Negative pressure deslagging dredging core pipe valve

A negative pressure, water-repellent technology, applied in valve details, multi-port valves, valve devices, etc., can solve the problems of complex structure of slag discharger, unfavorable smooth discharge, small discharge diameter, etc., to improve reliability and long-term performance. , The effect of low manufacturing cost and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

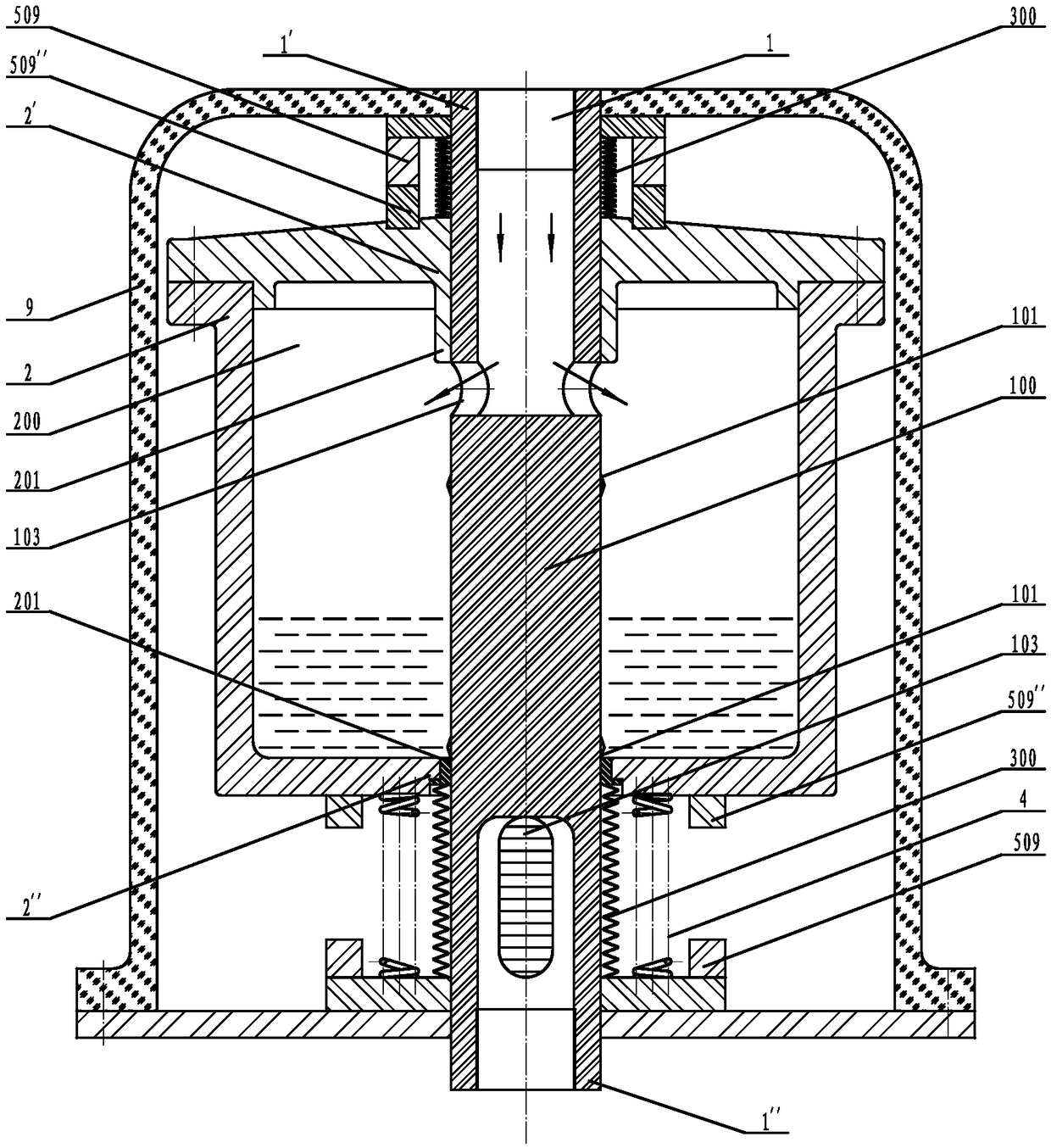

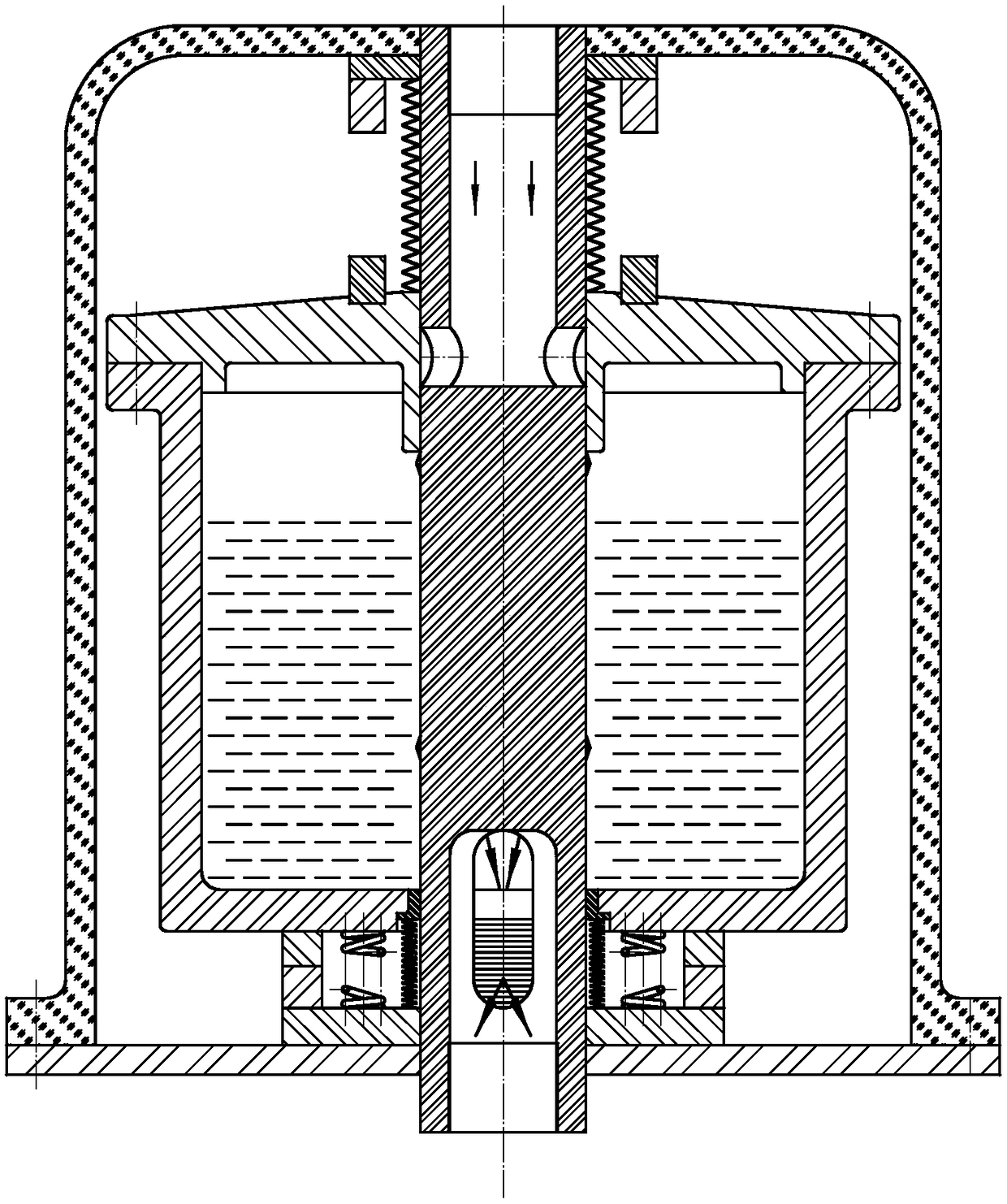

[0035] See attached figure 1 , 2 , the negative pressure slagging and draining core tube valve described in this embodiment, the valve core tube 1 is a sleeve tube I2' that runs through the valve body 2 from top to bottom, and the inner cavity of the valve body 2. 200, and the sleeve pipe II2" of the valve body 2; there is an axial partition 100 in the middle of the valve core pipe 1, and the partition 100 is composed of the inner core and the middle pipe section of the valve core pipe 1 radially radiating from the inner core; the axial two sides of the partition 100 They are respectively the two radial flow holes 103 of the input section 1' and the output section 1", wherein, the two flow holes 103 of the output section 1" are long and waist-shaped in the axial direction; The sealing surface of an annular spool 101 is a two-way slope and forms a sealing pair with the annular valve seat 201 of the throat of the sleeve pipe I2' and the sleeve pipe II2" respectively; the input ...

