Patents

Literature

109results about How to "Guaranteed bending quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

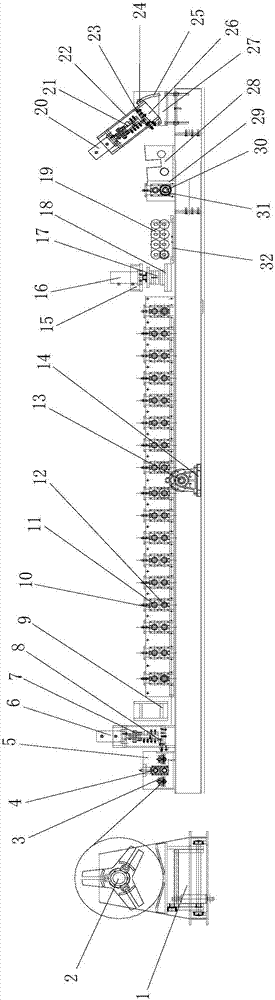

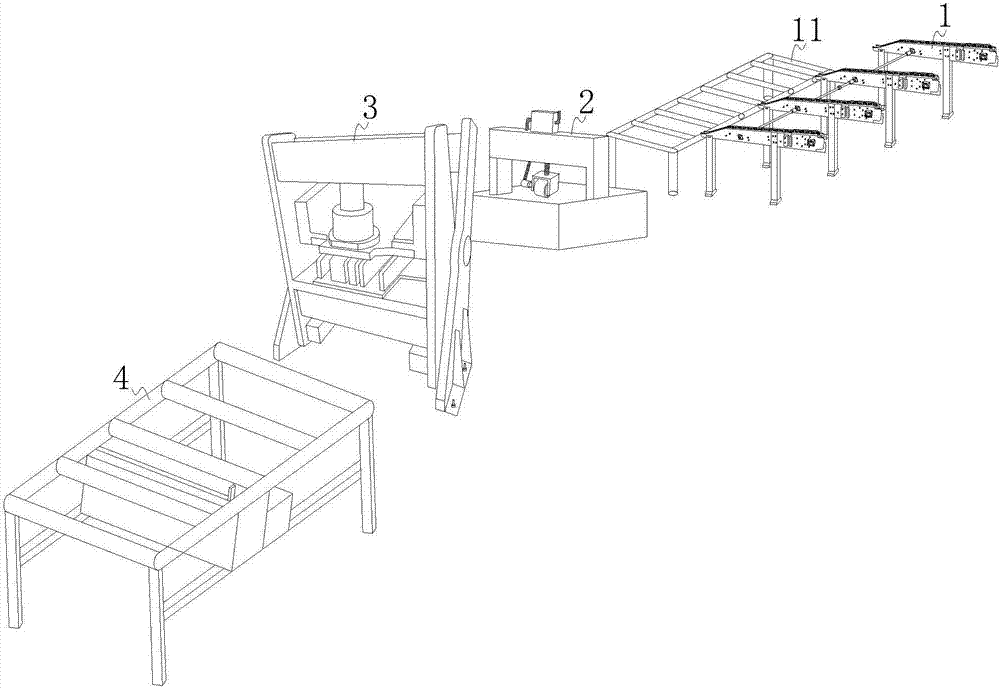

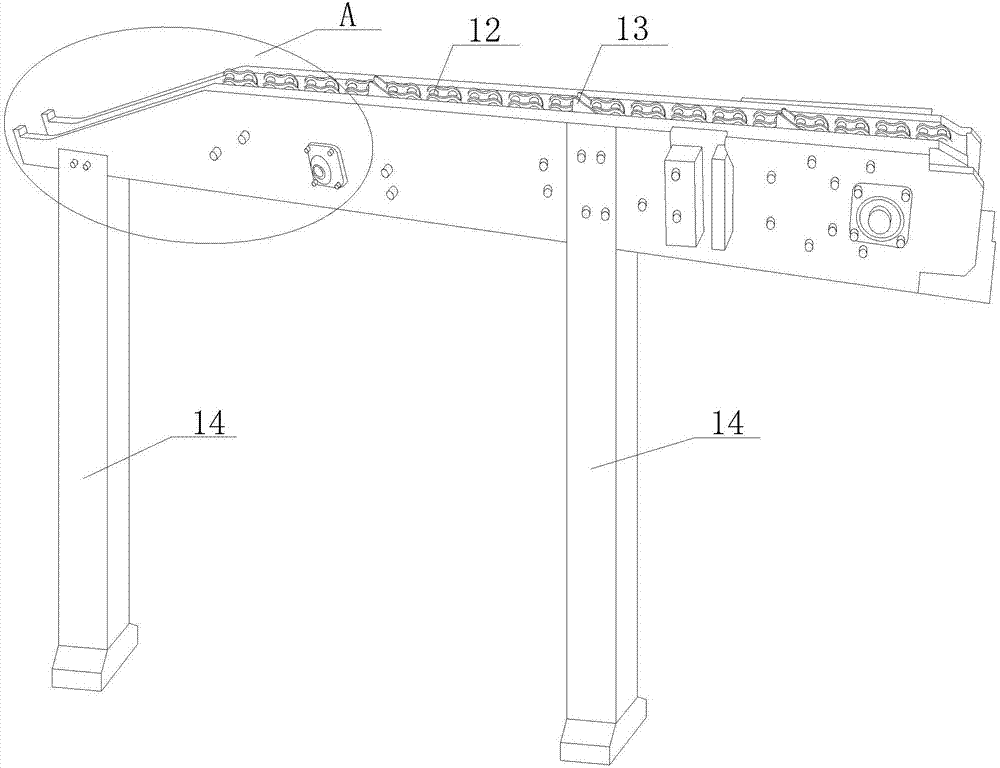

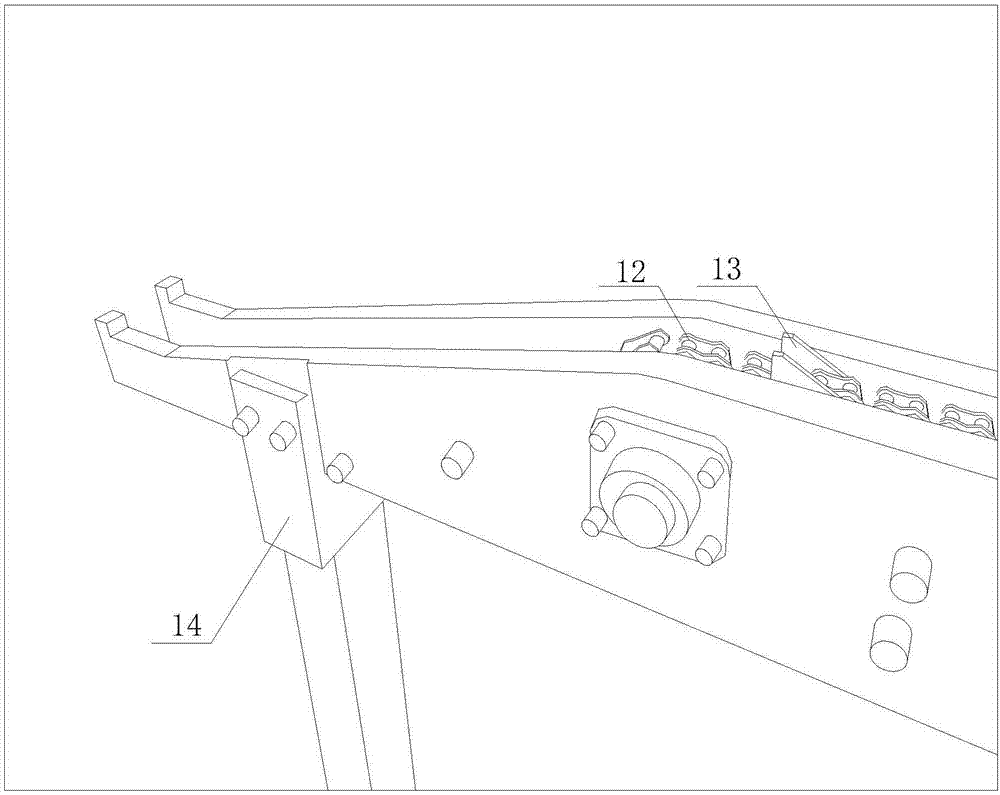

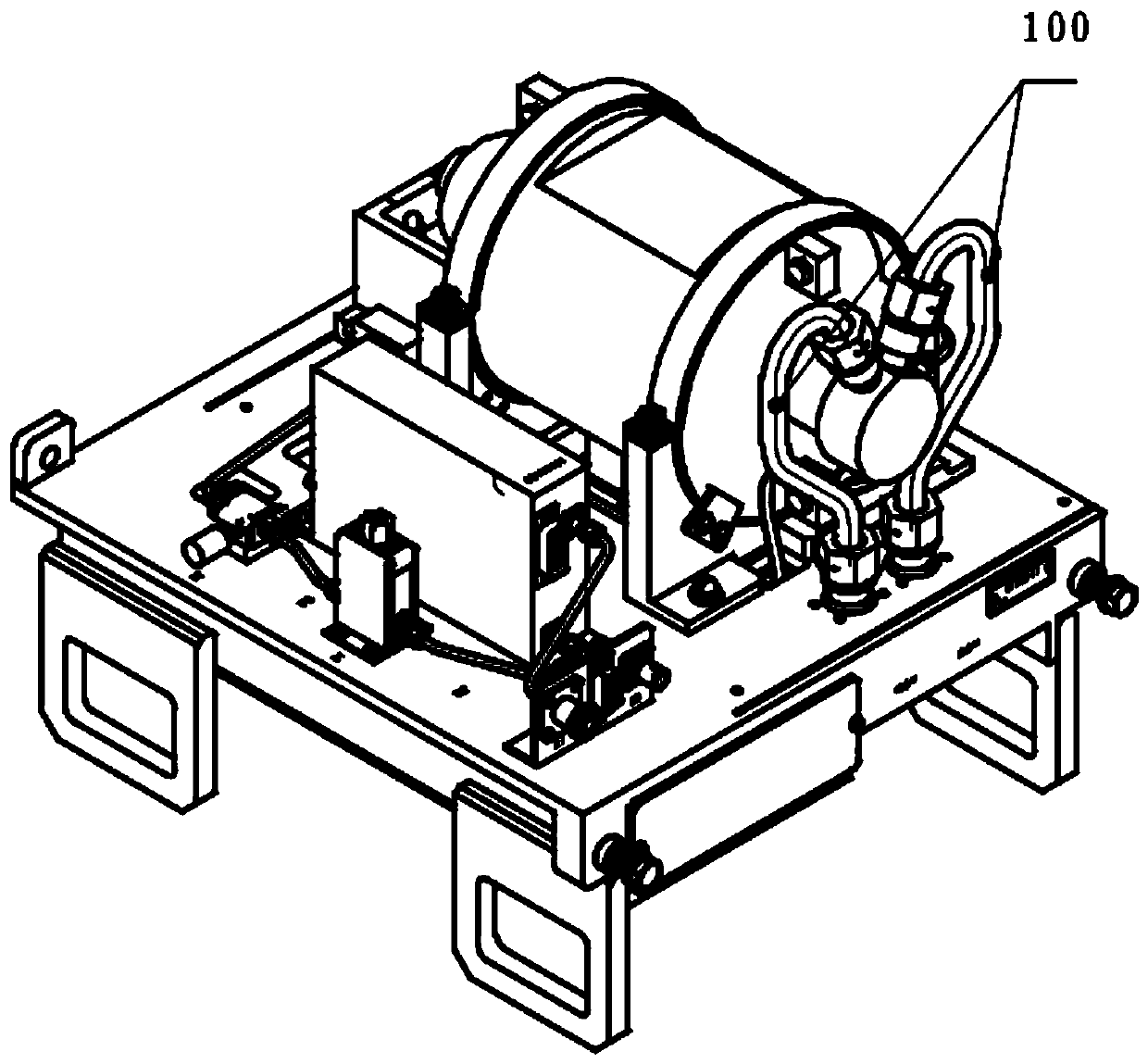

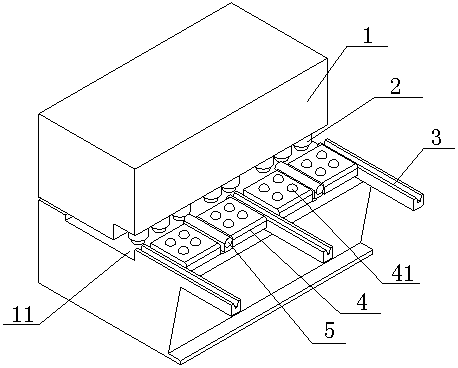

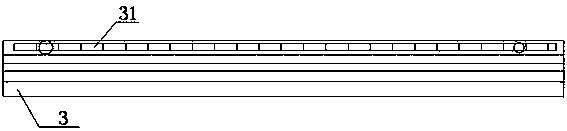

Panel bending automatic production line

ActiveCN104722610AFolding board is convenient and quickCompact structureMetal-working feeding devicesPositioning devicesProduction lineHydraulic cylinder

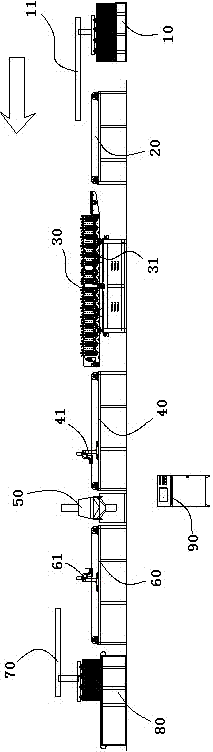

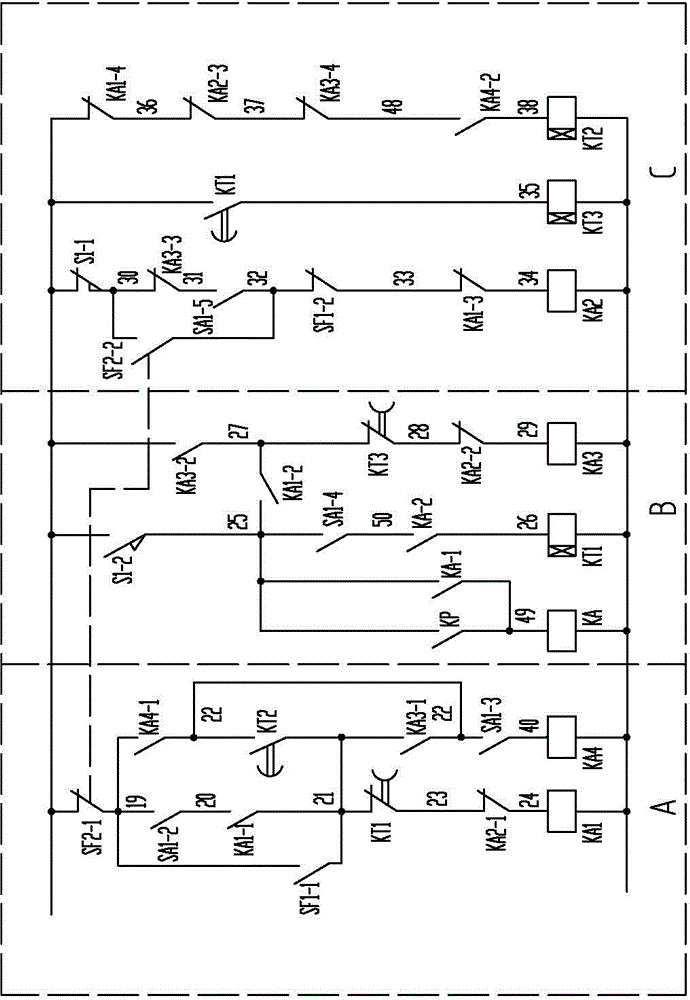

The invention discloses a panel bending automatic production line. The panel bending automatic production line comprises a feeding lifting table, a belt conveying platform, a cold bending molding machine, a first transition feeding table, a hydraulic panel bending machine, a second transition feeding table, a stacking mechanical arm, an output line and a control system which are sequentially arranged, wherein the control system is electrically connected the above mechanisms. The feeding lifting table is composed of four hydraulic cylinders, the first transition feeding table and the second transition feeding table are each composed of a conveying belt and a sensing positioning device, the stacking mechanical arm is composed of a sucker and a rotary arm, and the hydraulic panel bending machine is composed of a rack, a bending device, a panel pressing device and a hydraulic driving unit. By means of the panel bending automatic production line, panels in variable specifications and different modes can be bent so as to form a full-automatic production line, and can be bent in the modes such as a U type, a C type, a U type with turning edges and a C type with turning edges, mechanical automatic feeding and discharging devices and the accurate stacking device are arranged on the production line, and the aims of bending the panels in variable specifications and different modes and forming the full-automatic production line are achieved.

Owner:FOSHAN CITY NANHAI POPULA FAN

Slide block control system of hydraulic machine

ActiveCN103552276AChange directionPlay a role in buffering and stabilizingPressesGear pumpControl system

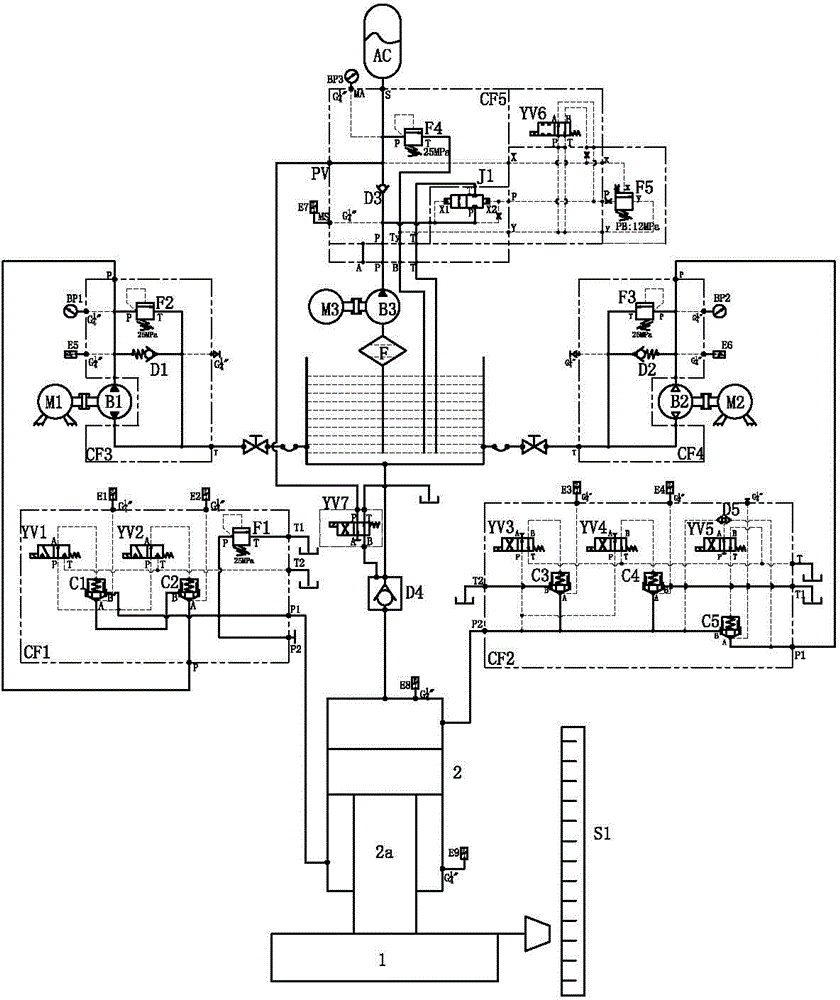

The invention relates to a slide block control system of a hydraulic machine. The slide block control system comprises a lower cavity safety module, an upper cavity safety module, a lower cavity pump source module, an upper cavity pump source module and a liquid filling valve constant pressure oil supply module, wherein an inlet of a medium-low flow rate pump of the liquid filling valve constant pressure oil supply module is communicated with an oil tank, an outlet of the medium-low flow rate pump is connected with an inlet of a third one-way valve, an outlet of the third one-way valve is connected with an energy accumulator, the bottom of the oil tank is downwards communicated with an upper cavity of a main cylinder through a liquid filling valve, a liquid control opening of the liquid filling valve is connected with an outlet of the third one-way valve through an electromagnetic reversing valve, an inlet of an upper cavity gear pump is connected with the bottom of the oil tank, an outlet of the upper cavity gear pump is connected with an upper cavity oil pipe of the main cylinder through the upper cavity safety module, an inlet of a lower cavity gear pump is connected with the bottom of the oil tank, and an outlet of the lower cavity gear pump is connected with a lower cavity oil pipe of the main cylinder through the lower cavity safety module. The gear pump can realize the flow direction change, the flow rate can be obtained through the calculation via the discharge capacity of the lower cavity gear pump and the rotating speed of a servo motor, the slide block fast descending or return speed can be accurately calculated, the motor does not rotate in the idling state, the noise is low, and the energy is saved.

Owner:江苏扬力液压装备有限公司

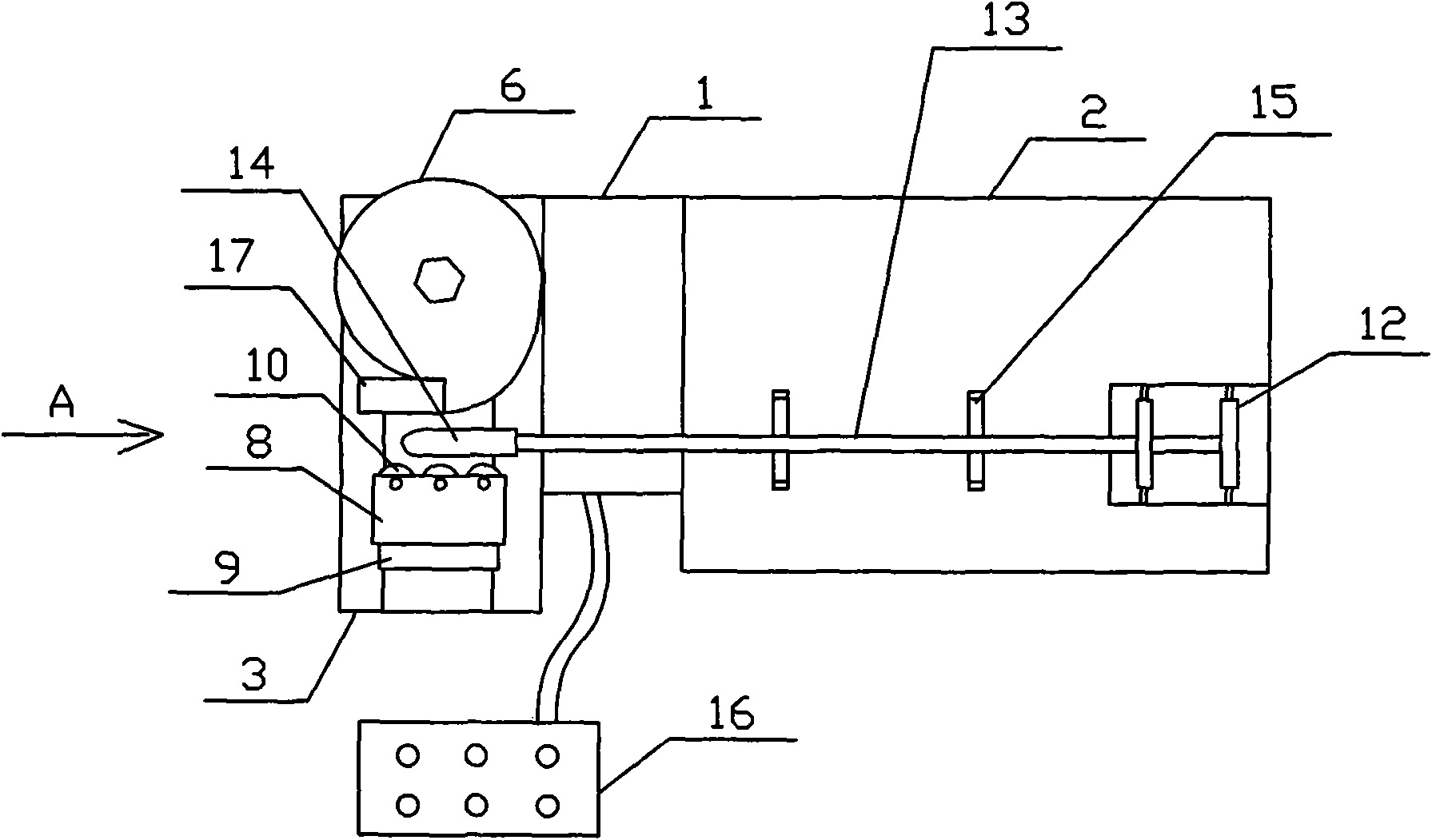

Processing method for cold bending pipes by medium frequency heating

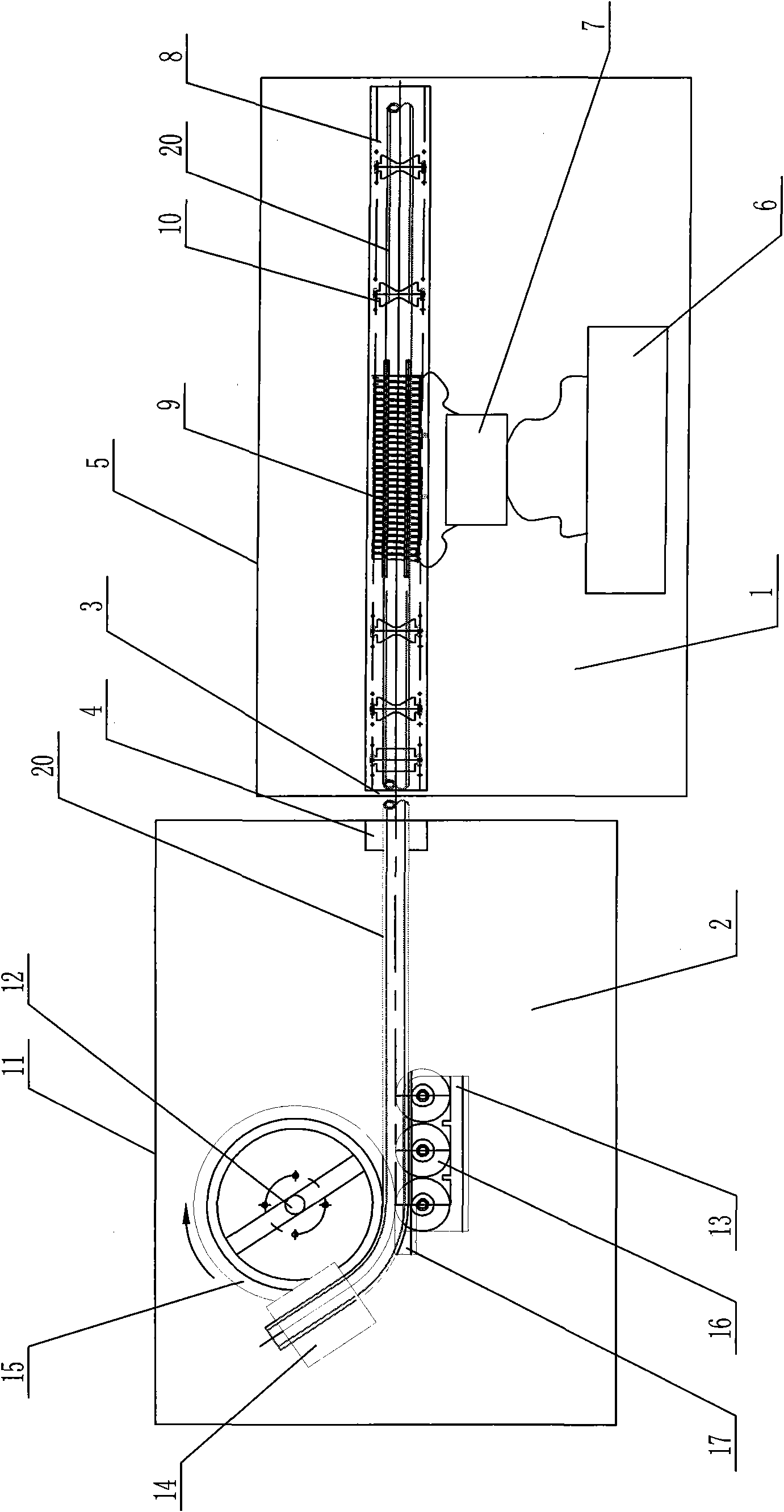

ActiveCN101623724AHeating evenlyHeating environmental protectionCoil arrangementsMetal-working feeding devicesMedium frequencyEngineering

The invention discloses a processing method for cold bending pipes by medium frequency heating, comprising the following steps: firstly, heating the part, which is required to be bent, of a pipeline to certain temperature by adopting the medium frequency heating mode, and then bending the pipeline. The method has the advantages that the design is reasonable, the heating effect is good, the work efficiency is high, the pipeline bending quality is good and the labor intensity of workers is reduced, and the method can provide good productivity benefits for the enterprises.

