Fire preventing and extinguishing gel preparation method and coal mine fire preventing and extinguishing method

A technology of anti-fire extinguishing and gel, which is applied in fire prevention equipment, fire prevention, dust prevention, etc. It can solve the problems that the anti-fire extinguishing gel does not use natural polymer materials, cannot capture coal spontaneous combustion, and is difficult to achieve the desired effect. Improve fire prevention efficiency, good environmental protection effect, and oxygen isolation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

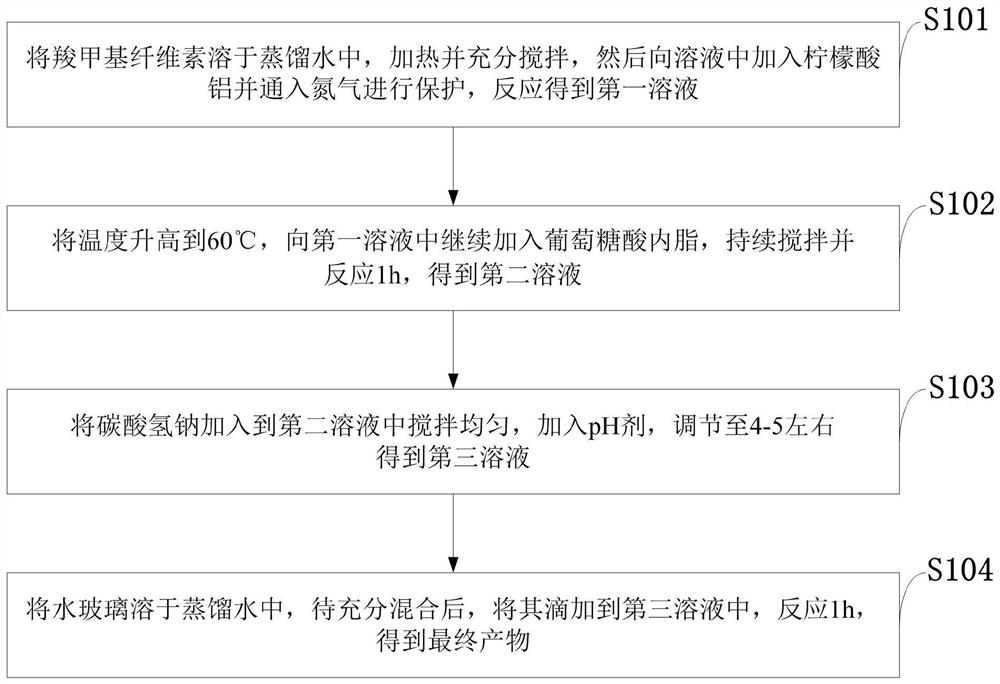

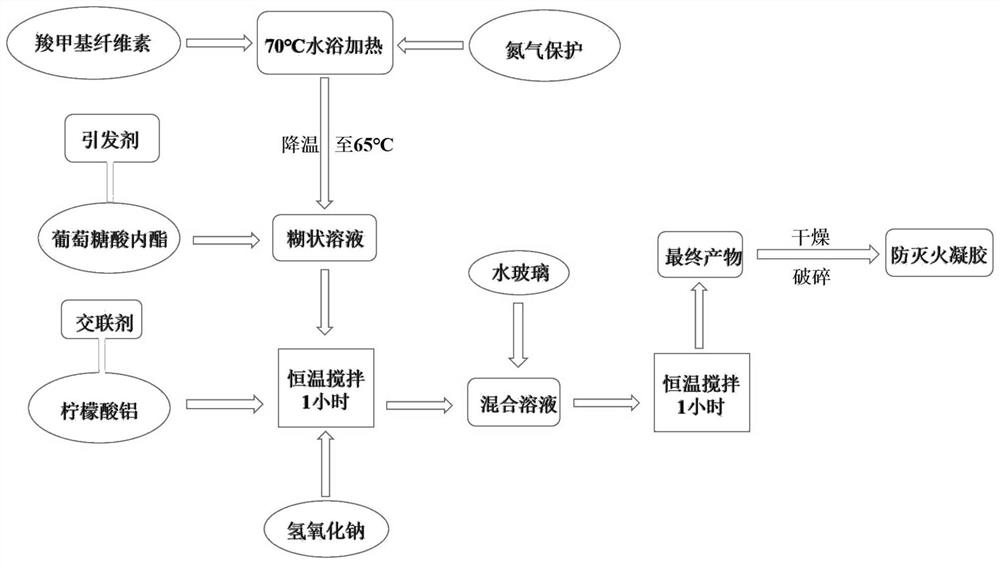

[0038] Such as figure 1 Shown, the preparation method of the anti-fire extinguishing gel provided by the invention may further comprise the steps:

[0039] S101: dissolving carboxymethyl cellulose in distilled water, heating and fully stirring, then adding aluminum citrate to the solution and passing nitrogen gas for protection, and reacting to obtain the first solution;

[0040] S102, raising the temperature to 60° C., continuing to add gluconolactone to the first solution, stirring continuously and reacting for 1 hour, to obtain a second solution;

[0041] S103: adding sodium bicarbonate into the second solution and stirring evenly, adding a pH agent, and adjusting it to about 4-5 to obtain a third solution;

[0042] S104: Dissolving the water glass in distilled water, and after being thoroughly mixed, adding it dropwise to the third solution, and reacting for 1 hour to obtain a final product.

