Method for weakening hard waste rock inclusion layer in coal seam through hydraulic presplitting in underground coal mine deep hole

A technology with gangue layer and hard layer is applied in the field of hard gangue layer in the weakened coal seam with deep hole hydraulic pre-cracking in coal mines. Damage degree, improve start-up time, and achieve the effect of safe and efficient production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

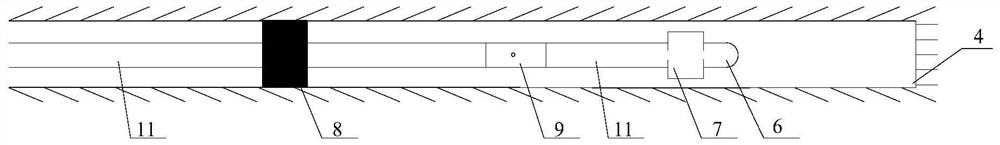

[0031] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings.

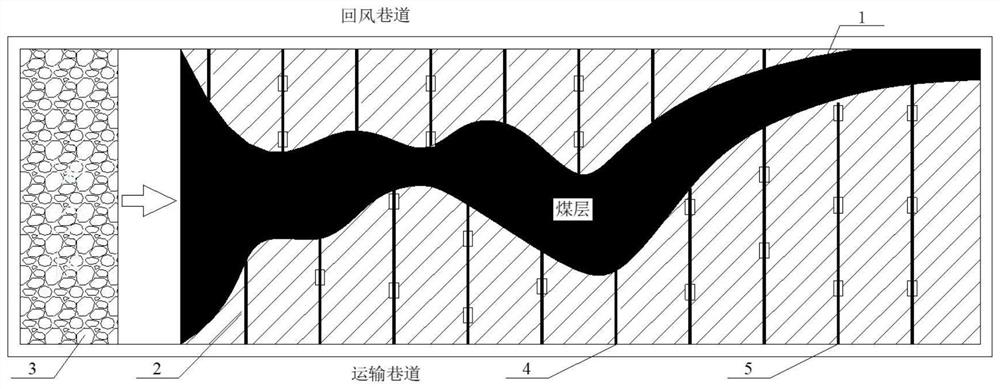

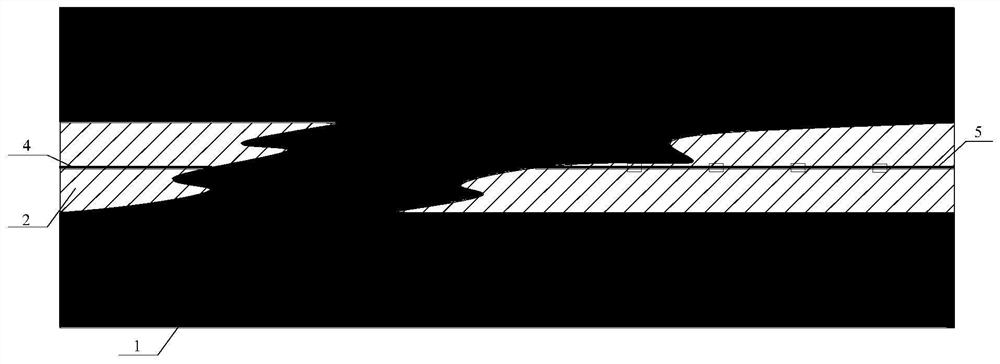

[0032] see Figure 1 to Figure 5 , the invention discloses a method for deep-hole hydraulic pre-cracking in a coal mine to weaken the hard gangue layer in a coal seam, which specifically includes the following steps:

[0033] The first step: determine the occurrence form and scope of the hard gangue layer in the mining face.

[0034] Specifically, it can be realized through the following process. First, according to the spatial parameters of gangue inclusion in the coal seam exposed by ground geological survey drilling (such as the thickness of gangue inclusion, lithology of inclusion gangue, elevation of the floor of gangue inclusion, etc.), the gangue inclusion within the mine range can be compiled. Spatial geometric shape map (such as thickness distribution co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com