Owner:HENAN HUADIAN JINYUAN PIPING

Bending device with bending degree being adjusted conveniently and for production of electronic product

Owner:ZHENGZHOU TIANSHUN ELECTRONICS TECH CO LTD

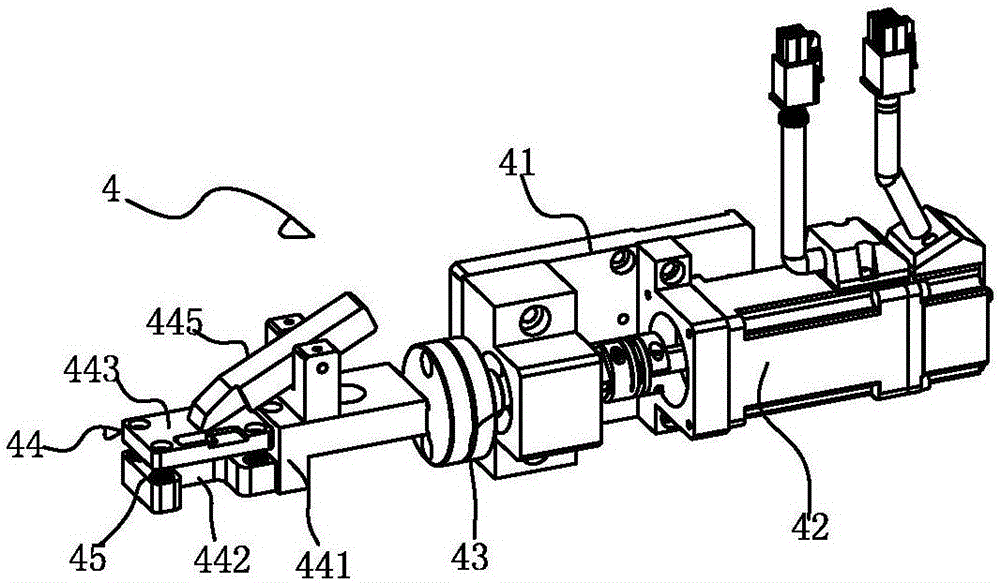

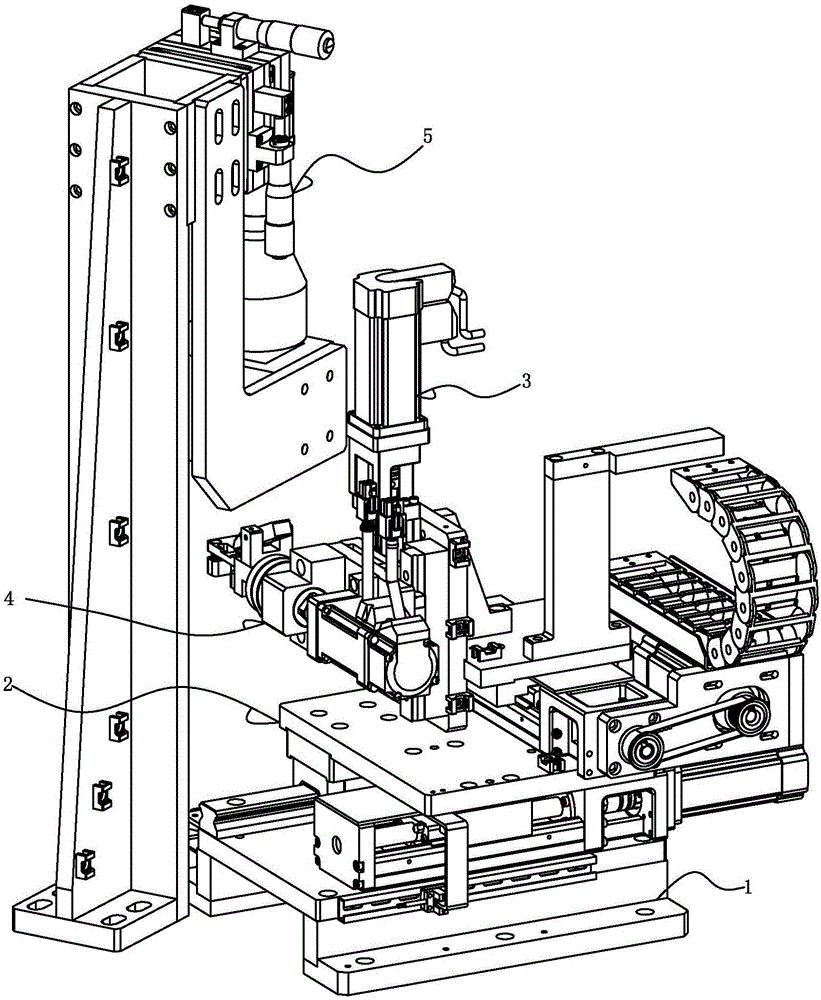

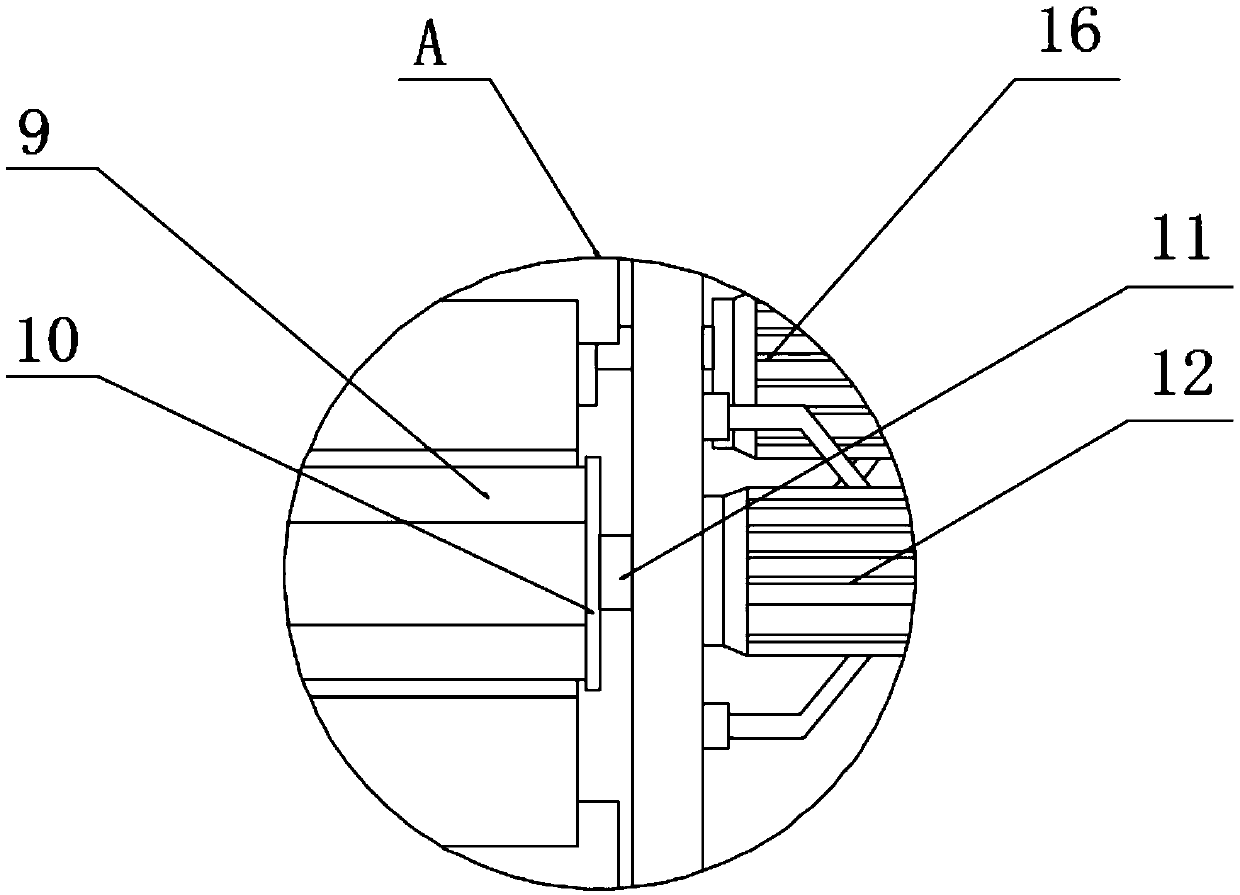

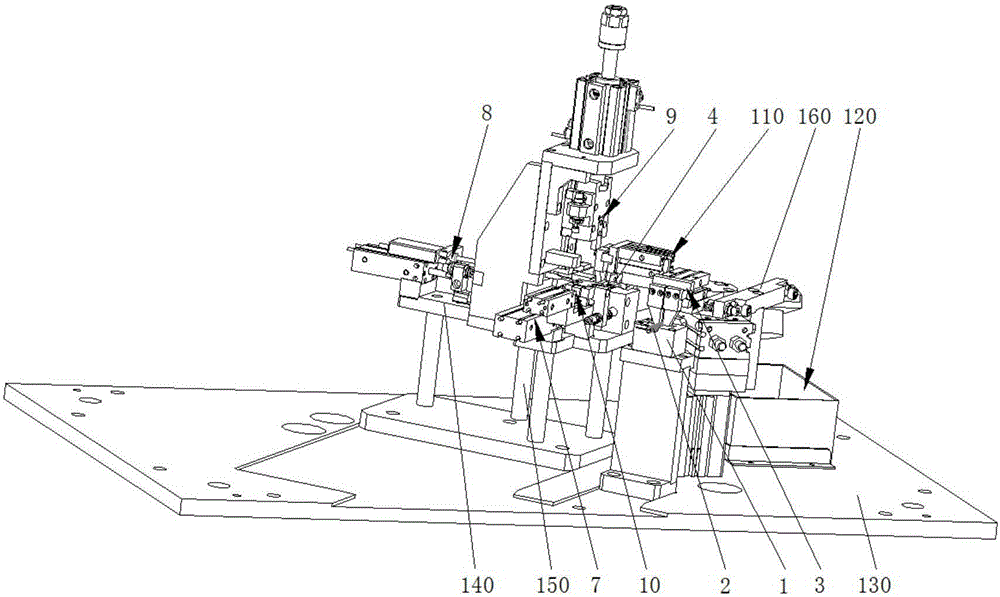

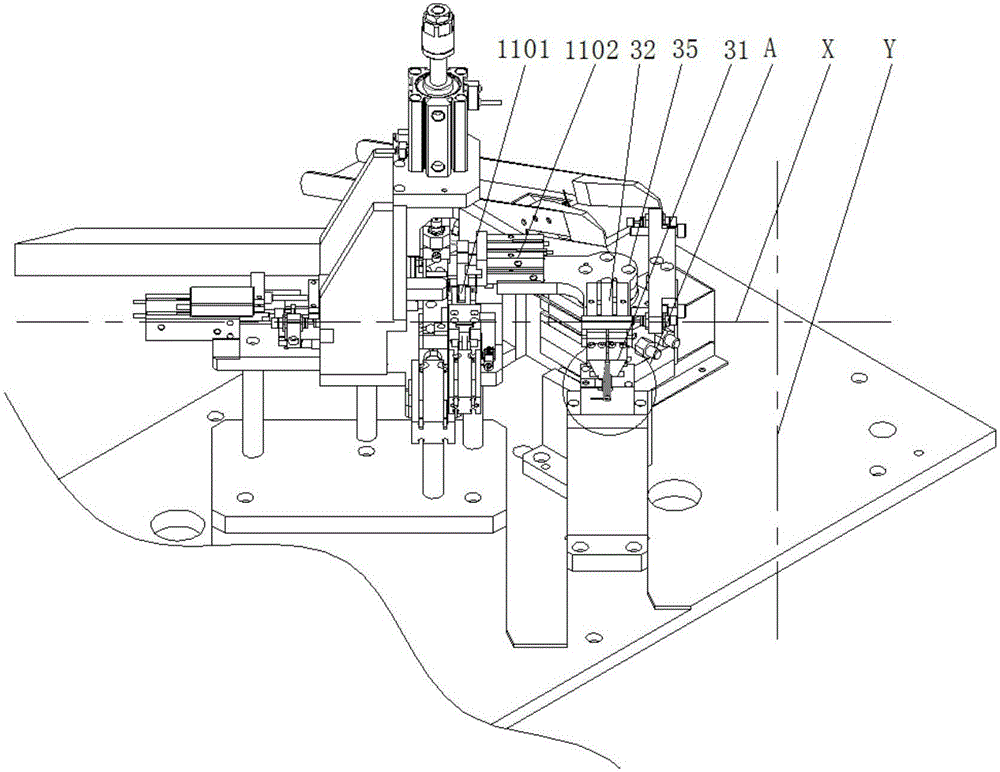

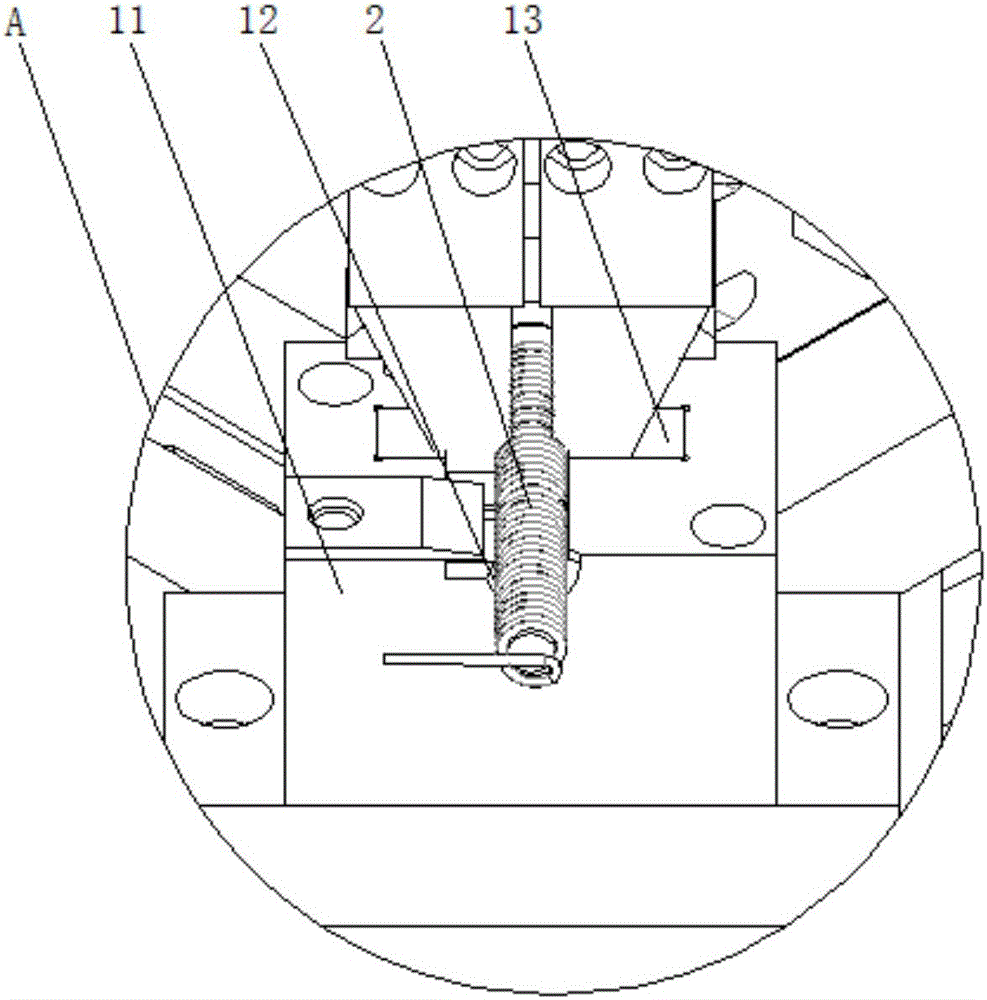

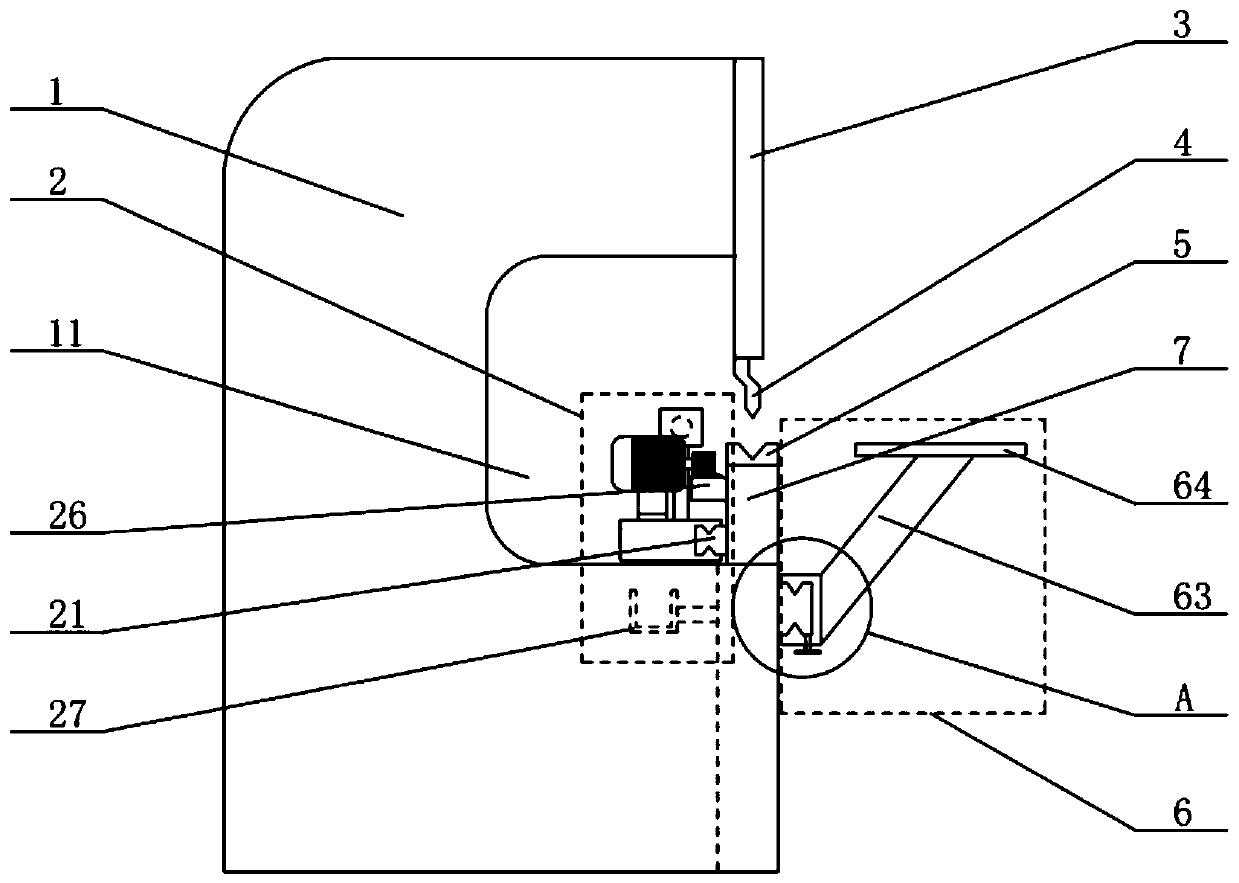

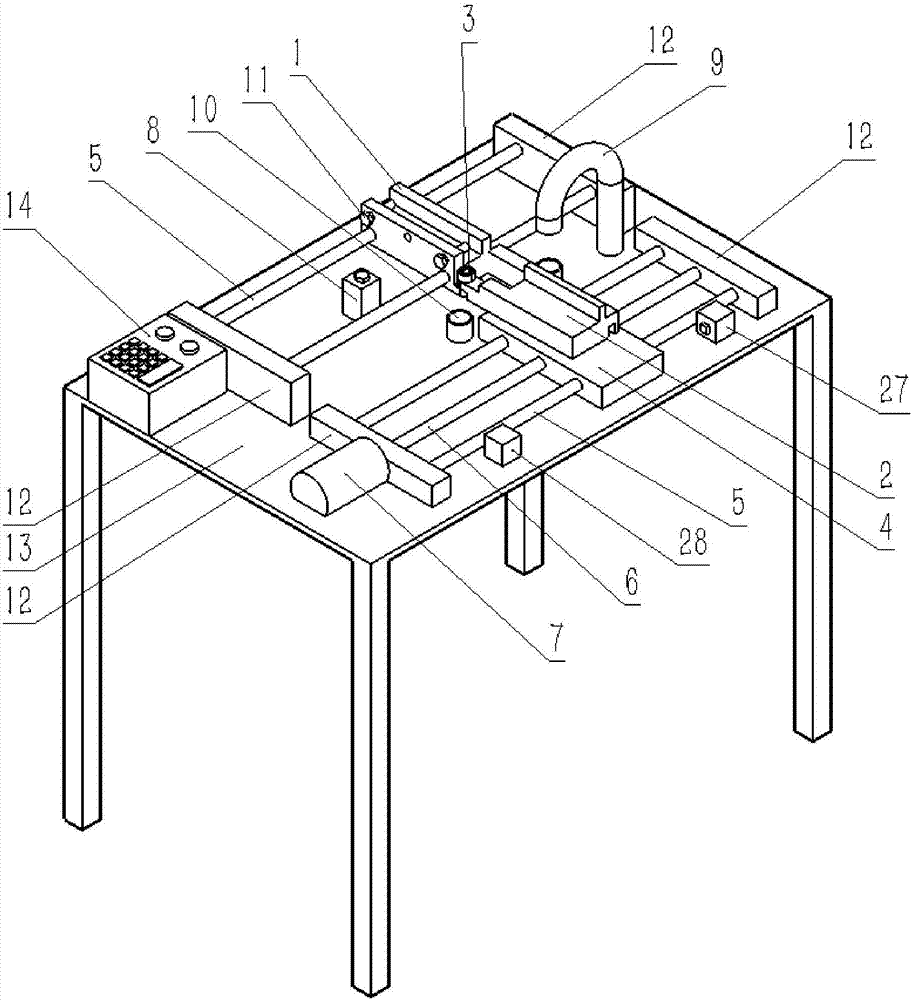

Visual automatic bending alignment mechanism

ActiveCN106455332AGuaranteed accuracyGuaranteed bending qualityPrinted circuit manufactureReducerDrive motor

The invention discloses a visual automatic bending alignment mechanism which comprises a base, an XY mobile platform mechanism mounted at the upper end of the base, a clamping bending mechanism mounted on the XY mobile platform mechanism through a Z-axis drive mechanism and a visual alignment mechanism mounted beside the base, wherein the visual alignment mechanism cooperates with the XY mobile platform mechanism to perform automatic shift compensation for the clamping bending mechanism; and the clamping bending mechanism comprises a mounting seat mounted on the Z-axis drive mechanism, a drive motor mounted on the mounting seat, a speed reducer and a bending chuck detachably assembled with the speed reducer. In the invention, the visual alignment mechanism photographs the state of the bending chuck after selecting a bending flexible printed circuit board to capture the features, and calculates the position; and then, the XY mobile platform mechanism performs automatic shift compensation for the clamping bending mechanism according to the data obtained by the visual alignment mechanism, so that the accuracy of bending alignment can be guaranteed, the bending quality is guaranteed, and the market competitiveness is remarkably high.

