to the other side of the intermediate connecting rod and arranged opposite to the palm. The cost is controlled easily, and the pneumatic drive active and passive joint hybrid type Chinese massage robot is easy to operate.

Owner:镇江康乐服务机器人有限公司

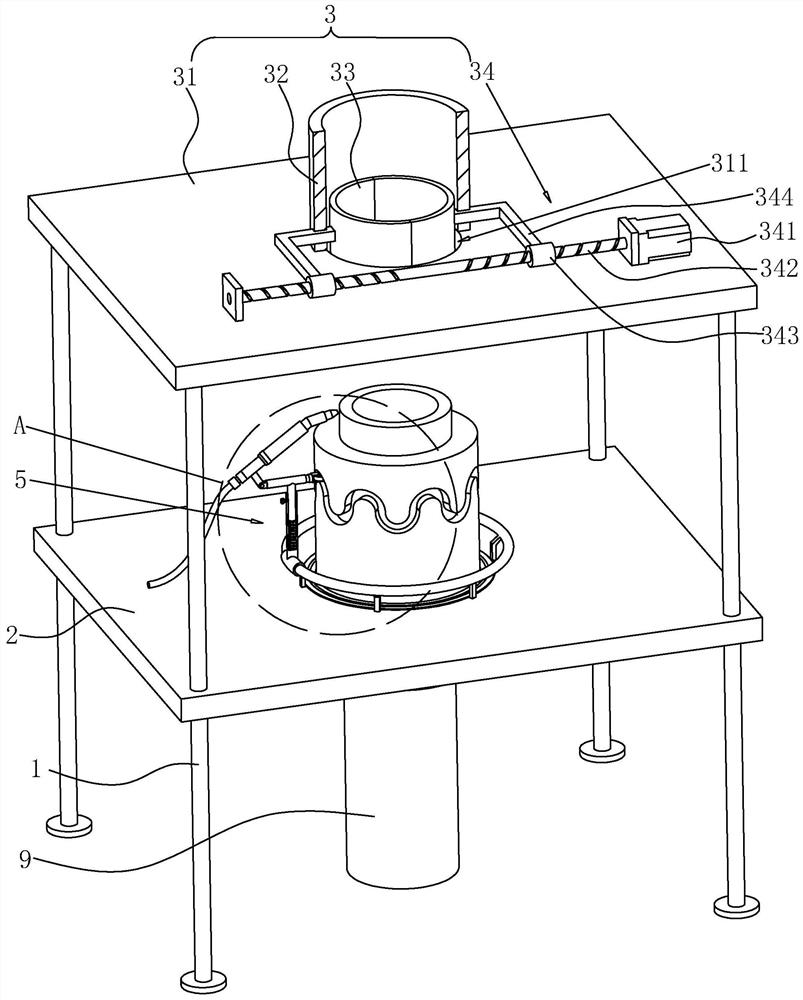

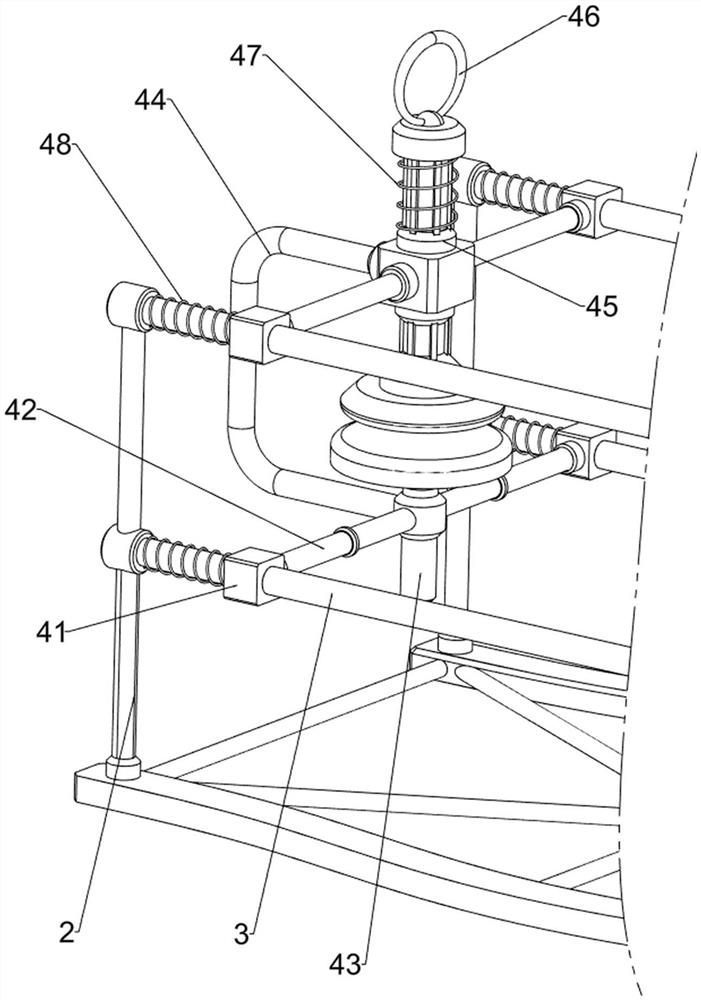

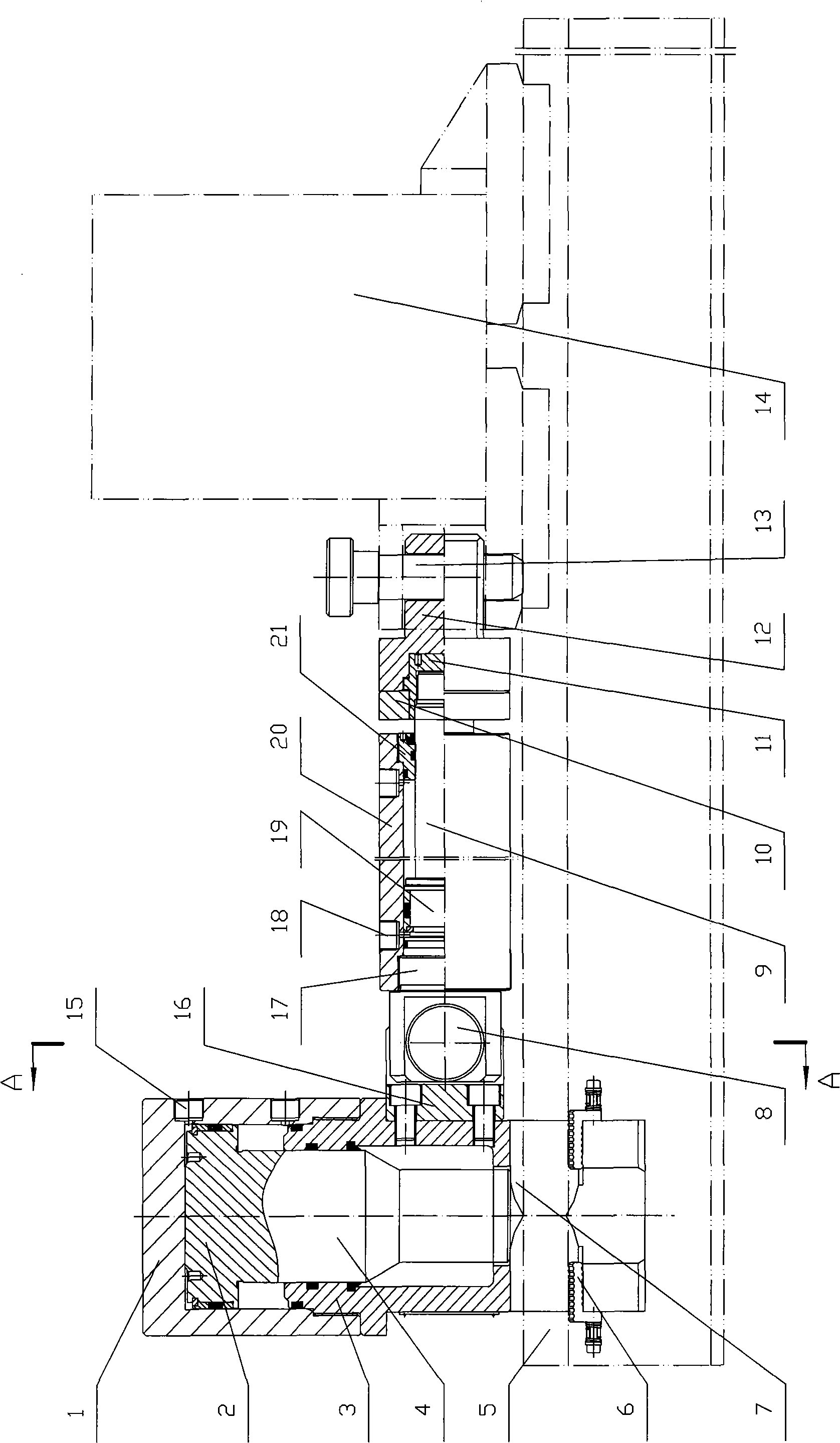

Deep pile foundation construction device and construction method thereof

ActiveCN112922013AReduce difficultyGuaranteed welding accuracyWelding/cutting auxillary devicesAuxillary welding devicesButt jointArchitectural engineering

The invention relates to a deep pile foundation construction device and a construction method thereof, and belongs to the technical field of pile foundation construction. The deep pile foundation construction device comprises a rack, a positioning plate is arranged on the rack, a positioning hole allowing steel casings to be inserted is formed in the positioning plate, a positioning butt joint mechanism is arranged on the position, located above the positioning plate, of the rack, and the positioning butt joint mechanism is used for performing coaxial butt joint on the two steel casings; and a welding gun, an adjusting mechanism and a driving mechanism are further arranged on the positioning plate, the welding gun is used for welding the abutting position of the two steel casings, the adjusting mechanism is used for adjusting the height of the welding gun, and the driving mechanism is used for driving the welding gun to do circular motion around the steel casings. The deep pile foundation construction device has the effect of reducing the difficulty of embedding the steel casings in a deep pile foundation.

Owner:成都城投建筑工程有限公司

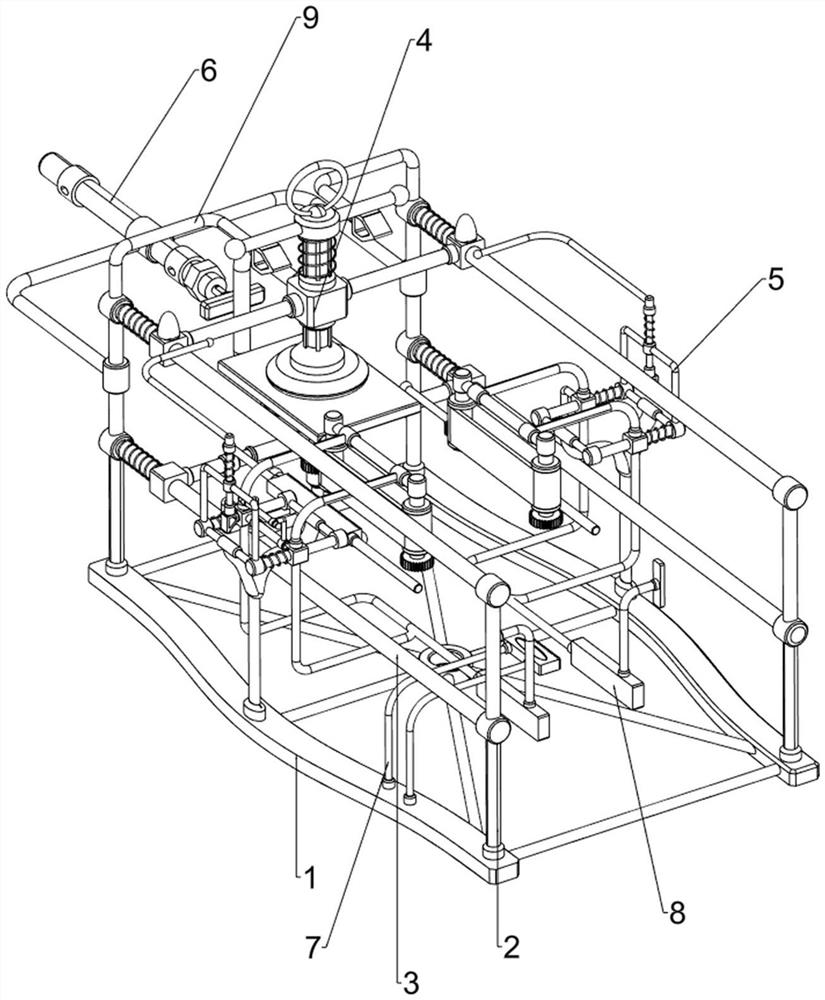

Edge trimming equipment for mobile phone cover plate production

ActiveCN112496942AAchieve clampingAutomatic forward movementEdge grinding machinesGrinding work supportsEngineeringStructural engineering

The invention relates to mobile phone cover plate trimming equipment, in particular to edge trimming equipment for mobile phone cover plate production. The invention provides edge trimming equipment for mobile phone cover plate production that facilitates clamping and automatic multi-edge polishing. The edge trimming equipment for mobile phone cover plate production comprises: a bottom plate and support columns, wherein the support columns are arranged on the four sides of the bottom plate; first sliding rods connected between the tops and the middles of the support columns on one side and between the tops and the middles of the support columns on the other side; clamping mechanisms arranged between one sides of the first sliding rods; and polishing mechanisms arranged on the two sides ofthe middle of the bottom plate. Through cooperation of a pulling mechanism and the clamping mechanisms, the pulling mechanism pulls the clamping mechanisms upwards, a mobile phone cover plate is placed between the clamping mechanisms, and the effect of clamping the mobile phone cover plate is achieved.

Owner:贵州亮成电子有限公司

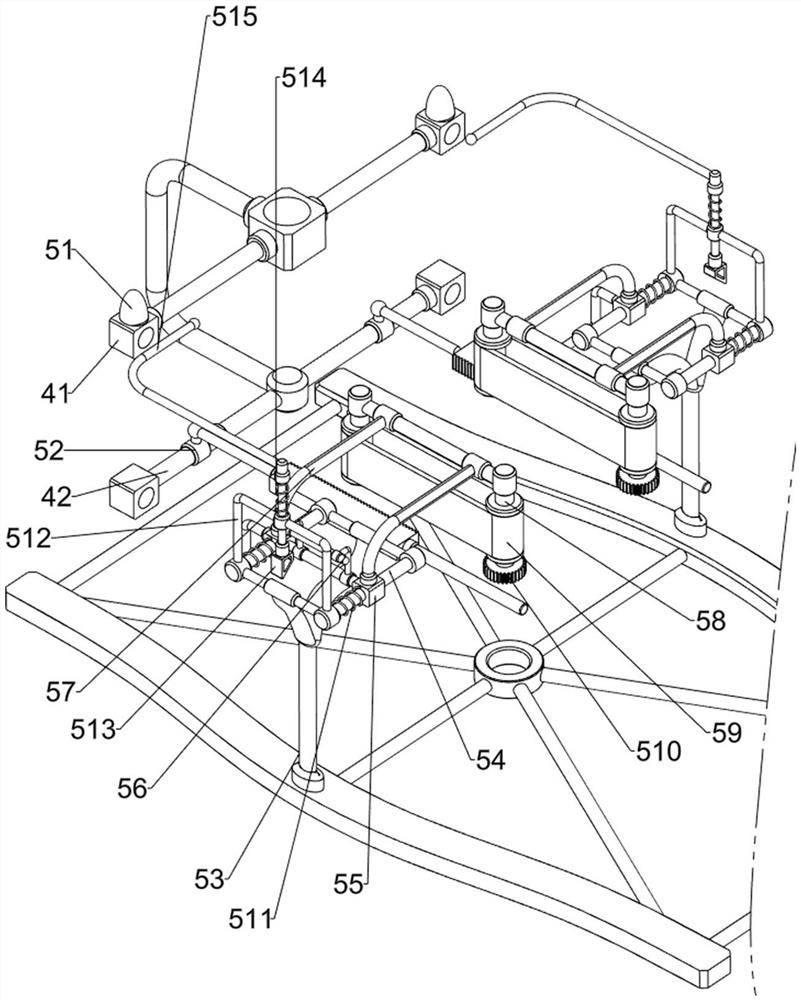

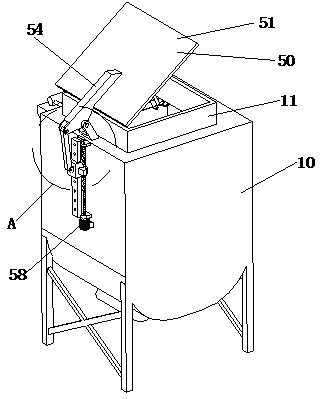

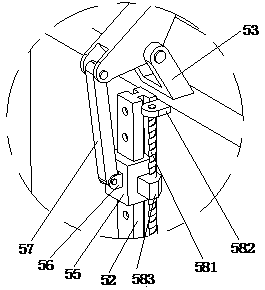

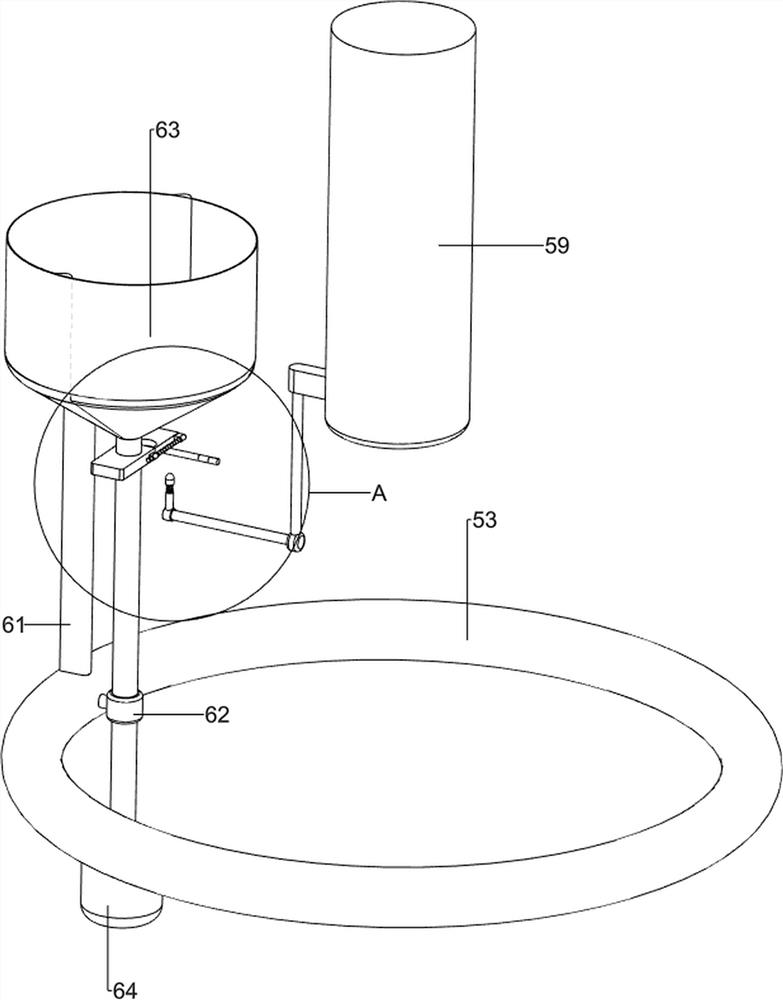

Sprinkling vinegar device for making vinegar

InactiveCN110396465AEasy to pour vinegarSolve technical problems with automatic tiling operationsVinegar preparationEngineering

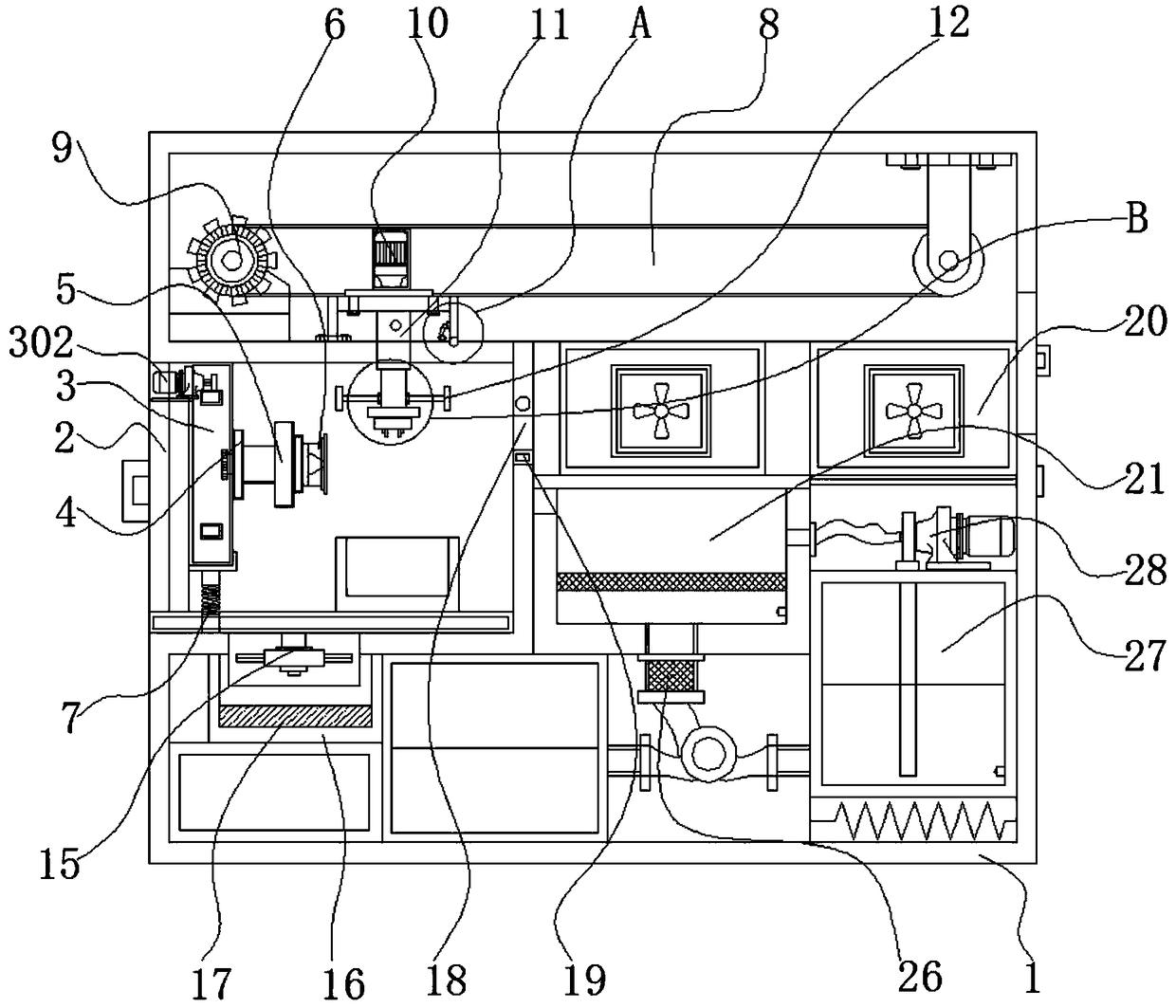

The invention discloses a sprinkling vinegar device for making vinegar, and belongs to the technical field of vinegar processing equipment. The sprinkling vinegar device comprises a vinegar making cabinet. The inside of the vinegar making cabinet is provided with a vinegar grain paving mechanism, an evenly spraying vinegar mechanism and a mixing and stirring mechanism, the top of the vinegar making cabinet is provided with a feeding port, the side wall of the vinegar making cabinet is provided with a feeding port closure assembly, the inside of the vinegar making cabinet is provided with a filter net, the vinegar grain paving mechanism includes a guide hopper, a moving material assembly and two guide rails respectively arranged on the inner wall of the two sides of the vinegar making cabinet, each guide rail is provided with a sliding block, and the bottom of the vinegar making cabinet is provided with a drainage pipeline. The sprinkling vinegar device has the beneficial effects that paving operation of vinegar grains can be realized through the vinegar grain paving mechanism, so that the vinegar grains can be laid on the filter net, sprinkling vinegar operation on the paved vinegar grains is convenient, moreover, cleaning operation of meshes of the filter net can be realized through the mixing and stirring mechanism, and mixing and stirring operation of the vinegar liquid canbe conducted at the same time.

