Radius-adjustable steel bar bending and rounding machine

An adjustable, steel bar technology, applied in the field of steel bar processing, can solve the problems of not being able to obtain the radius, poor practicability, and prone to deviation, etc., and achieve the effect of convenient and fast operation, convenient operation, and a smaller body shape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The following are specific embodiments of the present invention, and in conjunction with the accompanying drawings, further describe the technical solution of the present invention, but the present invention is not limited to these embodiments.

[0030] It should be noted that the words "left", "right", "upper" and "lower" used in the following description refer to directions in the drawings.

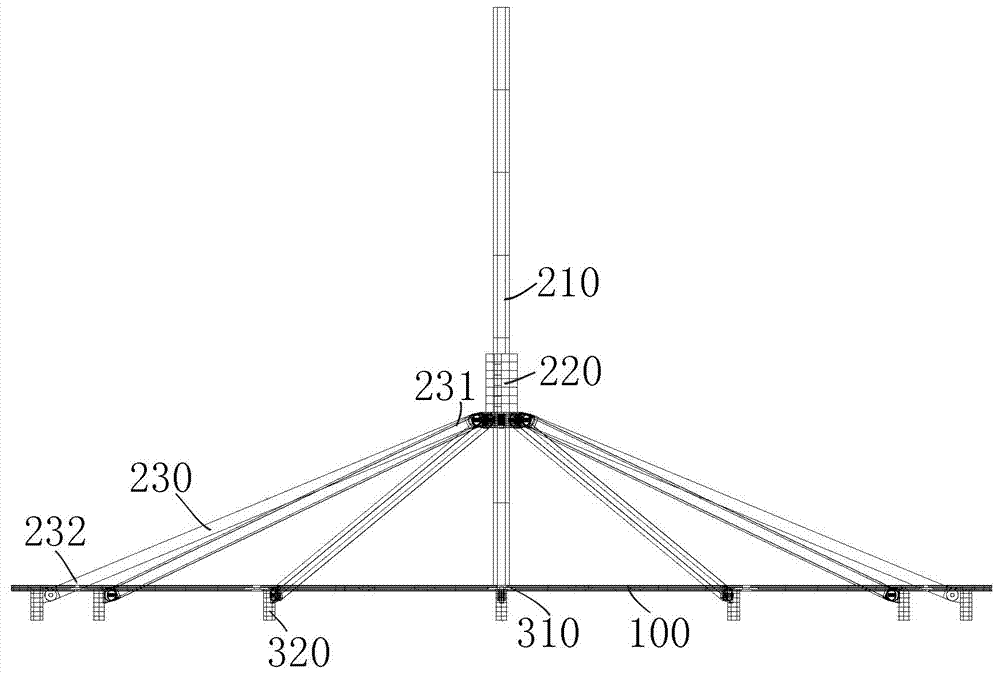

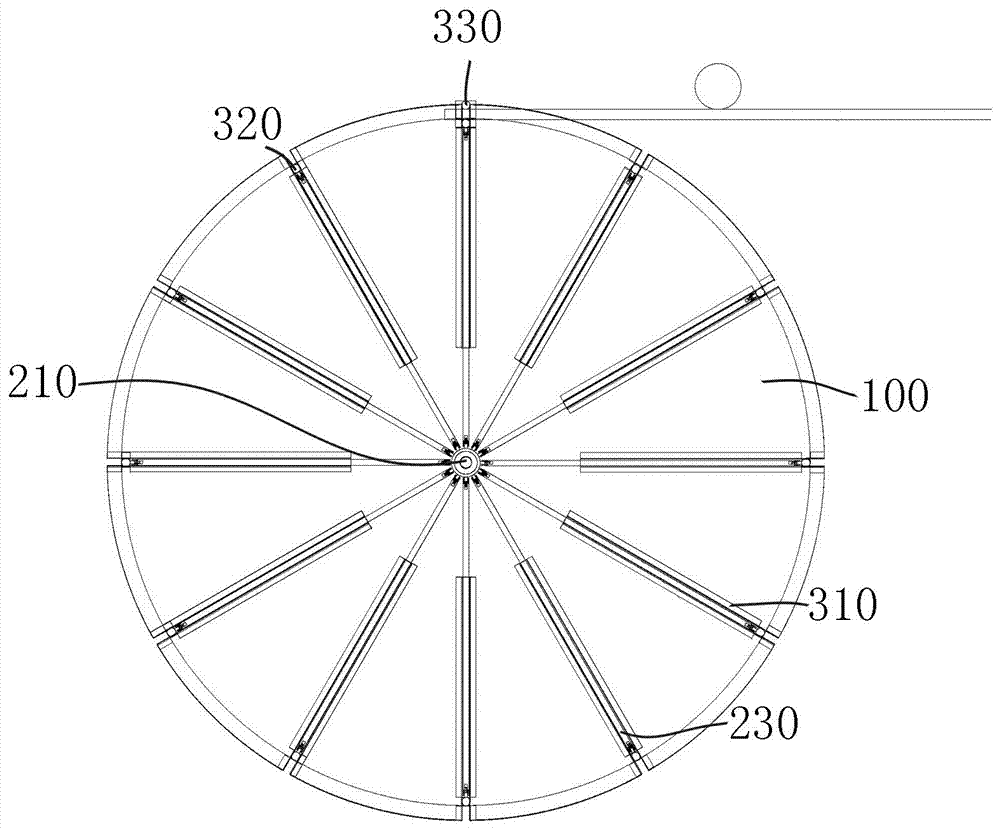

[0031] A radius adjustable steel bar welding and bending machine, such as figure 1 with figure 2 As shown, it includes an operation console 100 , a diameter adjustment locking assembly 200 and a connection assembly 300 .

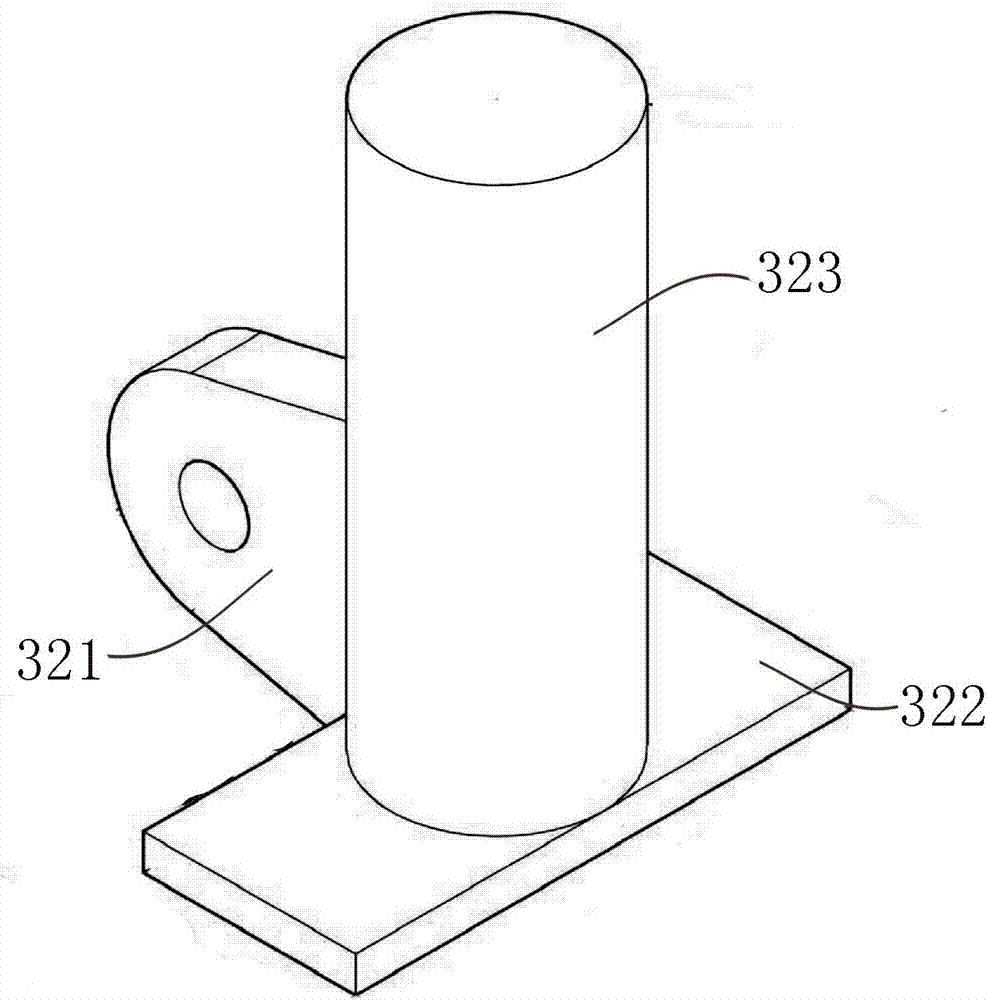

[0032] The connection assembly 300 includes a plurality of radial guides 310 and corresponding members 320 of the radial guides 310 radially arranged on the operating table 100 . In this embodiment, the radial guides 310 are 12 through grooves along the radial direction of the console 100 , and all the radial through grooves divide the console into equal par...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com