Patents

Literature

42results about How to "Timely transport" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

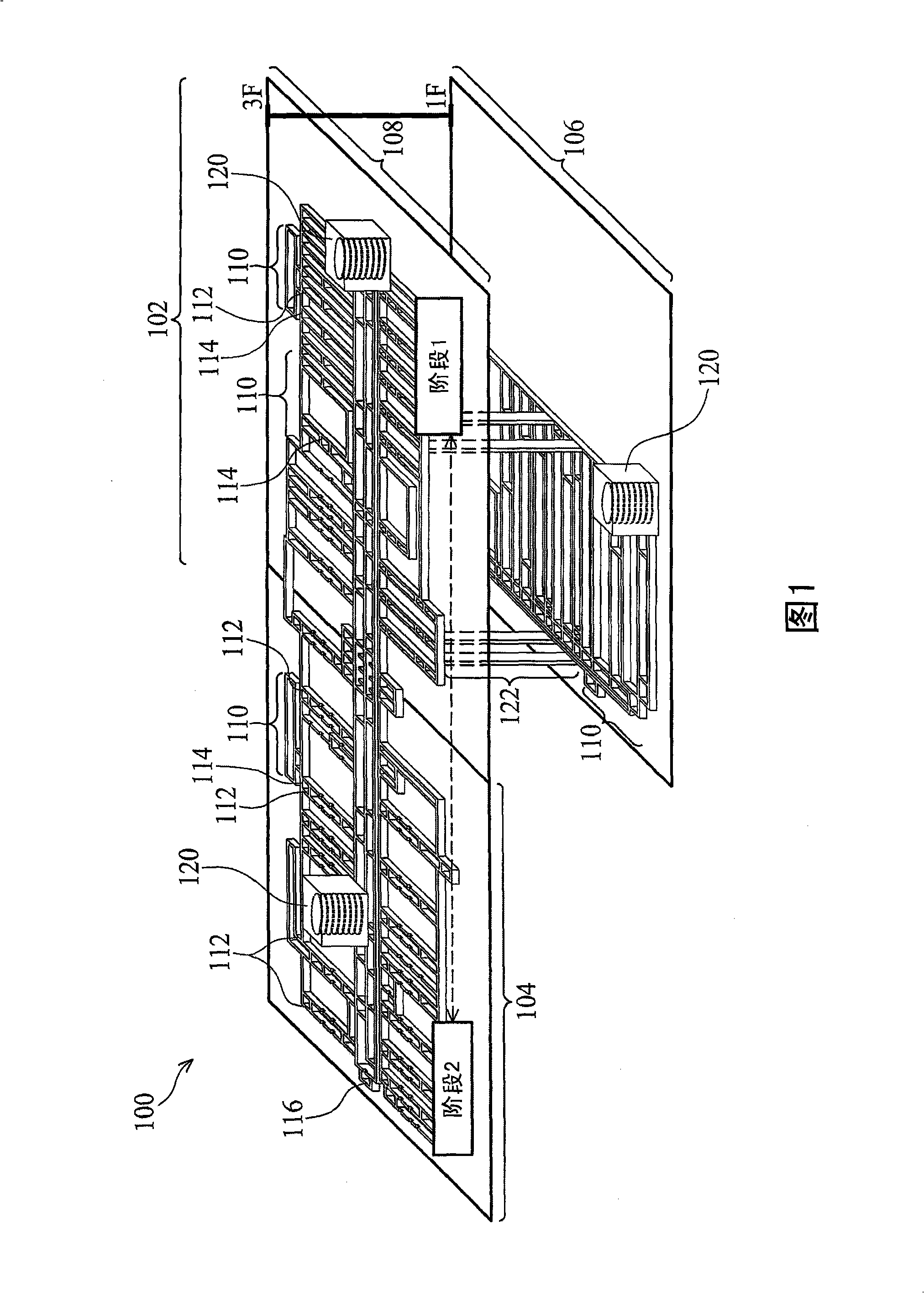

Construction method for dismounting high-rise cast-in-place concrete building

InactiveCN102852344AAvoid enteringSolve puzzles that cannot be dismantledBuilding repairsFloor slabArchitectural engineering

The invention discloses a construction method for dismounting a high-rise cast-in-place concrete building. The construction method comprises the following steps of: (1) carrying out security checking calculation on bearing capability according to a load applied to a building structure when a building dismounting machine carries out dismounting operation among floors; arranging ejecting and supporting structures between the adjacent floors from a floor to be constructed to the bottom, wherein the ejecting and supporting structures are respectively ejected and fastened against an upper floor plate and a lower floor plate; and the quantity of floors in need of arranging the ejecting and supporting structures, and the quantity and the arrangement positions of the ejecting and supporting structures can be determined according to data obtained through the security checking calculation; (2) building a protection facility and erecting a passageway; (3) hoisting, assembling and debugging the building dismounting machine; and (4) crushing and dismounting the floors by using the floor dismounting machine. With the adoption of the construction method for dismounting the high-rise cast-in-place concrete building, provided by the invention, the bearing capabilities of a plurality of layers of floors are overlapped by using the ejecting and supporting structures, so as to provide the security for a large-size machine to do upstairs operation. The difficult problem that the large-size machine cannot be used for dismounting the high-rise building can be solved.

Owner:CHONGQING BLASTING CONSTR +1

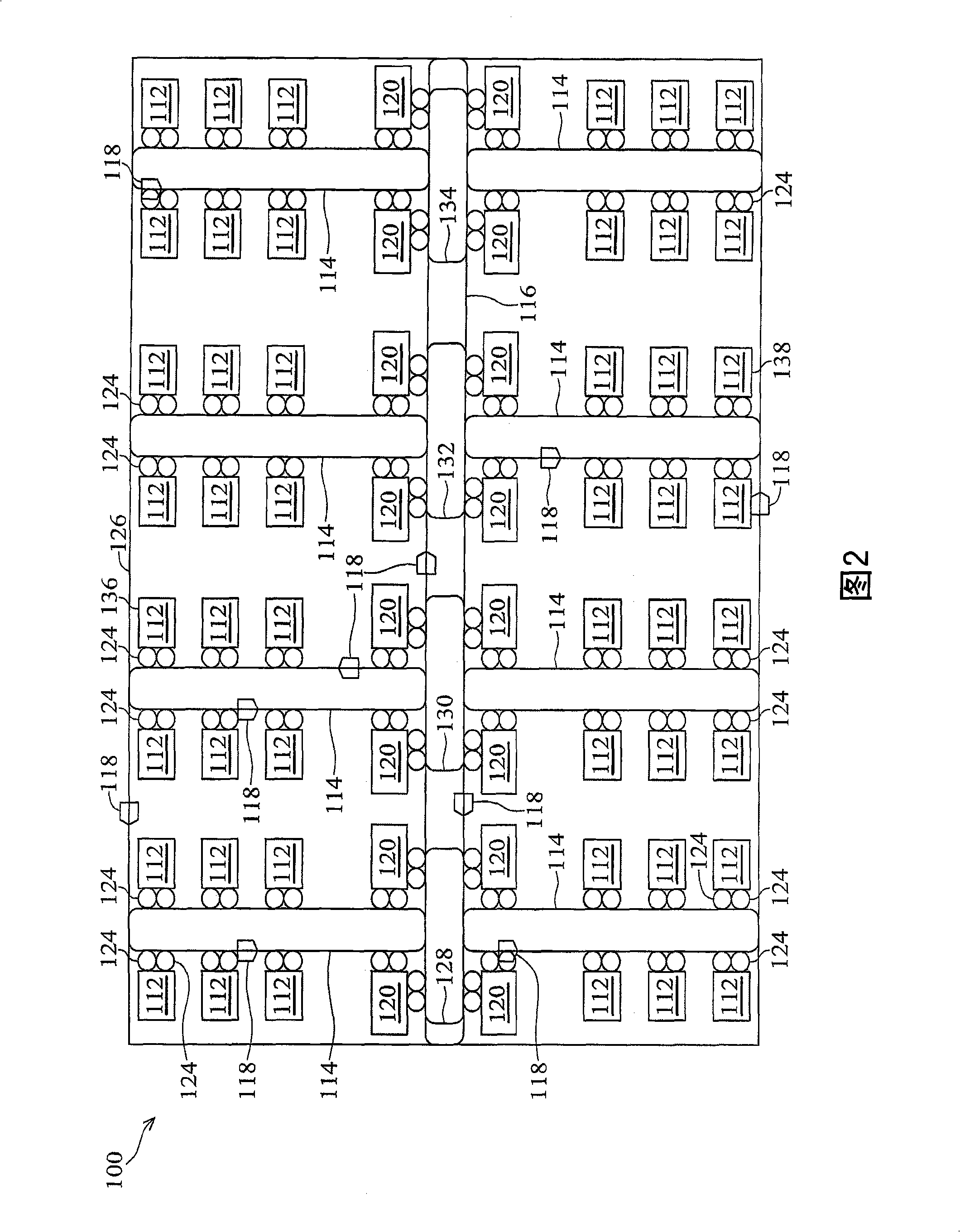

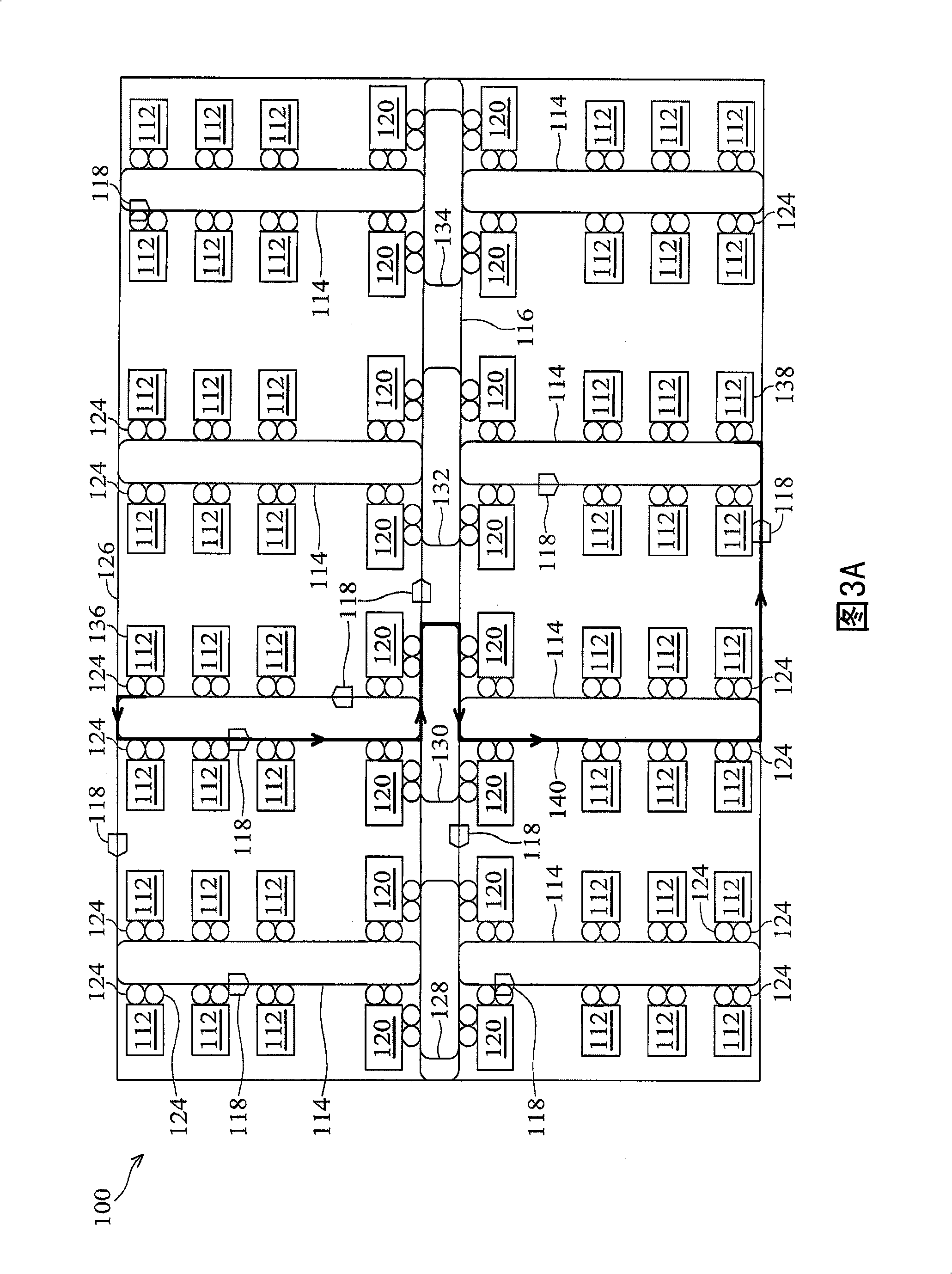

Method and system for factory automation system

ActiveCN101281404ATimely transportReduce trafficSemiconductor/solid-state device manufacturingForecastingTraffic volumeWafer fabrication

In one aspect a factory automation system for a wafer fab is provided. The factory automation system comprises: a manufacturing execution system for providing lot information; a material control system for providing dynamic traffic information; an automated material handling system for providing static route information; and a real-time dispatching system to select a destination and a route for a wafer carrier in response to a transfer request. In another aspect a method of transferring a wafer lot within a wafer fabrication facility using a factory automation system is provided. The method comprises: receiving a transfer request to move the wafer lot from a first position to a second position within the fab; obtaining lot information, dynamic traffic information, and static traffic information; using the information to select a route between the first position and the second position; and executing the transfer using the selected route.