Owner:王玉杰

Soybean screening and cleaning all-in-one machine

The invention discloses a soybean screening and cleaning all-in-one machine. The machine comprises a feeding box, a machine box and a cleaning box, a screening plate is arranged below a feeding hole,a collecting plate is arranged below the screening plate, collecting holes are formed in the screening plate, the collecting holes communicate with the upper end of the cleaning box through a first material conveying pipe, a partition plate is obliquely arranged in the cleaning box, a filter screen is arranged below the partition plate, a material falling gap is formed between one higher end of the partition plate and the inner wall of the cleaning tank, the side wall of the cleaning box is connected with a water inlet pipe and an impurity removal pipe, a discharge end of the first material conveying pipe, the water outlet end of the water inlet pipe are located above the material falling gap, a feeding end of the impurity removal pipe is positioned above the lower end of the separation plate, the bottom of the cleaning box is connected with a sewage discharge pipe, a second material conveying pipe is arranged at the bottom of the filter screen, wherein one end of the second material conveying pipe is connected with a drying box, a first valve is arranged on the second material conveying pipe, and a second valve is arranged on the sewage discharging pipe.

Owner:SHANDONG CROP GERMPLASM CENT

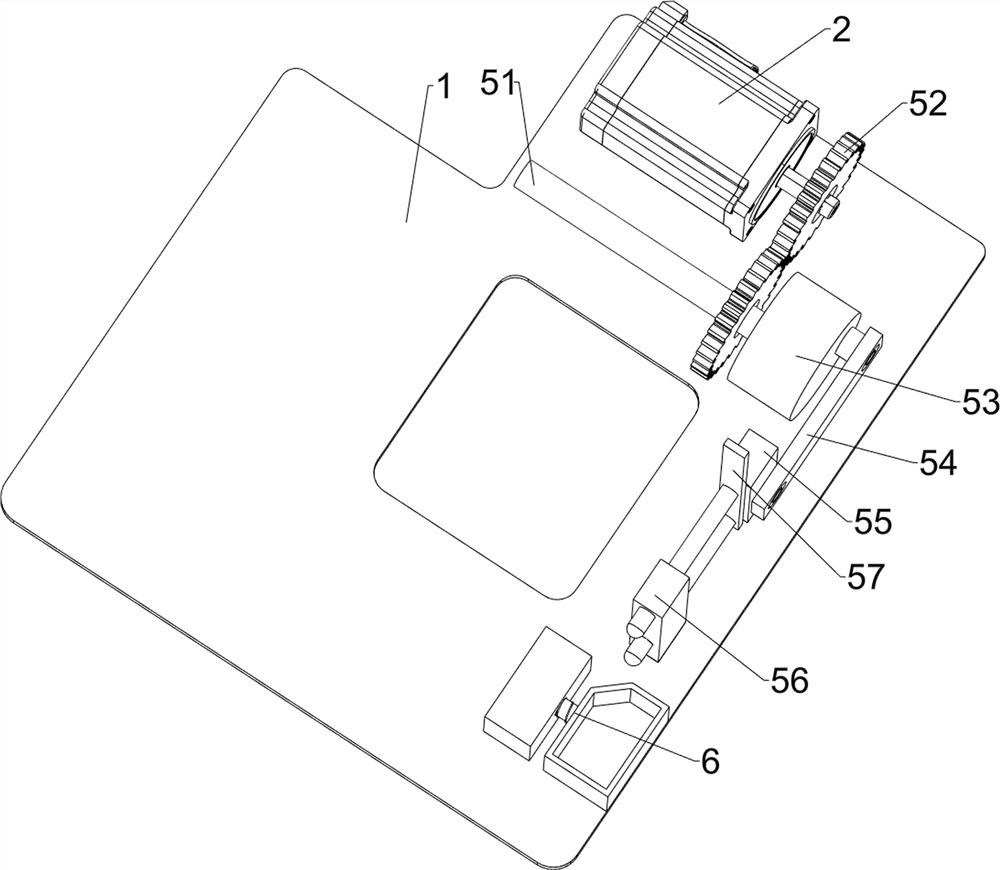

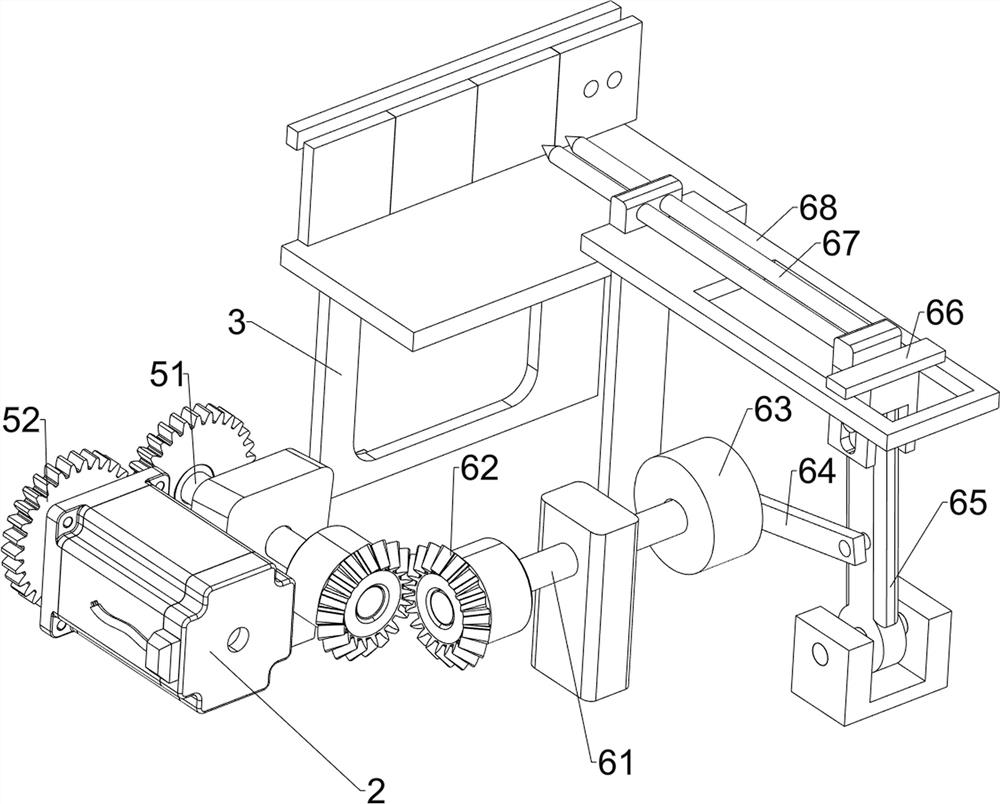

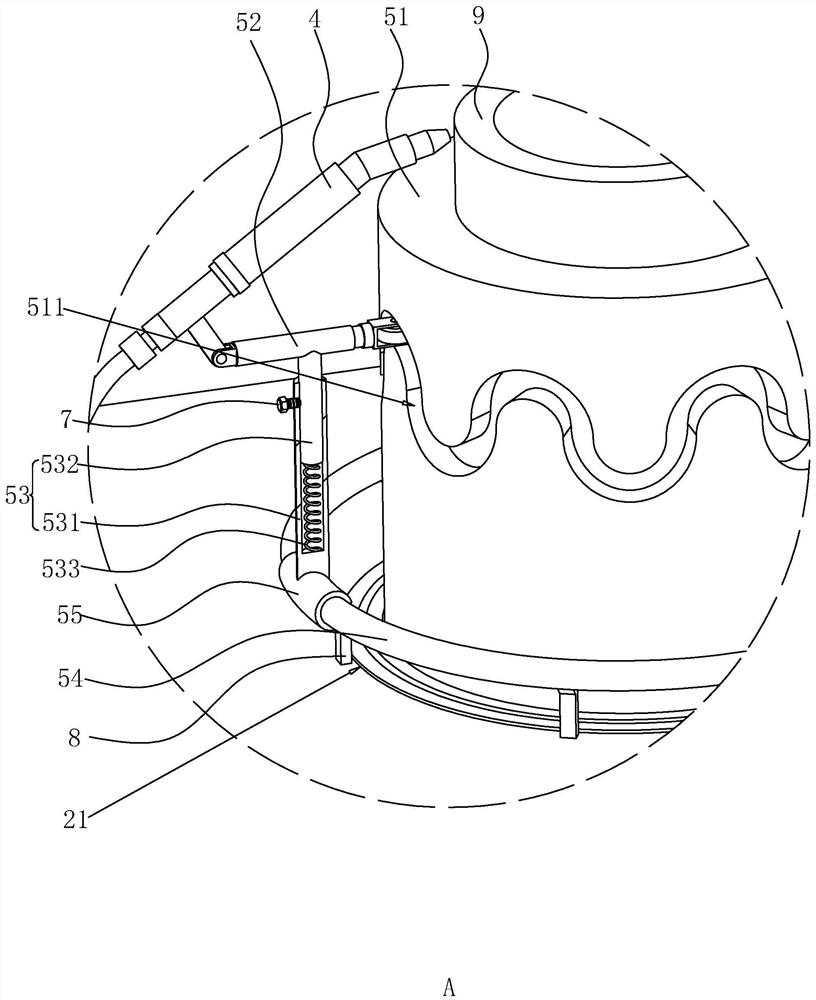

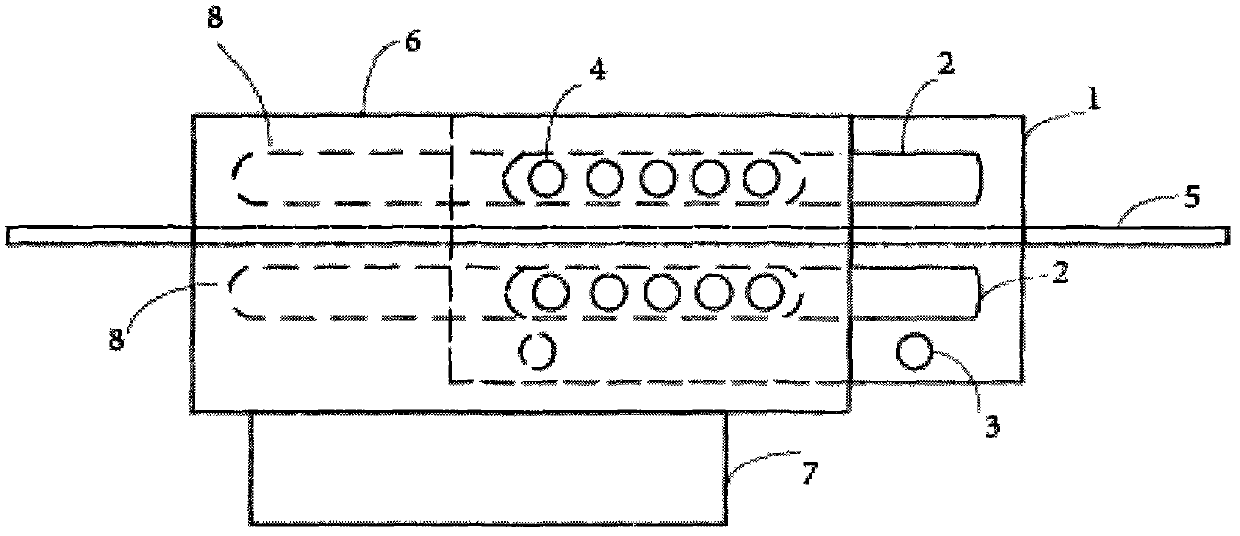

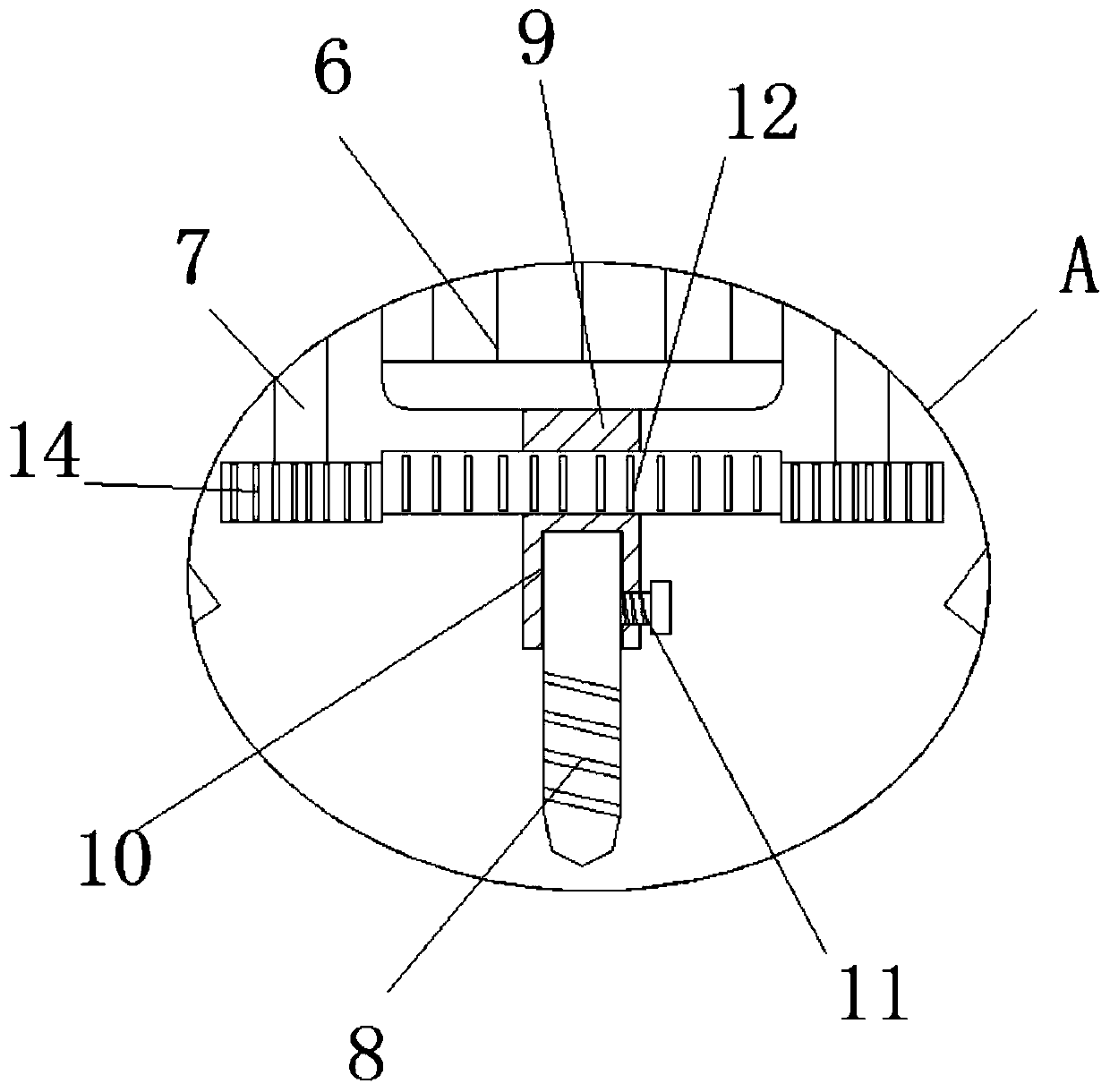

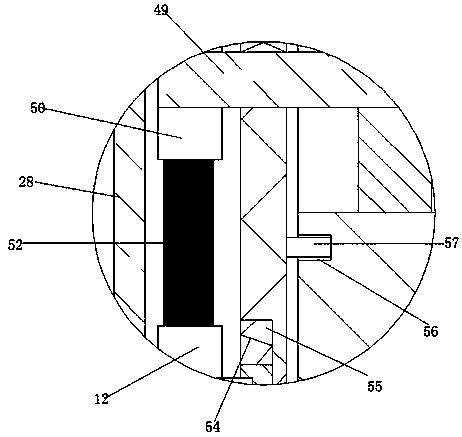

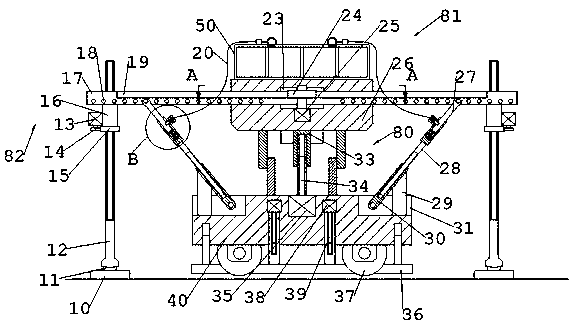

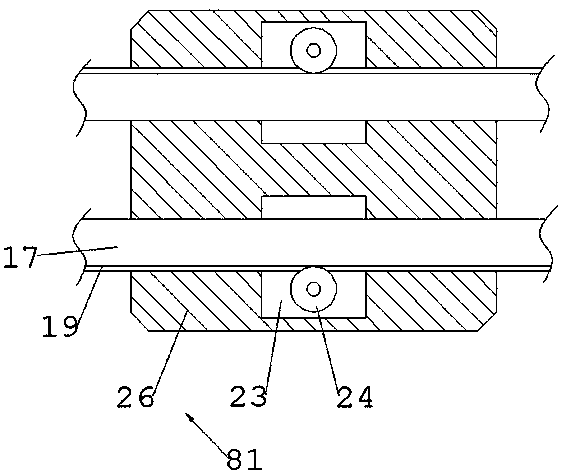

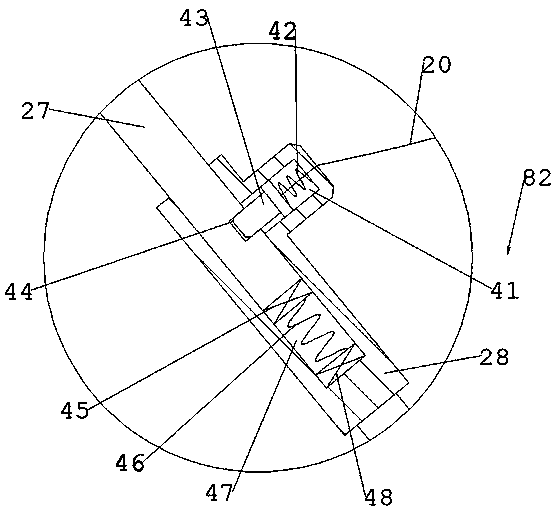

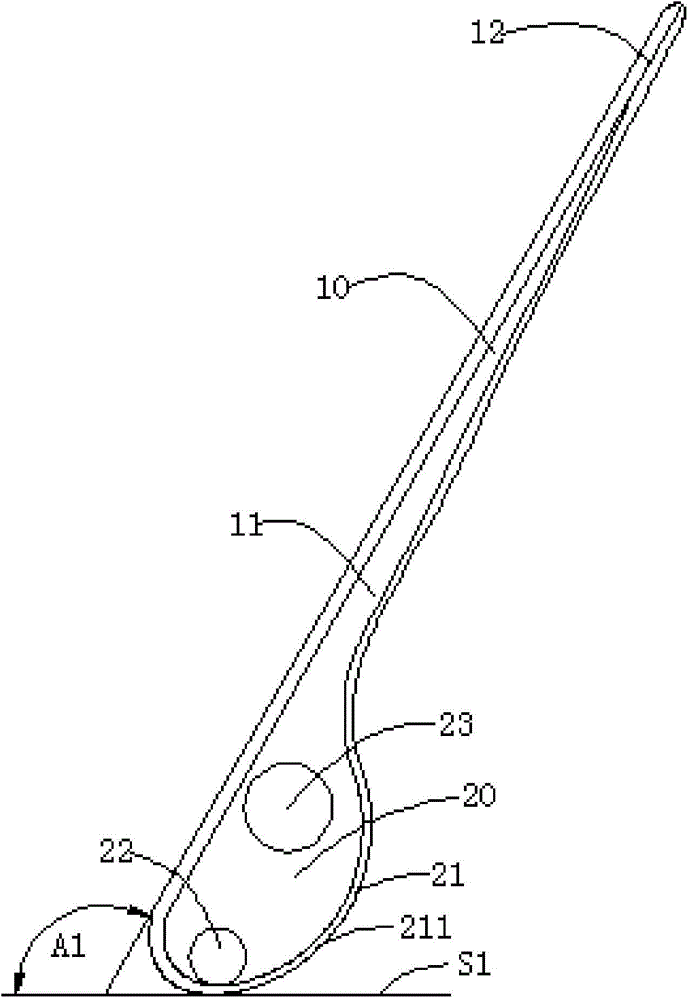

String clamping equipment for racquet stringing machine

The invention relates to a string clamping equipment for a racquet stringing machine. The string clamping equipment for the racquet stringing machine mainly comprises an orientation device, a string clamping device, an elastic device, a clamping degree adjusting device and a fixing device. The string clamping equipment is connected with and fixed on one clamping sheet of a string clamping block through the fixing device, so that the string clamping equipment and the string clamping block can realize linkage. The string clamping equipment can be positioned on the extending line of the central line of the string clamping block by adjusting the position of a position adjusting hole, in the fixing device, of the orientation device, so that the clamped ball string is positioned at the correct clamping position of the string clamping block without manual operation. The frictional resistance between the string clamping device of the string clamping equipment and the ball line is more than the frictional resistance between the string clamping block and a pedestal of the string clamping block, so that the ball line, the string clamping equipment and the string clamping block can realize linkage without manual operation. The string clamping equipment simplifies the manual operation step in a string clamping process, reduces human error, avoids damage to the ball line and improves the tension precision of the ball line.

