Linear movement core sleeving assembly method of large motor stator

A technology of linear movement and motor stator, applied in electromechanical devices, electric components, manufacturing of motor generators, etc., can solve problems such as falling, rotor vibration, complex equipment structure, etc., to improve safety production efficiency, low labor intensity, and ensure assembly. quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

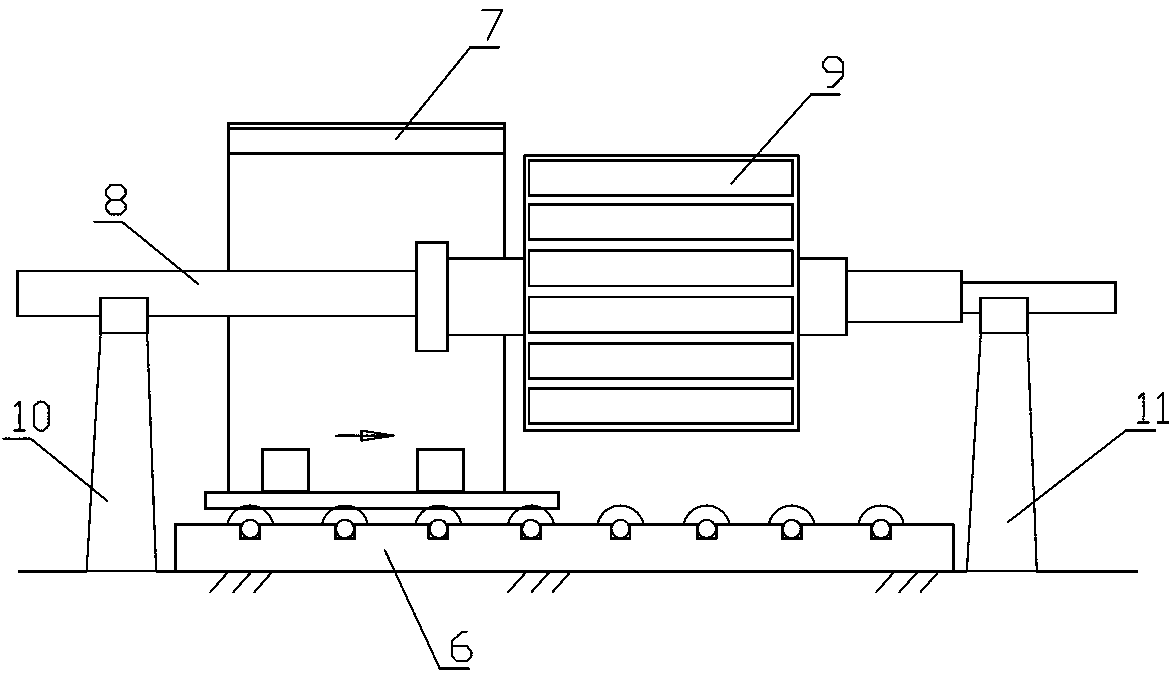

[0026] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

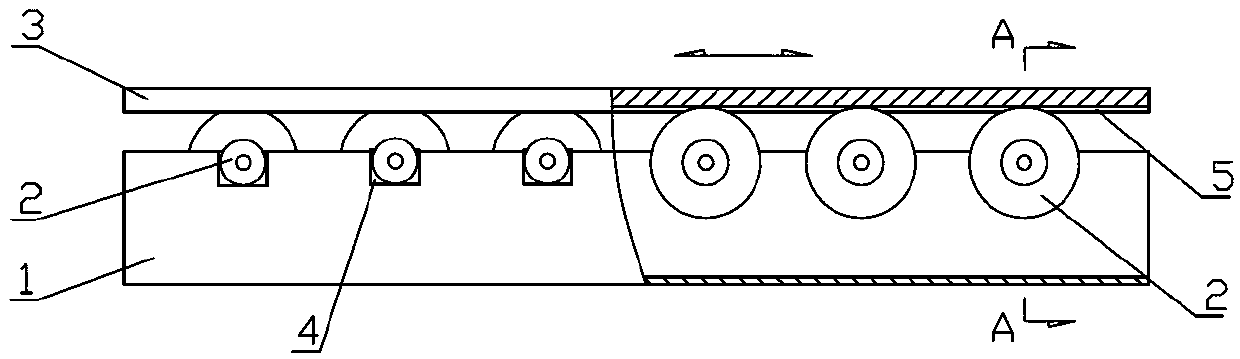

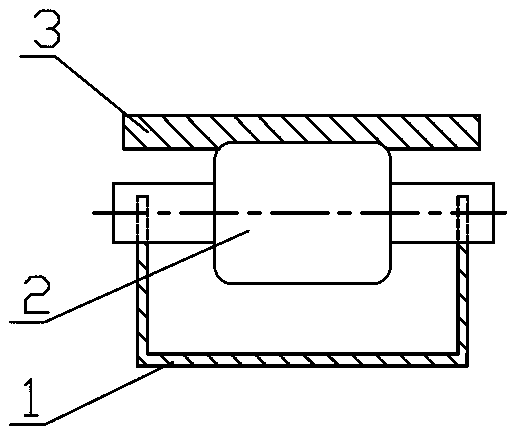

[0027] See figure 1 , figure 2 , is a structural schematic diagram of an embodiment of the roller-type transfer device of the present invention, including a trough-shaped base 1, a roller 2 and a slide plate 3, and more than three rollers 2 are arranged in parallel on the trough-shaped base 1, and the bottom of the slide plate 3 is carried on the rollers On the outer circle of 2, a groove 4 is provided at the edges of two sides along the length direction on the groove-shaped base 1, and the two ends of the roller 2 are carried on the groove 4.

[0028] In order to prevent the slide plate from falling off under force and causing a safety accident, a depression 5 is provided in the contact area between the bottom of the slide plate 3 and the roller 2, and the depth of the depression is 1 / 6-1 / 3 of the radius of the roller.

[0029] Since the movin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com