Owner:TAIWAN SEMICON MFG CO LTD

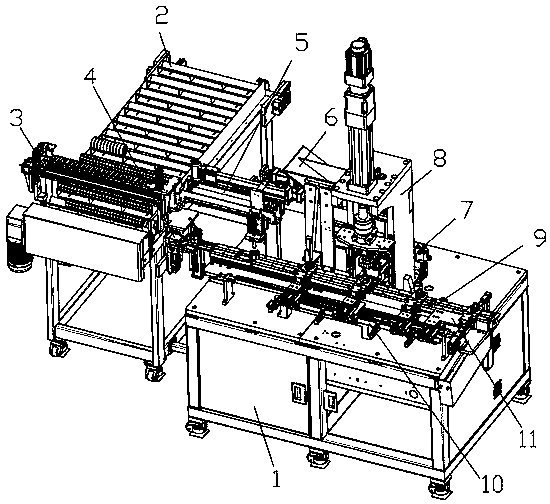

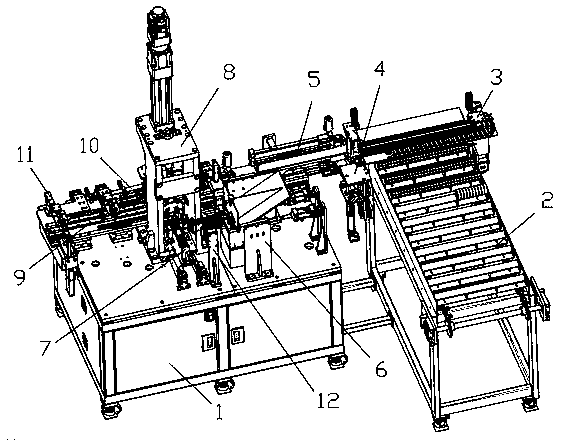

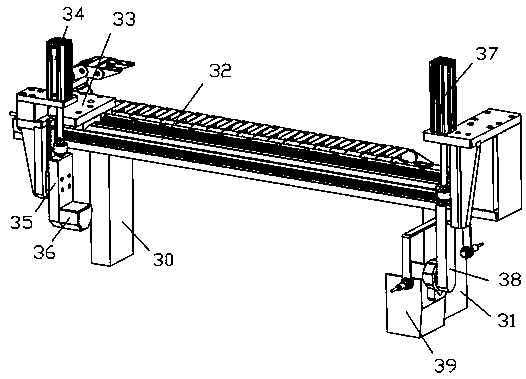

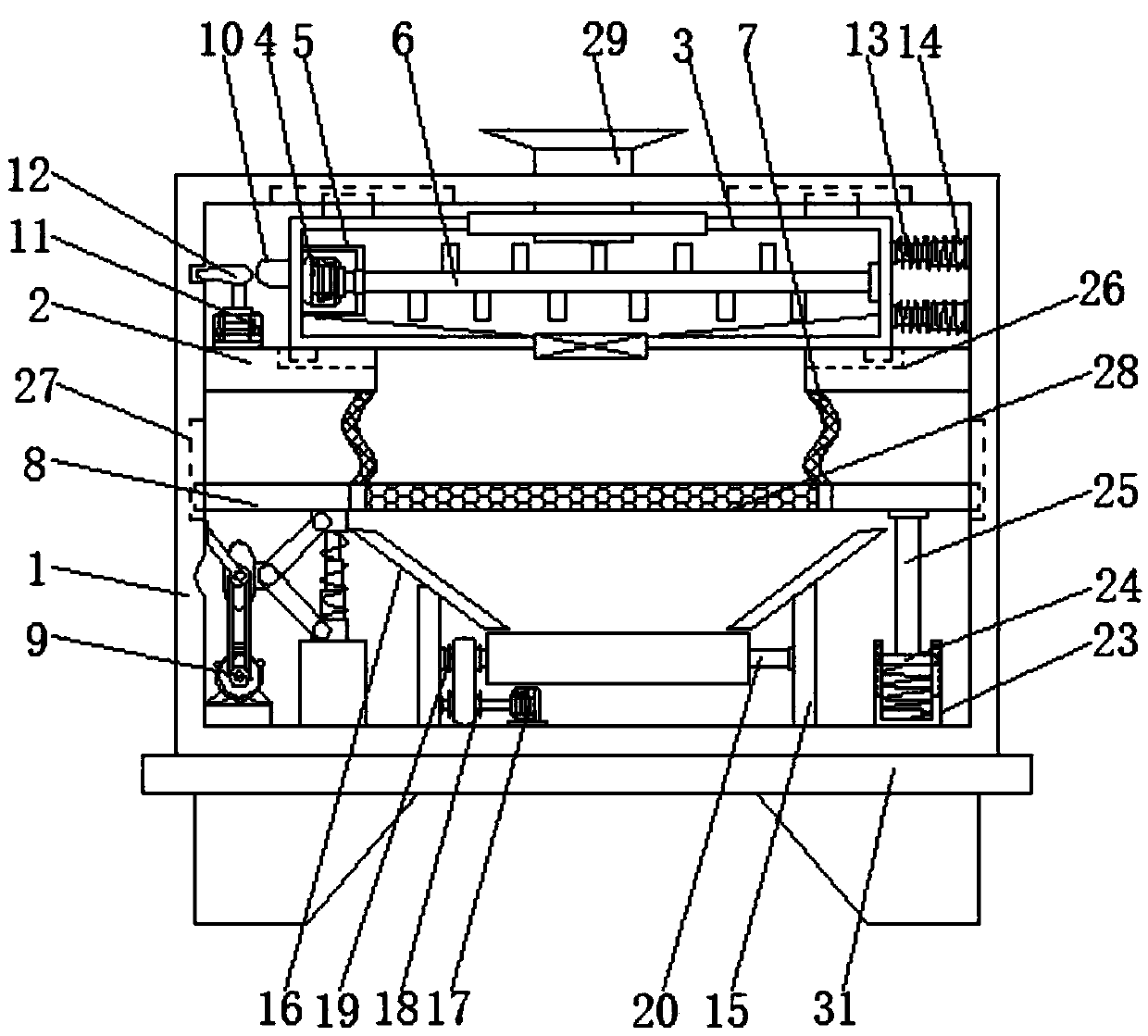

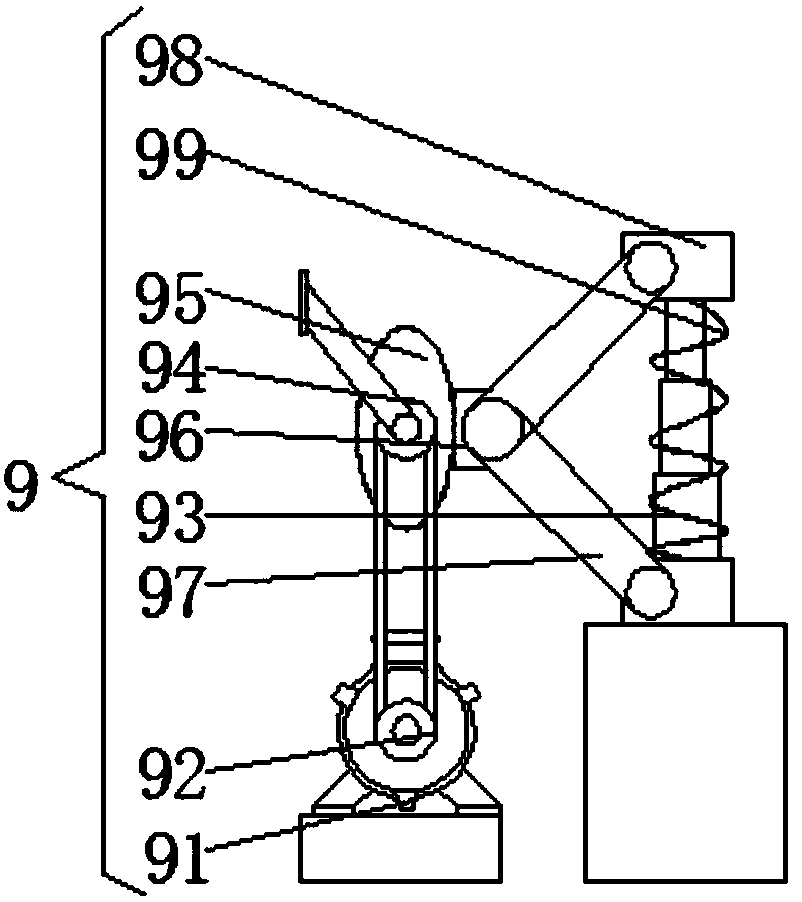

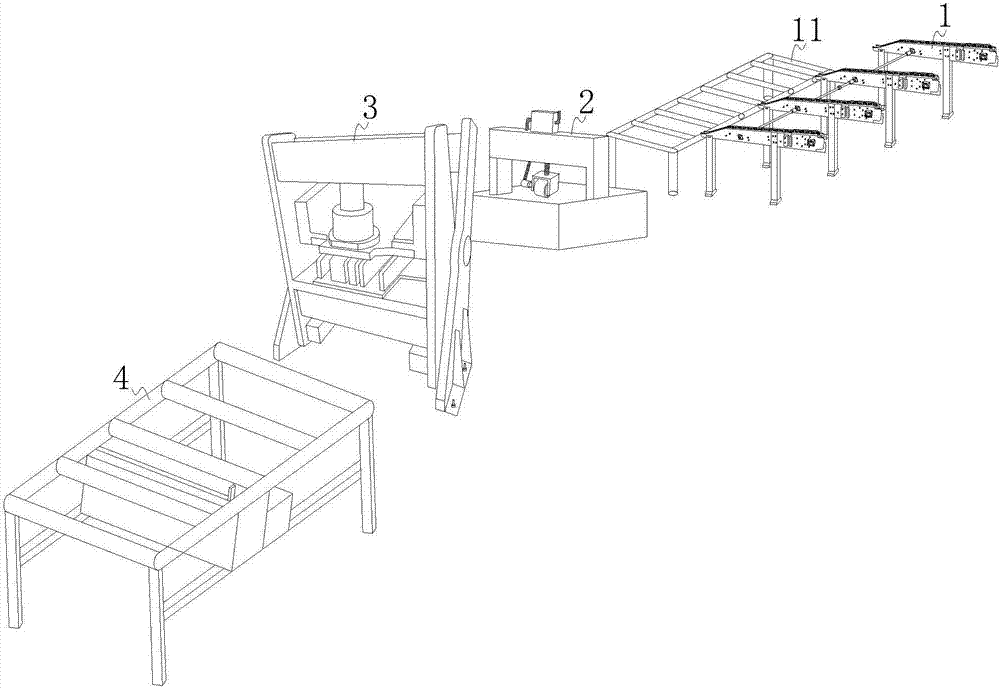

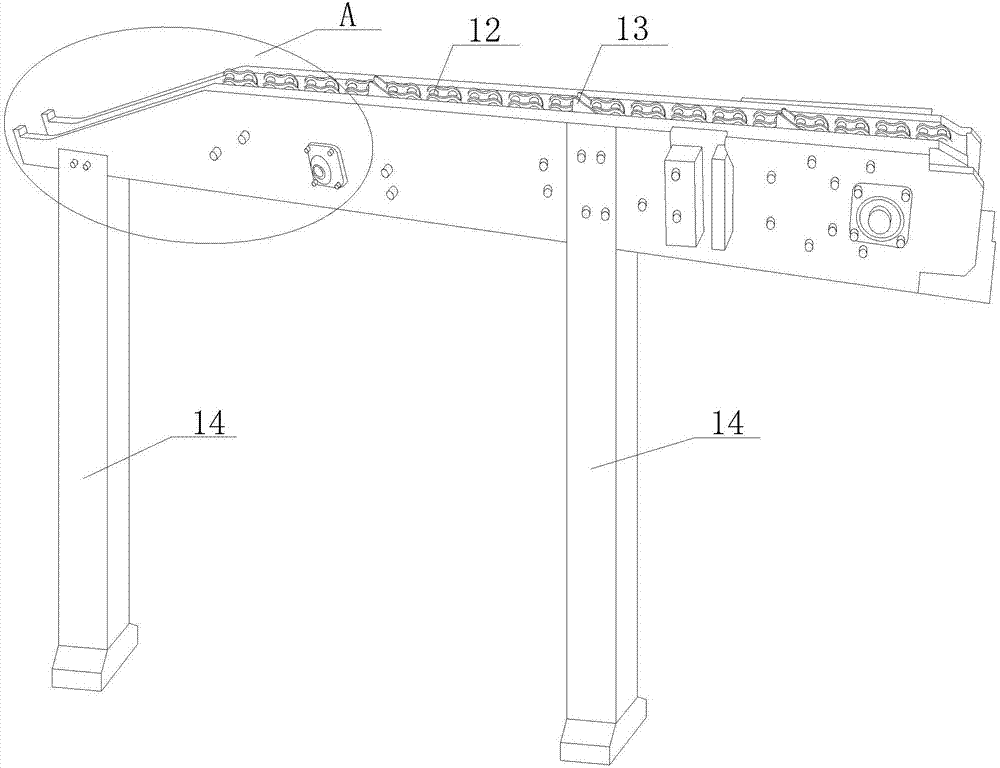

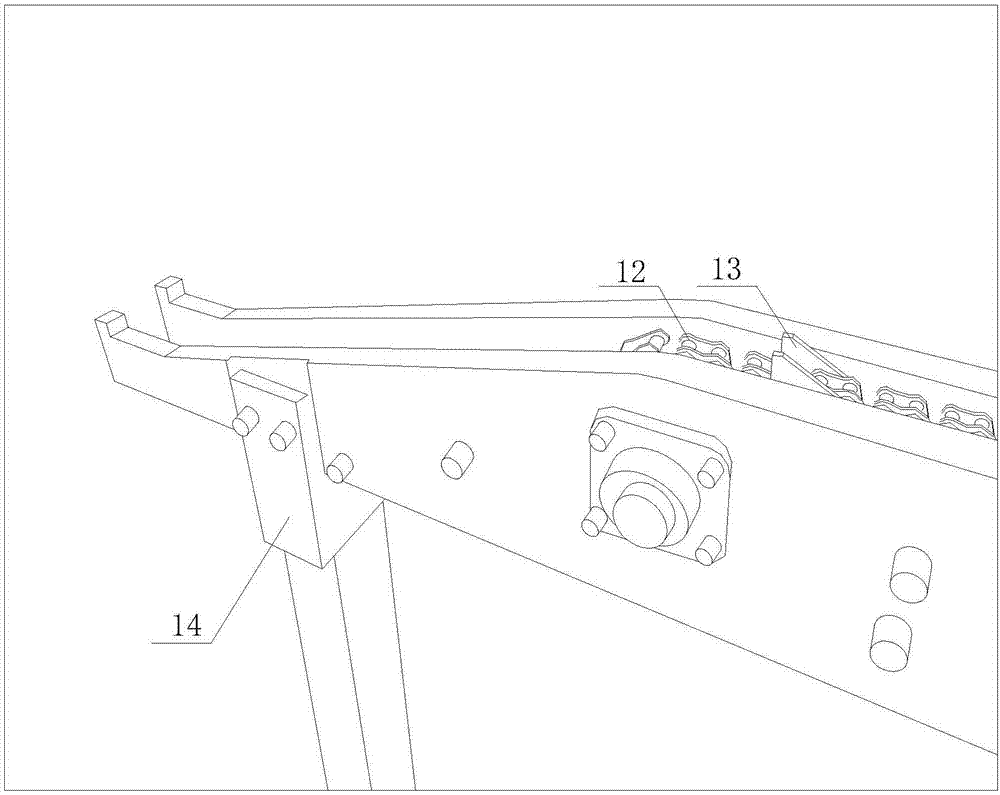

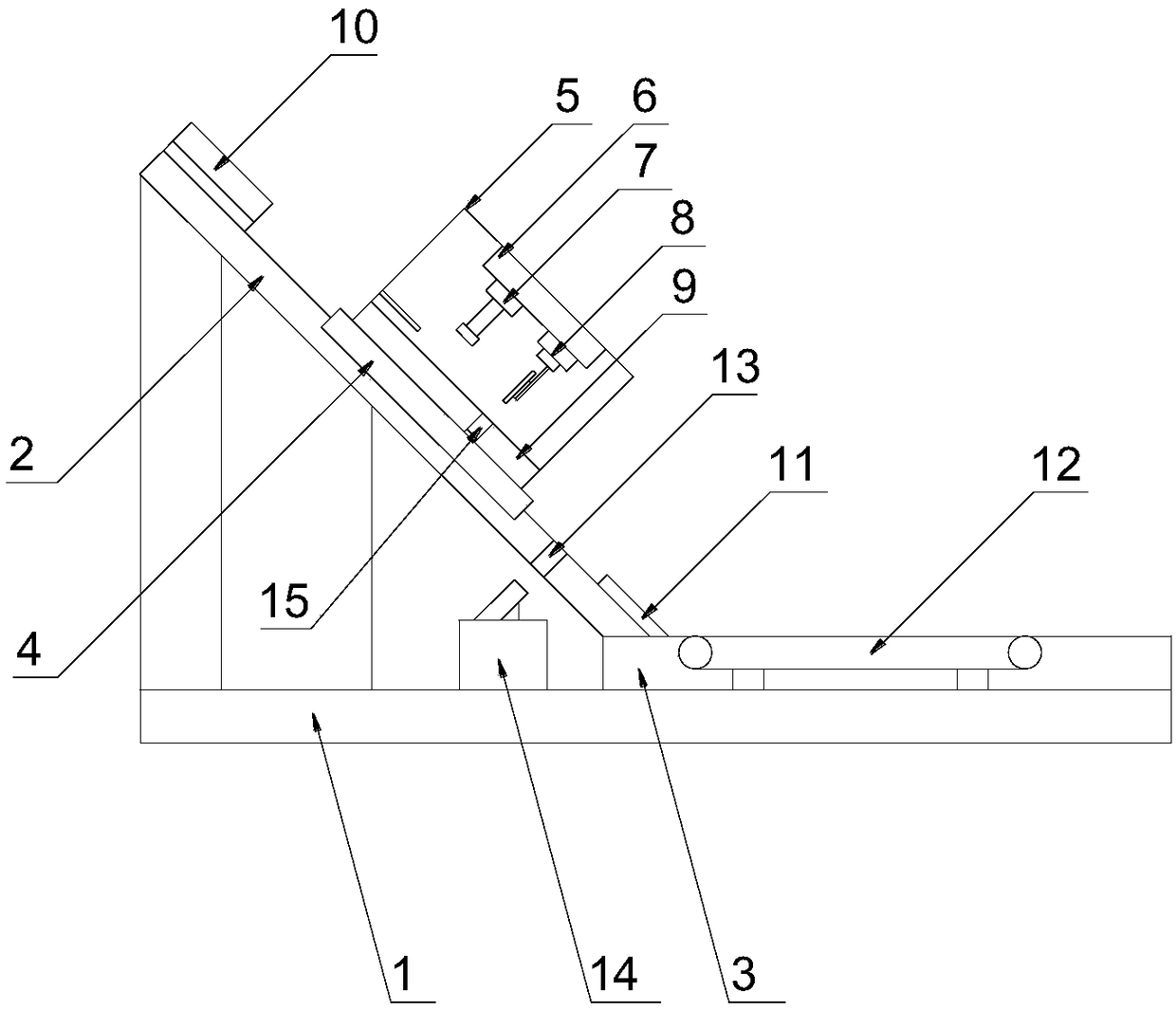

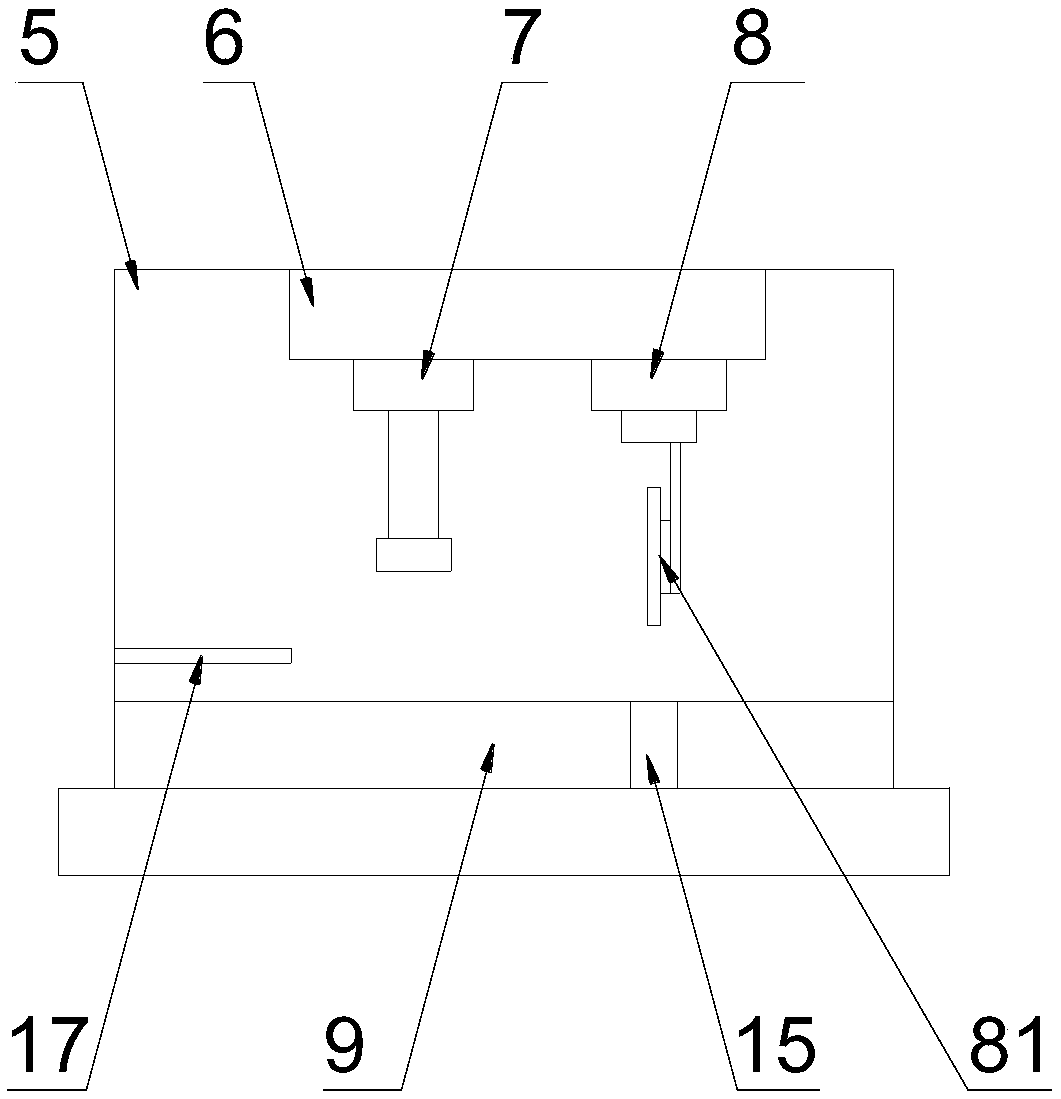

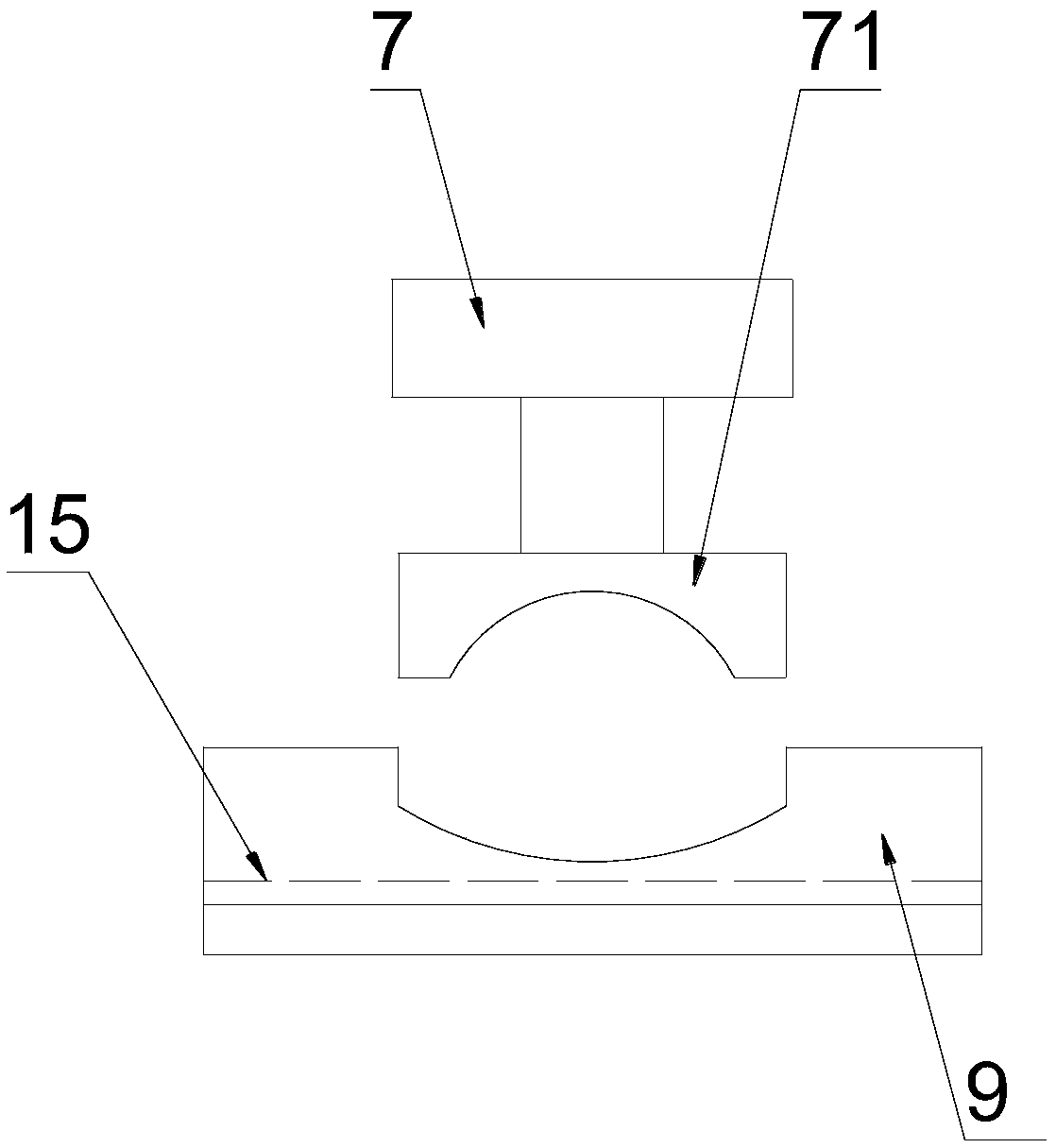

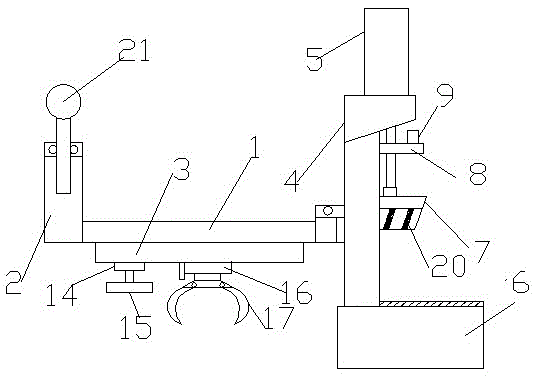

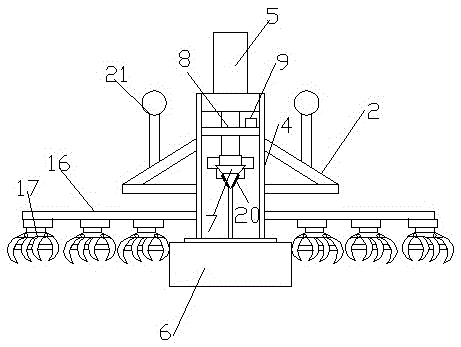

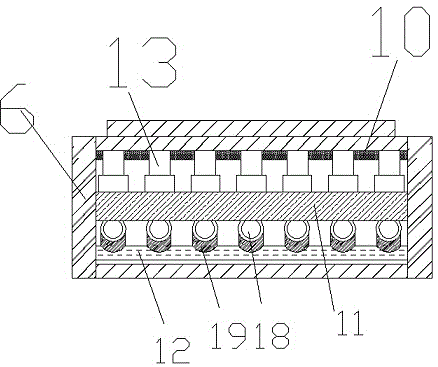

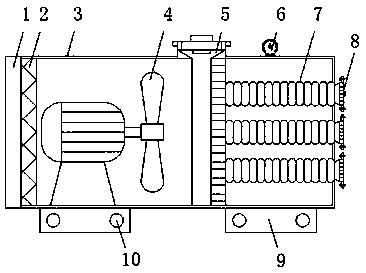

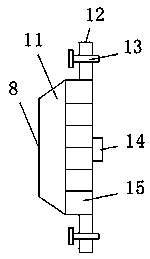

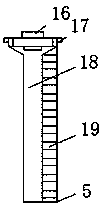

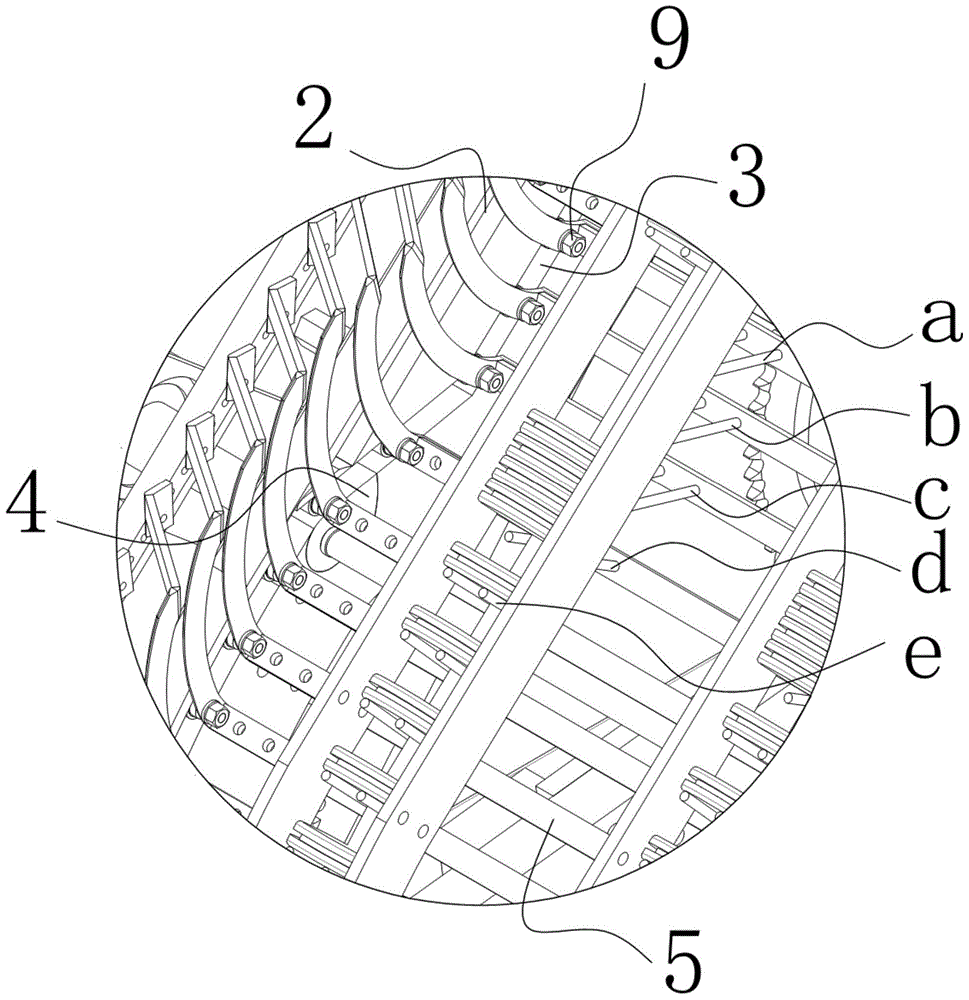

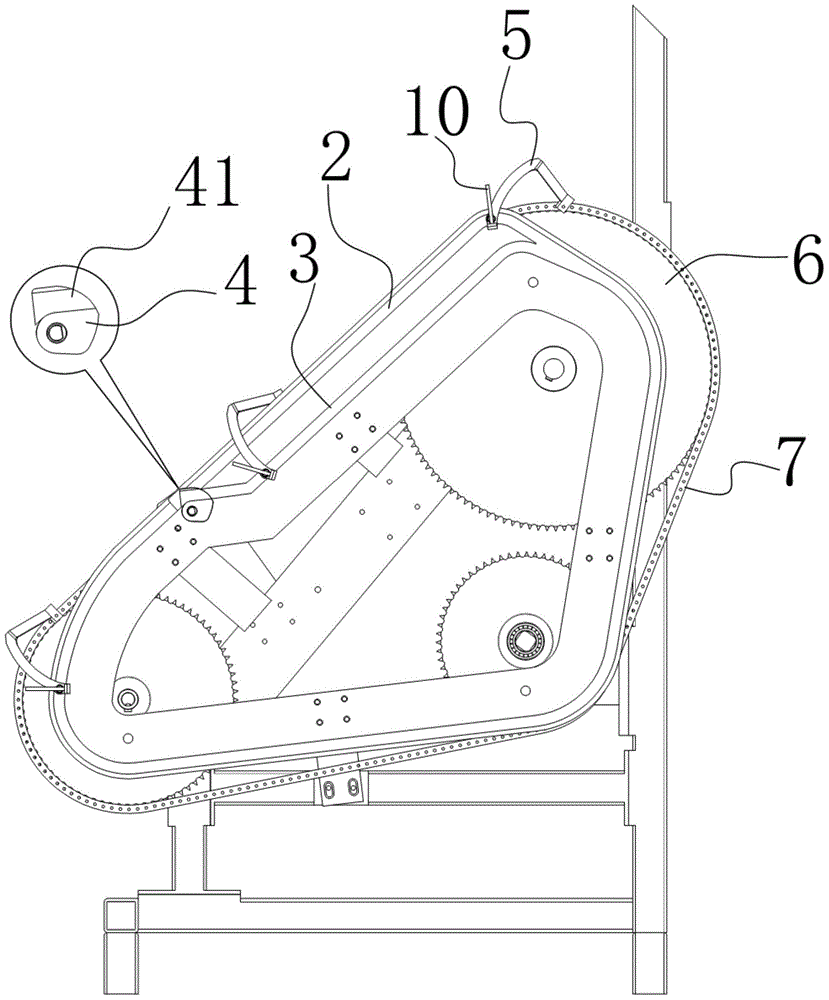

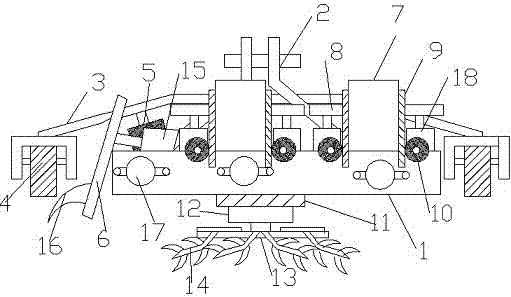

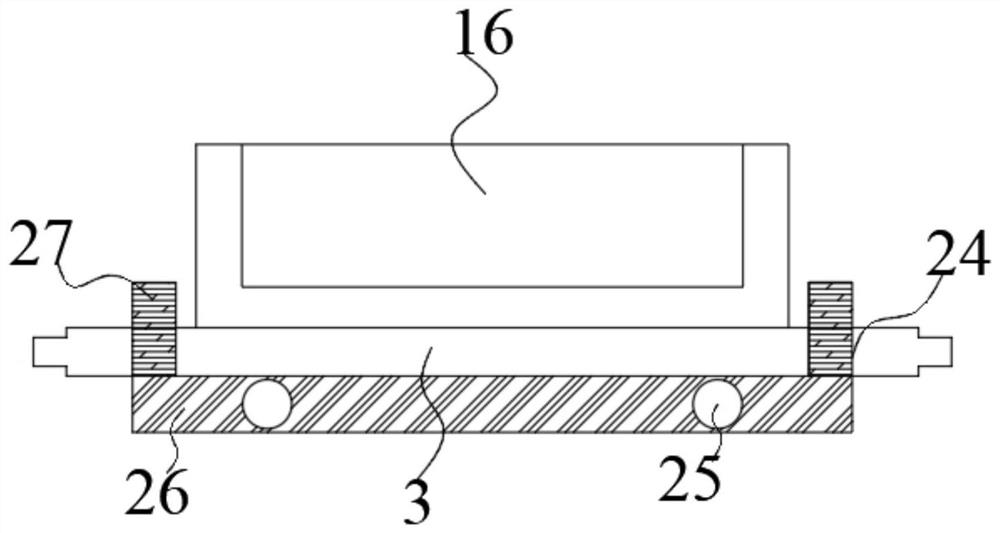

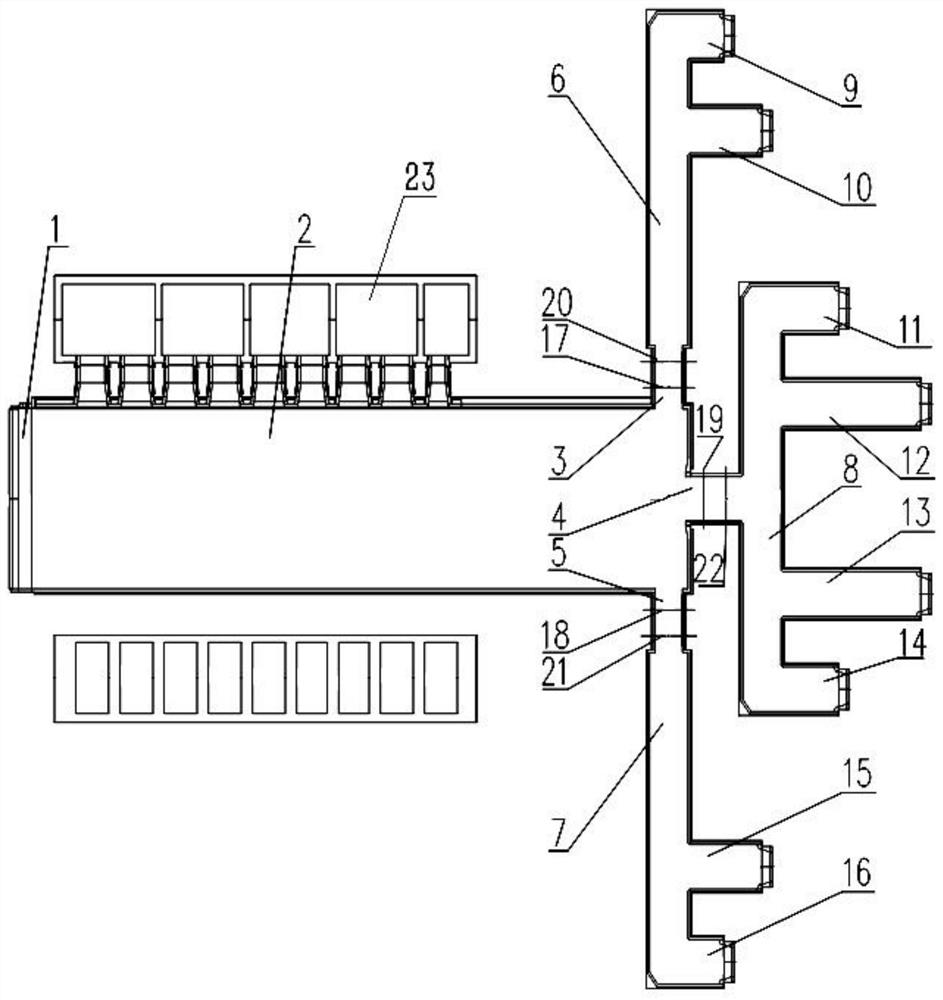

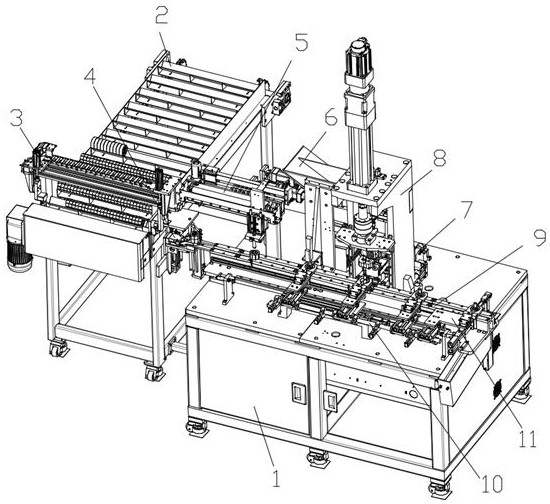

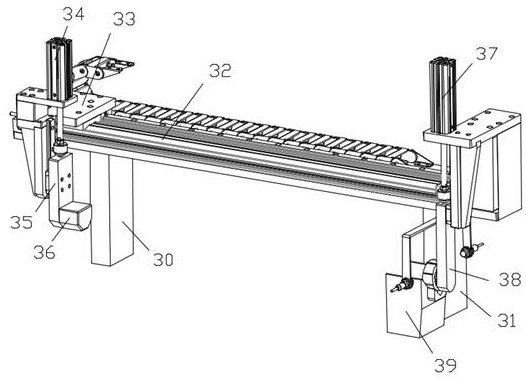

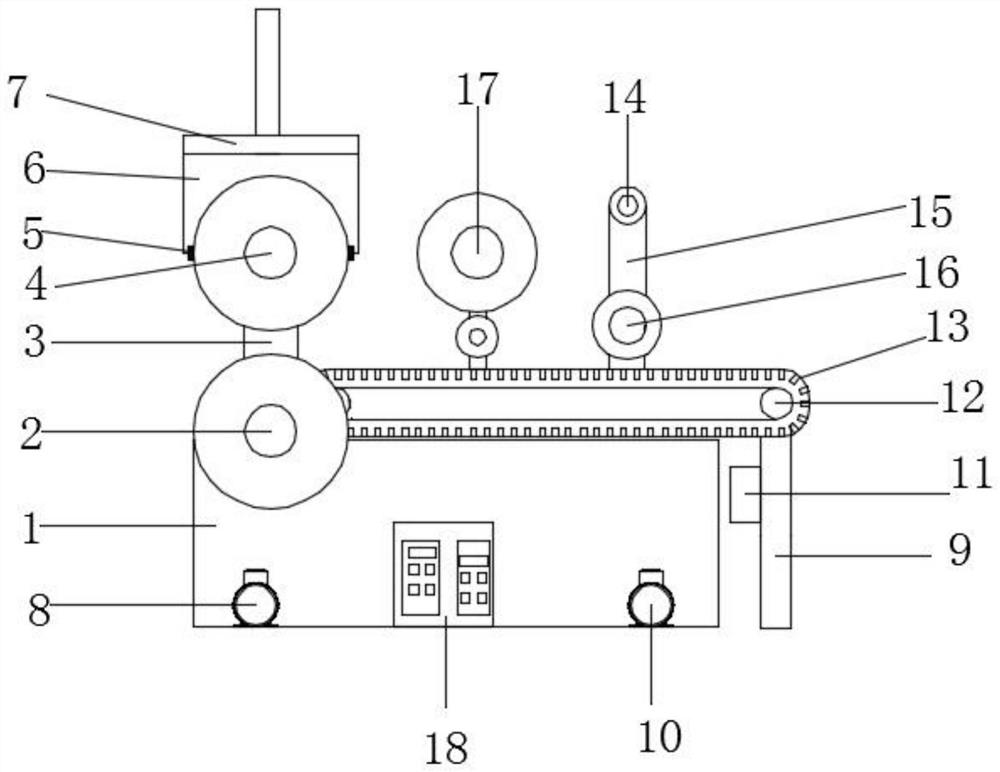

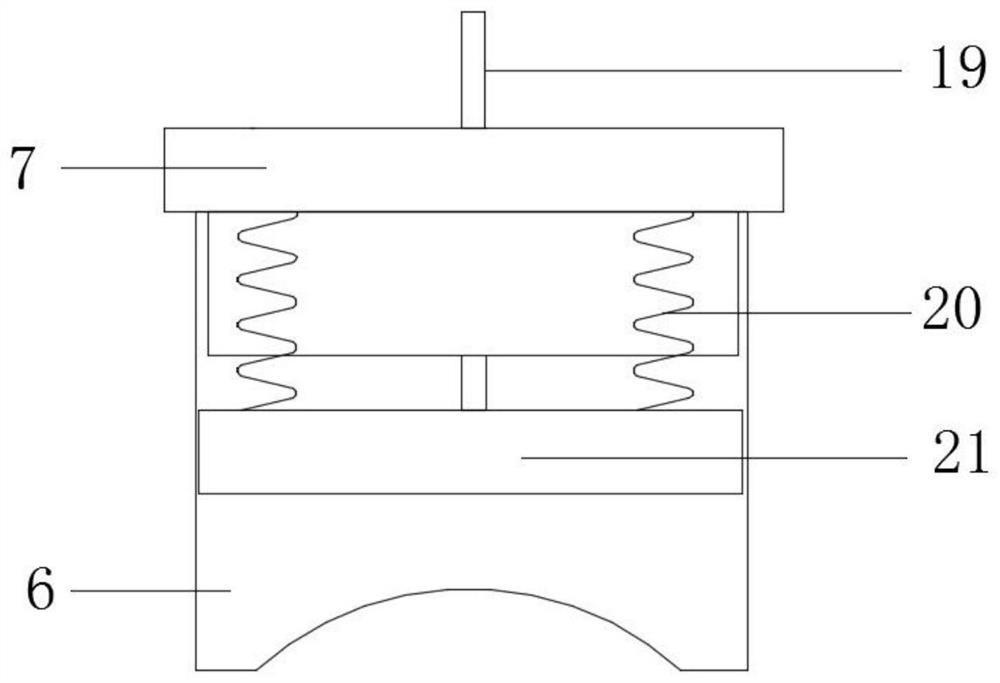

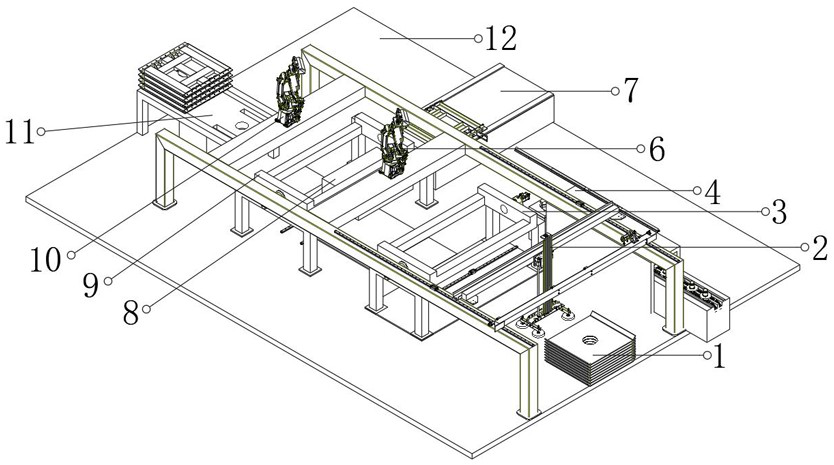

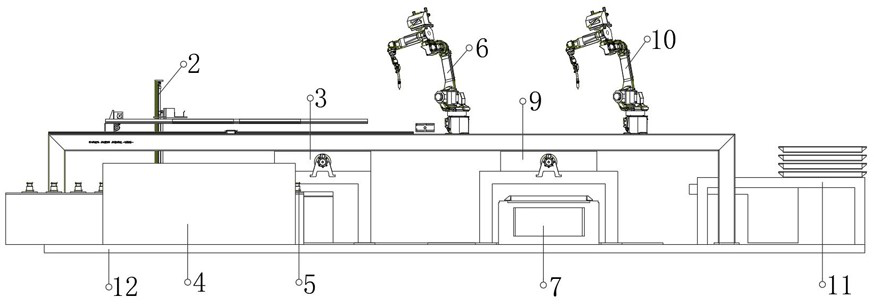

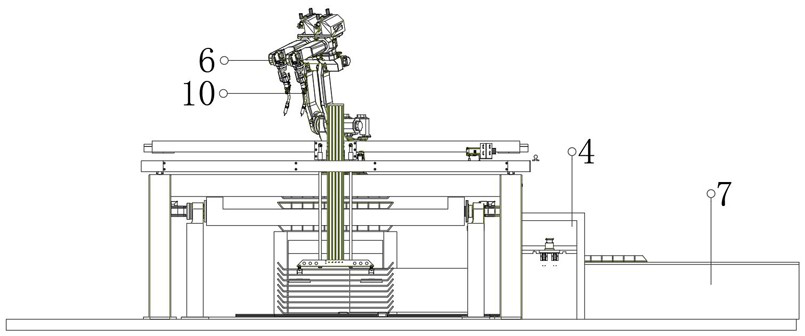

Automatic press-fitting equipment for motor shaft

ActiveCN111318868AFit closelyAccelerateManufacturing stator/rotor bodiesMetal working apparatusElectric machineryMotor shaft

The invention relates to automatic press-fitting equipment for a motor shaft. The automatic press-fitting equipment comprises a loading track conveying mechanism and a workbench, wherein the loading track conveying mechanism is located at the left side of the workbench; a chassis of the loading track conveying mechanism is fixedly connected to the left part of the workbench through a fixed frame;a track feeding mechanism, a motor shaft loading and press-fitting mechanism and an unloading mechanism are arranged on the upper surface of the workbench; the track feeding mechanism is horizontallyfixed to the front side of the upper surface of the workbench; the motor shaft loading and press-fitting mechanism is located at the rear side of the track feeding mechanism; the unloading mechanism is arranged at the position of a discharge hole of the track feeding mechanism; the loading track conveying mechanism comprises a loading conveying chain device, a pushing device and a loading turnoverdevice; the pushing device is located above a discharge hole of the loading conveying chain device; and the loading turnover device is located at the right side of a discharge hole of the loading conveying chain device. The automatic press-fitting equipment has high degree of automation and a high market application value, improves work efficiency, and saves labor cost.

