Blade spring type power current inserting-connecting device

A plug-in device and leaf spring type technology, which is applied to the two-part connection device, the parts of the connection device, the coupling device, etc., can solve the problems of long troubleshooting time, many terminals, and increased downtime, so as to improve safety. High production efficiency, large conduction current, and reliable connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

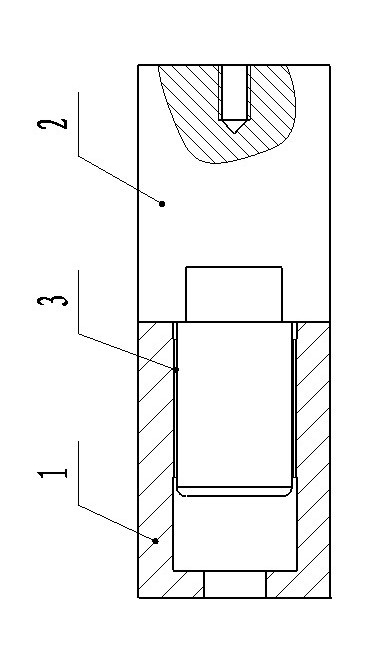

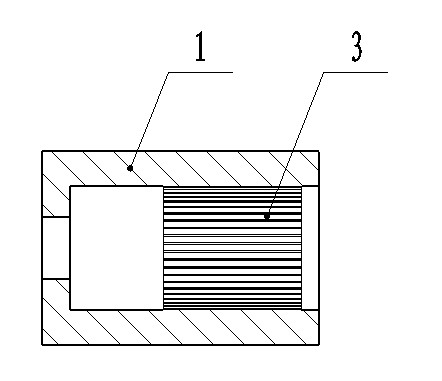

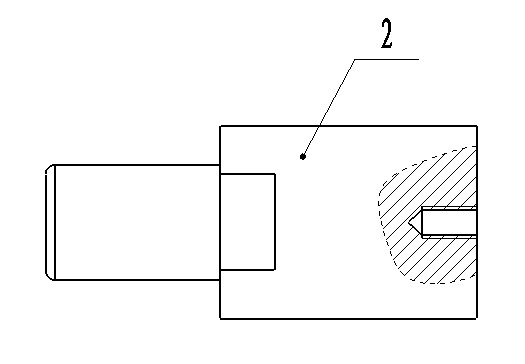

[0013] Such as Figures 1 to 3 As shown, the leaf spring type power current plug-in device of the present invention includes: a female connector 1 and a male connector 2, the female connector 1 is a hollow cylindrical metal tube, and the front end aperture ratio of the female connector 1 metal tube is The central aperture is small, and the inner wall of the metal tube of the female connector 1 is equipped with a leaf spring 3. The leaf spring 3 is an elastic metal sheet folded into a zigzag shape. The spring 3 can also be realized by adding protrusions on the inner wall of the metal tube of the female connector 1 , and the leaf spring 3 can make the connection between the female connector 1 and the male connector 2 reliable.

[0014] The male connector 2 is a cylindrical metal rod. The front end of the male connector 2 is a small cylinder that is compatible with the inner wall of the metal tube of the female connector 1. The rear end of the male connector 2 has an axial hole. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com