Owner:东莞东聚电子电讯制品有限公司

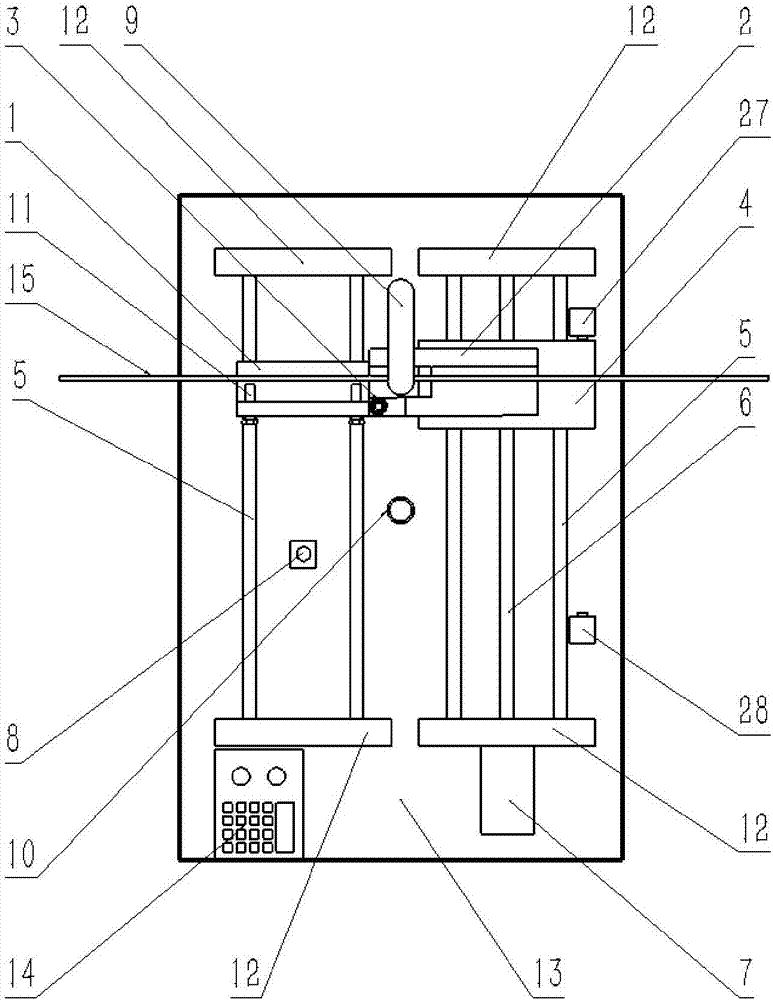

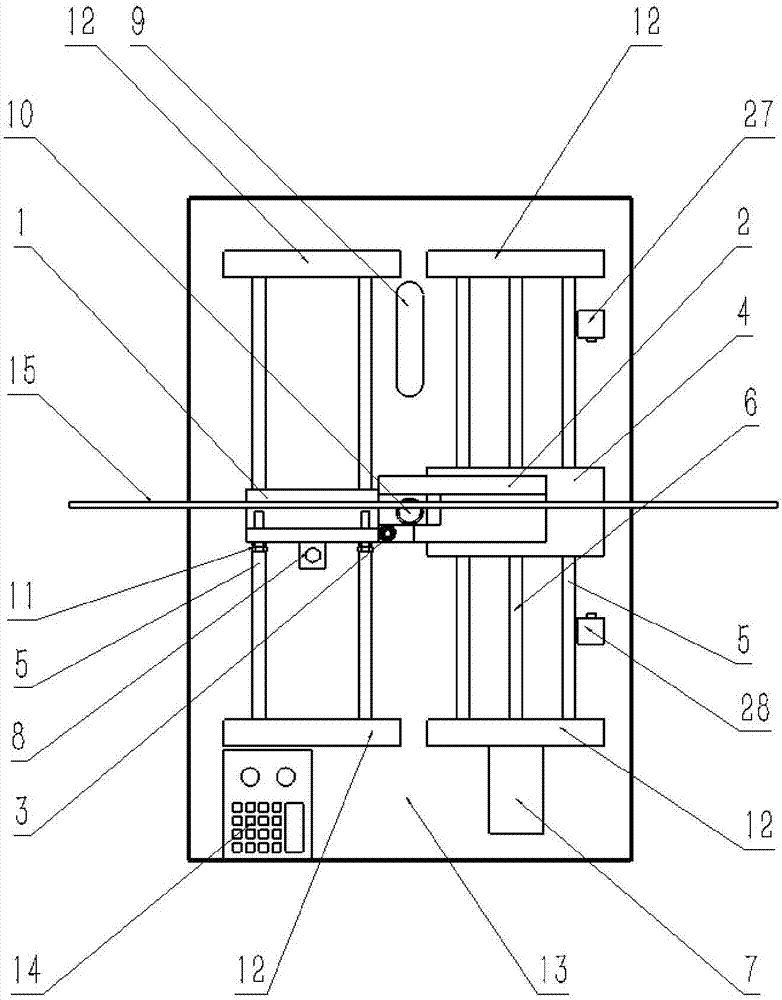

Plate bending machine and method

PendingCN109079006AGuaranteed bending qualityImprove bending accuracyShaping toolsMetal-working feeding devicesAgricultural engineeringPress brake

The invention discloses a plate bending machine and method. The plate bending machine comprises a case, a bending device is arranged in the case, the bending device comprises an upper fixing block, the upper fixing block is fixedly connected with the case, a lower fixing block is arranged at the bottom of the upper fixing block, a first hydraulic rod is arranged at the bottom of the lower fixing block, an output shaft of the first hydraulic rod is fixedly connected with the lower fixing block, a heater is arranged on the surface of each of the upper fixing block and the lower fixing block, a bending block is arranged on one side of the upper fixing block and the lower fixing block, a second hydraulic rod is arranged at one end of the bending block, and an output shaft of the second hydraulic rod is fixedly connected with the bending block. The bending device is provided, the heaters heat the plate to ensure the plate at a high temperature, the bending block is driven by the second hydraulic rod to bend the plate up or down as needed to ensure the bending quality of a right angle, and the bending block is also driven by the second hydraulic rod to fix the plate.

Owner:大连绿云科技有限公司

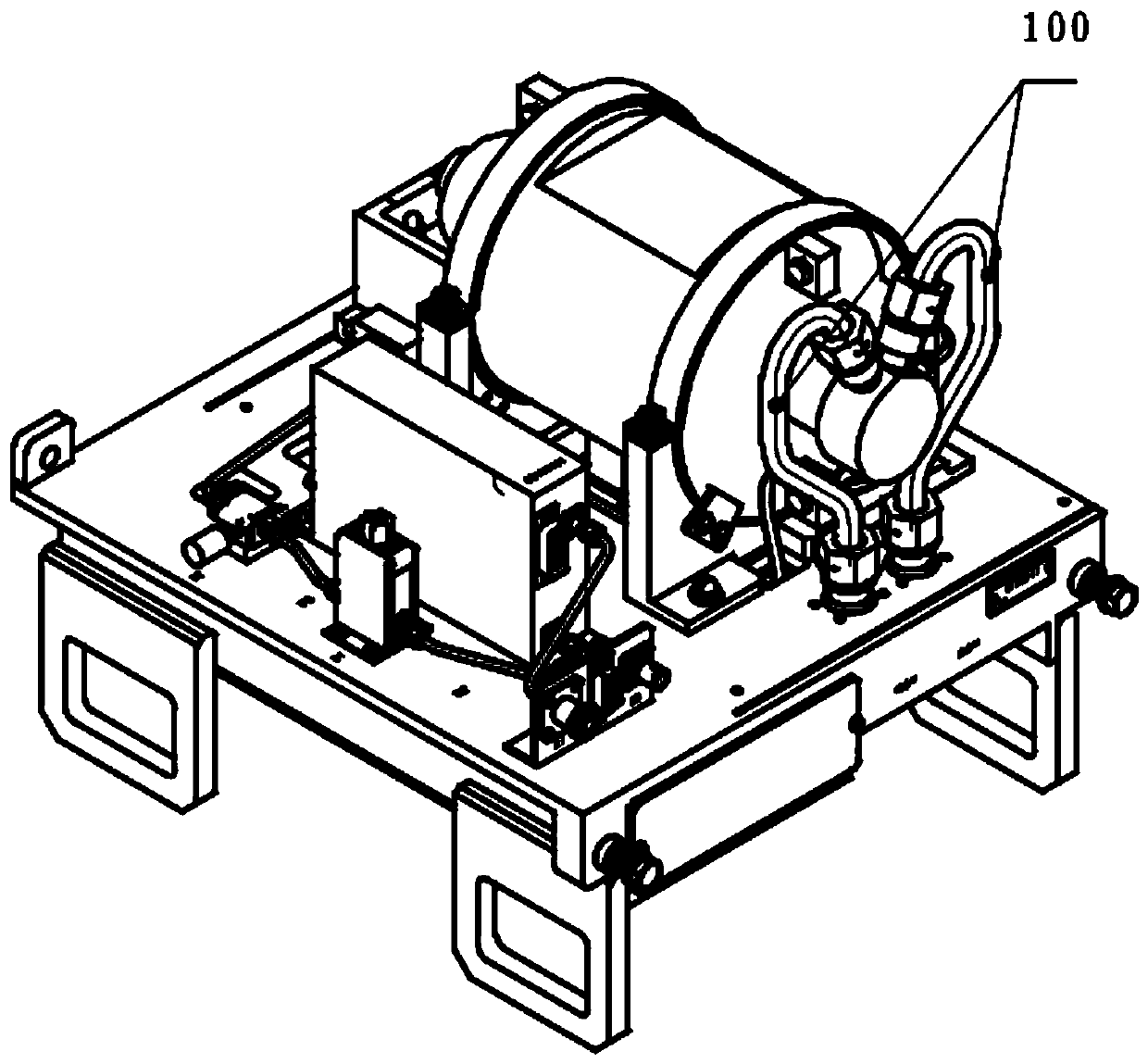

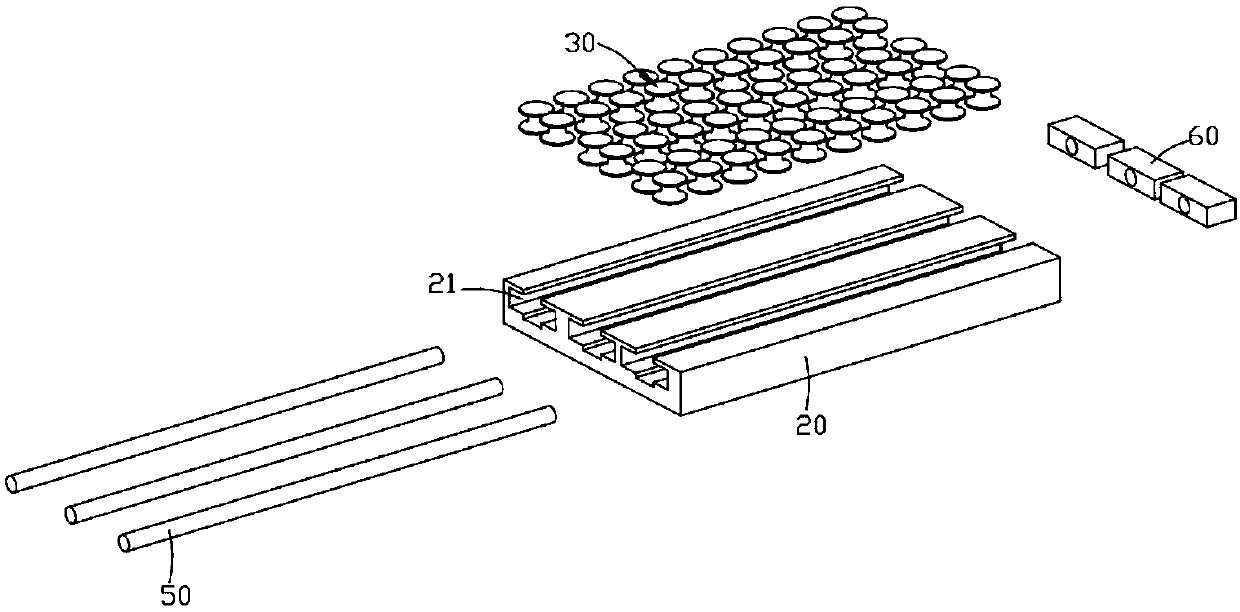

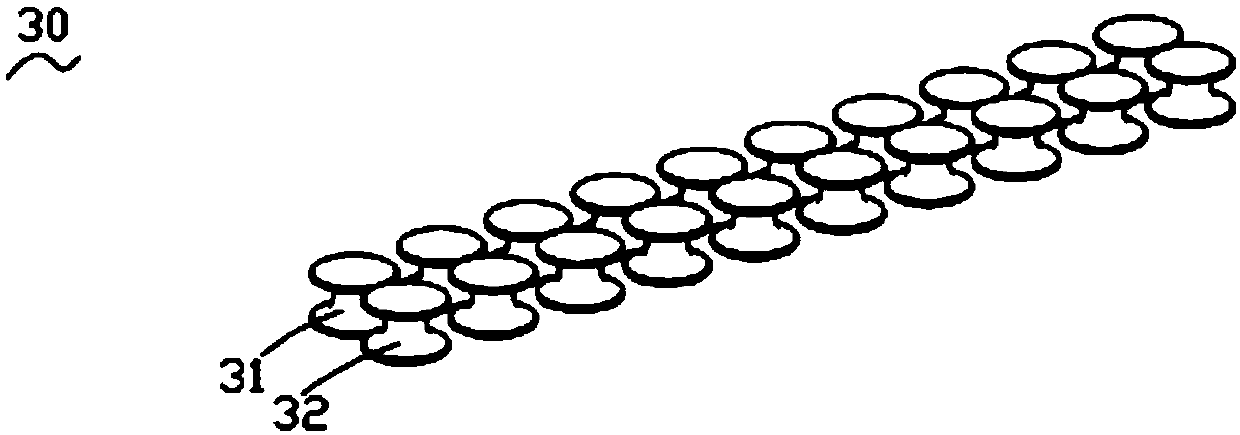

Inductive coil automatic assembling and bending device and method

The invention discloses an inductive coil automatic assembling and bending device and method. The inductive coil automatic assembling and bending device comprises a first coil positioning block used for placement of a coil; a coil moving mechanism used for moving the coil on the first coil positioning block to a second coil positioning block; a magnetic core conveying line used for providing a magnetic core; a dislocating mechanism used for containing the magnetic core conveyed by the magnetic core conveying line and enabling the magnetic core to be aligned to or staggered with the coil; a magnetic core conveying mechanism used for pushing the magnetic core into the coil when the magnetic core on the dislocating mechanism is aligned to the coil on the second coil positioning block; a coil bending mechanism used for down-pressing a wire at the opening end of the coil on the dislocating mechanism and enabling the bending part to block the opening end; a coil pressing mechanism used for limiting the coil to the second coil positioning block; and a discharging mechanism used for moving the electromagnetic coil finished processing on the second coil positioning block into a product region. The inductive coil automatic assembling and bending device avoids the problem of unstable fixation of the coil and the magnetic core caused by gluing, is high in degree of automation and greatly increases the processing efficiency.