Owner:NINGBO WANJI BEARING CO LTD

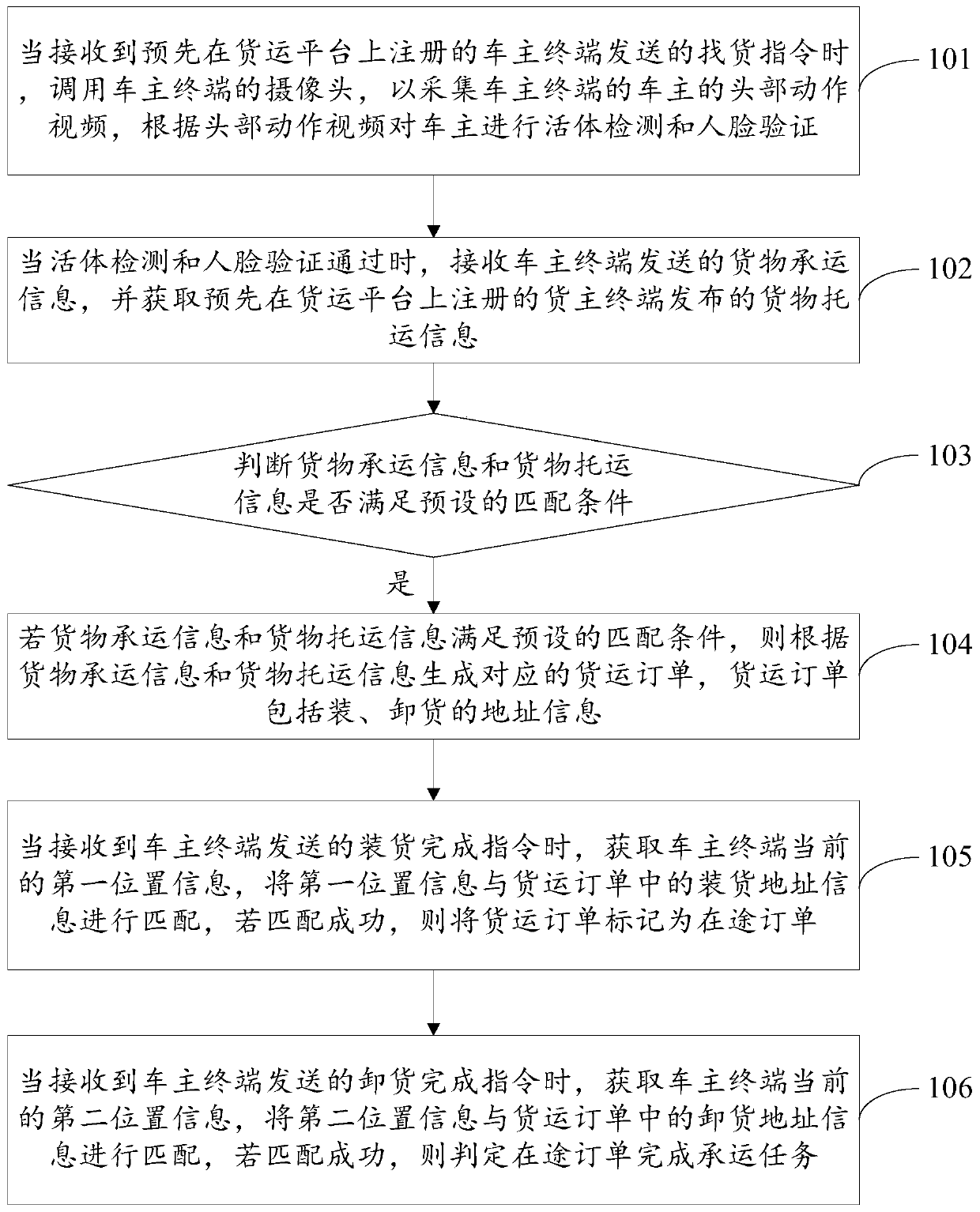

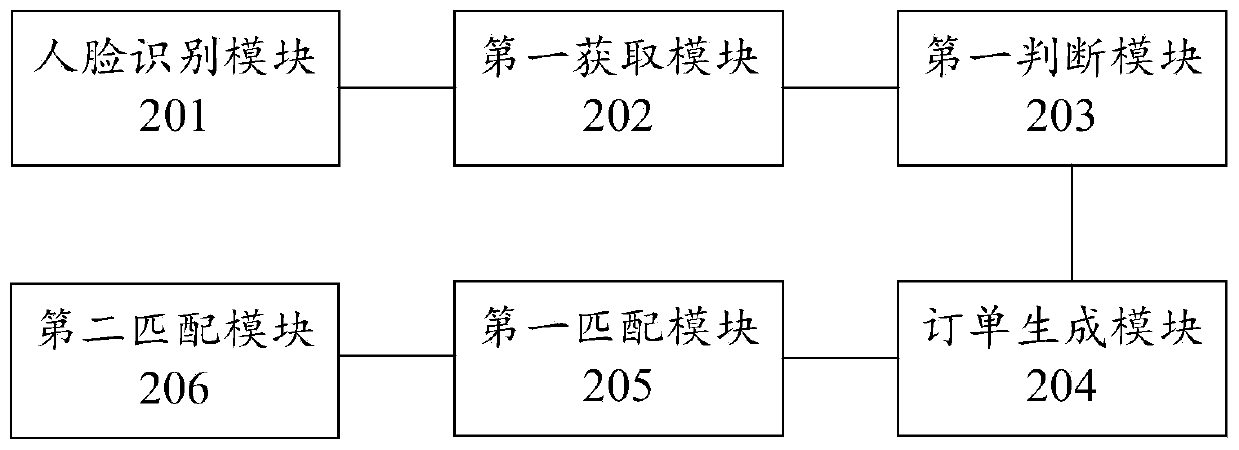

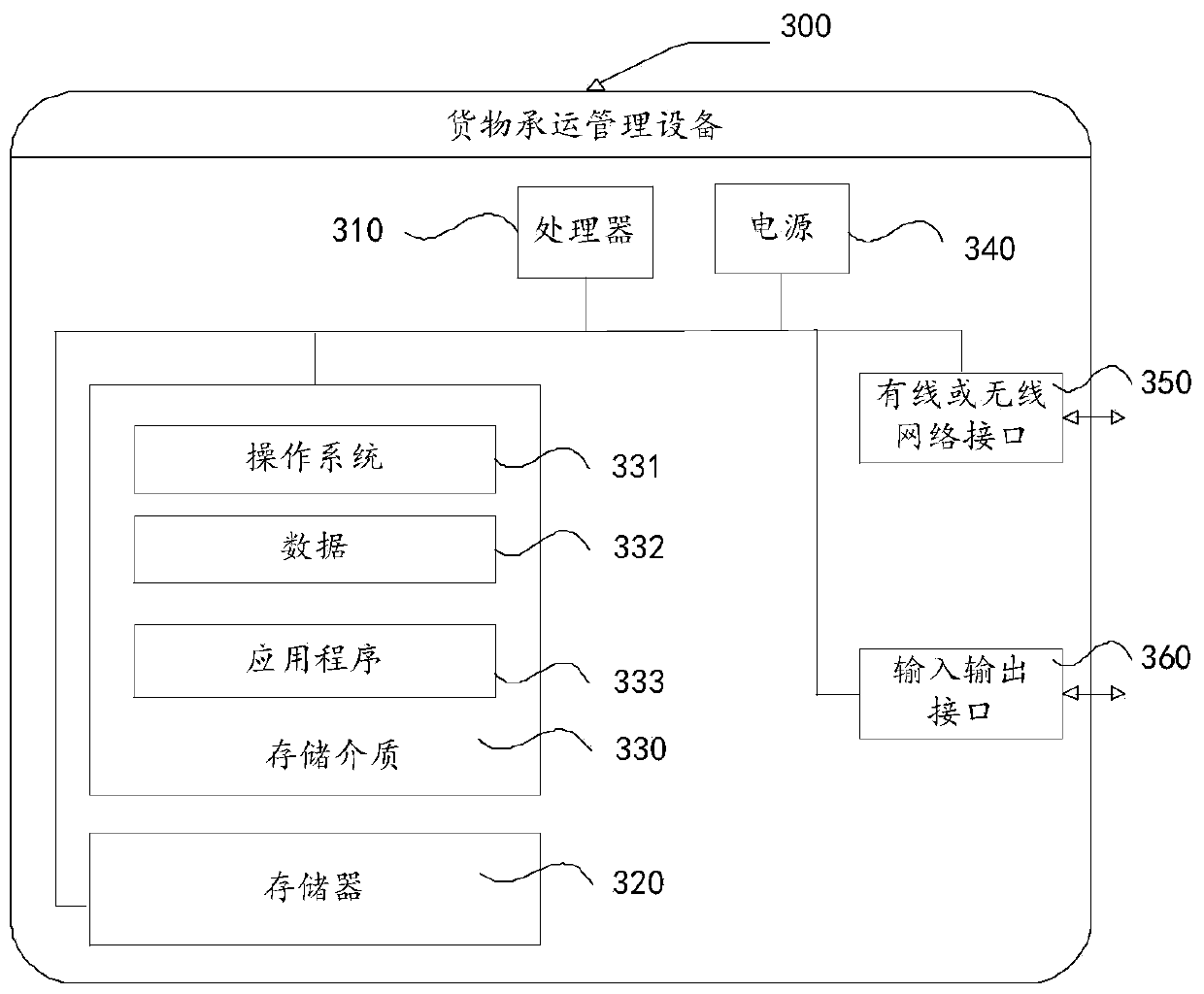

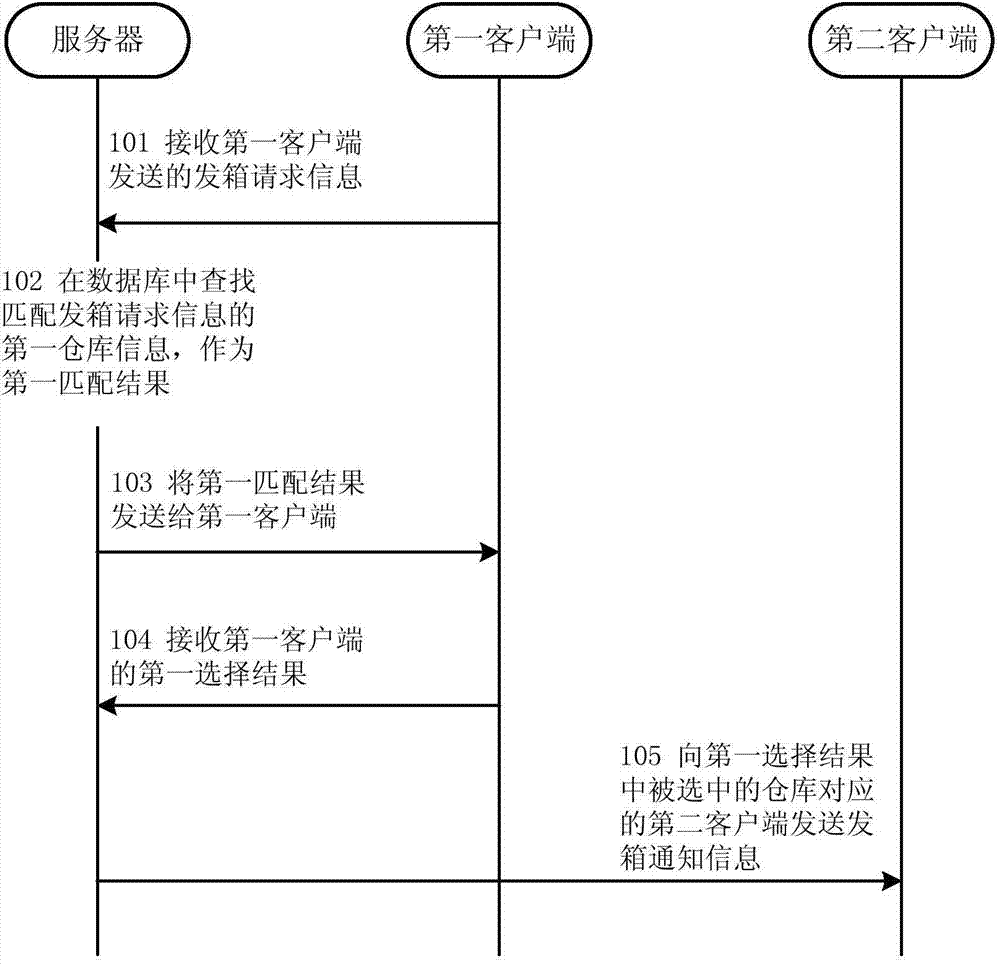

Cargo carrying management method and device, equipment and storage medium

PendingCN111260297ATimely transportGuaranteed incomeLogisticsSpoof detectionLogistics managementFace verification

The invention relates to the field of logistics management, discloses a cargo carrying management method and device, equipment and a storage medium, and is used for solving the problems of poor cargotransportation timeliness, high cost and opaque transportation process in the prior art. The method comprises the steps of: when a goods finding instruction sent by a vehicle owner terminal is received, performing living body detection and face verification on a vehicle owner; when the verification is passed, receiving cargo carrying information sent by the vehicle owner terminal, and obtaining cargo consignment information issued by the cargo owner terminal; when the two meet a preset matching condition, generating a corresponding freight order; when a loading completion instruction is received, obtaining and matching current first position information of the vehicle owner terminal with loading address information in the order, and if matching succeeds, marking the freight order as an in-transit order; and when an unloading completion instruction is received, obtaining and matching current second position information of the vehicle owner terminal with unloading address information inthe order, and if matching succeeds, judging that the in-transit order completes the carrying task.

Owner:SHANGHAI DONGPU INFORMATION TECH CO LTD

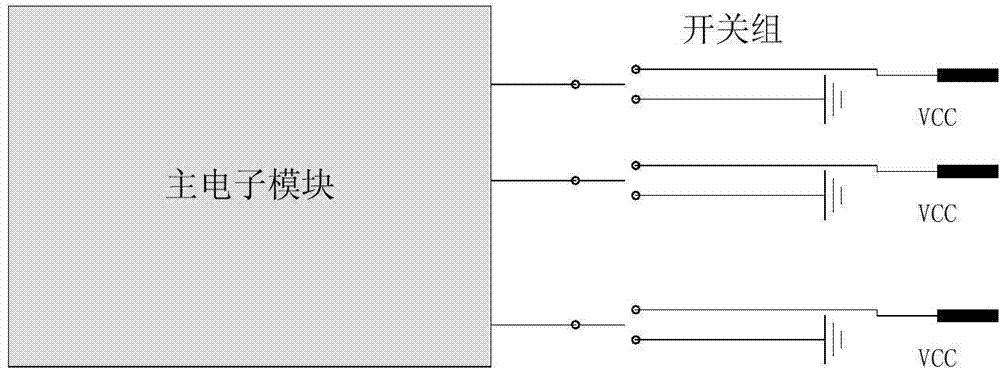

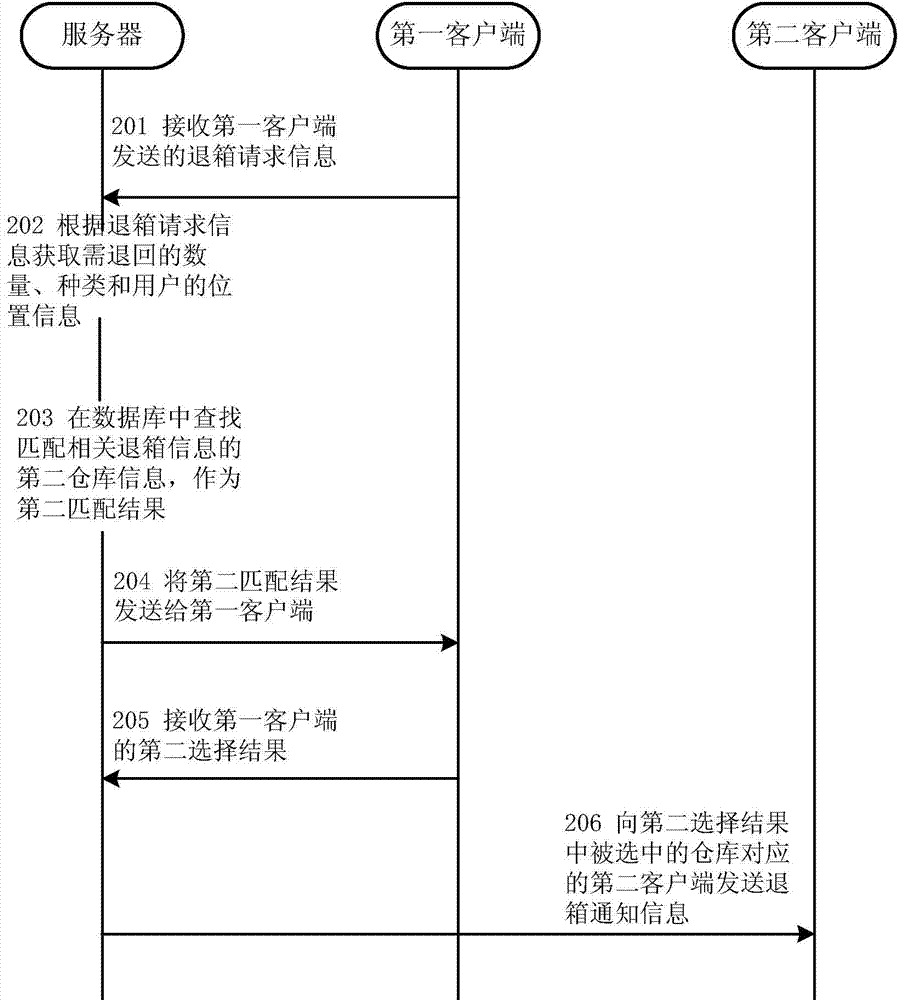

Sharing method and system for recyclable logistics appliances

The invention relates to communication technologies, and discloses a sharing method and system for recyclable logistics appliances. A server performs return processing of the recyclable logistics appliances according to the storage conditions and position information of warehouses, so that optimal distribution of the recyclable logistics appliances is achieved. Furthermore, the corresponding relation between sent marks of the recyclable logistics appliances and position information of a user is stored in the server, so that in the box return process, it is only needed to acquire related box return information according to the marks of the recyclable logistics appliances without repeated input of the user, operation is convenient, and the box return speed is increased.

Owner:SHANGHAI HONGYAN RETURNABLE TRANSIT PACKAGINGS CO LTD

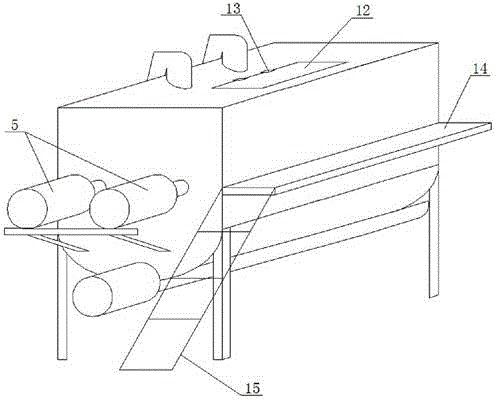

Portable rapid fine sand screening device

InactiveCN107930762AReduce sand screening processImprove work efficiencySievingRotary stirring mixersScreening proceduresWorkload

The invention discloses a portable rapid fine sand screening device, and relates to the technical field of building construction. The portable rapid fine sand screening device comprises a fixing box.Fixed plates are fixedly connected with the two sides of the inner wall of the fixing box. A stirring box is in sliding connection with the tops of the fixed plates through sliding blocks. One side ofthe inner wall of the stirring box is fixedly connected with a first motor. A protective housing is fixedly connected with one side of the inner wall of the stirring box and located outside the firstmotor. An output shaft of the first motor is fixedly connected with a stirring shaft. The bottoms of the fixed plates are fixedly connected with movable plates through soft pads. The bottom of the inner wall of the fixing box is fixedly connected with a shaking device through a base. According to the portable rapid fine sand screening device, the problems of low sand screening speed and poor screening effect of an existing sand screening machine are solved, screened sand meets the effect expected by people, sand screening procedures are reduced, working efficiency of sand screening is improved, workloads of people are relieved, and a large quantity of resources are saved.

Owner:易亮

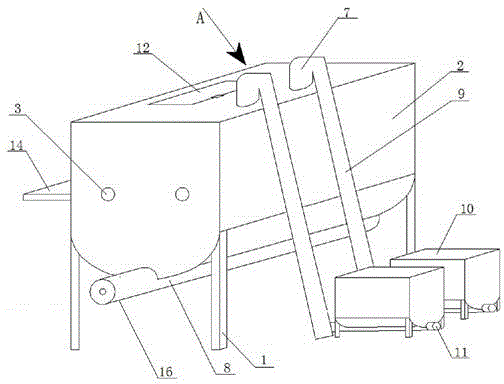

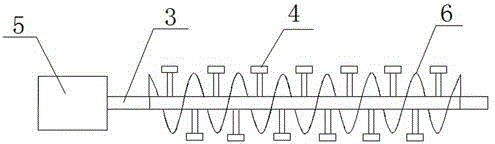

Pepper powder blending apparatus

InactiveCN105413511ASimple structureEasy to operateRotary stirring mixersMixer accessoriesScrew conveyorEngineering

The present invention relates to a pepper powder blending apparatus. The apparatus comprises a stirring apparatus, a bracket and a blending tank mounted on the bracket, wherein the stirring apparatus comprises a stirring shaft mounted in the blending tank, stirring blades fixedly connected to the stirring shaft, and a driving apparatus for driving the stirring shaft. A first horizontal screw conveyor for conveying materials out of the tank is arranged at bottom of the blending tank, wherein the horizontal screw conveyor extends out of the blending tank. At least two feeding openings are formed in the top of the blending tank. The blending apparatus provided by the present invention is simple in structure and easy to operate, so that the labor is saved, the working environment is improved, the work efficiency is improved, and the mechanical degree of pepper processing is improved, and therefore the pepper processing and production are more clean and hygienic.

Owner:GANSU XINGNONG CHILI IND DEV

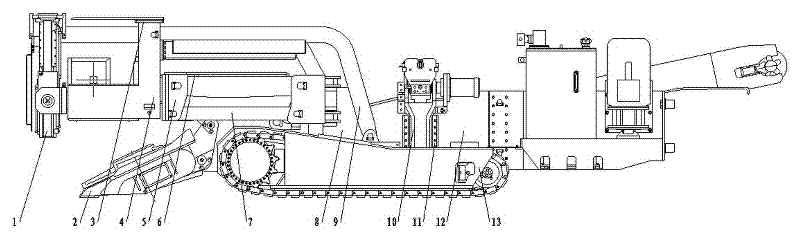

Anchor rod transloading set

ActiveCN102536312ATimely transportImprove delivery capacityMine roof supportsUnderground transportEngineeringTransfer mechanism

The invention belongs to the technical field of underground equipment in a coal mine and particularly relates to an anchor rod transloading set which solves the problem that existing underground equipment in the coal mine cannot be suitable for mines with small section roadways and mines with coal beds in poor geological conditions. The anchor rod transloading set comprises a chassis, a transloading mechanism and a scraper conveyer. The bottom disc is provided with the transfer mechanism and comprises a main frame, a left crawler frame, a right crawler frame and a tail frame. Lifting mechanisms are respectively arranged at the top parts of the left crawler frame and the right crawler frame. The top parts of the lifting mechanisms are connected with a worktable, and the front part of the worktable is connected with a front anchor protector. A rear anchor protector is arranged at the rear part of the main frame. Temporary supports are further hinged on the left crawler frame and the right crawler frame. The invention has the beneficial effects that the anchor rod transloading set can be used for mines with small section roadways and mines with coal beds in poor geological conditions, the complete machine is arranged compactly, the structure is reasonable, the anchor protector part has high degree of automation and fast support speed, and the anchor rod transfer set has large loading capacity, strong climbing ability and can protect and transfer at the same time.

Owner:TAIYUAN INST OF CHINA COAL TECH & ENG GROUP +1

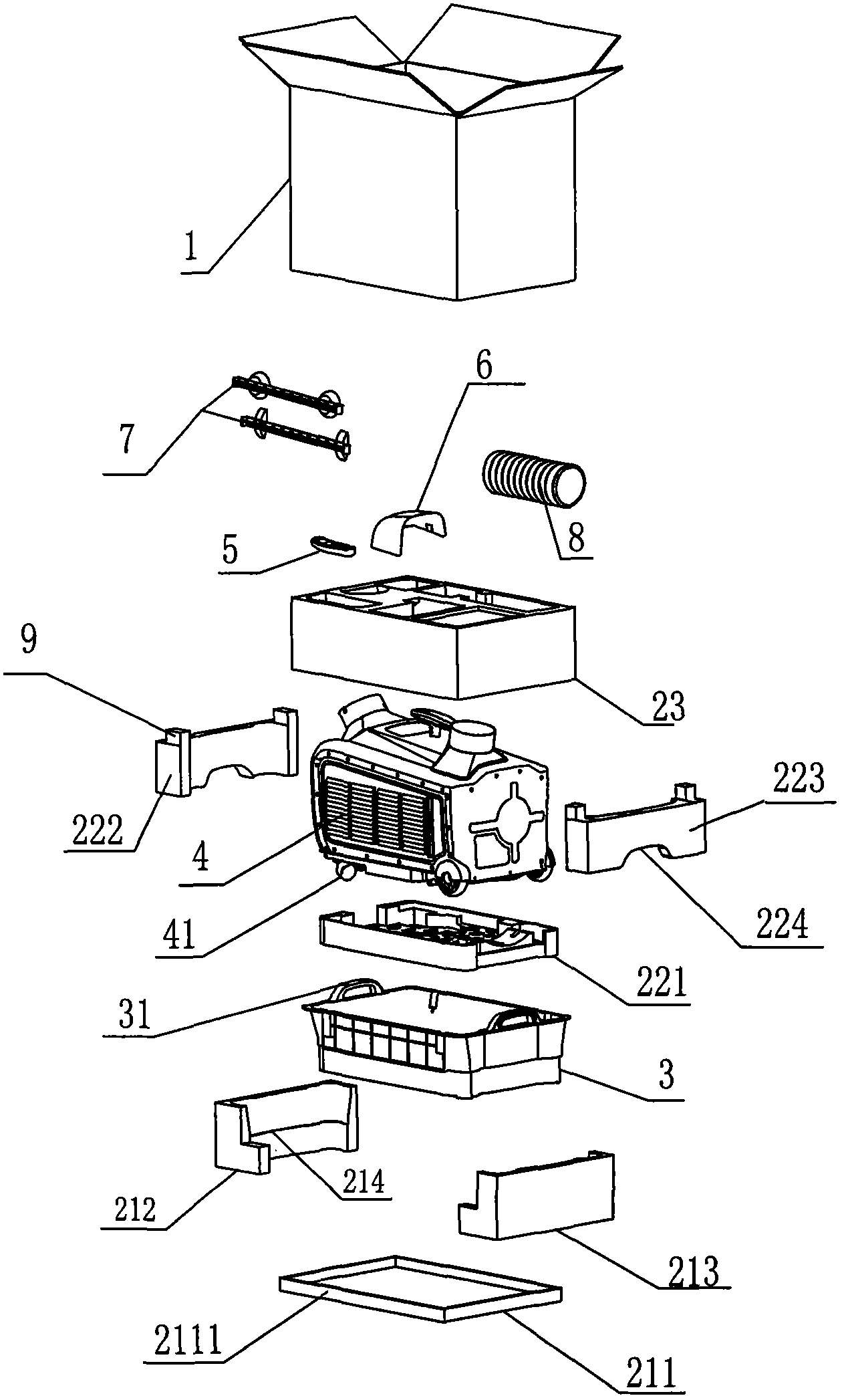

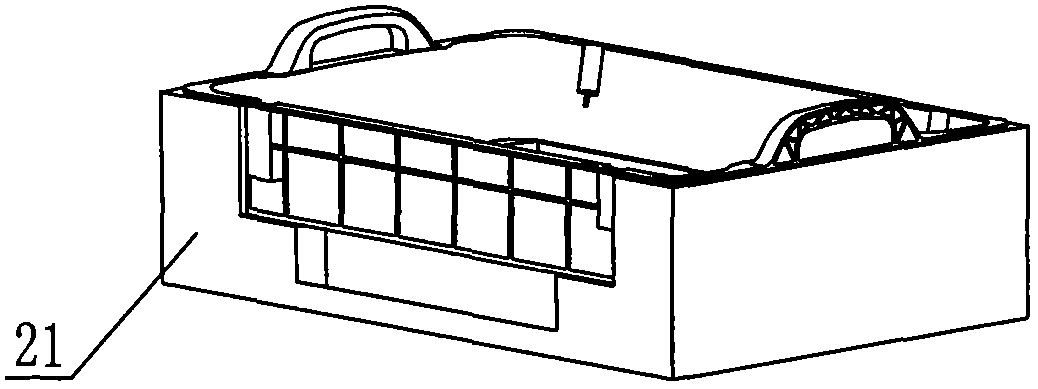

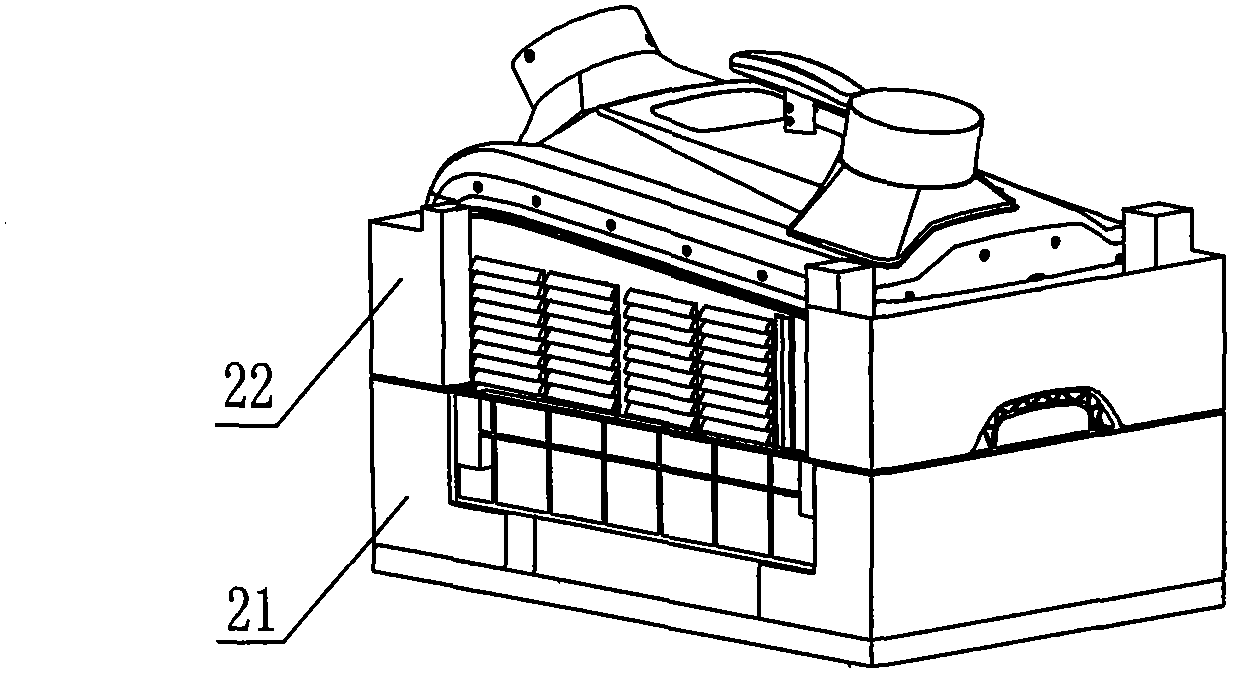

Packaging structure of mobile air conditioner and installation method thereof

InactiveCN103213774ATightly designedFine workmanshipPackaging vehiclesContainers for machinesEngineeringElectrical and Electronics engineering

