Pepper powder blending apparatus

A technology of mixing device and chili powder, which is applied in the direction of mixers with rotating stirring devices, mixers, dissolving, etc., can solve the problems of uneven mixing, health hazards of staff, low efficiency, etc., to avoid eddy current phenomenon, Save labor and improve the working environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

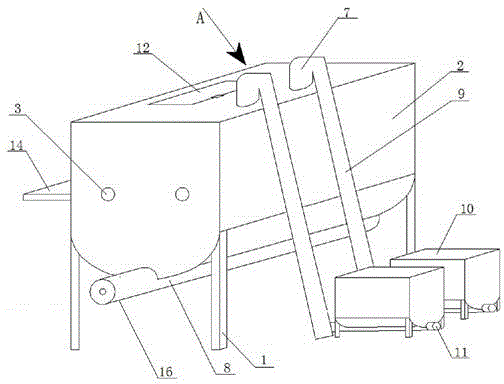

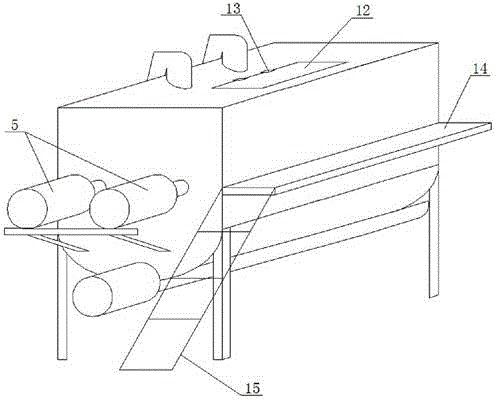

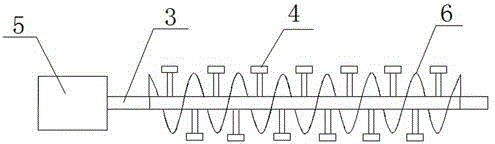

[0028] As shown in the figure, the present invention includes a stirring device, a support 1 and a mixing box 2 installed on the support 1 , and the mixing box 2 is horizontally fixed on the support 1 . The top side of the mixing box 2 is provided with two feeding ports 7; the bottom of the mixing box 2 is arranged in an arc shape, and the middle of the arc-shaped bottom is installed along the axial direction of the stirring shaft 3 of the stirring device. There is a first horizontal screw conveyor 8, that is, the first horizontal screw conveyor 8 is installed at the lowest point of the mixing box, and one end of the first horizontal screw conveyor 8 extends out of the mixing box 2, and the first horizontal screw conveyor 8 The bottom of the screw conveyor 8 extending out of the mixing box 2 is provided with a material outlet 16, and the chili powder is transported out of the mixing box 2.

[0029] The feeding port 7 is communicated with the discharge port of the screw elevato...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com