Owner:新井田智能装备(江苏)有限公司

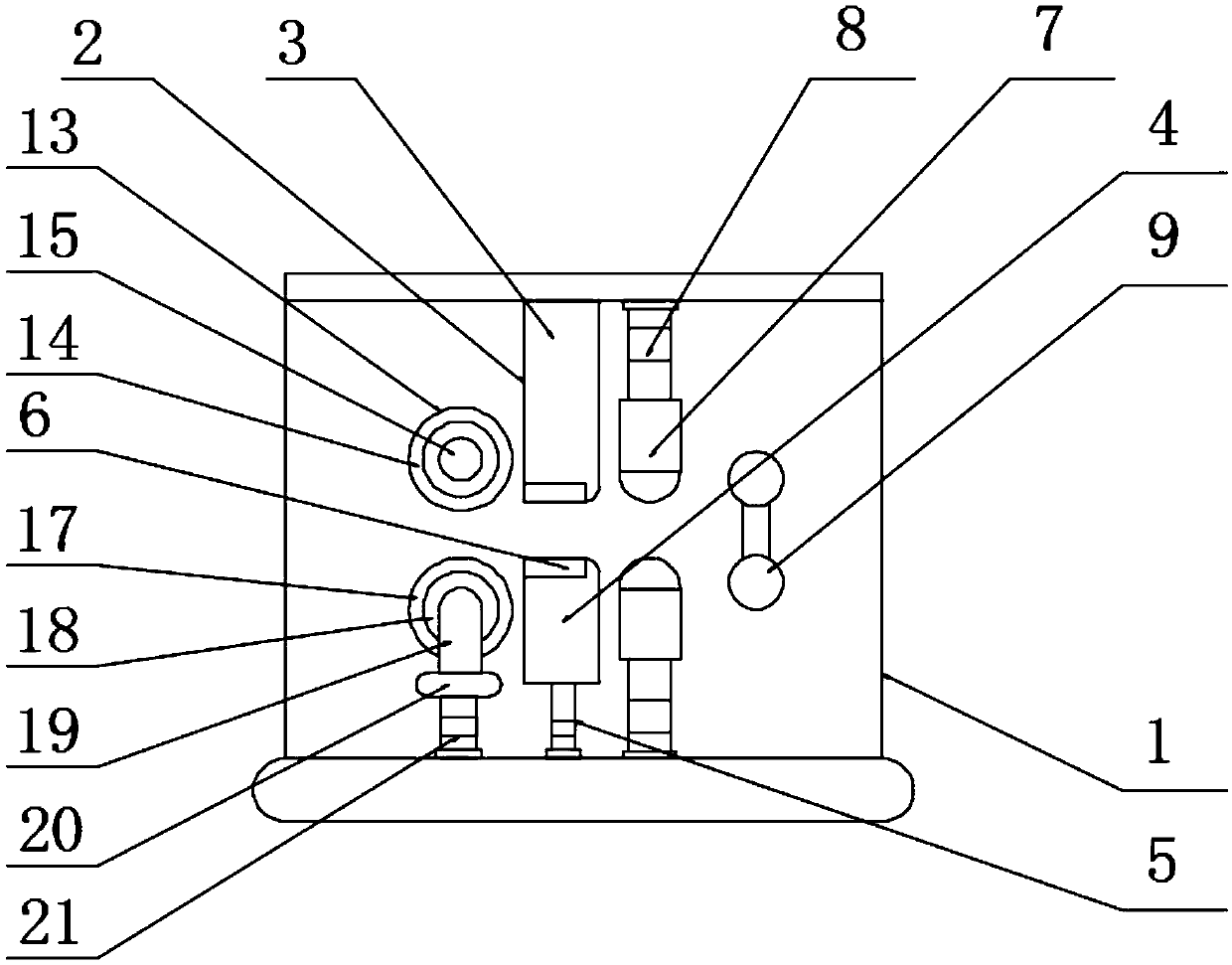

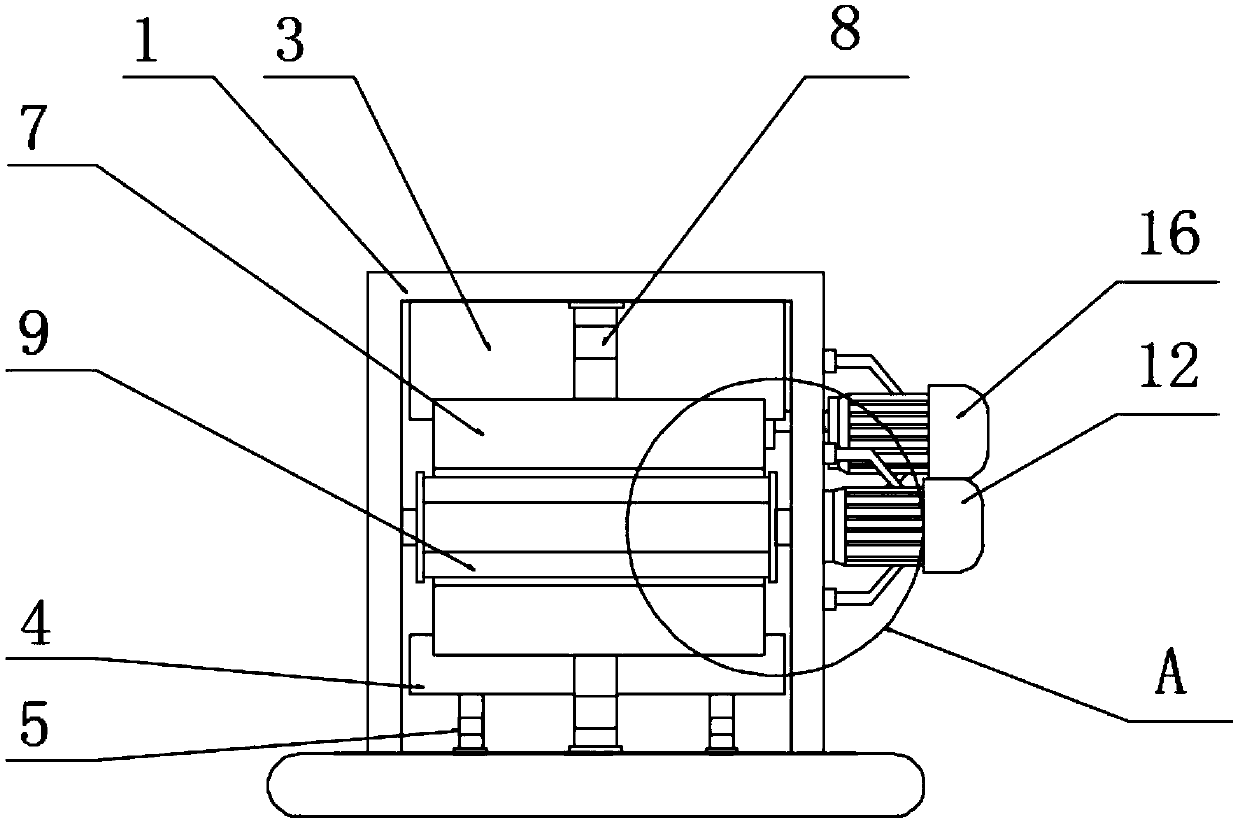

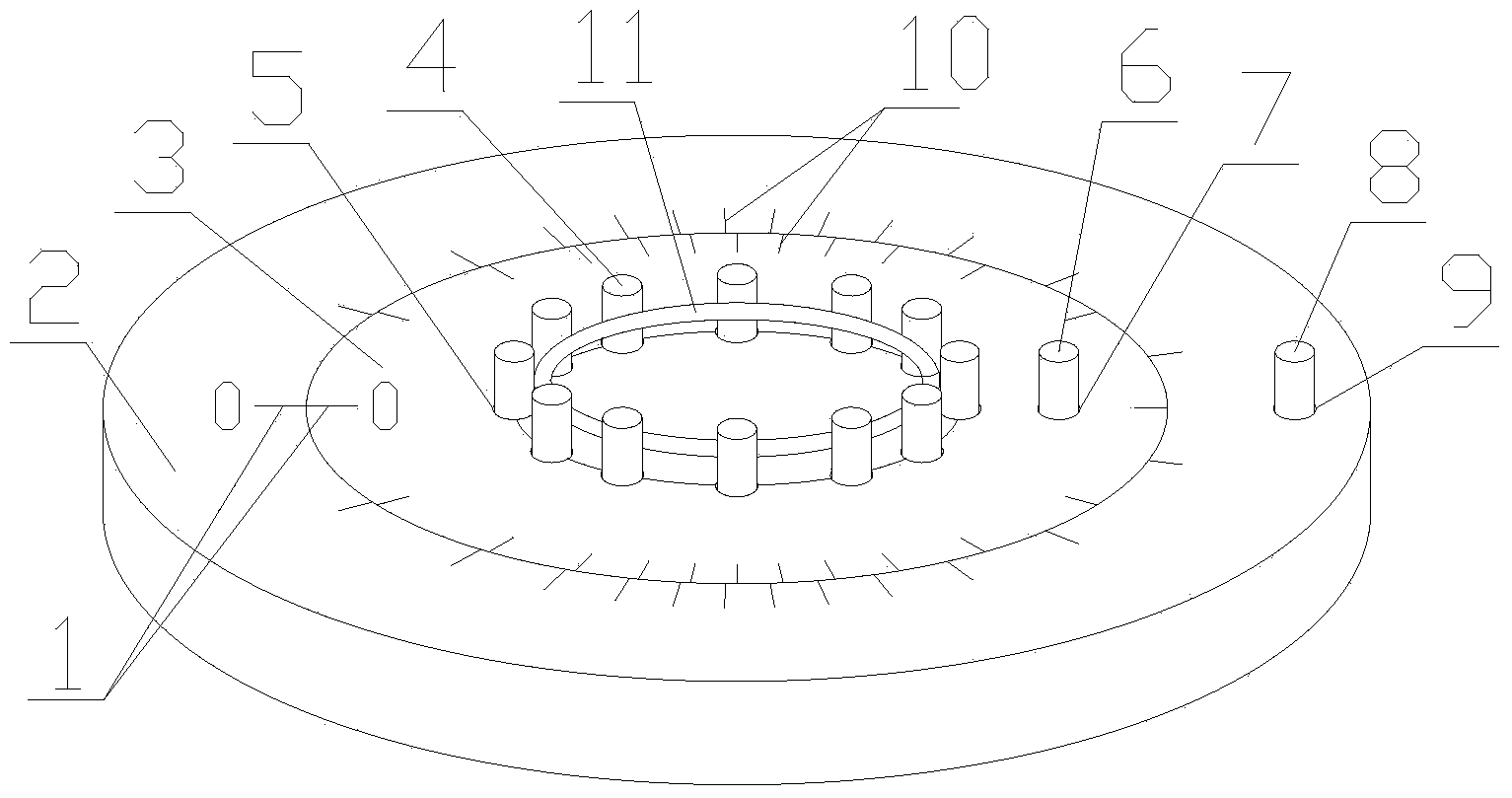

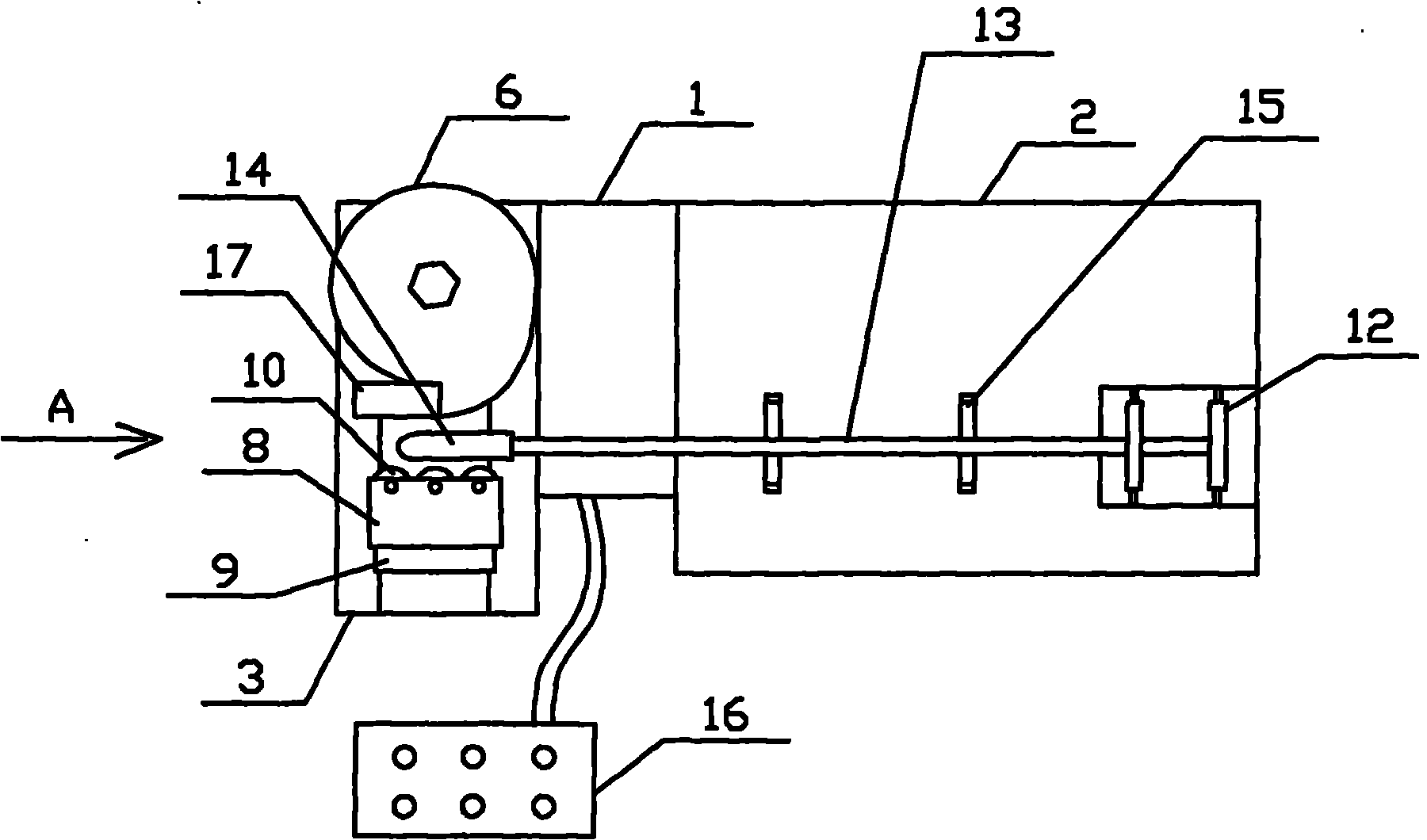

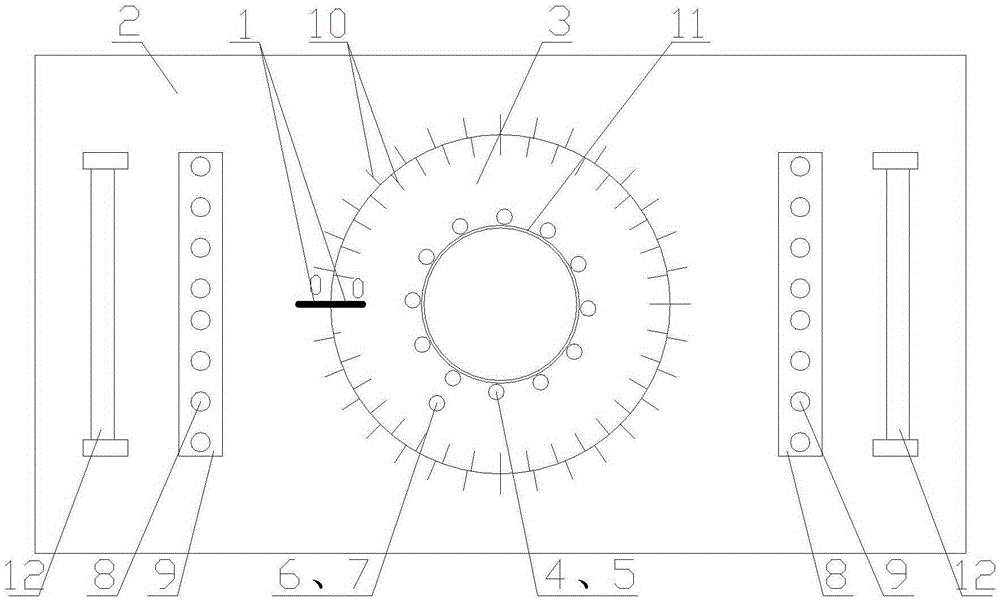

Semiautomatic steel bar bender

InactiveCN104226857AIncrease the scope of applicationReasonable size and location designRebarMachine tool

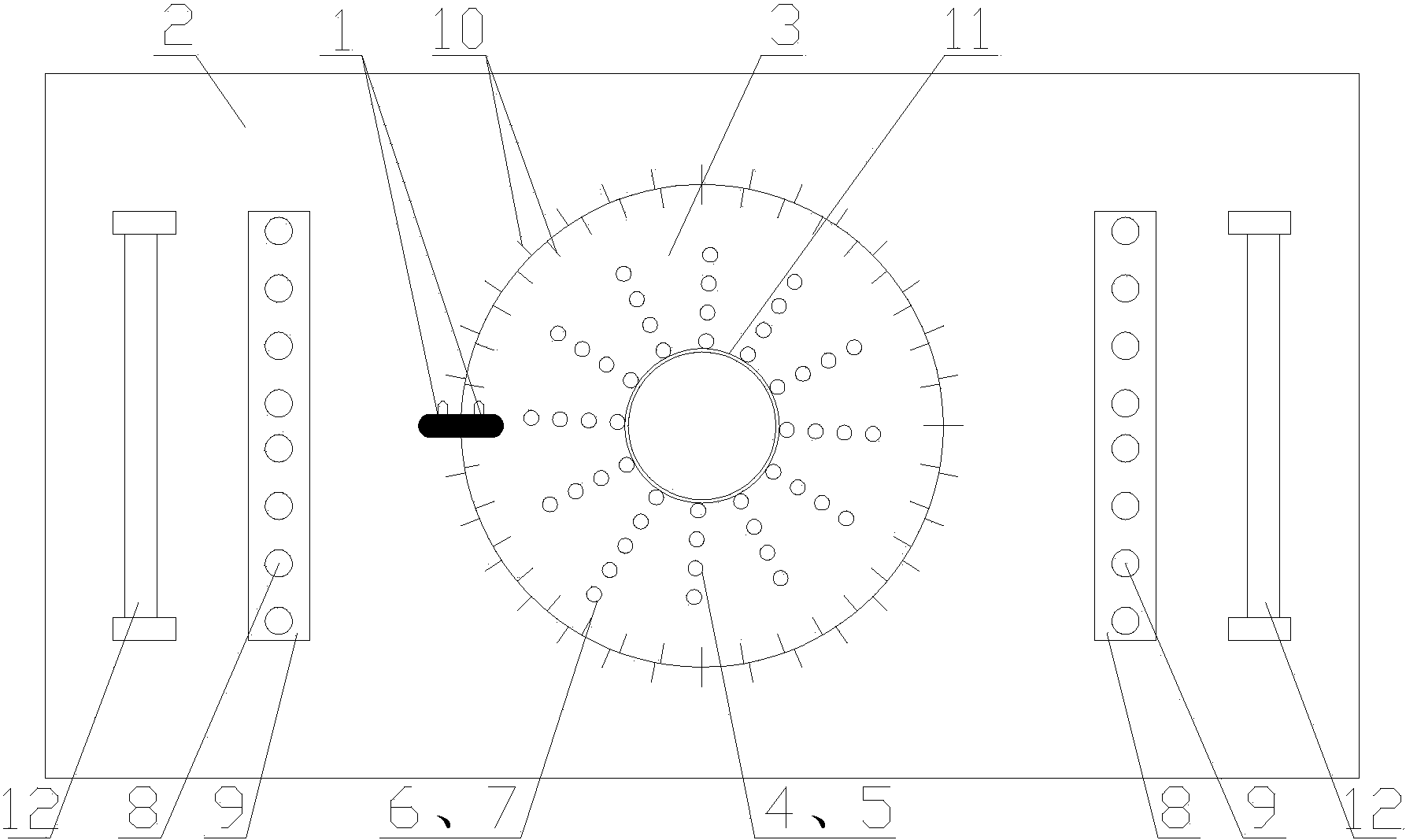

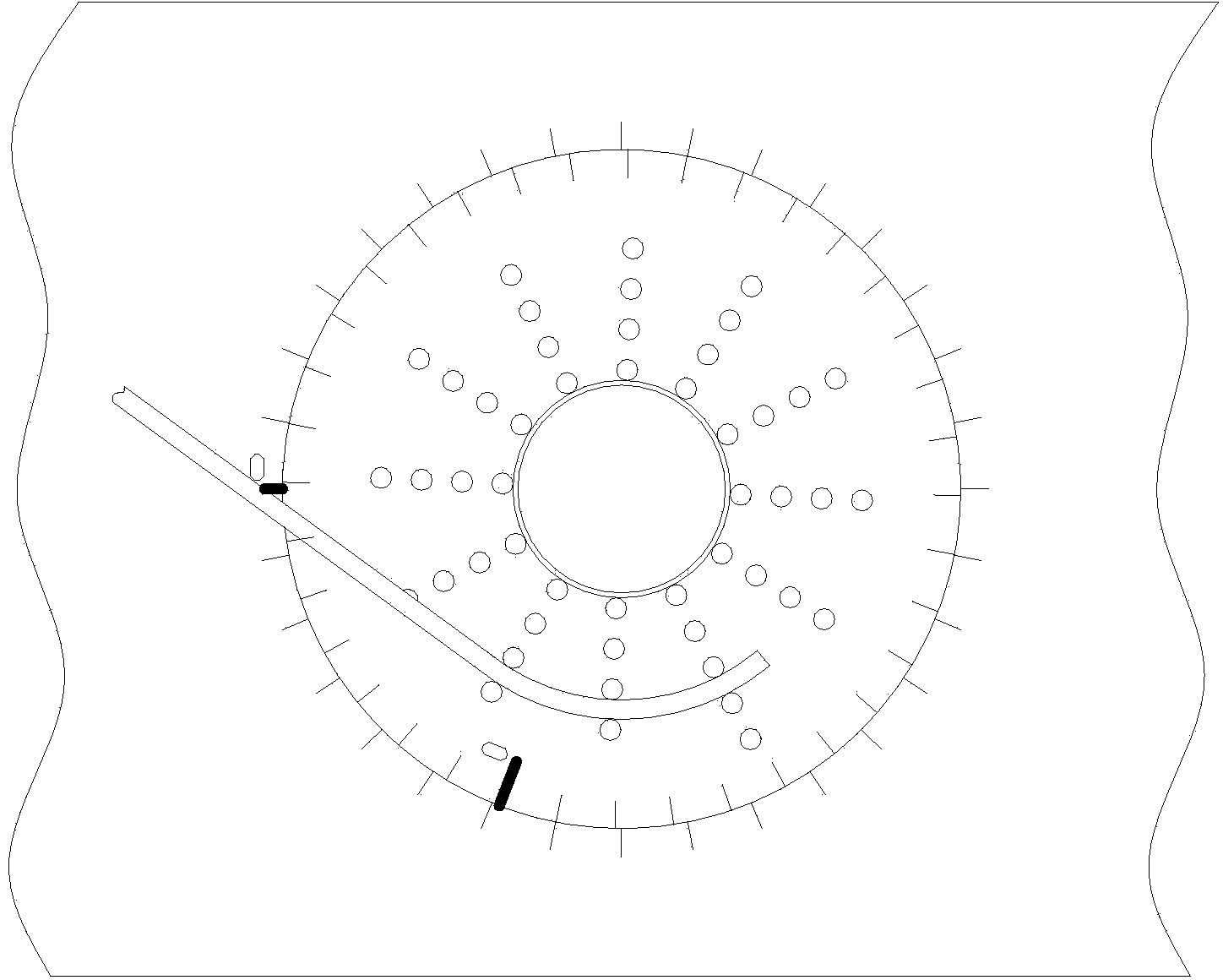

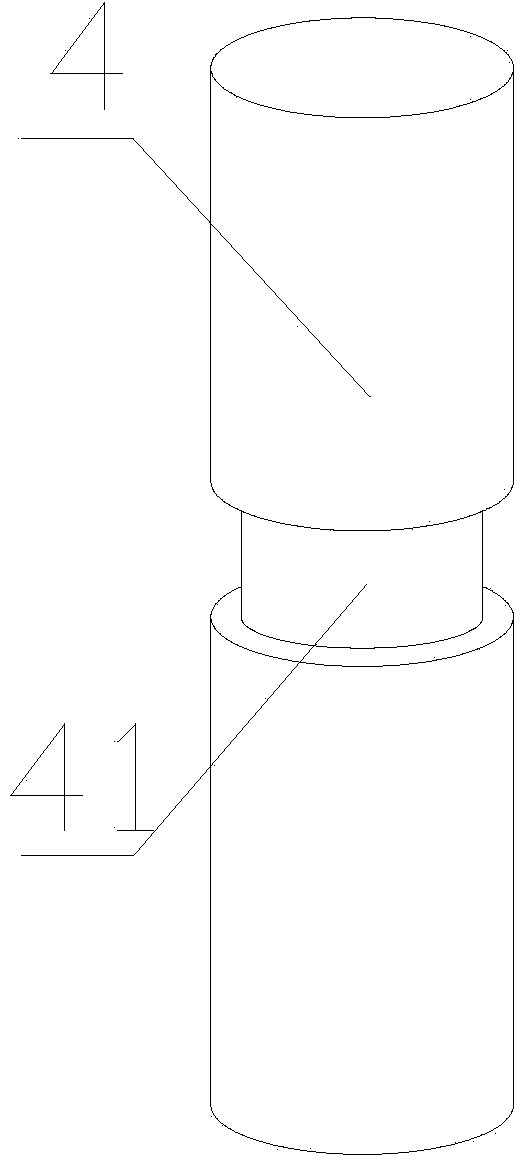

The invention discloses a semiautomatic steel bar bender, which relates to the technical field of steel bar-bending equipment. The invention aims to provide the semiautomatic steel bar bender which can deal with steel bars with different bending radii. The technical scheme of the invention is as follows: the semiautomatic steel bar bender comprises a machine bed, a working plate which is connected with the machine bed is arranged on the top of the machine bed, a rotary disk is arranged at the center of the working plate, the rotary disk is connected with a power mechanism in the machine bed and can rotate around the axis of the rotary disk, a plurality of positioning shaft holes and clamping shaft holes are evenly distributed along the circumferential direction of the rotary disk on the rotary disk, the positioning shaft holes form a plurality of concentric circles on the rotary disk, positioning shafts and clamping shafts are respectively correspondingly placed in the positioning shaft holes and the clamping shaft holes, backing pin blocks and rollers are arranged on both sides of the working plate, and backing pins are arranged on the backing pin blocks. The invention is applicable to steel bar bender.

Owner:FUZHOU COLLEGE OF FOREIGN STUDIES & TRADE

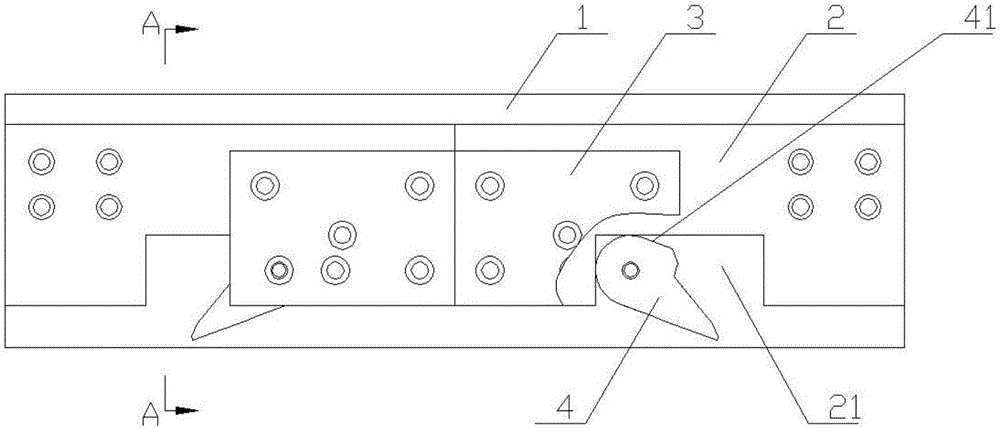

Limiting and fixing device for bending machine

PendingCN110666004AGuaranteed bending qualitySimple structureMetal-working feeding devicesPositioning devicesStructural engineeringMachine

The invention discloses a limiting and fixing device for a bending machine, and relates to the technical field of manufacturing of bending machines. The limiting and fixing device comprises a plate shearing machine main body, a limiting device, a movable plate, an upper mold, a lower mold, a material supporting device, and a working table, wherein a working area is arranged in the middle of the front part of the plate shearing machine main body, the movable plate is arranged the upper part of the front part of the plate shearing machine body, the movable plate is connected with a hydraulic device of the plate shearing machine body, the upper mold is connected under the movable plate, the working table is arranged on one side of the working area, the lower mold is arranged right on the working table, the material supporting device is arranged on the front part of the plate shearing machine main body, and the limiting device is arranged on the inner side of the working table. The limiting and fixing device has the advantages that the structure is simple, a plate can be limited and fixed without manual operation of labor, and the occurrence of safety accidents is avoided while the bending quality of the plate is ensured.