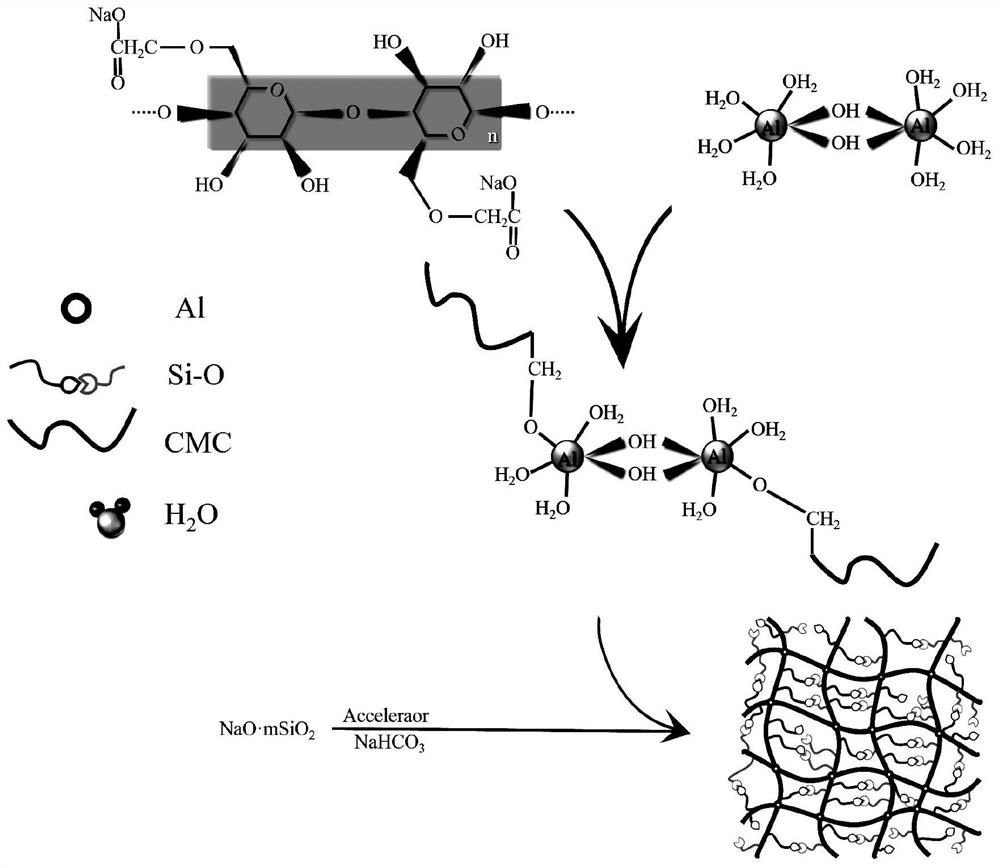

[0043] In the present invention, the first solution is obtained by reacting fo...

Embodiment 1

[0046]The preparation method of the anti-fire extinguishing gel provided by the present invention comprises weighing 3g of carboxymethyl cellulose and dissolving it in 200ml of water under the condition of 85°C. Adjust the temperature to 65°C, add 0.1g gluconolactone to the solution, stir at a constant temperature for 30min, then slowly add 3g of aluminum citrate into the beaker, stir at a constant temperature for 30min, then add sodium bicarbonate, continue heating and stirring for 1h to obtain For the final product, add an appropriate amount of NaOH to adjust the pH value to 4 to obtain a high-temperature resistant and highly water-absorbent fire-fighting gel G1, and test related properties.

Embodiment 2

[0048] The preparation method of the anti-fire extinguishing gel provided by the present invention comprises weighing 2.5g carboxymethyl cellulose and dissolving it in 200ml water under the condition of 85°C; Adjust the temperature to 65°C, add 0.1g gluconolactone to the solution, stir at constant temperature for 30min, then slowly add 3g of aluminum citrate into the beaker, stir at constant temperature for 30min, then add sodium bicarbonate, continue heating and stirring for 1h, After obtaining the final product, add an appropriate amount of NaOH to adjust the pH value to 4 to obtain high-temperature resistant and highly water-absorbent fire-fighting gel G2, and test related properties.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com