Sheet material punching structure for buildings and bridges

A technology for bridges and hole structures, applied in the directions of cleaning methods and appliances, boring/drilling, maintenance and safety accessories, etc. Easy to operate and avoid clogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

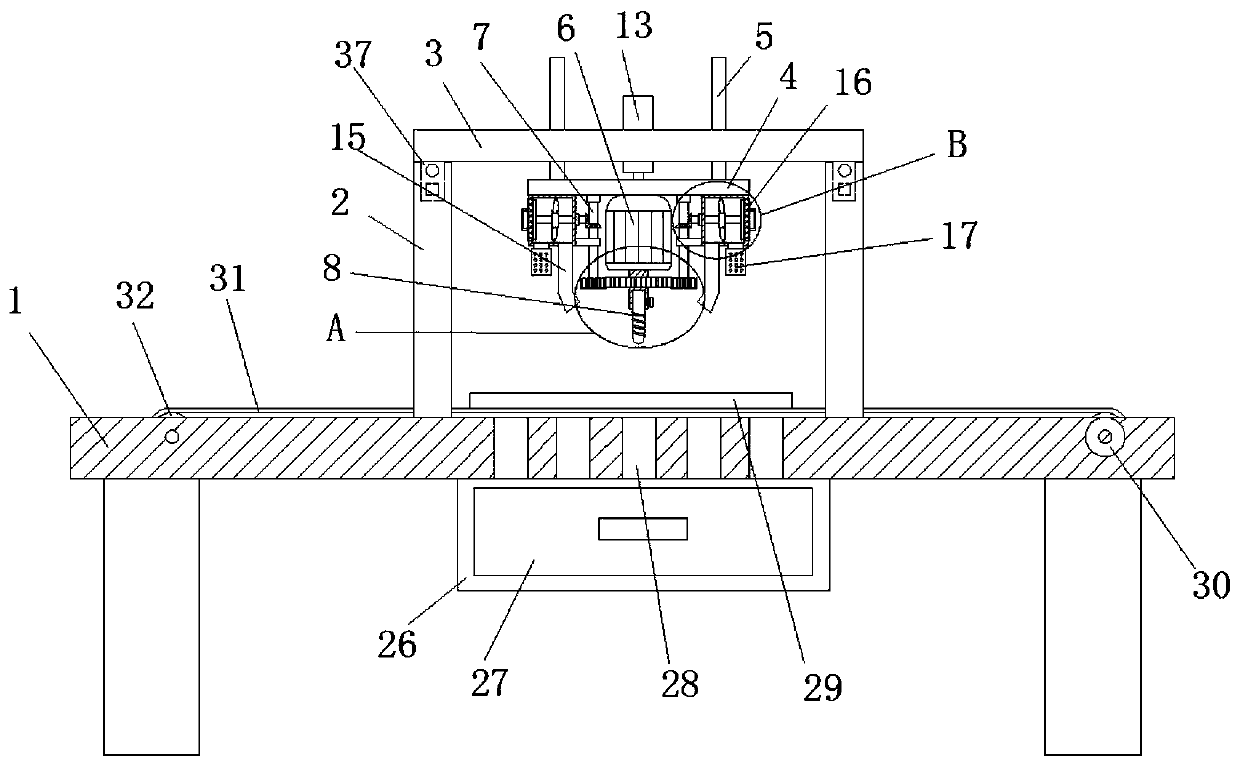

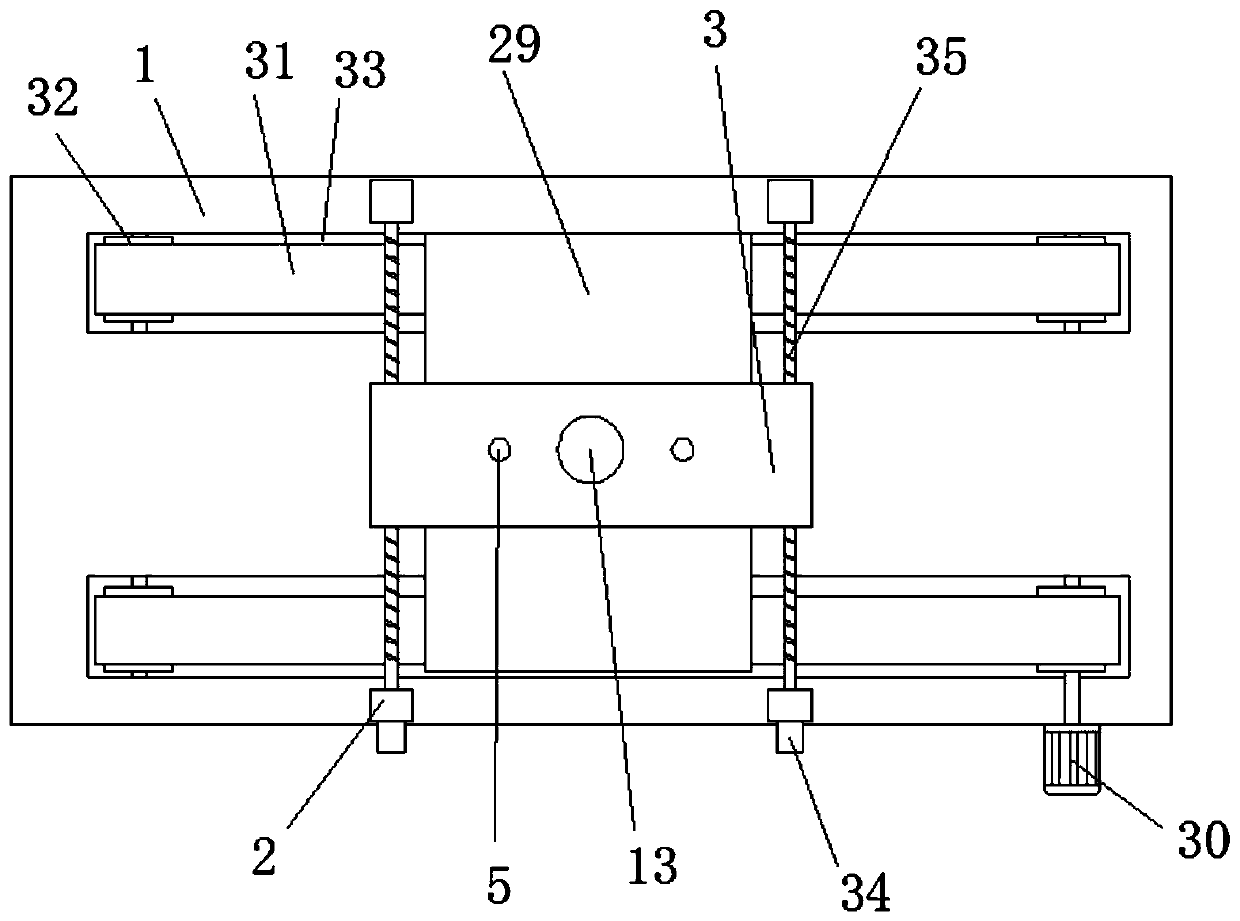

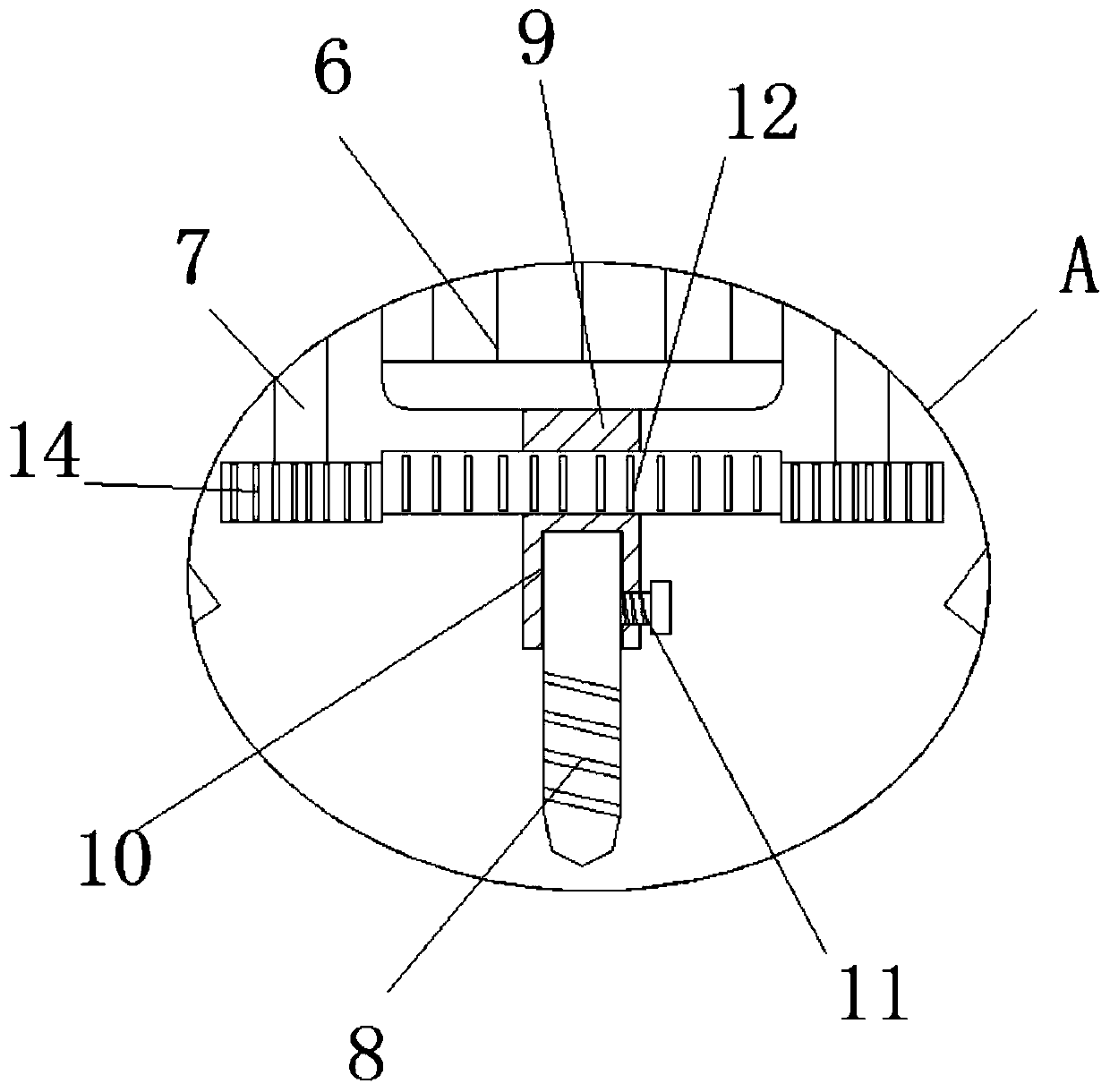

[0032] refer to Figure 1-6 , a plate punching structure for buildings and bridges, comprising a work plate 1, a transmission mechanism is arranged on the top of the work plate 1, a plate 29 is placed on the transmission mechanism, and the top of the work plate 1 is fixedly connected with four poles 2, four Each pole 2 is movably connected with the same top plate 3, and the two poles 2 located on the same horizontal line are connected with a driving mechanism. The top plate 3 is compatible with the two driving mechanisms. There is a propulsion motor 13, the output shaft of the propulsion motor 13 is fixedly connected with a lifting plate 4, the bottom of the lifting plate 4 is fixedly connected with a motor 6, the output shaft of the motor 6 is fixedly connected with a round shaft 9, and the bottom of the round shaft 9 is movably connected There are drill bits 8, two vertical shafts 7 are installed symmetrically on the bottom of the lifting plate 4, and the two vertical shafts...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com