Application of permeate liquid generated in production of concentrated milk, electrolyte beverage and preparation method of electrolyte beverage

An electrolyte and permeate technology, which is applied in applications, dairy products, milk preparations, etc., can solve problems such as the need to use additives, poor powder stability, and inability to effectively supplement milk mineral salts and proteins, so as to improve poor stability and steps Simple, easy to promote the effect of industrial application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

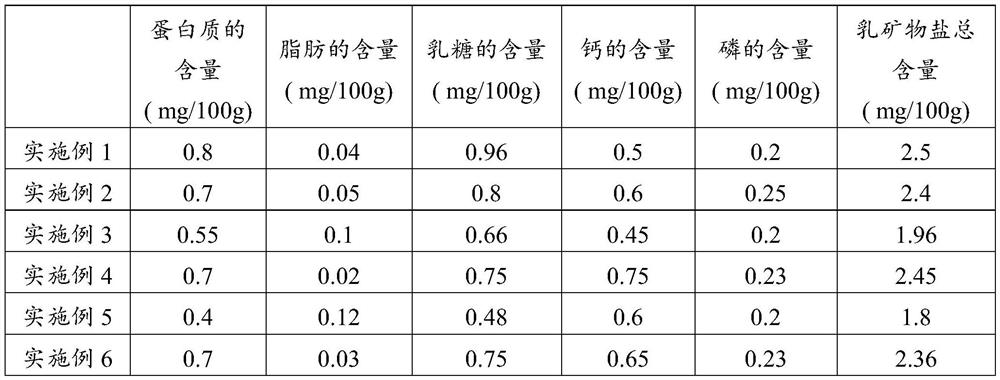

Examples

Embodiment 1

[0042] This embodiment provides an electrolyte drink, the preparation method of which is as follows:

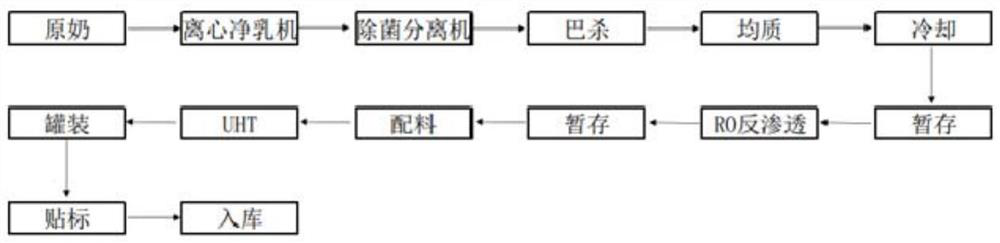

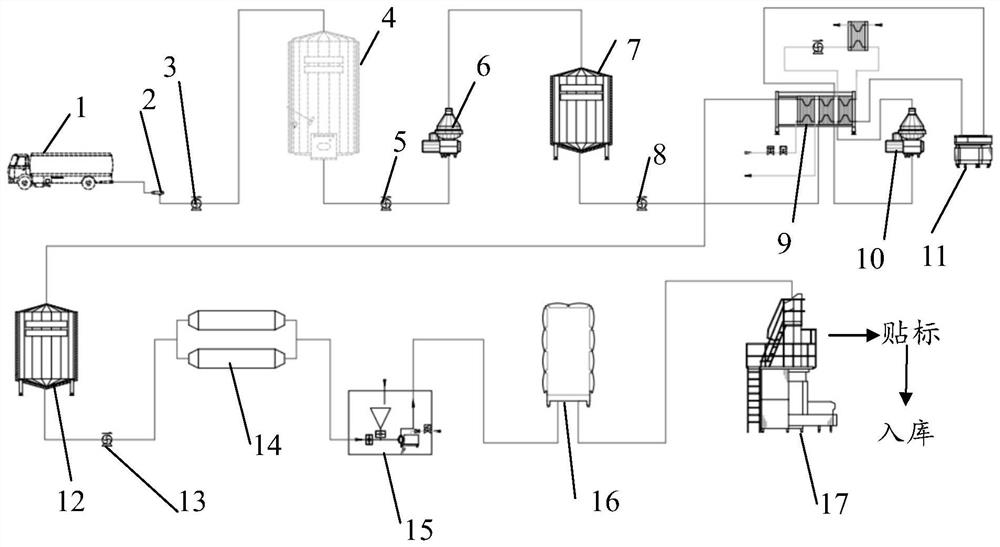

[0043] The production process is:

[0044] Milk collection→milk cleaning→sterilization and separation→pasteurization (first sterilization)→homogenization→cooling→reverse osmosis→temporary storage→ingredients→UHT (second sterilization)→filling→labeling→storage;

[0045] The specific steps are:

[0046]Milk cleaning: 2000kg of raw milk collected is processed for milk cleaning. The specific operation is that the raw milk is put into a centrifugal milk cleaning machine to separate and remove impurities such as hair, dust, bovine epithelial cells, and white blood cells.

[0047] Sterilization and separation: the raw milk obtained in the above steps is processed by a sterilizing separator at a temperature of 75°C, so that the removal rate of spores is 90%, and the removal rate of cell bodies is 55%;

[0048] Sterilization: use pasteurization process, temperature 85 ℃, keep warm f...

Embodiment 2

[0055] This embodiment provides an electrolyte drink, the preparation method of which is as follows:

[0056] The production process is:

[0057] Milk collection→milk cleaning→sterilization and separation→pasteurization (first sterilization)→homogenization→cooling→reverse osmosis→temporary storage→ingredients→UHT (second sterilization)→filling→labeling→storage;

[0058] The specific steps are:

[0059] Milk cleaning: 3000kg of raw milk collected is processed for milk cleaning. The specific operation is that the raw milk is put into a centrifugal milk cleaning machine to separate and remove impurities such as hair, dust, bovine epithelial cells, and white blood cells.

[0060] Sterilization and separation: the raw milk obtained in the above steps is processed by a sterilizing separator at a temperature of 85°C, so that the removal rate of spores is 86%, and the removal rate of cell bodies is 70%;

[0061] Sterilization: use pasteurization process, temperature 72 ℃, keep warm ...

Embodiment 3

[0068] This embodiment provides an electrolyte drink, the preparation method of which is as follows:

[0069] The production process is:

[0070] Milk collection→milk cleaning→sterilization and separation→pasteurization (first sterilization)→homogenization→cooling→reverse osmosis→temporary storage→ingredients→UHT (second sterilization)→filling→labeling→storage;

[0071] The specific steps are:

[0072] Milk cleaning: 2000kg of raw milk collected is processed for milk cleaning. The specific operation is that the raw milk is put into a centrifugal milk cleaning machine to separate and remove impurities such as hair, dust, bovine epithelial cells, and white blood cells.

[0073] Sterilization and separation: the raw milk obtained in the above steps is processed by a sterilizing separator at a temperature of 80°C, so that the removal rate of spores is 90%, and the removal rate of cell bodies is 60%;

[0074] Sterilization: use pasteurization process, temperature 95 ℃, keep warm ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com