Owner:南通福马重型机床制造有限公司

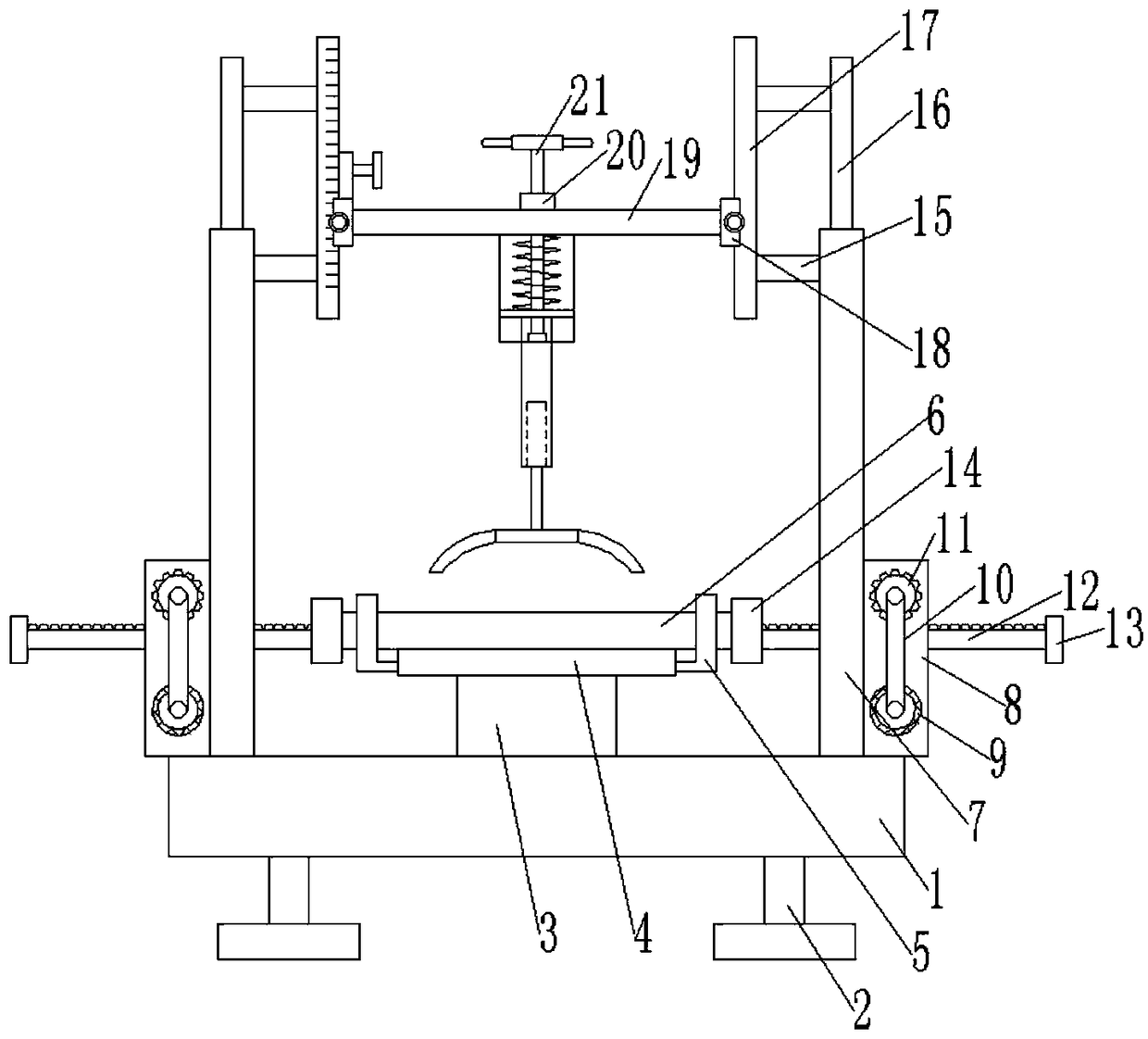

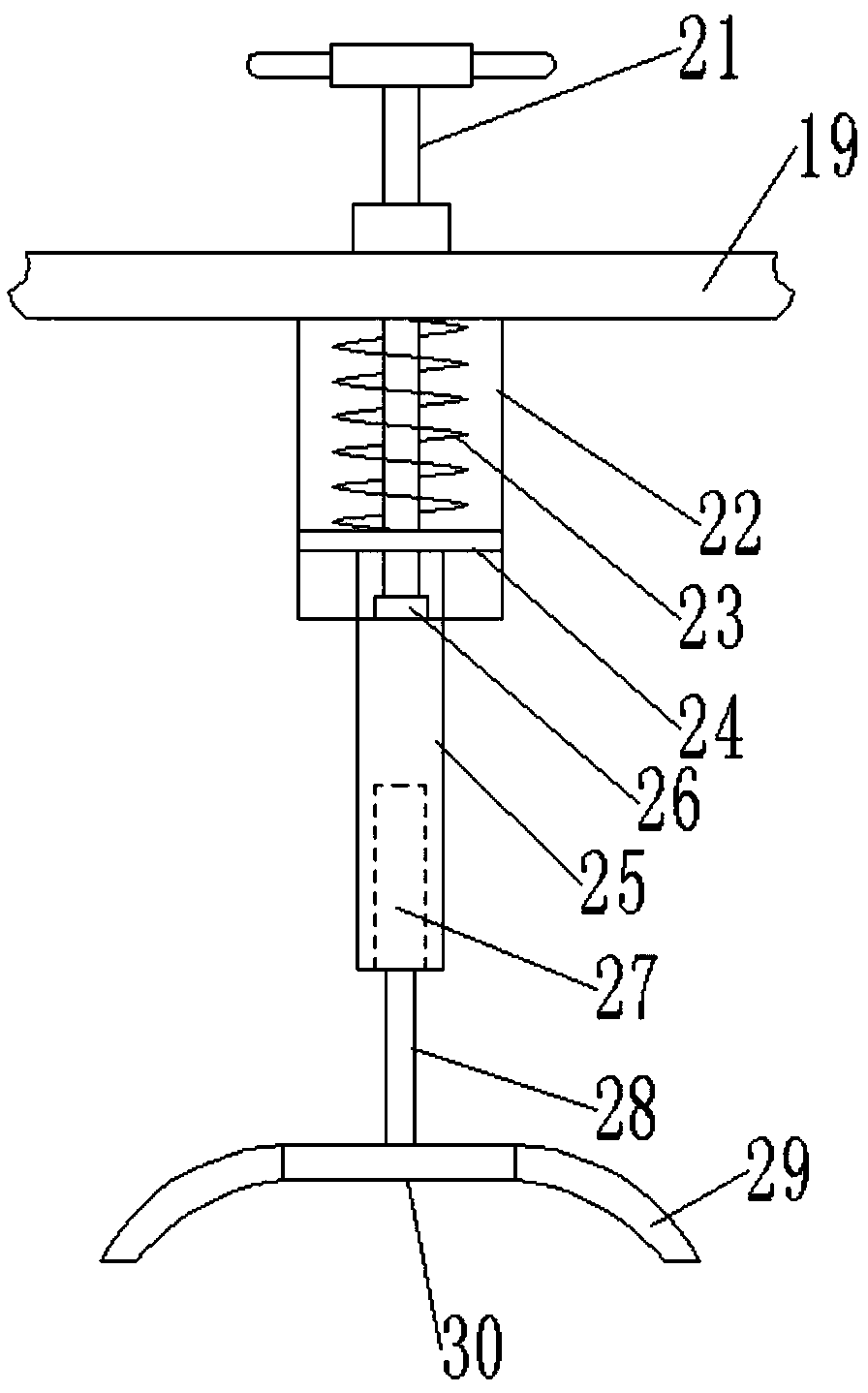

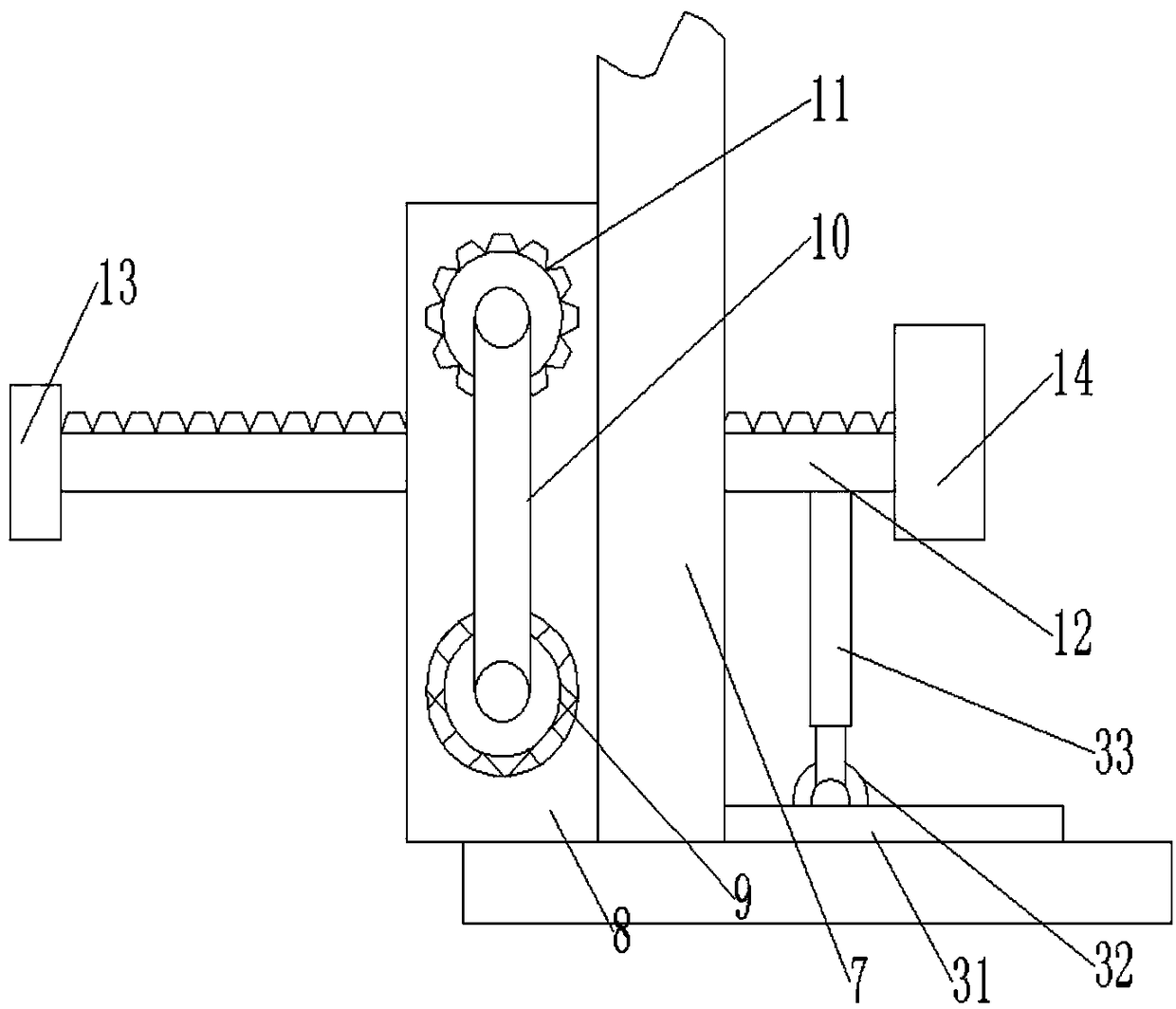

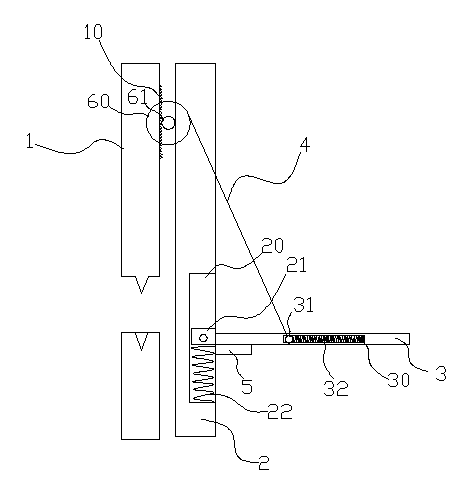

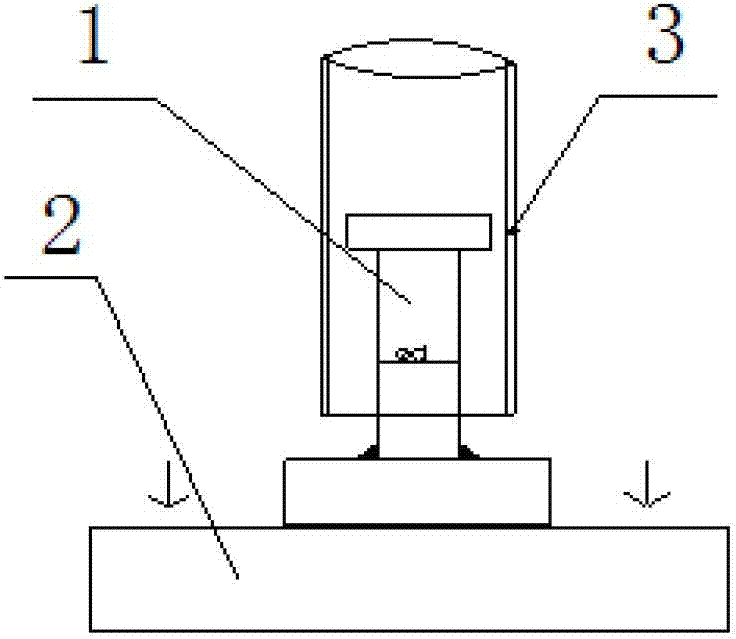

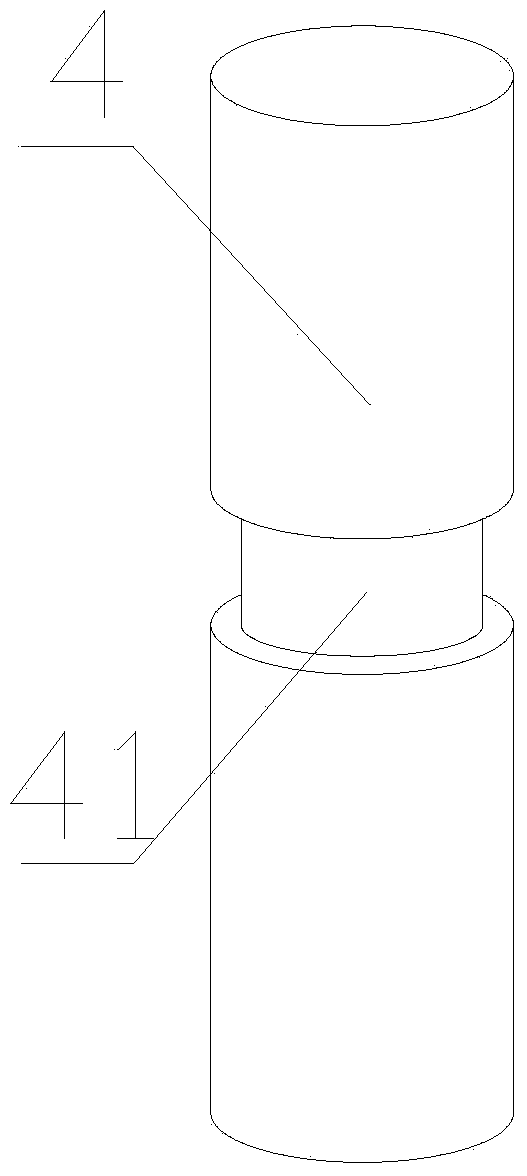

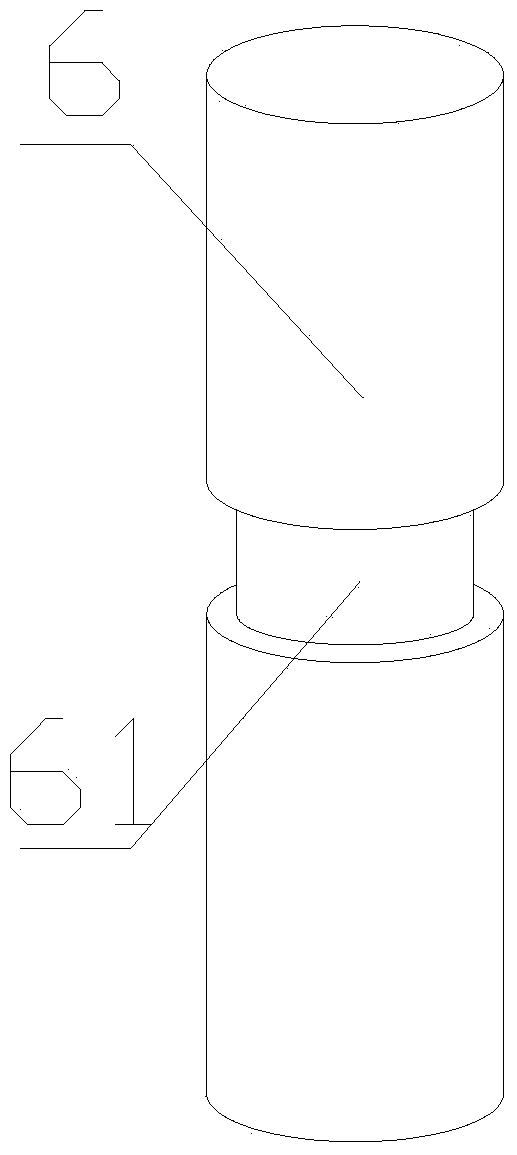

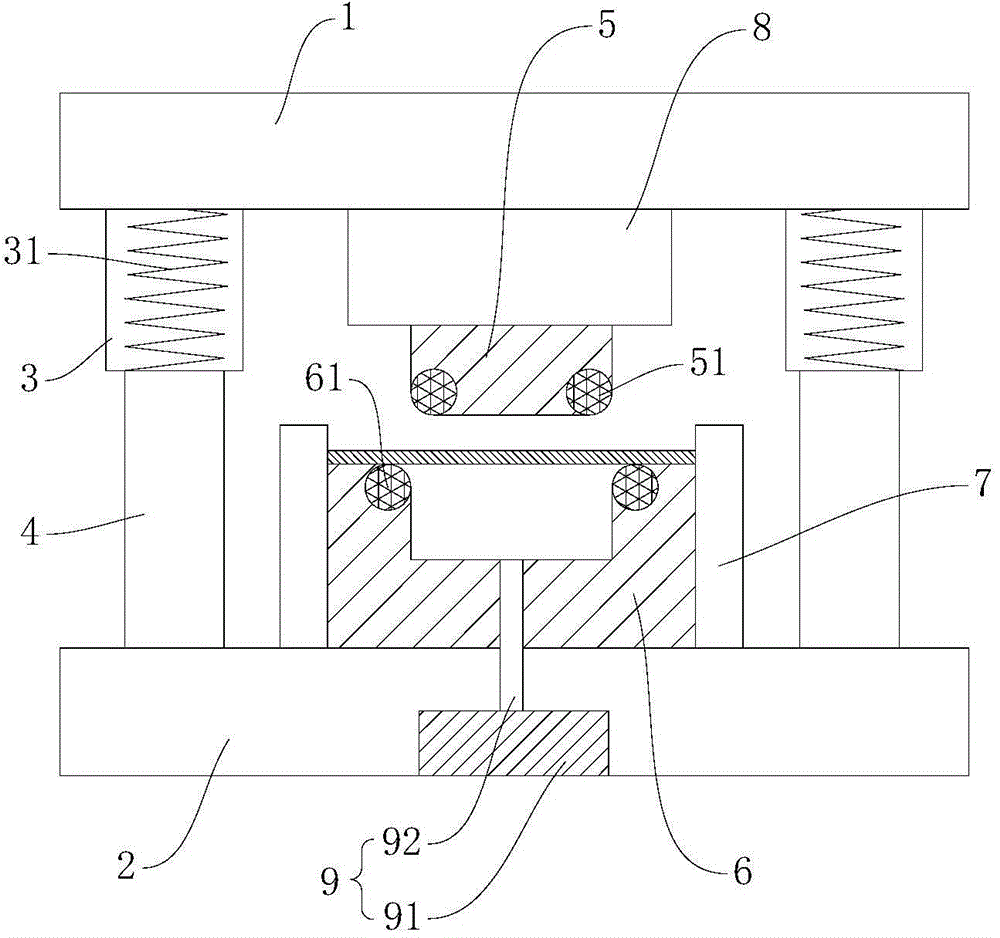

Supporting plate mechanism used for bending machine

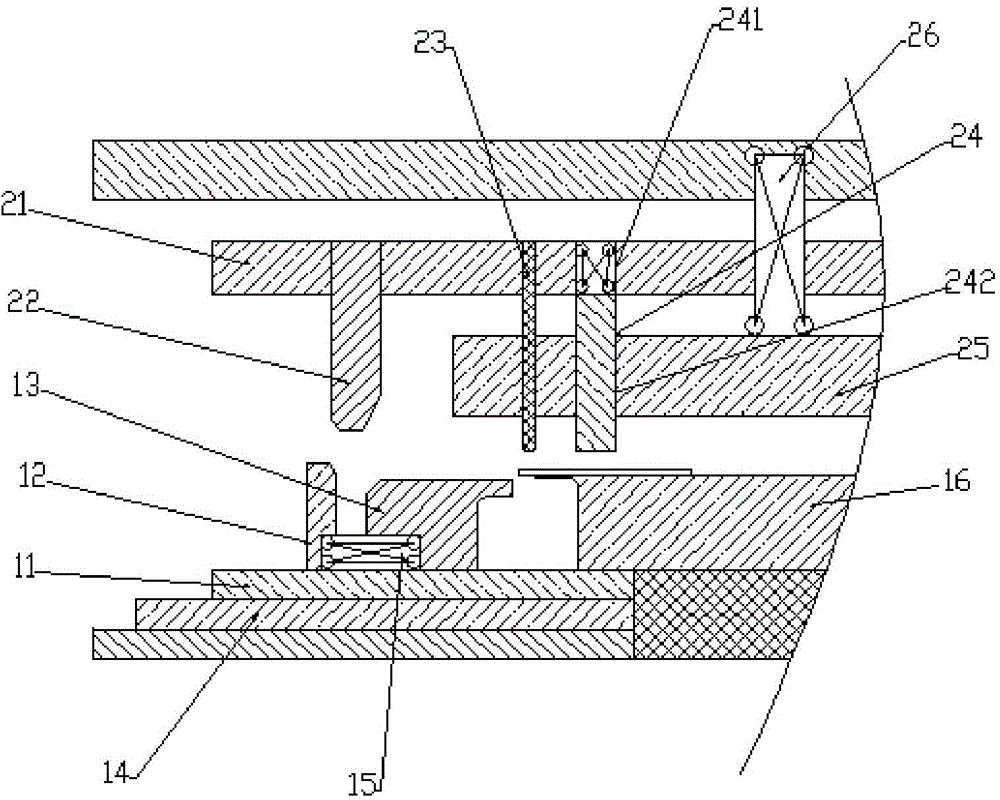

InactiveCN103100601AGuaranteed bending qualityMetal-working feeding devicesPositioning devicesEngineeringMechanical engineering

The invention discloses a supporting plate mechanism used for a bending machine. The supporting plate mechanism used for the bending machine comprises a bending machine pressure head and further comprises an installation support arranged on the position of a feeding inlet of the bending machine, a sliding groove is formed in the installation support, and a sliding block is arranged in the sliding groove. The supporting plate mechanism used for the bending machine further comprises a first spring, one end of the first spring abuts against the lower end face of the sliding groove, the other end of the first spring abuts against the sliding block, a material supporting plate is rotationally arranged in the sliding block, a sliding rail is formed in the side wall of the material supporting plate, a rolling shaft and a second spring are arranged in the sliding rail in a sliding mode, the rolling shaft abuts against the second spring, a gear is rotationally arranged on the installation support, a gear face meshed with the gear is arranged on the pressure head, and the gear is meshed with the gear face. The supporting plate mechanism used for the bending machine further comprises a sliding rope, one end of the sliding rope is connected with the gear, and the other end of the sliding rope is connected with the rolling shaft. In the bending process of a plate body, the material supporting plate always supports the plate body, bending quality is ensured, and the supporting plate mechanism used for the bending machine guarantees that plate material can not directly fall onto a work table after formation of the plate material.

Owner:NINGBO LINGTONG TELECOM EQUIP

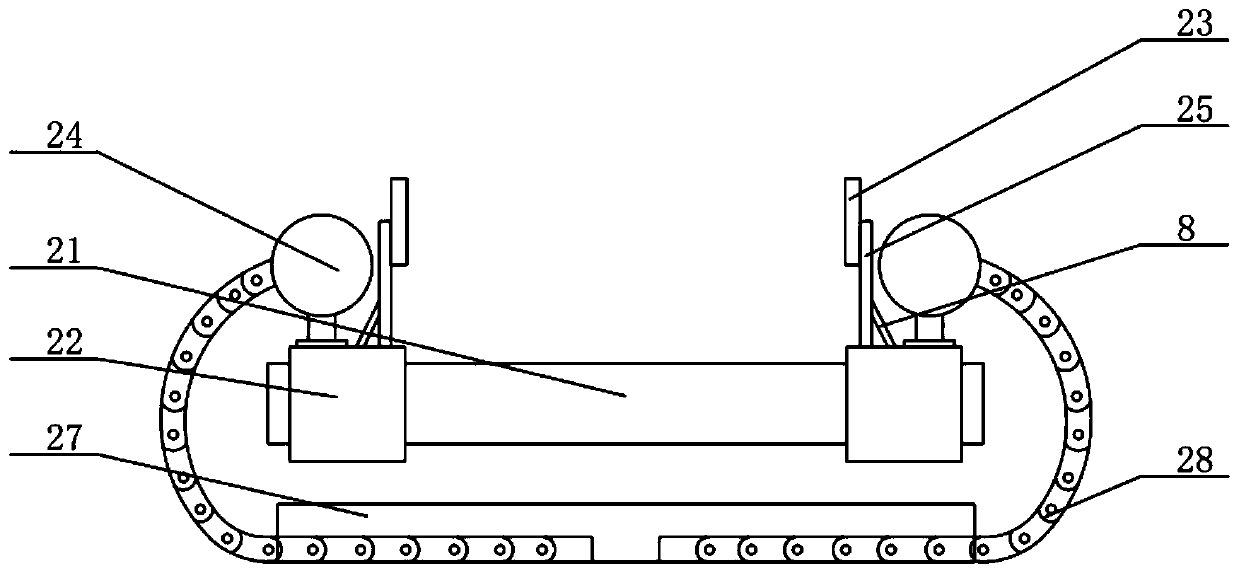

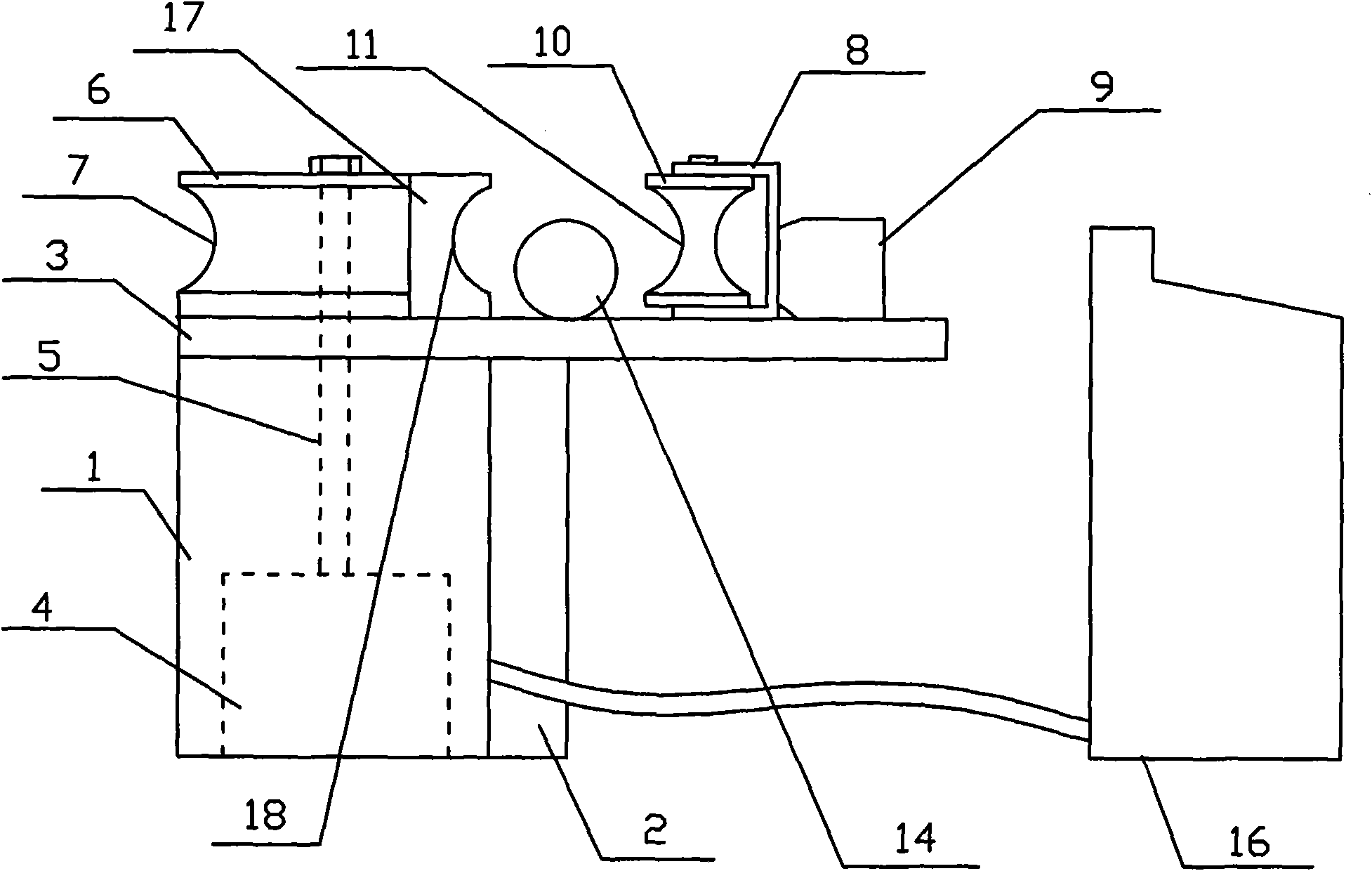

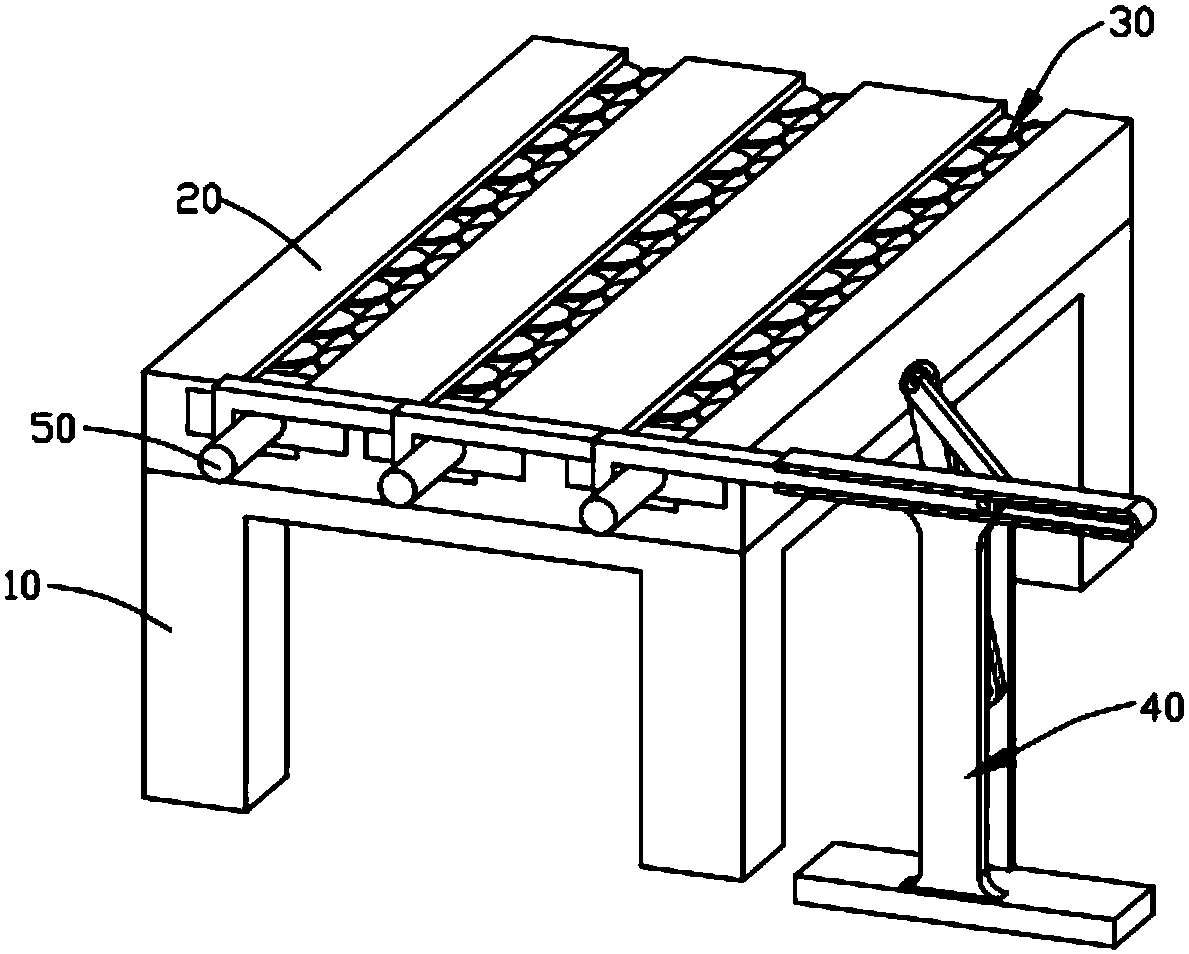

Water sump bending plate production line

PendingCN107398501AReduce in quantitySmall footprintMetal-working feeding devicesPositioning devicesStructural engineeringSmall footprint

The invention discloses a water sump bending plate production line. The water sump bending plate production line comprises a rack, wherein the rack is provided with a feeding mechanism, a feedstock guiding device, a front shearing device, a side hole punching device, a main engine forming device, a tail hole punching device, a side dismantling device, a bending device and a shearing device in sequence from front to back; the middle part of the rack is provided with a power device, and the power device is connected to the main engine forming device in a transmission manner. The water sump bending plate production line is reasonable in design and is integrated onto the rack, and feeding and discharging are performed continuously, so that the bending efficiency and bending quality are guaranteed, the quantity of workers is greatly reduced, the cost is also reduced while the amount of labor is alleviated, and the whole production line is small in occupied area, low in cost and high in practicability and is applicable to popularization.