The invention relates to a packaging structure of an air conditioner and an installation method thereof, and belongs to the technical field of household electric appliances packaging. The packaging structure comprises an outer packaging box and an inner packaging box, wherein the inner packaging box comprises a packaging part for a water receiving box under the air conditioner, a packaging part for a main body of the air conditioner in the middle and a packaging part for accessories on the upper part; the packaging part for the water receiving box under the air conditioner comprises a base support and water receiving box foam A and B; a concave step is arranged inside the water receiving box foam A and B respectively; both ends of the water receiving box of the air conditioner are extruded and placed on the concave step; the packaging part for the main body of the air conditioner comprises bottom foam of the main body of the air conditioner and front and back foam A and B of the air conditioner; upper arc-shaped notches at the lower middle part of the front and back foam A and B are respectively connected with an arc-shaped convex handle of the water receiving box of the air conditioner in an embedded manner; and the main body of the air conditioner is placed on the bottom foam of the main body of the air conditioner. Moreover, the invention also comprises the installation method. The packaging structure has the beneficial effect that the structure is used for packaging three parts of the water receiving tank of the air conditioner, the main body of the air conditioner and the accessories, so that the product is prevented from being damaged during the transportation process.

Owner:CI XI TUO YING ELECTRICAL

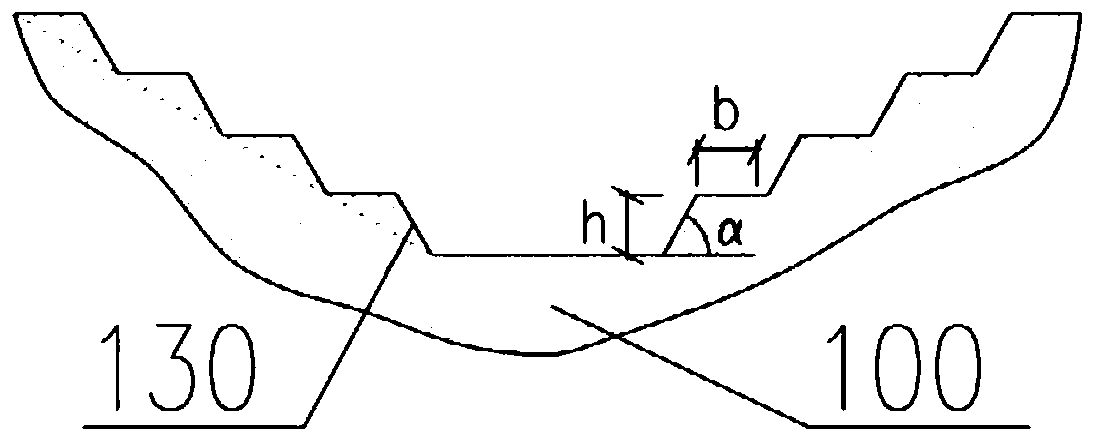

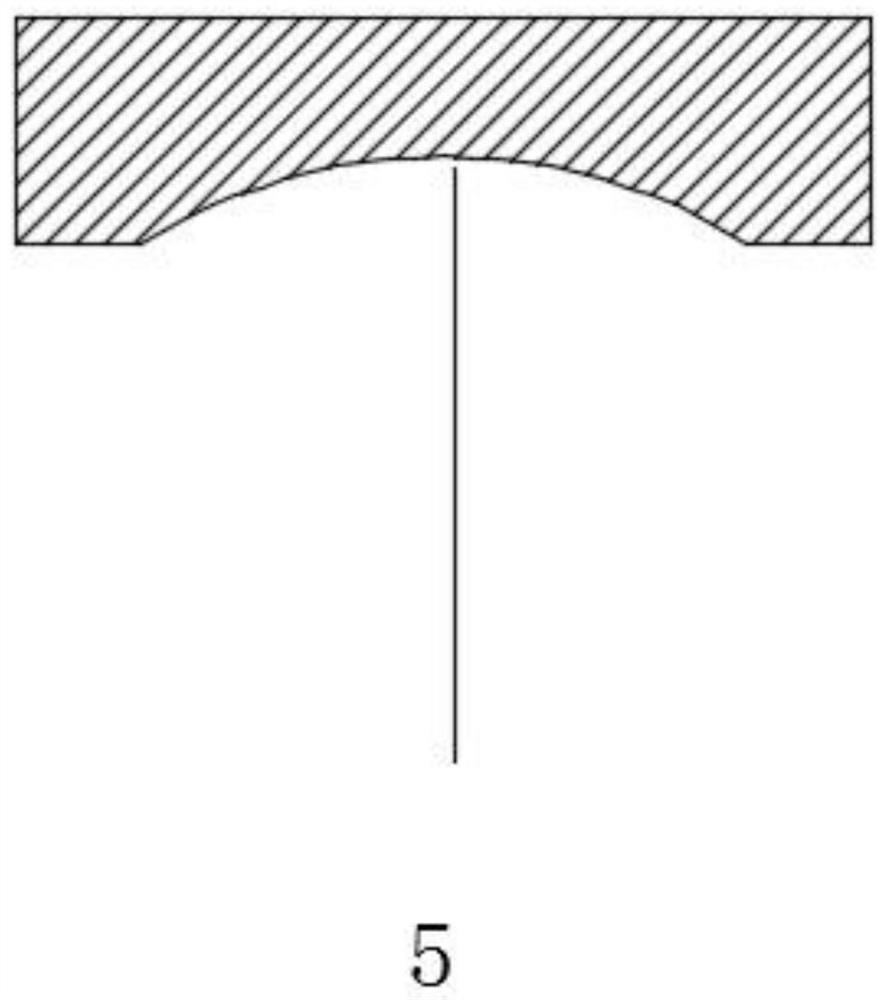

Dough slicer

InactiveCN104489014ARealize quantitative dicingSimple structureDough dividingDough shaping and dividing combinationEngineeringMechanical engineering

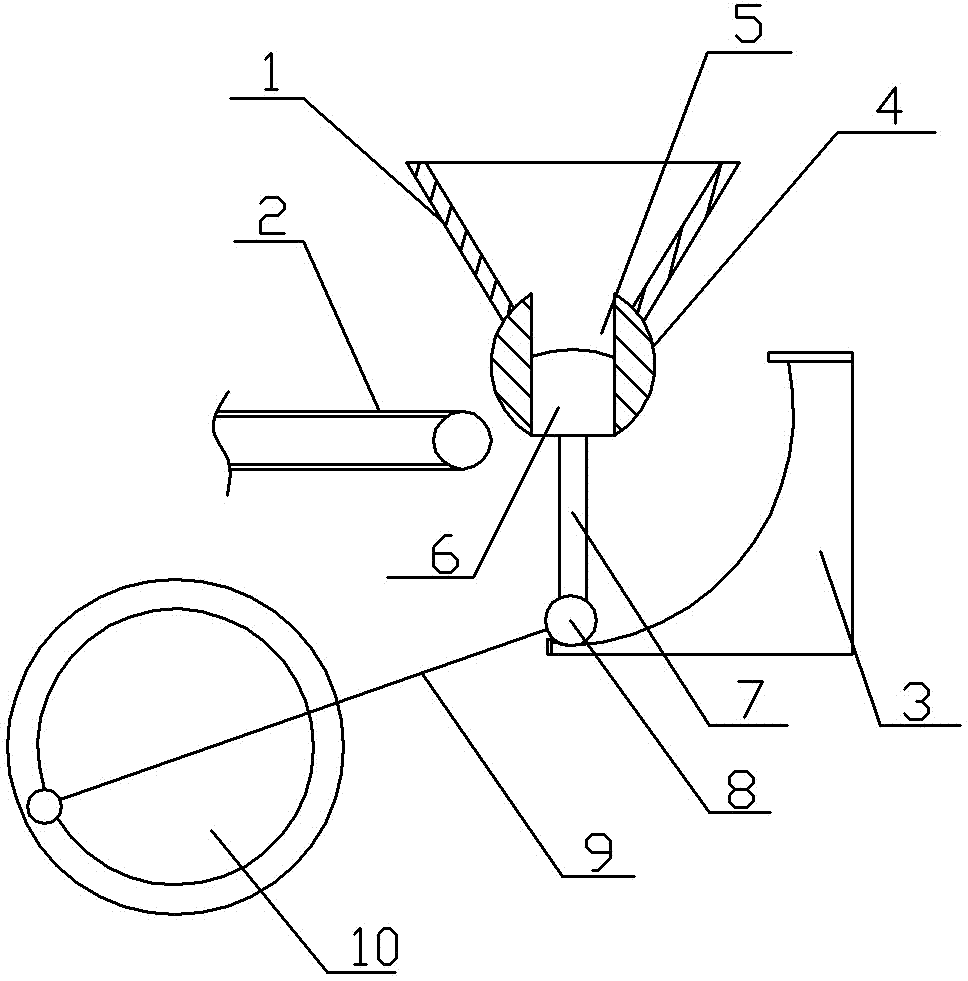

The invention belongs to the technical field of food processing machinery, and relates to a dough slicer. The dough slicer comprises a conical hopper and a rack, wherein the rack is rotationally connected with a storage roller with a round cross section at an outlet of the conical hopper, and the storage roller is provided with a quantitative groove the opening of which is in contact with the outlet of the conical hopper along the radial direction; the quantitative groove is internally matched with a push block in a sliding mode; a piston rod is fastened to the lower end of the push block; the lower end of the piston rod is provided with a roller which is in contact with an arc guide rail the curvature of which is sequentially increased from top to bottom; the roller is hinged with a connecting rod which is eccentrically connected to a rotation wheel. The dough slicer is simple in structure, and can be used for slicing dough quantitatively, and improving the slicing efficiency.

Owner:CHONGQING YUANXIANG FOOD

Vehicle queuing system and method

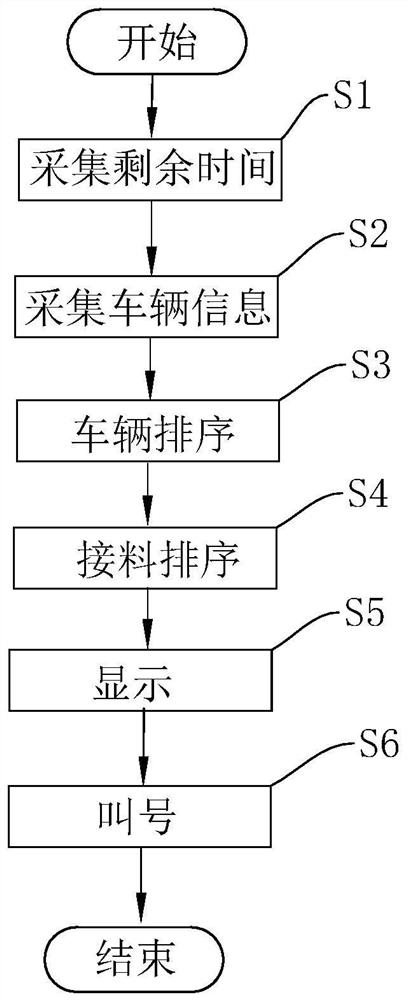

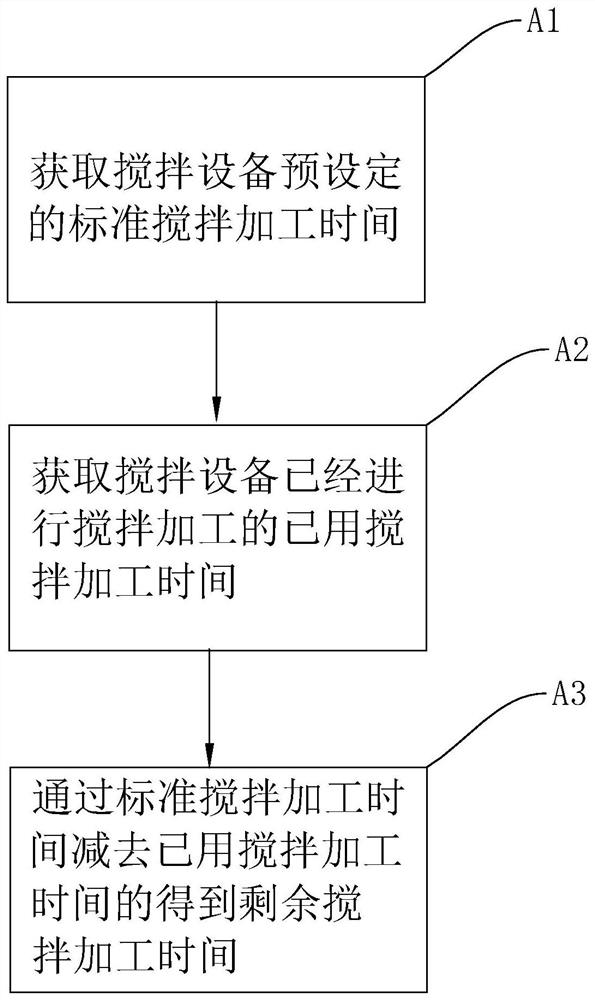

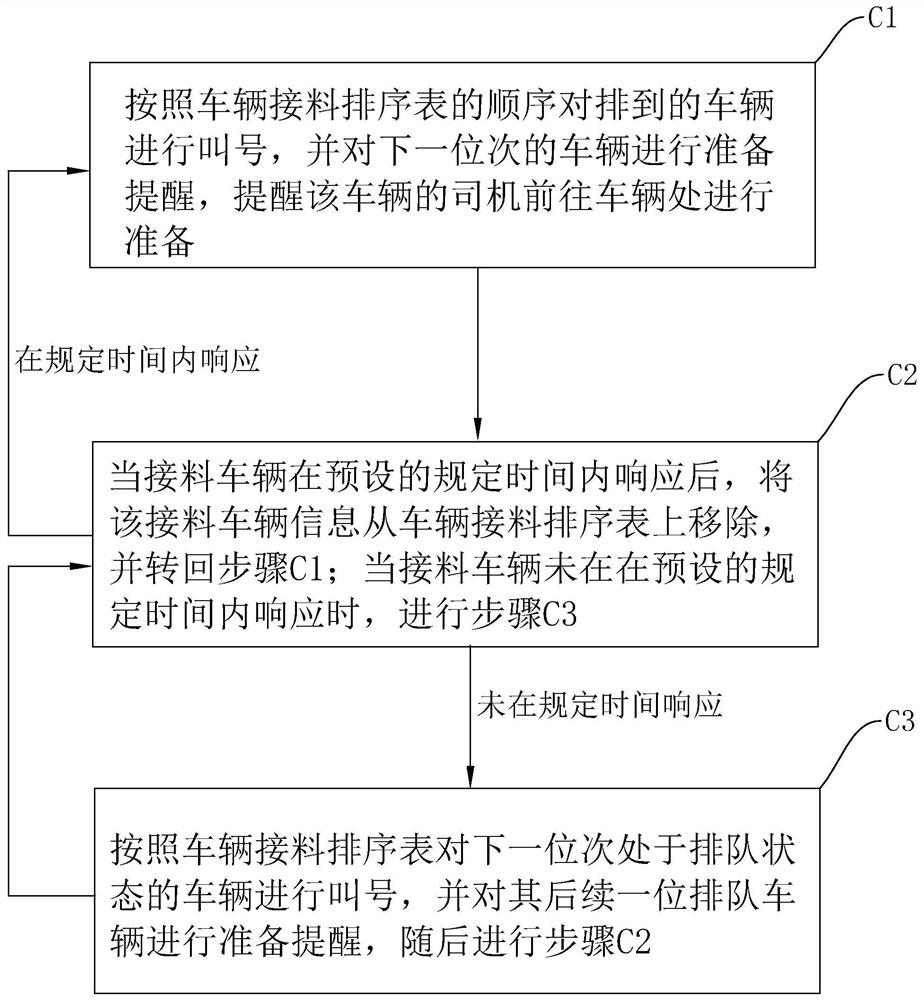

ActiveCN111906927AImprove management scheduling efficiencyImprove production and delivery efficiencyChecking apparatusCement mixing apparatusDisplay deviceReal time display

The invention relates to a vehicle queuing system and method, and relates to the technical field of concrete production. According to the technical scheme, the vehicle queuing method is characterizedby comprising the following steps that S1, the remaining stirring processing time of all stirring devices is collected; S2, vehicle information of transport vehicles parked in a waiting area is collected; S3, vehicle sorting is carried out, wherein sorting is carried out according to the sequence of the queuing time of the vehicles to generate a vehicle sorting table; S4, the discharging sequenceof all the stirring devices is sorted according to the remaining stirring processing time of all the stirring devices from low to high, and a vehicle receiving sorting table is generated according tothe vehicle sorting table; S5, the vehicle receiving sorting table, the vehicle sorting table and a discharging time table are displayed in real time through a display device; and S6, drivers of the vehicles are called before a preset time according to the sequence of the vehicle receiving sorting table. According to the vehicle queuing system and method, the management and scheduling efficiency of the vehicles can be improved, and the effect of improving the production and delivery efficiency of a concrete mixing station is achieved.

Owner:苏州上建杭鑫混凝土有限公司 +1

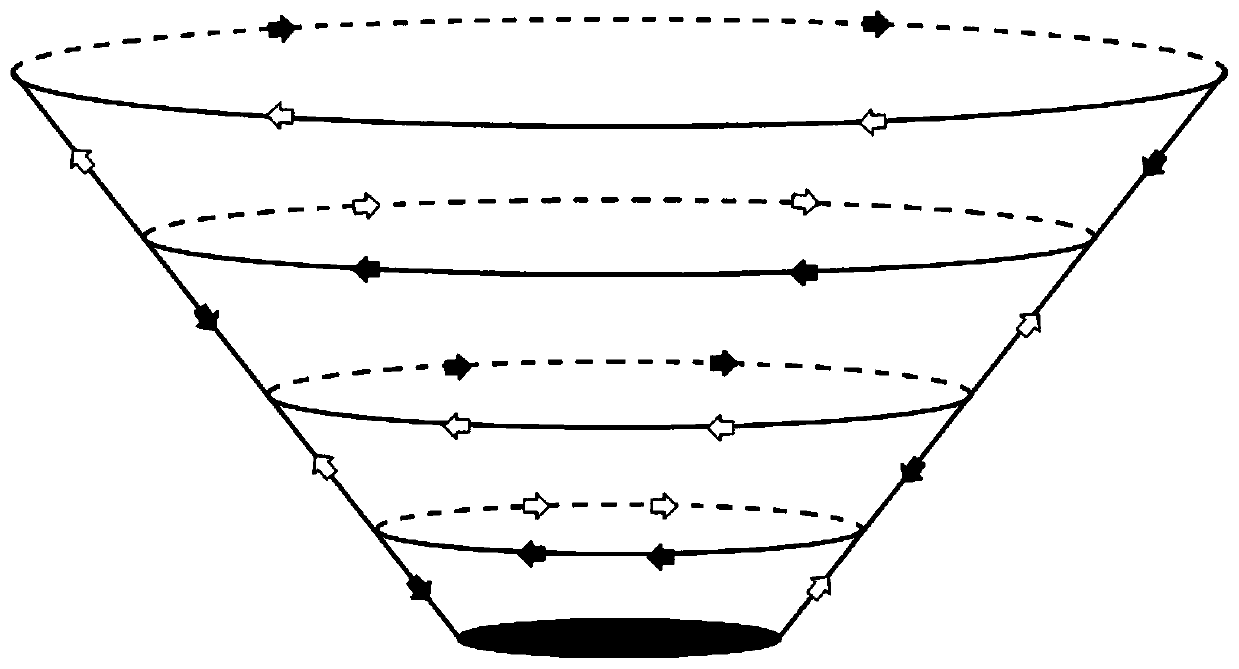

Safe mining method and safe mining structure for valley type domestic garbage landfill

ActiveCN110541420AEasy accessPrevent subsidenceRoadwaysClimate change adaptationResource utilizationEngineering

The invention discloses a safe mining method and a safe mining structure for a valley type domestic garbage landfill, and belongs to the field of solid waste resource utilization. The mining method comprises four main technical units of development transportation, drainage, slope stabilization and ventilation, wherein the development transportation technology is that independent ascending and descending roads which are built through a multilayer annular horizontal road and an ascending and descending connection ramp is adopted; the drainage technology is that rainwater is drained by self flowing in an external intercepting ditch, a pump station inside is divided by areas, the drained sewage is lifted in a grading way to the top for treatment and then is drained after reaching the standard;the slope stabilization technology is that a double slope protection technology of geogrids and ecological bags is adopted; and the ventilation technology is a technology of combining natural guide and artificial forced ventilation. A safe and efficient reservoir area constructed by the safe mining method is used for developing a transportation road, and the stored garbage is timely transported out from the mining position; and moreover, the safety of the mining operation of the landfill is fully guaranteed through improvement on drainage, slope stability and ventilation.