Owner:张秉钧

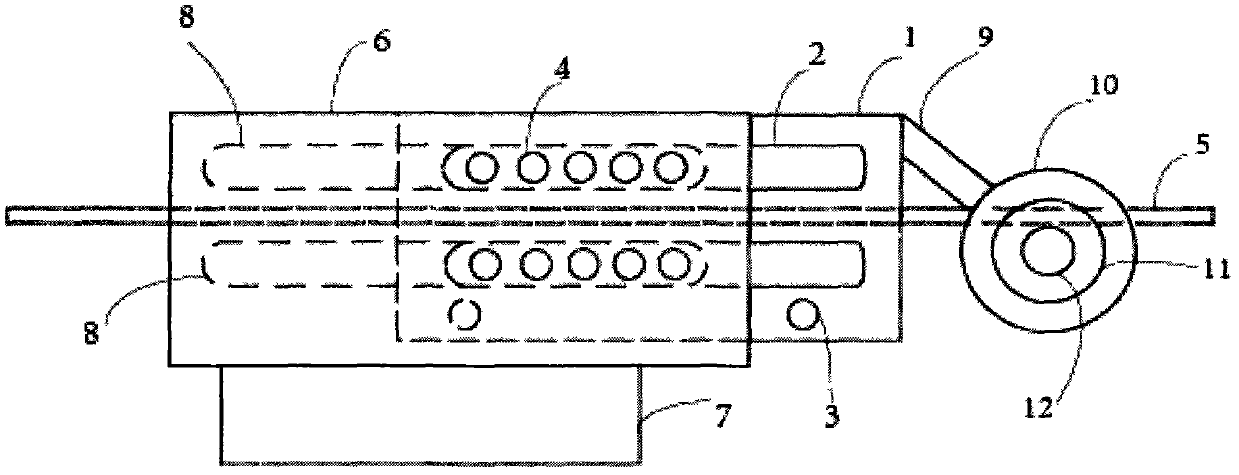

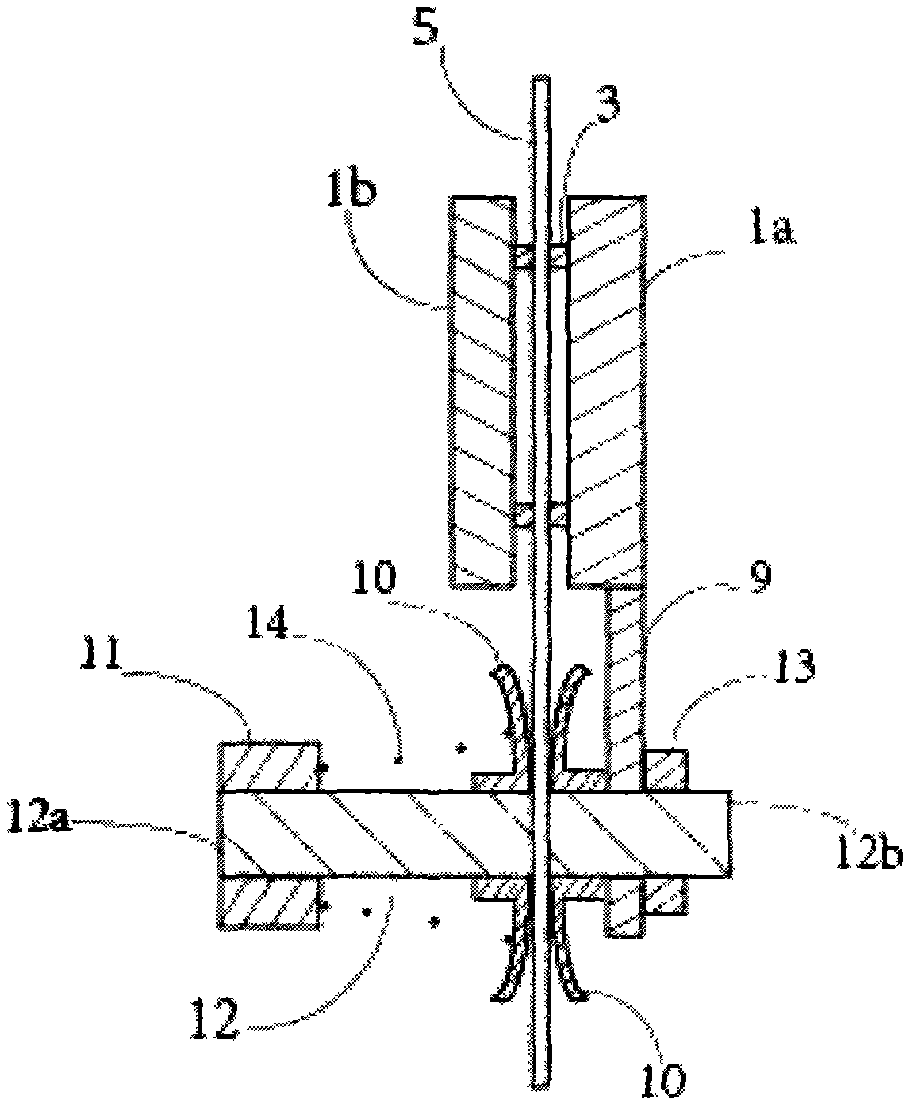

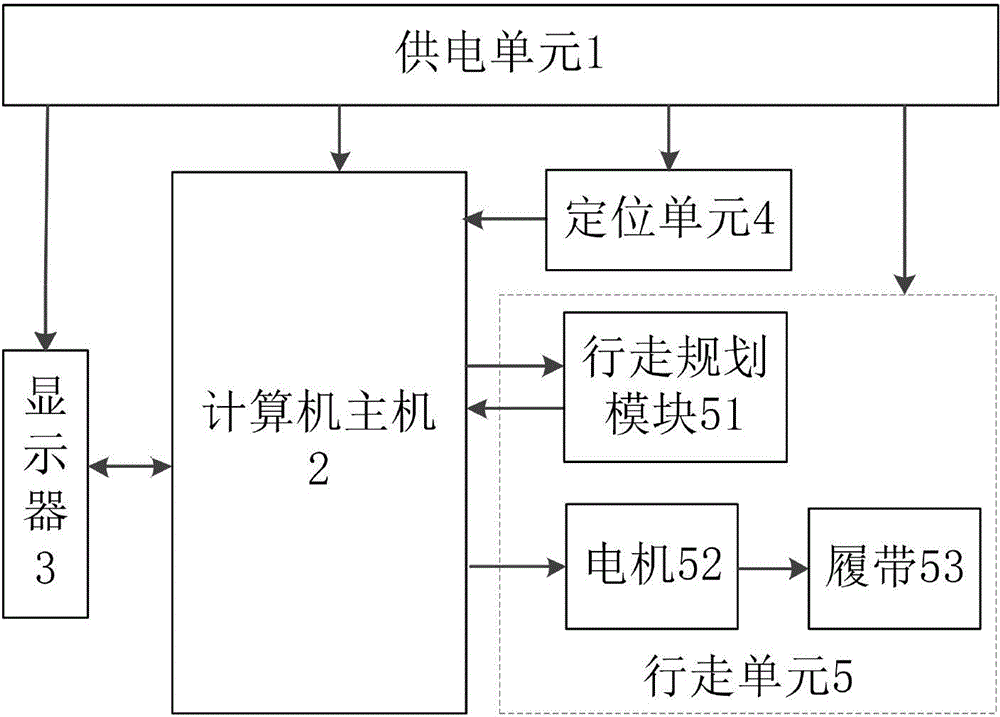

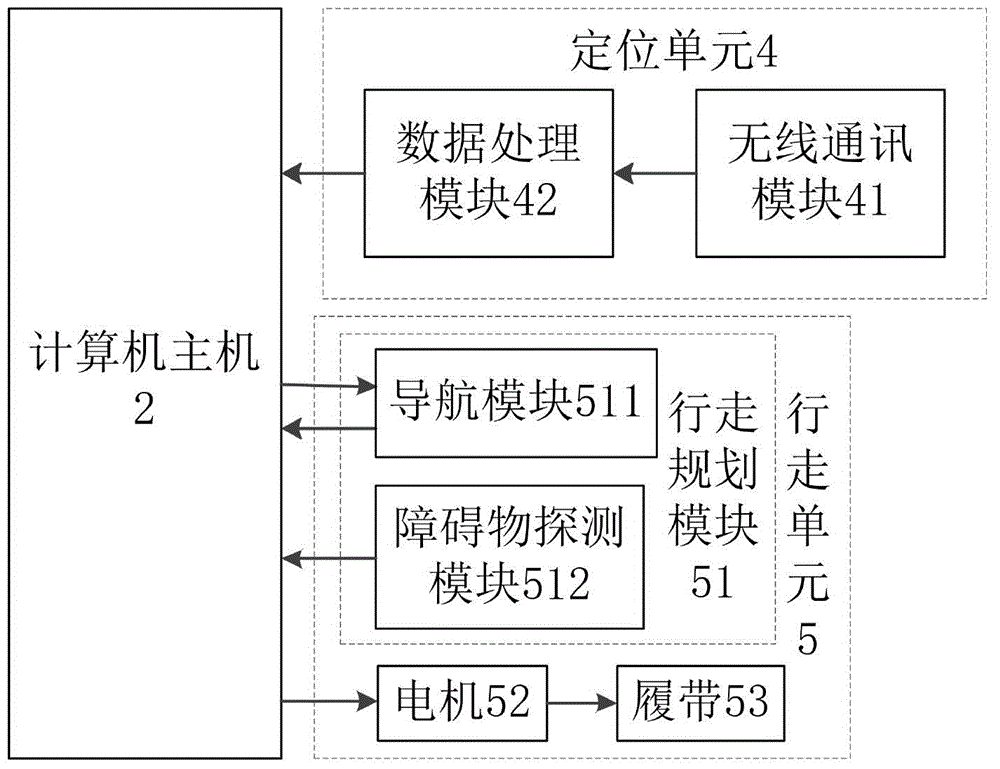

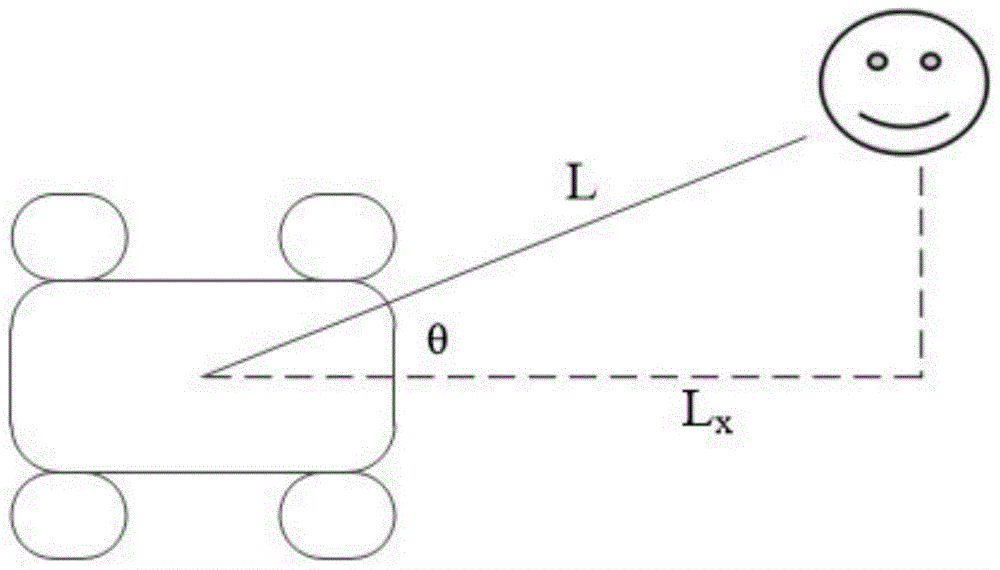

Computer capable of moving intelligently

ActiveCN104965514AConvenience to workHigh activityPosition/course control in two dimensionsRemote controlComputer module

The invention relates to a computer capable of moving intelligently, which is characterized by comprising a power supply unit, a computer host, a display, a positioning unit and a walking unit, wherein the power supply unit is connected with the computer host, the display, the positioning unit and the walking unit; the display, the positioning unit and the walking unit are all connected with the computer host; the positioning unit determines position information of a user and the information is transmitted to the computer host; the computer host controls the walking unit to move in front of the user according to the position information of the user; the user can transmit the position information of the user to the computer host in a remote control mode or a sound control mode; and further the walking unit comprises a walking planning module, a motor and a track, and the walking planning module comprises a navigation module and an obstacle detection module. The computer capable of moving intelligently has the beneficial effects that the user carries out remote control or sound control on the computer of the invention via an intelligent terminal, the computer can automatically move in front of the user, and great convenience is brought to work and life of people.

Owner:高世恒

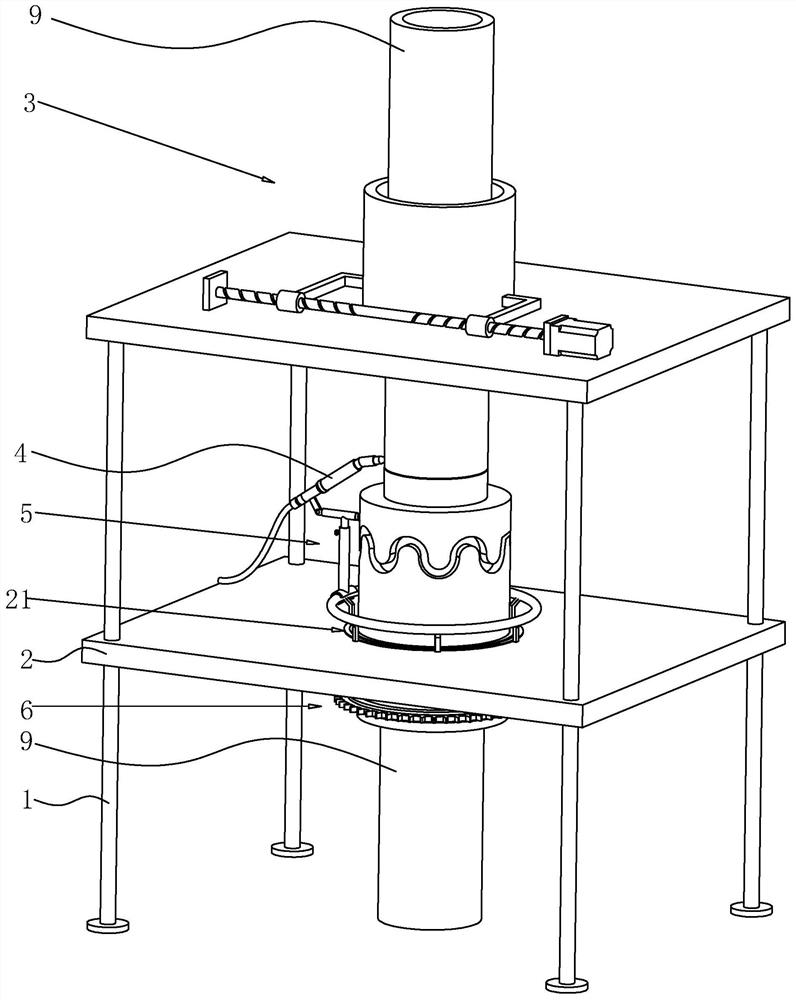

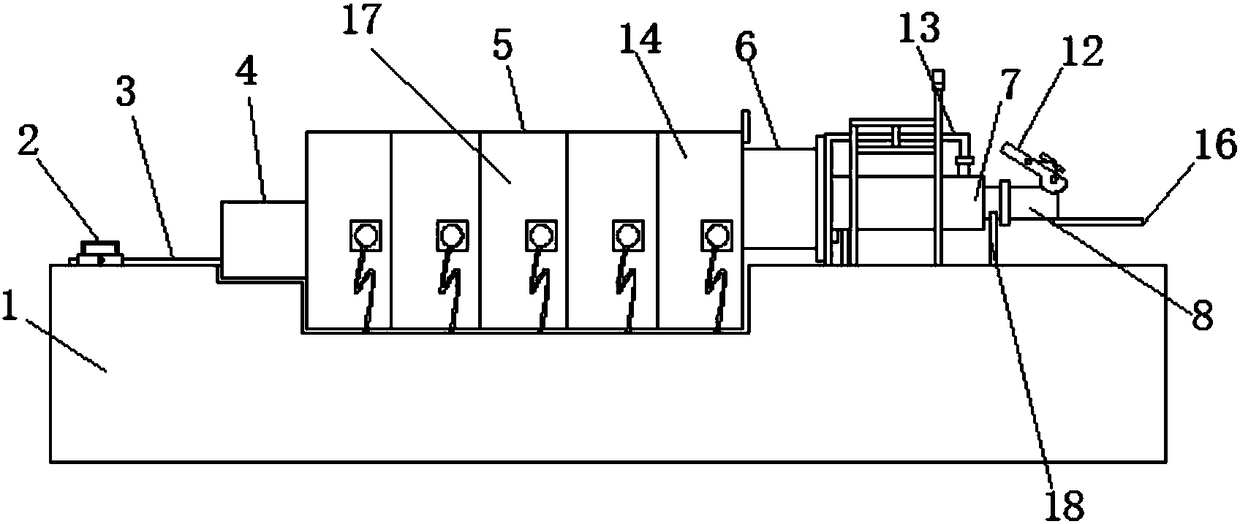

High-temperature hydrogen furnace for sintering ceramic tube

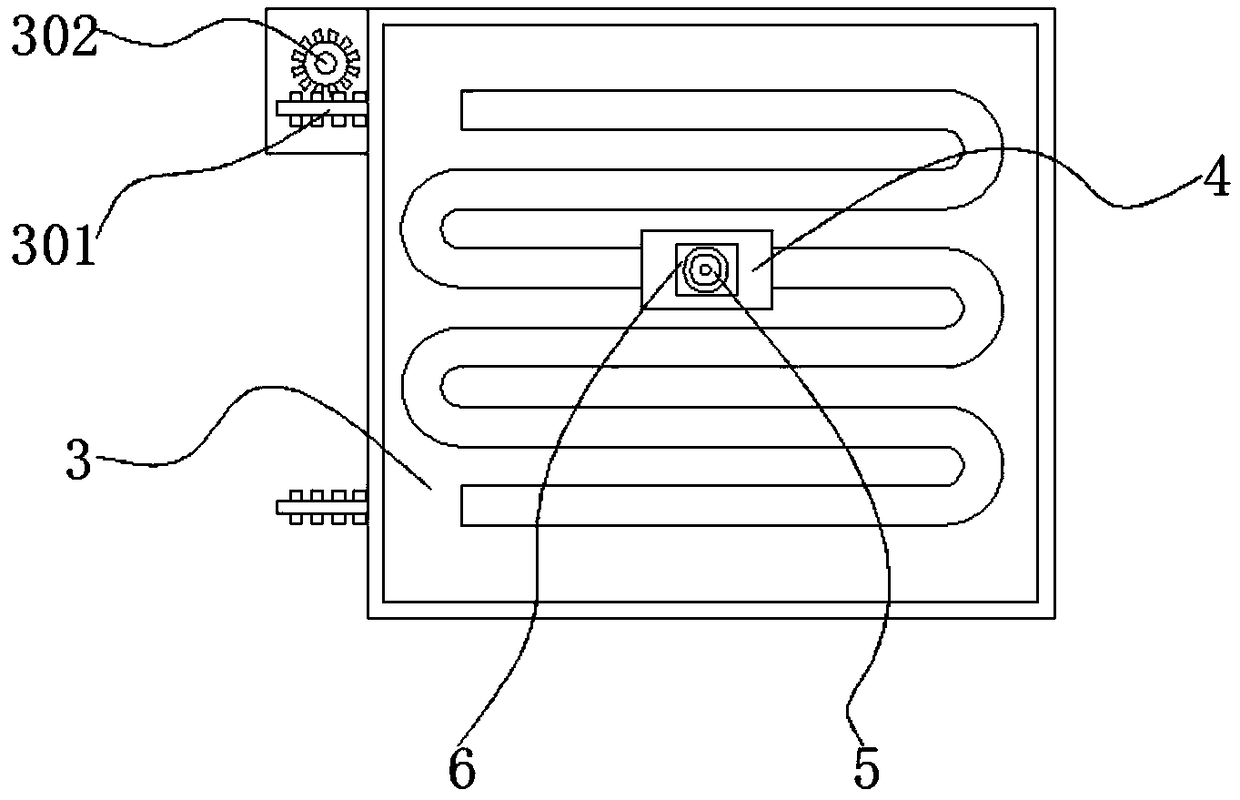

PendingCN108253781AImprove cooling efficiencyAct as a cooling bufferCharge composition/stateFurnace typesHydrogenWater cooling

The invention discloses a high-temperature hydrogen furnace for sintering a ceramic tube. The high-temperature hydrogen furnace comprises a supporting table, a boat and a corundum box, wherein the upper end of the supporting table is provided with a sintering furnace, the two ends of the sintering furnace are provided with a feeding hole and a connecting zone respectively, the feeding hole is connected to one end of the sintering furnace and communicates with the inside of the sintering furnace, and one end, far away from the feeding hole, of the sintering furnace is connected with the connecting zone; the sintering furnace is divided into five zones, the sintering furnace comprises a high-temperature zone and a buffer zone, the buffer zone is connected with the connecting zone, the high-temperature zone is arranged in the middle of the sintering furnace, a cooling zone is connected to the end, away from the sintering furnace, of the connecting zone, a guide rail is arranged on the supporting table, the guide rail penetrates through the sintering furnace, the cooling zone and a discharge hole, and a push handle is movably arranged on the surface of the guide rail. According to thehigh-temperature hydrogen furnace, a condensation water connecting pipe which is used for inputting water circularly is arranged, so that the condensate water can be circularly processed; and the guide rail which penetrates through the whole process can automatically move the ceramic tube, so that less manual participation is achieved.

