Silicon-calcium inorganic high-strength heat insulation composite wallboard

A thermal insulation composite, calcium-silicon technology, applied in thermal insulation, walls, building components, etc., can solve the problems of complex construction process, low strength, slow solidification, etc., and achieve good thermal insulation effect, high compressive strength and moderate density. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

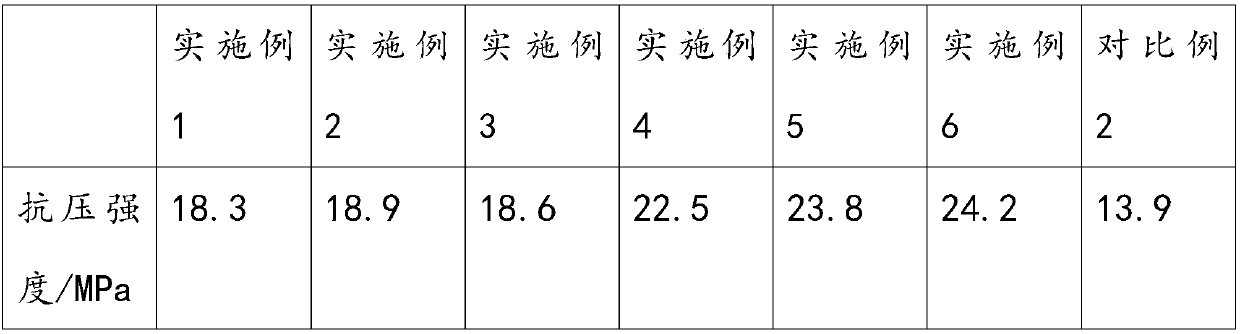

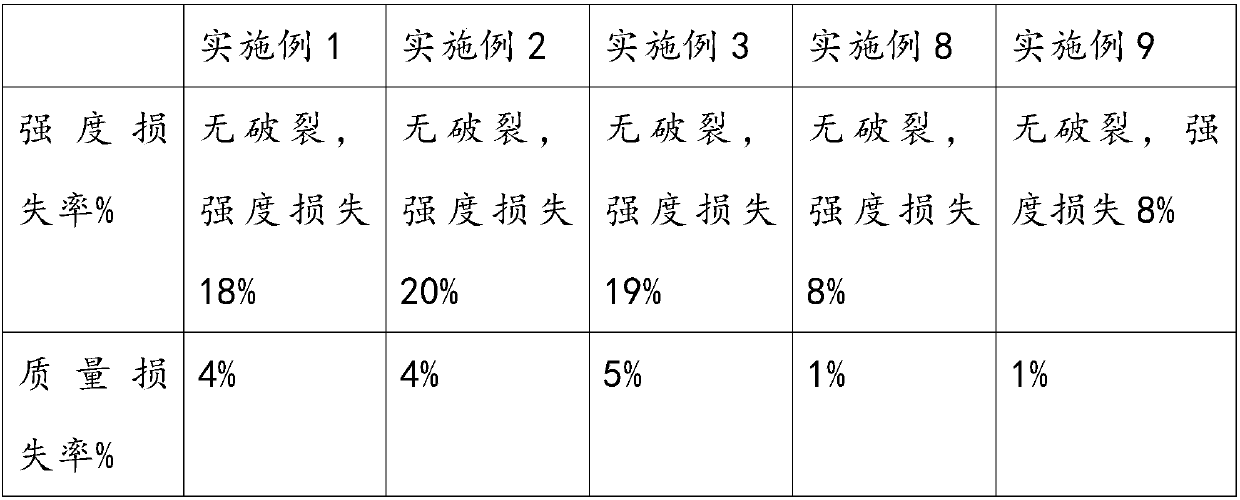

Embodiment 1

[0026] A silicon-calcium inorganic high-strength thermal insulation composite wallboard is prefabricated from a core material and a leather material. The core material includes the following components by weight: 150 parts of 525 cement, 500 parts of calcium silicate, 10 parts quick-drying powder, 80 parts calcium silicon powder, 16 parts iron oxide, 250 parts calcium powder, 10 parts lithium carbonate, 50 parts gypsum powder, 40 parts silane, 6 parts fiber, 4 parts azodicarbonamide, neutral water 1200 parts; the leather raw materials include 50 parts of sodium chloride, 55 parts of sodium silicate, 90 parts of calcium silicate powder, 90 parts of 525 cement, 6 parts of construction sand, 12 parts of steel mesh, 5 parts of fiber and 760 parts of neutral water .

[0027] The preparation method of the above-mentioned calcareous inorganic high-strength thermal insulation composite wallboard is carried out according to the following steps:

[0028] (1) Prepare the mold, put the s...

Embodiment 2

[0031] A silicon-calcium inorganic high-strength thermal insulation composite wallboard is prefabricated from a core material and a leather material. The core material includes the following components by weight: 200 parts of 525 cement, 400 parts of calcium silicate, 9 parts of quick-drying powder, 70 parts of calcium silicon powder, 15 parts of copper oxide, 200 parts of limestone, 8 parts of lithium carbonate, 30 parts of gypsum powder, 35 parts of aluminate, 3 parts of fiber, 3 parts of n-pentane, 900 parts of neutral water The leather raw materials include 46 parts of sodium chloride, 50 parts of potassium silicate, 72 parts of calcium silicate powder, 80 parts of 525 cement, 5 parts of construction sand, 10 parts of steel wire mesh, 8 parts of fiber, and 750 parts of neutral water. .

[0032] The preparation method of the above-mentioned calcareous inorganic high-strength thermal insulation composite wallboard is carried out according to the following steps:

[0033] (1...

Embodiment 3

[0036] A siliceous-calcium inorganic high-strength thermal insulation composite wallboard is made from core material raw materials and leather material raw materials by pouring. The core material raw materials include the following components by weight: 100 parts of 525 cement, 600 parts of calcium silicate, 12 parts of quick-drying powder, 96 parts of calcium silicon powder, 18 parts of alumina, 300 parts of high alumina, 15 parts of lithium carbonate, 80 parts of gypsum powder, 55 parts of silane, 8 parts of fiber, 5 parts of petroleum ether, 1500 parts of neutral water The leather material includes 55 parts of sodium chloride, 67 parts of lithium silicate, 110 parts of calcium silicate powder, 100 parts of 525 cement, 8 parts of construction sand, 15 parts of steel wire mesh, 3 parts of fiber, and 780 parts of neutral water.

[0037] The preparation method of the above-mentioned calcareous inorganic high-strength thermal insulation composite wallboard is carried out accordin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com