A transmission device for handling printing plates and tray

A printing plate and lifting device technology, applied in printing plate, printing plate preparation, printing, etc., can solve problems such as printing plate difficulties, and achieve the effect of simplifying loading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

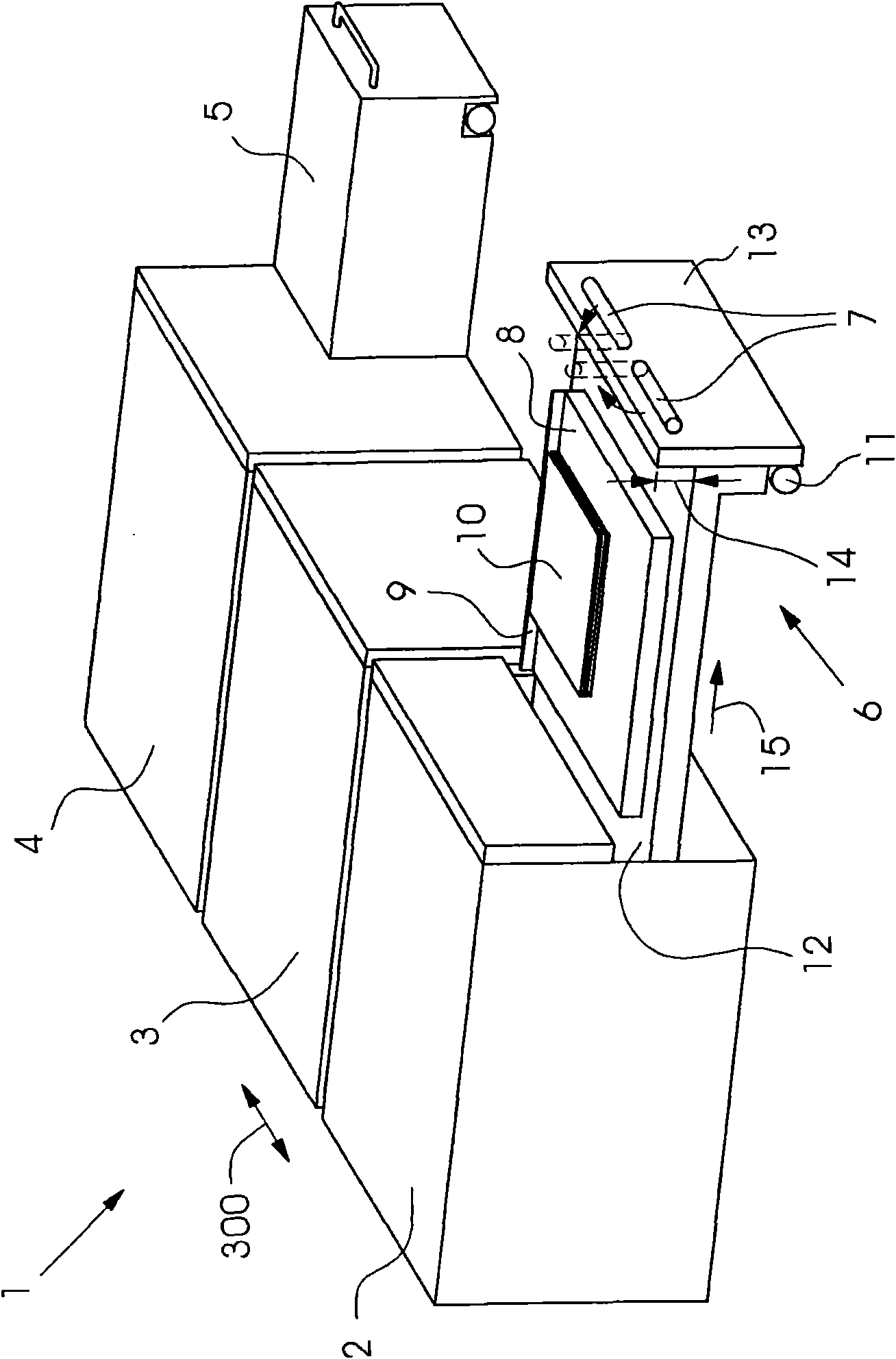

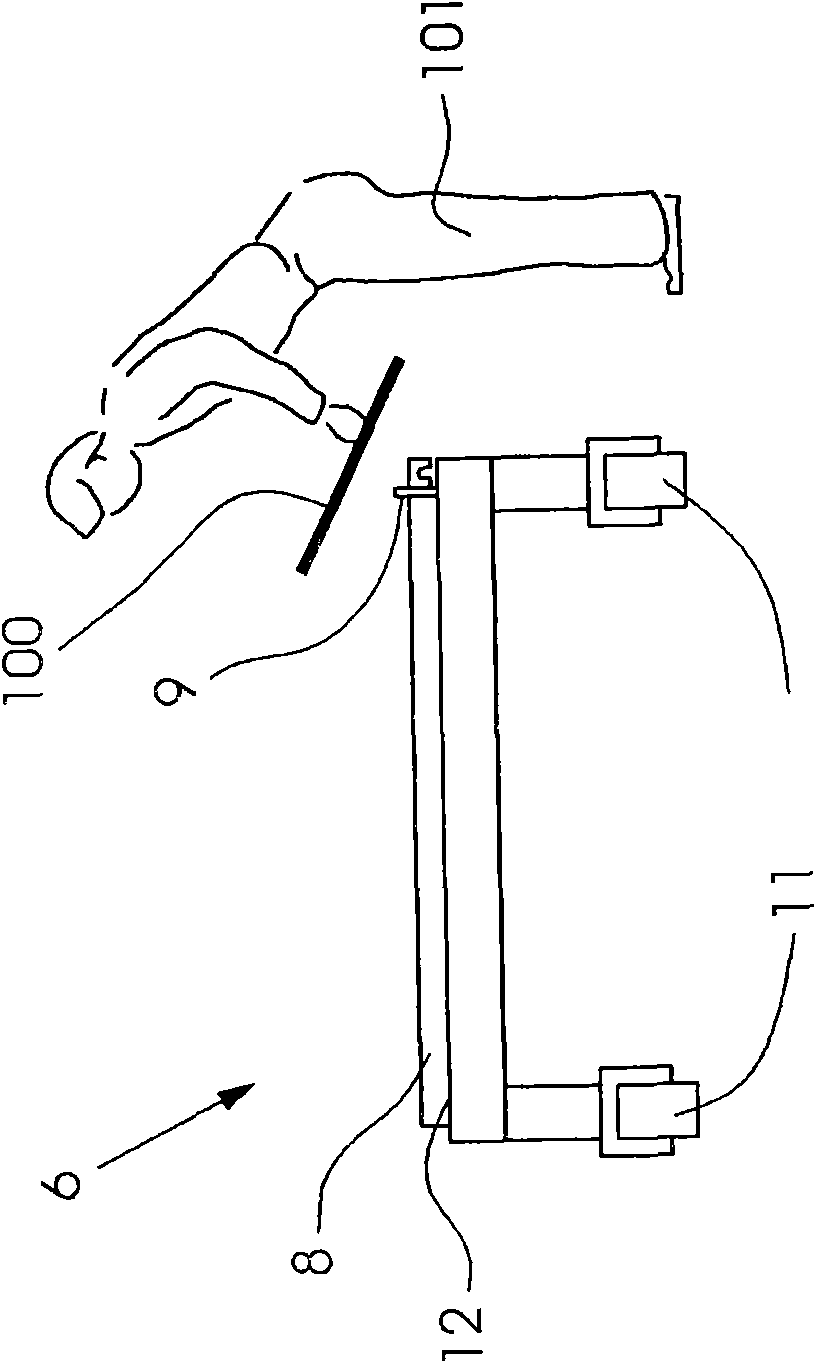

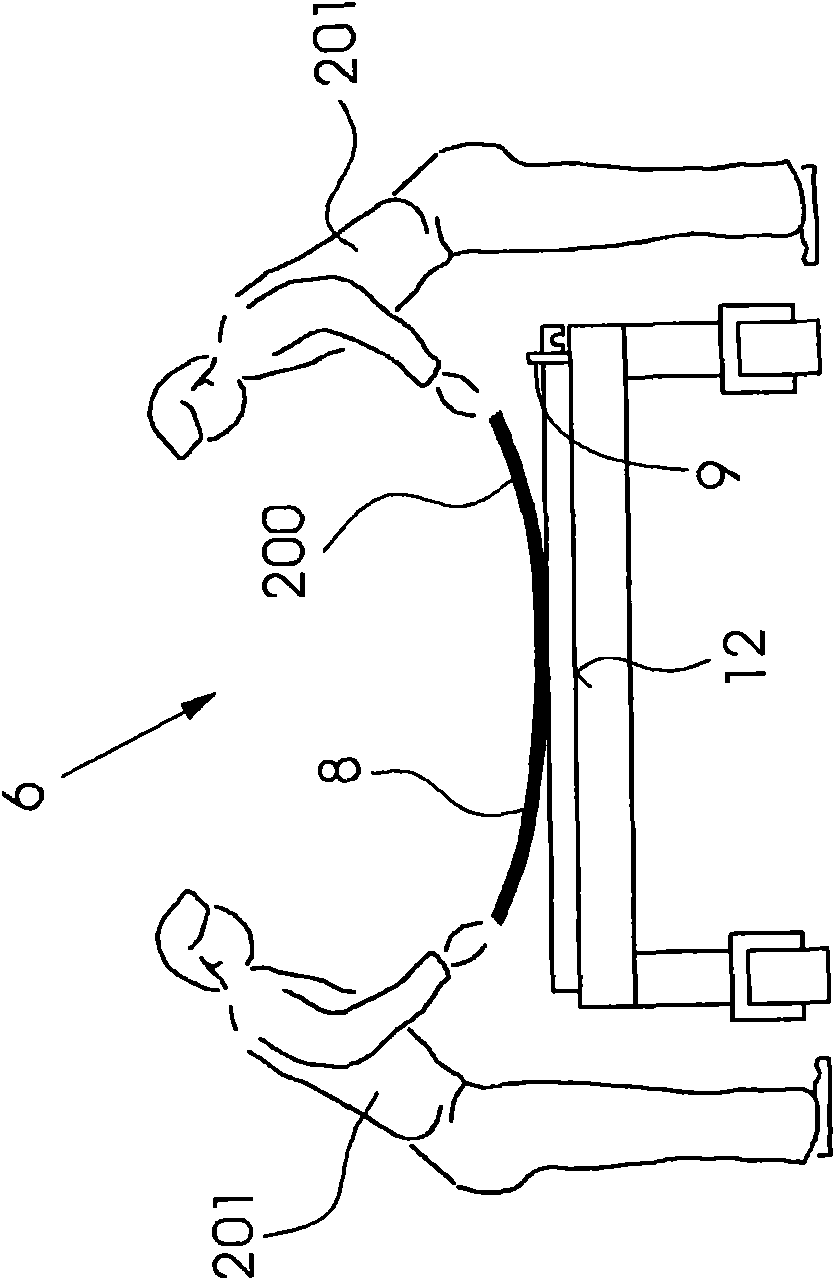

[0031] exist figure 1 1 shows a handling device 1 for printing plates 100, 200 which are to be transported from a storage device 2 to a printing plate exposer, not shown here, connected to the handling device.

[0032] The printing plates 100 are provided in the form of a stack 10 of printing plates on a pallet 8 .

[0033] The handling device 1 comprises a storage device 2 in the form of a cassette in which a plurality of pallets 8 with printing plate stacks 10 are provided one above the other.

[0034] The pallets 8 can be moved horizontally from the storage device 2 into the lifting device 3 in a first direction 300 .

[0035] In the lifting device 3 the pallet can be moved in the vertical direction 304 by means of a lifting mechanism (not shown here). A plurality of positions can thus be obtained in the lifting device 3 .

[0036]In a first position in the lifting device 3 , the printing plates 100 of the printing plate stack 10 can be transported to a separating device...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com