Owner:浙江新光阳照明股份有限公司

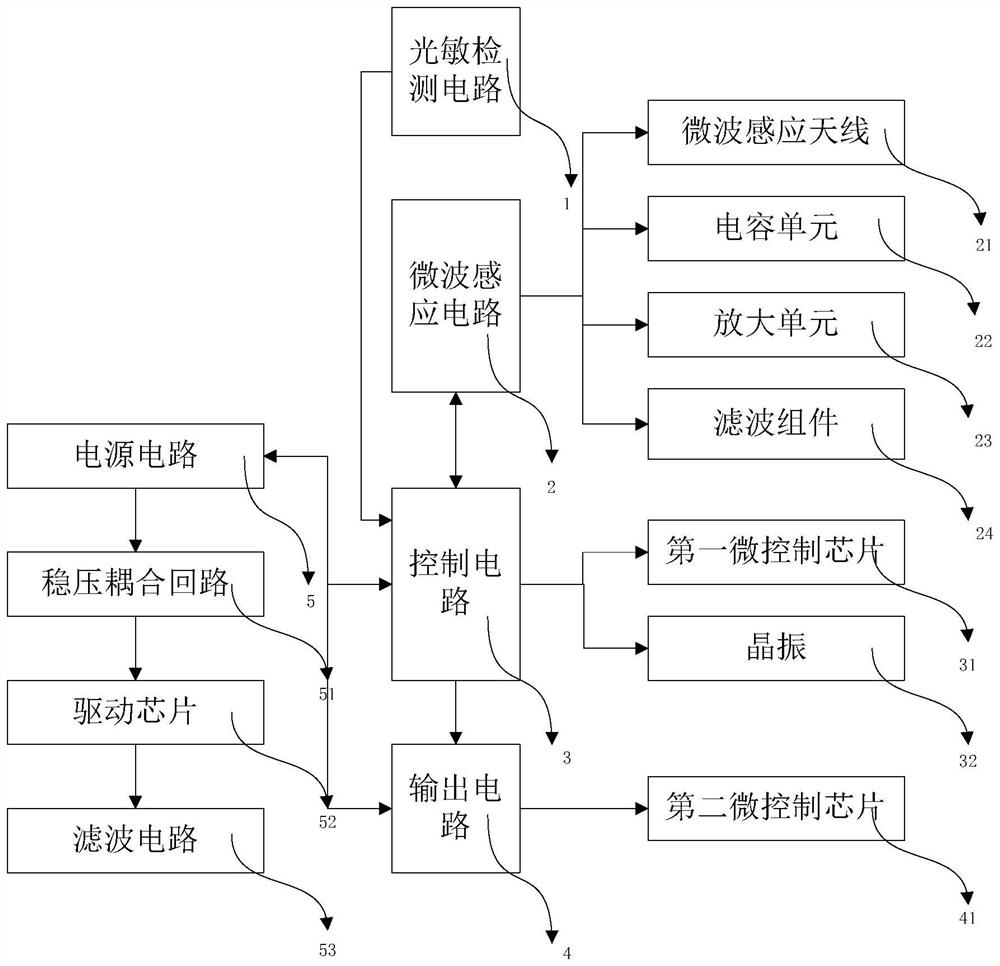

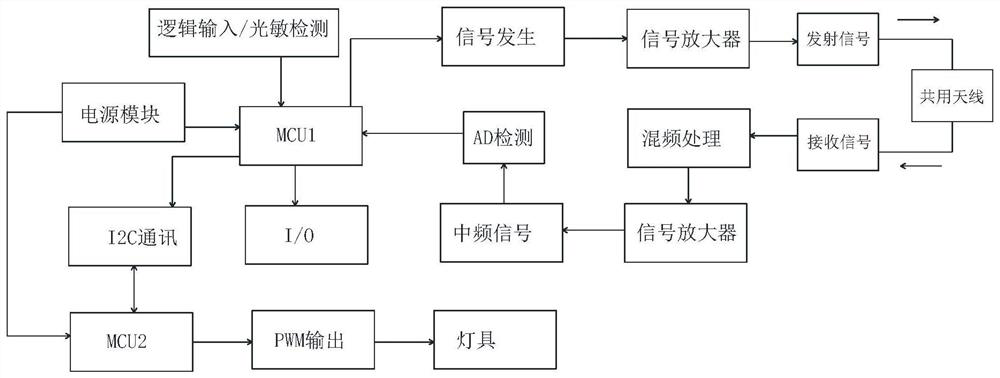

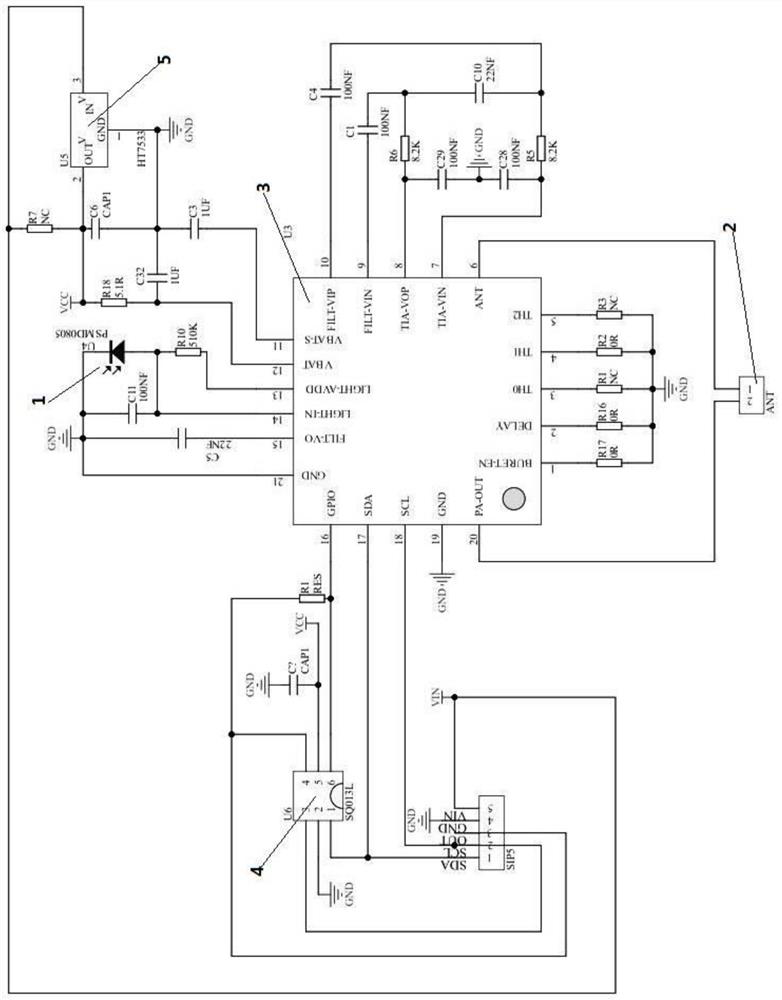

Illuminating device based on microwave radar induction

PendingCN114793379AGood consistencySuper cost-effectiveElectrical apparatusCalibration algorithmUltra low power

The invention discloses a microwave radar induction lighting device. A microwave transceiver, a radar intermediate frequency amplification circuit, a signal processor and the like are integrated on a single chip at the same time, and the device has good consistency and ultrahigh cost performance. Due to the fact that a self-adaptive calibration algorithm is integrated on the chip, various interference problems can be effectively solved, and reliability and practicability of the sensor are greatly improved. An ultra-low power consumption framework is adopted, power consumption is low, and wide voltage is supported; a signal processor is integrated in the chip and can directly output an inductive control signal, and a complete microwave inductive sensor is formed by matching a small number of components on the periphery; manual control can be reduced, when a person enters the detection range of the device, the microwave detector works to light the lamp, and when the person leaves the detection range, the lamp is automatically turned off. The device has strong anti-interference capability and is not interfered by external environmental factors.

Owner:宁波市盈芯微电子科技有限公司

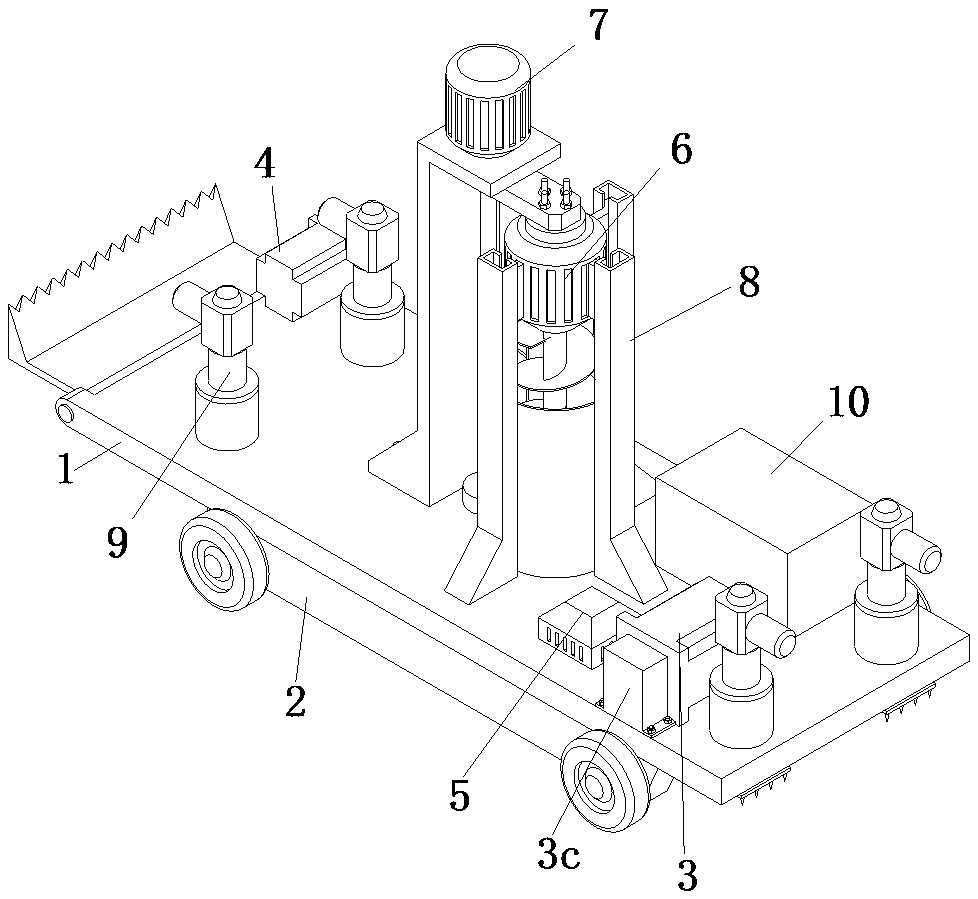

Sheet material punching structure for buildings and bridges

InactiveCN111558739ADrilling position can be adjustedAvoid cloggingCleaning using toolsPositioning apparatusPunchingArchitectural engineering

The invention belongs to the technical field of sheet material punching, particularly relates to a sheet material punching structure for buildings and bridges. Aiming at solving the problems that an existing punching device is single in function, sheet materials need to be manually moved, the sheet materials cannot be automatically fixed, and chippings cannot be collected, the following scheme isprovided. According to the scheme, the device comprises a working plate, a conveying mechanism is arranged at the top of the working plate, the sheet materials are placed on the conveying mechanism, four supporting rods are fixedly connected to the top of the working plate, the four supporting rods are movably connected with the same top plate, the supporting rods located on the same horizontal transverse lines are connected with driving mechanisms, the top plate is matched with the two driving mechanisms, a propelling motor is embedded in the working plate, a lifting plate is fixedly connected to an output shaft of the propelling motor, and a motor is fixedly connected to the bottom of the lifting plate. According to the device, the operation is convenient, the sheet materials can be automatically moved, the sheet materials can be automatically fixed, and the chippings can be collected.

Owner:顾轩波

Universal pipeline inner wall derusting device

InactiveCN111390675ASimple structureEasy to operateRevolution surface grinding machinesGrinding/polishing safety devicesElectric machineDust control

The invention discloses a universal pipeline inner wall derusting device. The universal pipeline inner wall derusting device comprises a shell and a power device located in the shell; the power devicecomprises a derusting power cavity; the right end wall of the derusting power cavity is fixedly connected with a motor; four derusting devices uniformly distributed around the motor are arranged in the shell; each derusting device comprises a through groove communicating the derusting power cavity with the outer end face of the shell; a dust removing device is arranged on the right side of the power device; and the dust removing device comprises a second rotating shaft in power connection with the right side of the motor. The device is simple in structure, convenient to operate, and capable of performing derusting treatment on pipelines in different pipe diameters; meanwhile, the device can automatically move, and can perform derusting on pipelines in different lengths, the manual derusting labor is greatly improved, meanwhile, removed rust can be automatically blown out of the pipelines, and the device is convenient and fast.

Owner:福州脉弧科技有限公司

A kind of fruit quality screening and classification device

ActiveCN112547468BEasy to collect and placeAutomatic movementSievingScreeningProcess engineeringIndustrial engineering

Owner:伊春市特瑞森林食品有限公司

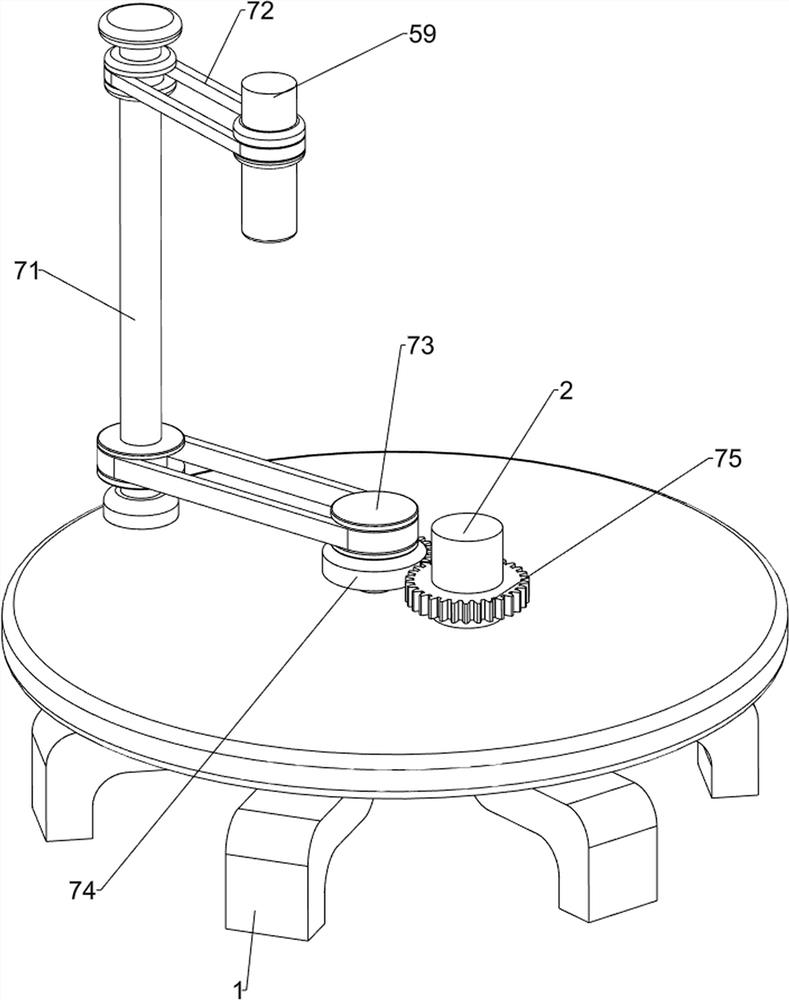

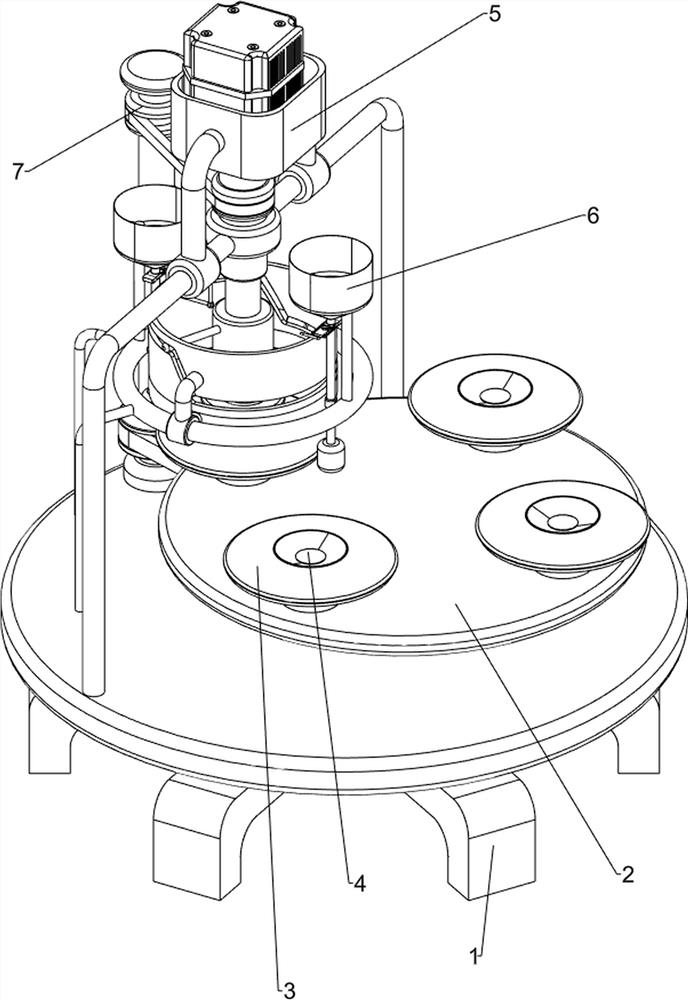

Porcelain plate edge coloring device for ceramic industry

ActiveCN112123528ASave time at workReduce workloadCeramic shaping apparatusComposite materialCircular disc

The invention relates to a coloring device, in particular to a porcelain plate edge coloring device for a ceramic industry. The porcelain plate edge coloring device for the ceramic industry can automatically move a porcelain plate and automatically color the porcelain plate. The porcelain plate edge coloring device for the ceramic industry comprises a base, a rotating tray, rotating discs, suckers, a rotating mechanism and paint adding mechanisms, and the rotating tray is arranged on the base in a rotating mode. The rotating discs are uniformly and rotatably arranged on the rotating tray. Thesuckers are arranged on the rotating discs. The rotating mechanism is arranged on the left side of the base. The paint adding mechanisms are arranged on the rotating mechanism. According to the porcelain plate edge coloring device for the ceramic industry, through the design of the rotating mechanism, rotation of the porcelain plate can be achieved to be matched with work of the paint adding mechanisms, the porcelain plate does not need to be manually held to be sequentially colored, and a large amount of working time is shortened; and through the design of the rotating mechanism, the porcelain plate can be automatically moved, a plurality of porcelain plates can be placed on the rotating mechanisms at a time, and the porcelain plate edge coloring device is more suitable for large-batch processing and coloring.