Owner:NANJING UNIV +2

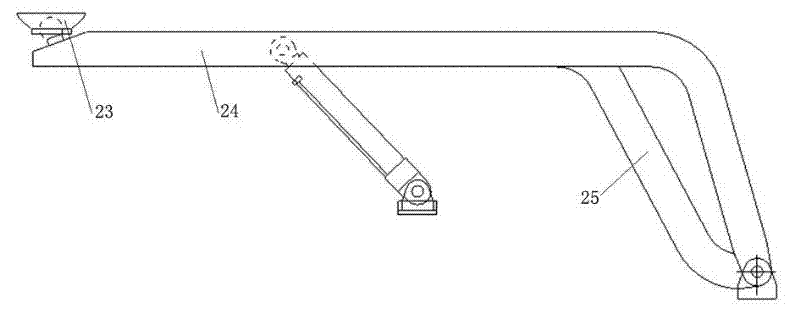

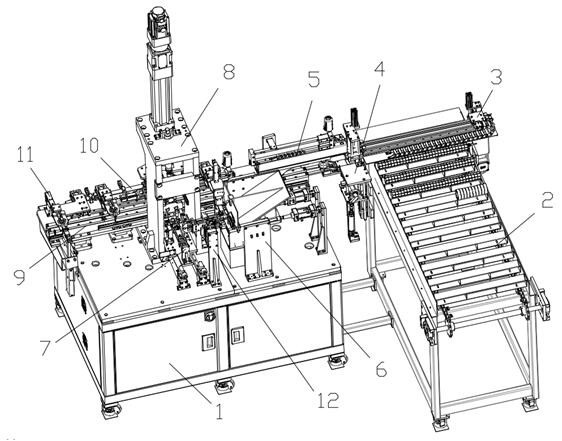

Automobile longitudinal beam bending production device

InactiveCN107008785AMeet production requirementsTimely transportMetal-working feeding devicesVehicle componentsProduction lineEngineering

The invention is suitable for the technical field of automobile longitudinal beam production, and provides an automobile longitudinal beam bending production device. The device comprises a feed device, a stroke detection device, a bending device and a discharge device. The feed device comprises a bearing device and multiple conveying devices. The stroke detection device comprises a main frame body, a stroke measurement mechanism and a numerical control feedback mechanism. The stroke measurement mechanism is arranged in the main frame body, is arranged over a production line and makes elastic contact with a longitudinal beam. The bending device comprises a fixed mechanism and a swing mechanism. The swing mechanism is hung on the fixed mechanism through supporting shafts arranged on the two sides. A hydraulic servo drive device is connected with a numerical control system. The discharge device comprises a supporting frame and a push device. The push device comprises a motor, a control panel and a movement device. The control panel is electrically connected with the movement device and the motor. The push device is fixedly connected with the supporting frame. In this way, bending production of the automobile longitudinal beam can be automatic, the production efficiency can be improved, and potential safety hazards can be reduced.

Owner:WANLONG IND SHOUGUANG SHANDONG

A bamboo cutting machine with fixed length for lantern production is disclosed

InactiveCN108890785APrevent the phenomenon of detaching from the third fixing memberTimely transportGripping devicesCane mechanical workingFixed frameEngineering

The invention discloses a fixed-length bamboo cutting machine for lantern production, which comprises a base, a first work table, a second work table, a cutting device, a first fixing part and a second fixing part. The cutting device comprises a frame, a moving member, a third fixing member, a fixing member, a first driving mechanism, a second driving mechanism, a pressing member and a knife assembly. The first worktable is inclined on the base, the second worktable is horizontally arranged on the base, and the first worktable and the second worktable are connected and arranged; The cutting device is arranged on the first workbench, and the moving part is slidably arranged on the first workbench. The third fixing part is arranged on the moving part, and the third fixing part is provided with a cutting groove; The machine frame is arranged on the movable part, and the fixing frame is arranged on the top of the machine frame. A first driving mechanism and a second driving mechanism are arranged at the bottom of the fixture. The invention only needs one positioning, can obtain the fixed length cutting of the bamboo, does not need repeated measurement, saves labor, is simple in operation and convenient in use.

Owner:望江县红和木业灯饰有限公司

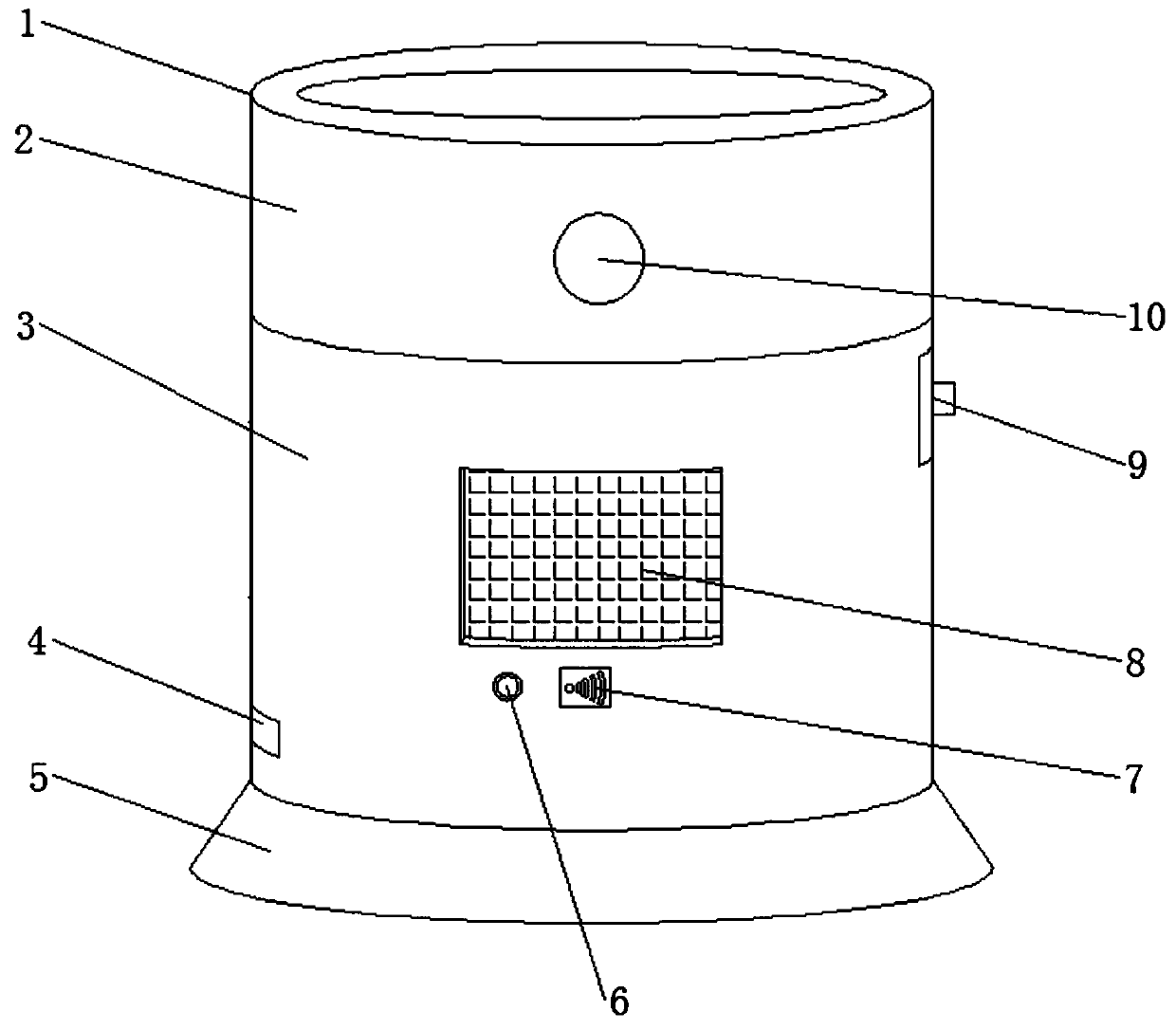

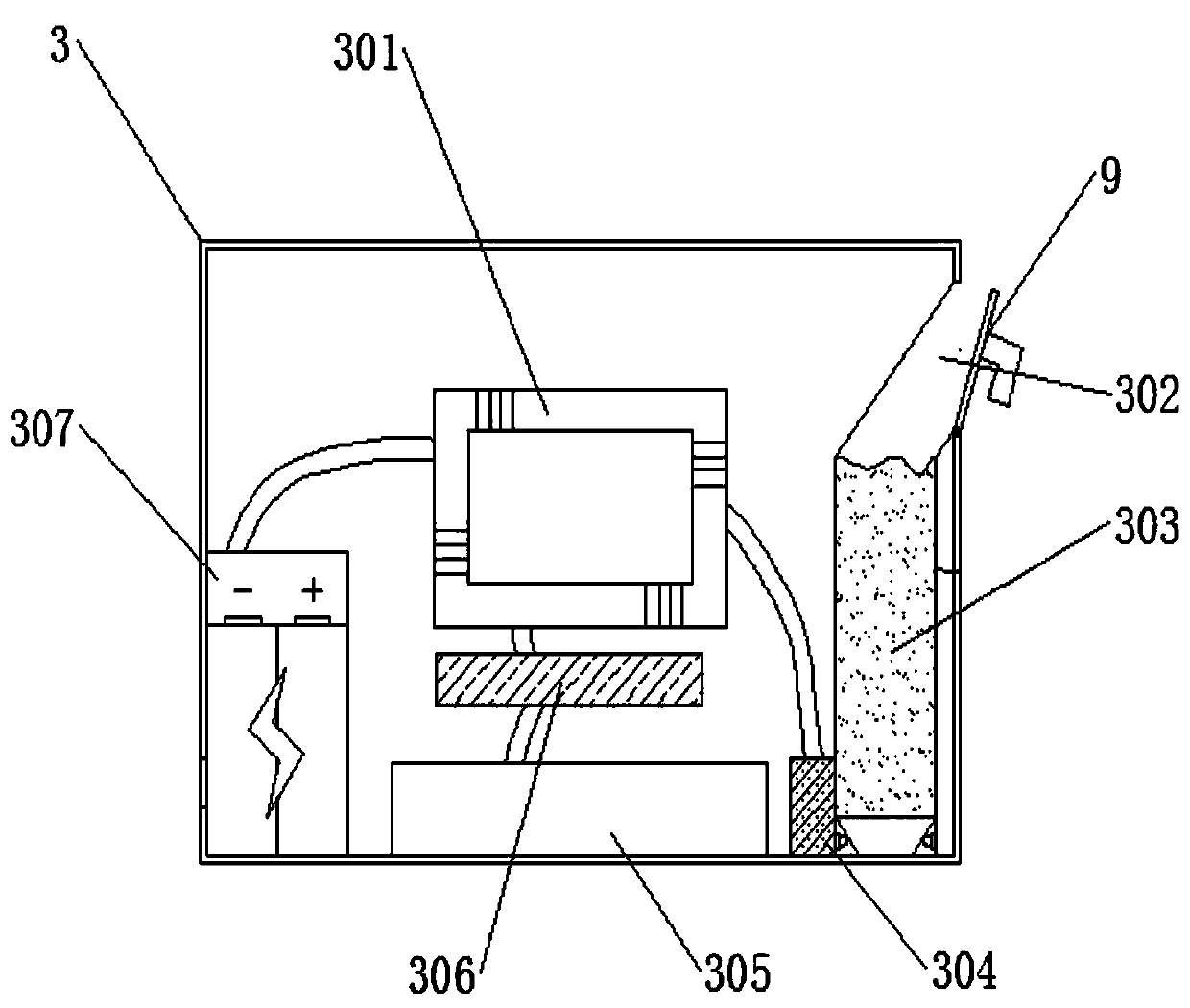

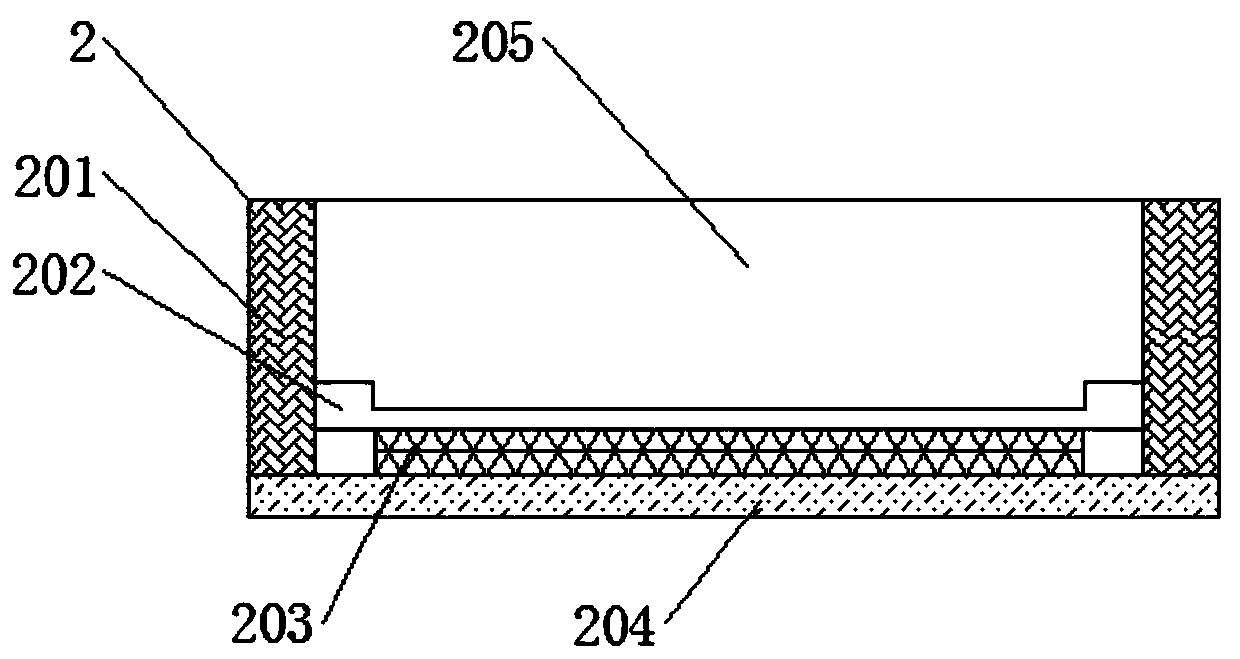

Kitchen robot

The invention discloses a kitchen robot which comprises a kitchen robot body, an upper case, a middle case and a lower case. The middle case is fixedly connected to the middle of the kitchen robot body; the lower case is fixedly connected to the bottom part of the middle case; the upper case is fixedly connected to the top part of the middle case; a built-in part is fixedly connected to the middle of the inner part of the upper case; a controller is fixedly connected to the bottom part of the inner part of the upper case; a lifting table is fixedly connected to the top part of the controller; the lifting table goes down to drive a dish on a movable plate to go down into the built-in part so as to enable the dish to be placed, and the robot moves to convey the disk to a destination; the movable plate stretches upwards, so that working personnel can conveniently take the dish away; and when a sensor senses no weight on the top part, the movable plate can be controlled to go down, so that the dish can be conveniently conveyed in time, the best eating time of the dish is maintained, meanwhile, the workload of working personnel is further greatly reduced, and the kitchen robot has a wide development prospect in the future.

Owner:BEIJING ROC THEURGY TECH

Combined wood splitting equipment

ActiveCN105479568ACompact and stable structureFlexible and stable operationWood splittingHydraulic cylinderInductor

The invention provides combined wood splitting equipment. The combined wood splitting equipment comprises a cross beam, wherein a support arm is connected to one end of the cross beam, and a wood splitting location mechanism is fixedly arranged at the other end of the cross beam; an inner chamber is arranged in the bottom of the cross beam, and a balance-support wood grabbing mechanism is arranged in the inner chamber; the wood splitting location mechanism comprises a support frame body, a hydraulic cylinder, a shakeproof backing plate and a splitting knife; a location inductor is arranged on the support plate; a rubber pad, a plywood and a bottom plate are sequentially arranged in an inner cavity of the shakeproof backing plate; a plurality of shakeproof bars sequentially extend from the top of the inner cavity of the shakeproof backing plate, and each of the shakeproof bars penetrates through the rubber pad and is in clamping-fixation connection with the plywood; the balance-support wood grabbing mechanism comprises a cylinder, a balance block, tier poles and wood grabbing arms; and the tier poles are rotationally arranged at the two sides of the inner chamber, and the plurality of wood grabbing arms are sequentially arranged on each of the tier poles. The combined wood splitting equipment provided by the invention has the beneficial effects of being stable and compact in structure, flexible and stable in running, high in wood splitting efficiency, accurate in location, and timely in transferring, thus ensuring a processing effect.

Owner:王金青

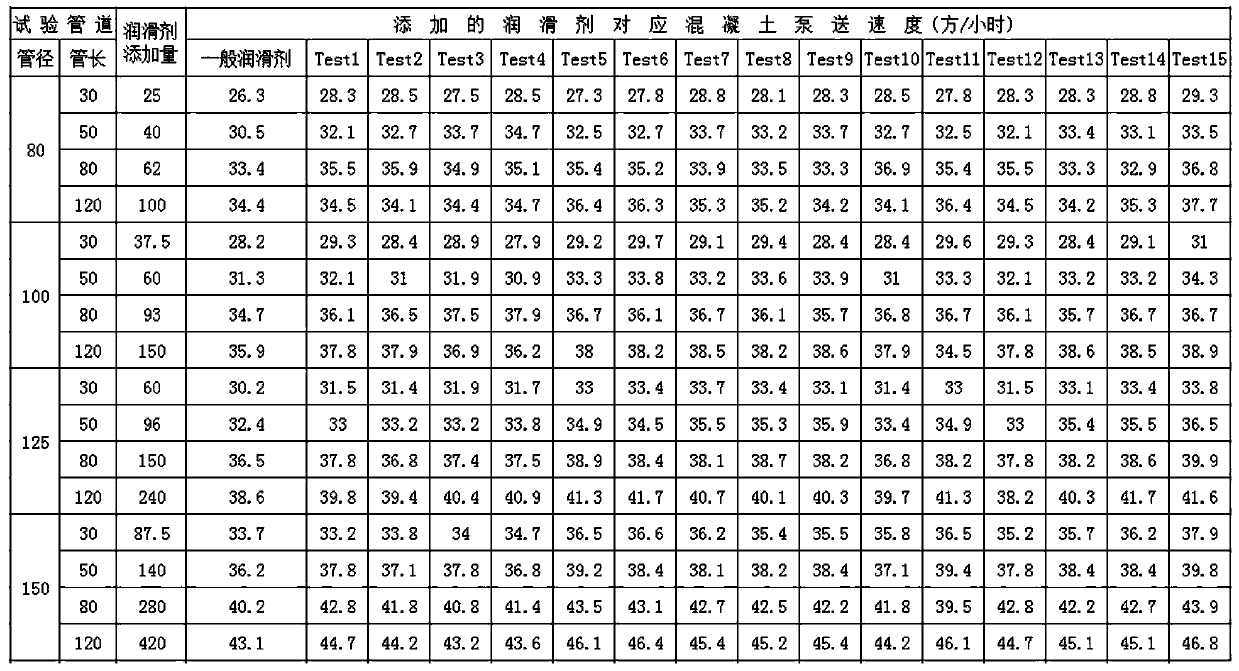

Lubricating agent for concrete pump pipeline

InactiveCN109735386AIncrease flow rateTimely transportLubricant compositionPentaneSurface-active agents

The invention discloses a lubricating agent for a concrete pump pipeline. The lubricating agent comprises, in weight percent, 12%-14.5% of polyacrylamide, 7.3%-9.7% of retarders, 15.3%-19.8% of hydroxyethyl methyl cellulose, 4.3%-6.5% of sodium coconut oil alcohol sulfate, 5.5%-7% of pentane asphaltene and the balance water. The sodium coconut oil alcohol sulfate serves as a hydrophilic surface active agent. According to the lubricating agent, the flow velocity of concrete can be greatly improved, and concrete pumping efficiency is higher.

Owner:重庆富典建筑工业化制品有限公司

Device of fast case heat dissipation

InactiveCN108874085APlay the role of portable installationRapid coolingDigital data processing detailsMechanical engineeringEngineering

The invention discloses a device of fast case heat dissipation. The device includes an air inlet, a housing body and heat dissipation conducting devices. The air inlet is disposed at one side of the housing body. A dust filtering net is mounted in a moving manner at one side which is inside the housing body and is adjacent to the air inlet. A fan is mounted at one side which is of the dust filtering net and faces away from the air inlet. A cooling placement main-body is mounted at one side which is of the fan and faces away from the dust filtering net. A hand basket is mounted at one end of the cooling placement main-body. A gas collection cylinder is mounted at one side which is of the hand basket and faces away from the fan. The heat dissipation conducting devices are connected to the gas collection cylinder through rubber hoses. The number of the heat dissipation conducting devices and the number of the rubber hoses are both three. Pipe connectors are mounted at one end which is ofthe heat dissipation conducting devices and is adjacent to the rubber hoses. Disc air taps are mounted at one end which is of the pipe connectors and faces away from the rubber hoses. Temperature probes are mounted at middle ends of one side which is of the disc air taps and faces away from the pipe connectors. The device has the advantages of dustproof filtering, partitioning heat dissipation, fast cooling and the like.