Owner:无锡中博锐机械有限公司

Back plate engraving die

The invention discloses a back plate engraving die. The back plate engraving die comprises an upper die assembly and a lower die assembly. A base is arranged below the lower die assembly. The lower die assembly comprises a forming male die, a lower sliding block and a lower sliding cushion plate. The lower sliding block is arranged on the lower sliding cushion plate, and a lateral pushing forming punch and a lower die push block are arranged on the lower sliding block. A male die cushion block is arranged on the right side of the lower sliding block. The forming male die is arranged on the male die cushion block. The upper end of the forming male die extends leftwards to form an auxiliary male die, and the lower end face of the auxiliary male die is higher than the upper end face of the lateral pushing forming punch. The upper die assembly comprises an upper die base, an upper die slotting tool, an upper die positive punch, an upper die plate and an engraving punch, wherein the upper die slotting tool is arranged at the bottom of the upper die base, and the upper die positive punch and the engraving punch are fixed to the bottom of the upper die base and penetrate through the upper die plate; the upper die positive punch is located on the left side of the engraving punch. According to the back plate engraving die, engraving and two times of bending can be finished through one procedure, and efficiency is improved; the size of a bent product is accurate, and the product bending quality is guaranteed.

Owner:昆山电子羽电业制品有限公司

Automobile longitudinal beam bending production device

InactiveCN107008785AMeet production requirementsTimely transportMetal-working feeding devicesVehicle componentsProduction lineEngineering

The invention is suitable for the technical field of automobile longitudinal beam production, and provides an automobile longitudinal beam bending production device. The device comprises a feed device, a stroke detection device, a bending device and a discharge device. The feed device comprises a bearing device and multiple conveying devices. The stroke detection device comprises a main frame body, a stroke measurement mechanism and a numerical control feedback mechanism. The stroke measurement mechanism is arranged in the main frame body, is arranged over a production line and makes elastic contact with a longitudinal beam. The bending device comprises a fixed mechanism and a swing mechanism. The swing mechanism is hung on the fixed mechanism through supporting shafts arranged on the two sides. A hydraulic servo drive device is connected with a numerical control system. The discharge device comprises a supporting frame and a push device. The push device comprises a motor, a control panel and a movement device. The control panel is electrically connected with the movement device and the motor. The push device is fixedly connected with the supporting frame. In this way, bending production of the automobile longitudinal beam can be automatic, the production efficiency can be improved, and potential safety hazards can be reduced.

Owner:WANLONG IND SHOUGUANG SHANDONG

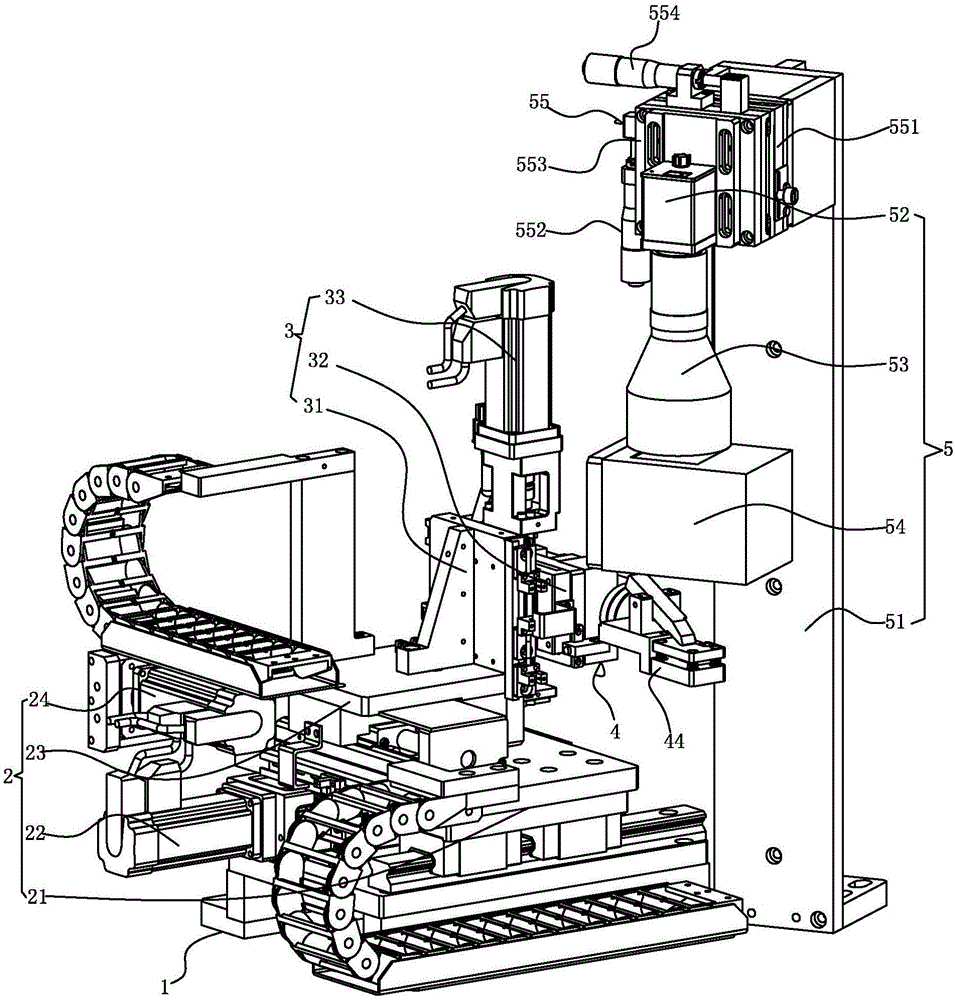

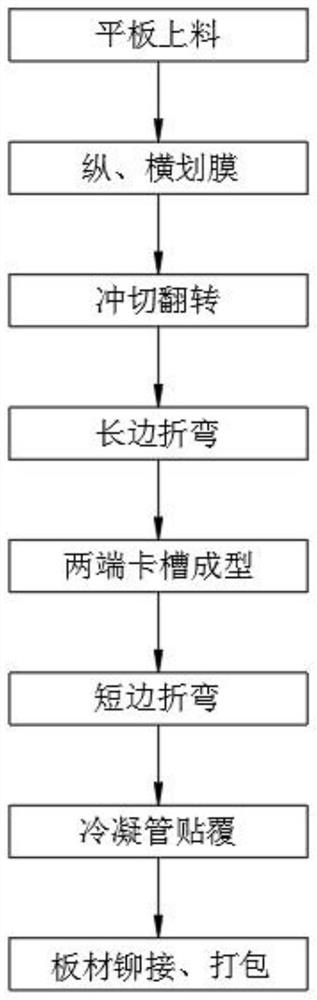

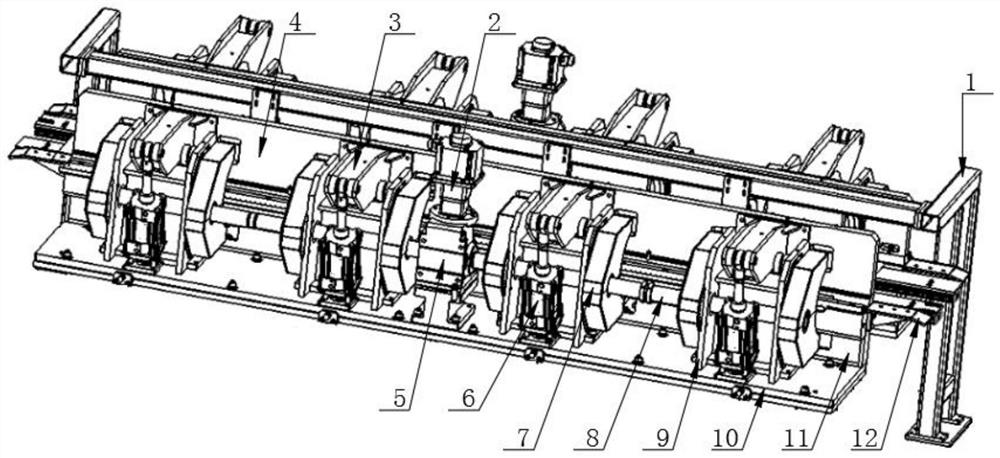

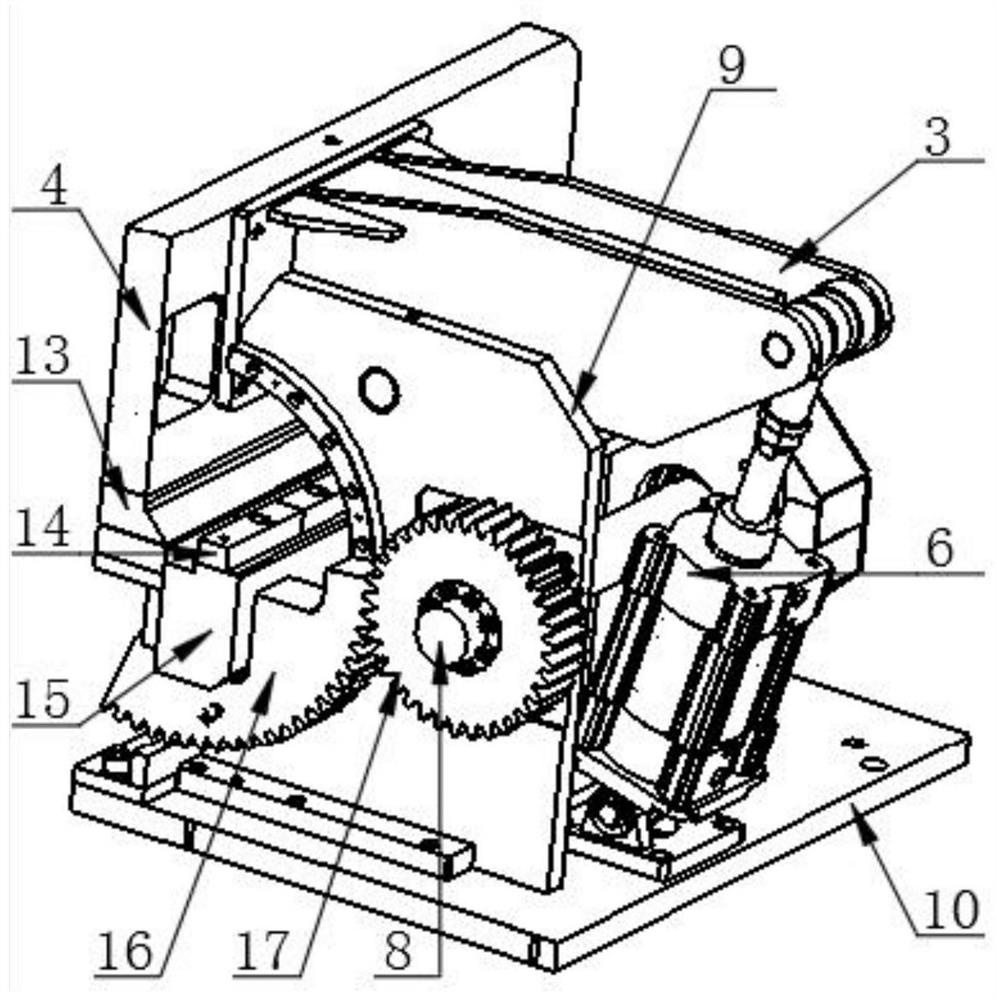

Forming technology for refrigerator side plate

ActiveCN111974842AGuaranteed positioningImprove bending accuracyMetal-working feeding devicesPositioning devicesRobot handMechanical engineering

The invention discloses a forming technology for a refrigerator side plate. The forming technology includes the following steps that panel feeding is conducted, wherein the refrigerator side plate ofthe metal plate type is placed on a transferring vehicle, the transferring vehicle is a movable type double-layer and multi-line shipping transferring vehicle, and an external mechanical hand is usedfor putting the refrigerator side plate on the transferring vehicle to a conveying line; longitudinal and transverse film scratching is conducted, wherein a cold blade is used for conducting longitudinal film scratching and then conducting transverse film scratching on the refrigerator side plate on the conveying line, a film layer wrapped on the refrigerator side plate is scrapped off, and manualtearing is conducted; punching and overturning are conducted; and three times of punching and trimming removing are conducted on the refrigerator side plate obtained after film layer removing on theconveying line, feature holes with different sizes are formed, and a punched burr edge of the refrigerator side plate is overturned, positioned and transferred to the first-stage bending position. Bymeans of the forming technology for the refrigerator side plate, all the production steps and equipment of the refrigerator side plate can be matched to meet the requirement for the automatic production technology, and therefore the forming quality and the work efficiency of the refrigerator side plate are improved.

Owner:ANHUI KINGPOWER EQUIP & MOLD MFR

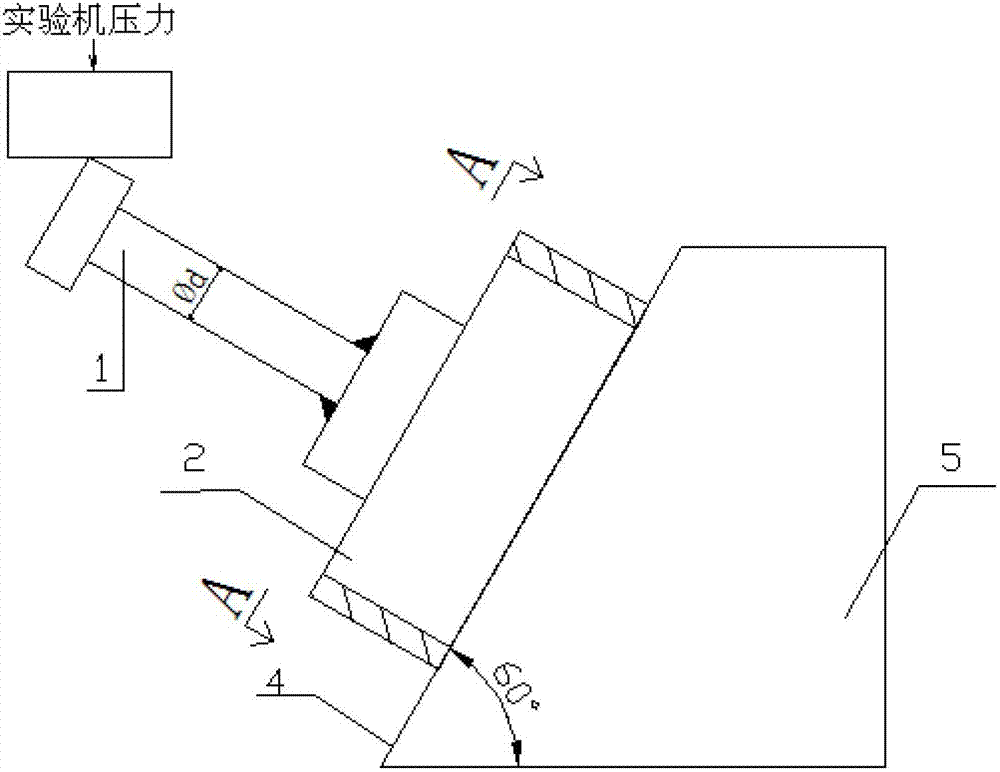

Male pin bending device

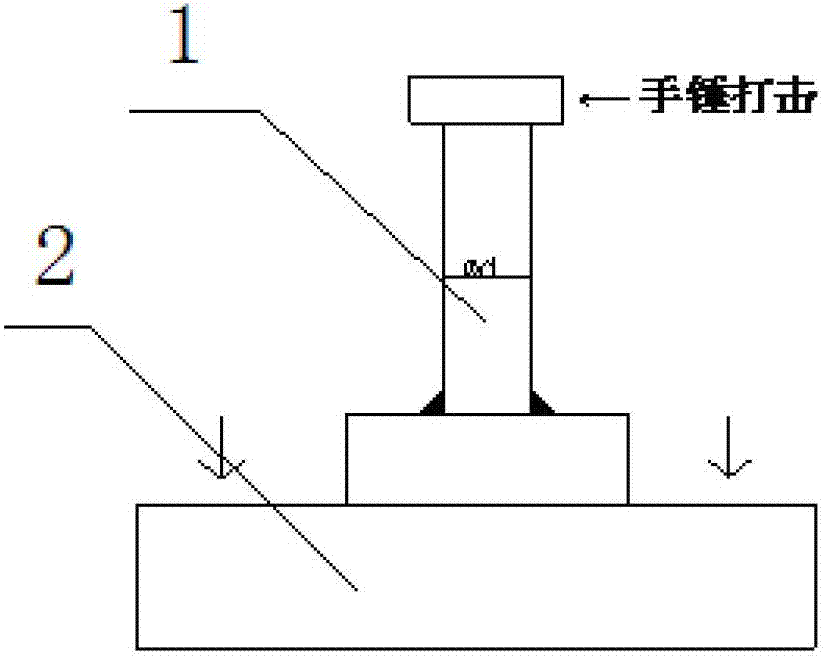

ActiveCN103076237ASimple structureGuaranteed bending qualityMaterial strength using steady bending forcesMachine pressEngineering

The invention relates to a male pin bending device, which belongs to the technical field of metal performance tests. The male pin bending device comprises a triangular base with an inclined plane, wherein the inclination included angle of the inclined plane and the triangular base is 60 degrees; a welding stud fixing base is perpendicularly arranged on the inclined plane. The male pin bending device can not only bend welding studs through pressing machine experiment equipment, but also has a simple structure.

Owner:JIANGSU HUNING STEEL MECHANISM

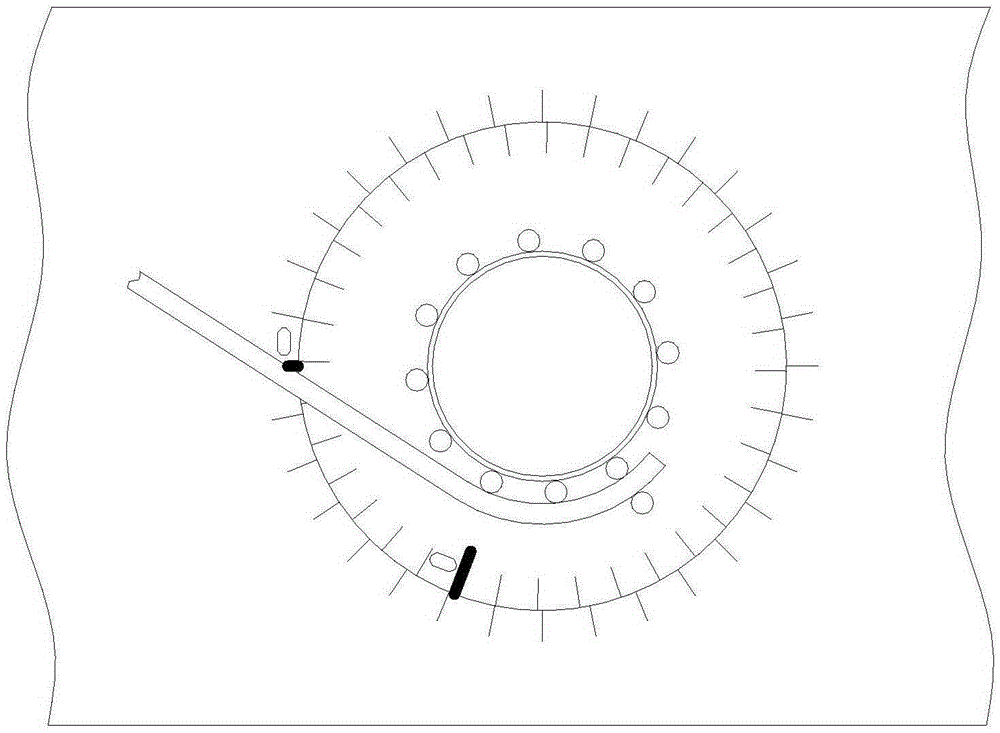

Graduation line steel bar bender

The invention discloses a graduation line steel bar bender, which relates to the technical field of steel bar bending molding equipment, and aims to provide the graduation line steel bar bender with accuracy in bending angle. The graduation line steel bar bender has the technical scheme that the graduation line steel bar bender comprises a working plate located on the top part of a machine body, a locating shaft and a clamping shaft, wherein the working plate comprises a fixed plate and a rotary plate; the rotary plate is connected with a drive device in the machine body and is rotated around the axis of the rotary plate; a plurality of locating shaft holes and clamping shaft holes are uniformly distributed in the rotary plate along the circumferential direction of the rotary plate; the locating shaft and the clamping shaft are respectively and correspondingly placed in the locating shaft holes and the clamping shaft holes; graduation lines are respectively arranged on the fixed plate and the rotary plate; the number of the graduation lines on the rotary plate is more than the number of the graduation lines on the fixed plate. The rotated angle of the rotary plate can be obtained through the position relationship between zero graduation lines on the fixed plate and the rotary plate, and the graduation line on the rotary plate coincident to the graduation line on the fixed plate. The invention is applicable to the steel bar bender.