Owner:潮州市凯博陶瓷制作有限公司

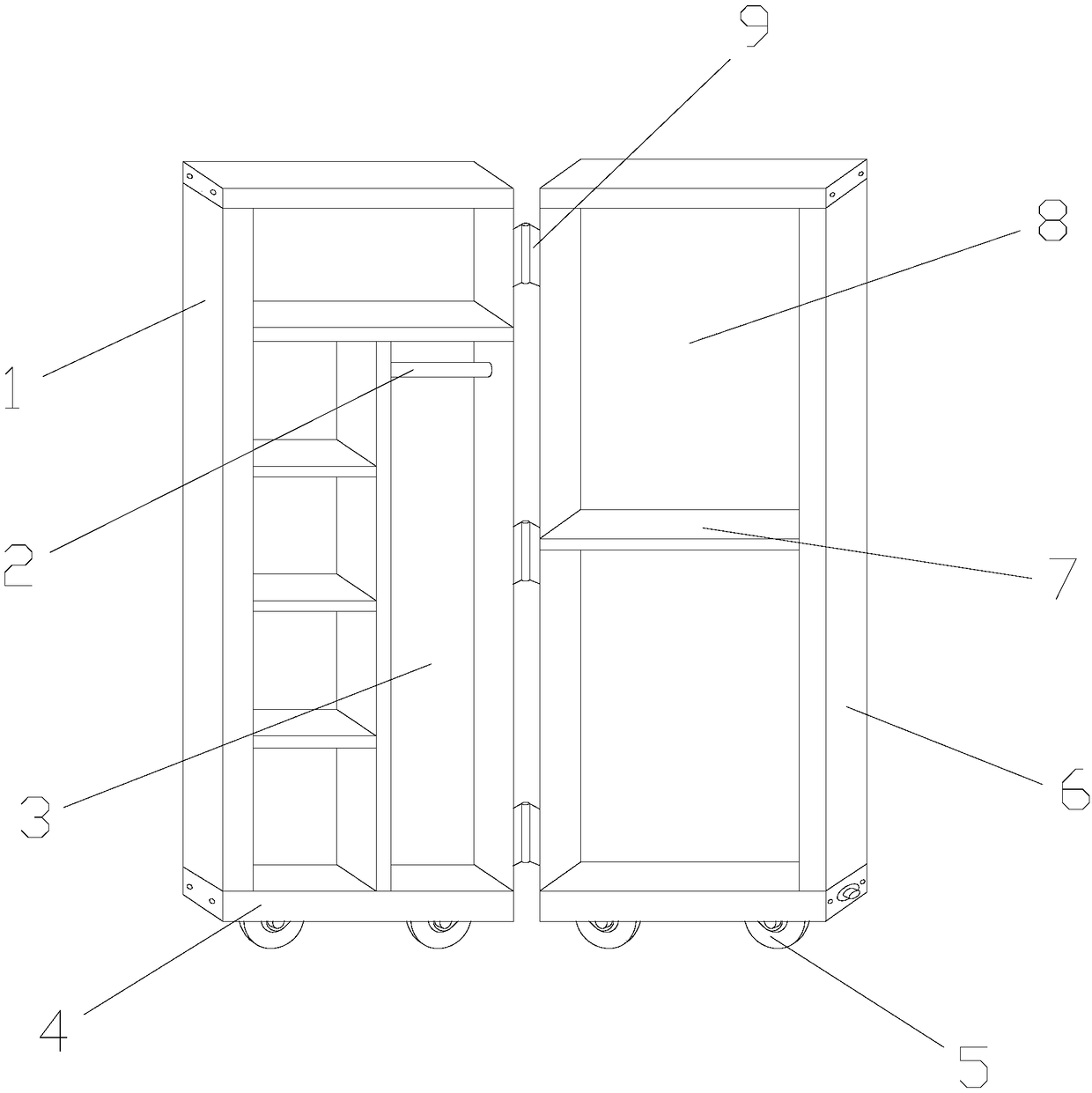

Double-layer folding wardrobe

InactiveCN108378571AAutomatic movementPrevent movementWardrobesFolding cabinetsEngineeringMechanical engineering

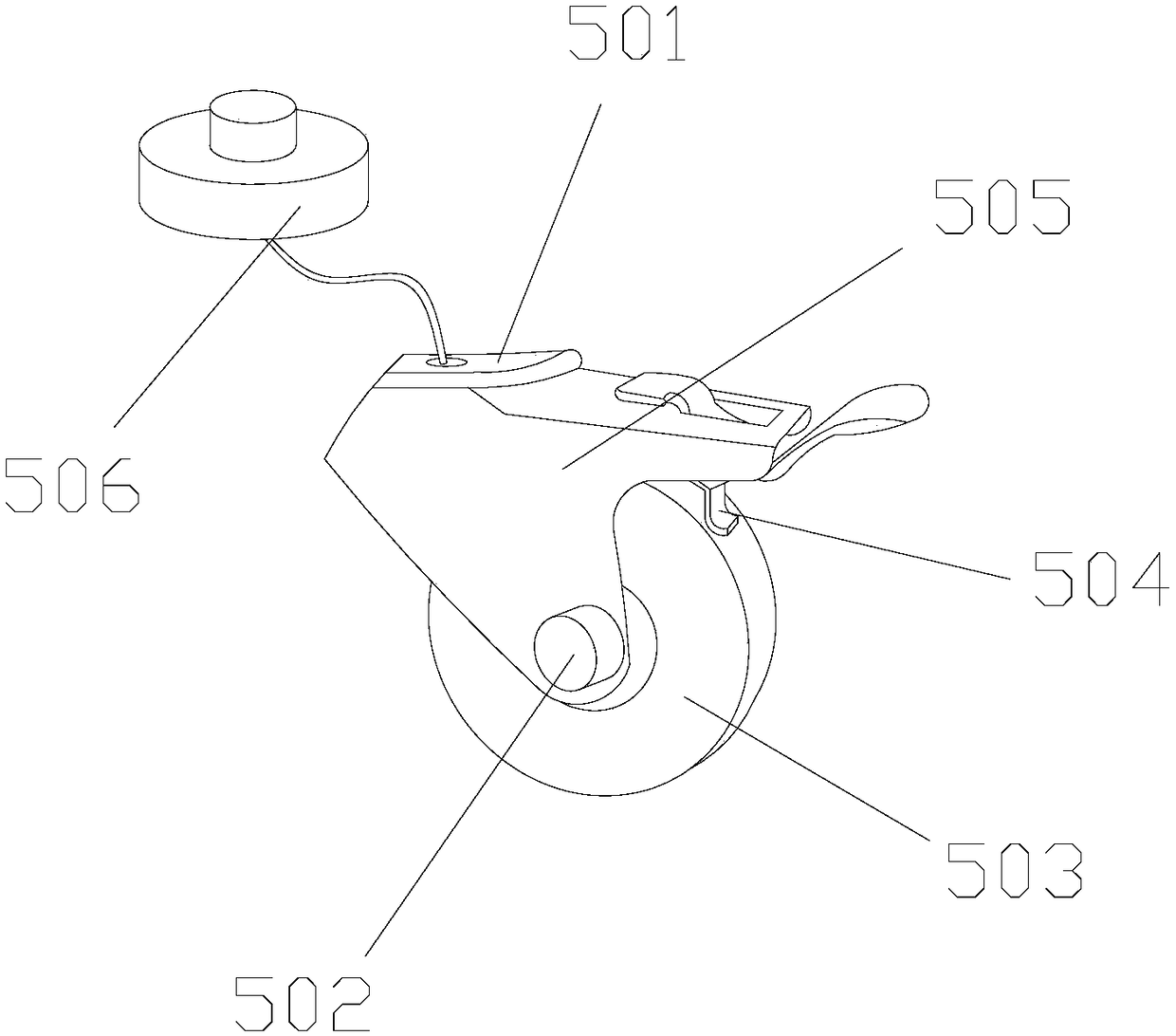

The invention discloses a double-layer folding wardrobe, which structurally comprises a left-side wardrobe, a cylindrical rotating shaft, a long cabinet, a base, a rotating wheel device, a right-sidewardrobe, a partition plate, a locker, and hinges, wherein the left-side wardrobe is hinged with the right-side wardrobe through the hinges, and the left-side wardrobe is connected with the base through bolts; the cylindrical rotating shaft is embedded and connected into the long cabinet, and the base is connected with the rotating wheel device through bolts; the right-side wardrobe and the lockerare of an integrated structure, and a control processor is connected with a control button through a power line; the upper end of a fixing rack is provided with the control processor, and a brake isarranged on the fixing rack; a roller wheel is connected with the fixing rack through a rotating shaft. The double-layer folding wardrobe disclosed by the invention has the advantages that the controlprocessor and the fixing rack are connected together in structure, and the control processor is controlled by the control button, so that the wardrobes at both sides can move, thereby solving the problem that objects in the wardrobe are too heavy to move the wardrobe.

Owner:望江县喜来美家具有限公司

Intelligent etching machine having automatic cleaning and anti-collision function

ActiveCN109310010AEasy to carveAutomate installationConductive material chemical/electrolytical removalEngineering

The invention relates to an intelligent etching machine having an automatic cleaning and anti-collision function. The etching machine includes a main body, an installation plate, a dust cover and a spring rod; a drawing box is installed on the left side of the main body; a track box is placed on the right side of the drawing box; the main body and the drawing box are in movable connection, and thedrawing box and the track box are in movable connection; the installation plate is installed on the right side of the track box; an engraving head is placed on the right side of the installation plate; the installation plate is connected to the track box through screws; the dust cover is installed on the top of the engraving head; the dust cover and the engraving head are in movable connection; the spring rod is placed under the track box; and the track box and the spring rod are in movable connection. The beneficial effects of the etching machine are that, through the arrangement of an anti-shake plate, the possible that the device shakes during working can be reduced, the changes of engraving lines of the device caused by shaking and collision can be decreased, and therefore, the generation of unqualified products can be prevented.

Owner:NANJING LI HANG IND INST OF BIONIC TECH LTD

Building construction ladder capable of conveniently moving

InactiveCN111021698AStrong carrying capacityConvenience to workBuilding scaffoldsMotor shaftArchitectural engineering

The invention discloses a building construction ladder capable of conveniently moving. The building construction ladder comprises a base box, a construction platform is arranged on the upper side of the base box, and front and rear symmetrical gear spaces are arranged in the construction platform. When a first motor is started, the first motor drives a first motor shaft to rotate, the first motorshaft rotates to drive a supporting plate to move downwards, the base box can be supported upwards, and up and down lifting movement can be achieved, so that a worker conveniently processes differentheights during working, more materials can be stored, the higher bearing capacity is achieved, automatic movement can be achieved, working of the worker can be facilitated, and the work efficiency isimproved.

Owner:缙云松弛自动化科技有限公司

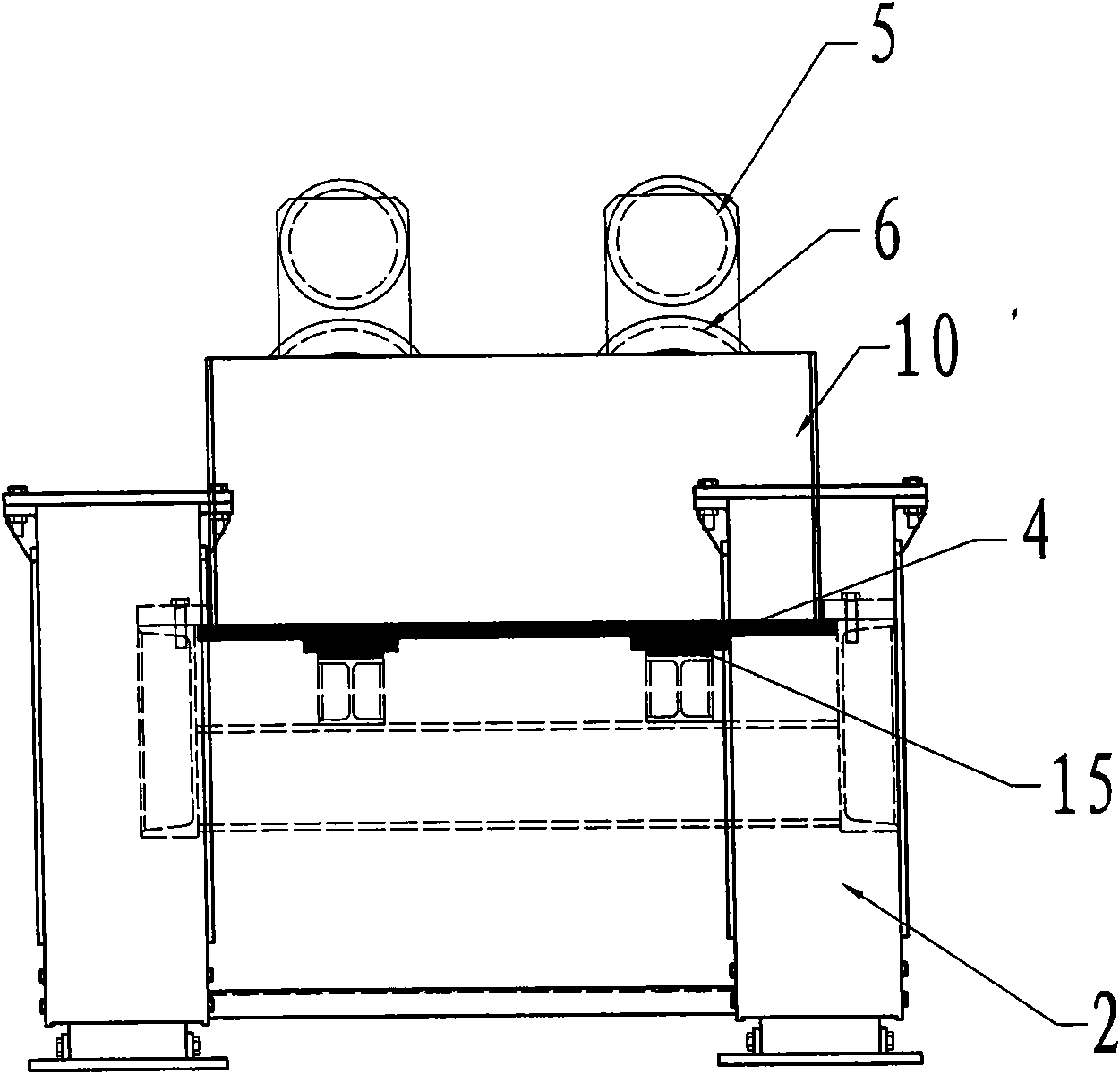

Large-sized apparatus pushing apparatus

InactiveCN101475132AImprove work efficiencyIncrease job securityLifting devicesHoisting equipmentsEngineeringH shaped