Owner:刘清泉

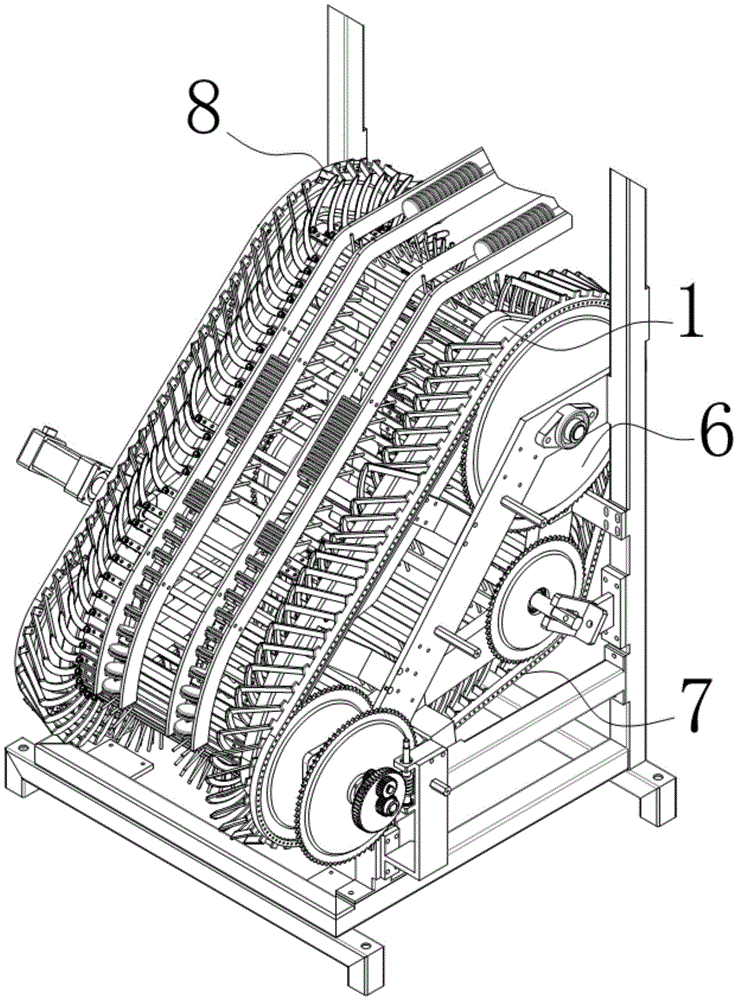

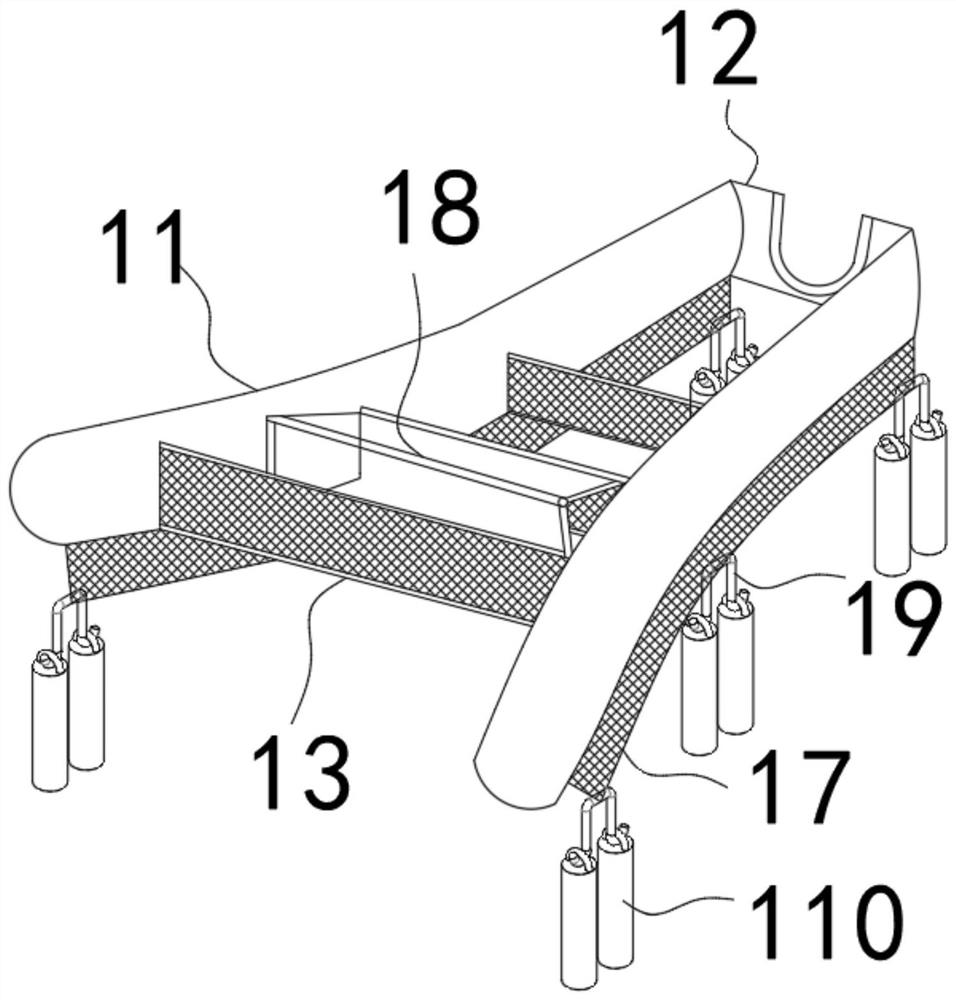

Climbing and arranging transportation mechanism for biscuits

The invention discloses a climbing and arranging transportation mechanism for biscuits. The climbing and arranging transportation mechanism for the biscuits comprises a main track, a branch track and a plurality of biscuit pushers, wherein the main track is provided with a track dividing seat, one end of the branch track is connected with the track dividing seat and forms an acute angle with the main track, and the other end is connected with the main track at a preset position; the biscuit pushers are arranged along the main track, when the biscuit pushers pass through the track dividing seat, the biscuit pushers continue to run along the main track or branch track under the control of the track dividing seat. Through arranging the track dividing seat, main track and branch track, the biscuit pushers can advance and enter different tracks according to preset modes to match with biscuits or separate from biscuits and timely transport biscuits after arriving at a preset number. The climbing and arranging transportation mechanism for the biscuits is capable of counting intelligently, grouping according to preset numbers and arranging continuously, simple in structure and low in cost.

Owner:佛山市顺德区力升机械有限公司

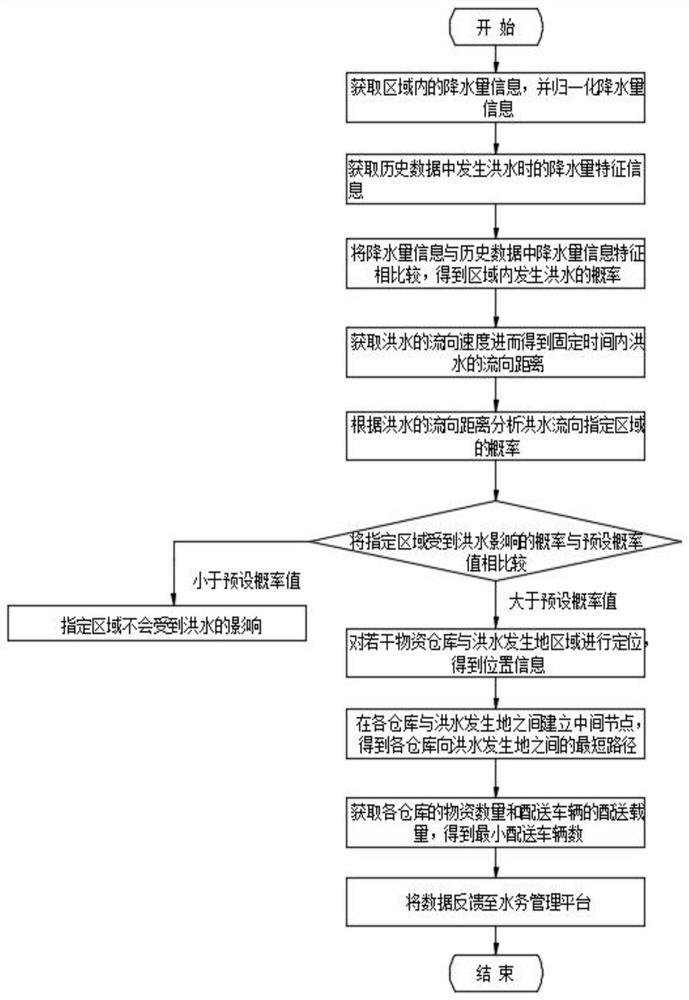

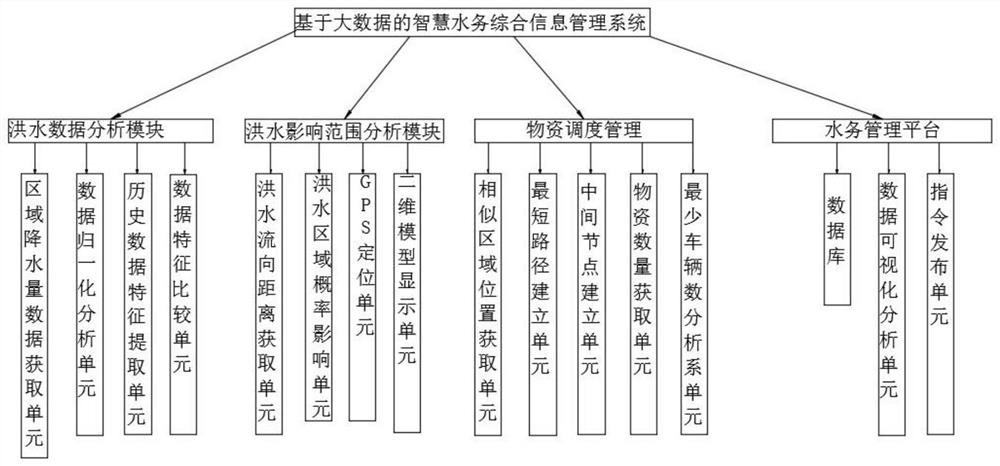

Smart water comprehensive information management system and method based on big data

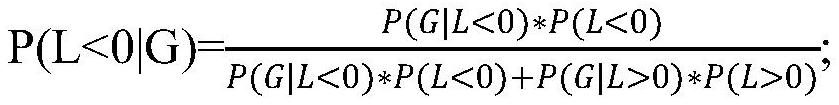

ActiveCN113888039BTimely transportWill not affect the loss of people's propertyMathematical modelsClimate change adaptationEnvironmental resource managementSmart water

The invention discloses a smart water comprehensive information management system based on big data. The system includes a flood data analysis module, a flood impact analysis module, a material dispatch management module and a water management platform; the flood data analysis module is used to obtain the precipitation in the area. information, according to the precipitation information to analyze the probability of floods in the area; the flood impact analysis module is used to analyze the degree of impact of floods on the designated area; so as to determine the probability of floods in the designated area, if the degree of impact is high, notify the designated area in time Flood control measures are taken; the material dispatch management module is used for dispatching and distributing materials to the designated area according to the impact of floods on the designated area; thus, material distribution can be performed in the designated area; the water management platform is used for saving data and publishing Instructions; through the flood impact analysis module, the impact of floods on the area can be prevented in time.

Owner:江苏天汇空间信息研究院有限公司

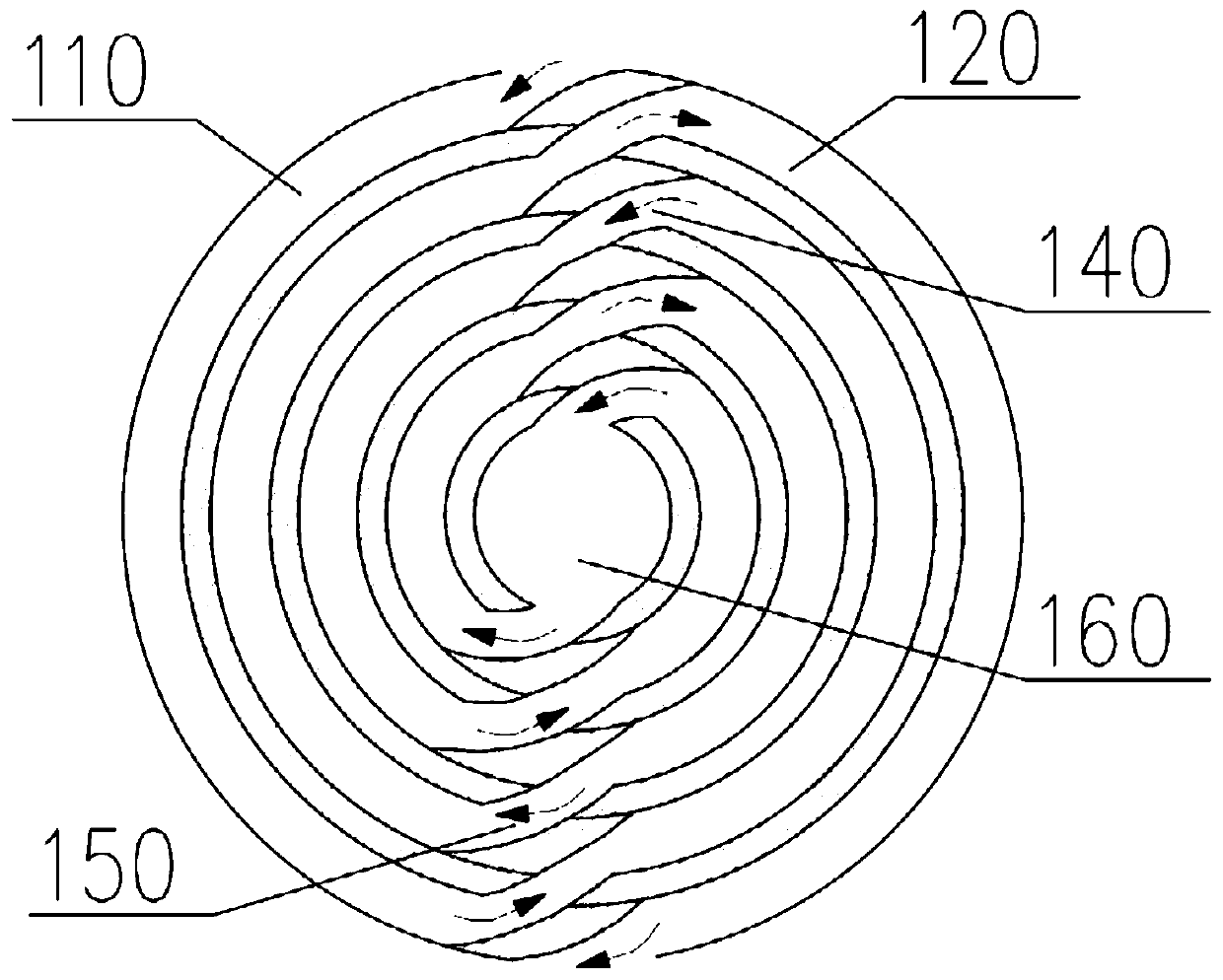

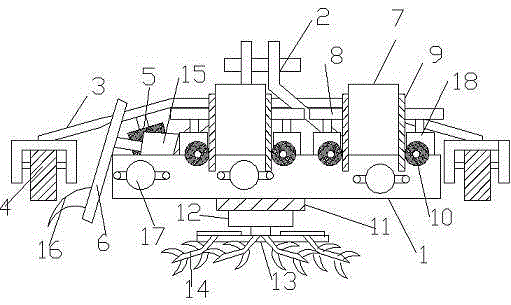

A Frame Mechanism of Combined Agricultural Auxiliary Equipment

ActiveCN105409370BRealize position adjustmentSave resourcesAgricultural undercarriagesElectric machineEngineering

The invention provides a rack body mechanism of combined type agricultural auxiliary equipment. The rack body mechanism comprises a balance disc; a connecting arm is fixed at the top of the balance disc, a moving frame is arranged above the balance disc, each end of the moving frame is provided with a roller wheel, and the bottom of the moving frame is connected and fixed to the balance disc through a first air cylinder; a scraper and a plurality of moving chambers are sequentially arranged along the external circumferential face of the balance disc, the two ends of each moving chamber are provided with extension plates in an extending manner, and each extension plate is connected and fixed to the balance disc through a second air cylinder; locating line blocks are arranged at the two ends of each moving chamber and are matched with locating pulley grooves in the balance disc; and the bottom of the balance disc is connected and fixed to a motor through an elevator, the motor is connected and fixed to a rotary rod frame, and a plurality of mowing blades are sequentially arranged on the rotary rod frame. The rack body mechanism has the beneficial effects that the design is reasonable, diversified, stable and compact; and the operation is flexible and stable, shifting and transporting are timely, the working efficiency is increased, and agricultural requirements are met.

Owner:HAIMEN THE YELLOW SEA ENTREPRENEURSHIP PARK SERVICE CO LTD

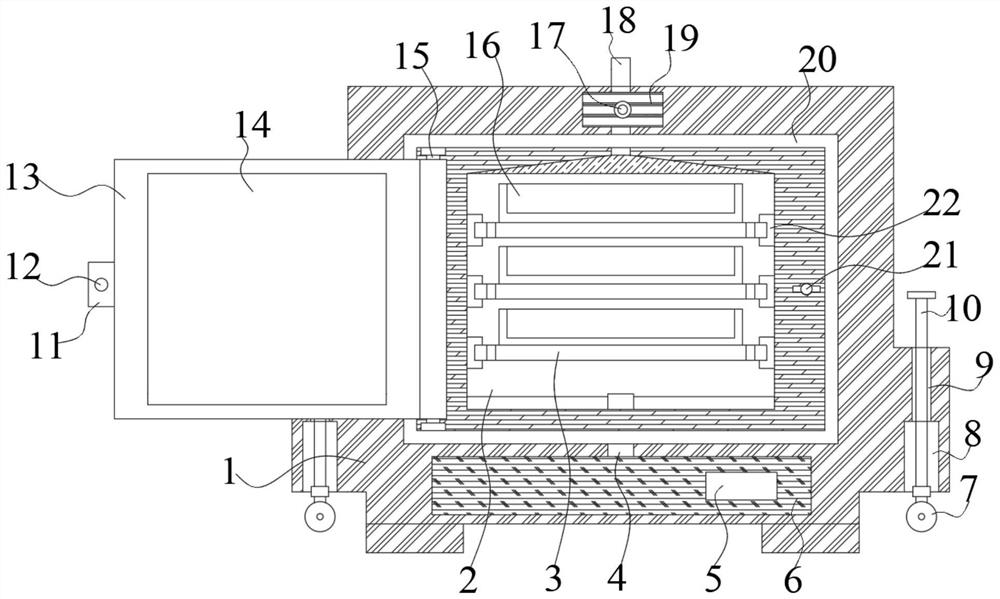

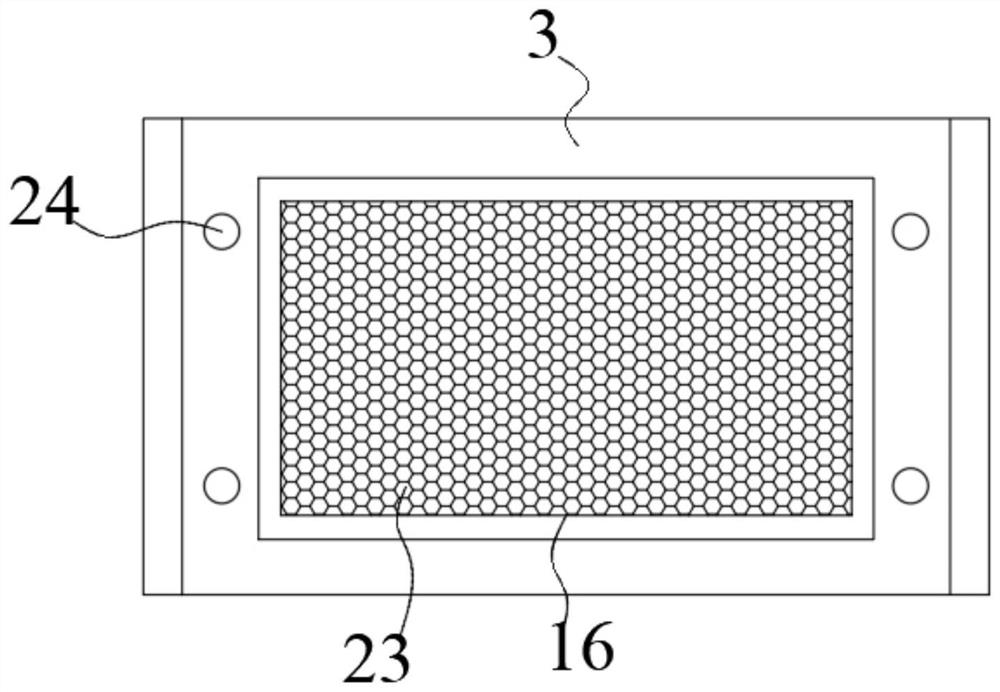

Cleaning sterilizer for pressure-reducing boiling type cleaning of medical instruments

InactiveCN112337858AThorough cleaning and disinfectionTimely transportLavatory sanitoryCleaning using liquidsEngineeringApparatus instruments

The invention discloses a cleaning sterilizer for pressure-reducing boiling type cleaning of medical instruments, and belongs to the technical field of medical instrument cleaning and sterilizing equipment. The cleaning sterilizer comprises a machine body, wherein a steam generator is arranged inside the machine body, the upper surface of the steam generator is connected with one end of an air inlet pipe, the other end of the air inlet pipe extends to the inner wall of the bottom surface of a groove, the inner side wall of the groove is fixedly connected with a sliding rail, and the inner sidewall of the sliding rail is in sliding connection with the outer side wall of a transverse plate. According to the cleaning sterilizer, the medical instruments are placed inside a storage groove so that pressure-reducing boiling type cleaning and sterilizing can be carried out on the medical instruments under the action of the steam generator and a pneumatic electric control valve, then an inserting vertical rod is inserted along a vertical hole, a grip is held tightly so that the transverse plate can be driven to slide along the sliding rail under the action of a supporting plate, and then the cleaned and sterilized medical instruments can be transported out of the groove in time without cooling; and the device is simple in structure, high in practicability and suitable for being widelypopularized and used.

Owner:崔鹏

A flat glass furnace

The present invention provides a flat glass furnace, comprising: a melting part, one end of the melting part is provided with a feeding port; a conveying passage, the conveying passage includes a plurality of main passages, and all the main passages are parallel to each other and perpendicular to each other The center line of the melting part is set, and the ends of all the main passages communicate with the other end of the melting part; each main passage is provided with at least one branch passage perpendicular to it, and all the branch passages are connected to each other. parallel. The invention is used to solve the problem in the prior art that the single-line forming cannot match the existing large-tonnage kiln.