Owner:SICHUAN DINGRUI HYDRAULIC EQUIP MFR

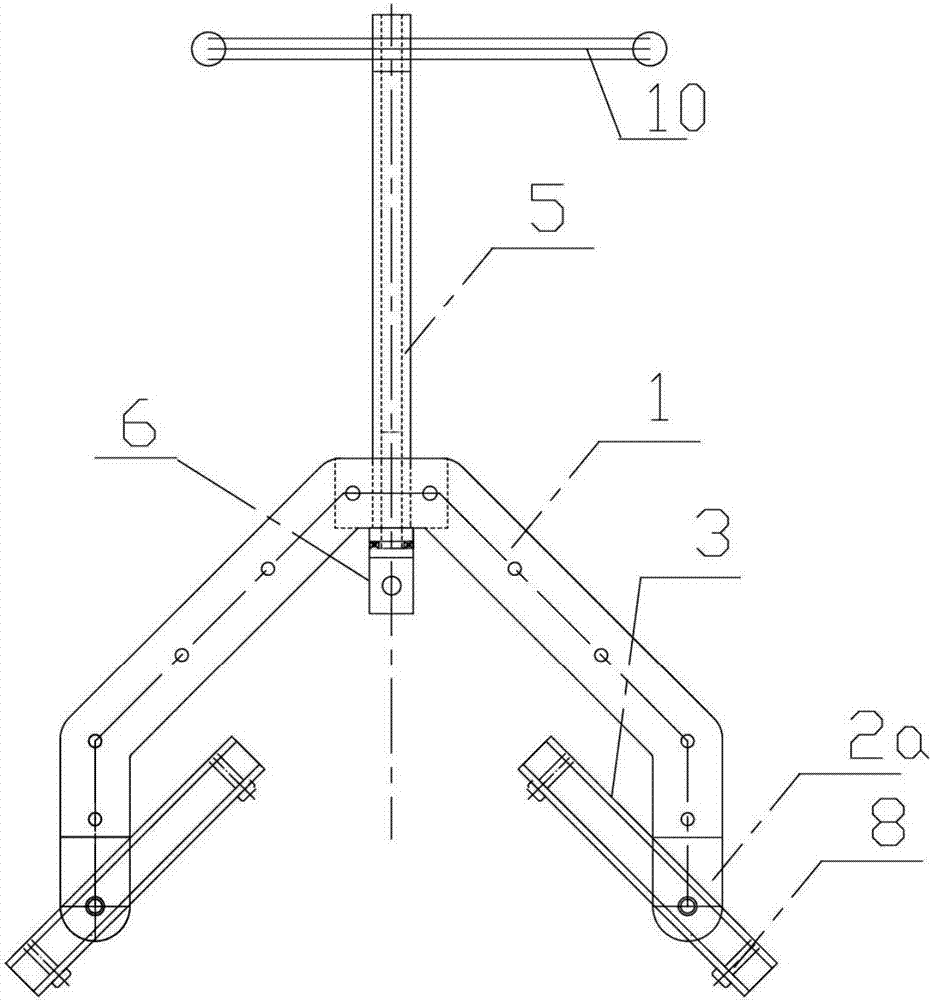

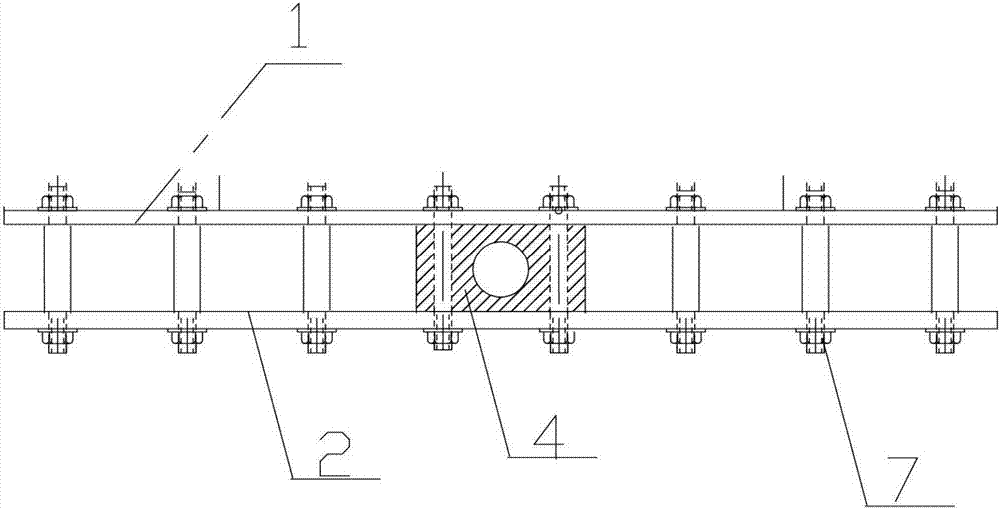

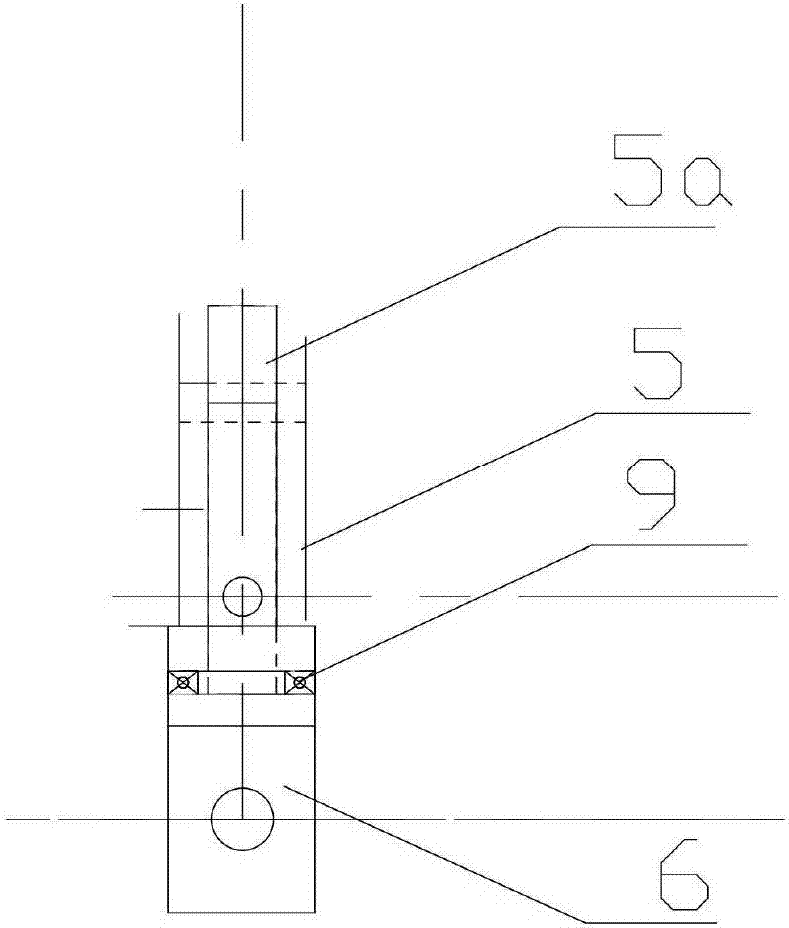

Grounding grid reinforcing steel bar bending device

The invention discloses a grounding grid reinforcing steel bar bending device. A front fixing plate and a back fixing plate each comprise a top connecting arm, a left support arm and a right support arm, each left support arm and the corresponding right support arm are distributed in a splayed manner, and the upper end of each left support arm and the upper end of the corresponding right support arm are connected to the two ends of the corresponding top connecting arm correspondingly; the lengths of the left support arm and the right support arm of the back fixing plate are larger than those of the left support arm and the right support arm of the front fixing plate, the lower portions of the left support arm and the right support arm of the back fixing plate are downwards bent to form vertical bending parts, and the front fixing plate and the back fixing plate are connected through front and back fixing plate bolts; the lower portions of the vertical bending parts of the left support arm and the right support arm are hinged to reinforcing steel bar rotation box iron through rotating pins, a lead screw base is connected between the top connecting arms of the front fixing plate and the back fixing plate, and a through hole is formed in a reinforcing steel bar fixing frame; and the lower portion of the lead screw is fixedly provided with a lead screw penetrating needle which extends into the reinforcing steel bar fixing frame, and a bearing is arranged between the lead screw penetrating needle and the reinforcing steel bar fixing frame. The grounding grid reinforcing steel bar bending device is simple in structure and convenient to carry, and reinforcing steel bars can be quickly and effectively bent and machined.

Owner:STATE GRID CHONGQING ELECTRIC POWER

Prebending mechanism of preassembled hasp

The invention relates to the field of processing of vehicle parts, in particular to an automatic prebending mechanism of a preassembled hasp. The automatic prebending mechanism comprises a linear driving unit, a guide unit and a pressing head; the linear driving unit is fixed on a frame; the pressing head is hinged to a moving end of the linear driving unit, and is freely suspended; the linear driving unit drives the pressing head and the guide unit to relatively move; the guide unit includes a base, a guide pin and a guide plate, wherein the guide pin is fixed on the base; any one of the base and the guide plate is fixed on the frame, and the other one is connected with the pressing head; the linear driving unit pushes the guide plate or the base to move; and when a gap of the guide plate moves to the guide pin position, the front end of the guide plate sinks, and the pressing head presses the hasp on a preassembled part to downwards bend to realize free prebending of the hasp. The guide unit provides a special moving rail to the pressing head, so that the consistency of each moving trajectory of the pressing head can be guaranteed, the bending quality is guaranteed, the working efficiency is improved, and the cost is saved.

Owner:CHERY AUTOMOBILE CO LTD

Thermoplastic FRP rib bending device

The invention provides a thermoplastic FRP rib bending device. The device comprises a fixing mechanism, a rotating mechanism, a slide block, a heater and a cooler. A spring is arranged between the fixing mechanism and the rotating mechanism; a guide rail penetrates through the fixing mechanism and the slide block; two ends of the guide rail are fixed on a working platform by a base; a stepper motor drives and controls the slide block through a lead screw; under the effect of the slide block, the rotating mechanism and the fixing mechanism can perform translation and rotation; through translation, FRP ribs move between the heater and the cooler; through rotation, the FRP ribs are bent; and the bending angles are 0-90 degrees. The device has such advantages as high automation degree, high machining precision, simple operation and low requirements on constructors and places.

Owner:HARBIN ENG UNIV

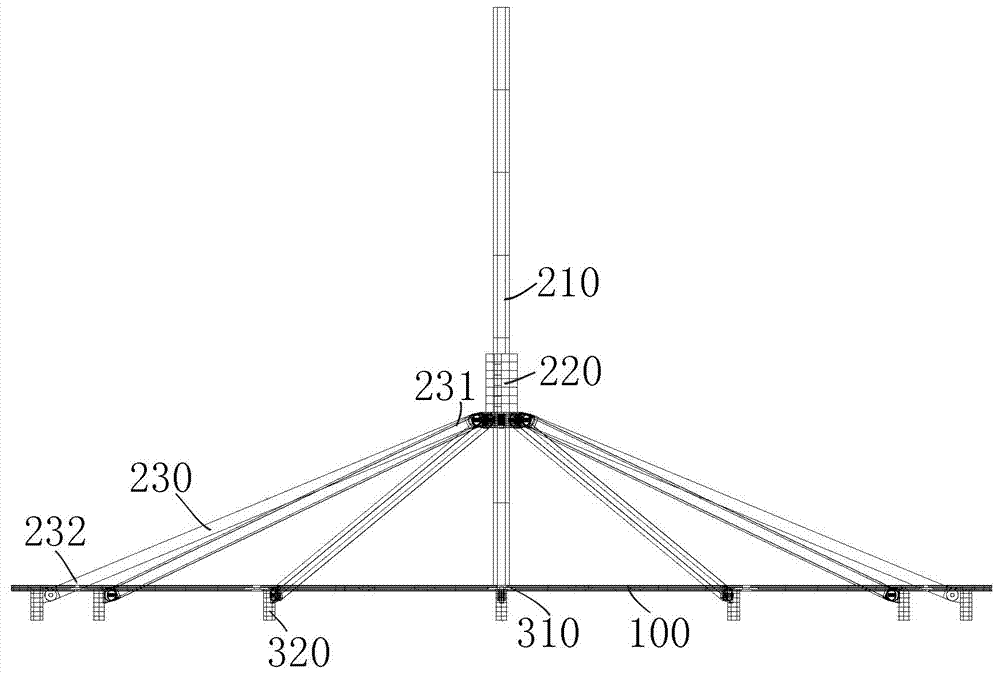

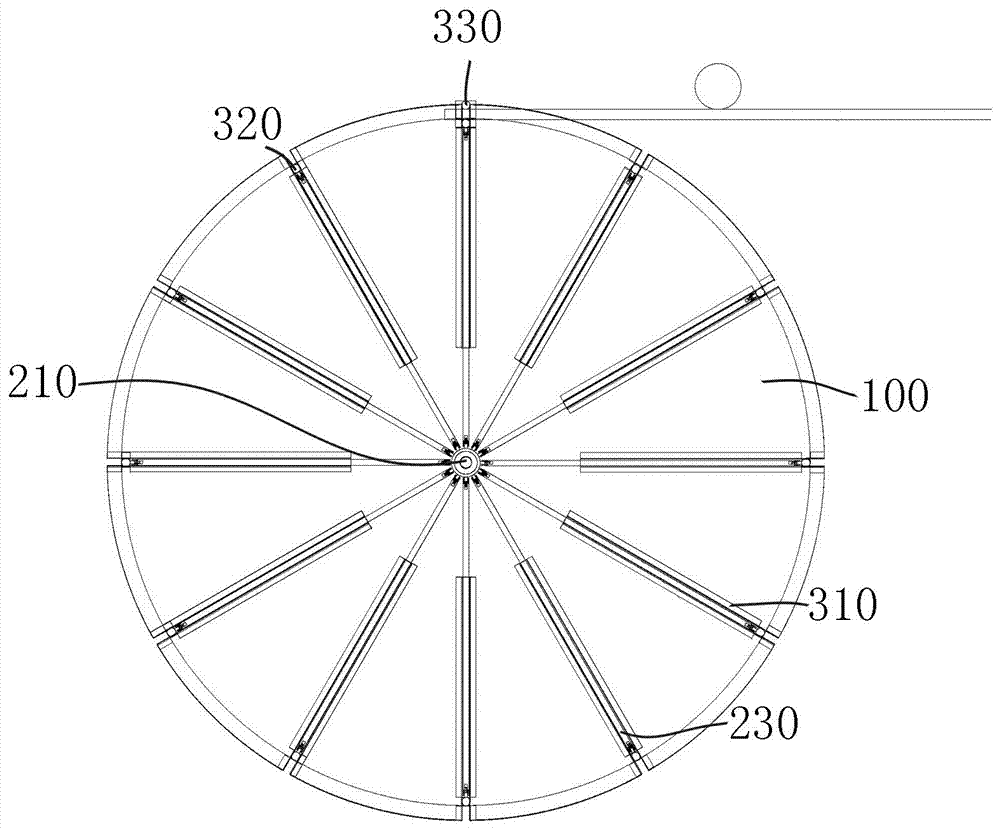

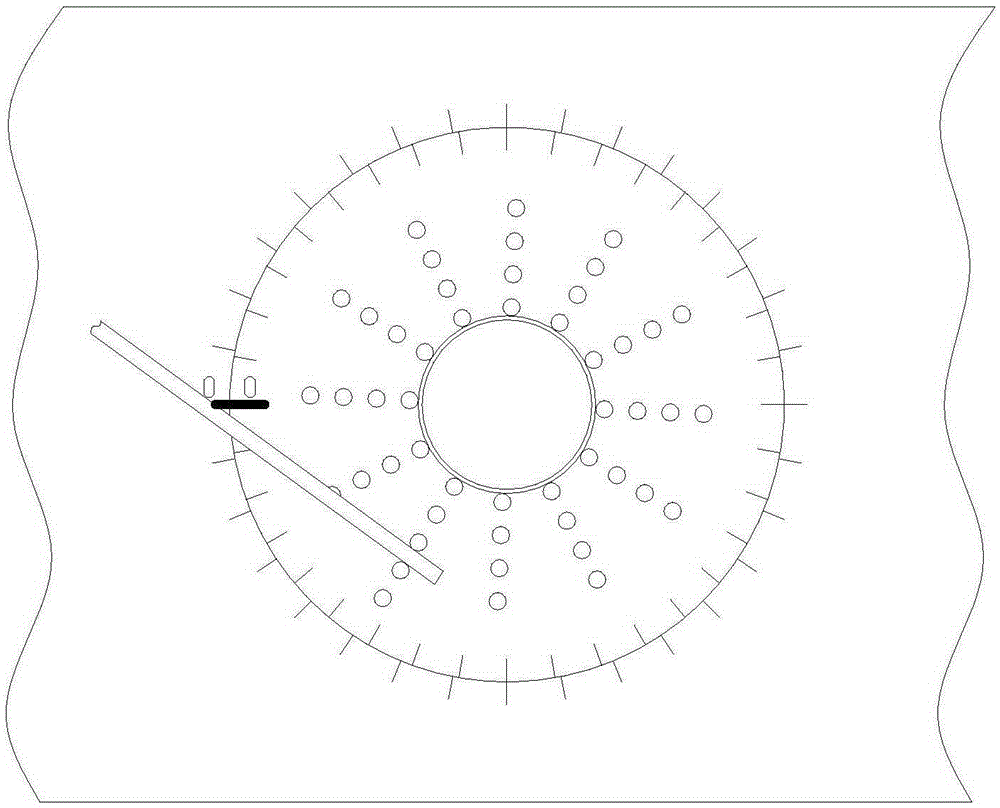

Radius-adjustable steel bar bending and rounding machine

The invention relates to the technical field of steel bar machining, in particular to a radius-adjustable steel bar welding, bending and rounding machine. The radius-adjustable steel bar bending and rounding machine comprises a rotatable operation table, a radius adjusting locking assembly arranged on the operation table and a connecting assembly. The radius-adjustable steel bar bending and rounding machine is characterized in that the connecting assembly comprises multiple radial guide parts arranged on the operation table in a radial shape and corresponding parts of the radial guide parts; the radius adjusting locking assembly comprises a main shaft rod, a sleeve and multiple supporting rods with the number corresponding to that of the radial guide parts; and each supporting rod is provided with a connecting end and a moving end, the connecting ends the hinged to the sleeve, and the moving ends are hinged to the corresponding parts. The radius-adjustable steel bar bending and rounding machine has the advantages of being simple in operation, fast, accurate and high in practicality.

Owner:THE 3RD ENG CO LTD OF CHINA RAILWAY 16TH BUREAU GRP CO LTD +1

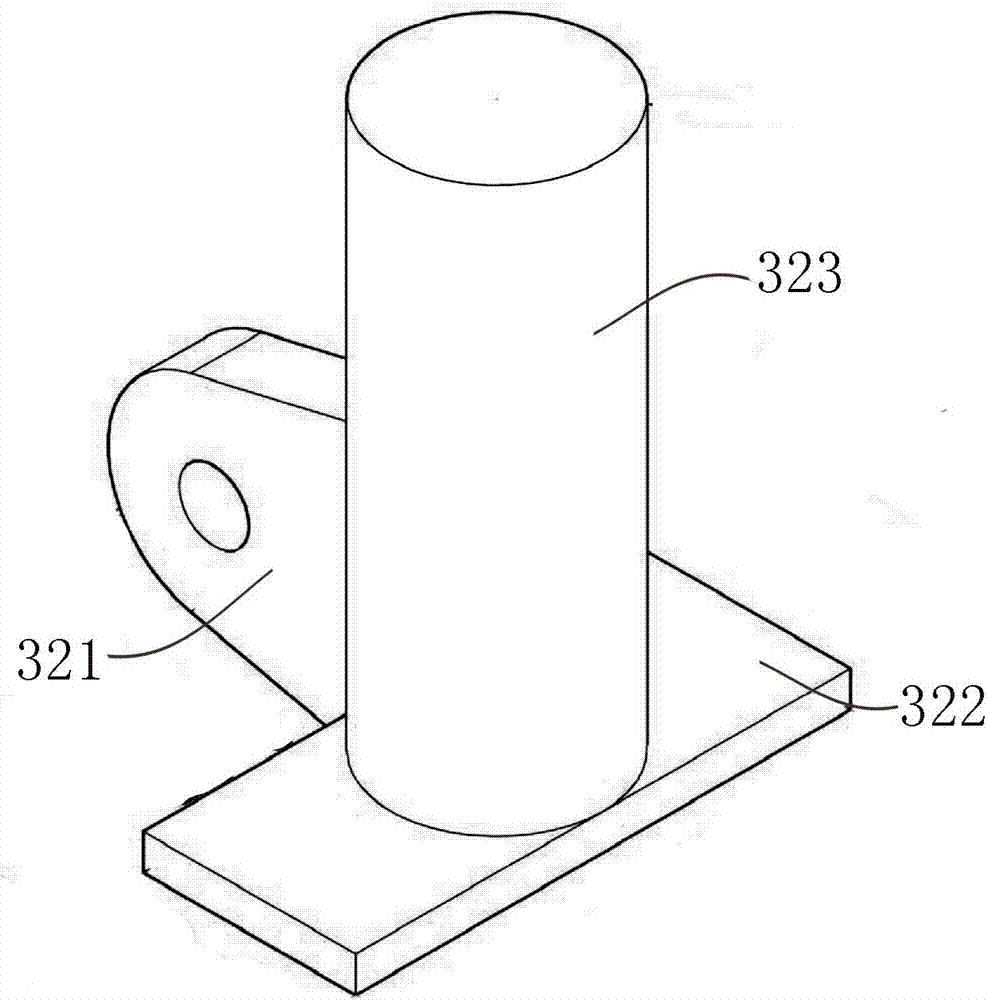

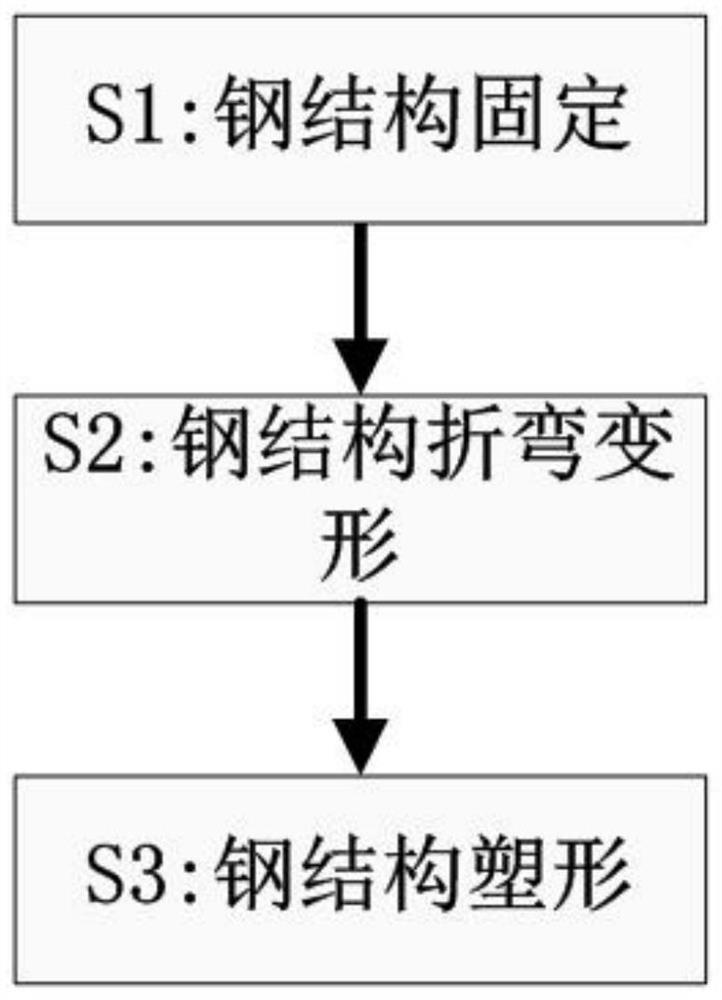

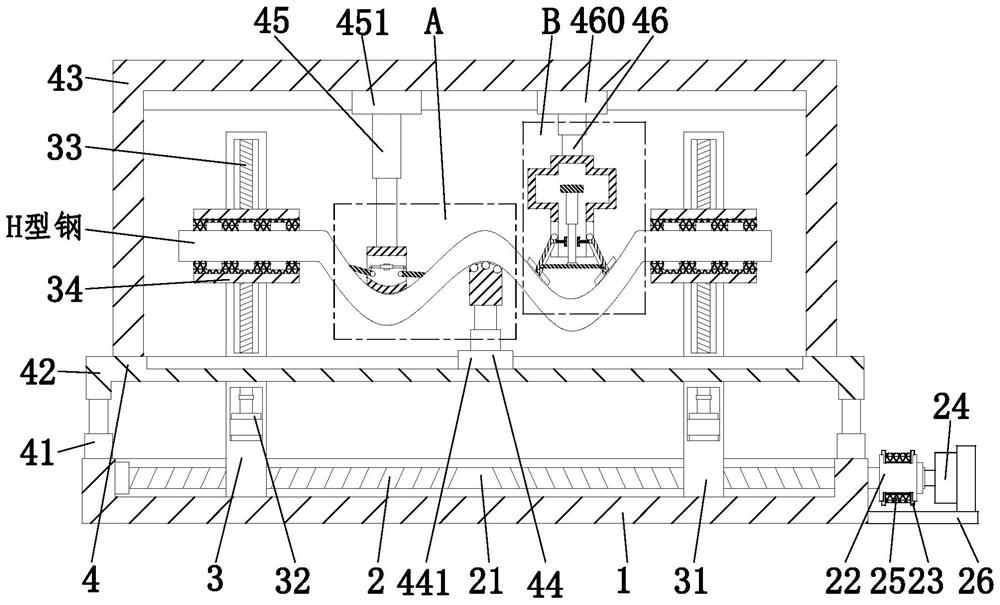

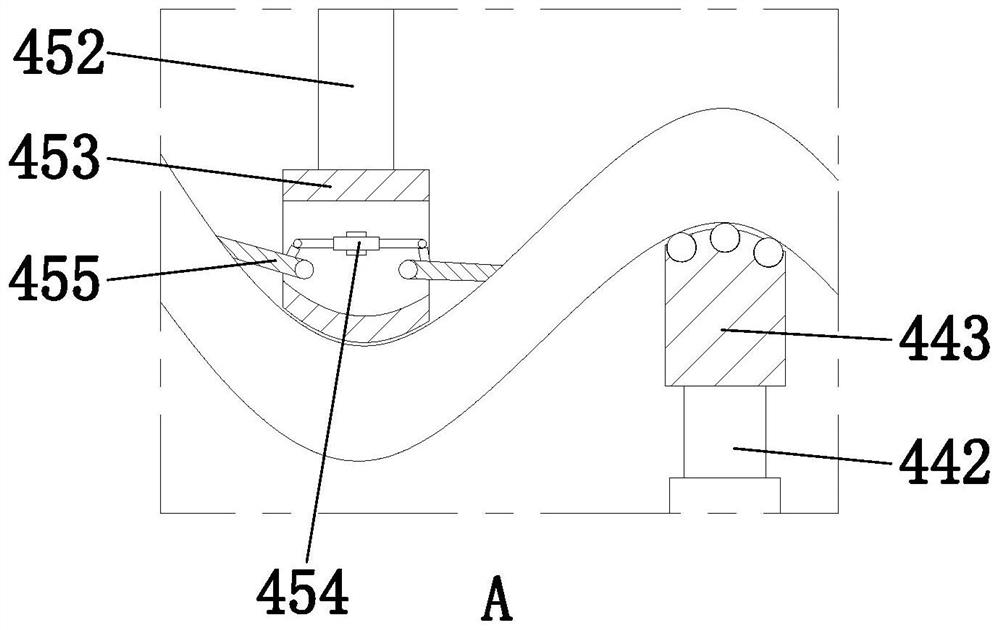

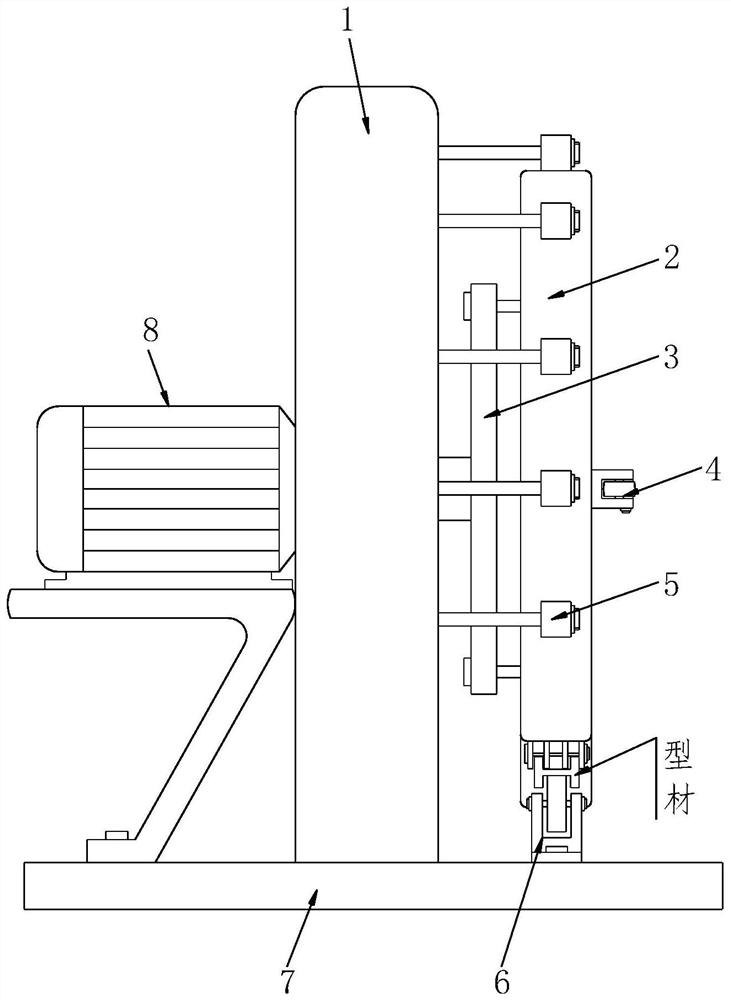

Manufacturing method of steel structure set-up profile steel connecting structure

InactiveCN112139316AGuaranteed structural formAvoid breakingMetal-working feeding devicesPositioning devicesUltimate tensile strengthMechanical engineering

The invention provides a manufacturing method of a steel structure set-up profile steel connecting structure. A bottom plate, a driving device, a fixing device and an actuating device are matched to complete manufacturing of the steel structure set-up profile steel connecting structure. The manufacturing method can be used for solving the problems that the bent position of H-shaped steel is proneto cracking and fracturing in the bending deformation process of the H-shaped steel at present; the stability of the H-shaped steel is affected; the outer wall of the H-shaped steel is difficult to bend and deform due to high strength of the H-shaped steel, and the bent position of the H-shaped steel is prone to unsmooth transition; the H-shaped steel is large in size; and the H-shaped steel is difficult to deform in the bending process, so that the H-shaped steel is prone to shaking, and the bending of the H-shaped steel is affected.