Owner:周重威

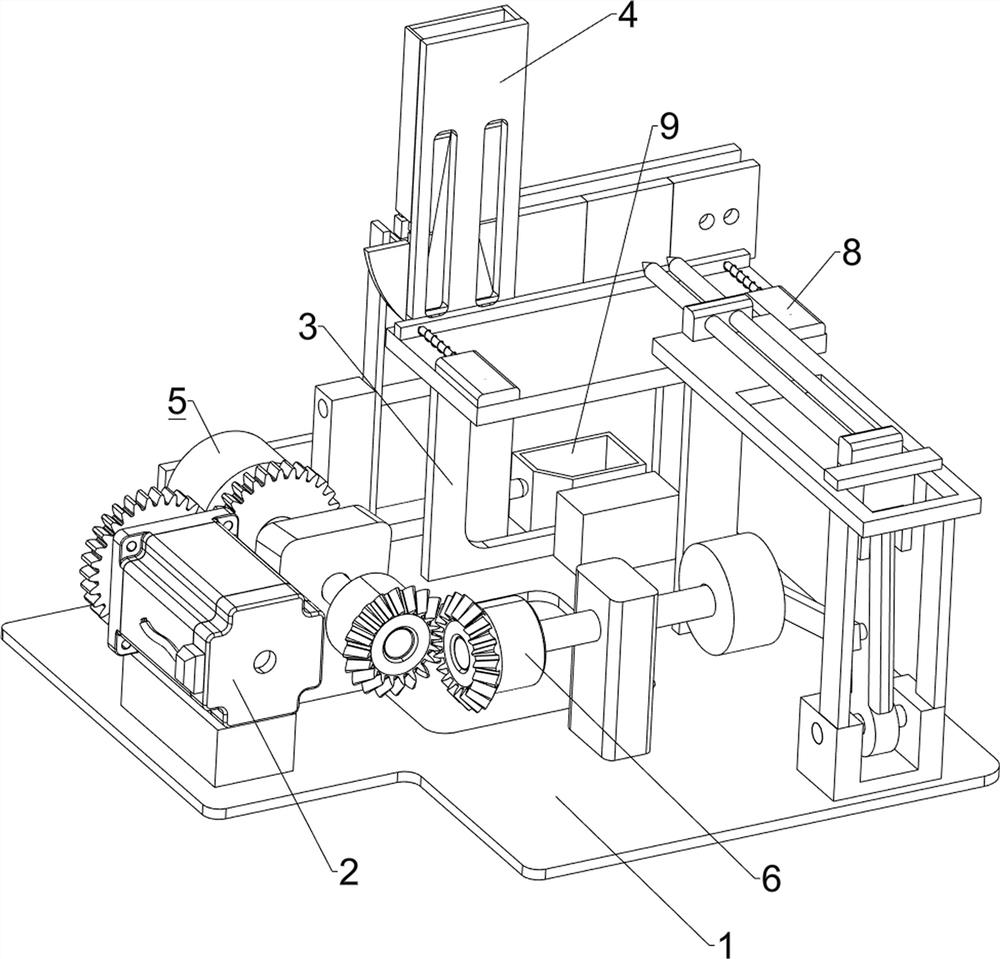

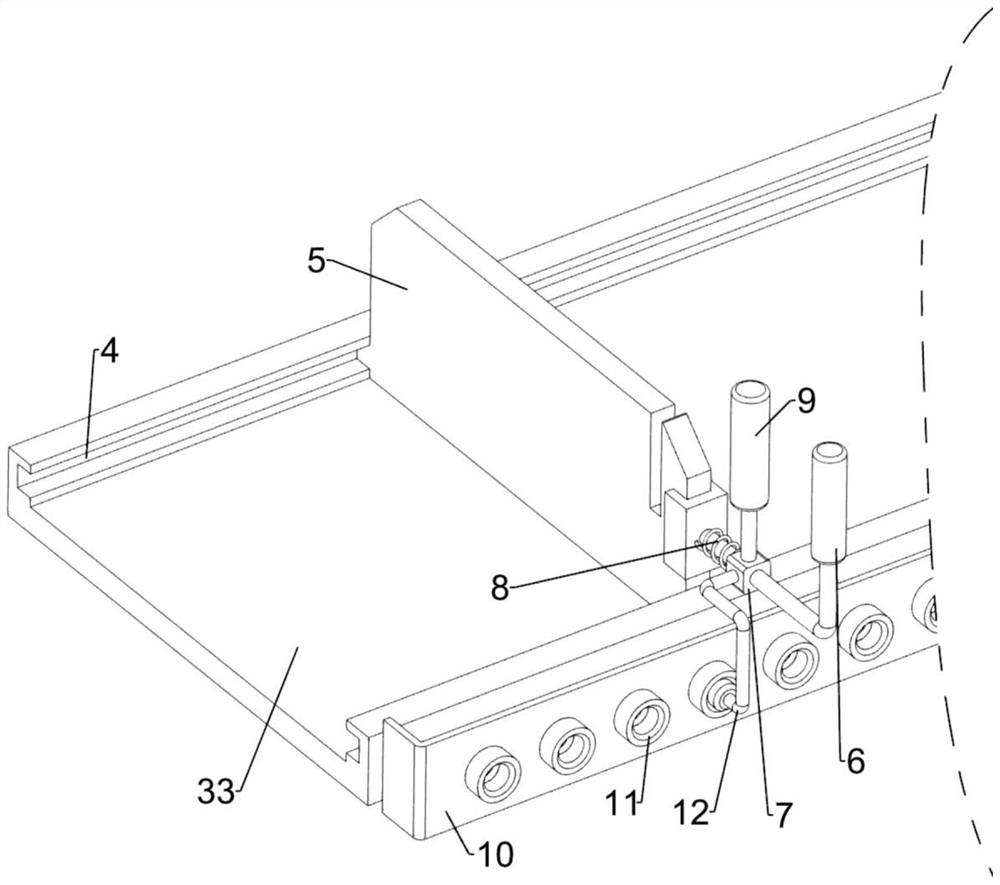

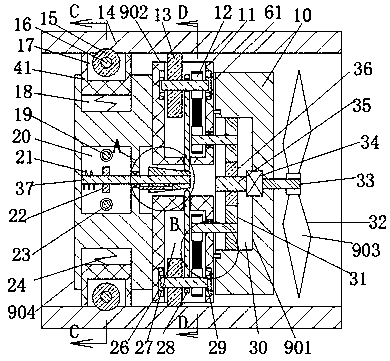

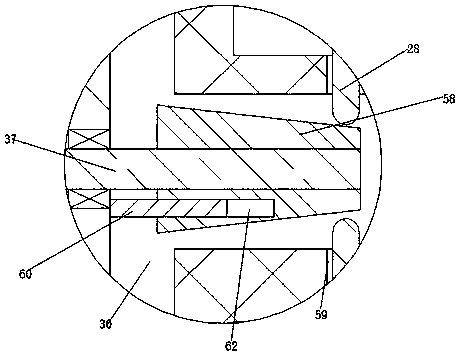

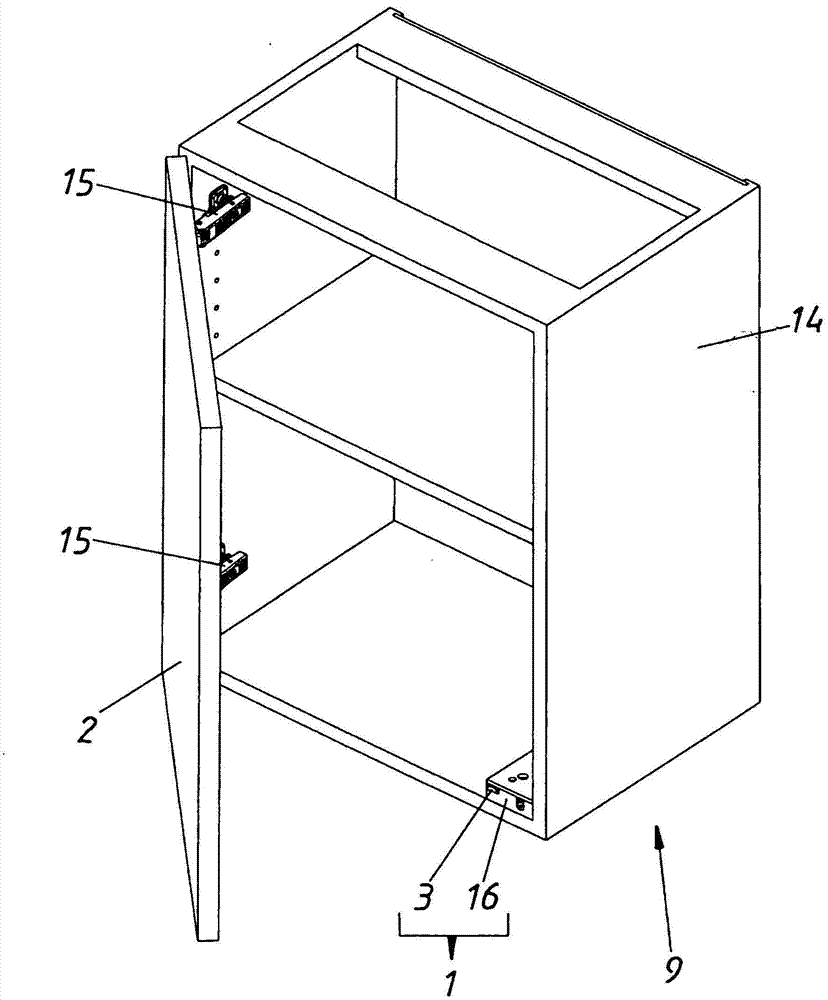

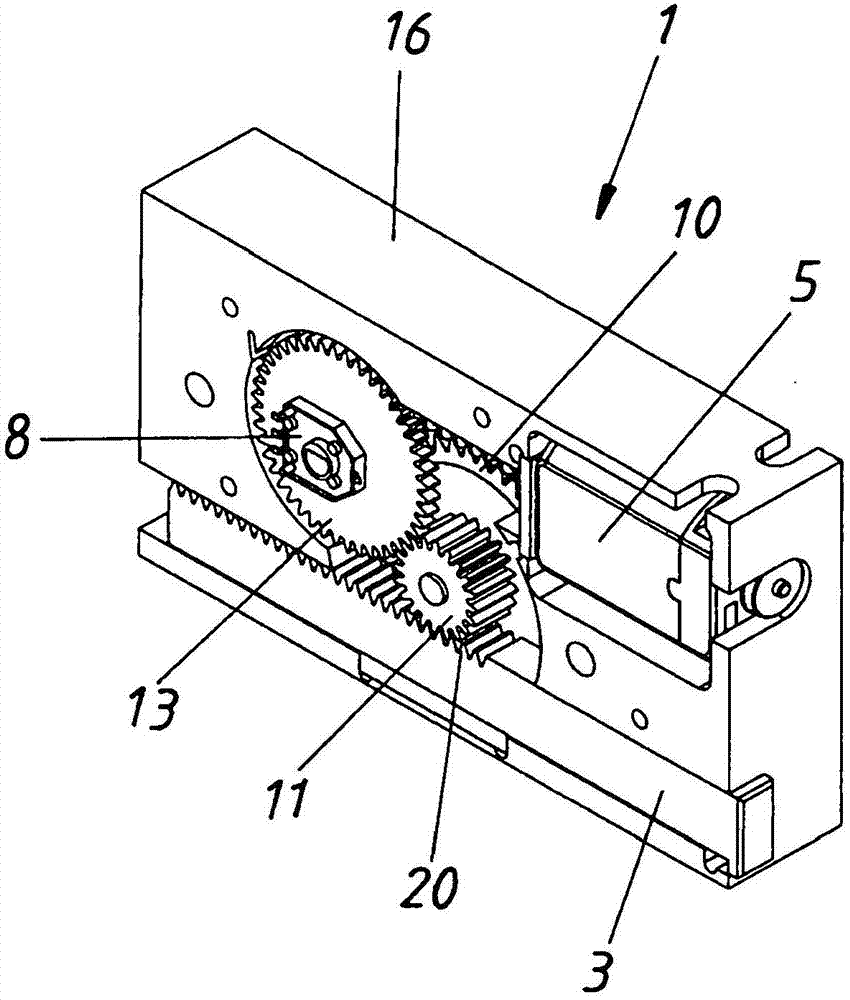

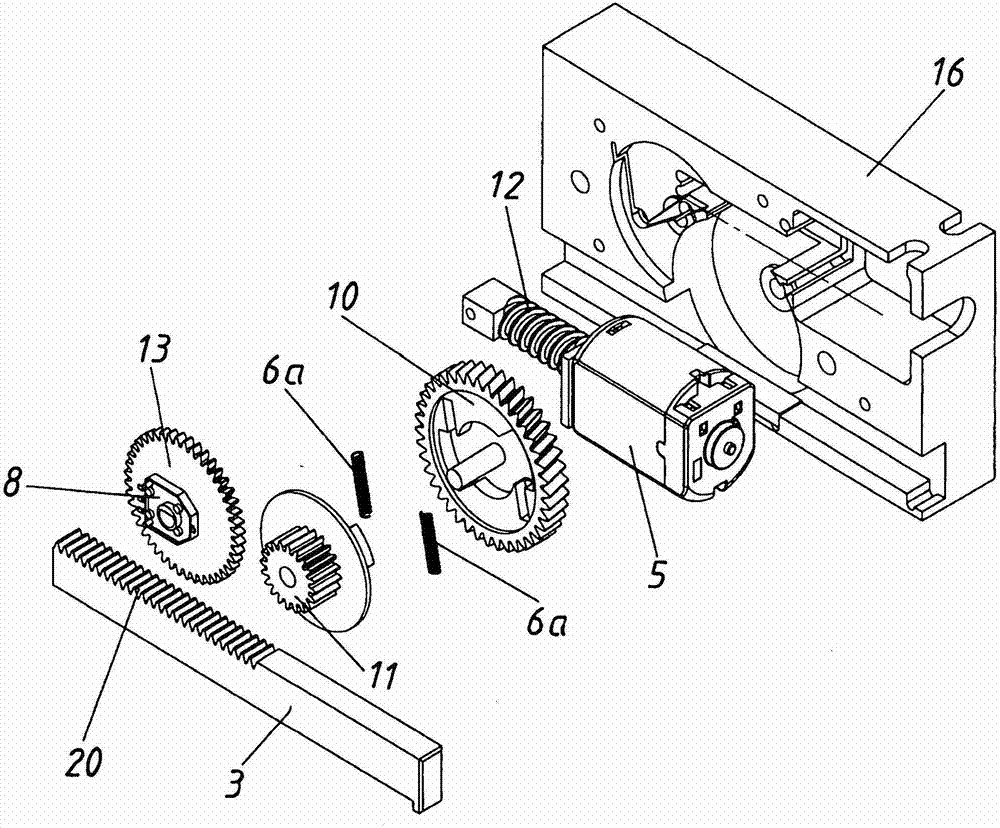

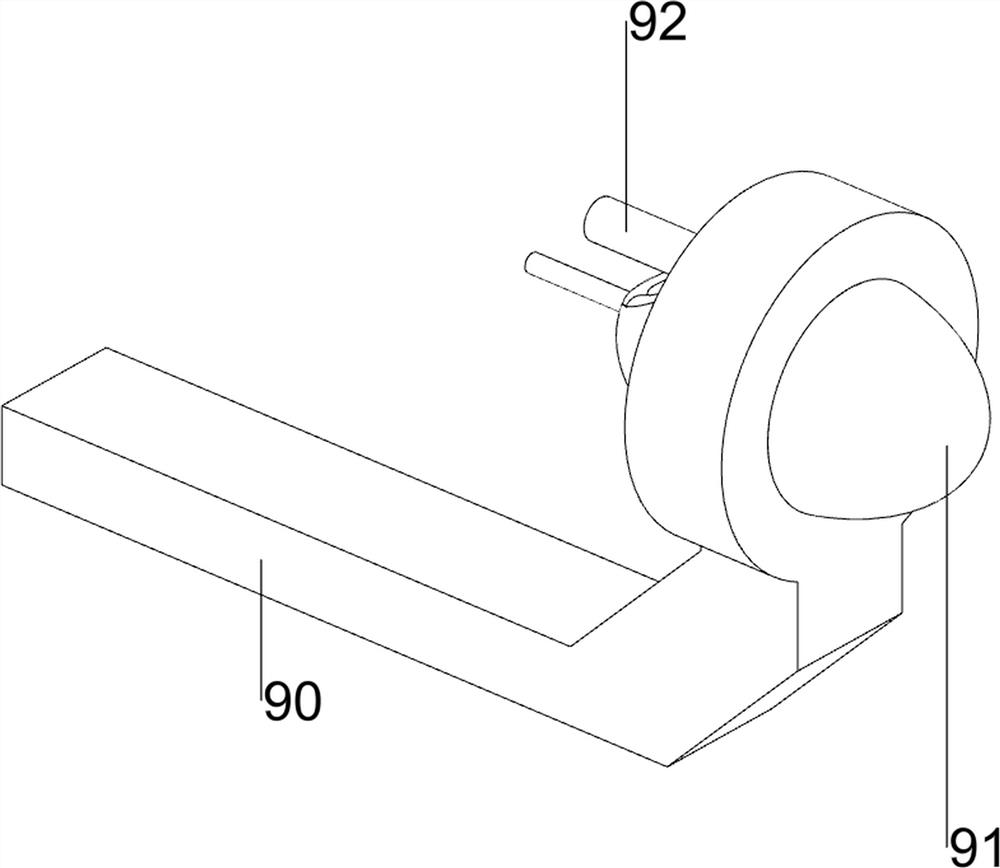

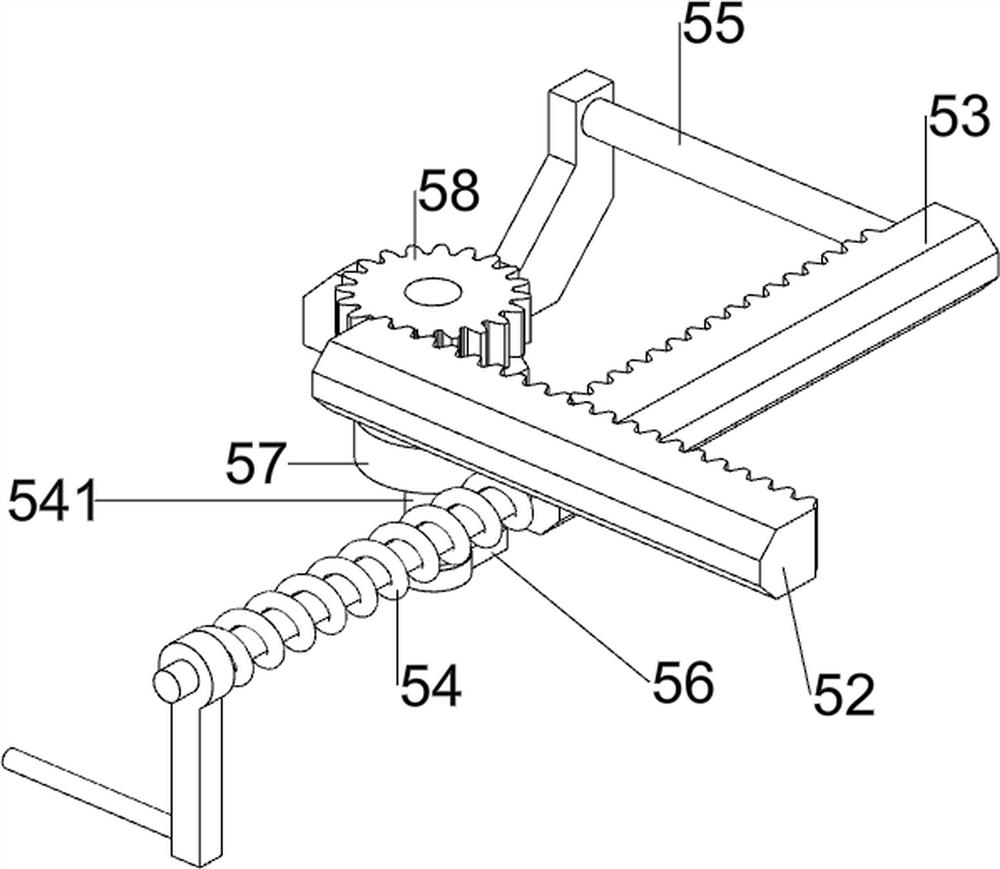

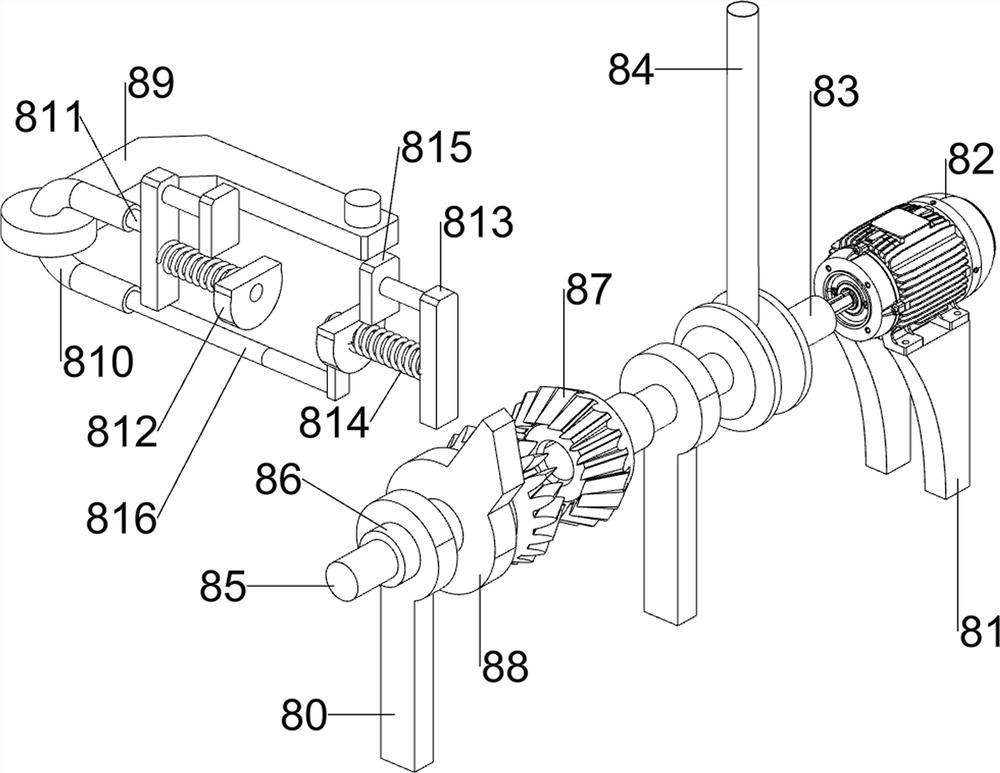

Ejecting device for a movable furniture part

ActiveCN103025205ADetectability is irrelevantReduce complexityPower-operated mechanismDrawersEngineeringElectrical drive

The invention relates to an ejecting device (1) for a movable furniture part (2), in particular a door or drawer, comprising an ejector (3), which can be moved between a first (Fig. 4) and a second position (Fig. 5), for ejecting the movable furniture part (2), a drive train (4) having an electrical drive unit (5) that drives the ejector (3) and a gear mechanism (19) that is arranged between the drive unit (5) and the ejector (3) and that has an output (20) that acts on the ejector (3), and an open-loop or closed-loop control device (7) for controlling the drive unit (5) in an open-loop or closed-loop manner, wherein a force accumulator (6) is integrated in the gear mechanism (19) between the drive unit (5) and the output (20), a monitoring device (8) connected to the drive train (4) can detect an unloading of the force accumulator (6); and report said unloading to the open-loop or closed-loop control device (7), and the open-loop or closed-loop control device (7) activates the electrical drive unit (5) in order to move the ejector (3) back to the first position (Fig. 4) after the unloading of the force accumulator (6) has been detected.

Owner:JULIUS BLUM GMBH

Anti-cracking paint brushing machine for square wooden dolls

PendingCN113083596ARealize automatic feeding processAutomatic movementLiquid surface applicatorsCoatingsMechanical engineeringIndustrial engineering

The invention relates to a painting machine, in particular to an anti-cracking painting machine for square wooden dolls. The technical problem to be solved by the invention is to provide the anti-cracking painting machine for the square wooden dolls which is uniform in paint brushing and time-saving and labor-saving. According to the technical scheme, the anti-cracking paint brushing machine for the square wooden dolls comprises a bottom plate, a baffle disc, a placing assembly and a top painting mechanism, wherein and the baffle disc is arranged in the middle of one side of the bottom plate, the placing assembly is arranged on one side of the bottom plate, and the top painting mechanism is arranged on the placing assembly. And through cooperation of a pushing mechanism, the placing assembly and the top painting mechanism, interval automatic feeding can be achieved, and meanwhile the dolls are painted.

Owner:郁昌友

A vertical automatic wall brick installation for building construction

ActiveCN110512844BAutomatic movementAids in clamping and fixingBuilding constructionsArchitectural engineeringElectric machinery

The invention discloses a vertical type automatic wall tile sticking device for building construction. The vertical type automatic wall tile sticking device includes a device body, a box with a hollowstructure is welded to one end of the device body, and the box is fixedly connected with a placement table with an integral structure; and a first-stage gear fixedly sleeves an output shaft of a biaxial motor. According to the vertical type automatic wall tile sticking device, the biaxial motor is arranged in the device body, meshing transmission of the first-stage gear and a second-stage gear, and a third-stage gear and a fourth-stage gear is utilized to drive two first-stage screw rods to rotate, the first-stage screw rods is utilized to drive first-stage nuts to move, a receiving plate isdriven to deflect through the first-stage nuts and a supporting rod, and thus wall tiles on the placement table are received; a servo motor is arranged on a bracket to drive second-stage screw rods torotate to clamp the wall tiles on a wall tile clamping plate; the positions of the wall tiles are sensed and monitored through a laser sensor, and a tile sticking arm is controlled to precisely fit and install the wall tiles; and then concrete is sprayed through spraying heads, and the wall tiles can be fixed stably and conveniently.