Embodiment 2

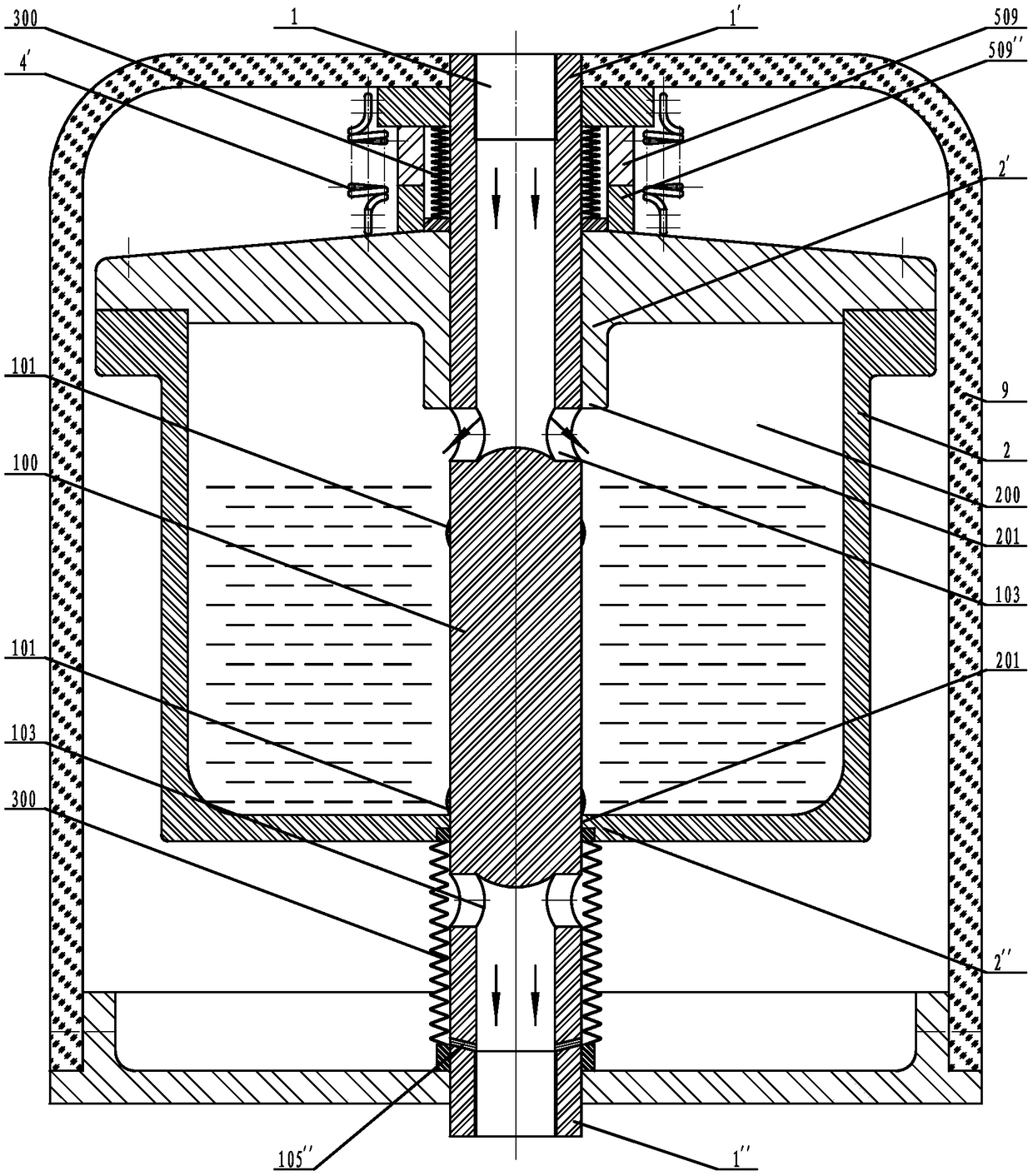

[0039] See attached image 3 , 4, the negative pressure slagging and draining core tube valve described in this embodiment, the valve core tube 1 is a sleeve tube I2' that runs through the valve body 2 from top to bottom, and the inner cavity of the valve body 2. 200, and the sleeve pipe II2" of the valve body 2; there is an axial partition 100 in the middle of the valve core pipe 1, and the partition 100 is composed of the inner core and the middle pipe section of the valve core pipe 1 radially radiating from the inner core; the axial two sides of the partition 100 The two radial flow holes 103 of the input section 1' and the output section 1" respectively; the sealing surfaces of the two annular spools 101 in the axial direction surrounding the partition 100 are circular arc slopes that are respectively connected to the sleeve tube I2' and the sleeve tube II2 The annular valve seat 201 of the "throat constitutes a sealing pair; the input section 1' and the sleeve pipe I2' a...

Embodiment 3

[0043] See attached Figure 5 , 6 , the negative pressure slagging and draining core tube valve described in this embodiment, the valve core tube 1 is a sleeve tube I2' that runs through the valve body 2 from top to bottom, and the inner cavity of the valve body 2. 200, and the sleeve pipe II2" of the valve body 2; there is an axial partition 100 in the middle of the valve core pipe 1, and the partition 100 is composed of the inner core and the middle pipe section of the valve core pipe 1 radially radiating from the inner core; the axial two sides of the partition 100 Two radial flow holes 103 of the input section 1' and the output section 1", wherein the two flow holes 103 of the output section 1" are long waists extending axially; the shaft surrounding and integrated with the partition 100 The sealing surfaces of the upper and lower annular spools 101 are one-way slope surfaces and respectively form a sealing pair with the annular valve seat 201 at the throat of the sleeve ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com