Owner:莫小雨

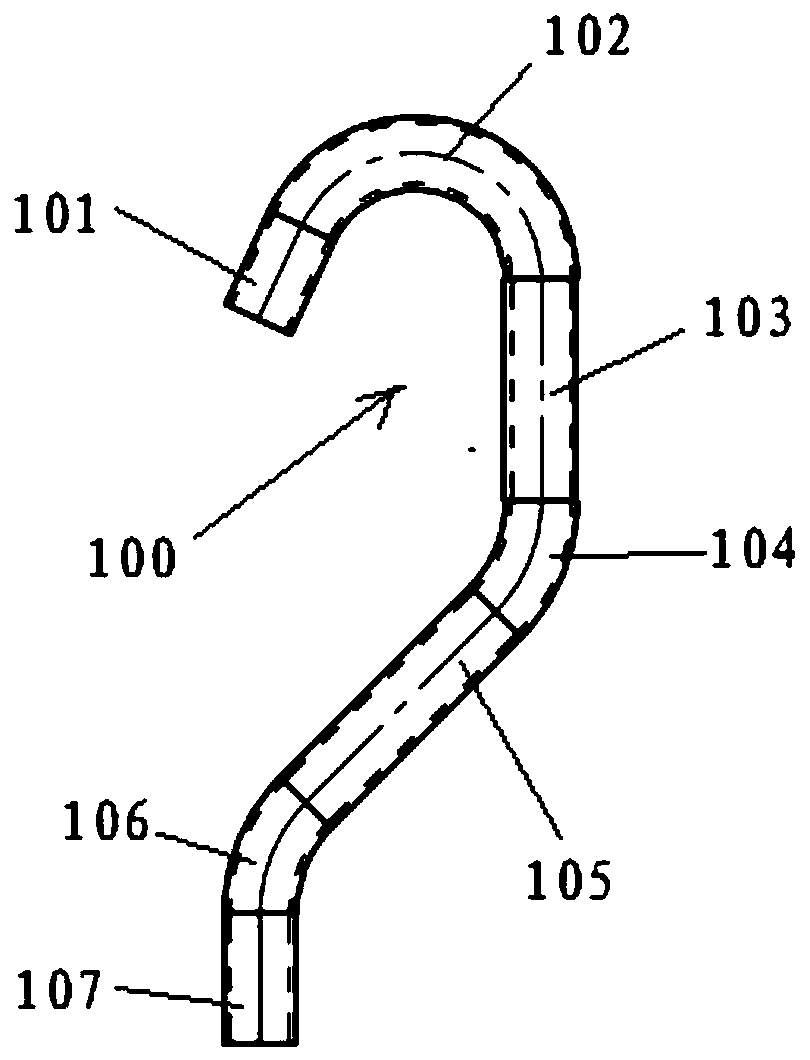

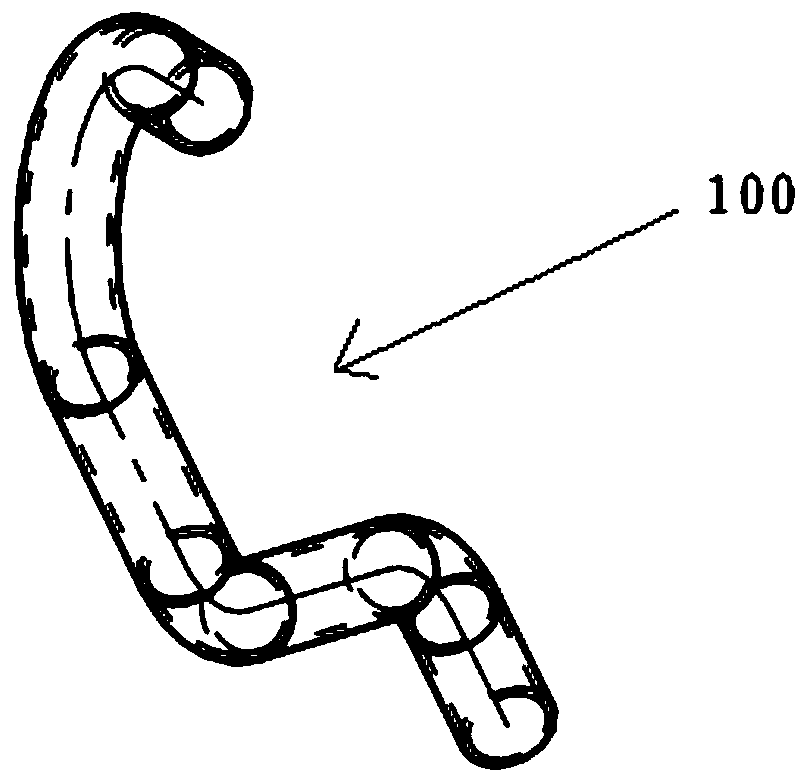

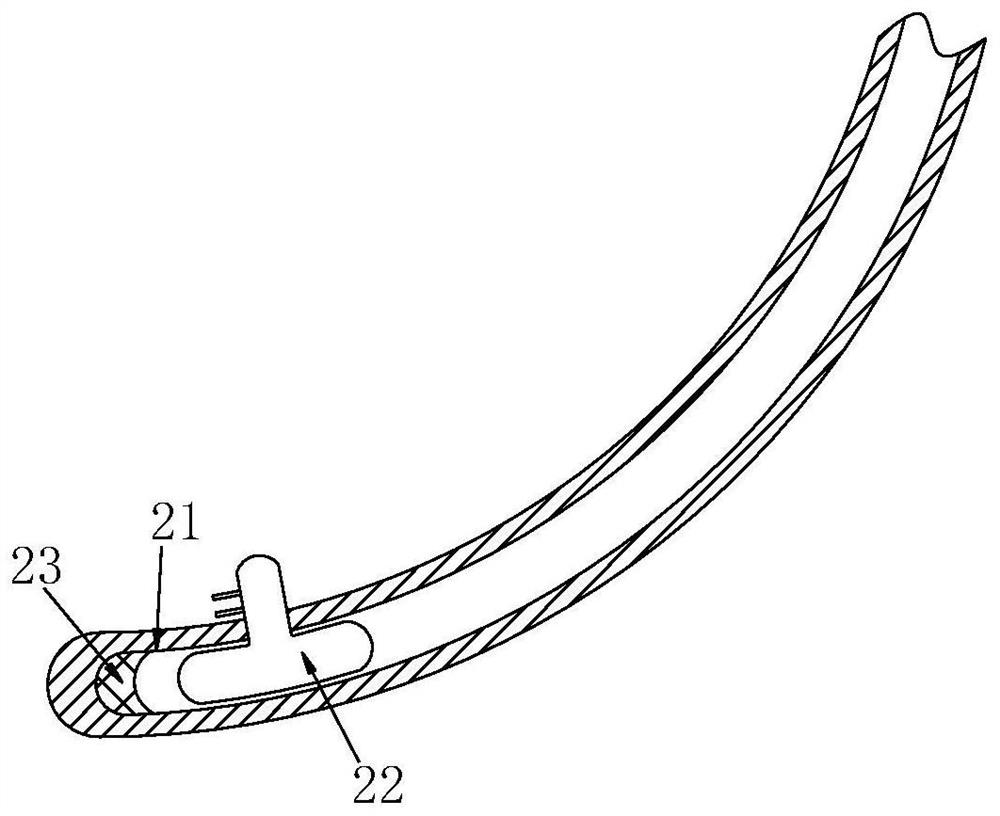

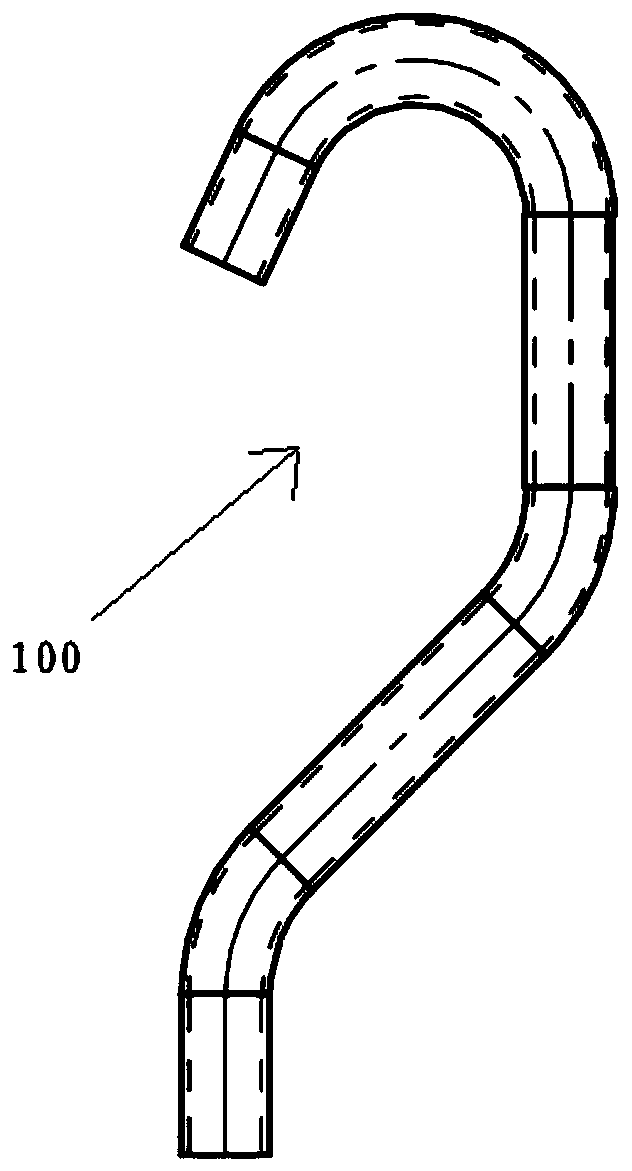

Copper pipe bend forming device and method and bent pipe product

InactiveCN110142317AGuaranteed bending qualityTo achieve the purpose of bendingEngineeringCopper tubing

The invention relates to a copper pipe bend forming device and method and a bent pipe product. The device comprises a base, a chuck and multiple rollers; the chuck and the multiple rollers are mountedon the base; an initial end of a copper pipe is clamped with the chuck; the copper pipe is bent around the multiple rollers in sequence to form multiple sections of bent products; the mounting positions and the shapes of the chuck and the rollers are set according to preset product parameters; when the chuck is clamped with the initial end of the copper pipe, the initial position and direction ofthe copper pipe are determined; the rollers can limit the direction of the copper pipe during bending to achieve the bend forming purpose; the mounting positions and the shapes of the chuck and the rollers are set according to the preset product parameters, preset products can be obtained after bending; and the device is suitable for manual manufacturing of small-batch bent pipe products, achieves the generality under the condition of guaranteeing the bending quality of the manual bent copper pipes to meet different bending shape requirements, and meanwhile, is convenient to use.

Owner:BEIJING INST OF RADIO MEASUREMENT

Hydraulic pipe bender

The invention discloses a hydraulic pipe bender comprising a worktable and a bender body, wherein the upper surface of the worktable is longitudinally connected with a first platform, one end of the first platform is arranged outside the worktable, a hydraulic system is arranged inside the worktable, a first turntable is arranged on the surface at the rear end of the first platform, the hydraulic system is connected with a vertical shaft which passes through the worktable, the first platform and the first turntable, the outer circumference of the first turntable is provided with a first arc groove, a movable fixing seat is arranged on the surface at the front end of the first platform, the other end of the bender body is provided with a fixing seat which is connected with a core rod, the other end of the core rod is connected with a core sleeve, a plurality of supporting seats are arranged on the bender body and arranged on the lower part of the core rod, and the worktable is connected with a control table by circuits. The invention has the advantages of saving production cost and ensuring bending quality.

Owner:NANTONG ZHONGLIAN S&T SERVICE

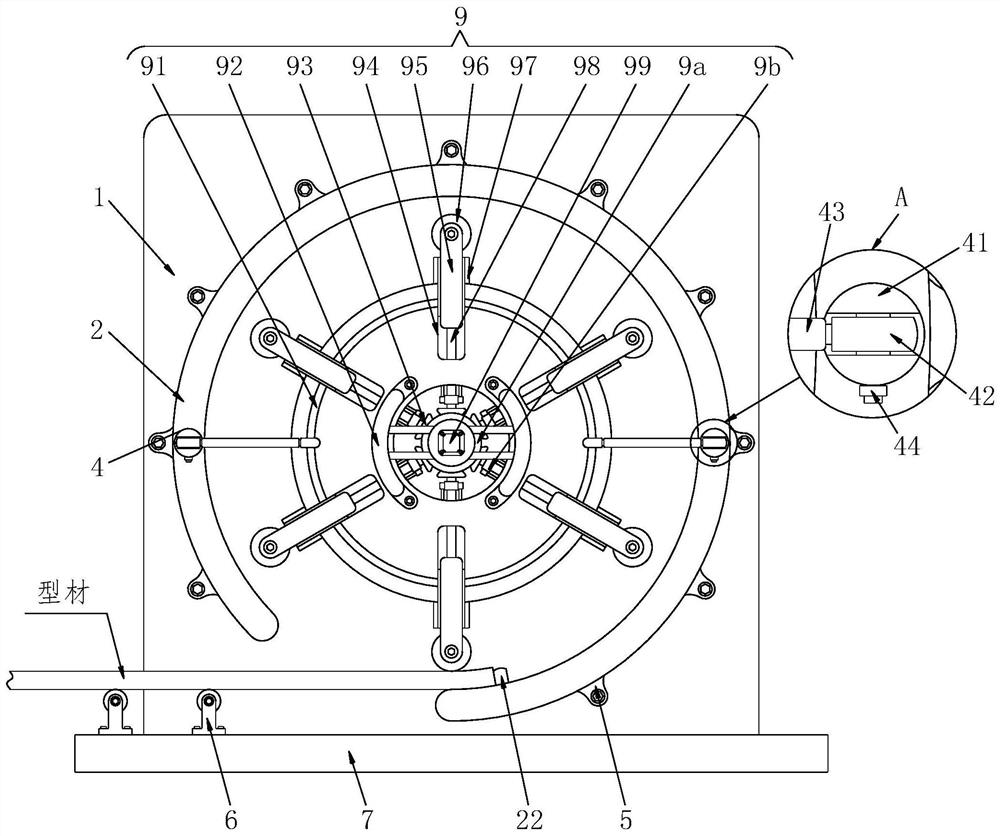

A kind of round bending machine for processing steel structure profile and processing round bending method

The invention relates to a steel structure profile machining and rounding machine and a machining and rounding method. The steel structure profile machining and rounding machine comprises a supportingplate, a round abutting plate, a driving rotary disc, a positioning assembly, fixing seats, a supporting frame, a base, a first motor and a rounding disc, wherein a first motor fixing frame is arranged on one side of the supporting plate; the first motor is mounted at the upper end of the first motor fixing frame; a first circular through hole is formed in the center of the interior of the supporting plate; an output shaft of the first motor penetrates through the first circular through hole; the driving rotary disc is fixed to the tail end of the output shaft in a welded mode; bolts are arranged in the circumferential direction of the driving rotary disc at equal intervals; mounting holes are formed in the circumferential direction of the rounding disc at equal intervals; the rounding disc is mounted on one side of the driving rotary disc through cooperation of the mounting holes and the bolts; the round abutting plate is arranged on the outer side of the rounding disc; the round abutting plate and the rounding disc are concentric; and the fixing seats are welded to the outer wall of the round abutting plate in the circumferential direction at equal intervals. The steel structureprofile machining and rounding machine has the characteristics of being rapid in forming, high in forming quality and wide in application range.

Owner:瑞安市安泰地矿建筑工程有限公司

Bending machine with assisted locating jig

InactiveCN103418644AWill not deformGuaranteed bending qualityMetal-working feeding devicesPositioning devicesPunchingEngineering

The invention relates to a bending machine with an assisted locating jig. The bending machine comprises a bending machine body, wherein the bending machine body is provided with a workbench for placing plates and a punching plate for extruding the plates, and one side of the punching plate is also provided with a group of positioning posts. The bending machine is characterized in that three equally spaced guiding rods are arranged on the workbench and are fixedly arranged on the workbench through bolts, a group of anti-deflection mechanism is arranged between every two adjacent guiding rods, each anti-deflection mechanism consists of two positioning plates and a smooth post which is horizontally and fixedly arranged between the two positioning plates, the positioning plates are fixedly arranged on the workbench through bolt bases, at least one smooth ball is embedded into each positioning plate, and the horizontal top end of each smooth post and the topmost end of the corresponding smooth ball are located on the same horizontal surface. The bending machine is used for high-precision bending, advance detection is carried out on the planes where to-be-bent plates are located by means of the anti-deflection mechanisms, head parts of the plates are prevented from deforming due to nonuniform extrusion force when the plates are bent, and the bending quality is ensured.

Owner:ENG EQUIP CO LTD SUZHOU SAI SIDE

Side bending mold for back plate

InactiveCN104826933AAvoid surface abrasionGuaranteed bending qualityShaping toolsEjection devicesEngineeringMechanical engineering

Owner:昆山电子羽电业制品有限公司

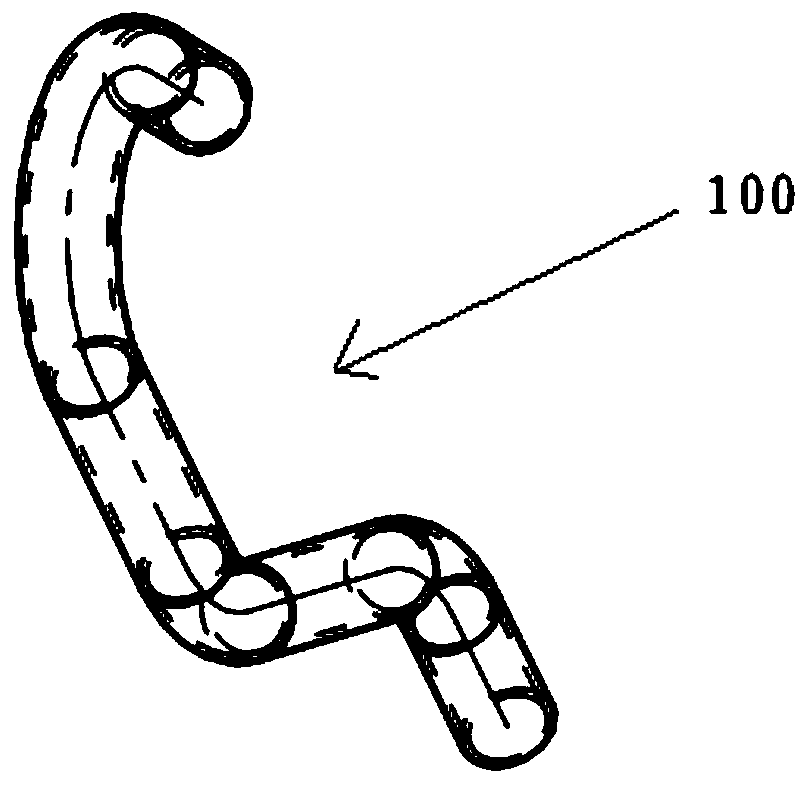

Copper pipe bend forming device

The invention relates to a copper pipe bend forming device. The copper pipe bend forming device comprises a bottom plate and a guide groove block. The guide groove block is fixedly mounted on the bottom plate, and an open curved groove with the shape matched with the preset product shape is formed in the guide groove block. The bottom plate is the mounting foundation of the guide groove block. According to the preset shape of a product needing bend forming, the corresponding open curved groove is formed in the guide groove block; when bending treatment is carried out, a copper pipe moves around the guide groove block to be matched with and attached to the open curved groove, and the bent copper pipe product in the needed shape can be obtained. The copper pipe bend forming device is suitable for manually manufacturing small-batch bent pipe products, the copper pipe bend forming device can achieve universality under the condition of guaranteeing the bending quality of the manual bent copper pipe products, different open curved grooves can meet different bent shape requirements, and meanwhile use is convenient.

Owner:BEIJING INST OF RADIO MEASUREMENT

steel bending machine

The invention discloses a steel bar bending machine which comprises a material seat, conveying wheel units, fixed blocks and a connecting rod mechanism; the material seat is mounted on a machine frame; grooves are formed in the material seat; the conveying wheel units used for conveying steel bars are arranged in the grooves; the fixed blocks located on one sides of the conveying wheel units are arranged in the grooves; and the connecting rod mechanism used for bending each steel bar at a 90-degree bending angle is located on one side of the material seat. The steel bar bending machine has the advantage of being simple in structure, and working efficiency of steel bar bending is improved greatly while labor intensity of a worker is reduced effectively.

Owner:广东宏安丰人防工程有限公司

Four-face enclosed box bending mold and using method thereof

ActiveCN106424372AChange the processing methodReduce processing difficultyShaping toolsMechanical engineeringEngineering

The invention discloses a four-face enclosed box bending mold and a using method thereof and belongs to the field of bending molds. The problems that in the prior art, during bending forming of specified structures, the bending precision is poor, and the labor intensity is high are solved. The mold comprises an upper mold body which comprises an upper mold base, an upper mold tool, a rotary tool base and a rotary tool. The upper mold tool is fixed to one side of the upper mold base. A rotary cavity is formed in the lower end of the upper mold tool. The rotary tool base is fixed to the outer side of the upper mold tool, and one end of the rotary tool base stretches out of the rotary cavity. The rotary tool is arranged in the rotary cavity and rotatably and fixedly arranged on the rotary tool base. By adoption of the mold, the bending precision can be effectively improved, the convenience of operation is improved, and therefore the production efficiency is improved, and the machining efficiency and quality can be further improved.

Owner:ANHUI LIYUAN NUMERICAL CONTROL CUTTING TOOL & PATTERNS MFG

Semi-automatic graduated steel bar bending machine

InactiveCN104259339BGuaranteed bending precisionStable clampingMetal working apparatusSemi automaticEngineering

The invention discloses a semi-automatic scale mark reinforcing steel bar bending machine, relates to the technical field of reinforcing bar bending forming devices, and aims at providing the semi-automatic scale mark reinforcing steel bar bending machine with the accurate bending angle. According to the technical scheme, the semi-automatic scale mark reinforcing steel bar bending machine comprises a machine tool. A working disc connected with the machine tool is arranged at the upper portion of the machine tool. A rotating disc is arranged at the center of the working disc and connected with a power mechanism inside the machine tool and rotates around the axis of the rotating disc. A plurality of positioning shaft holes and a plurality of clamping shaft holes are evenly distributed in the rotating disc in the circumferential direction of the rotating disc. Positioning shafts and clamping shafts are correspondingly placed in the positioning shaft holes and the clamping shaft holes respectively. The working disc and the rotating disc are each provided with scale marks. The number of the scale marks on the rotating disc is larger than the number of the scale marks on the working disc. Through the position relation between the zero scale mark on the working disc and the zero scale mark on the rotating disc and through the scale marks, coinciding with the scale marks on the working disc, of the rotating disc, the rotation angle of the rotating disc can be obtained.

Owner:SICHUAN DINGRUI HYDRAULIC EQUIP MFR

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com