Owner:滁州市恒瑞建设工程有限公司

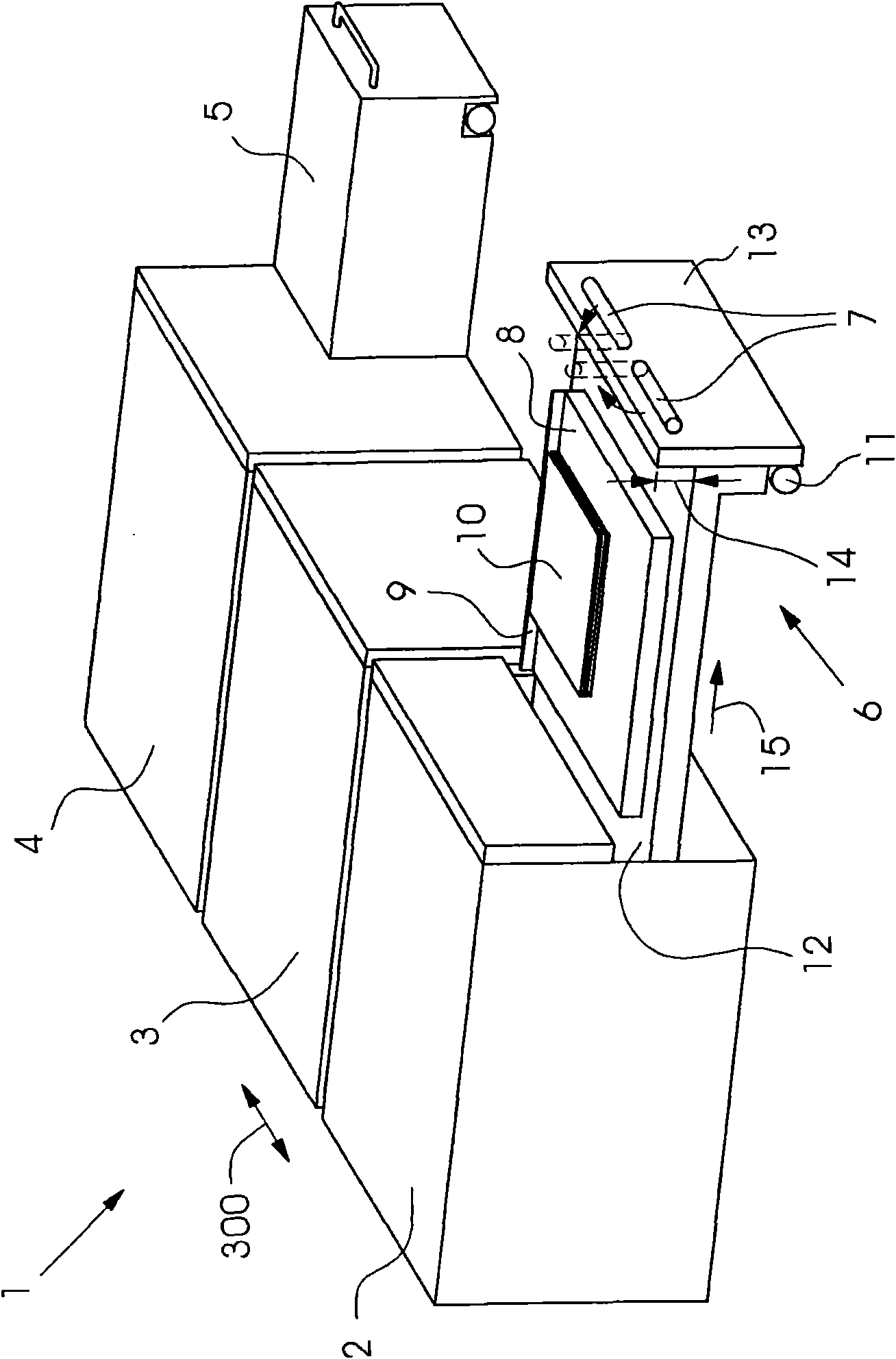

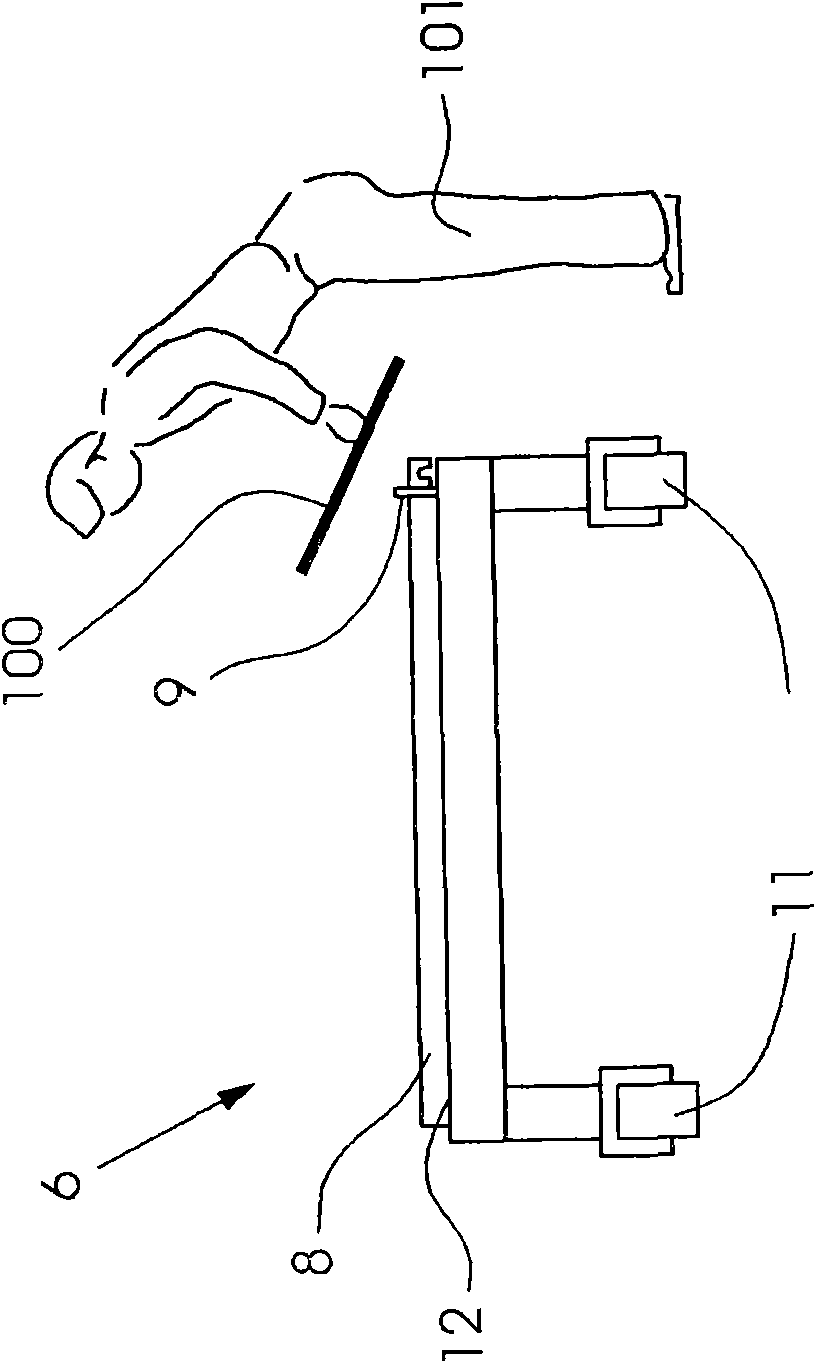

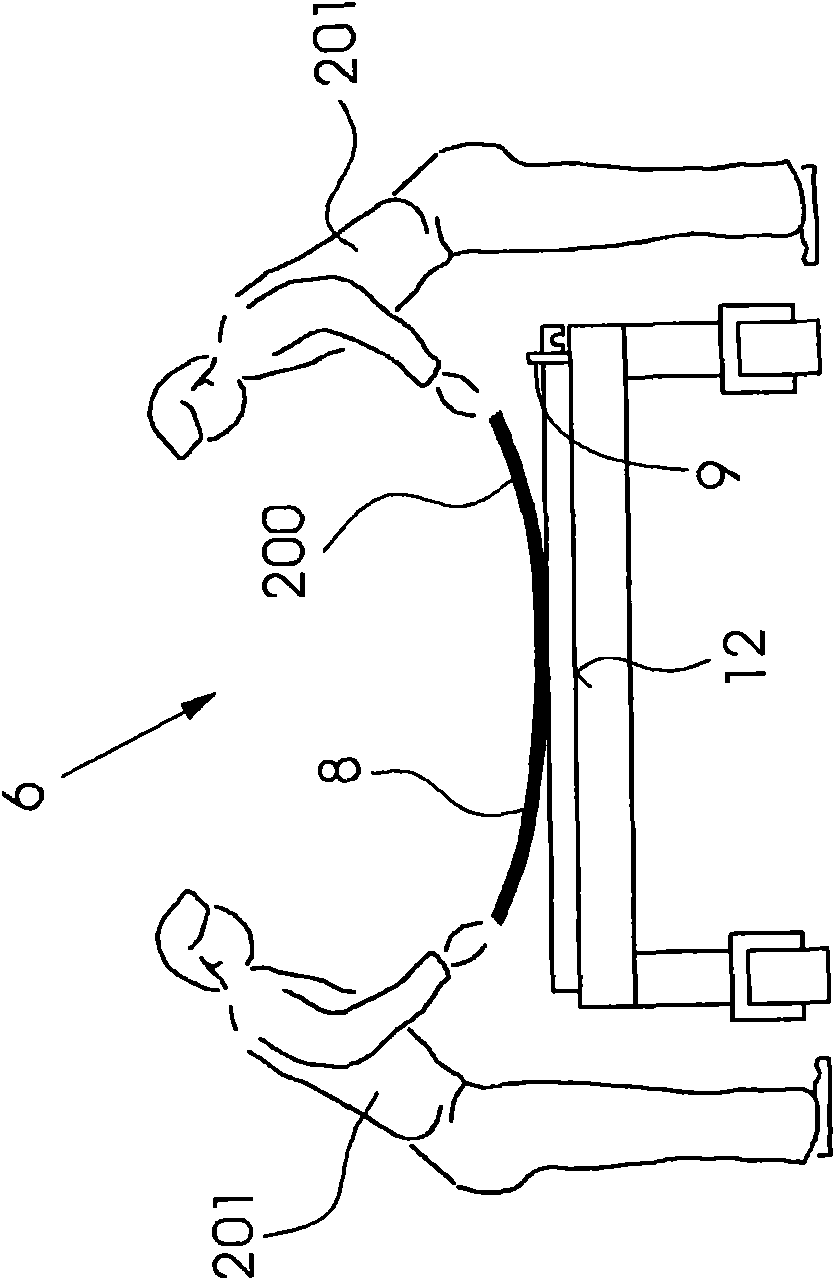

A transmission device for handling printing plates and tray

InactiveCN101525092AAvoid vertical movementEasy to placePrinting platesForme preparationEngineeringMechanical engineering

An apparatus and a method is provided for handling printing plates 100, 200 which are provided in the form of a printing plate stack 10 on at least one storage plane 8. If printing plates 200 having a particularly large format are required to set images on them in an exposer, loading cassettes for a magazine of cassettes is at least problematic. Therefore, a tray is moved out of a storage device via an adjacent lifting device into the lower region of the storage device, and is fed there to a drawer which can be moved out of the storage device. If the tray is situated on the drawer, the lattercan be moved by an operator in a second horizontal direction out of the handling apparatus, in particular out of the storage device. In this position, the tray can then be loaded in an ergonomically favorable manner.

Owner:HEIDELBERGER DRUCKMASCHINEN AG

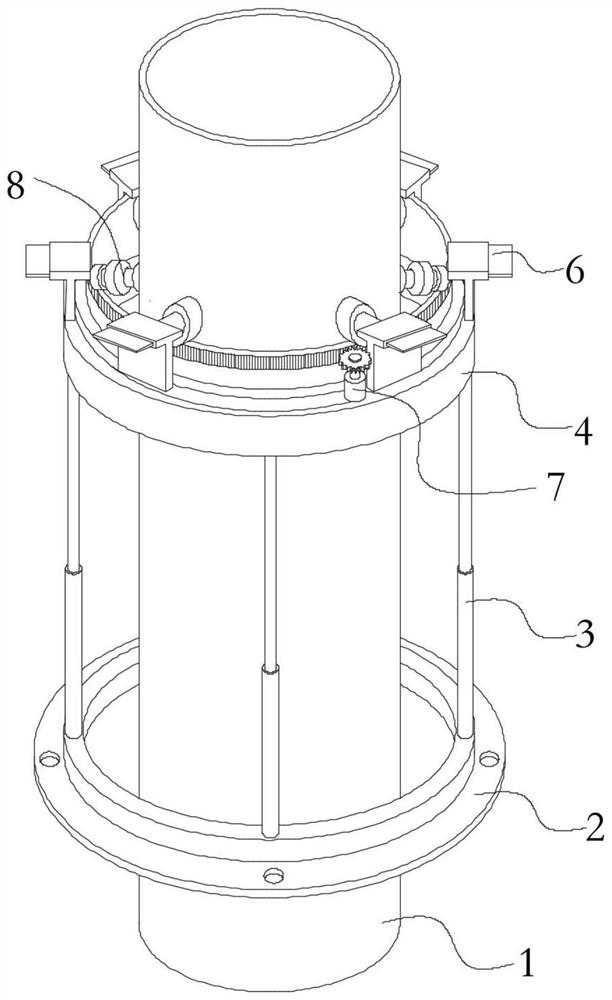

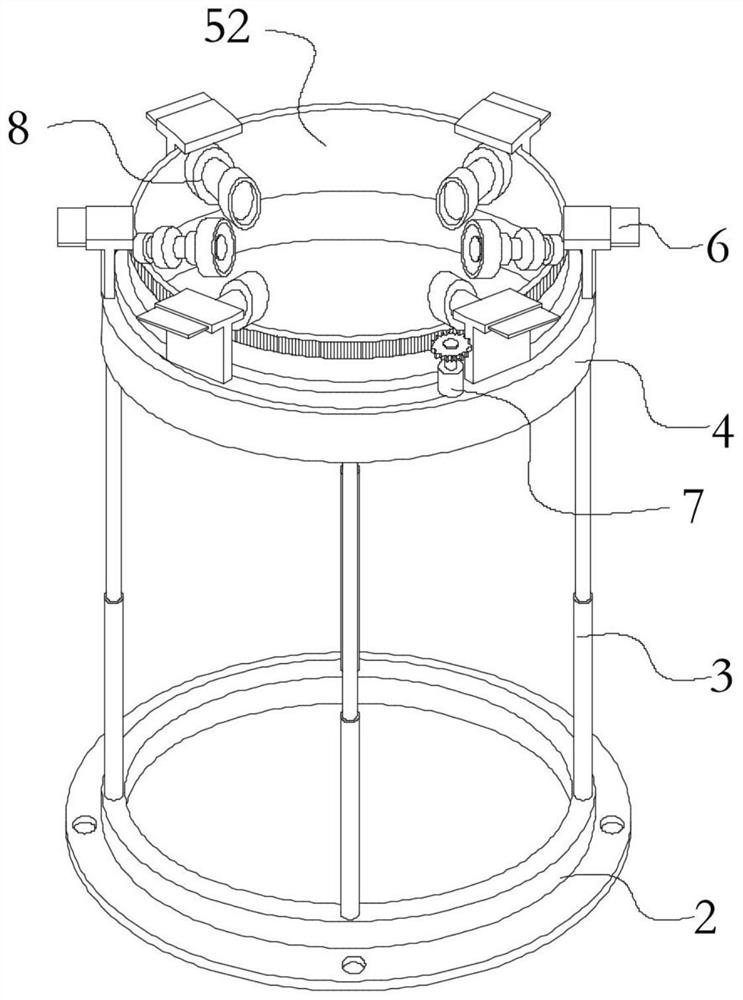

Industrial flaw detection device based on audio amplitude and frequency

InactiveCN112345650AAutomatic movementAnalysing solids using sonic/ultrasonic/infrasonic wavesStructural engineeringAudio frequency

The invention discloses an industrial flaw detection device based on audio amplitude and frequency, which comprises a pipeline to be subjected to flaw detection, wherein a flange plate is mounted at the end part of the pipeline to be subjected to flaw detection, a coaxial mounting ring is fixedly connected to the flange plate through a plurality of electric telescopic rods, and the mounting ring movably surrounds the outer side of the pipeline to be subjected to flaw detection; a supporting ring is fixedly connected to the inner side of the mounting ring, a slip ring is rotatably mounted on the supporting ring, a plurality of mounting bases are mounted at one end of the slip ring, annular teeth are arranged at the other end of the slip ring, the inner sides of the mounting bases extend towards the center of the mounting ring, and probe assemblies are fixedly connected to the ends of the inner sides of the mounting bases. According to the invention, the electric telescopic rods can drive the mounting ring to move on the outer side of the pipeline to be subjected to flaw detection, so that the probe assemblies are automatically moved to different positions of the pipeline to be subjected to flaw detection. The probe assemblies are symmetrically distributed at one end of the slip ring, and the rotation amplitude of the slip ring enables the probe assemblies to cover a complete circumference of the pipeline to be subjected to flaw detection.

Owner:安徽研实科技有限公司

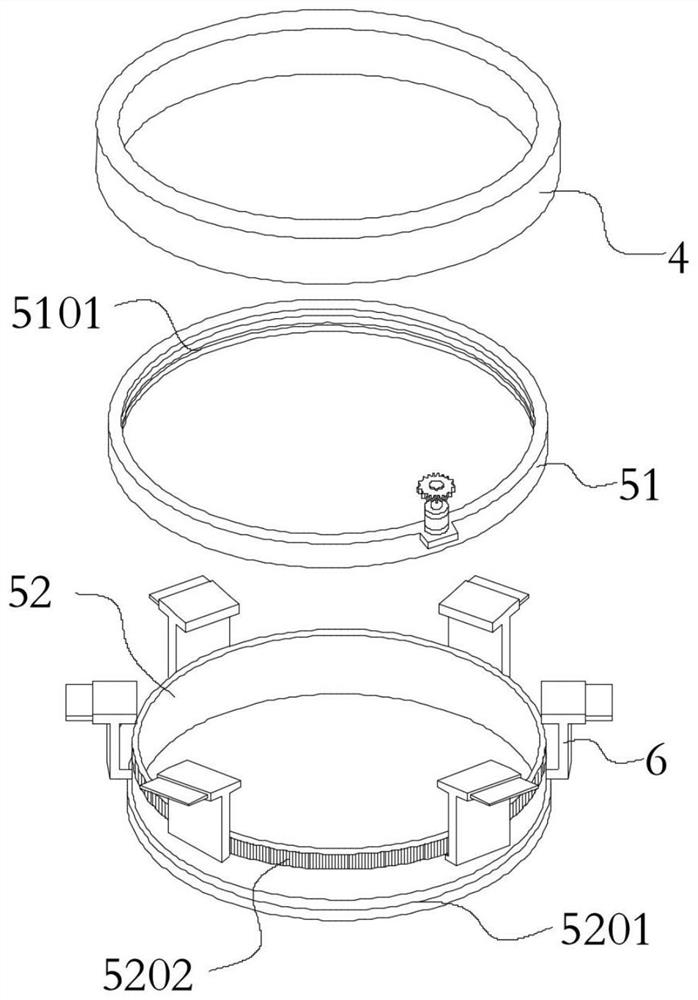

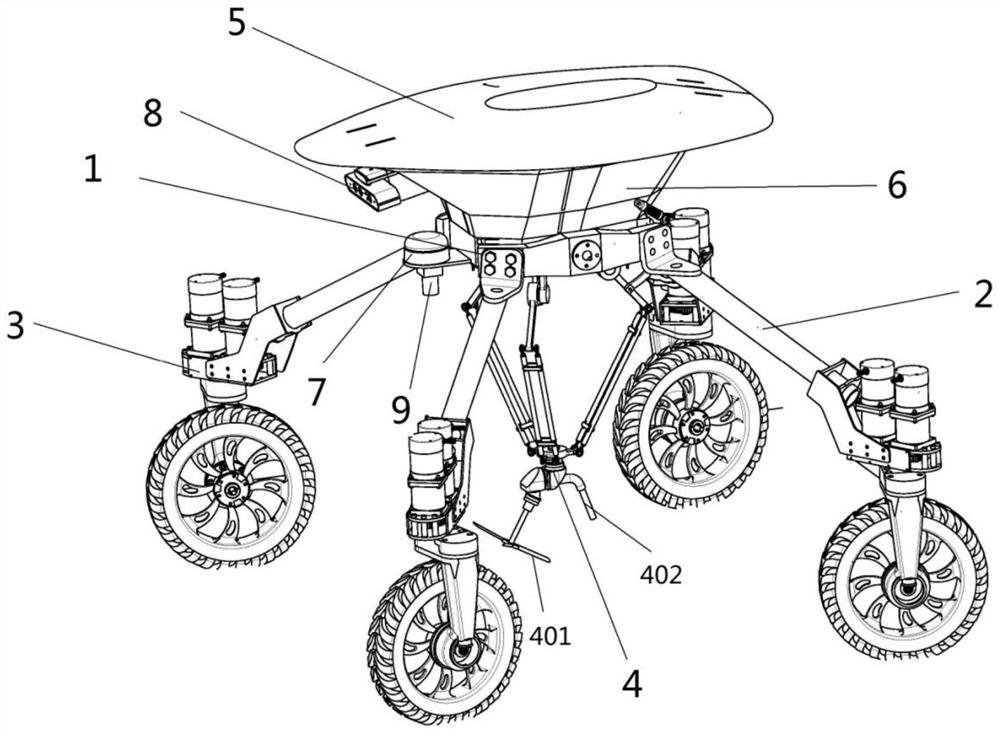

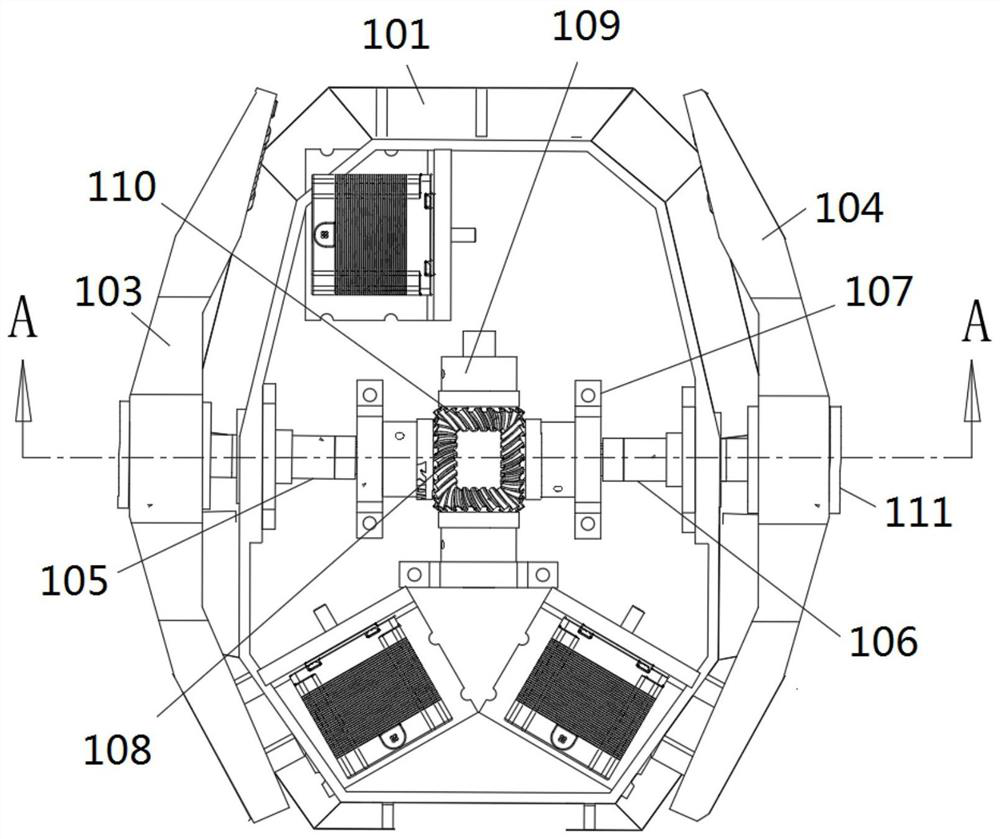

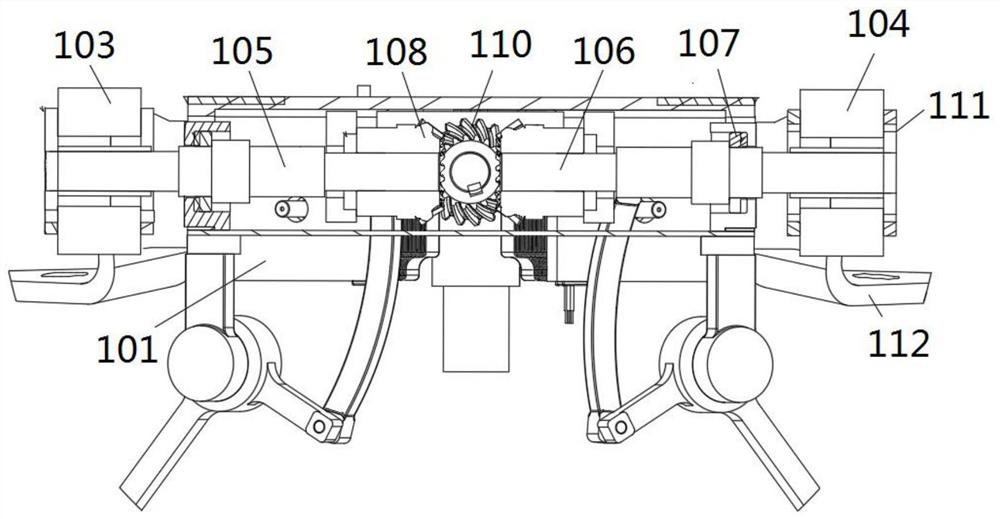

Weeding robot for pesticide spraying

InactiveCN111717300AImprove balanceSteering automaticVehicle body stabilisationMowersAutomatic steeringGear drive

The invention discloses a weeding robot for pesticide spraying. The weeding robot comprises a balancing device, a supporting arm, a walking device and a pesticide spraying weeding device; a left balance arm and a right balance arm are arranged on the two sides of a fixing frame; the left balance arm is connected with a balance gear through a left transmission shaft; the right balance arm is connected with a balance gear through a right transmission shaft; and two middle transmission gears are connected between the two balance gears in a meshed mode, so that the left balance arm can drive the right balance arm to rotate in an aligned mode when stressed to form balance, and the balance effect of the robot is improved. By arranging a steering motor on a power gearbox, the steering motor drives a steering gear to rotate through a first motor output shaft, a driving gear and a connecting gear, so that the steering gear rotates to a certain angle, the steering gear drives moving wheels to rotate through a connecting frame, and the robot can automatically steer.

