Production process of sewage biological denitrification composite carbon source with low C/N ratio

A composite carbon source and sewage biological technology, applied in water/sludge/sewage treatment, special compound water treatment, special treatment targets, etc., can solve the problems of poor safety, high cost, high consumption, etc., and achieve less air bubbles and shorter time , The effect of stable product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

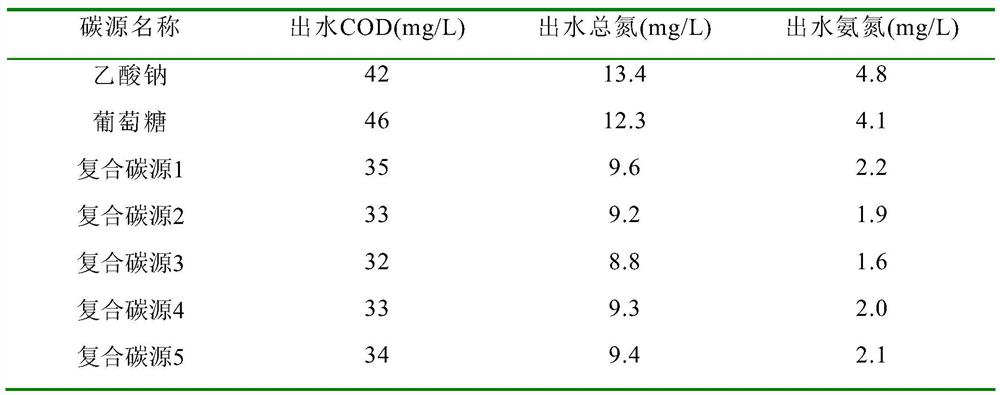

Examples

Embodiment 1

[0027] This embodiment provides a production process of a low C / N ratio sewage biological denitrification composite carbon source. The components of the composite carbon source are specifically: polyethylene glycol: 10%, sugarcane molasses: 15% by mass ratio , glycerol: 10%, glucose: 5%, sodium acetate: 5%, sodium propionate: 2%, the remainder is 53% water, and the sum of the above components is 100%; the production process of the composite carbon source is specific Include the following steps:

[0028] (1) Take water with a mass ratio of 26.5%, and heat it to 35°C;

[0029] (2) Get 5% glucose, 10% polyethylene glycol and 15% sugarcane molasses by mass ratio and dissolve them in the warm water of step (1) rapidly successively, stir and mix evenly for 10 minutes, and adopt a 200-mesh filter screen with an aperture Filtration forms solution A;

[0030] (3) Take water with a mass ratio of 10%, add 3.66% acetic acid and 1.54% propionic acid successively, and add a sodium hydroxi...

Embodiment 2

[0034]This embodiment provides a production process of a low C / N ratio sewage biological denitrification composite carbon source. The components of the composite carbon source are specifically: polyethylene glycol: 15%, sugarcane molasses: 20% by mass ratio , glycerol: 15%, glucose: 10%, sodium acetate: 10%, sodium propionate: 5%, water: 25%, the sum of the above components is 100%, and the production process of the composite carbon source specifically includes The following steps:

[0035] (1) Take water with a mass ratio of 12.5%, and heat it to 50°C;

[0036] (2) Get 10% glucose, 15% polyethylene glycol and 20% sugarcane molasses by mass ratio and dissolve them in the warm water of step (1) rapidly successively, stir and mix evenly for 10 minutes, and adopt a 100-mesh filter screen with an aperture Filtration forms solution A;

[0037] (3) get 4% water in mass ratio again, add 7.32% acetic acid and 3.85% propionic acid in mass ratio successively, and add a mass concentrat...

Embodiment 3

[0040] This embodiment provides a production process of a composite carbon source for sewage biological denitrification with a low C / N ratio. The components of the composite carbon source are specifically: polyethylene glycol: 12%, beet molasses: 15% by mass ratio , glycerol: 12%, glucose: 8%, sodium acetate: 8%, sodium propionate: 3%, water: 42%, the sum of the above components is 100%;

[0041] The production process of the composite carbon source specifically includes the following steps:

[0042] (1) Get 21% water by mass ratio, and heat to 40°C;

[0043] (2) Get 8% glucose, 12% polyethylene glycol and 15% beet molasses by mass ratio and dissolve them in the warm water of step (1) rapidly successively, stir and mix evenly for 10 minutes, and adopt a pore size of 150 mesh filter screen Filtration forms solution A;

[0044] (3) Get 10% water in mass ratio again, add 5.85% acetic acid and 2.31% propionic acid in mass ratio successively, and add a mass concentration of 50%, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com