Owner:CHINA TRIUMPH INT ENG

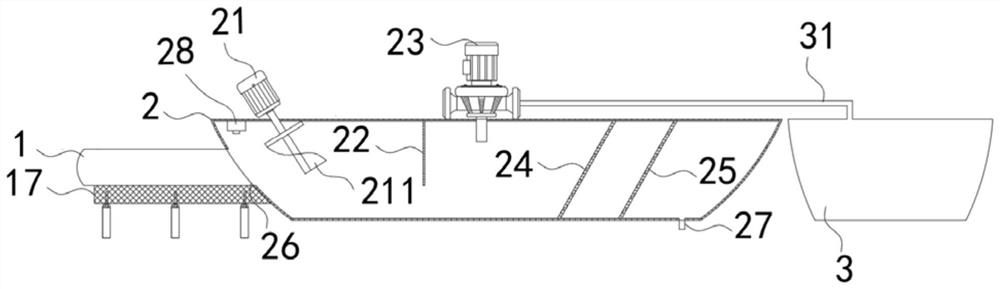

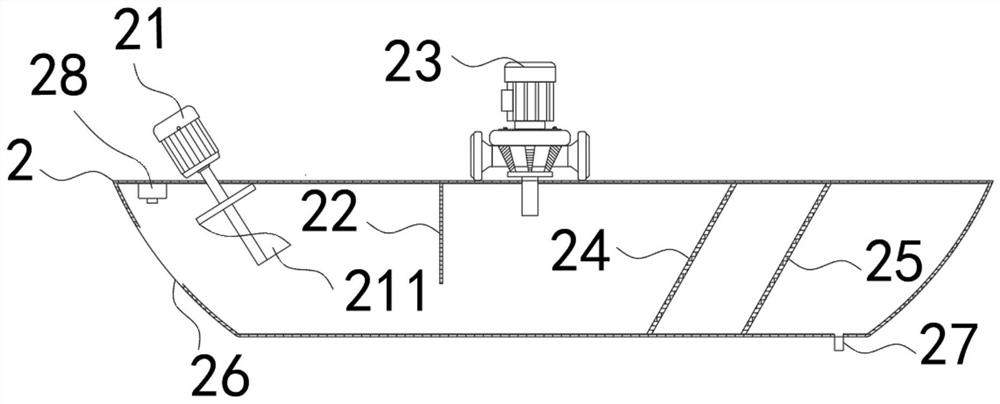

Intelligently controlled marine oil stain adsorption device

ActiveCN113981921AWeight increaseTimely transportWater cleaningGeneral water supply conservationOil separationMechanical engineering

The invention discloses an intelligently controlled marine oil stain adsorption device which comprises a first ship body, an oil guide assembly is arranged at the front end of the first ship body in the advancing direction, a first motor is arranged at the front end of the first ship body in the inflow direction, and a baffle is arranged at the upper end of the middle in the first ship body, a first water-permeable oil separation plate and a second water-permeable oil separation plate are arranged at the rear end in the first hull, a one-way water drainage opening is formed in the lower portion of the rear end in the first hull, floating bases are arranged on the two sides of the oil guide assembly, each floating base comprises two base bodies which form an included angle of 30 degrees, and one ends of the two floating bases are fixedly connected through a fixing plate, a U-shaped opening is formed in the fixing plate, a buffering assembly is arranged at the top end of the first filter screen and comprises a first bent plate, one end of the first bent plate is fixedly connected with the top end of the first filter screen, the other end of the first bent plate is rotationally connected with a second bent plate, and second filter screens are fixedly connected to the lower surfaces of the first bent plate and the second bent plate correspondingly, and the oil guide port is communicated with the U-shaped opening of the oil guide assembly.

Owner:YANTAI UNIV

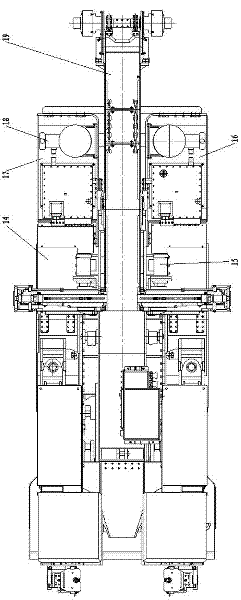

A motor shaft automatic press-fitting equipment

ActiveCN111318868BEasy to assembleTimely transportManufacturing stator/rotor bodiesMetal working apparatusElectric machineryEngineering

The invention relates to automatic press-fitting equipment for a motor shaft. The automatic press-fitting equipment comprises a loading track conveying mechanism and a workbench, wherein the loading track conveying mechanism is located at the left side of the workbench; a chassis of the loading track conveying mechanism is fixedly connected to the left part of the workbench through a fixed frame;a track feeding mechanism, a motor shaft loading and press-fitting mechanism and an unloading mechanism are arranged on the upper surface of the workbench; the track feeding mechanism is horizontallyfixed to the front side of the upper surface of the workbench; the motor shaft loading and press-fitting mechanism is located at the rear side of the track feeding mechanism; the unloading mechanism is arranged at the position of a discharge hole of the track feeding mechanism; the loading track conveying mechanism comprises a loading conveying chain device, a pushing device and a loading turnoverdevice; the pushing device is located above a discharge hole of the loading conveying chain device; and the loading turnover device is located at the right side of a discharge hole of the loading conveying chain device. The automatic press-fitting equipment has high degree of automation and a high market application value, improves work efficiency, and saves labor cost.

Owner:NINGBO WANJI BEARING CO LTD

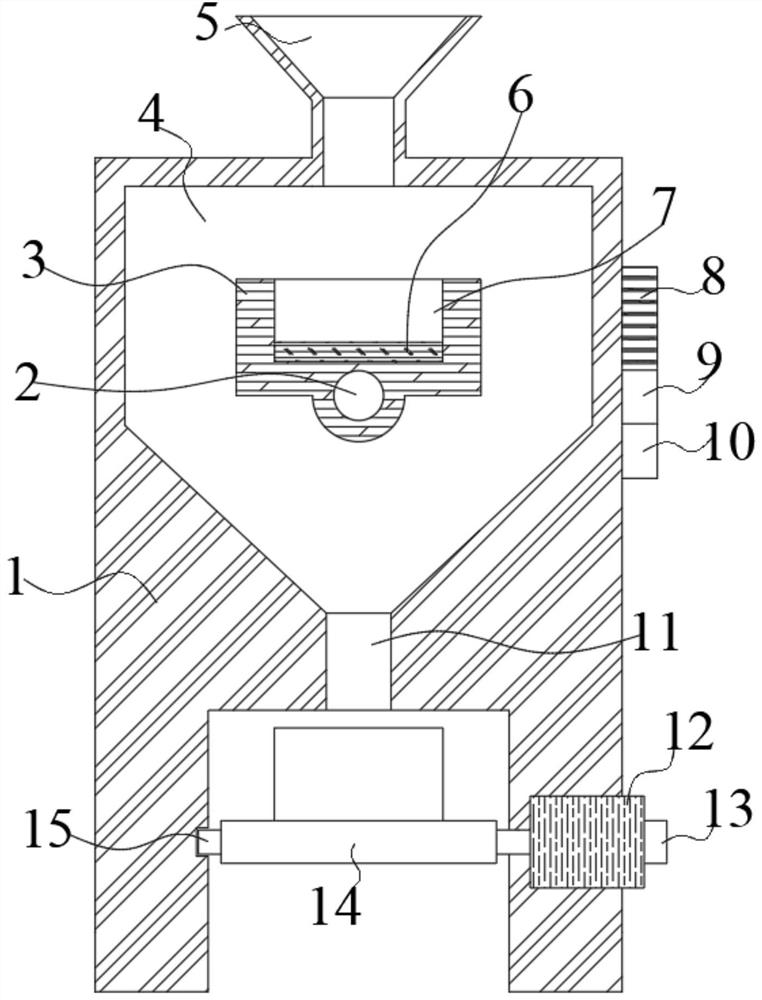

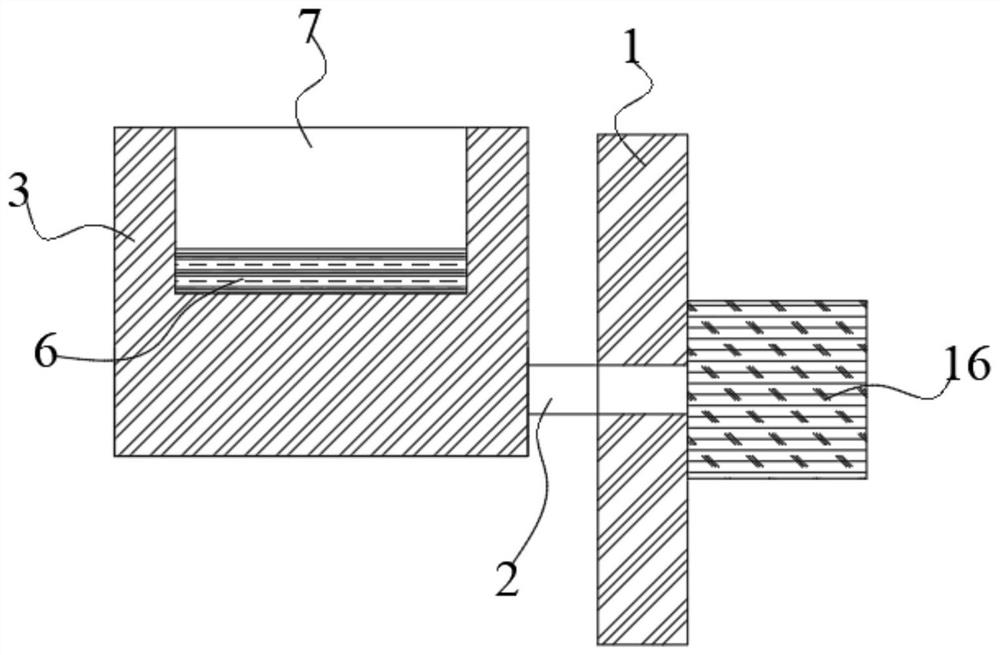

Automatic packaging device for granular or powdery articles

InactiveCN111731526AAvoid large variances in packaging volumeImprove qualitySolid materialRotational axisElectric machinery

The invention discloses an automatic packaging device for granular or powdery articles, and belongs to the technical field of automatic packaging equipment. The automatic packaging device comprises abox body, wherein one end of a feeding pipe is inserted into the upper surface of the box body, and the other end of the feeding pipe extends to the inner wall of the top surface of a storage cavity;a motor A is arranged on the outer surface of the box body; and the outer side wall of the motor A is connected with one end of a rotating shaft A in a sliding mode. According to the automatic packaging device, materials are placed into the storage cavity from the feeding pipe and fall into a groove, then the materials in the groove can be weighed in time through the operation of a weighing sensorand are displayed by a display, then the motor A operates to drive the rotating shaft A to rotate so as to drive a transverse plate to rotate, then the materials in the groove can fall and can be transported into a packaging box on the upper surface of a conveying belt through a discharging pipe, and then a finished product can be transported out of the box body in time by cooperating with the operation of a motor B. The device is simple in structure, high in practicability and suitable for being widely popularized and used.

Owner:哈工大(张家港)智能装备及新材料技术产业化研究院有限公司

Rack body mechanism of combined type agricultural auxiliary equipment

ActiveCN105409370AReasonable and perfect designFlexible and stable operationAgricultural undercarriagesElectric machineryEngineering

The invention provides a rack body mechanism of combined type agricultural auxiliary equipment. The rack body mechanism comprises a balance disc; a connecting arm is fixed at the top of the balance disc, a moving frame is arranged above the balance disc, each end of the moving frame is provided with a roller wheel, and the bottom of the moving frame is connected and fixed to the balance disc through a first air cylinder; a scraper and a plurality of moving chambers are sequentially arranged along the external circumferential face of the balance disc, the two ends of each moving chamber are provided with extension plates in an extending manner, and each extension plate is connected and fixed to the balance disc through a second air cylinder; locating line blocks are arranged at the two ends of each moving chamber and are matched with locating pulley grooves in the balance disc; and the bottom of the balance disc is connected and fixed to a motor through an elevator, the motor is connected and fixed to a rotary rod frame, and a plurality of mowing blades are sequentially arranged on the rotary rod frame. The rack body mechanism has the beneficial effects that the design is reasonable, diversified, stable and compact; and the operation is flexible and stable, shifting and transporting are timely, the working efficiency is increased, and agricultural requirements are met.

Owner:HAIMEN THE YELLOW SEA ENTREPRENEURSHIP PARK SERVICE CO LTD

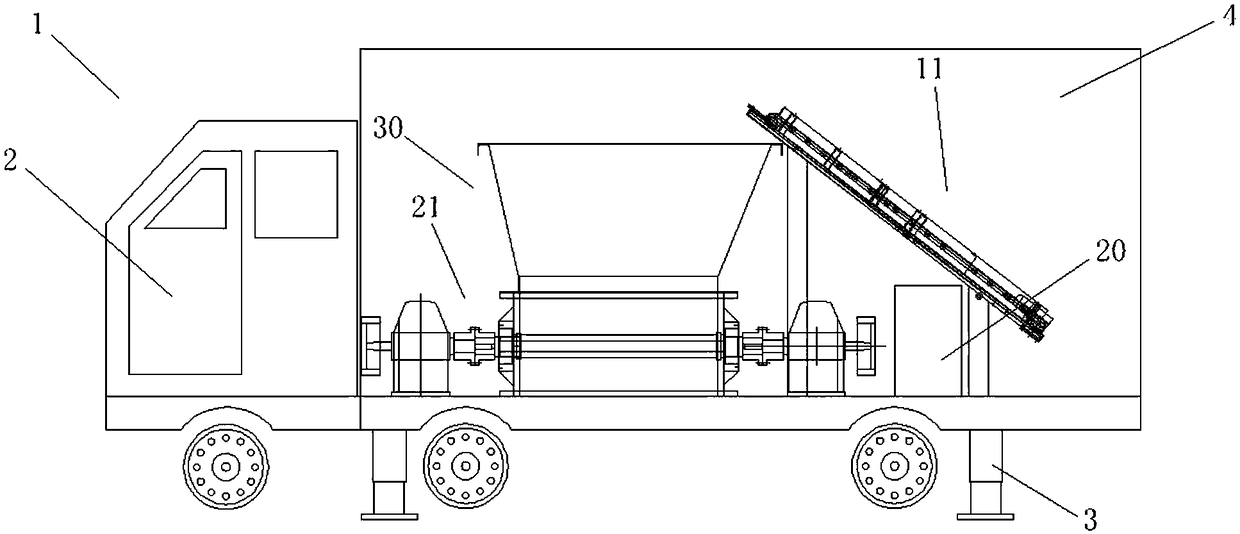

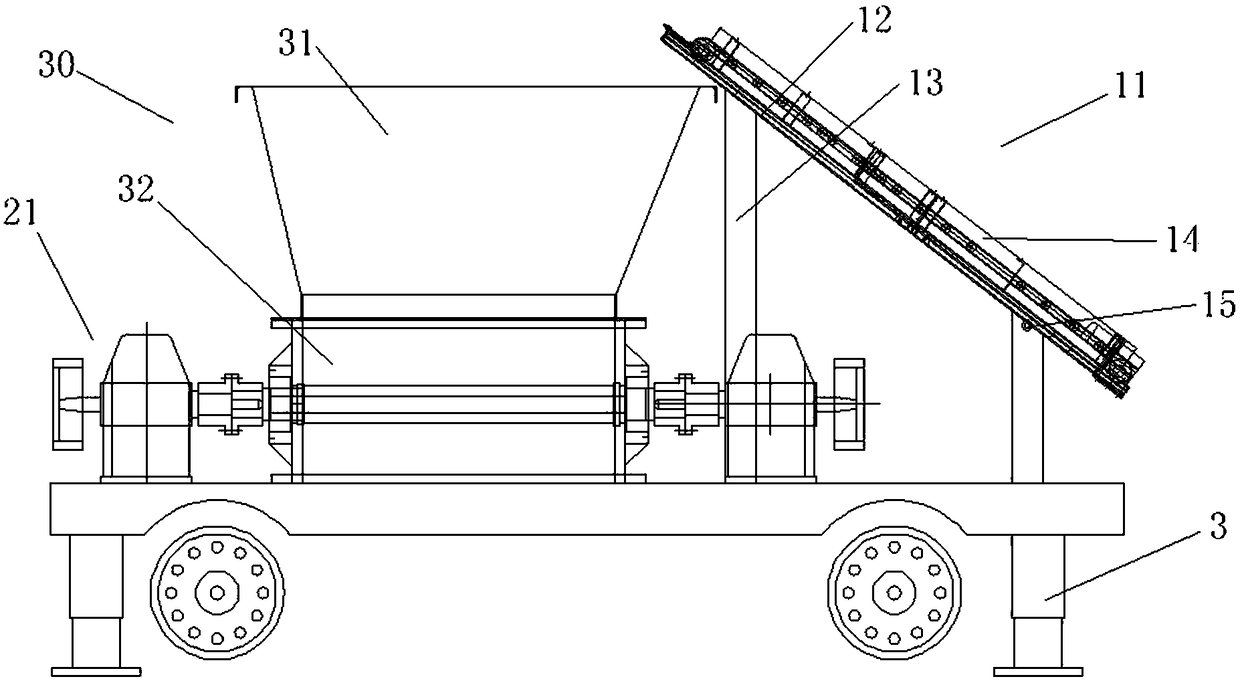

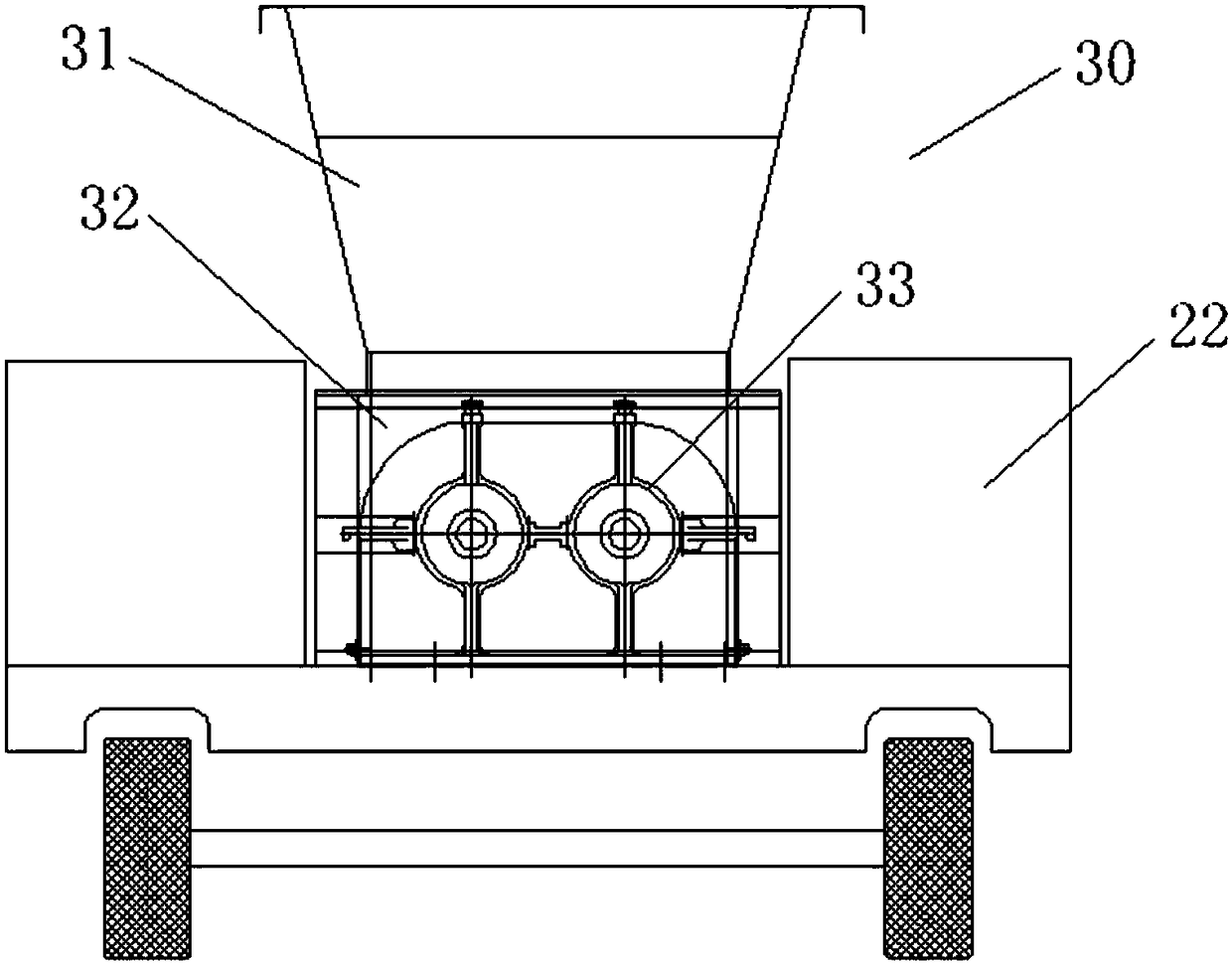

Mobile bulky waste disposal equipment

ActiveCN105750066BFast shippingTimely transportSolid waste disposalGrain treatmentsEngineeringGarbage disposal

The invention provides mobile large-piece garbage treatment equipment (1) which comprises a transporting vehicle (2), a treatment cabin (4) and a garbage treatment system, wherein the treatment cabin (4) is detachably combined with the transporting vehicle (2); the garbage treatment system is arranged inside the treatment cabin (4) and is configured to treat garbage inside the treatment cabin (4). By adopting the mobile large-piece garbage treatment equipment provided by the invention, rapid and timely treatment on large-piece garbage can be achieved, the garbage treatment cost is low, and the working intensity is also low.

Owner:中环创新科技发展(北京)有限公司

Smearing device for cold compress production

InactiveCN111921784ATimely supplementNo leaky effectLiquid surface applicatorsCoatingsCold compressesElectric machinery

The invention discloses a smearing device for cold compress production, and belongs to the technical field of smearing devices for cold compress production. The smearing device for cold compress production comprises a base, wherein a support frame A is welded at the top end of the surface of the base, the side, close to the base, of the support frame A is matched and rotatably connected with a roller, the side, far away from the base, of the support frame A is matched and rotatably connected with a smearing cylinder, the top end of the surface of the smearing cylinder is provided with a charging barrel, trowels are arranged on the left side and the right side of the surface of the charging barrel and close to the smearing barrel, a cover is matched and detachably connected to the side, faraway from the smearing barrel, of the charging barrel, a motor A is mounted on the inner wall of the base, and a tension control rod is welded to the top end of the surface of the base. By using theprinciple of the liquidity of liquid, raw materials in the charging barrel are driven by the smearing barrel to be uniformly smeared under the extrusion effect, the secondary film pressing treatment is directly carried out after the smearing, and therefore the situation that secondary pollution is caused in the subsequent process of cold compress production, and the effect is reduced is prevented.

Owner:傅红霞

Automatic welding device for traction seat plate

ActiveCN112809234AImprove effective utilizationRealize fully automatic weldingWelding/cutting auxillary devicesAuxillary welding devicesEngineeringDraw plate

The invention discloses an automatic welding device for a traction seat plate. The automatic welding device for the traction seat plate comprises a welding table, one end of the outer wall of the top of the welding table is fixedly connected with a welding table station, the outer wall of the top of an automatic traction plate welding mechanism body is fixedly connected with a support, the support is located above the welding table station, the outer portion of the top of the welding table is fixedly connected with a feeding mechanism, the feeding mechanism extends to the top of the support, a first welding and position-changing mechanism is fixedly connected to the outer wall of the top of the welding table, a first transverse plate is fixedly connected between the supports, the first transverse plate is located on the left side of the first welding and position-changing mechanism, and a first welding robot is fixedly connected to the outer wall of the top of the first transverse plate. According to the automatic welding device for the traction seat plate, the first welding robot and a second welding robot can be used for carrying out welding work on a traction plate, a traction pin and a reinforcing rib, the welded traction seat plate can be transported in time due to the arrangement of the station of a special conveying trolley after welding, and therefore the labor cost is reduced, and the production efficiency is improved.

Owner:山东宝金环保科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com