Owner:LIUZHOU VOCATIONAL & TECHN COLLEGE

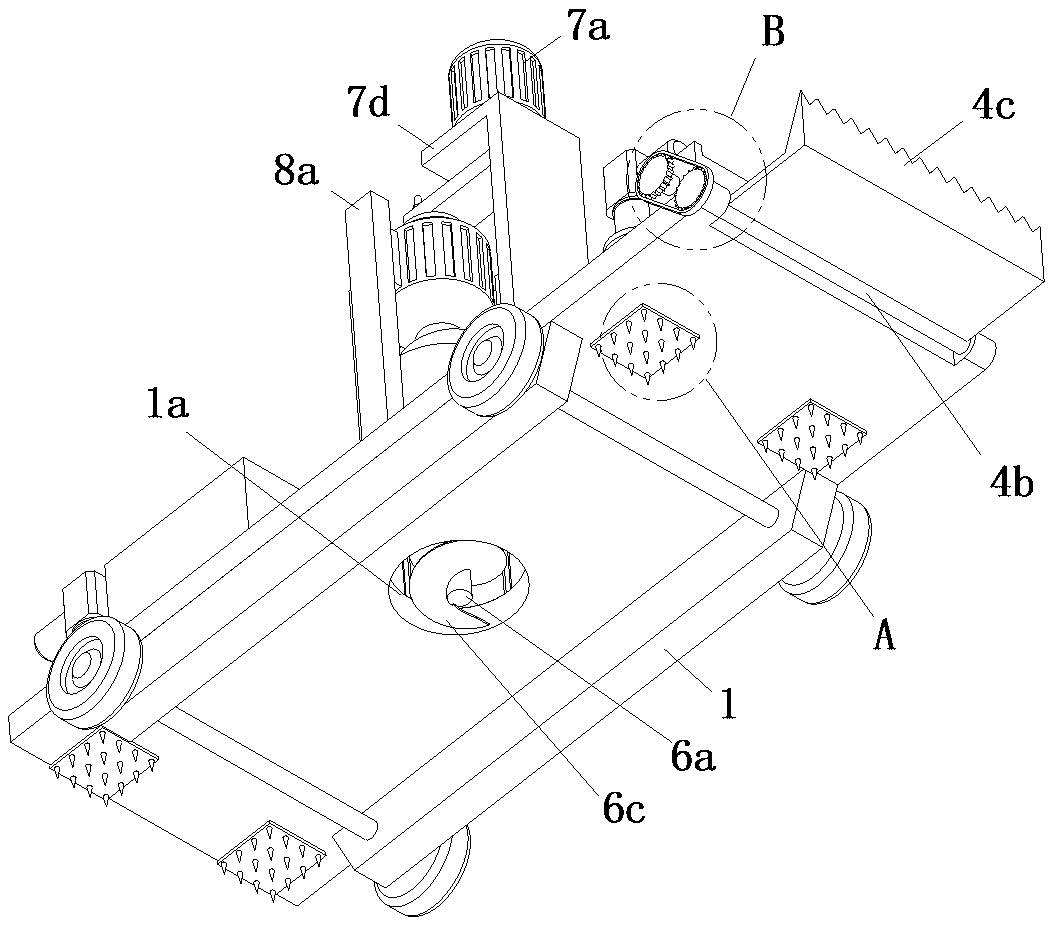

Portable excavator

InactiveCN108797678AAvoid leaningNo need to carrySoil-shifting machines/dredgersExcavatorEmbedded system

The invention relates to the field of excavators, in particular to a portable excavator. The portable excavator comprises a bottom plate, an excavating device, a moving device, a driving device, a soil shoveling device and a controller, wherein the moving device is arranged at the bottom of the bottom plate, the driving device is arranged at the rear end of the bottom plate, and the driving deviceis in transmission connection with the moving device; the excavating device comprises an excavating mechanism, a driving mechanism and a guiding mechanism, a through hole is formed in the middle of the bottom plate, the guide mechanism is arranged around the through hole, the excavating mechanism is arranged on the driving mechanism and the guide mechanism, four balancing devices are arranged onthe bottom plate, the soil shoveling device is installed at the front end of the bottom plate, a first cover cap is arranged beside the guide mechanism, a storage battery pack is arranged in the firstcover cap, and the storage battery pack, the excavating mechanism, the driving mechanism, the driving device, the soil shoveling device and the balancing device are electrically connected with the controller. The portable excavator can be automatically moved and does not need to be carried by workers, the whole equipment can keep the horizontal state during excavating operation, and soil blocks can be moved away through the soil shoveling device.

Owner:FOSHAN KUIFENG BUSINESS CONSULTATION SERVICES CO LTD

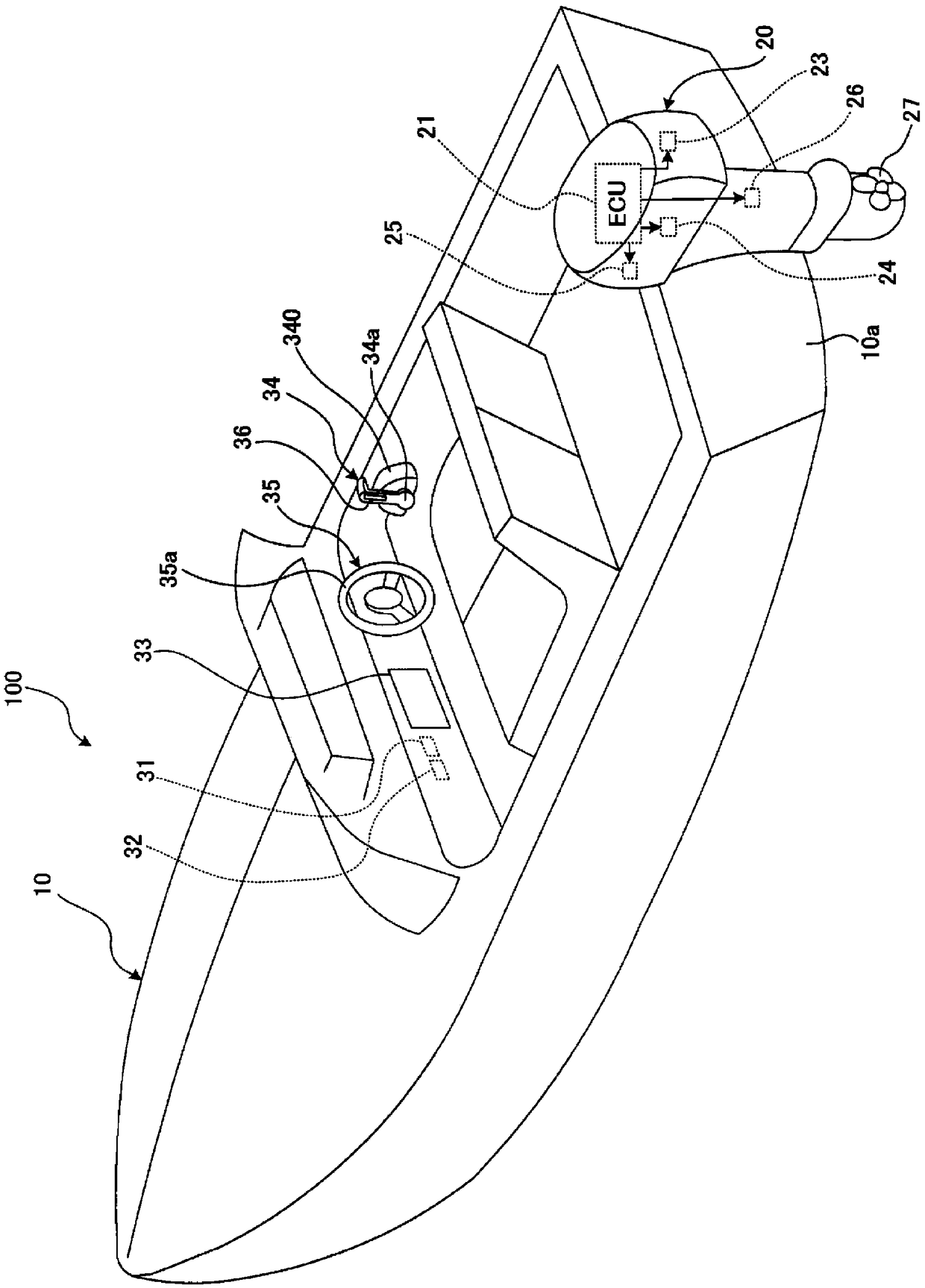

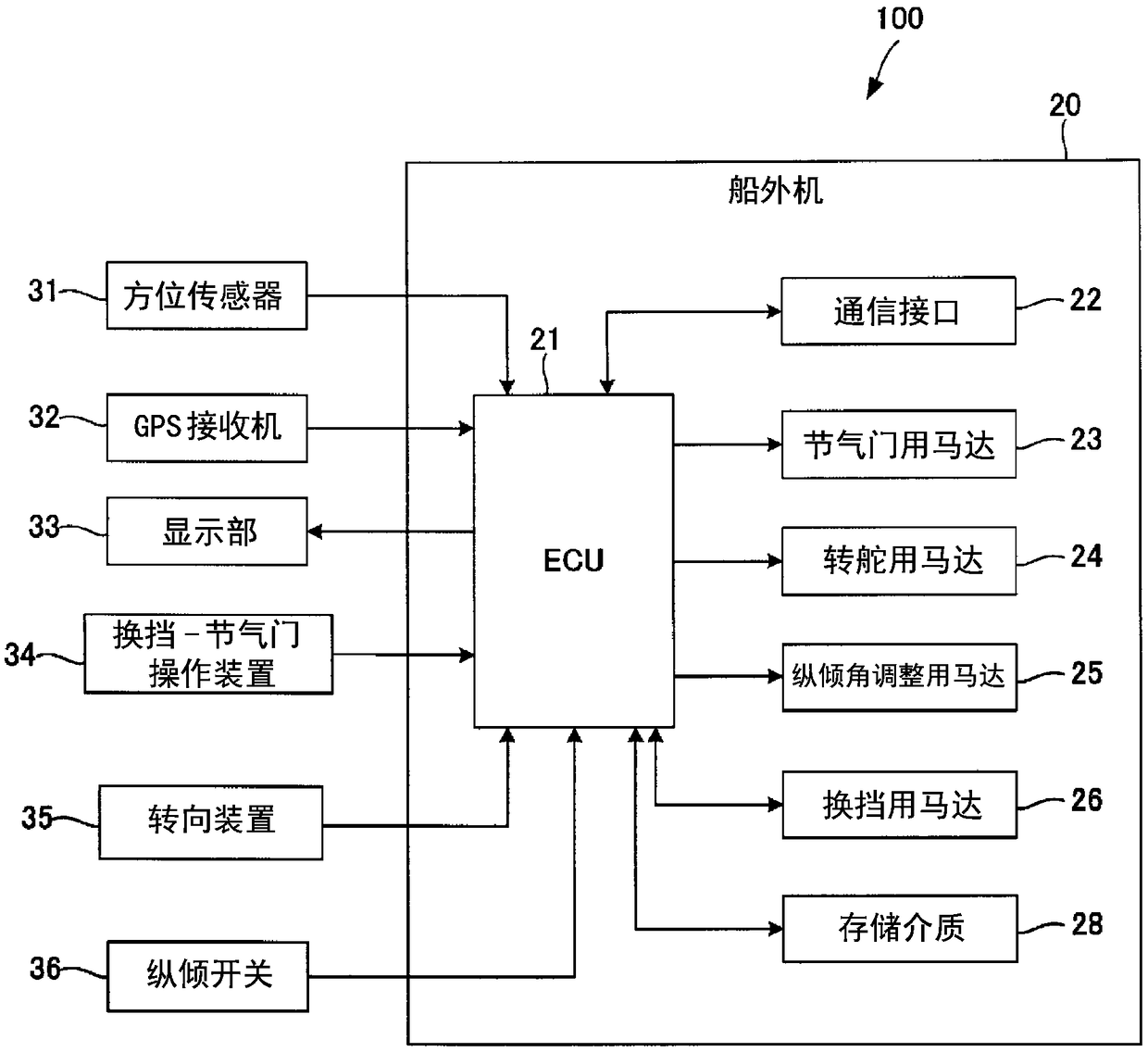

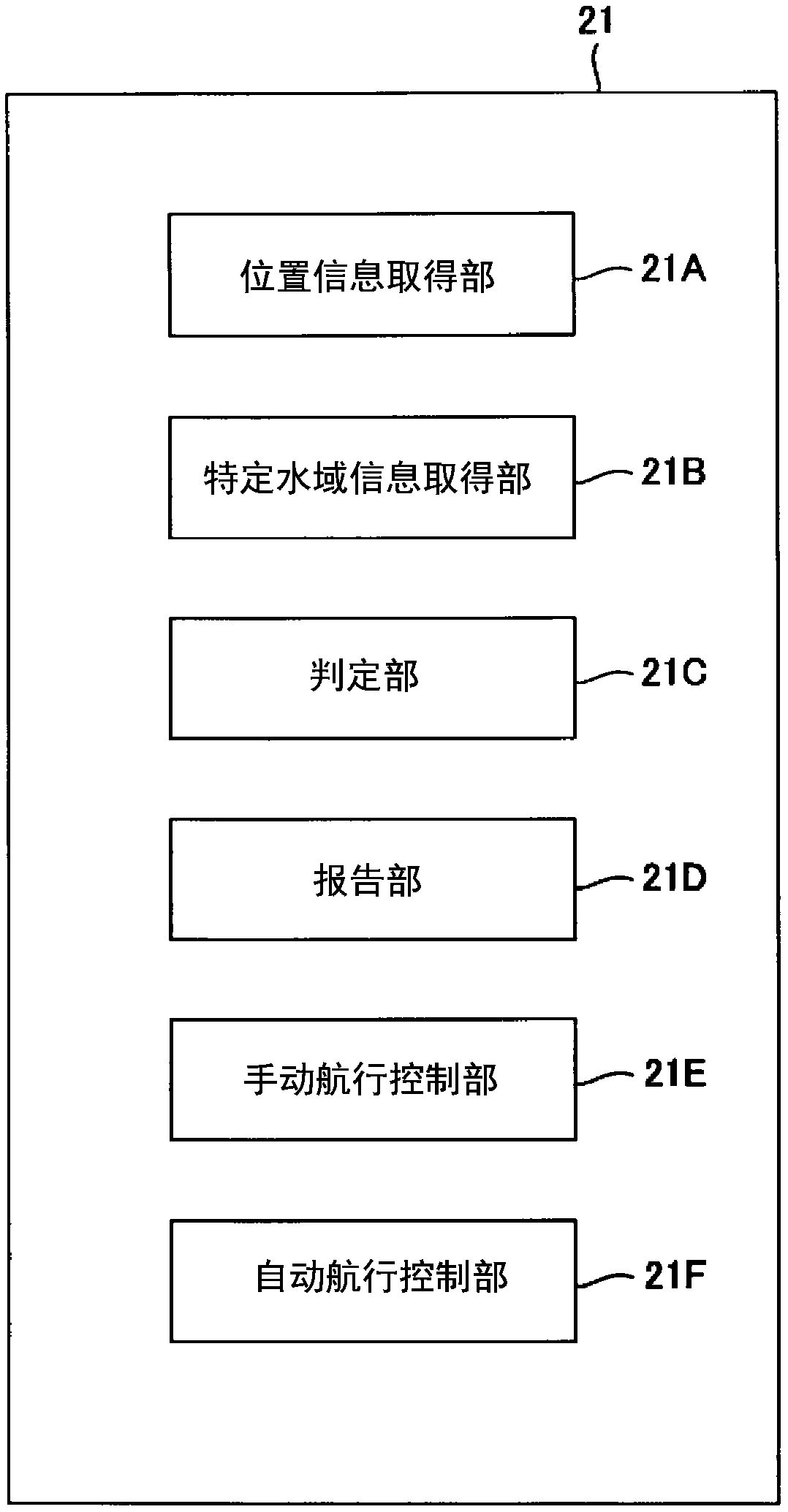

Propulsion unit control device

InactiveCN109195863AReduce the burden onNavigation safetySteering initiationsNavigational aid arrangementsHullThrottle

Provided is a propulsion unit control device for a ship, whereby safe navigation can be supported while reducing the burden on a ship operator by automatically controlling navigation of the ship whenthe ship is in specific waters in which navigation is limited or when the ship is near the specific waters. When it is determined that a ship hull 10 is in specific waters in a state in which an ECU 21 of an outboard motor 20 is controlling the speed and rotation direction of a propeller 27 and the orientation of the outboard motor 20 on the basis of a signal inputted from an operating part (shift / throttle operation device 34, steering device 35, trim switch 36), a transition is made to automatic piloting in which the speed and rotation direction of the propeller 27 and the orientation of theoutboard motor 20 are controlled without operation of the operating part.

Owner:HONDA MOTOR CO LTD

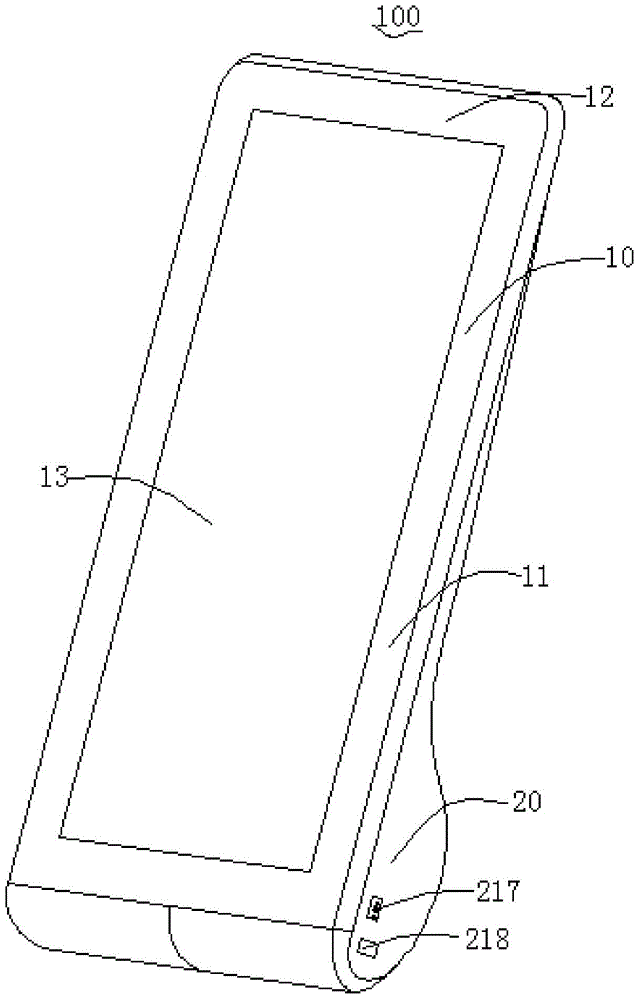

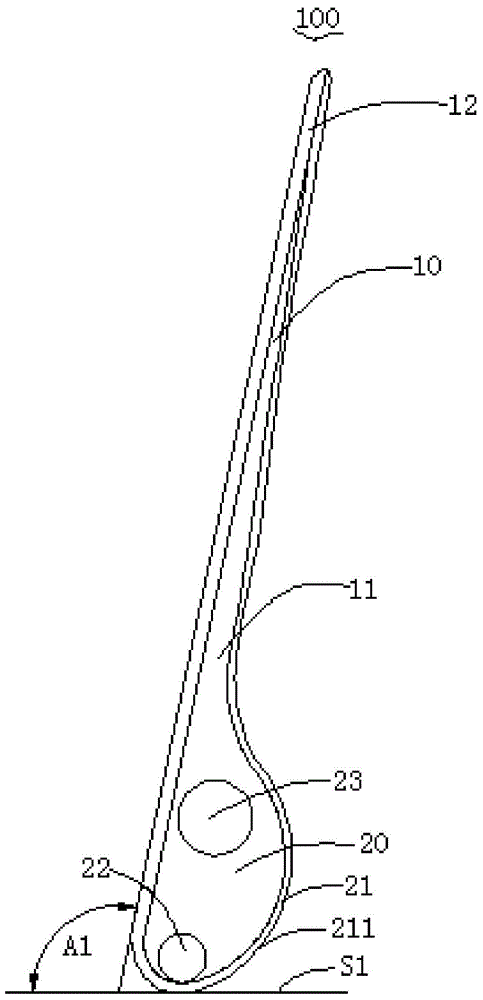

Electronic equipment and control method

ActiveCN104423455ABest use angleEasy to watchDigital data processing detailsArchitectural engineeringBearing surface

The invention discloses electronic equipment and a control method. The electronic equipment comprises a main body and a support section, wherein the main body is provided with a display unit; the support section is connected with the main body and is used for supporting the main body; the support section comprises a shell and a counterweight element; the counterweight element is movably arranged in the shell, so that the electronic equipment can be at least in a first stable support state and a second stable support state on a bearing surface; when the electronic equipment is in the first stable support state, a first angle is formed between the display unit and the bearing surface, so that the electronic equipment is lastingly and stably in the first support state; when the electronic equipment is in the second stable support state, a second angle is formed between the display unit and the bearing surface, so that the electronic equipment is lastingly and stably in the second support state; the first angle is different from the second angle; the first angle and the second angle are respectively greater than 0 degree and smaller than 180 degrees.

Owner:LENOVO (BEIJING) LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com